Preparation method of nano LiFel-xMxPO4/C lithium phosphate composite positive pole material

A life1-xmxpo4, composite positive electrode material technology, applied in the field of lithium ion battery positive electrode material preparation, can solve the problems of large fluctuations in phosphorus component content, unfavorable batch production, complex process steps, etc., achieve stable composition, promote smooth progress, and high The effect of reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

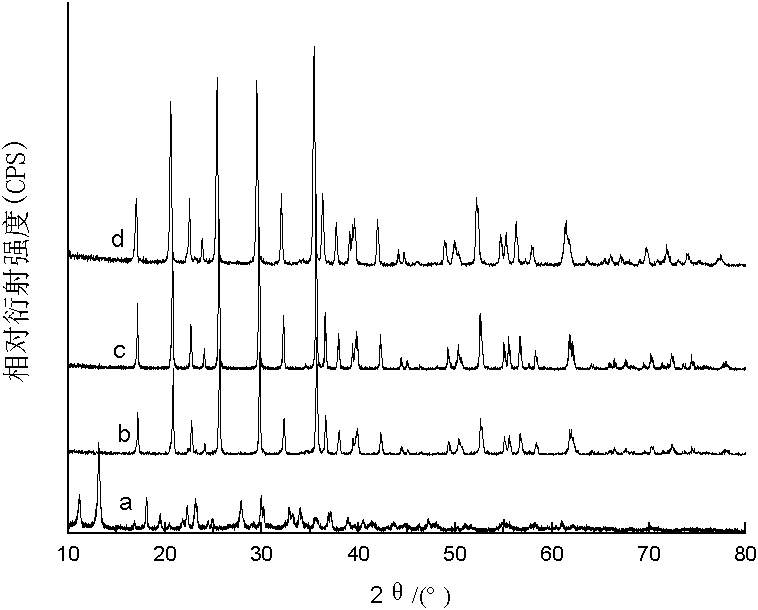

[0029] Weigh lithium dihydrogen phosphate, iron powder, and copper acetate in a molar ratio of 1:0.98:0.02, and add 5wt% glucose of the mixture, dispersed in deionized water, high-energy ball milling for 4h, and vacuum drying at 70°C to obtain the precursor. figure 1 a is its XRD pattern, no iron powder and LiH are found 2 PO 4 Diffraction peak, but the product Li after the complete reaction 3 PO 4 And Fe 3 (PO4) 2 . Placed in an atmosphere furnace, calcined at 600°C for 10 hours under the protection of argon and cooled to room temperature to obtain copper-doped nano-scale LiFePO 4 / C composite cathode material. It is determined that the composite cathode material contains 0.89wt% carbon. XRD tests that the material has a single olivine structure, and the first discharge capacity at 0.2C is 154mAh·g -1 ,Discharge capacity at 1C 140.5mAh·g -1 .

Embodiment 2

[0031] Weigh lithium dihydrogen phosphate, iron powder, lithium carbonate, and vanadium pentoxide in a molar ratio of 1:0.95:0.02:0.005, and add 6wt% sucrose in the mixture, and disperse in deionized water after high-energy ball milling for 5h, 90℃ The precursor is obtained by vacuum drying. Placed in an atmosphere furnace, calcined at 650°C under the protection of argon for 6 hours and cooled to room temperature to obtain lithium-vanadium doped nano-scale LiFePO 4 / C composite cathode material. It was detected that the composite cathode material contained 1.5wt% carbon, and the particle size was uniform about 100nm under high magnification SEM, and the discharge capacity was 130.2mAh·g at 3C. -1 , There is basically no attenuation after 70 cycles.

Embodiment 3

[0033] Weigh lithium dihydrogen phosphate, iron powder, lithium hydroxide monohydrate, and nano-silica in a molar ratio of 1:0.96:0.03:0.01, and add 10wt% polyvinyl alcohol to the mixture and disperse in deionized water-ethanol The mixed medium was subjected to high-energy ball milling for 6 hours and vacuum dried at 110°C to obtain a precursor. Placed in an atmosphere furnace, calcined at 700°C under the protection of argon and cooled to room temperature for 6 hours to obtain lithium-silicon doped nano-scale LiFePO 4 / C composite cathode material. The carbon content of the composite positive electrode material is 2.1wt%, and it can be seen from TEM that the particle size is 50-100nm, there is a good conductive carbon film connection between the particles, and the discharge capacity is 141mAh·g at 2C. -1 , There is basically no attenuation after 70 cycles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com