Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1014results about How to "Increase alkalinity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cement-based composite material used for 3D printing technology as well as preparation method and application thereof

ActiveCN104310918AEasy to get materialsLow costSolid waste managementHouse buildingConstruction 3D printing

The invention provides a cement-based composite material used for a 3D printing technology as well as a preparation method and application thereof. The cement-based composite material is prepared from the following raw materials based on the total weight of the composite material: 33%-40% of cement, 0%-8% of inorganic powder, 32%-38% of tailing machine-made sand, 2.5%-3% of a high-molecular polymer, 0.1%-0.5% of a water reducing agent and 16.7%-20% of mixing water; a composite thickening time control agent, a thixotropic agent, a volume stabilizer and the like are added into a mixture to prepare an inorganic composite material; and then the inorganic composite material can be directly pumped into a 3D printer for building to be applied to construction. The cement-based composite material is an inorganic material and the materials are easily available; a lot of industrial waste materials can be used; therefore, the cement-based composite material is low in cost, energy-saving and environment-friendly; the condensation time can be flexibly controlled, and the material has super early strength, good caking property and strong stability; the requirements of 3D printing construction continuity of the building and the building strength are met so that the house building has good global stability and use safety; and the application and popularization of 3D printing technology can be greatly promoted.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION

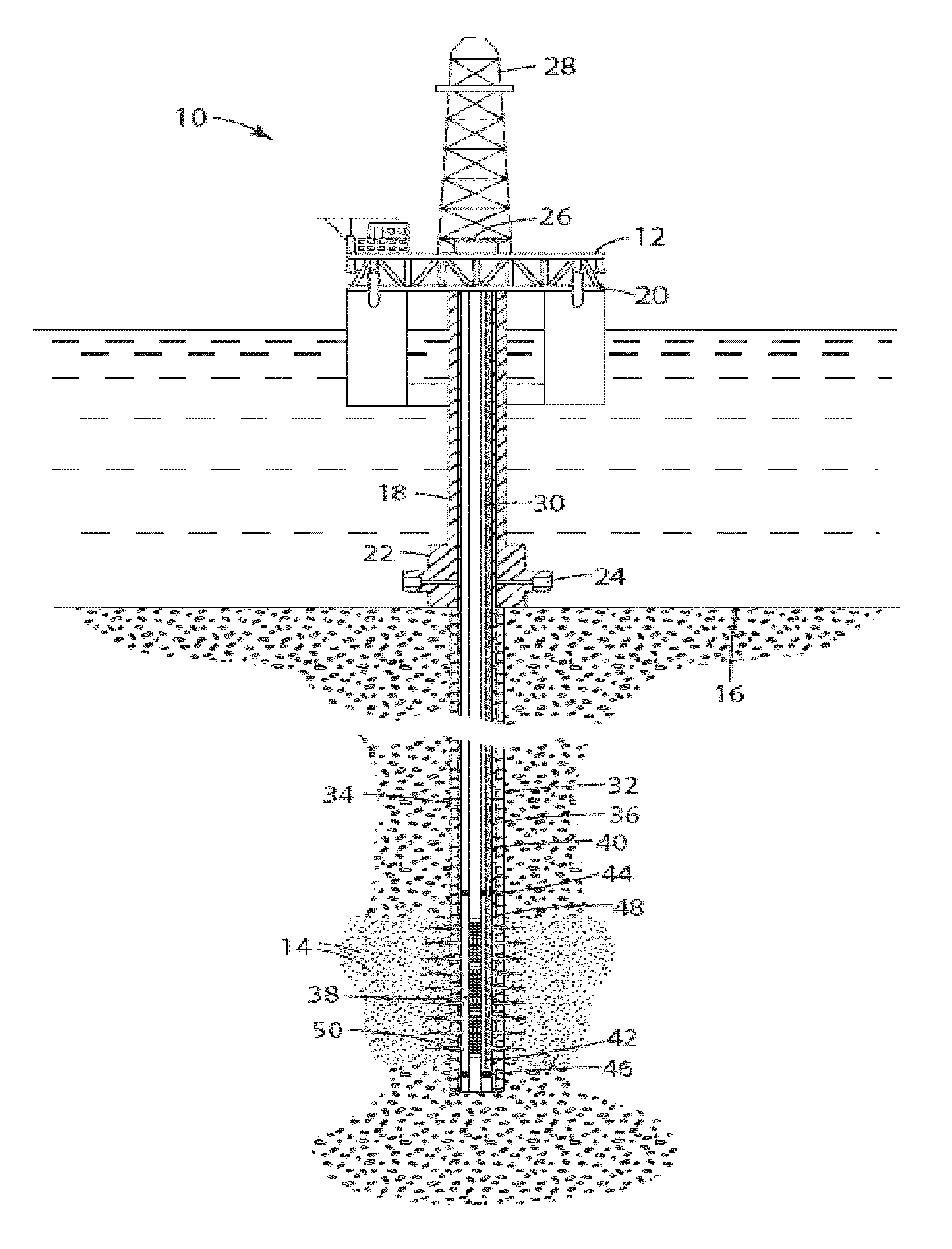

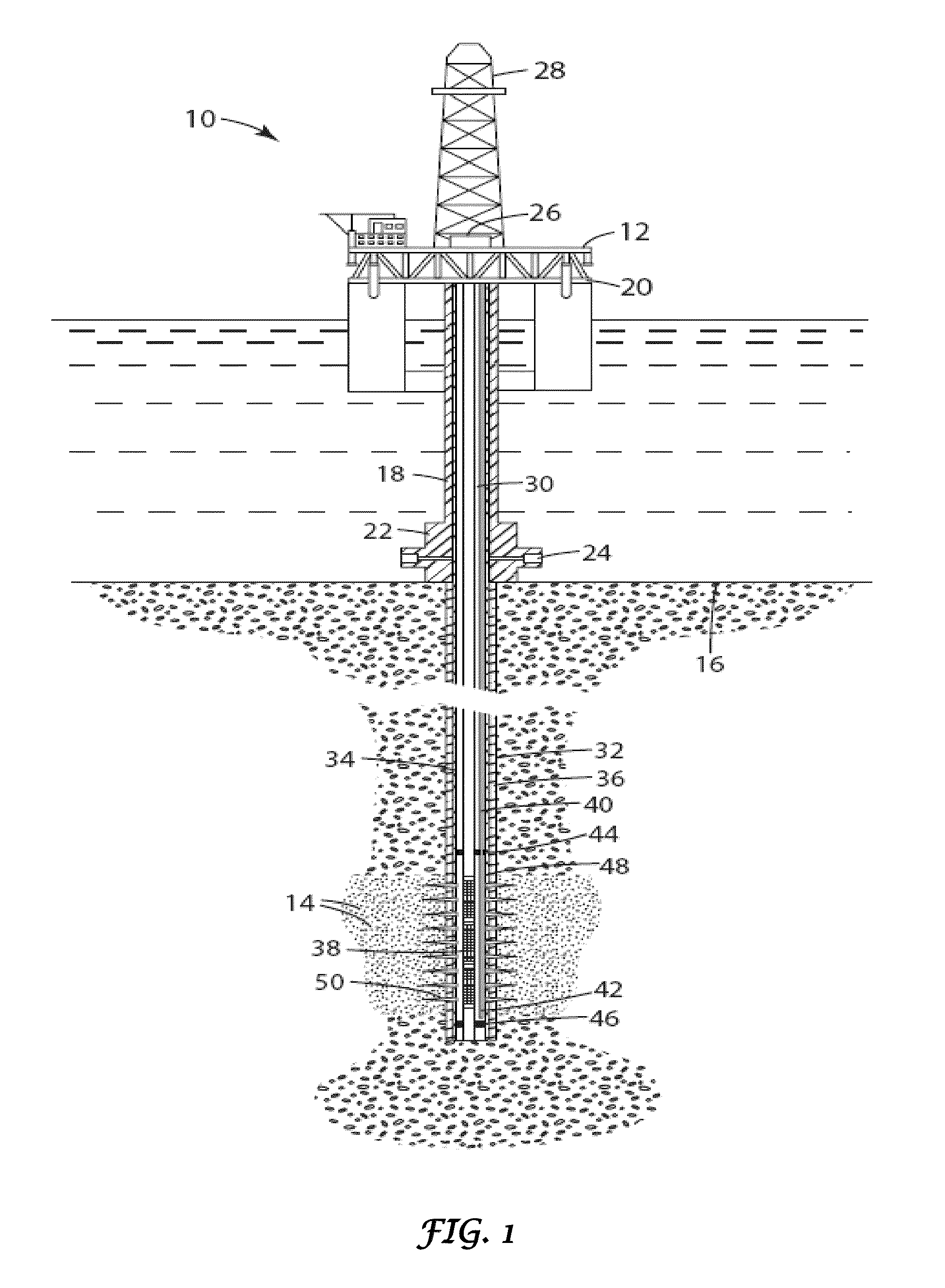

Process of using hard brine at high alkalinity for enhanced oil recovery (EOR) applications

ActiveUS20110059873A1Raise the pHReduce interfacial tensionFluid removalFlushingEnvironmental engineeringOrganic chemistry

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

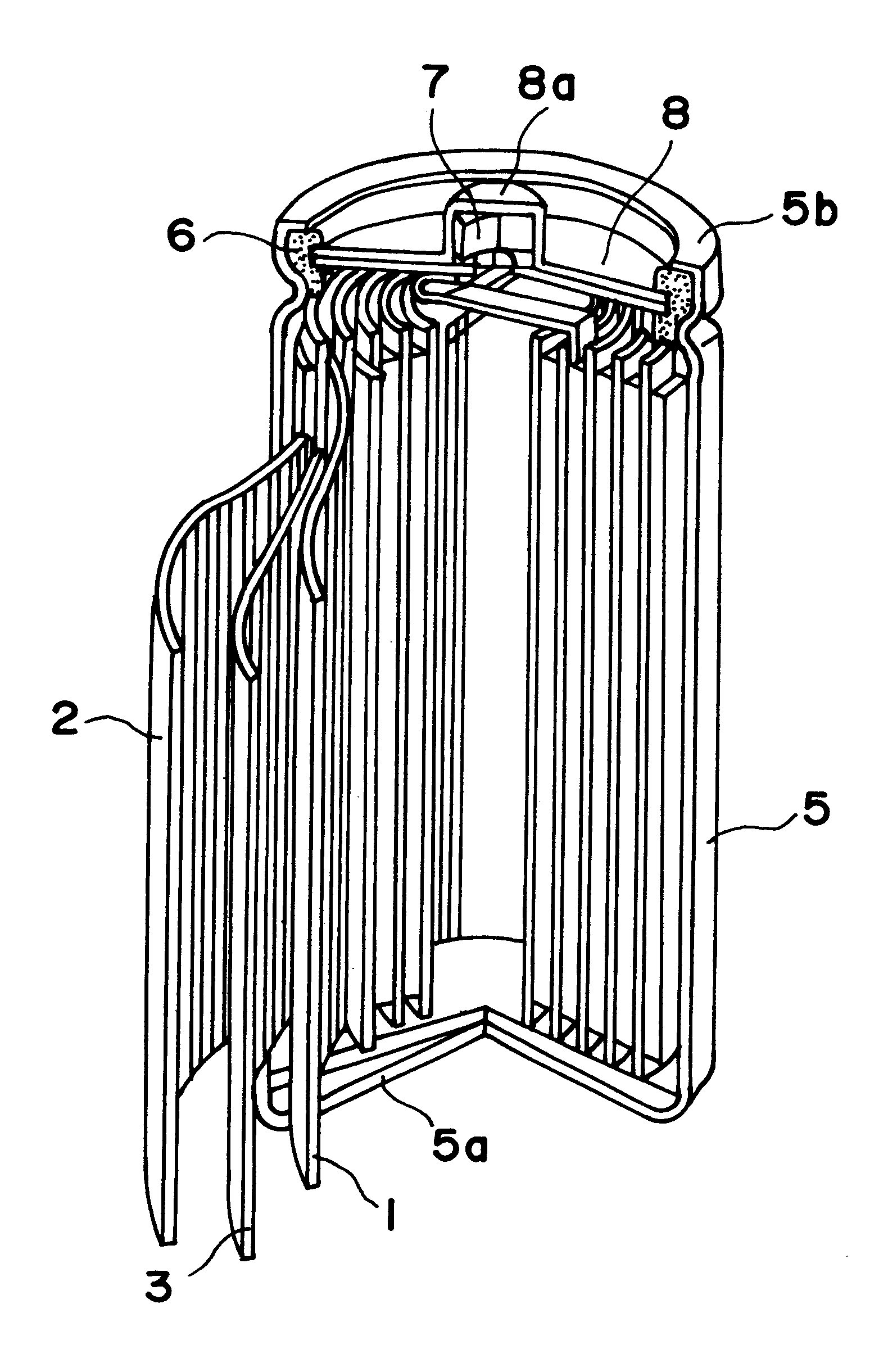

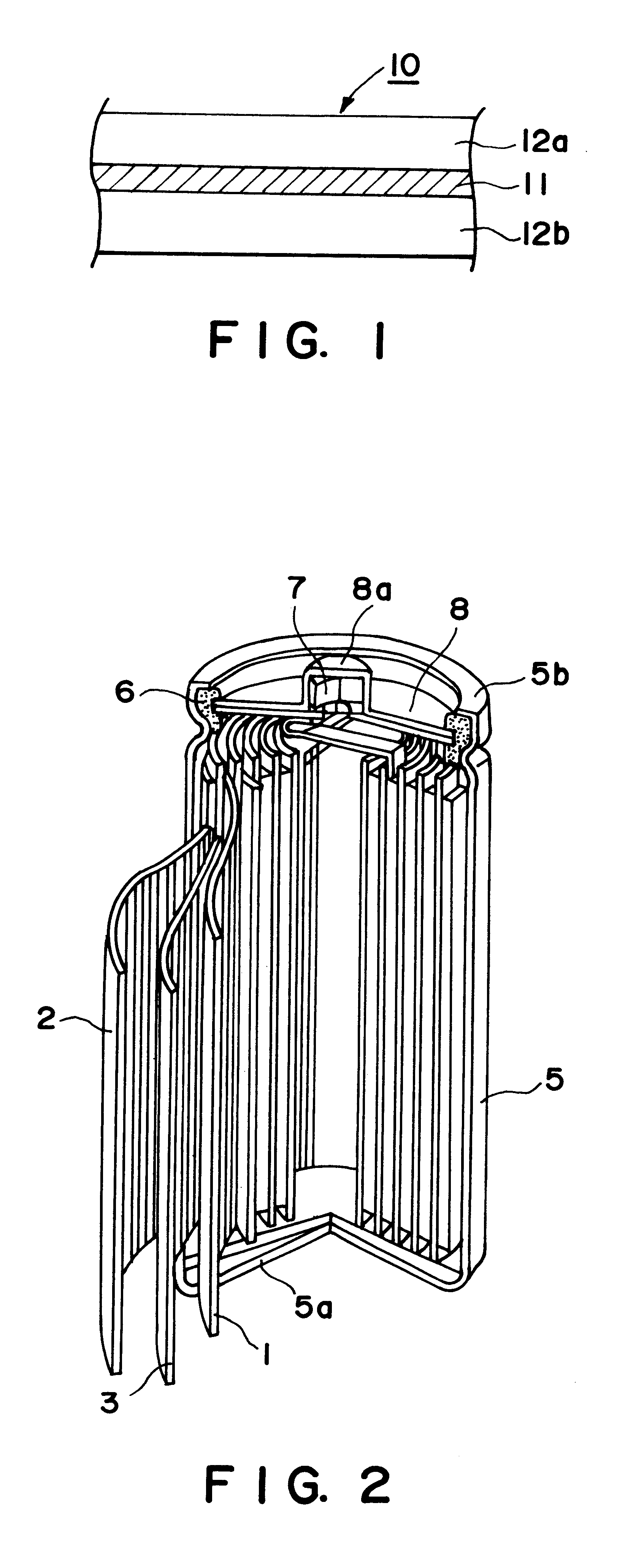

Binder solution and electrode-forming composition for non-aqueous-type battery

InactiveUS6200703B1Good gelHigh affinityNon-aqueous electrolyte cellsNon-aqueous electrolyte accumulator electrodesOrganic acidOrganic solvent

A vinylidene fluoride polymer binder solution for forming an electrode for a non-aqueous-type battery is formed by adding an acid, preferably an organic acid, as a stabilizer to a solution of a vinylidene fluoride polymer in an organic solvent. The acid is preferably added in an amount sufficient to ensure a pH of at most 9 when measured with respect to a 10-times dilution of the binder solution with deionized water. The acid addition is effective for preventing a problematic viscosity increase in the binder solution and also gelling of an electrode-forming composition formed by adding a powdery electrode material in the binder solution.

Owner:KUREHA KAGAKU KOGYO KK

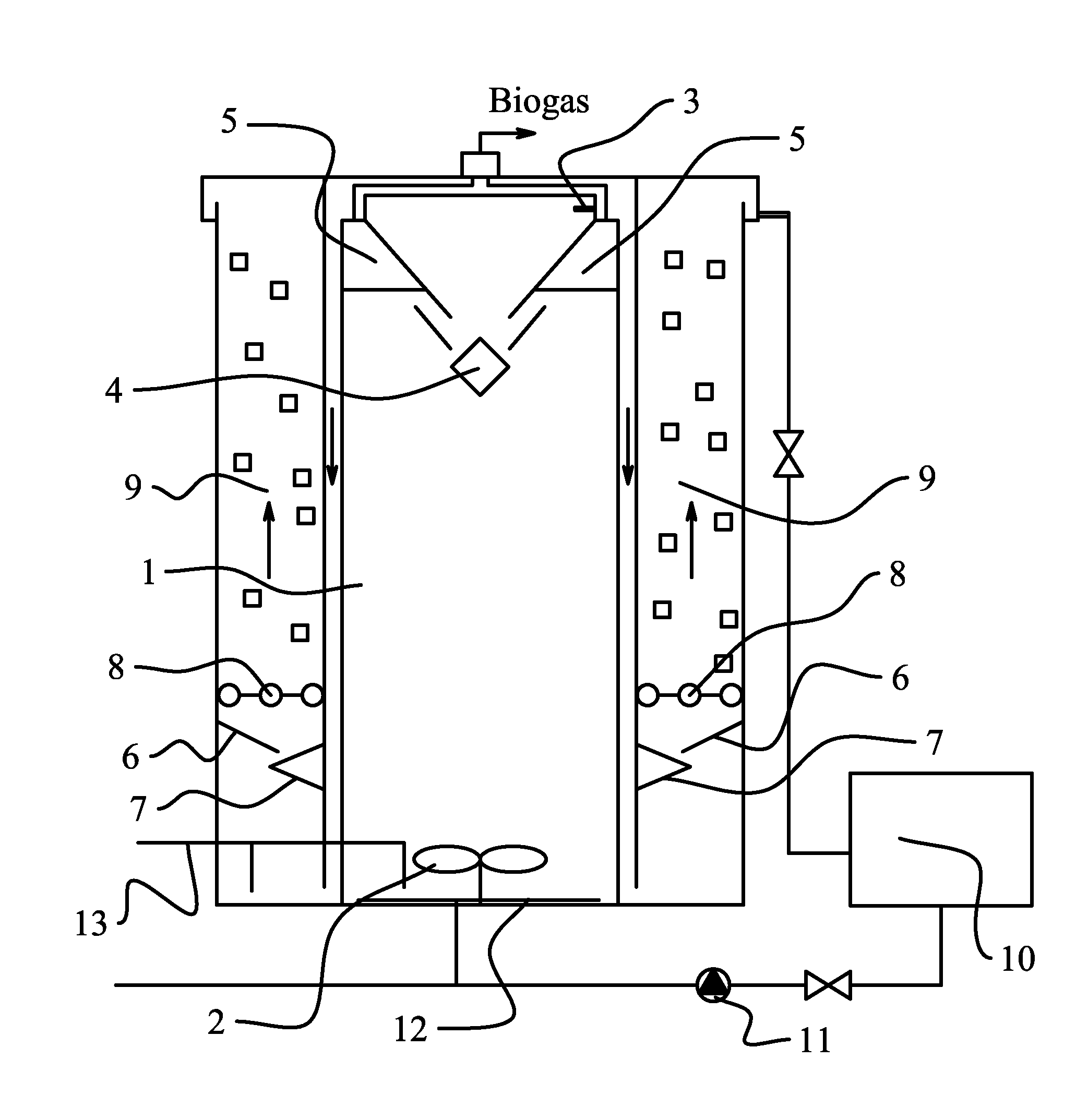

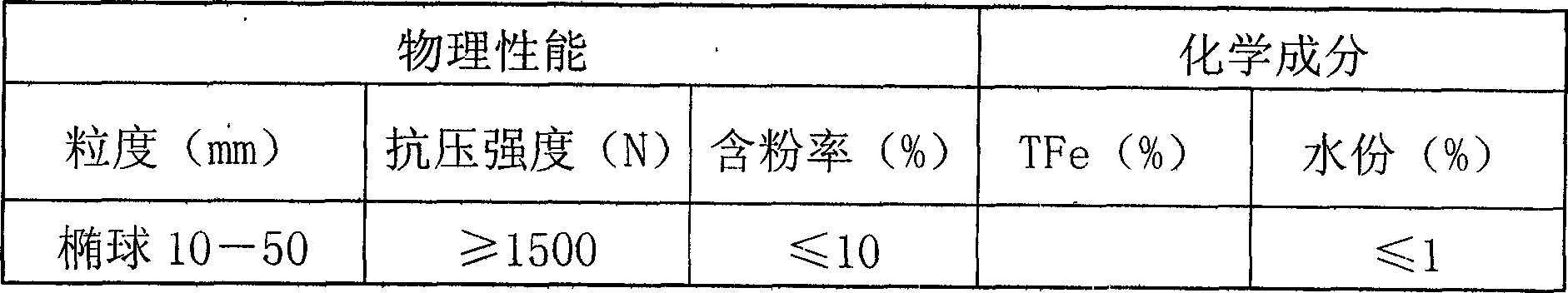

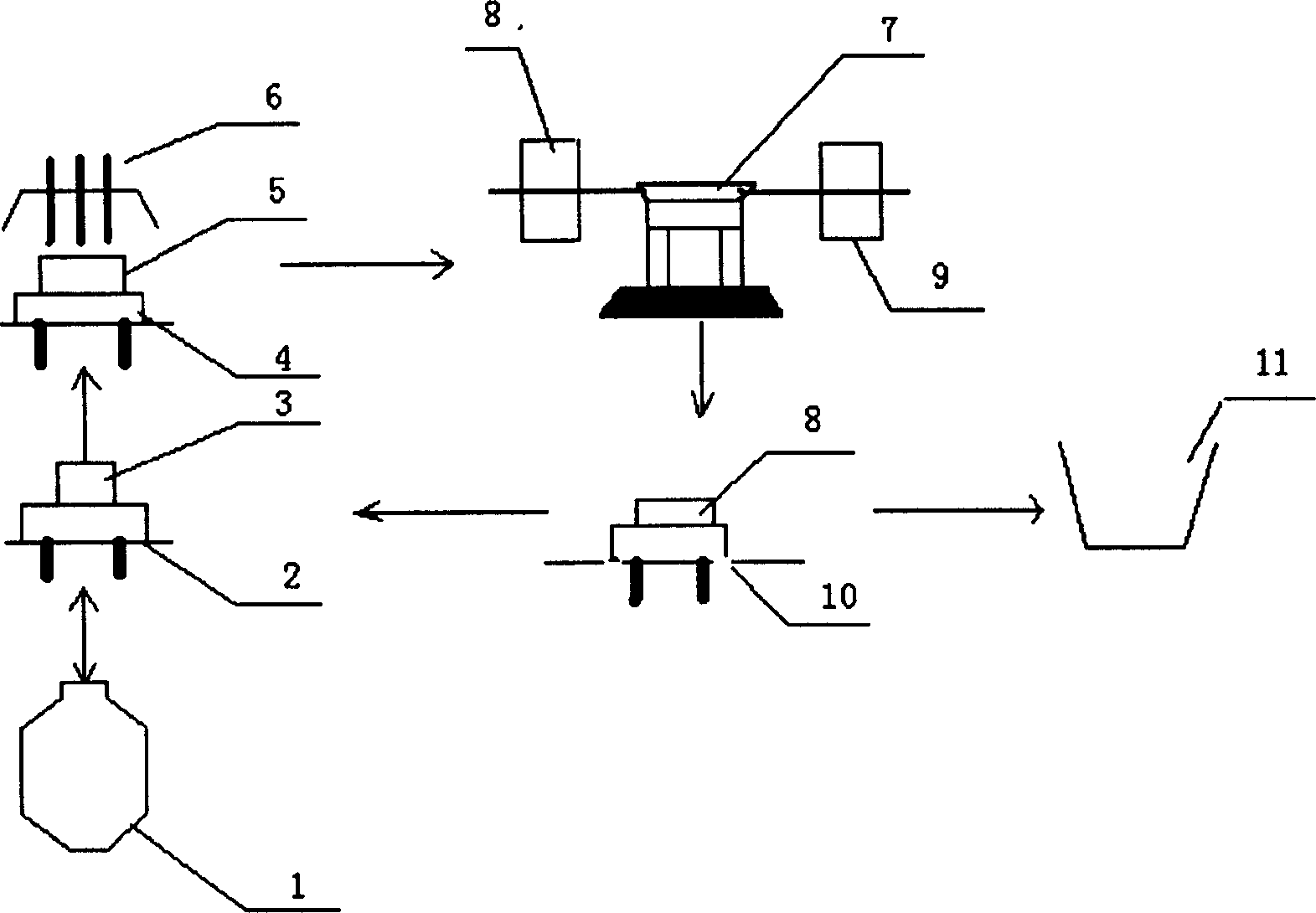

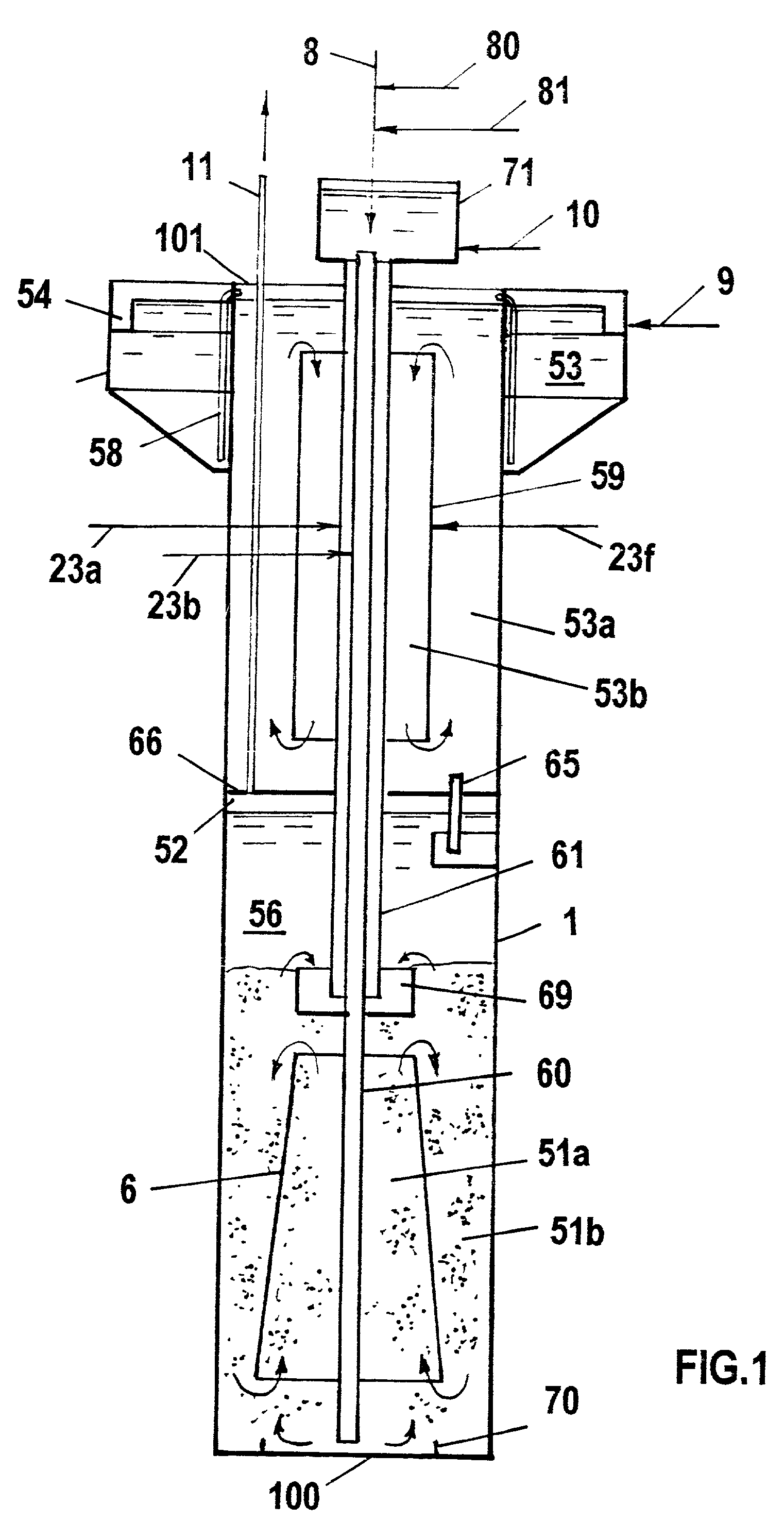

Integrated bioreactor and method of using the same for treatment of highly-concentrated organic wastewater

ActiveUS20120138527A1Increase concentrationIncrease alkalinityWater treatment parameter controlTreatment using aerobic processesRefluxPh monitors

An integrated bioreactor and its applications as well as a method for treatment of highly-concentrated organic wastewater using the same. The integrated bioreactor with a concentric columnar structure includes an inner layer and an outer layer, in which the inner layer is an upflow anaerobic sludge blanket (UASB) and the outer layer is a moving bed biofilm reactor (MBBR). The effluent of the MBBR is recycled into UASB via a reflux pump mounted between a water tank and the integrated bioreactor. A water outlet of the UASB is arranged with an on-line pH monitor and a mechanical agitation device is arranged on the top of a bottom water distributor. The bioreactor is low in cost, features friendly maintenance, stable operation, and high degree of automation, and can be applied under low temperature.

Owner:NANJING UNIV

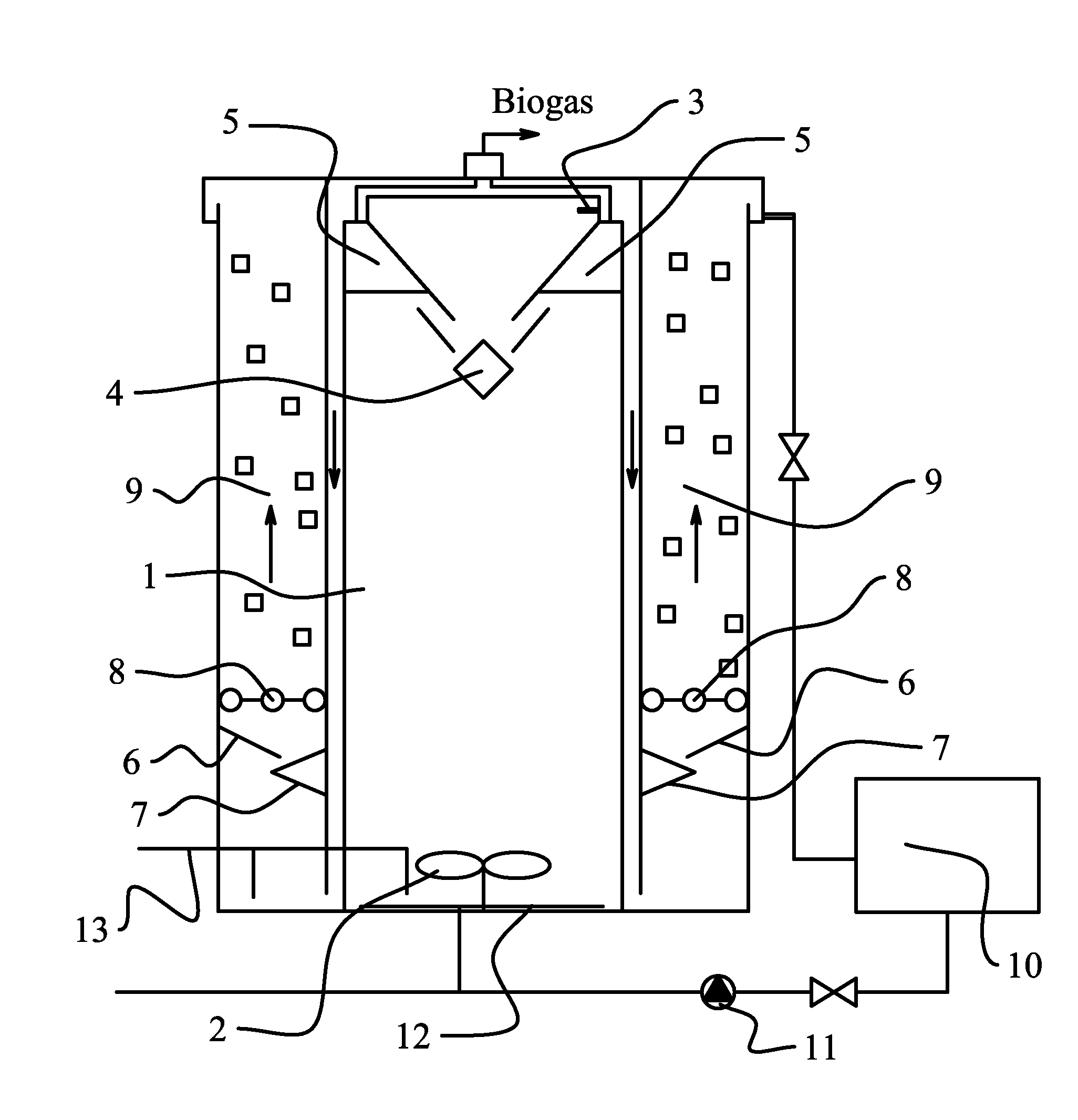

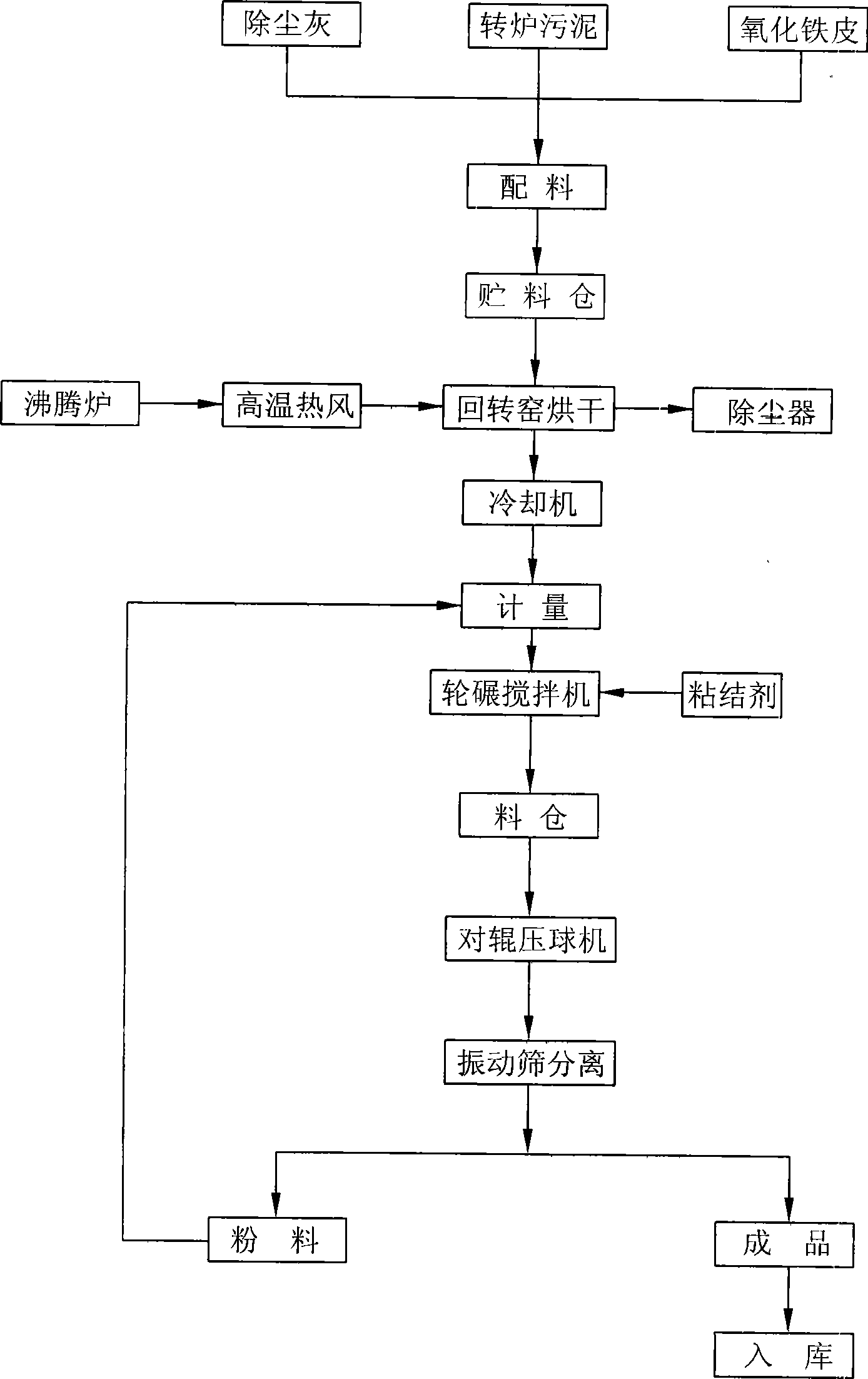

Method for utilizing iron containing metallurgical dust

The invention relates to a method for utilizing iron containing metallurgical dust, which comprises that: steel-making sludge, metallurgical dust-removing powder and iron scale are mixed; the mixed raw materials are sent into a rotary kiln and dried, and the drying temperature is determined according to moisture content of the raw materials and controlled to be between 300 and 500 DEG C; the dried materials are cooled by a cooler, the cooled materials are added with 5 to 10 percent of caking agent by weight, and the material and the caking agent are fully stirred evenly by a wheel-rolling mixer; and finally, the mixture is pressed into cooled agglomerated pellet products by a twin-roller machine, the pressure of the twin-roller machine is more than or equal to 500 Kg / cm<2>, and the cooled agglomerated pellet products are prepared into finished products after separation by a vibration sieve. The method has the advantages of low production energy consumption, high product strength, low moisture content and good quality, and can realize full effective utilization of resources; and the finished products of cooled agglomerated pellets can be directly used as a cooling agent and a slag former in steel making, can improve smelting effect and achieve functions of cooling and slag forming, and can be also used for blast furnace process.

Owner:SHAOGUAN QUJIANG SHENGDA EQUIP & MATERIALS

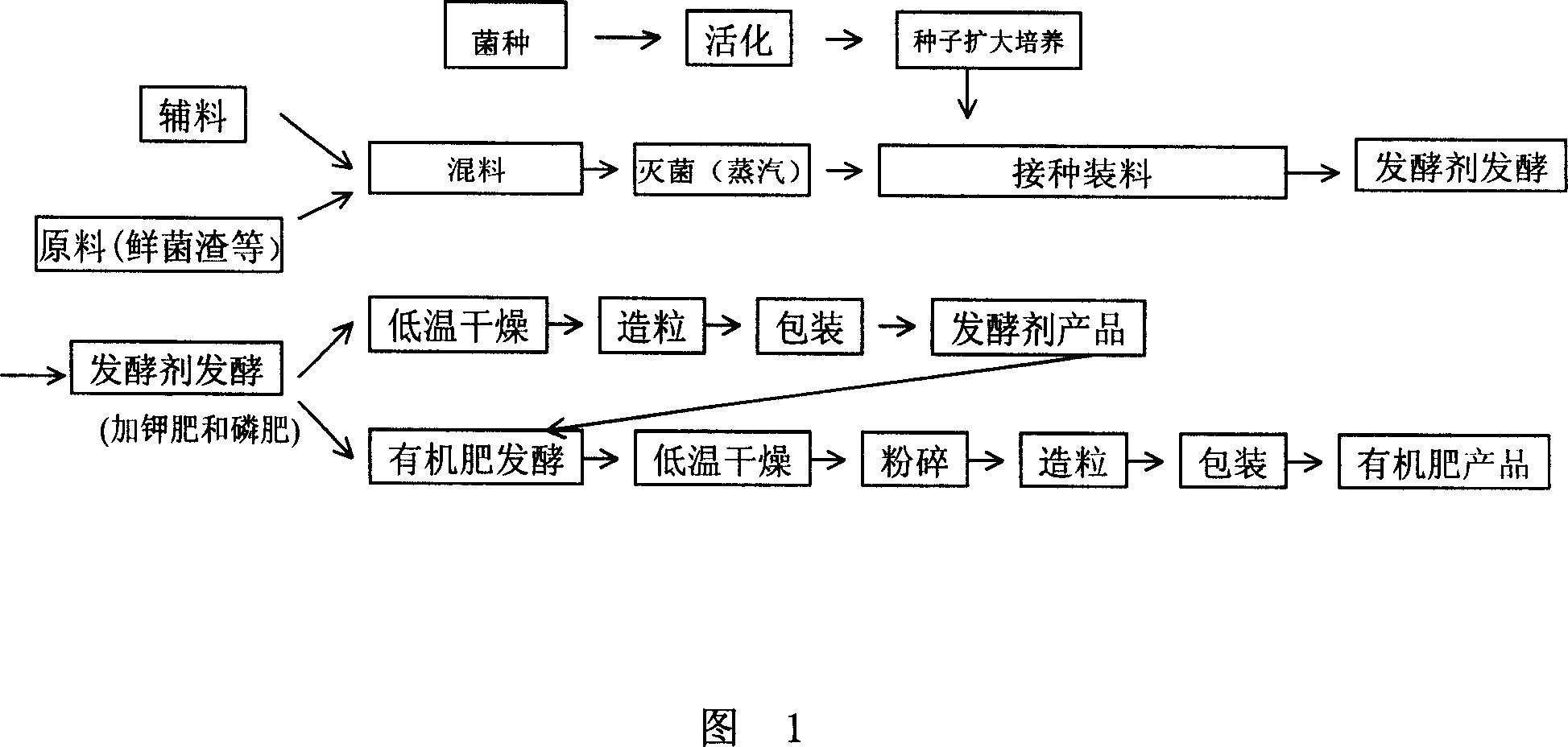

Fertilizer leaven and preparation method and application thereof

InactiveCN101041807ASimple processReduce manufacturing costFungiBacteriaBacillus licheniformisAzotobacter chroococcum

The invention discloses a method to prepare leaven of fertilizer and application, which is characterized by the following: allocating raw material with mass ratio at 10-80 wt industrial residue of ferment, 5-30 wt straw, 5-30 wt cake meal, 10-30 wt bran or rice bran, 1.5-2 wt aquacare, 0.5-1 wt NaCl and or amylaceum, and 1-30 wt brown ball Azotobacter (Azotobacter chroococcum), 1-30 wt bacillus megaterium (Bacillus megaterium), 1-30 wt bacillus licheniformis (Bacillus licheniformis), 1-30 wt plant lactobacillus (Lactobacillus plantarum) and 1-30 wt 1-5 strain of saccharomycopsis fibuligera (Saccharomycopsis fibuligera); producing the product.

Owner:北京世纪发展科技有限公司

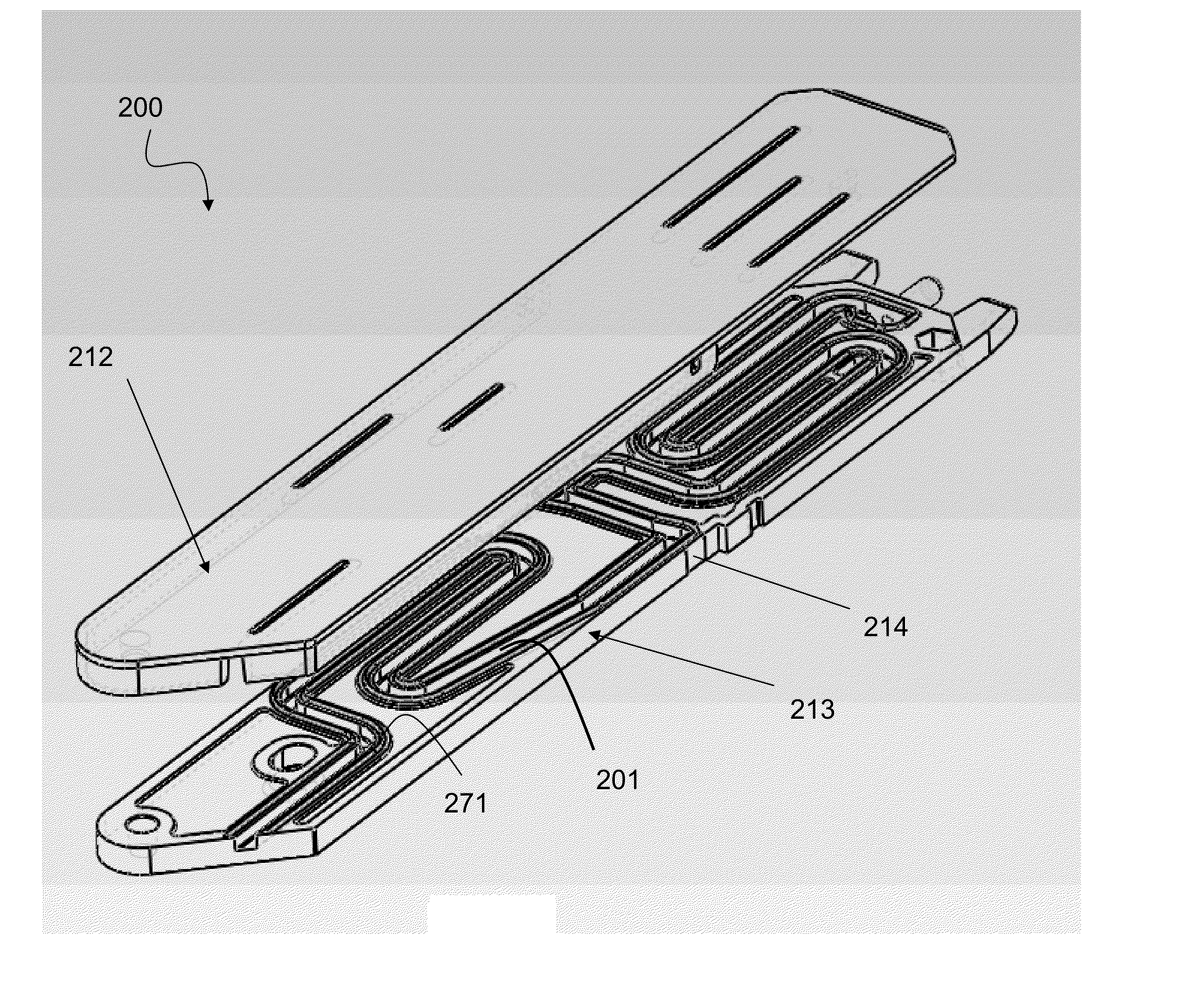

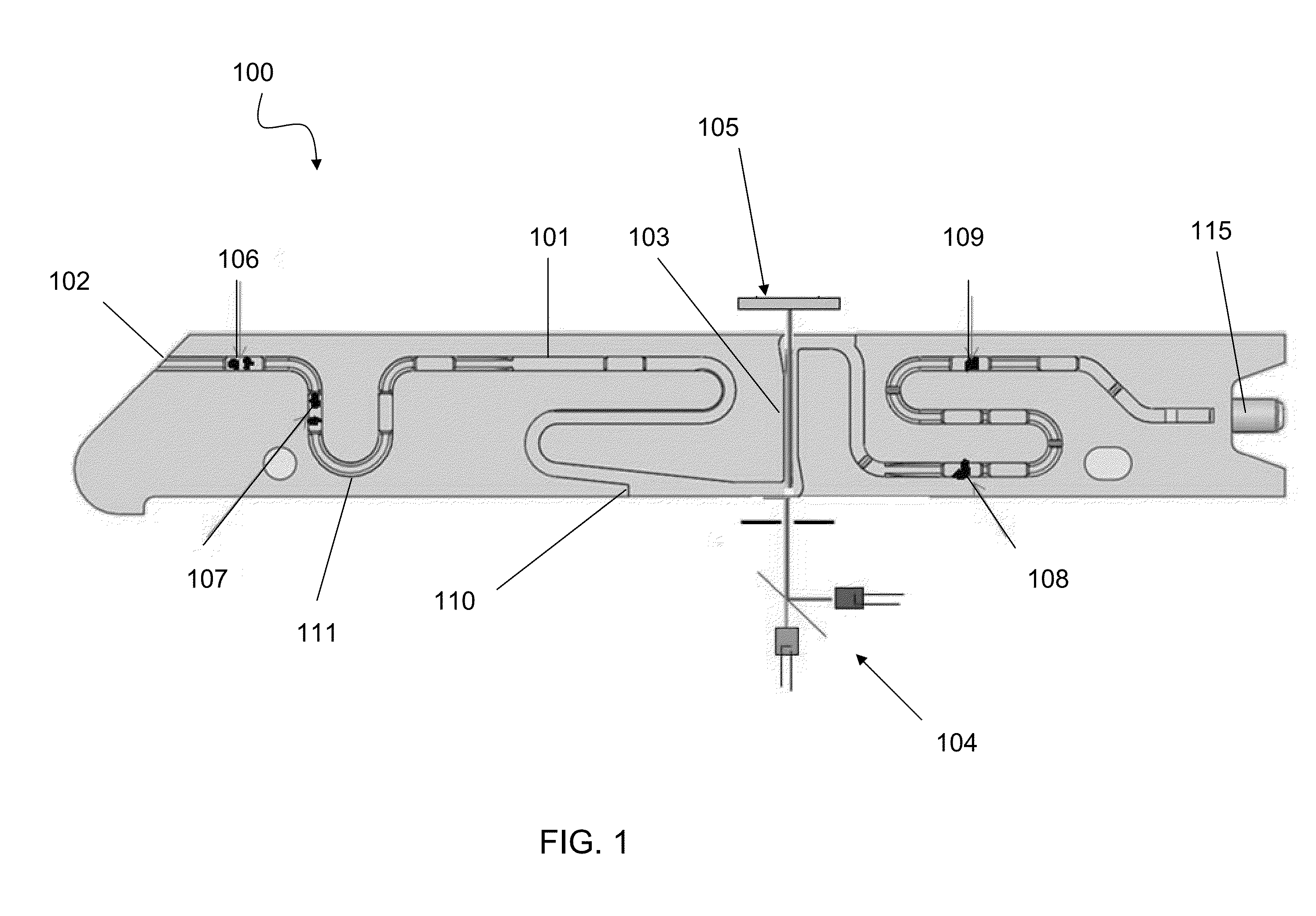

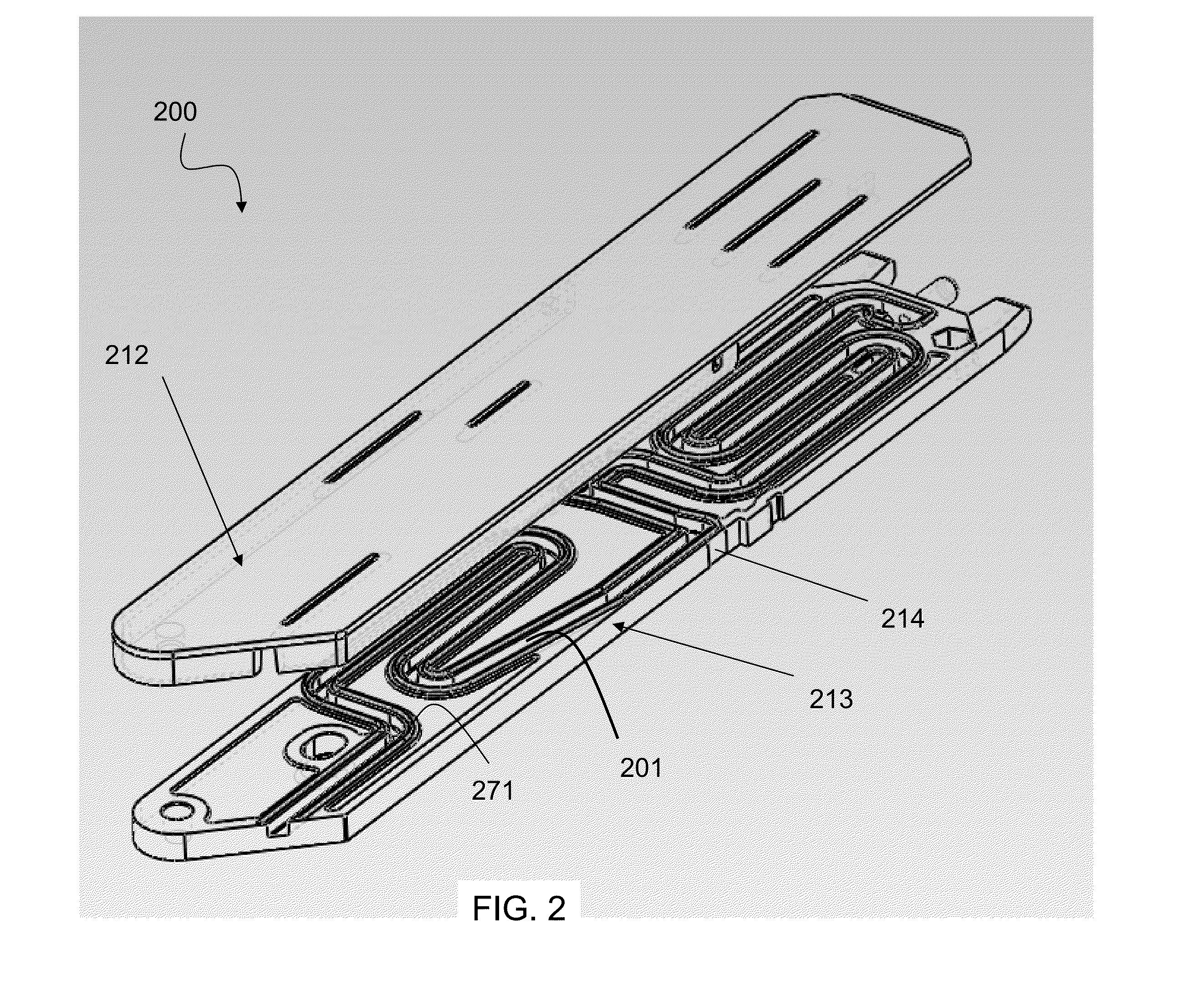

Mobile water analysis

ActiveUS20130330245A1Increase alkalinityFacilitate in-field chemical analysisAnalysis using chemical indicatorsMaterial analysis by observing effect on chemical indicatorCuvettePartial alignment

An embodiment provides a cuvette apparatus including: a lid and a body, the body including a fluid channel disposed therein; and the lid including at least one opening aligned with a portion of the fluid channel, thereby providing access to the fluid channel in the body. Other aspects are described and claimed.

Owner:HACH CO

Low-water ratio ethylbenzene dehydrogenation catalyst

ActiveCN1981929AIncrease alkalinityHigh activityHydrocarbonsMetal/metal-oxides/metal-hydroxide catalystsDehydrogenationRare earth

A catalyst for dehydrogenating ethylbenzene in the condition of low water ratio is prepared through adding at least two compounds of light RE elements other than Ce, and at least one oxide of metal chosen from Ca, Mg, Ba, B, Sn, Pb, Cu, Zn, Ti, Zr, V and Mo to the Fe-K-Ce-W system. It has high stability and activity.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing aquatic product cleaning agent based on shell powder

InactiveCN104877808AIncrease alkalinityImprove adsorption capacityDetergent compounding agentsOrganic non-surface-active detergent compositionsMicro nanoAquatic product

The invention provides a method for preparing an aquatic product cleaning agent based on shell powder. The method for preparing the aquatic product cleaning agent based on the shell powder comprises the steps that shells are dried or dried in sun after being degreased and desalted, high-temperature calcination and puffing are conducted after the shells are pulverized by means of a pulverizer, micro-nano crushing is conducted on the calcinated shell powder after cooling, and the natural aquatic product cleaning agent is obtained by adding a natural cleaning assistant. According to the method for preparing the aquatic product cleaning agent based on the shell powder, greasy dirt and fishy matter on the surface of aquatic products can be effectively absorbed and removed, the intrinsic character of food is not changed, the sterilization function and the freshness retaining function are achieved, the cleaning agent is safe, non-toxic and degradable, the aquatic product can be directly eaten or cooked after being cleaned, and the cleaning agent is suitable for cleaning various aquatic products.

Owner:ZHEJIANG OCEAN UNIV

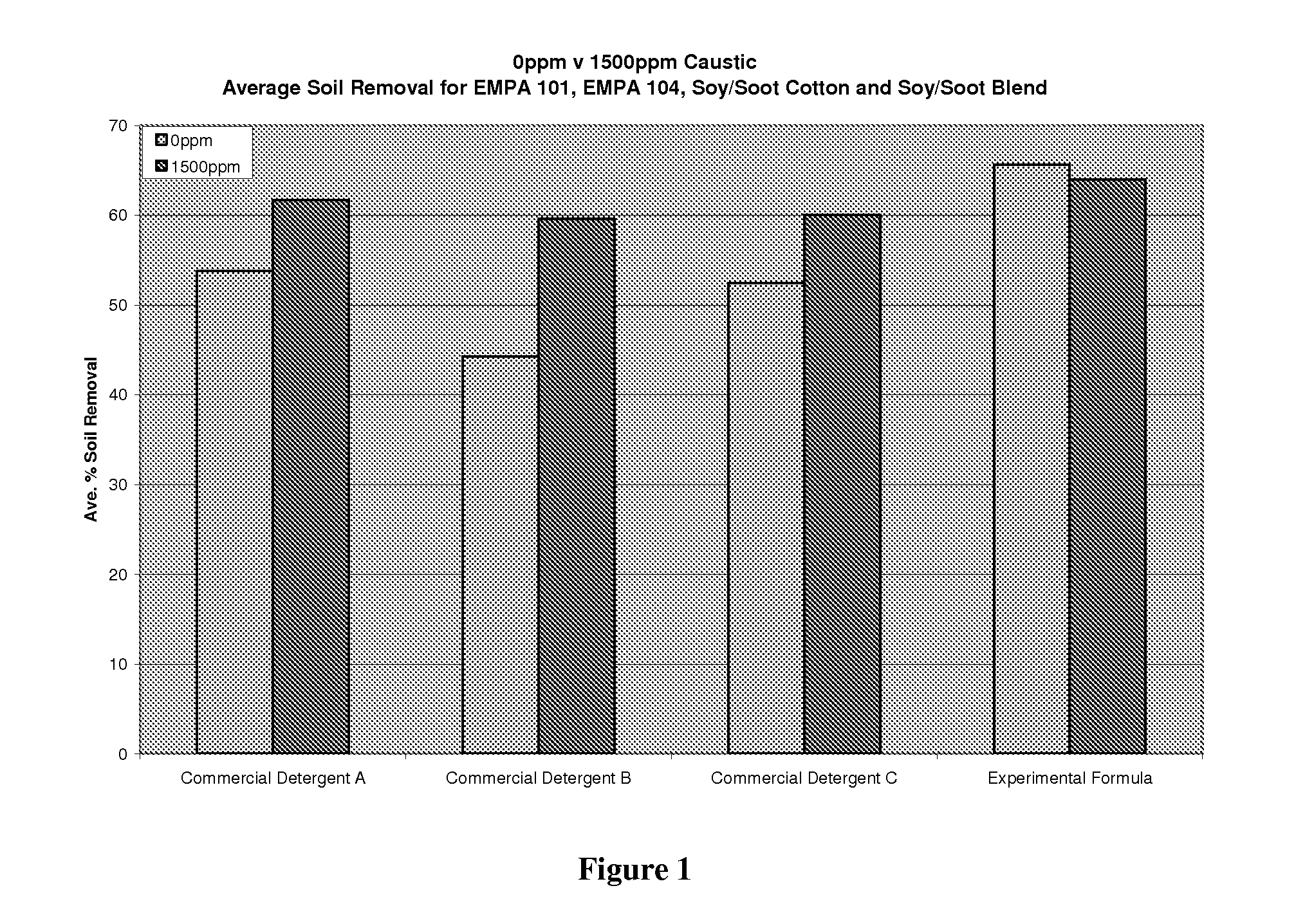

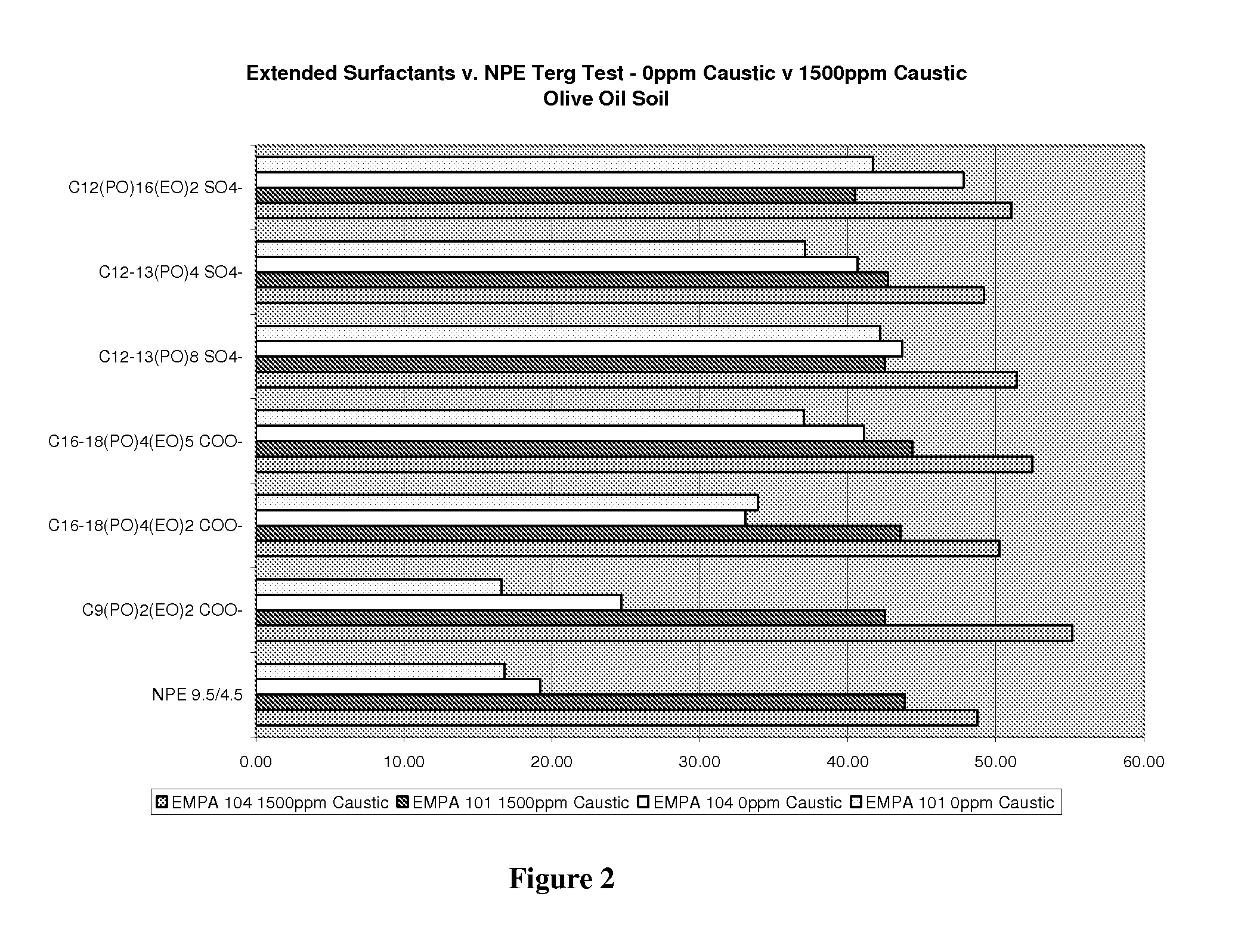

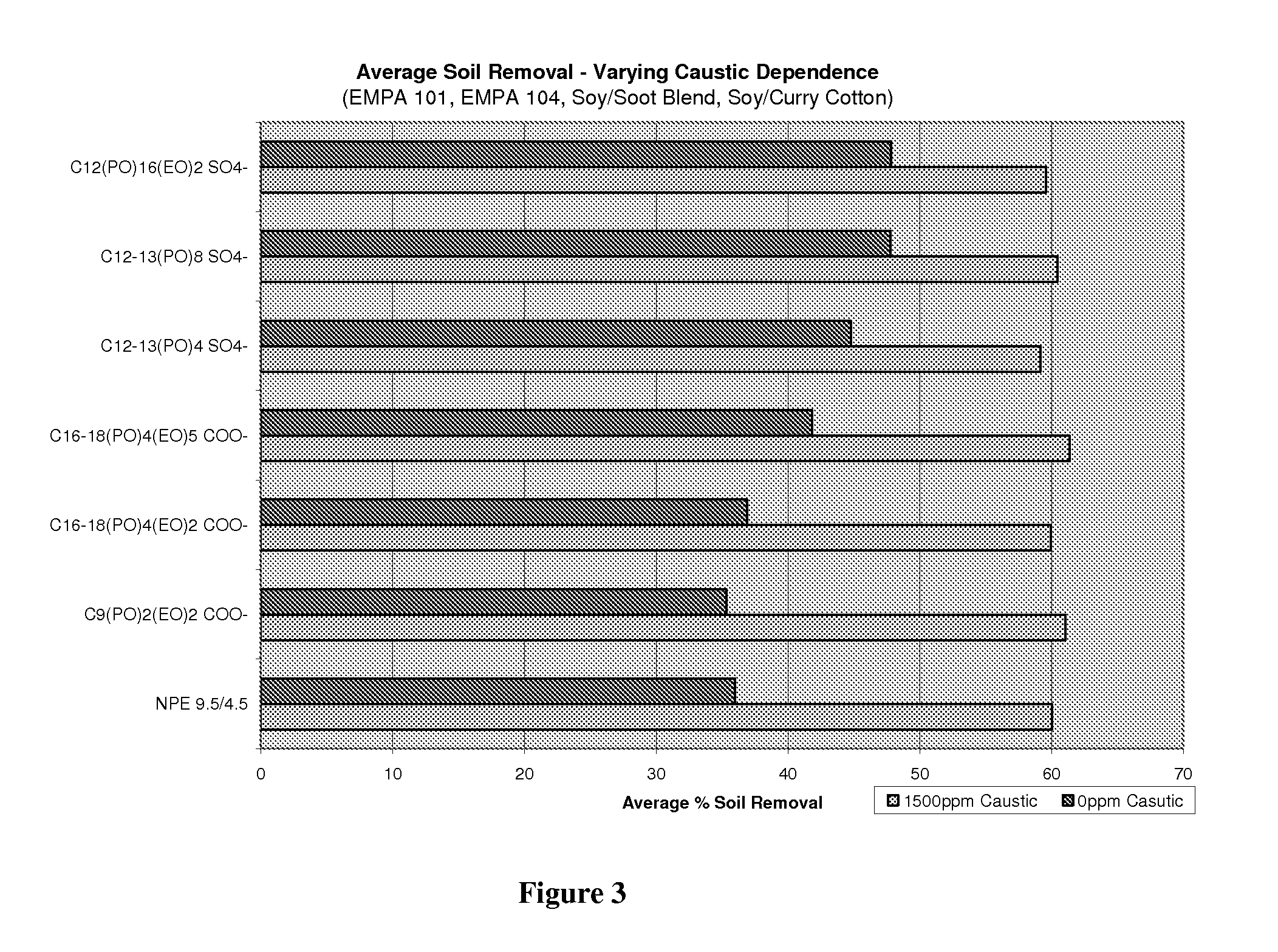

Reduced caustic laundry detergents based on extended chain surfactants

ActiveUS20120066840A1Reduce dependenceEasy to cleanOrganic detergent compounding agentsNon-ionic surface-active compoundsEmulsionSurface cleaning

The invention discloses synergistic combinations of surfactants blends and cleaning composition. In certain embodiments a surfactant system is disclosed which includes extended anionic surfactants, linker surfactants, and a multiply charged cation component. This system forms emulsions with, and can remove greasy and oily stains, even those comprised of non-trans fats. In another embodiment anionic surfactants are combined with a solvent, and amine oxide to remove sunscreen stains. The compositions may be used alone, as a pre-spotter or other pre-treatment or as a part of a soft surface or hard surface cleaning composition.

Owner:ECOLAB USA INC

Method for reclaiming and cyclic utilizing residue molten steel slag in steel making

InactiveCN1804047AWell mixedReduce oxidationBlast furnace componentsBlast furnace detailsSulfurSludge

The method to pour residual hot steel sludge for recovery in steel production comprises: a. after casting, pouring the residual steel sludge into empty ladle; b. conveying the sludge to converter and tapping; c. refining; d. casting; repeating. This invention makes full use of the sulfur capacity and strong reducibility to absorb inclusion and improve liquid steel cleanness rapidly, overcomes the consumption for low-melting, and reduces pollution and cost.

Owner:HEBEI IRON AND STEEL

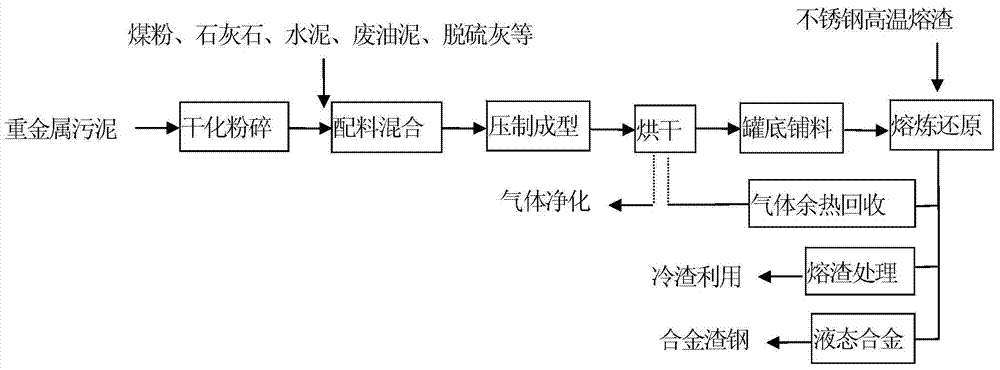

Method for treating heavy metal sludge by using stainless steel molten slag

InactiveCN104512988AIncrease productionIncrease temperatureSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesSludgeMetallurgy

The present invention discloses a method for treating heavy metal sludge by using stainless steel molten slag. The method comprises drying crushing, material matching mixing, pressing molding, drying, tank bottom material spreading, smelting reduction, gas purification, molten slag treating, metal recovery and other steps, and specifically comprises that: after heavy metal sludge is subjected to pre-treatment, a certain proportion of ingredients are matched, and the sludge agglomerate is adopted as the bottom spreading material and is placed into a stainless steel molten slag tank to carry out a harmless treatment on the sludge agglomerate. According to the present invention, the characteristics of high production amount, high temperature and rich sensible heat resource of the stainless steel molten slag are adopted, and the stainless steel molten slag is adopted to treat the heavy metal sludge, such that the harmless treatment on the hazardous components and the resource on the valuable material are achieved, the method is the new attempt crossing the industry, and the waste heat resource can be effectively utilized so as to achieve the waste treatment adopting the waste.

Owner:BAOSHAN IRON & STEEL CO LTD +1

High-ore-matching-ratio brown iron ore sintering technology

The invention relates to a high-ore-matching-ratio brown iron ore sintering technology. The weight ratio of brown iron ore and powdered iron in raw material proportion is (5-19):1, the moisture content of the first mixing is controlled to be 7%-8%, the mixing time lasts for 2-3minutes, and the temperature of the mixture is 50-62 DEG C; the moisture content of second mixing pelletizing is controlled to be 7-9%, the pelletizing time lasts for 2-3.5minutes, and the temperature of materials is 52-65 DEG C; the thickness of grate-layer materials in distribution is 20mm, and a sintering material layer is 780-900mm thick; the ignition temperature for sintering is1050-1150 DEG C, and the ignition time lasts for 1.8-2.2minutes; and the negative pressure for sintering is 12-15kpa, the machine speed is 0.9-1.2m / min, the vertical sintering speed is 29-34mm / min, the air leakage rate is no more than 40%, the cooling negative pressure is 11-14kpa, the temperature of a cooling section of a sintering machine is reduced to 250 DEG C below. By using the high-ore-matching-ratio brown iron ore sintering technology, energy is saved, consumption is reduced, cost is decreased and benefit is increased.

Owner:唐山瑞丰钢铁(集团)有限公司

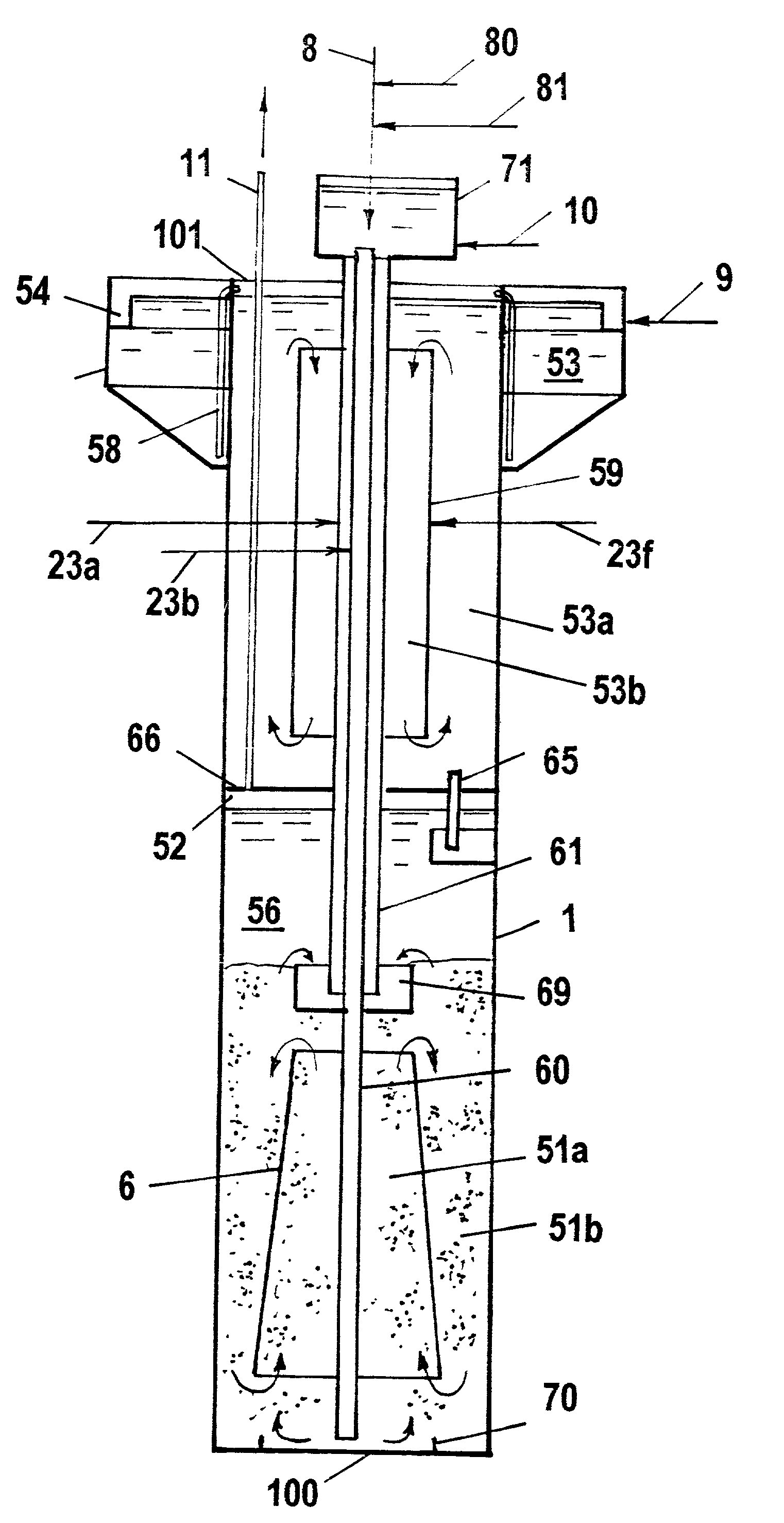

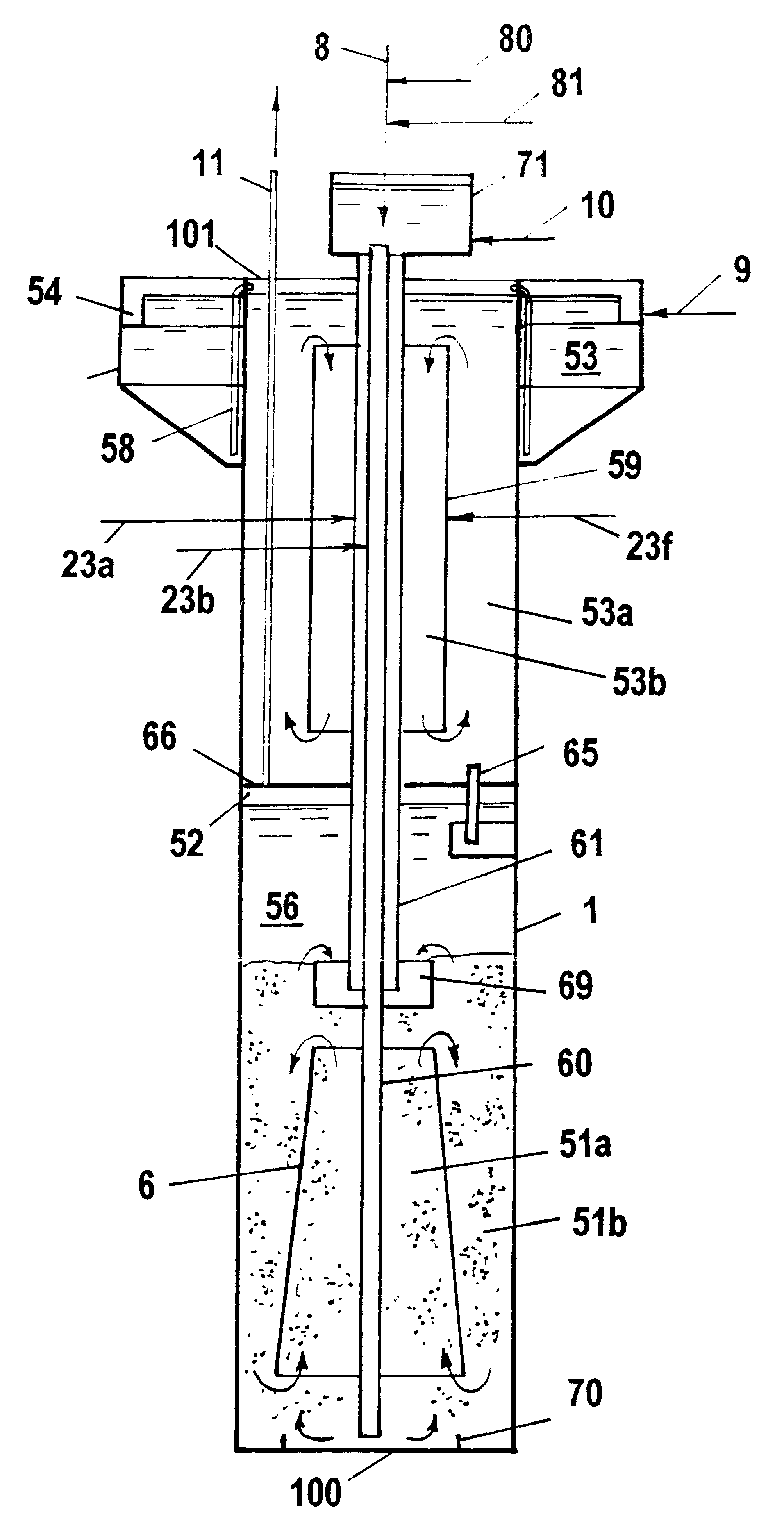

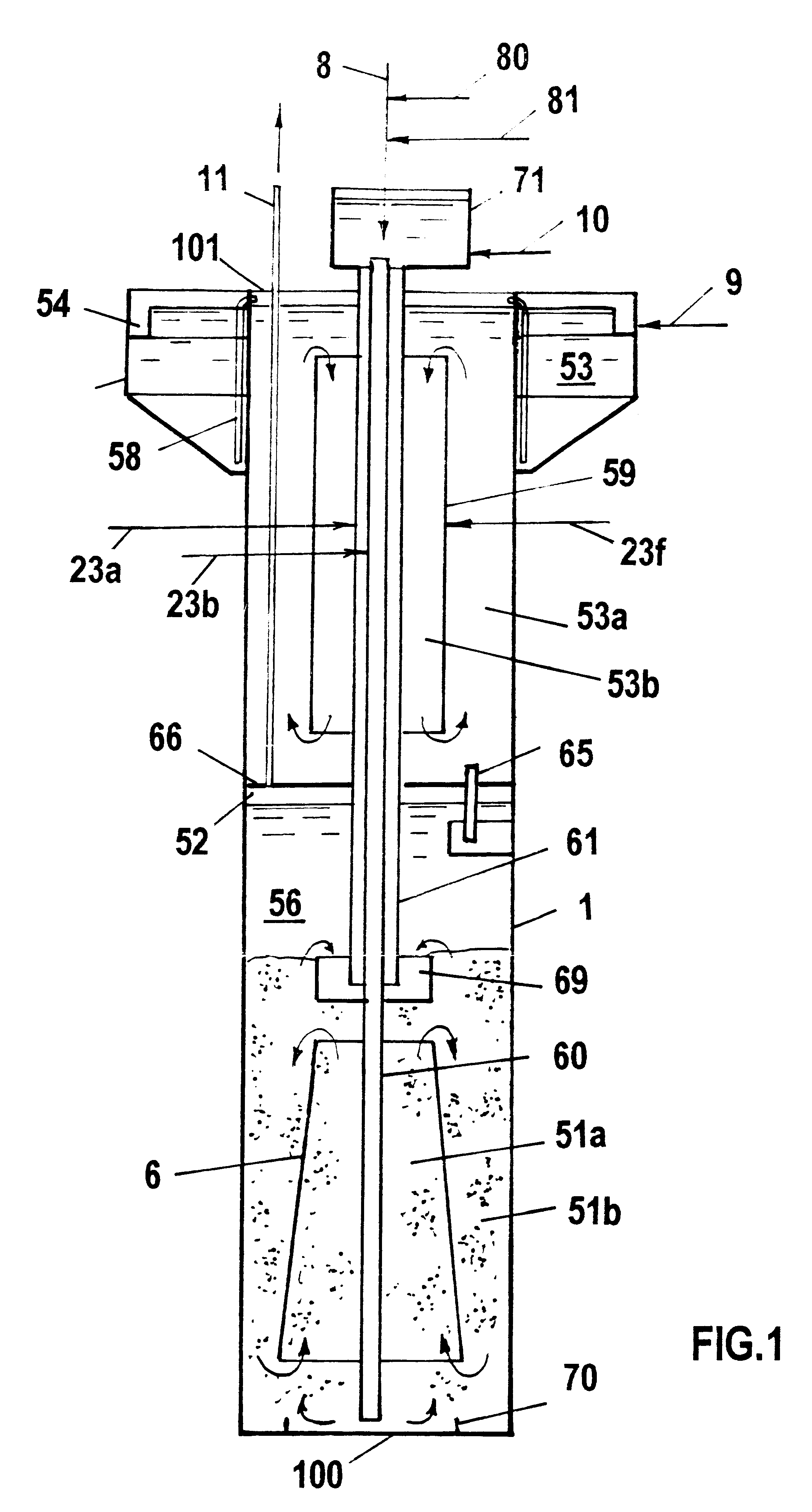

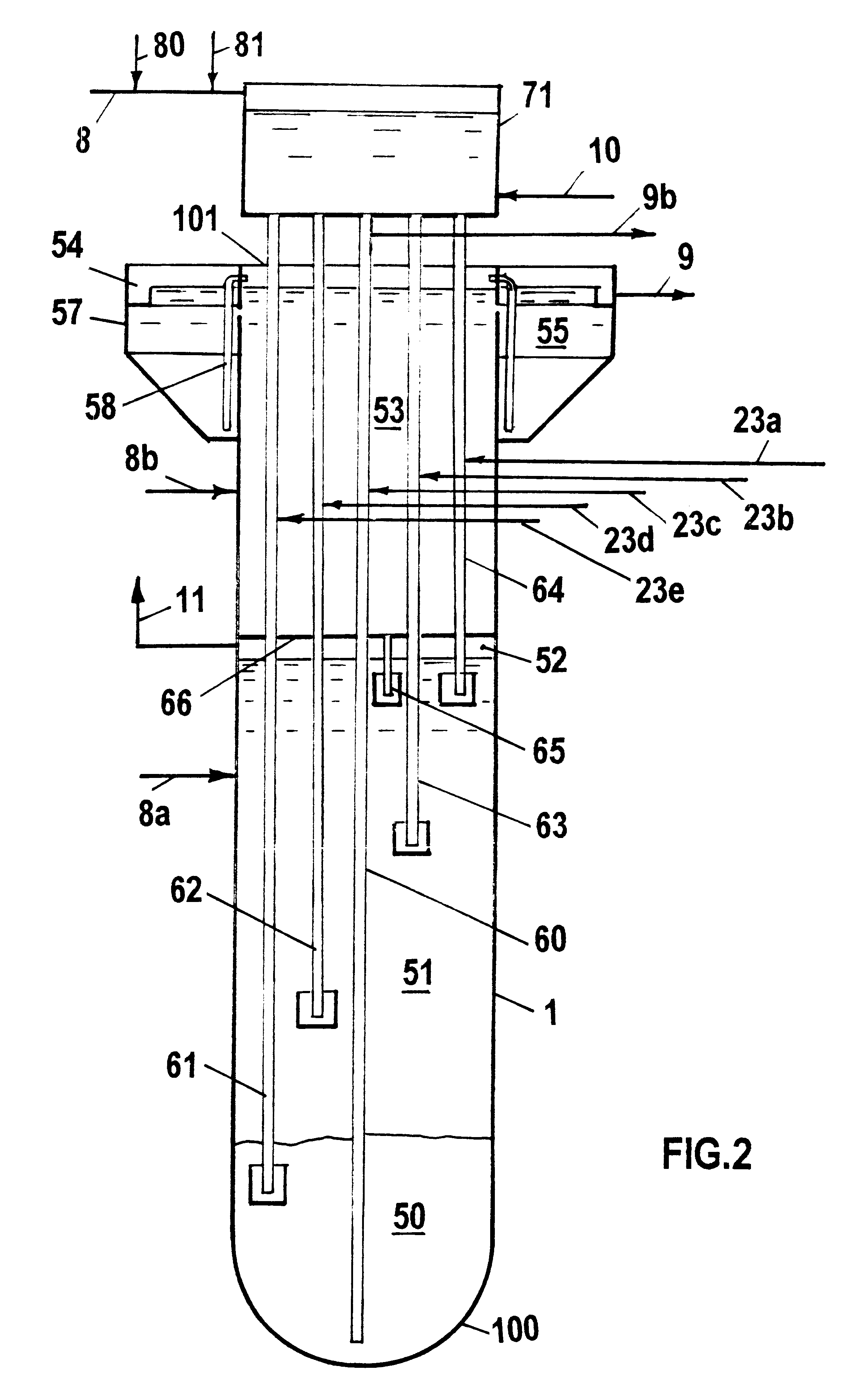

Biological treatment process

InactiveUS20030085171A1Easy to operatePromote repairGas production bioreactorsWaste based fuelAlkalinityDistillation

This is a method of waste treatment in tall reactors having with anaerobic biological stage in the lower section of the reactor and another treatment stage in the upper section of the reactor, these stages are separated by an essentially horizontal partition. Presurized digestion gases generated in the anaerobic section are collected under the partition. The process is further improved by providing a recuperable alkalinity and stripping of biologically generated carbon dioxide so that the free carbon dioxide concentratioon in the anaerobic mixed liquor is very low and a methane-rich digestion gas is produced. Production of presirised methane-rich digestion gas is the major benefit of the process. Ather improvements are in the controllable gaslift mixing with gases other than digestion gases, improved process performance with increasing operating temperatures due to bioheating, and improved solid-liquid separation due to the use of the distillation techniques making use of the bioheating and heat recycle.

Owner:KHUDENKO BORIS M

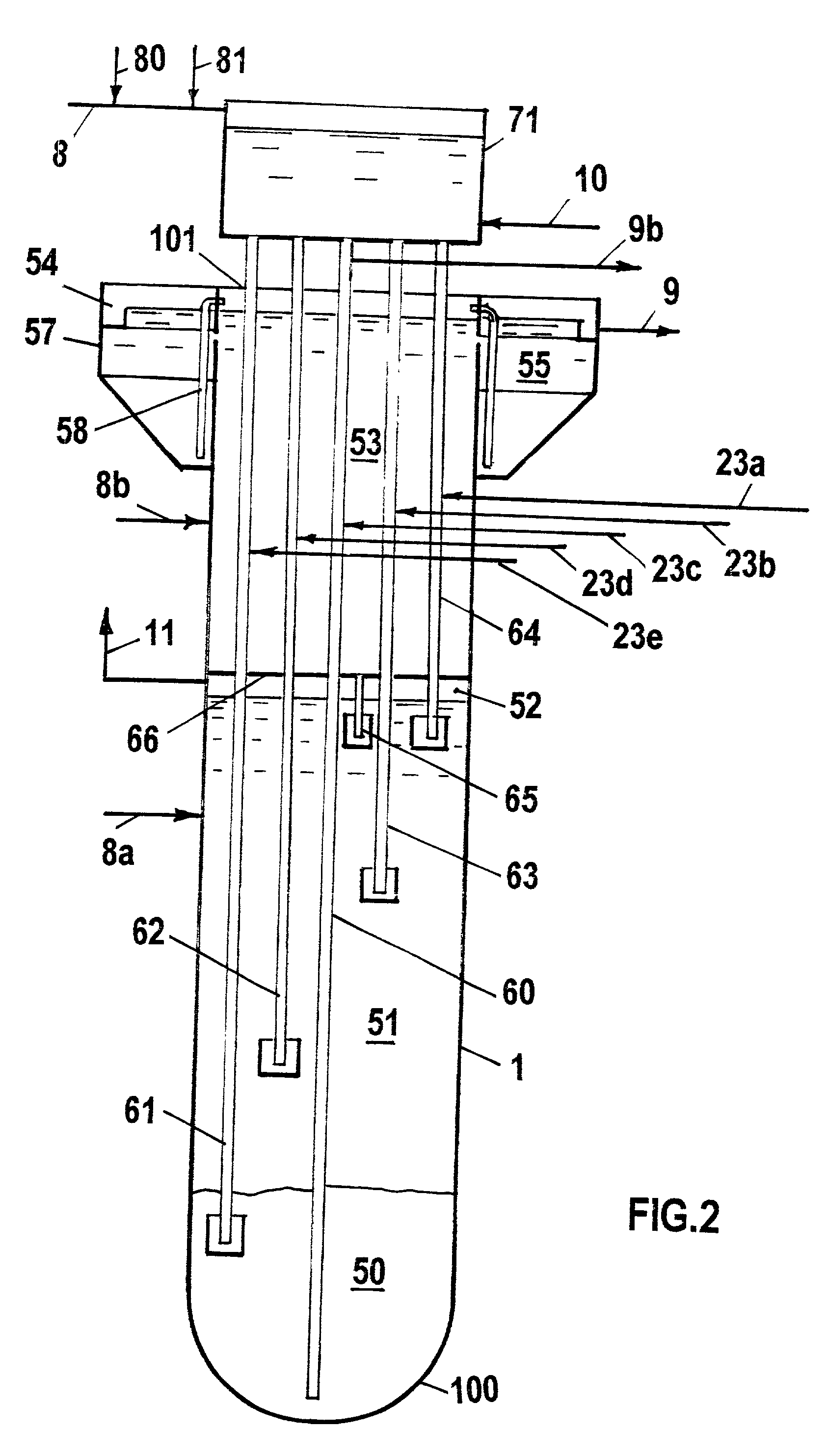

Gelatinization material of phosphoaluminic salt system

InactiveCN1498870AIncreased durabilityIncreased hydration rateCalcium biphosphateChemical composition

A cementing material is a cement whose main components are calcium phosphoaluminate, calcium aluminate and calcium phosphate. Its clinker contains such chemical components (wt%) as CaO (30-60), Al2O3 (17-50), SiO2 (1-15), P2O5 (10-30), Fe2O3 (1-8) and MgO (1-7). Its advantages are high and early strength, high refractory nature, and high compatibility with existing cement.

Owner:胡佳山

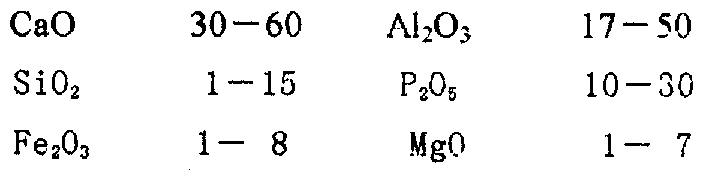

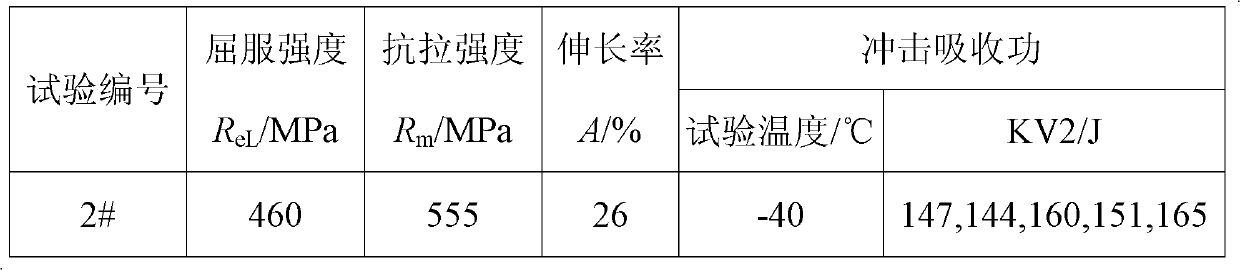

High-alkalinity high-tenacity low-hydrogen agglomerated flux and preparation method thereof

ActiveCN102601544AImprove weld metal toughnessImprove low temperature impact toughnessWelding/cutting media/materialsSoldering mediaSodium silicateHydrogen content

The invention discloses a high-alkalinity high-tenacity low-hydrogen agglomerated flux, which comprises the following components by weight: 18-21.5% of MgO, 33-35% of CaF2, 15-20% of Al2O3, 17-21% of SiO2, 3.5-8% of CaO, 1-5% of MnO, 2-5% of BaCO3, and less than or equal to 3% of FeO, wherein the total weight of the components is 100%. The invention further discloses a preparation method of the high-alkalinity high-tenacity low-hydrogen agglomerated flux, which comprises the steps of: mixing the raw materials and performing dry agitation, adding sodium silicate that accounts for 20wt% of the mixed powder, performing wet agitation, sending the materials to a pelletizer to pelletize, entering into a drying furnace after being dried by hot wind, drying at 180-230 DEG C, screening after discharge and then entering into a sintering furnace, sintering in the sintering furnace at 830-860 DEG C and discharging, and finally, screening and cooling to obtain the high-alkalinity high-tenacity low-hydrogen agglomerated flux. The flux provided by the invention solves the problems that a current flux is poor in toughness of weld metal and high in diffusible hydrogen content in deposited metal.

Owner:BAOJI YUSHENG WELDING MATERIAL

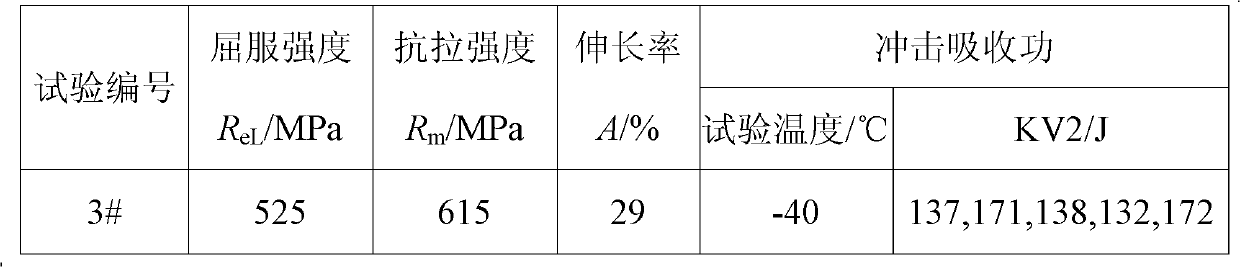

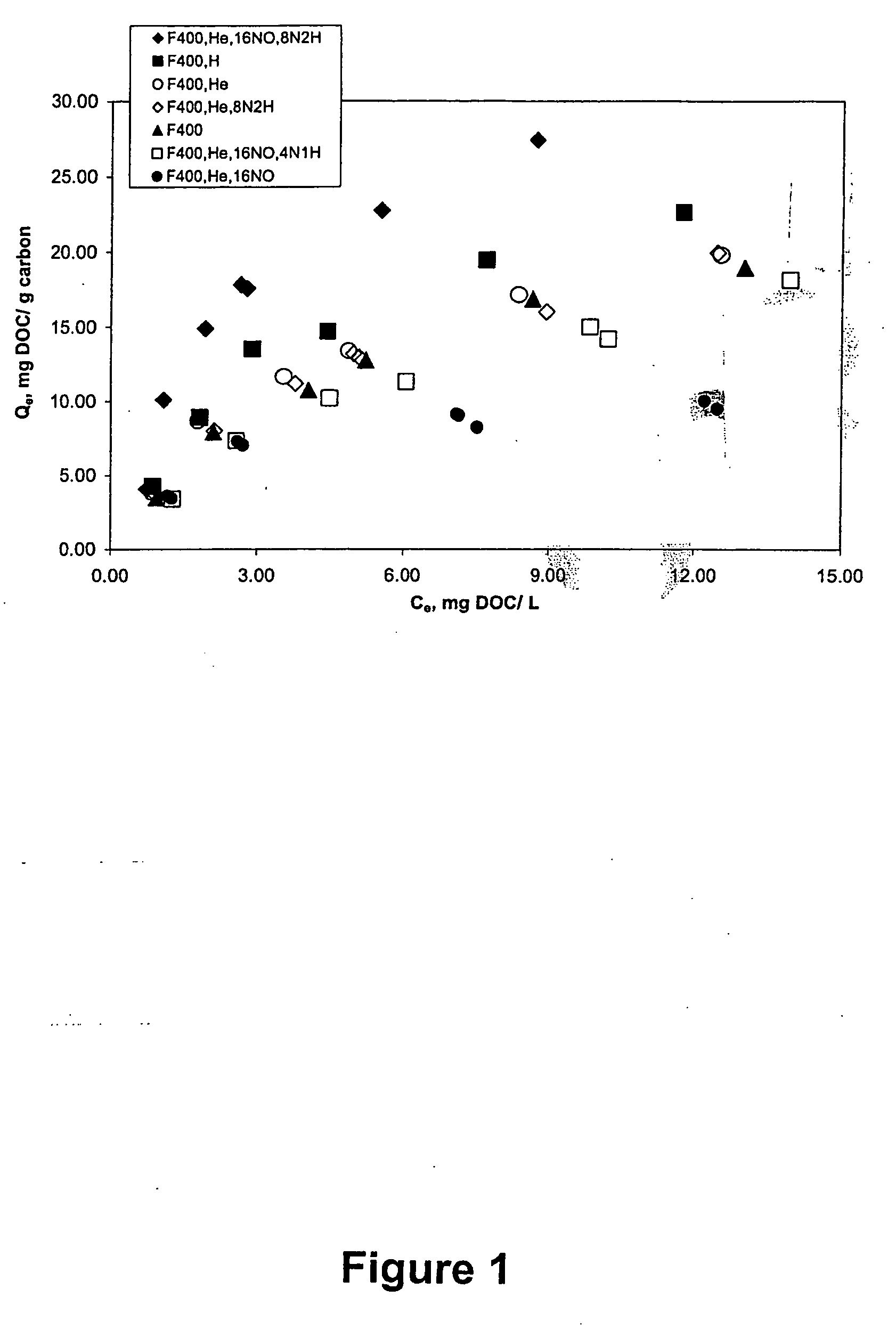

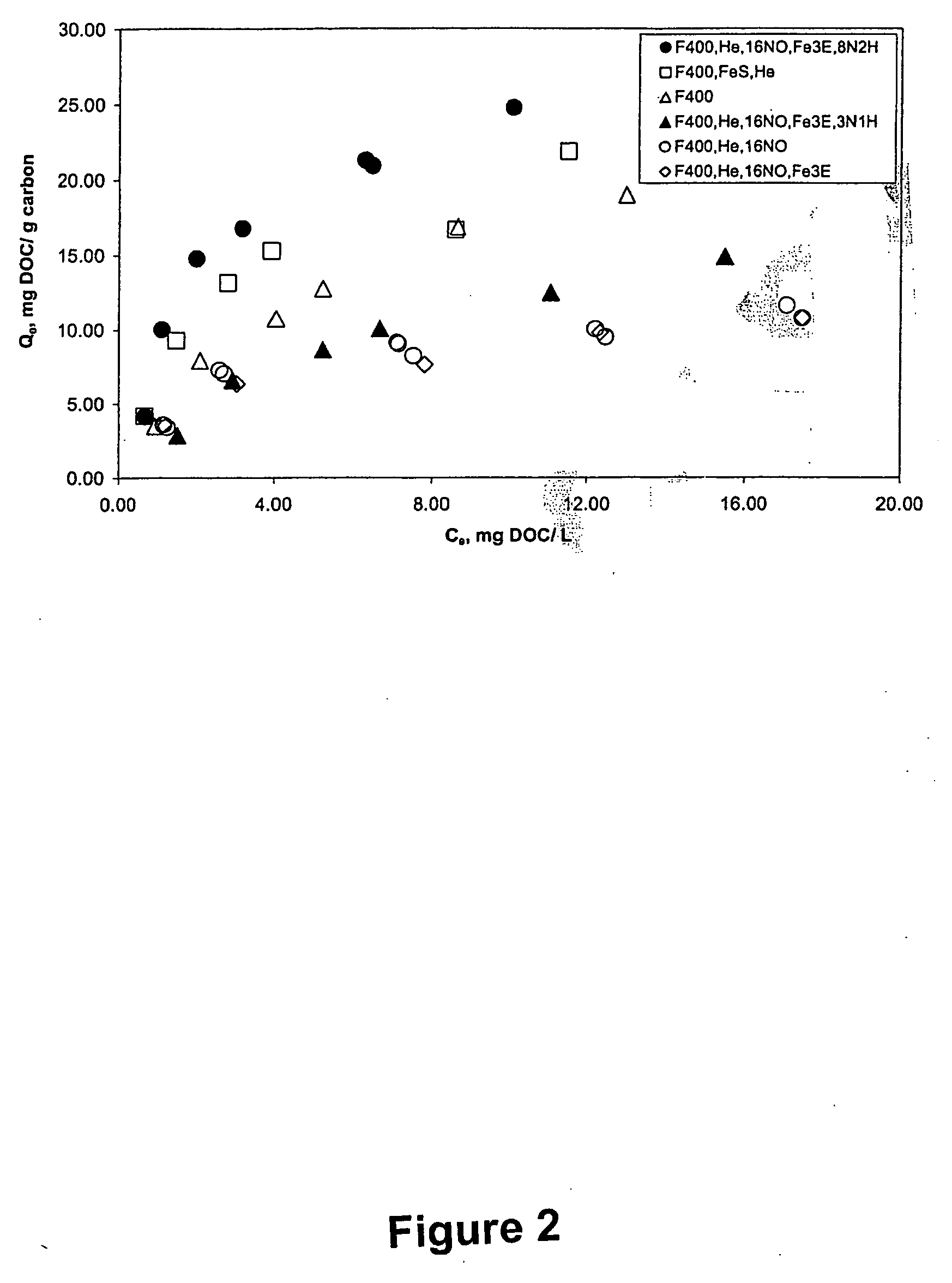

Activated carbon exhibiting enhanced removal of dissolved natural organic matter from water

InactiveUS20060157419A1Increase surface areaIncrease volumeSolid sorbent liquid separationWater/sewage treatment by sorptionNatural organic matterMedicine

Owner:CLEMSON UNIV RES FOUND

Biological treatment process

InactiveUS6984323B2Easy to operatePromote repairGas production bioreactorsWaste based fuelDistillationEnvironmental engineering

Owner:KHUDENKO BORIS M

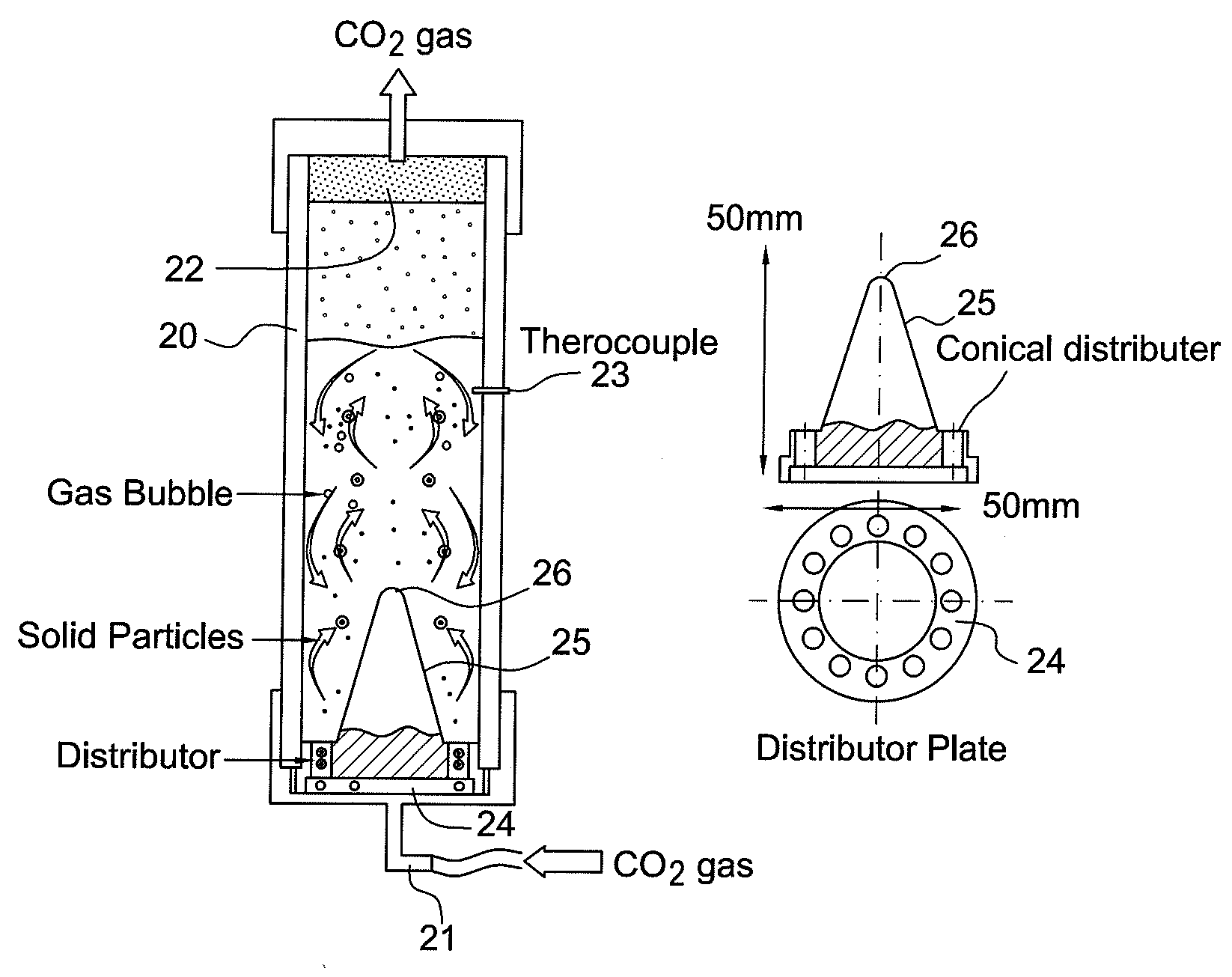

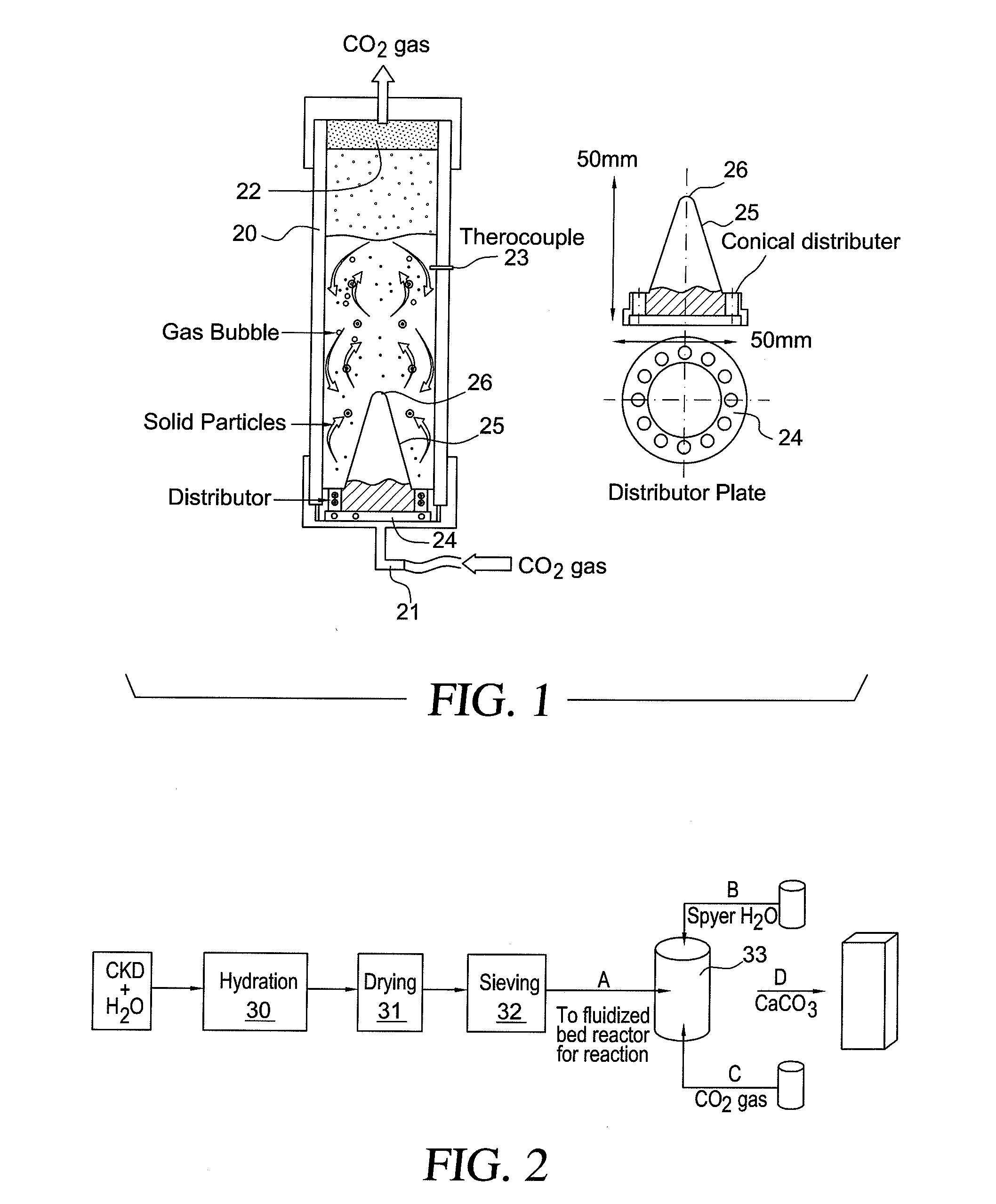

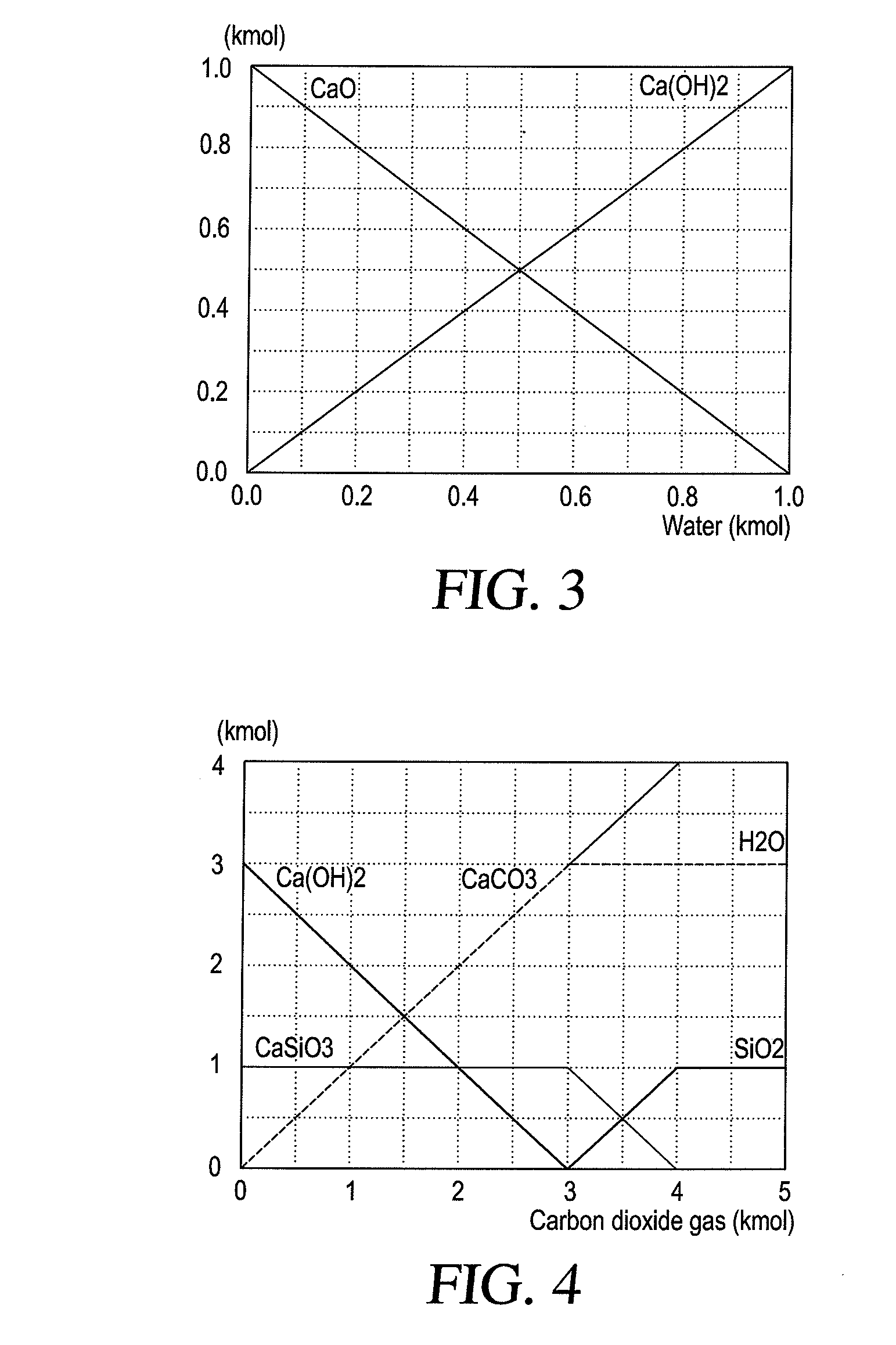

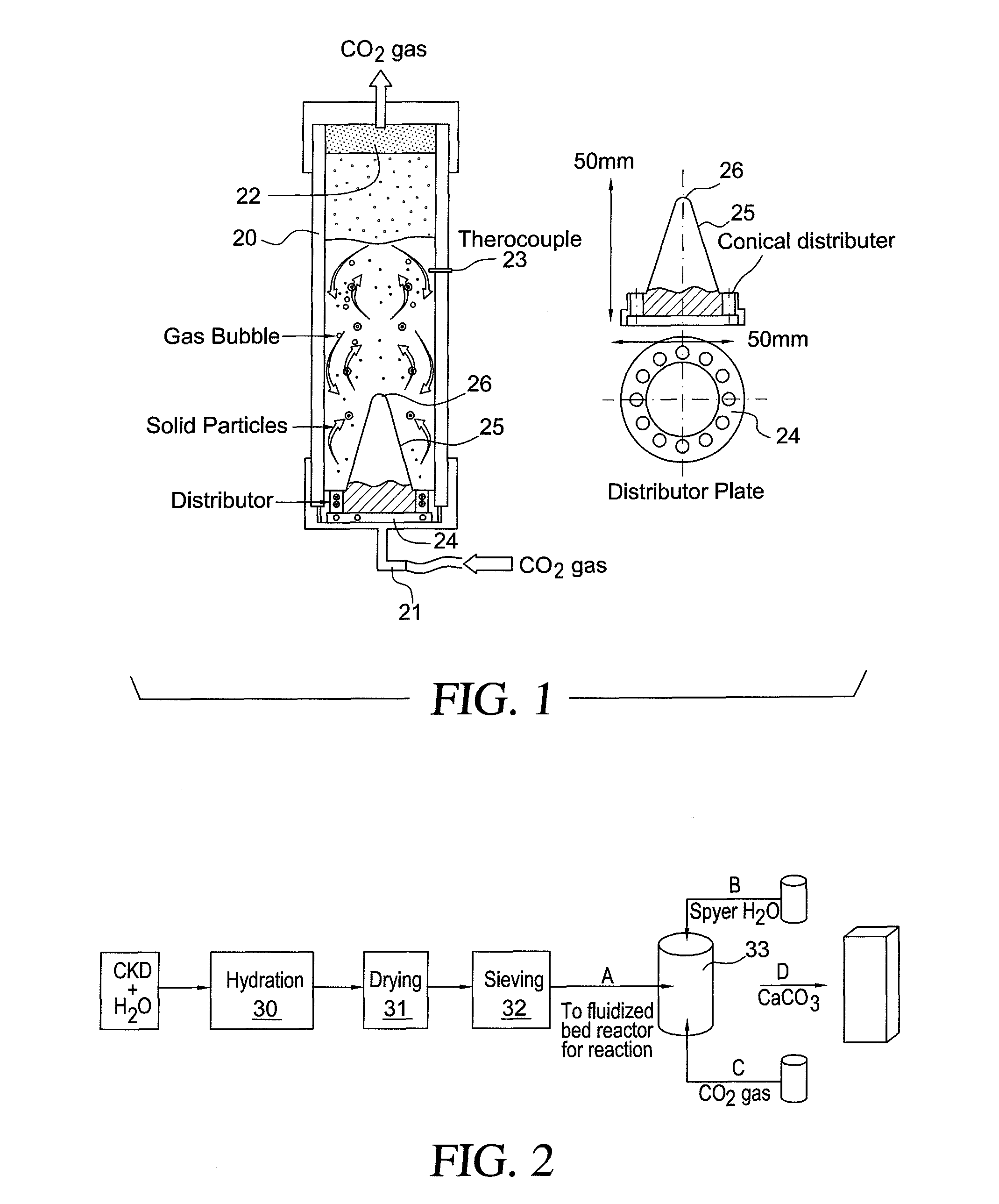

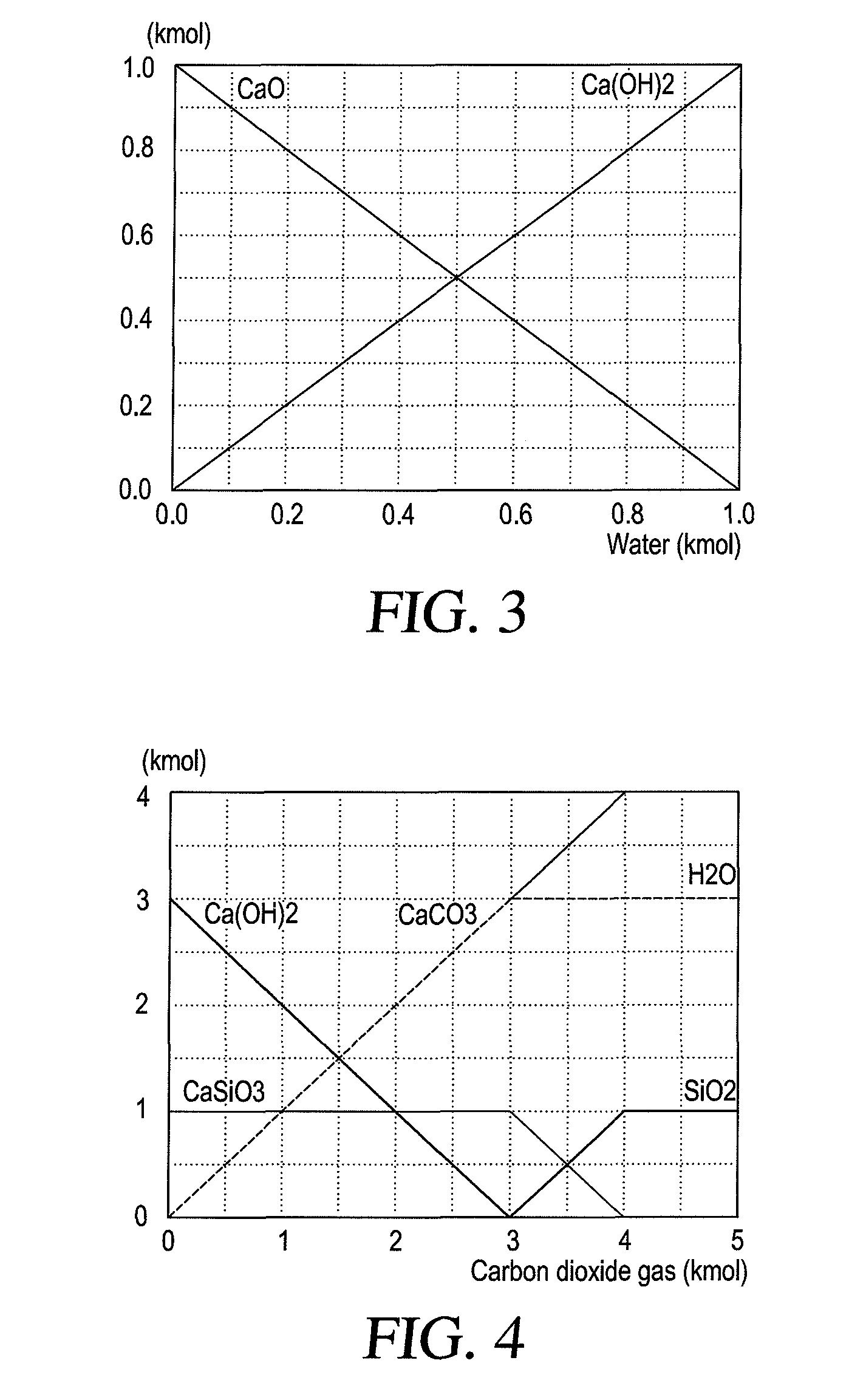

Method for treating cement kiln dust

InactiveUS20090283016A1Reduce solubilityMore stabilitySolid waste managementCarbon captureCarbonationCalcium hydroxide

A method for treating cement kiln dust containing alkaline metal salts includes the steps of hydration (formation of calcium hydroxide), dehydration i.e. drying, fractionation by sieving and carbonation (reaction of the fractionated moistened cement kiln dust) with CO2 gas in a fluidized bed reactor.

Owner:UNITED ARAB EMIRATES UNIVERSITY

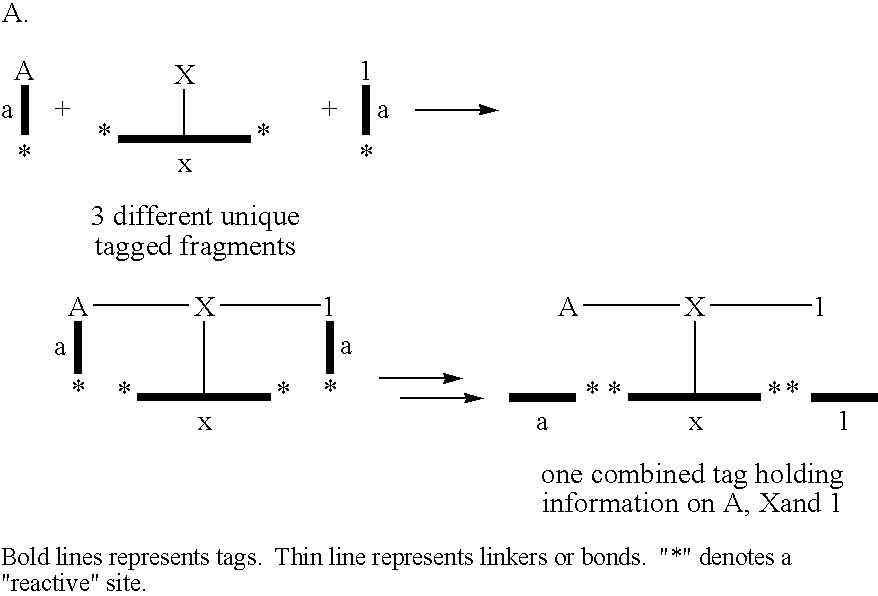

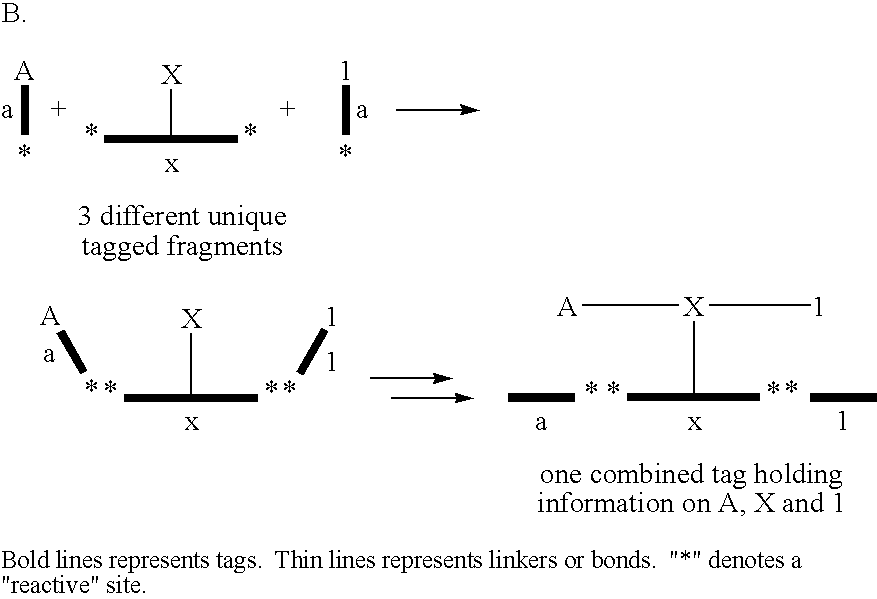

Method for selecting a chemical entity from a tagged library

ActiveUS20060292603A1Reduce noiseGood conditionMicrobiological testing/measurementLibrary screeningCompound (substance)Unique identifier

Disclosed is a method for determining the identity of a chemical entity having a preselected property. The chemical entity is identified from a library composed of a plurality of different chemical entities each appended to unique identifier tags. An anti-tag having the capability of specifically interacting with the unique identifier tag is recovered during the method and used for identification purposes.

Owner:NUEVOLUTION AS

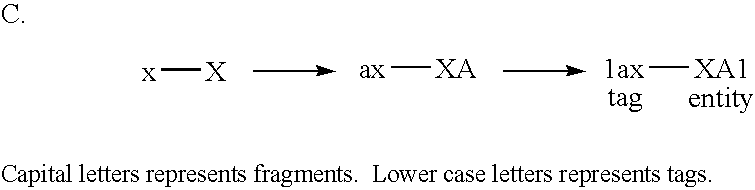

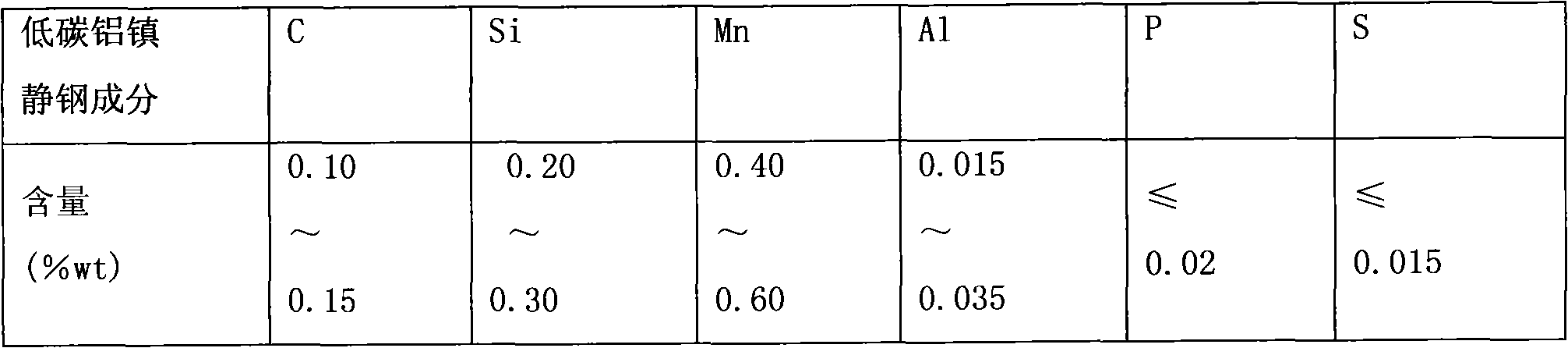

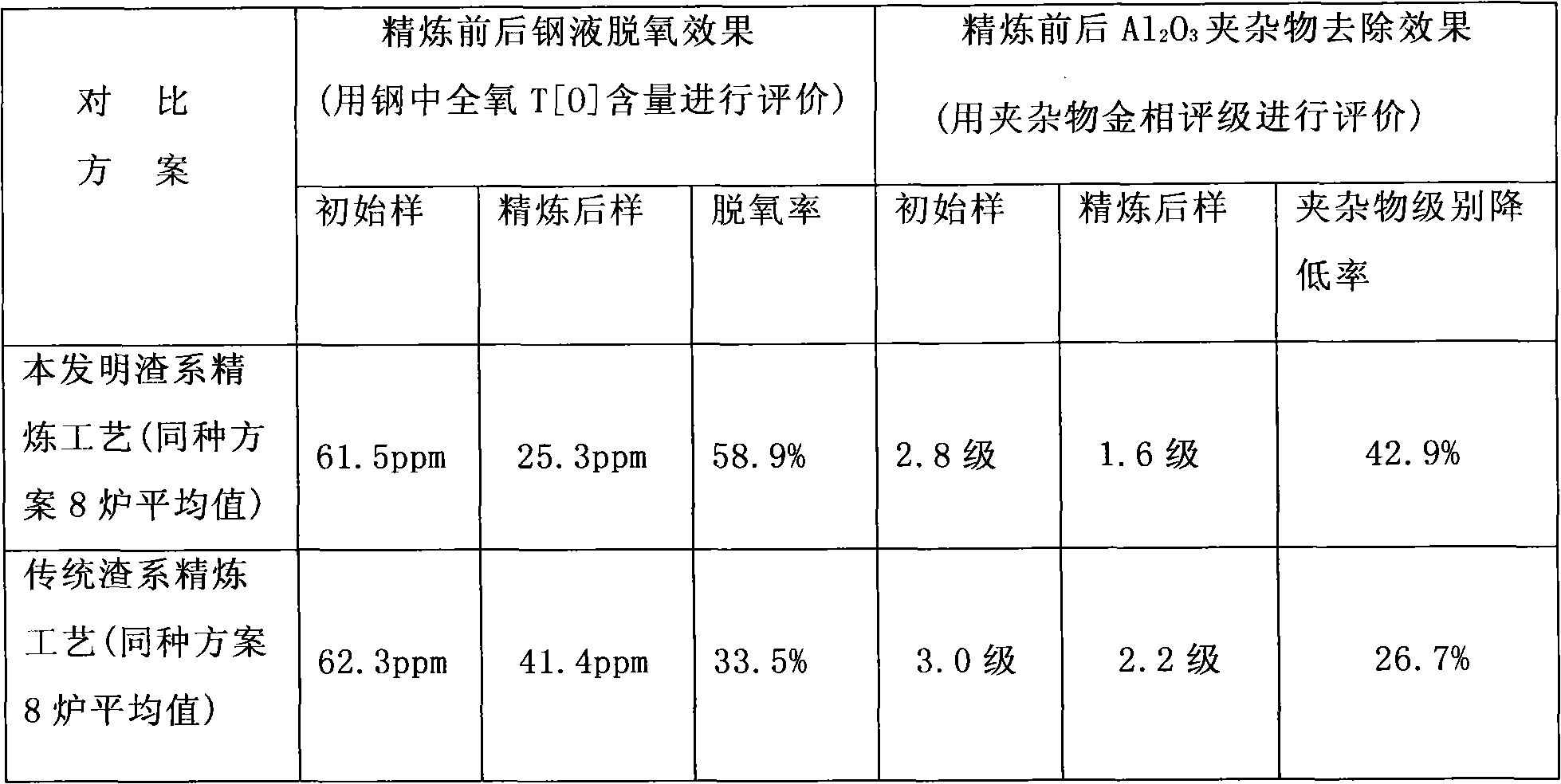

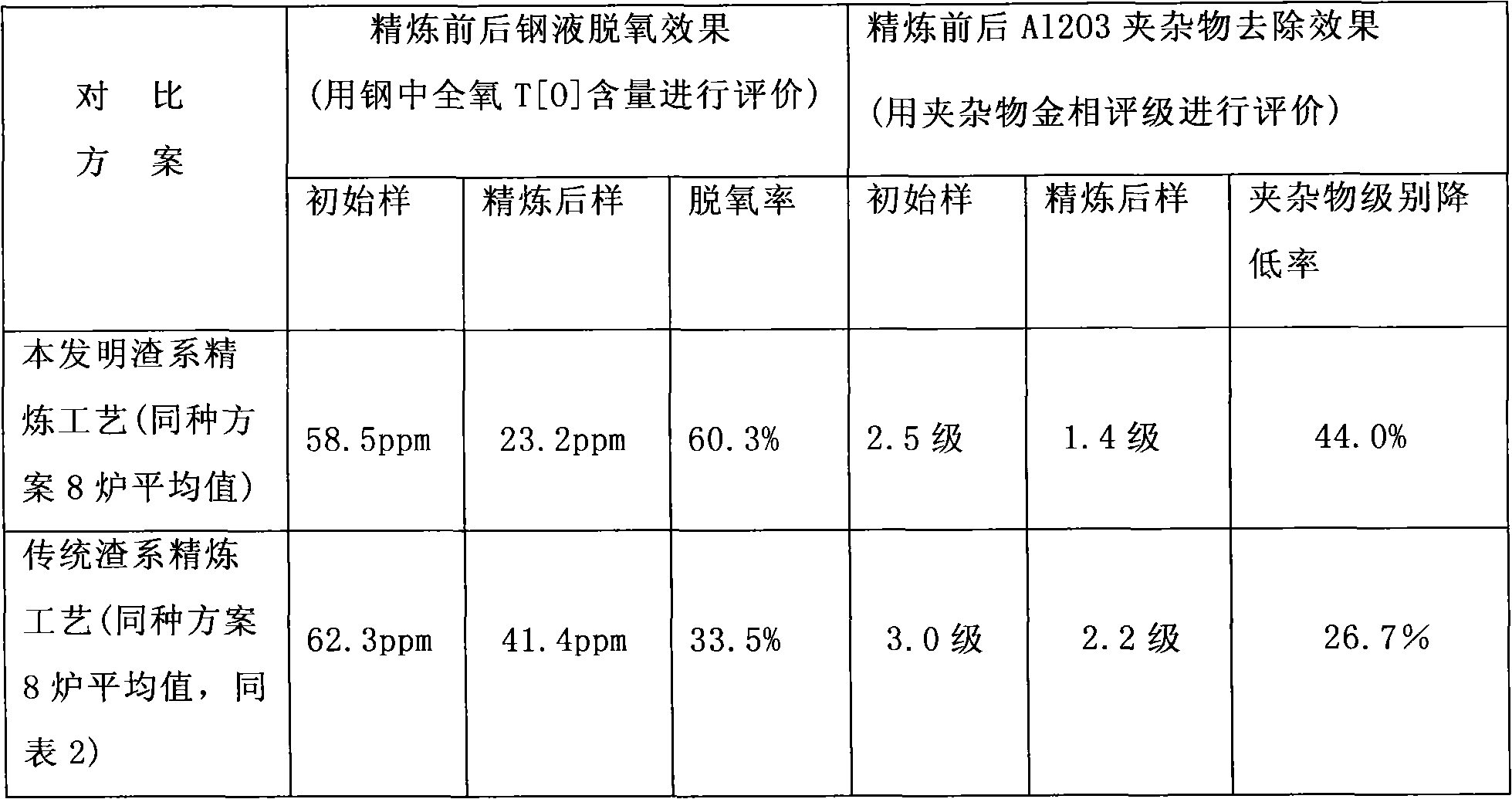

Rare earth oxide-containing steelmaking refining slag, and preparation method and using method thereof

ActiveCN102002556ALower melting temperatureGood liquidityProcess efficiency improvementReduction rateMagnesium

The invention belongs to the technical field of steelmaking refining and relates to rare earth oxide-containing steelmaking refining slag, and a preparation method and a using method thereof. The invention is characterized in that: a refining slag system comprises the following chemical components in percentage by mass: 40 to 55 percent of calcium oxide (CaO), 6 to 25 percent of aluminum oxide (Al2O3), 3 to 16 percent of cerium trioxide (Ce2O3), 3 to 10 percent of magnesium oxide (MgO), 3 to 15 percent of silicon oxide (SiO) and 1 to 6 percent of calcium fluoride. The refining slag system hashigh melting property, melting temperature of between 1,300 and 1,370 DEG C, low viscosity value of 0.1 to 0.3 Pa.s at the steelmaking temperature of between 1,550 and 1,600 DEG C and high flowability. Molten steel refining tests in a 200-kg induction furnace, a 100-t combined blown converter and a 60-t arc furnace show that compared with the traditional refining slag system, the refining slag system provided by the invention has deoxidizing rate and impurity level reduction rate of over 15 percent and effectively improving refining efficiency.

Owner:ZHONGXING ENERGY EQUIP

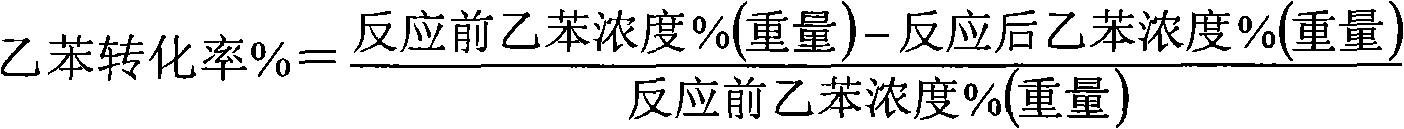

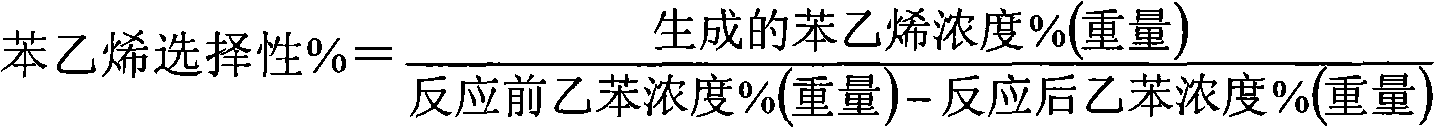

Ethylbenzene dehydrogenation catalyst with low steam-to-oil ratio and preparation method thereof

ActiveCN102371161AIncrease alkalinityImprove stabilityHydrocarbonsMetal/metal-oxides/metal-hydroxide catalystsCaesium compoundTungsten

The invention relates to an ethylbenzene dehydrogenation catalyst at a low steam-to-oil ratio and mainly aims to overcome the problem that low-potassium catalysts in the prior art have poor stability under the condition of a low steam-to-oil ratio. According to the invention, a caesium compound and at least one selected from the group consisting of rare earth oxides, i.e., Sm2O3, Eu2O3, Gd2O3 andDy2O3, are added into the catalytic system of iron-potassium-cerium-tungsten-magnesium; therefore, the above mentioned problem is well overcome, and the prepared catalyst can be used in industrial production of styrene through dehydrogenation of ethylbenzene.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for treating cement kiln dust

InactiveUS8043426B2Reduce releaseHighly effectiveSolid waste managementCinker content reductionCalcium hydroxideFluidized bed

A method for treating cement kiln dust containing alkaline metal salts includes the steps of hydration (formation of calcium hydroxide), dehydration i.e. drying, fractionation by sieving and carbonation (reaction of the fractionated moistened cement kiln dust) with CO2 gas in a fluidized bed reactor.

Owner:UNITED ARAB EMIRATES UNIVERSITY

Low-carbon and low-silicon steel deoxidation process

The invention relates to a low-carbon and low-silicon steel deoxidation process, comprising the following process flow: converter taping: tapping when the content of oxygen at the end point of the converter is over 500ppm; adding carbon powder at the beginning of the tapping for rough deoxidation, measured by the carbon dust of 0.15-0.25kgper ton of steel; adding aluminum iron for deoxidation alloying when the tapping is carried out to be 1 / 2 or 2 / 3, measured by the aluminum iron of 1.5-2.5kg / t steel; opening a steel ladle to an argon flushing station; supplementing aluminum iron: measuring the oxygen content of the steel ladle by using an oxygen probe, supplementing aluminum iron according to the measured oxygen content and adjusting the content of the oxygen of the steel ladle to be less than 50ppm; and flushing argon at the beginning of tapping at the flow of 300-400NL / min and adjusting the flow of bottom blowing argon gas to be 50-80NL / min when the steel ladle is opened to the argon flushing station for softly blowing argon. By using the carbon powder to deoxidize instead of the aluminum iron, the invention not only saves the cost of alloy, but also improves the purity of molten steel.

Owner:TANGSHAN GUOFENG IRON & STEEL

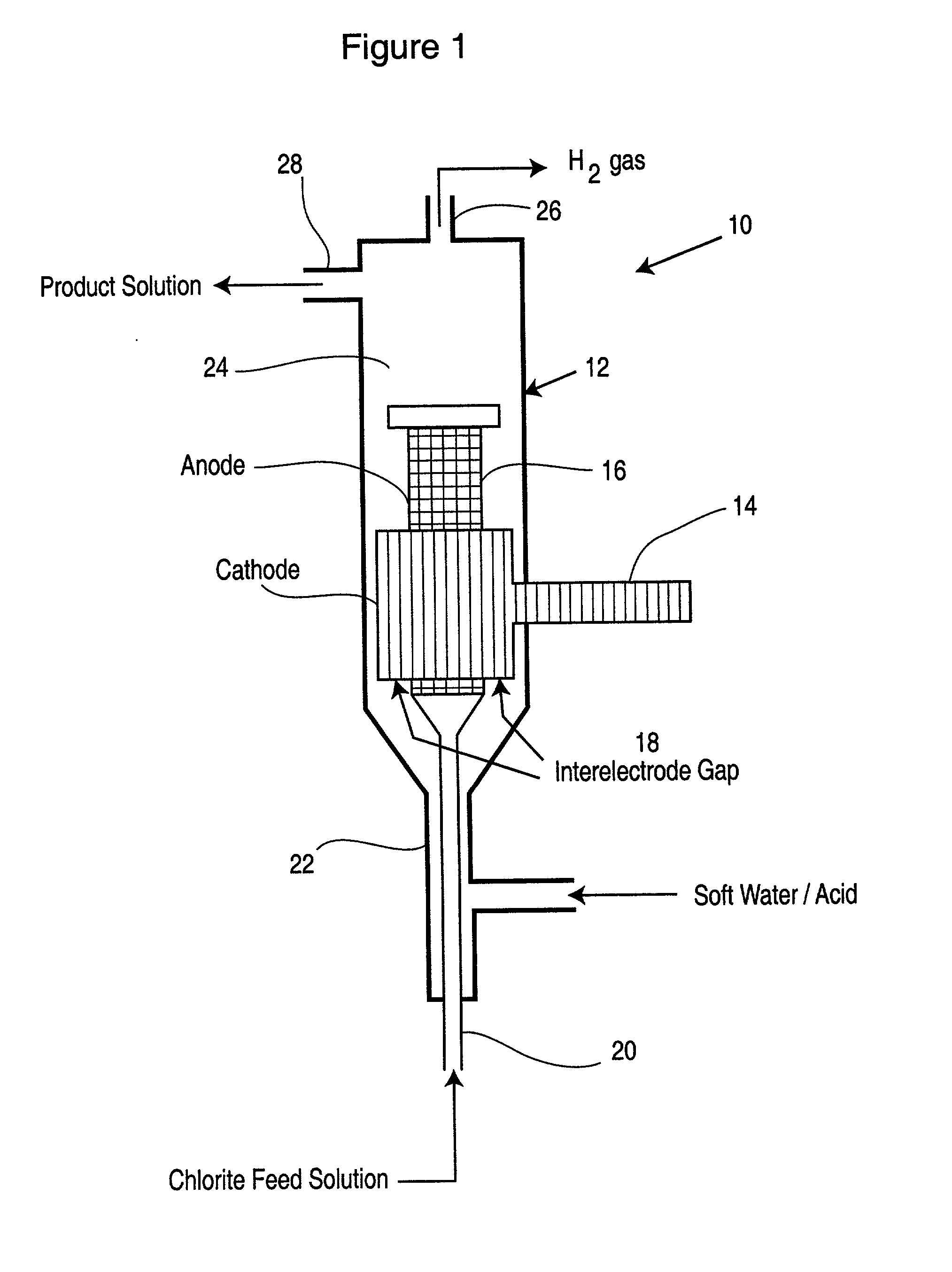

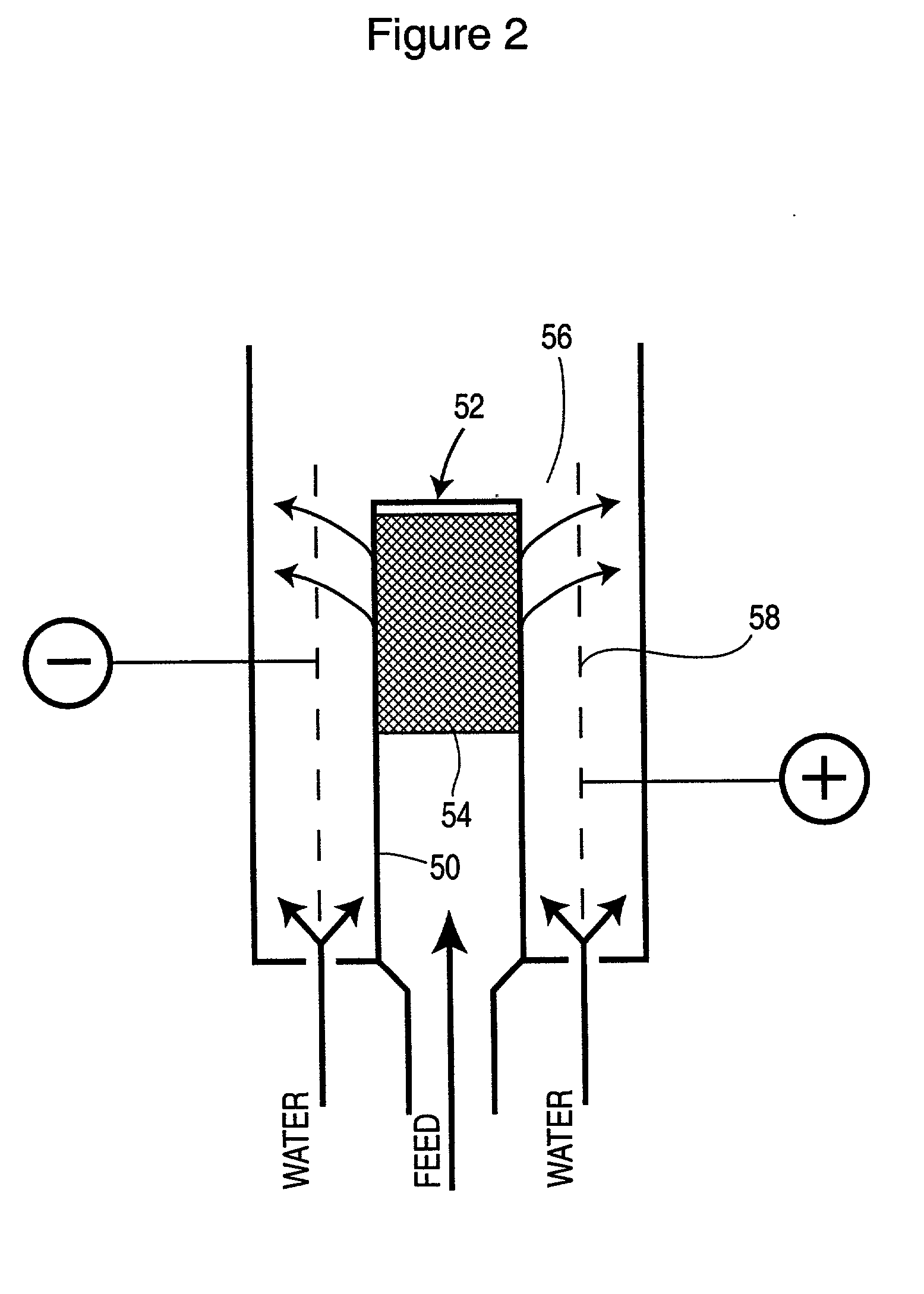

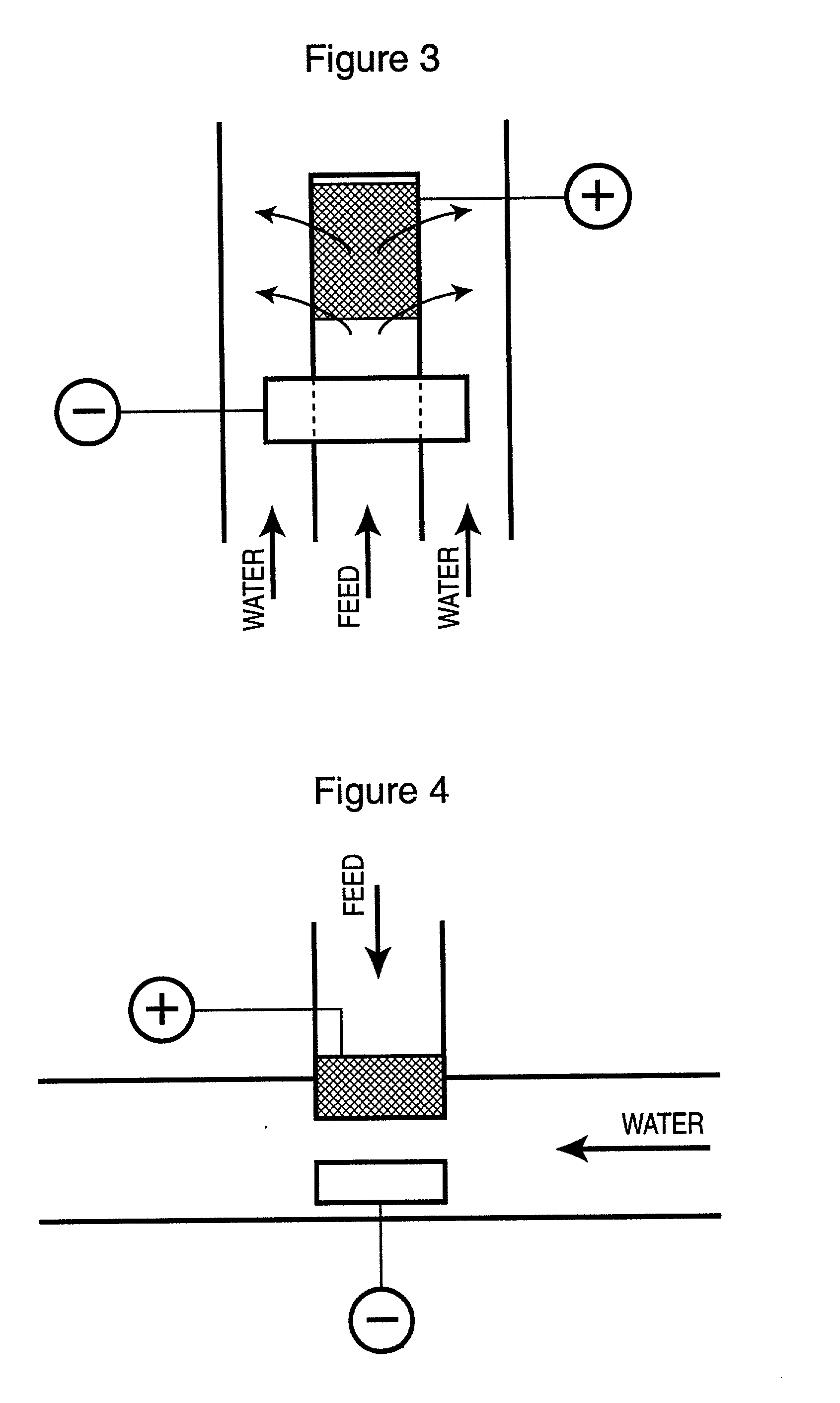

Electrolytic process for the production of chlorine dioxide

InactiveUS20030000848A1Speed up the conversion processIncrease contributionCellsPhotography auxillary processesSodium chloriteAqueous solution

Chlorine dioxide is produced at high conversion rates from aqueous sodium chlorite solution by electrochemical oxidation in an undivided electrochemical cell. The cell utilizes an anode of high surface area through which the aqueous sodium chlorite solution flows into an interelectrode gap between the anode and a cathode. Water or acidified water is fed into the interelectrode gap to function as catholyte and also to dilute the electrolyzed sodium chlorite solution to provide an aqueous solution of chlorine dioxide exiting from the electrochemical cell.

Owner:STERLING PULP CHEM +2

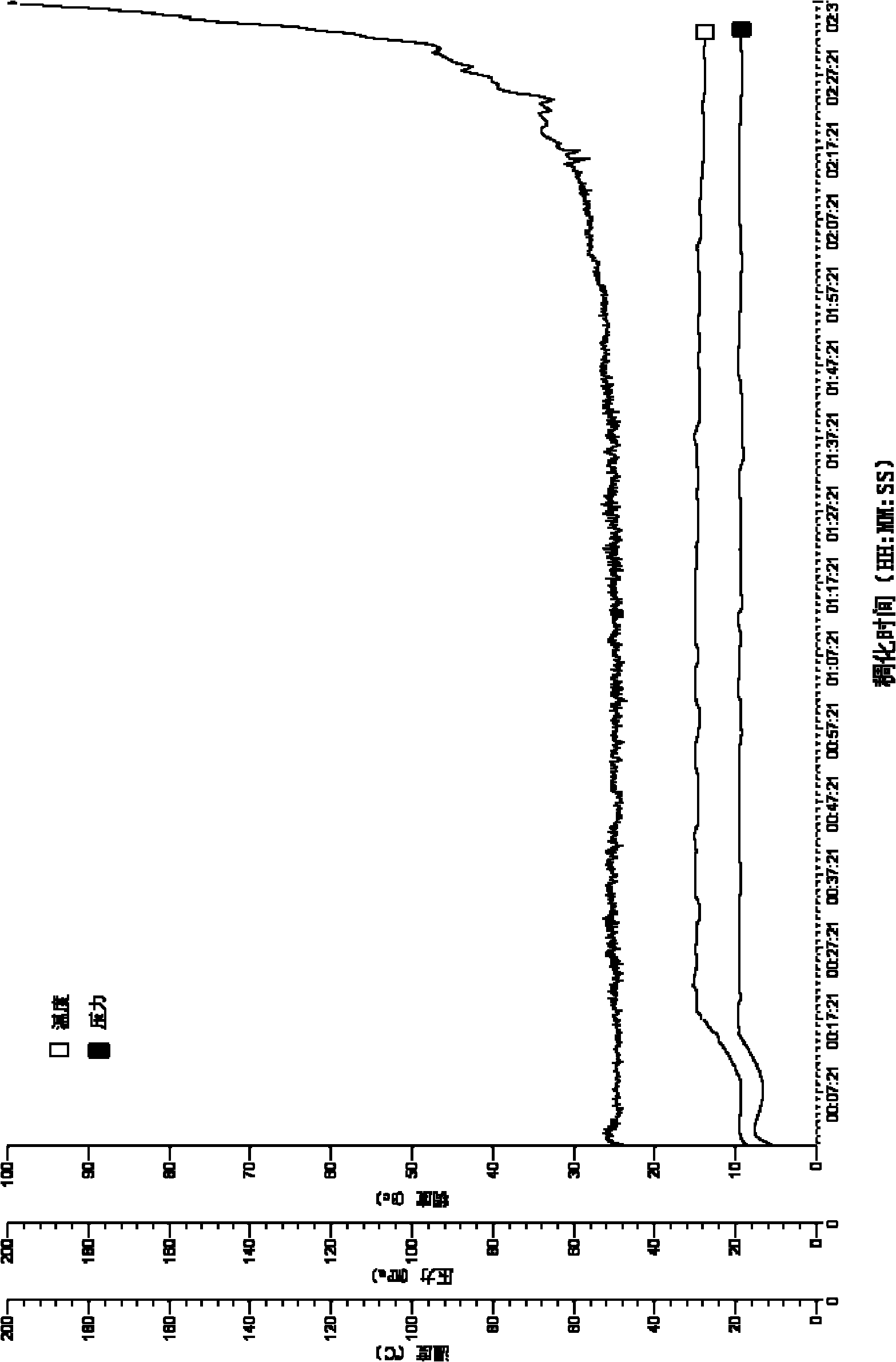

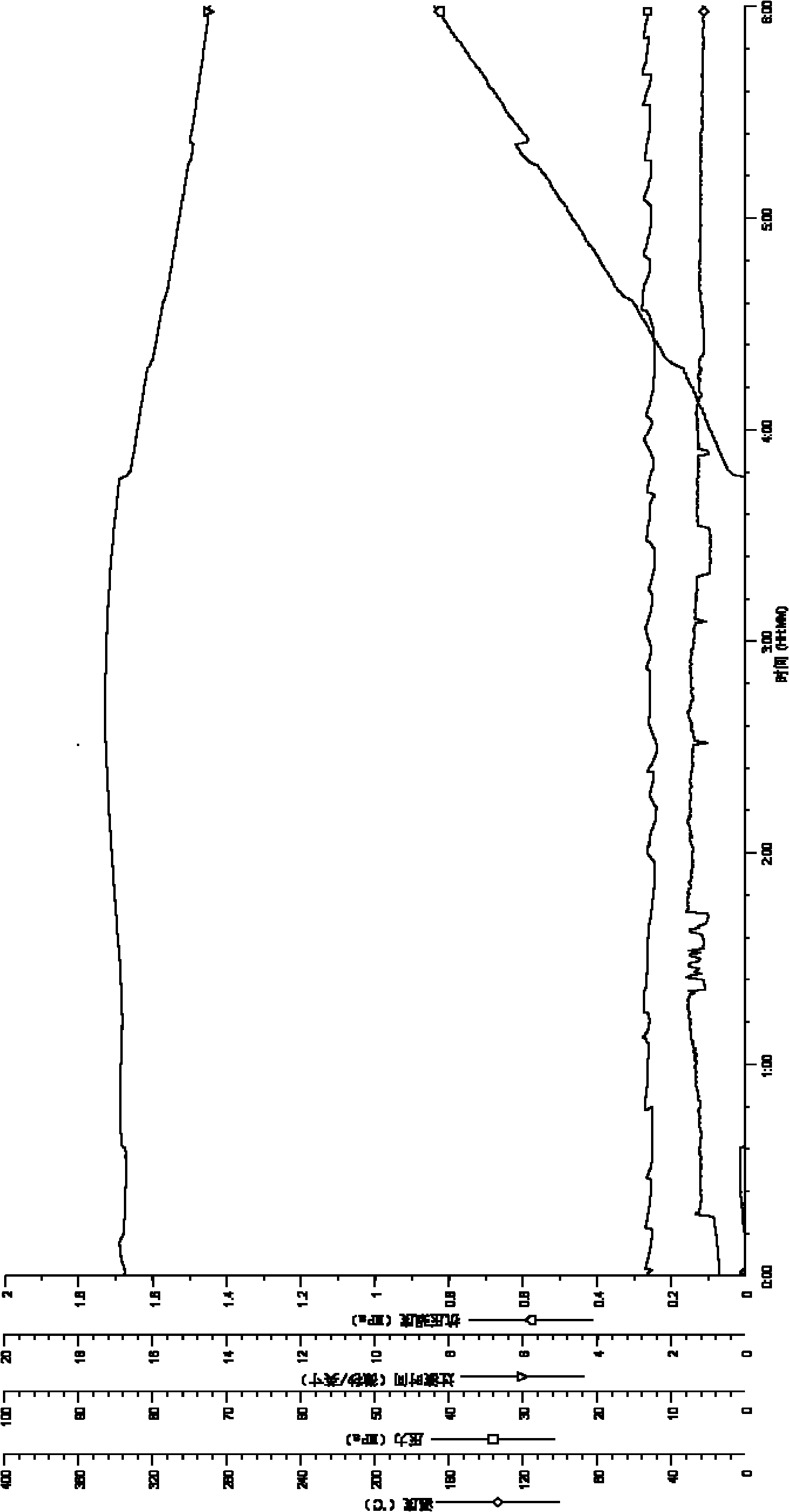

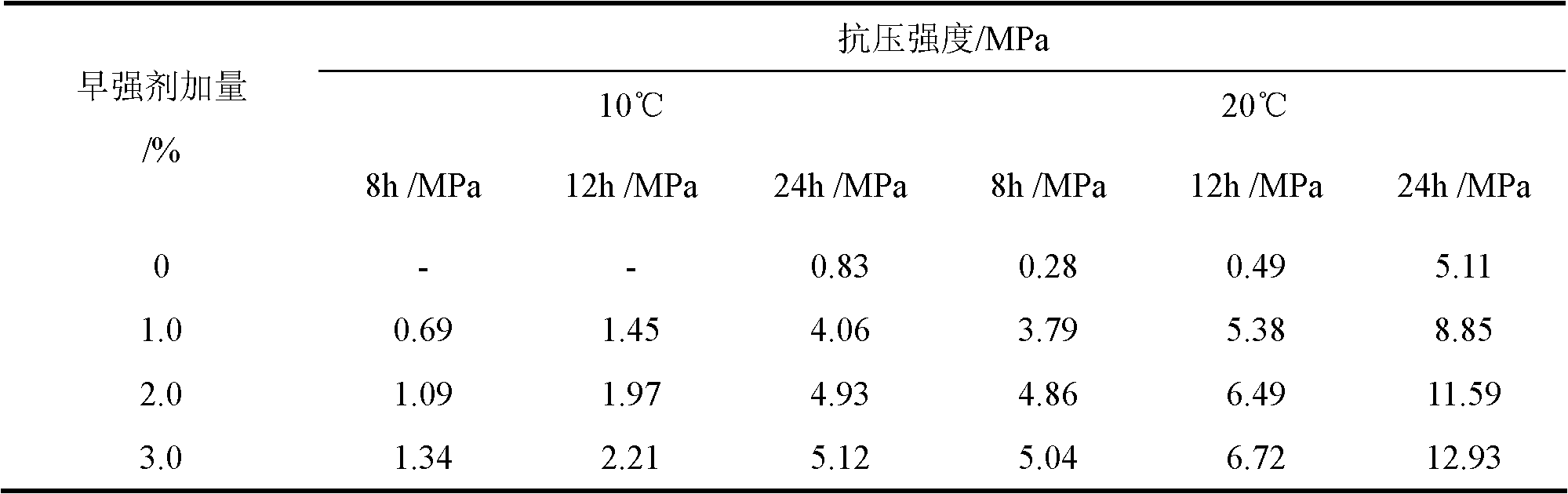

Deepwater cementing low-temperature early strength agent

InactiveCN101864285APromotes hydration processImprove compactnessDrilling compositionTriisopropanolamineCement paste

The invention relates to a deepwater cementing low-temperature early strength agent. The low-temperature early strength agent comprises the following components in percentage by weight: 33 to 66 percent of alkali metal bromides, 6 to 16 percent of sodium metaaluminate, 15 to 35 percent of alkali metal hydroxides, 8 to 15 percent of silicon dioxide and 0.8 to 1.5 percent of alcamines organics, wherein the alkali metal bromides are a mixture of one, two or more of NaBr, KBr and LiBr; the alkali metal hydroxides are NaOH, KOH or a mixture of the NaOH and KOH; and the alcamines organics are triethanolamine, triisopropanolamine or a mixture of the triethanolamine and triisopropanolamine. The deepwater cementing low-temperature early strength agent has small influence on rheological behaviour of cement paste at low temperature, can prompt the cement paste to be solidified rapidly at low temperature and reach higher early strength, shortens the thickening time of the cement paste at lower temperature and can well meet the requirements of the cementing construction of a surface casing under the conditions of low temperature, shallow gas and the like.

Owner:SOUTHWEST PETROLEUM UNIV

Ultra-pure steel corrosion-free type covering agent and production method thereof

The invention discloses an ultra-pure steel corrosion-free type covering agent and a production method thereof. The covering agent comprises the following components in percentage by weight: not more than 6 percent of SiO2, 40 to 45 percent of CaO, 7 to 11 percent of MgO, not more than 1.5 percent of Fe2O3, 29 to 35 percent of Al2O3, not more than 1 percent of Na2O, not more than 1 percent of F and not more than 1 percent of fixed carbon. The invention has the advantages that: premelting type refining slag, premelting type aluminum-calcium slag, calcium aluminate cement and light-roasted dolomite carbon-free low-silicon high-alkalinity materials are used as raw materials, the materials are reasonably matched with one another, and a covering slag atomization granulation production process is used for production, so that the covering agent has the advantages of high spreadability, no incrustation and no silicon addition, is easy and convenient to operate and use, improves the quality ofpurified molten steel during use, is granular, does not have dust pollution, and the like.

Owner:HENAN TONGYU METALLURGY MATERIALS GRP

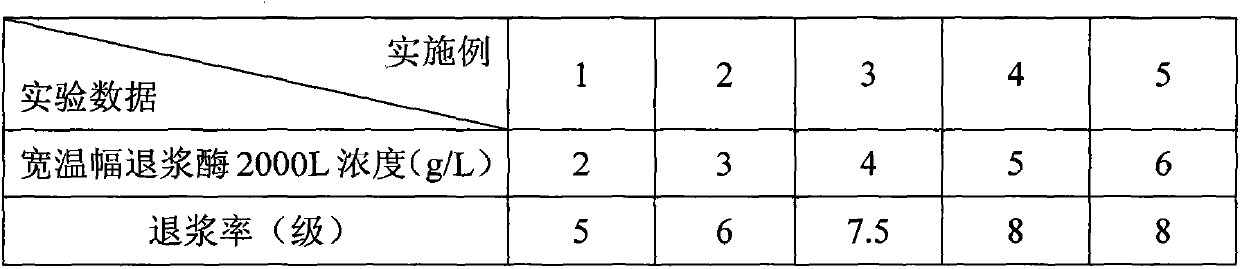

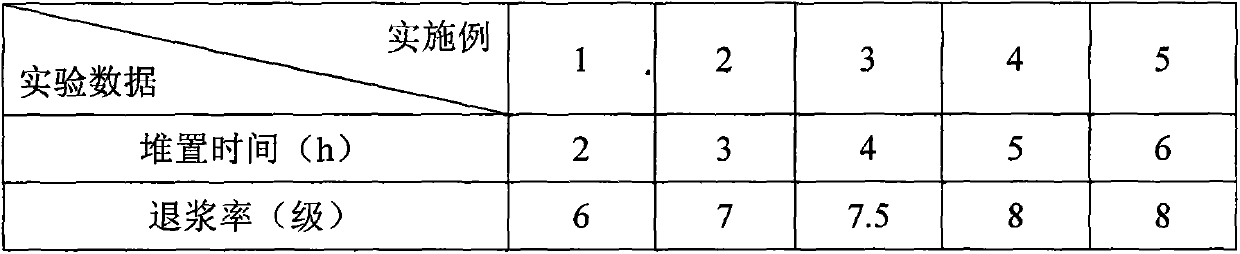

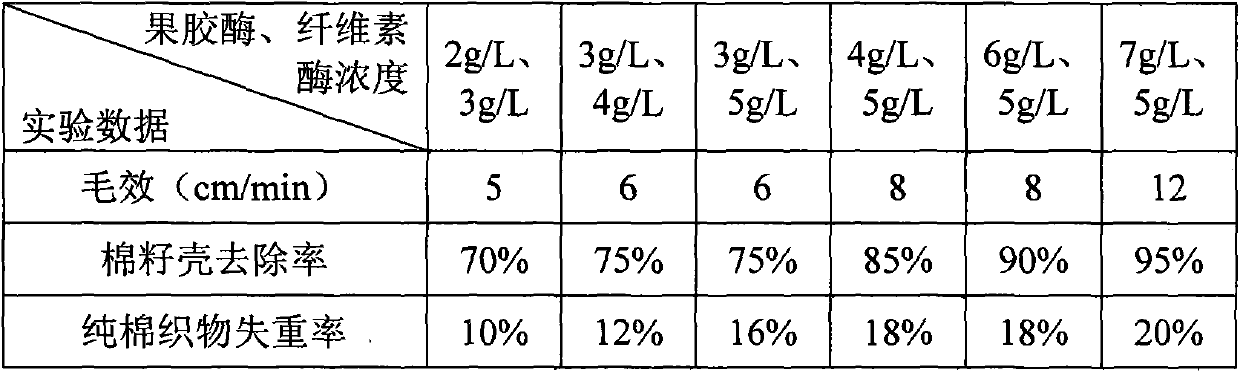

Dyeing treatment process for pure cotton fabrics based on pure natural biological preparations

ActiveCN103437141AHarm reductionEasy to operateShrinkingFabric breaking/softeningWastewaterEngineering

The invention discloses a dyeing treatment process for pure cotton fabrics based on pure natural biological preparations, which is designed for solving the technical problems that the environment is seriously harmed in an existing pure cotton fabric dyeing treatment process, and the human health is harmed in an application process. The adopted technical scheme is as follows: the dyeing treatment process comprises the steps of singeing, desizing, boiling-out, bleaching, dyeing, softening treatment and preshrinking treatment, and the key point is that biological preparations, which are respectively a desizing enzyme solution, a boiling-out enzyme solution, glucose oxidase solution and a plant dye, are respectively adopted in the steps of desizing, boiling-out, bleaching and dyeing. The dyeing treatment process has the technical effects that the operation is simple; the pure natural biological preparations almost do not contain any toxic substance, and wastewater produced in the treatment process is less and biodegradable, so that under the premise of keeping the characteristics such as softness, sweat absorption, comfortableness and naturalness and the like of pure cotton fabrics, the harm to the environment is alleviated, and the harm to human body is avoided, and therefore, the process has a zero-pollution environmental friendliness characteristic.

Owner:HEBEI NINGFANG GRP

Ladle refining slag modifier, preparation method and slag modifying method

InactiveCN101519712AStrong fluxing effectImprove flux effectProcess efficiency improvementSteelmakingImpurity

The invention belongs to the technical field of steelmaking and refining, and discloses a ladle refining slag modifier, a preparation method and a slag modifying method. The slag modifier comprises the following chemical components in percentage by mass: 30 to 60 percent of CaO, 30 to 60 percent of Al2O3, 2 to 10 percent of MgO2, 2 to 10 percent of B2O3, and less than 8 percent of impurities. The slag modifying method using the slag modifier comprises that: the slag modifier is hoisted to the front of a refining furnace after a steelmaking furnace discharges steels, and then is directly fed into ladles, or the slag modifier can also be fed into the furnace along with other slags at a refining station; the components of modifying slag are determined according to the ladle residue amount and components, desulfuration amount and steel deoxidation product amount; and the modifying slag for controlling the ladle slag comprises the following components according to the adding amount: 48 to 54 percent of CaO, 26 to 32 percent of Al2O3, 6 to 8 percent of MgO, 2 to 4 percent of B2O3, and 0 to 8 percent of SiO2, wherein the modifying slag is better if the content of the SiO2 is lower. The slag modifier has the capabilities of quickly manufacturing the slag, improving desulfuration and deoxidation of the refining slag and accommodating and absorbing deoxidation products, and is simple to prepare and convenient to store, transport and use.

Owner:JIANGSU UNIV

High-basicity refining slag for slag washing of revolving furnace steel-making

InactiveCN101139644AIncrease alkalinityLow melting pointManufacturing convertersProcess efficiency improvementAlkalinityForeign matter

The invention relates to a high-alkalinity refining slag and a preparing method for the slag for scrubbing slag of a converter, which comprises active lime, fluorspar and industrial pure alkaline that are mixed evenly in a disk mixer. The chemical components of the slag by weight are: 70.0%<=CaO<= 88%, 0<SiO2<=3.0%, 0<Al2O3<=4.5%, 2.0%<=Na2O<=4.1%, 8.0%<=CaF2<=13.3%, 0<MgO<= 5.2% and the remainder are igloss elements and trace foreign matters such as P and S, etc., the binary alkalinity CaO / SiO2>=23.3. When the high-alkalinity refining slag is used for scrubbing slag when tapping in the converter, the melting is fast, and no splashing will occur, the desulfurization efficiency is high and steady, and can meet the requirements for refining, deoxidizing and removing non-metallic foreign matters.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com