Deepwater cementing low-temperature early strength agent

A low-temperature early-strength agent and cementing technology, applied in the field of oil and gas well cementing, can solve problems such as single temperature conditions, temperature sensitivity, and large hydration heat release, so as to increase the liquid phase temperature, promote formation, and improve early strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

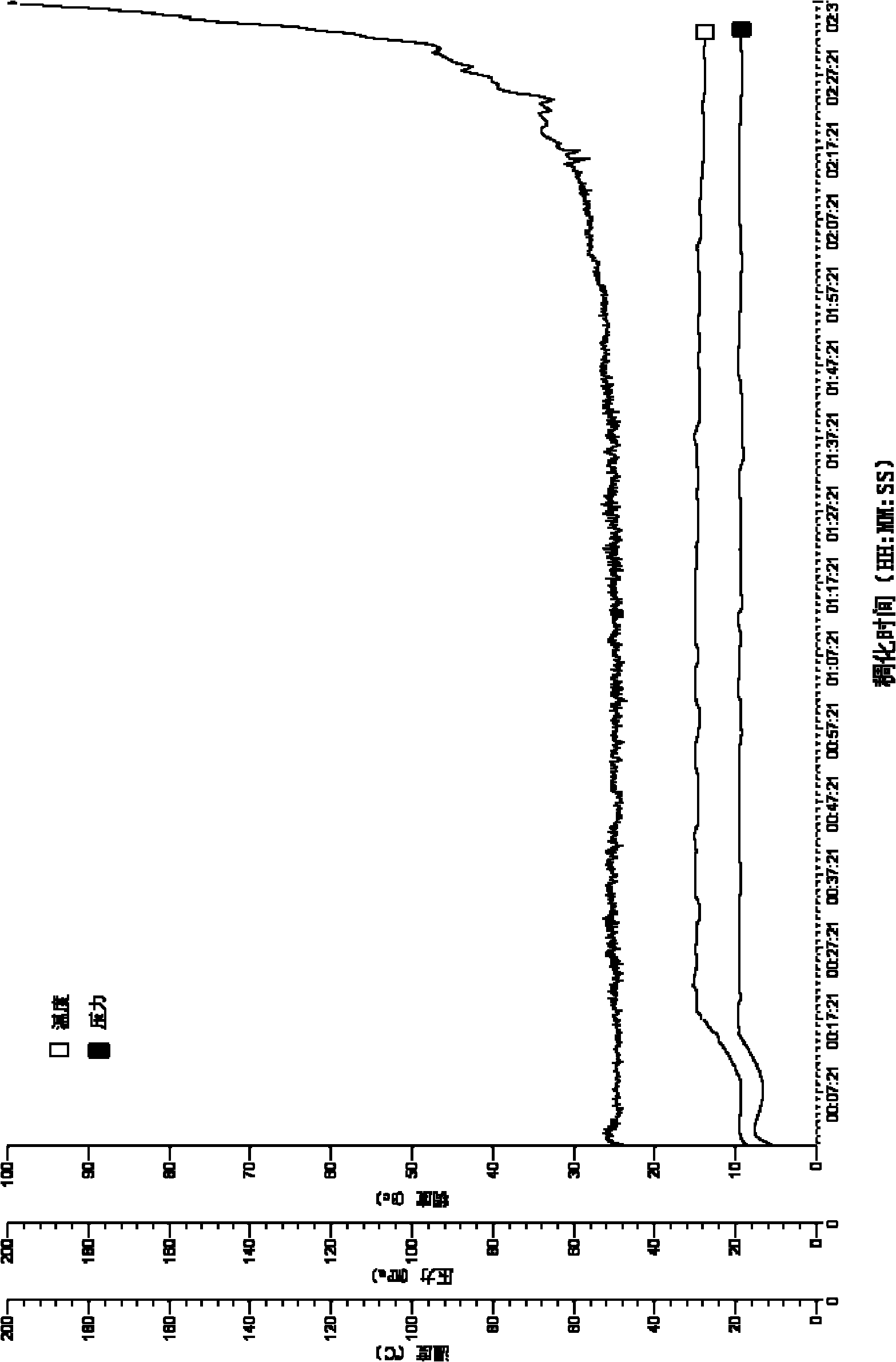

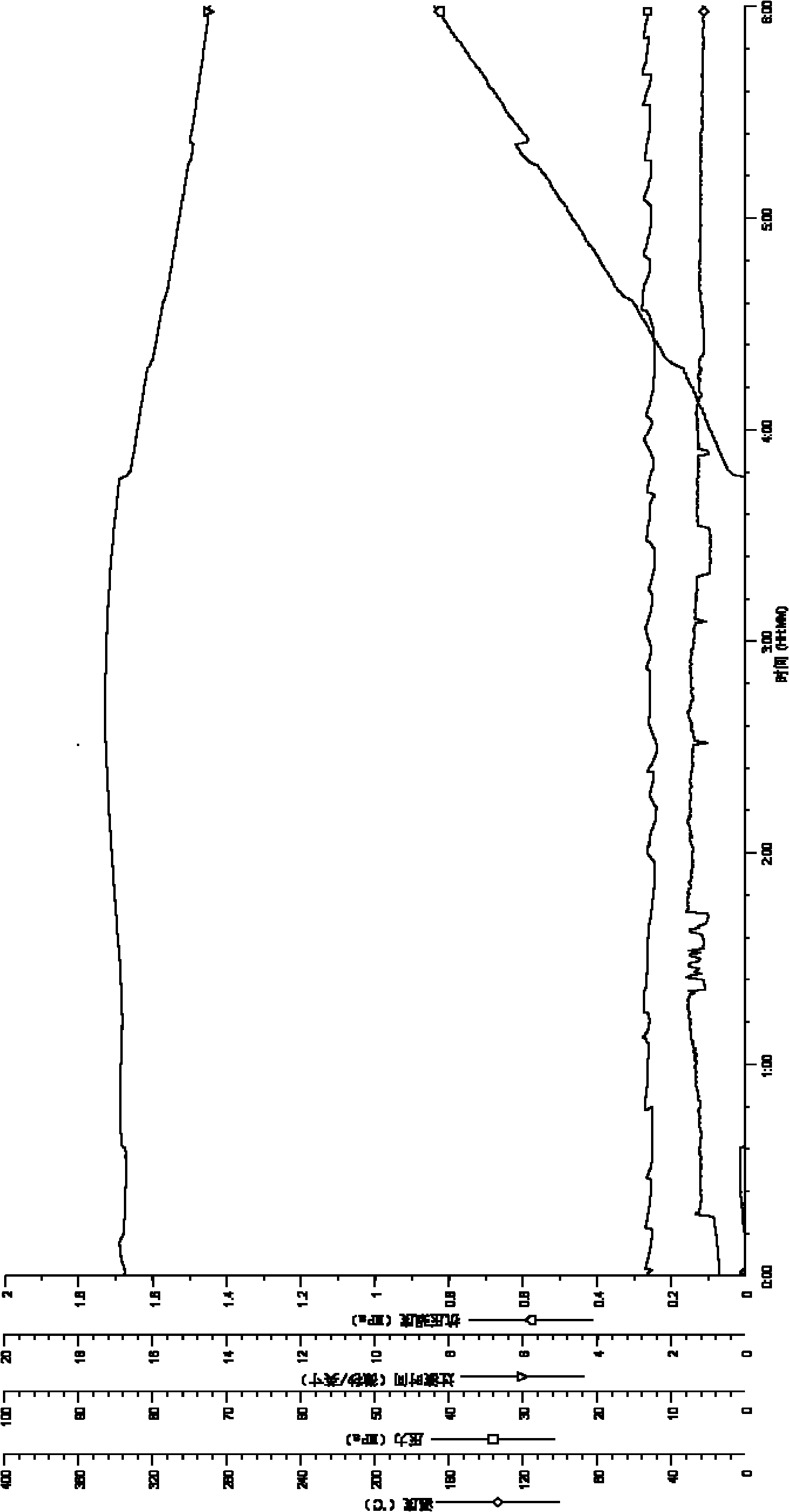

Method used

Image

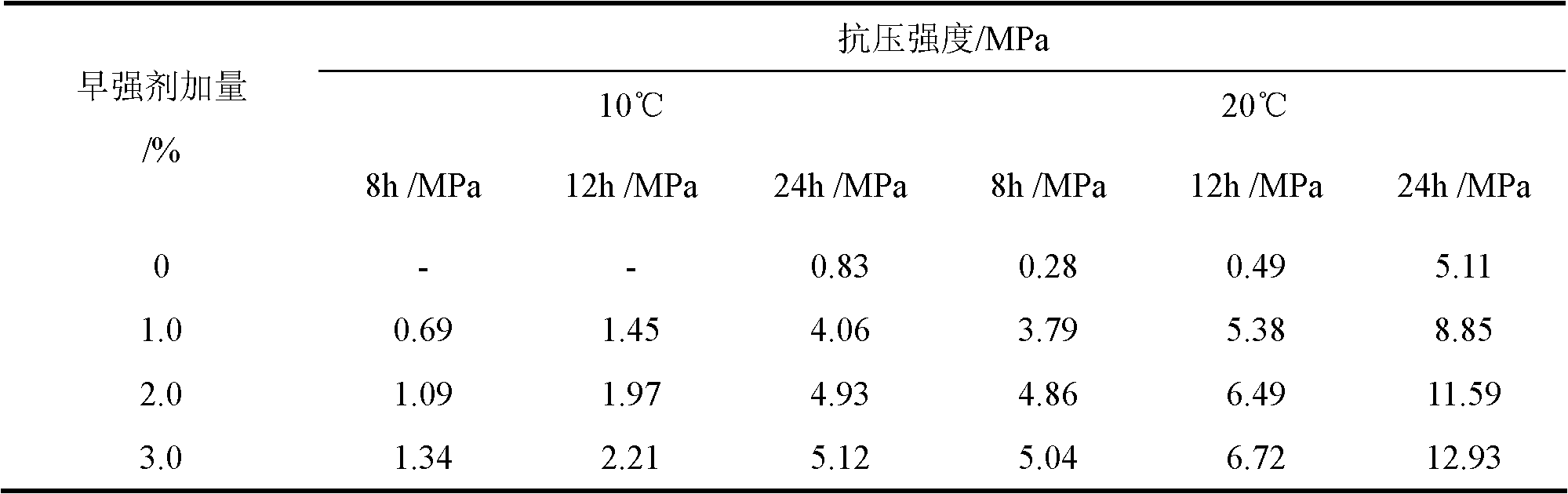

Examples

Embodiment 1

[0023] Weigh 35% Potassium Bromide, 15% Sodium Metaaluminate, 35% Potassium Hydroxide, 14% Silicon Dioxide, 1% Alcoholamine organic matter according to the above ratio; weigh Potassium Bromide, Sodium Metaaluminate , Potassium Hydroxide, Silicon Dioxide, and Alcoholamines are sequentially added into the mixer and mixed evenly to obtain the low-temperature early-strength agent "ZQ-1" of the present invention.

Embodiment 2

[0025] Weigh 30% sodium bromide, 30% potassium bromide, 7% sodium metaaluminate, 24% sodium hydroxide, 8% silicon dioxide, 1% alcohol amine organic matter according to the above ratio; Sodium, potassium bromide, sodium metaaluminate, sodium hydroxide, silicon dioxide, and alcohol amine organic substances are sequentially added into the mixer and mixed evenly to obtain the low-temperature early strength agent "ZQ-2" of the present invention.

Embodiment 3

[0027] Weigh 53% sodium bromide, 12% sodium metaaluminate, 15% sodium hydroxide, 9.2% silicon dioxide, 0.8% alcohol amine organic matter according to the above ratio; weigh the sodium bromide, sodium metaaluminate , Sodium Hydroxide, Silicon Dioxide, and Alcoholamines are sequentially added into the mixer and mixed evenly to obtain the low-temperature early-strength agent "ZQ-3" of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com