Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

73results about How to "Low early strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

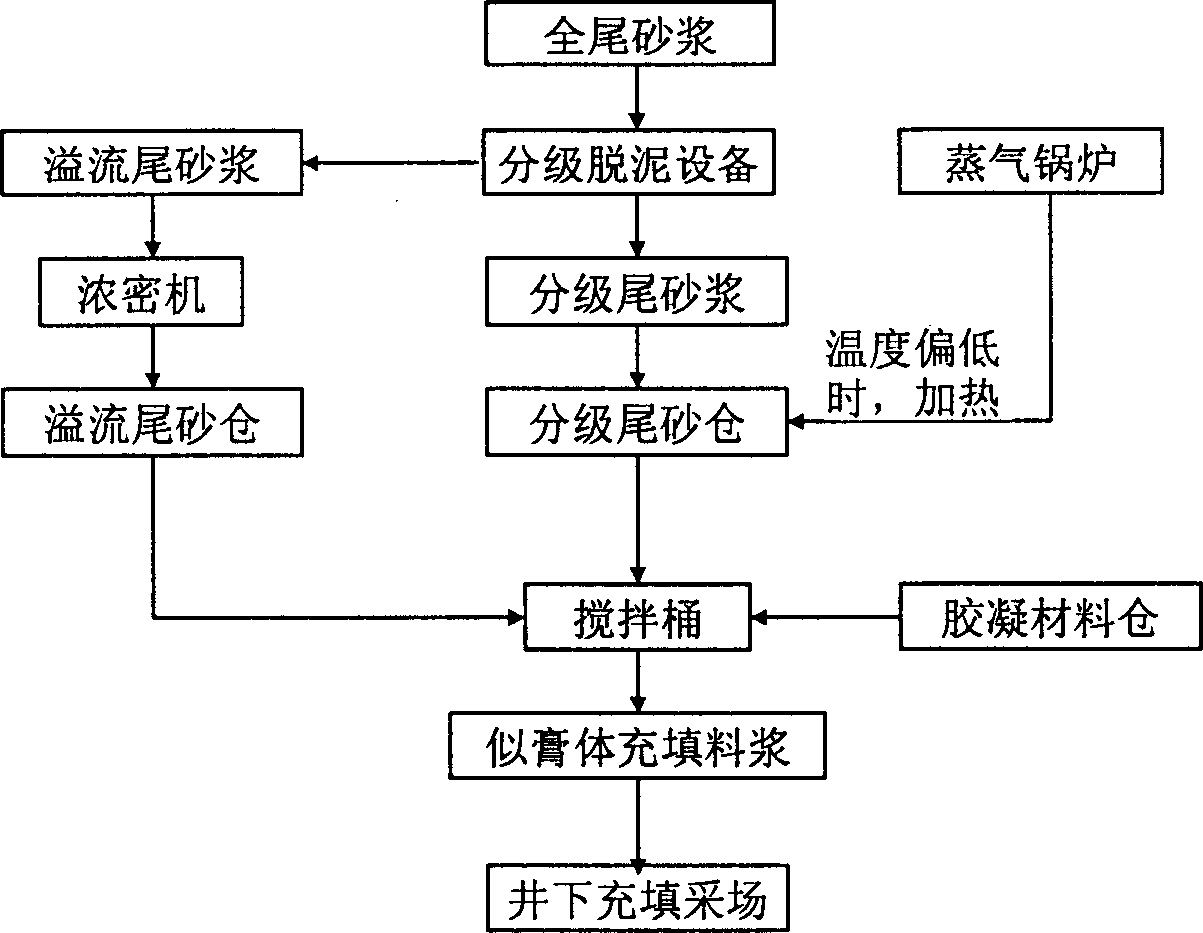

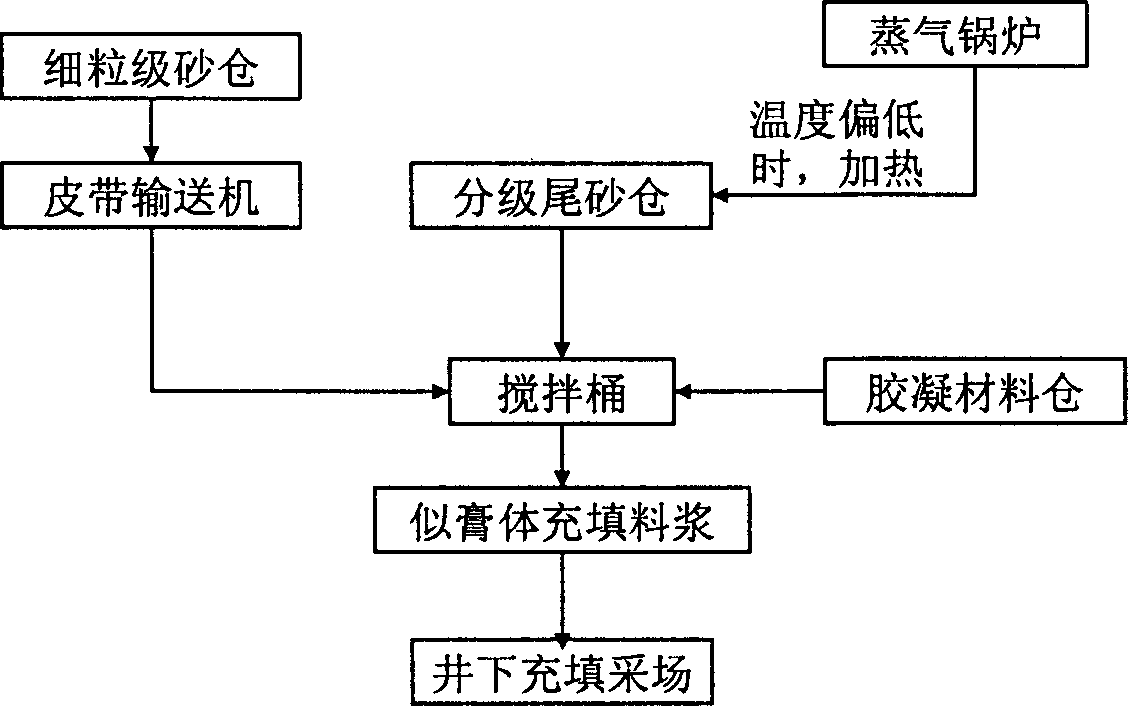

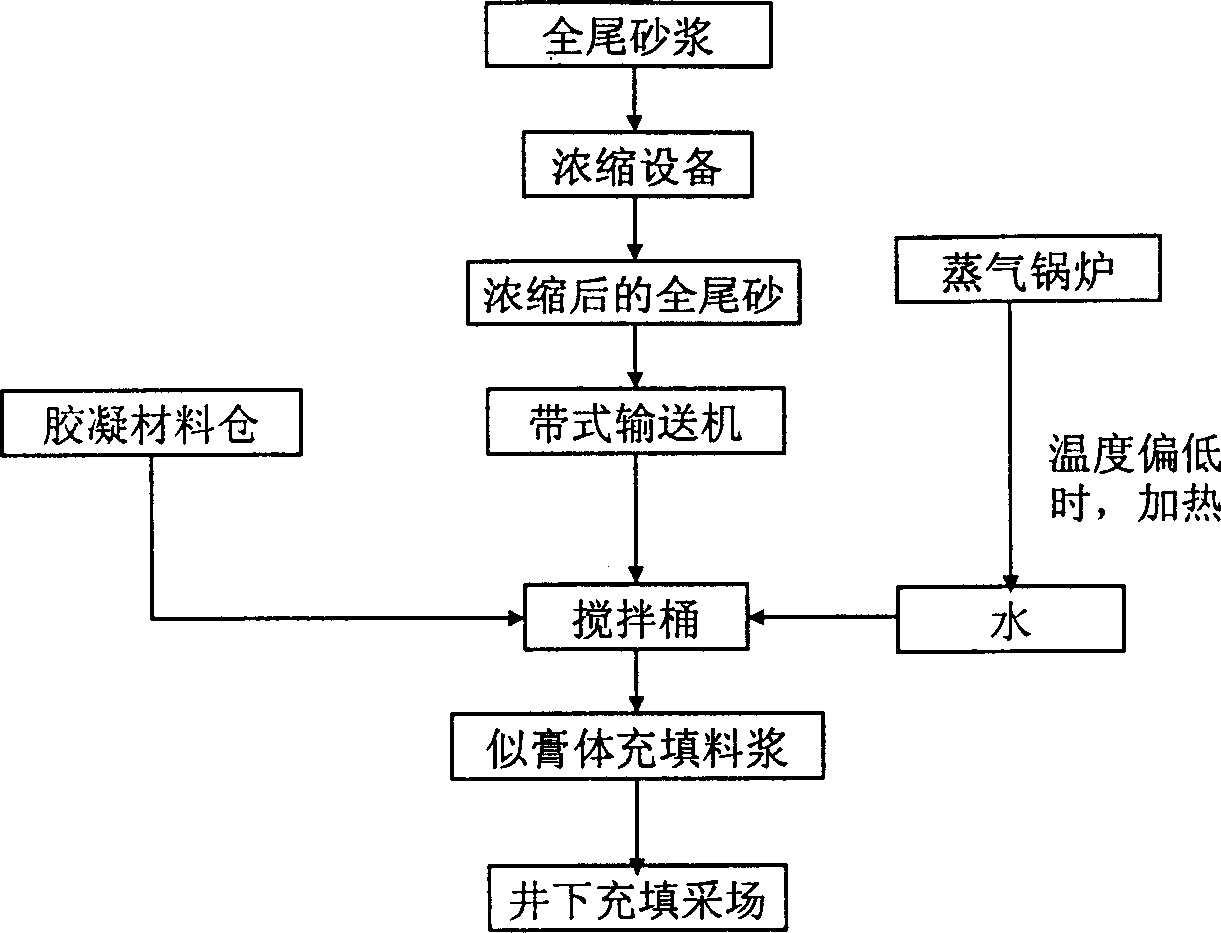

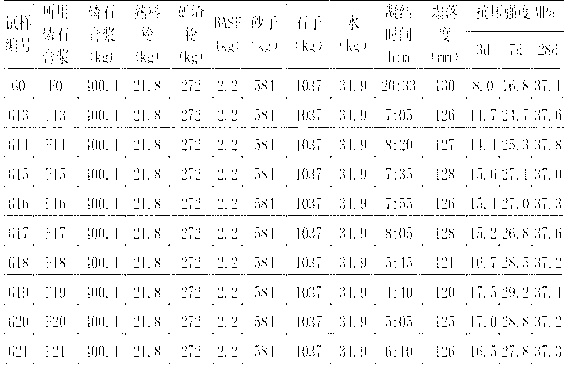

Cementing materials for filling, slurry and preparing and filling processes

InactiveCN1424275AReduce manufacturing costLess investmentSolid waste managementMaterial fill-upSlurrySulfur containing

A gelatining material similar to cream for filling underground working surface is preapred from the Ca-contained non-crystal and microcrystal material, alkali and / or sulfur contained exciting material, active material, aggregate and regulator. A filling slurry is prepared from said gelatining material, filling aggregate, fine particles, regulator and water through heating to at least 18 deg.C and proportional mixing.

Owner:CHINA UNIV OF MINING & TECH (BEIJING) +2

Modified phosphogypsum and preparation method thereof

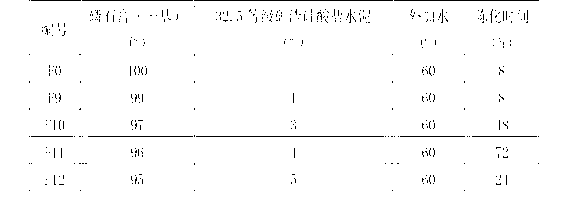

The invention belongs to the field of building materials and concretely relates to modified phosphogypsum and a preparation method thereof. The modified phosphogypsum is characterized by being formed by mixing, wetly grinding and then aging phosphogypsum, general-purpose silicate cement and water, wherein the accounted dry-basis mass percentages of the phosphogypsum and the general-purpose silicate cement are as follows: 95-99 percent of phosphogypsum and 1-5 percent of general-purpose silicate cement, and the sum of the accounted dry-basis mass percentages of the phosphogypsum and the general-purpose silicate cement is 100 percent; and the addition quantity of the water is 50-70 percent of the total mass of the phosphogypsum and the general-purpose silicate cement, and the addition quantity of the water includes the quantity of free water in the phosphogypsum. The method has the advantages of simple process, no need of high-temperature curing, less admixture dosage and low cost, and the coagulating time of phosphogypsum-based cement concrete can be shortened by the modified phosphogypsum which is prepared by the method.

Owner:武汉亿胜科技有限公司

Low-viscosity high-strength environmentally friendly double-component glue solution and preparation method thereof

ActiveCN105885704AHigh viscosityLow viscosityNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesEnvironmental resistanceAdhesive

The invention provides a low-viscosity high-strength environmentally friendly double-component glue solution and a preparation method thereof and relates to a sodium silicate-polyurethane double-component adhesive which can be used in the industries of construction and building materials and the like. The low-viscosity high-strength environmentally friendly double-component glue solution is prepared from sodium silicate and / or potassium silicate and polyisocyanate and their derivatives and further at least contains a coupling agent and / or coupling agent and polyol ester and / or alcohol ether suitable for being matched with the sodium silicate, the polyurethane component is prepared from polyisocyanate and an end-NCO prepolymer of polyether polyol and / or polyether glycol of the polyisocyanate, the mixture contains NCO 10-26%, and the matching ratio of the two components is in positive correlation with the specific gravity of the sodium silicate and is in negative correlation with the modulus of the sodium silicate within a certain range and is 1 to 0.7-2.5. The silane coupling agent is firstly added during preparation, and then the polyol ester and / or the alcohol ether is added after uniform stirring. The low-viscosity high-strength environmentally friendly double-component glue solution has low viscosity, excellent wettability and adhesion and good bonding strength and waterproof and weather-resisting properties, is adjustable in adaptation period, is naturally cured, makes the surface tough, bright and clean and is low-carbon, environmentally friendly, flame-retardant, rustproof, simple in process and low in cost.

Owner:CHONGQING LIERDA SCI & TECH DEV +1

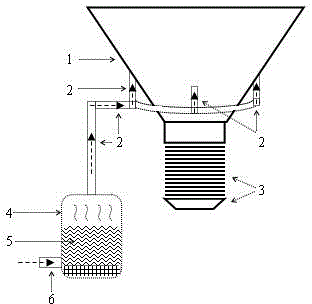

Active mineral waste residue powder production system and technological process thereof

InactiveCN103801443AImprove finenessEasy to prepareGrain treatmentsWorking environmentMaterials science

The invention relates to an active mineral waste residue powder production system and a technological process of the system. In the mineral waste residue powder production process, the speed of a conveyed material is adjusted, the air quantity is controlled, and a powder concentrator is optimized and reformed, so that the fineness and the specific surface area of the superfine slag powder are greatly improved; a preparation method of the active mineral waste residue powder is simple; empty grinding and full grinding are prevented, so that running and labor intensity can be lightened, the maintenance cost is reduced, the work environment is improved, the whole grinding process is automatically controlled, and the whole grinding process is optimized; the active mineral waste residue powder production system has the advantages of being reasonable in structure and convenient to operate.

Owner:李培彦

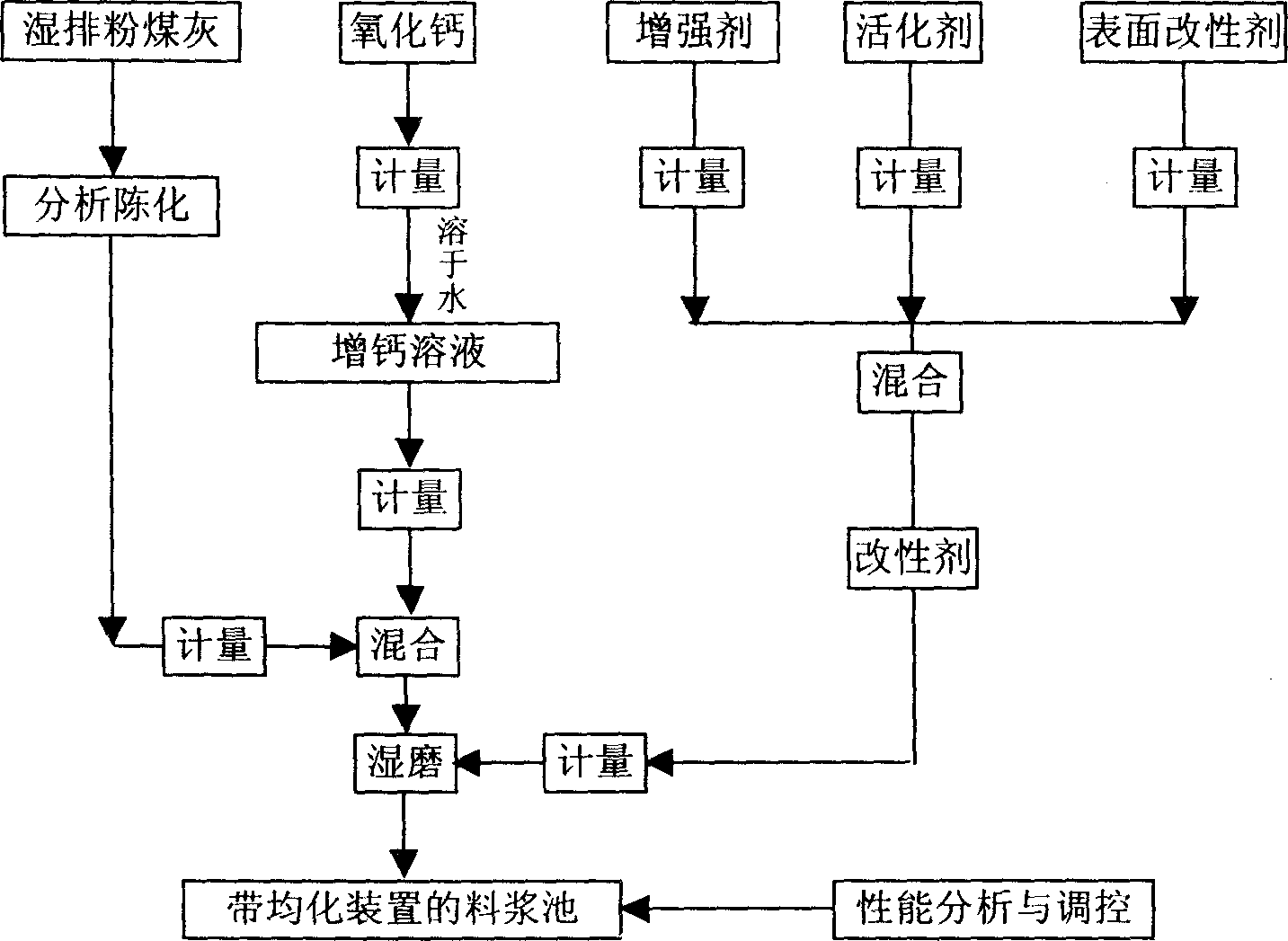

High-activity admixture slurry made of wet fly-ash and method for preparing same

The invention discloses high-active doping slurry and preparing method, which comprises the following parts: 55-65 percent wet-discharge coal ash, 30-44 percent calcium-increasing solution and 1-5 percent modifier, wherein the calcium-increasing solution is calcium hydroxide solution; the modifier is composed of 10-30 percent reinforcer, 20-40 percent surface modifier and 30-50 percent activist.

Owner:WUHAN UNIV OF TECH

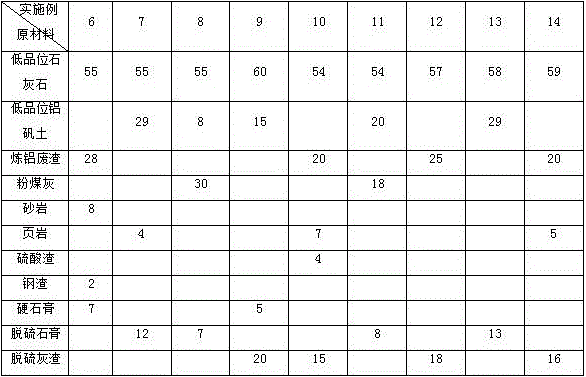

Cement clinker and preparation method thereof

The invention discloses a cement clinker and belongs to the technical field of cement clinker production. The clinker is prepared from the following raw materials in percentage by mass: 30 to 60 percent of calcareous materials, 0 to 25 percent of siliceous materials, 10 to 40 percent of aluminum materials, 0 to 10 percent of ferrous materials and 5 to 20 percent of gypsum materials; a mineral composition of the clinker is prepared from 10 to 40 percent of C4AS, 25 to 40 percent of C2S and 10 to 30 percent of C4AF. According to the clinker disclosed by the invention, the iron content of the cement clinker is low, and the seawater erosion resisting ability of the clinker is improved; the cement clinker is especially suitable for marine engineering.

Owner:JIAHUA SPECIAL CEMENT

Fly ash surface modifying material and using method thereof

InactiveCN104961369AImprove liquidityDoes not affect setting timeSolid waste managementWater reducerSURFACTANT BLEND

The invention provides a fly ash surface modifying material and a using method thereof. The fly ash surface modifying material is prepared with a surfactant commonly used as a concrete admixture and an air entraining agent. The fly ash surface modifying material is prepared by dissolving the surfactant and the air entraining agent in water to prepare a modifying material water solution, forming a modifying material atomized agent through an atomizer, utilizing compressed air to feed the modifying material atomized agent into a fly ash bin from the bottom of the fly ash bin to be fully mixed with fly ash so as to enable carbon particles in the fly ash to pre-adsorb the surface modifying material. Microporous surfaces of the carbon particles are blocked, so that adsorption effect, on a water reducing agent, of the fly ash surface modifying material when the fly ash is used for concrete is reduced, and fluidity of the concrete is improved; the modifying material adhered on the surfaces of other spherical particles of the fly ash can play a role in lubricating, so that fluidity of fly ash concrete is further improved; the surface modifying material is extremely low in consumption, and a gas arch breaking device originally in the fly ash bin can be utilized to complete surface modification of the fly ash, so that the fly ash surface modifying material and the using method are low in cost.

Owner:TONGJI UNIV

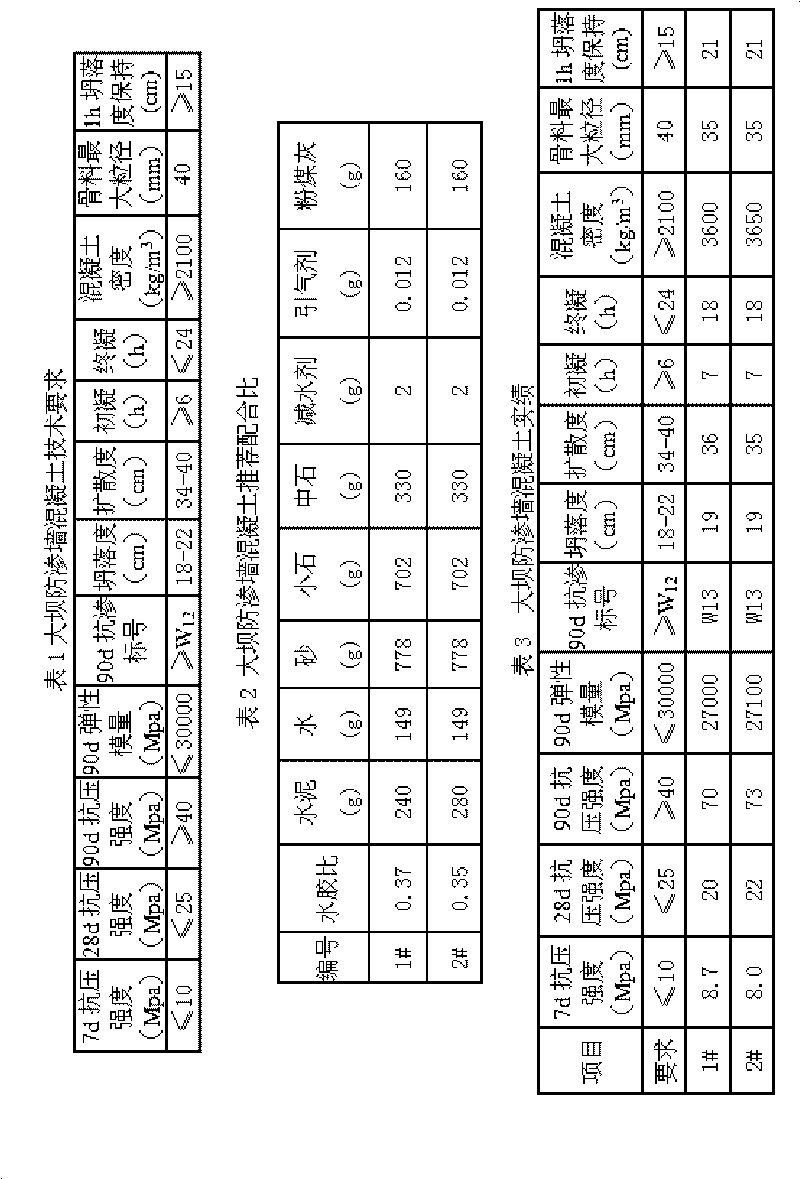

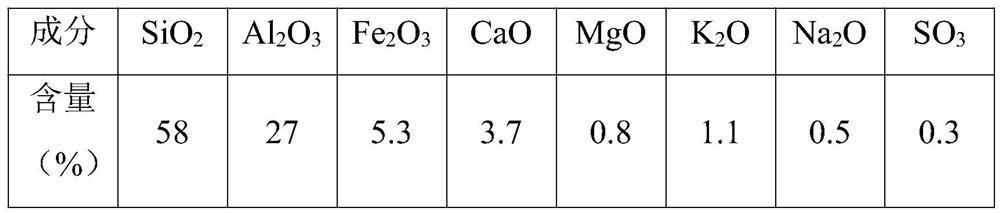

Cement clinker and hydraulic engineering cement for impervious wall of dam and application thereof

ActiveCN101723606AMeet the design requirementsImprove compactnessBarrages/weirsPortland cementEnvironmental engineering

The invention belongs to the field of buildings, in particular to a cement clinker, hydraulic engineering cement for an impervious wall of a dam and application thereof. The invention provides a cement clinker with optimized mixture ratio, wherein the cement clinker is prepared into cement which is applied to the hydraulic engineering cement for the impervious wall of the dam and has the characteristics of low strength at early stage and high strength at late stage. The cement clink comprises the following minerals in percentage by weight: 25-40 percent of C3S, 42-63 percent of C2S, 1-3.5 percent of C3A, 11-16 percent of C4AF and 0-2 percent of inevitable impurities. The concrete prepared from the cement clinker and the cement as raw materials has the characteristics of low hydration heat, low strength at early stage, high strength at late stage, non-hanging strength and the like, is suitable for hydraulic engineering of the impervious wall of the dam and can replace special hydraulic engineering cement for the concrete prepared from the traditional moderate-heat cement, low-heat cement or general purpose portland cement.

Owner:JIAHUA SPECIAL CEMENT

Technological process for producing pipe pile by using fine-ground metallurgical slag and fine-ground high silicon sand multiple infiltration method

InactiveCN1443634AReduce dosageImprove early strengthShaping reinforcementsMetallurgical slagPortland cement

The present invention is aimed at providing a technological process for producing pipe pile by adopting fine-ground metallurgical slag and fine-ground high-silicon sand reblending method. When said invented technique is used to produce pipe pile, the fine-ground metallurgical slag and fine-ground high-silicon sand can be mixed according to a certain proportion, and said mixture can be substitutedfor 30%-60% of high-grade Portland cement or general Portlant cement with above 42.5-level to produce pipe ile. Said method not only can utilize furnace slag, but also reduce addition quantity of cement, and raise early-strength and after-strength of pipe pile concrete.

Owner:FUJIAN DADI CONCRETE PILE

Construction organization method of complete set of tunnel mechanical equipment

ActiveCN108915696AImprove management abilityImprove the construction work environmentUnderground chambersTunnel liningArchitectural engineeringMechanical equipment

The invention discloses a complete set of tunnel mechanical equipment, which specifically refers to an excavation trolley (or an excavation gantry), a drainage and steel bar binding trolley, a liningtrolley, a spray maintenance trolley, a ditch cable trough trolley, an inverted arch self-propelled hydraulic trestle and a wet spray manipulator, referred to as five trolleys, one trestle and one wetspray machine. A construction organization method matched with the complete set of mechanical equipment comprises the following construction organization steps: S1, hole excavation; S2, initial support; S3, inverted arch lining; S4, arched wall lining; S5, ditch cable troughs and the complete set of mechanical equipment. The construction organization method is reasonable, effectively improves tunnel management effect, improves construction operation environment, ensures construction safety and quality, improves construction progress and is worthy of promotion.

Owner:CHINA RAILWAY SEVENTH GRP CO LTD +1

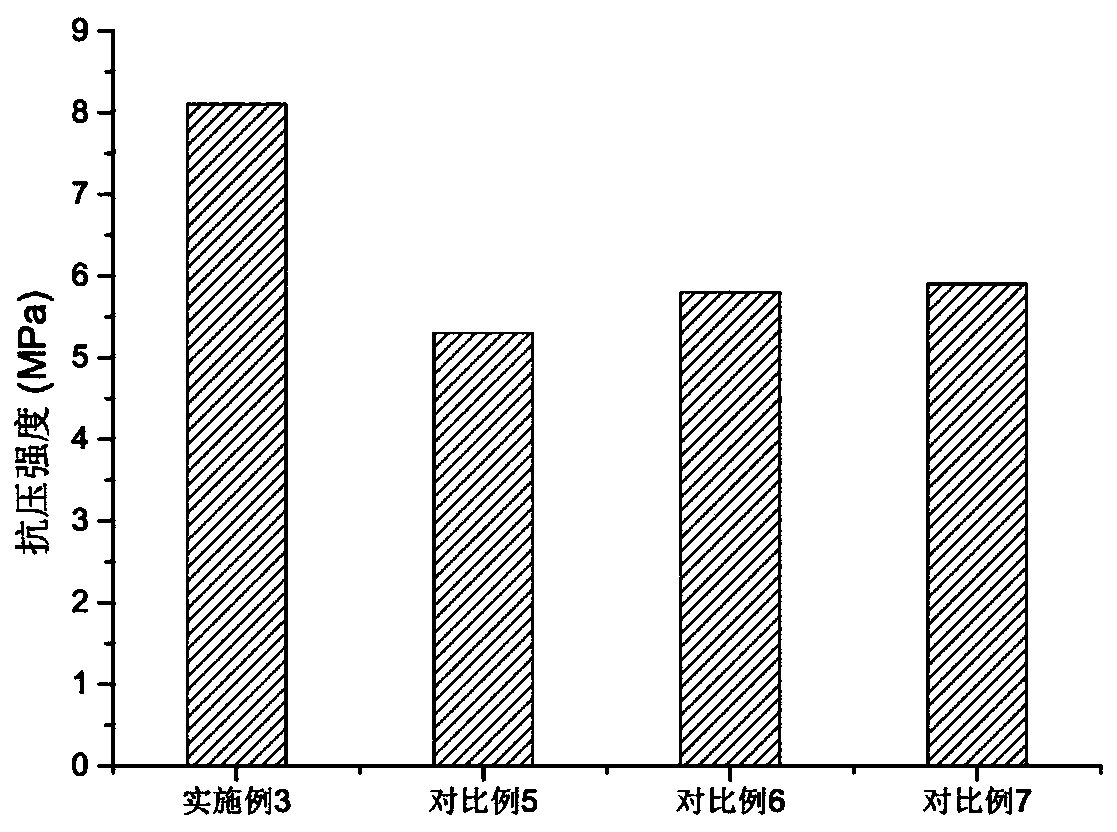

Oil shale ash and fly ash co-doped mineral aggregate concrete and preparation method thereof

InactiveCN113264735ALow early strengthReduced compressive strengthSolid waste managementCement productionMining engineeringWater reducer

The invention discloses an oil shale ash and fly ash co-doped mineral aggregate concrete and a preparation method thereof, and belongs to the technical field of concrete. The oil shale ash and fly ash co-doped mineral aggregate concrete is prepared from the following raw materials in parts by mass: 130 to 150 parts of cement, 50 to 70 parts of oil shale ash, 90 to 110 parts of fly ash, 700 to 750 parts of quartz sand, 1100 to 1200 parts of gravel, 5 to 8 parts of alkali activator, 4 to 6 parts of water reducing agent and 150 to 170 parts of water. By improving the formula of the concrete, all the raw materials in the formula can generate a synergistic effect, so that when the oil shale ash and the fly ash replace a part of cement to prepare the concrete, the strength of the concrete is kept equivalent to that of unreplaced concrete, and the use amount of the cement is greatly saved; meanwhile, the utilization rate of the oil shale ash and the coal ash is increased.

Owner:BEIHUA UNIV

Low-heat Portland cement with high early strength and preparation method and application thereof

InactiveCN110204228AHigh heat of hydrationHigh low heat of hydrationCement productionCrack resistanceSlag

Owner:CHINA BUILDING MATERIALS ACAD

Cement solidified waste and toxic chromium slag processing method thereof

ActiveCN105314940AImprove liquidityImprove adhesionSolid waste managementPregnant leach solutionFiber

The invention relates to a cement solidified waste. The cement solidified waste comprises 13-27% of converter slag, 8-12% of desulphurization ash, 25-32% of chromium slag, 5-15% of fly ash, 4-8% of cement, 4.5-6.5% of emulsified bitumen, 1-2% of fibers, and the balance of water. The converter slag and the chromium slag are mixed and are ground to 40-100 meshes, all raw materials are mixed and stirred until uniformity, the obtained mixture is put in a die, and is solified to form a mold, and the die is removed 24-36h later. The Cr<6+> leaching concentration is greatly reduced, and it is guaranteed that the concentration of Cr<6+> in a leaching concentration is lower than the concentration standard of national standard GB5085.3 danger waste upper limit.

Owner:ANGANG STEEL CO LTD

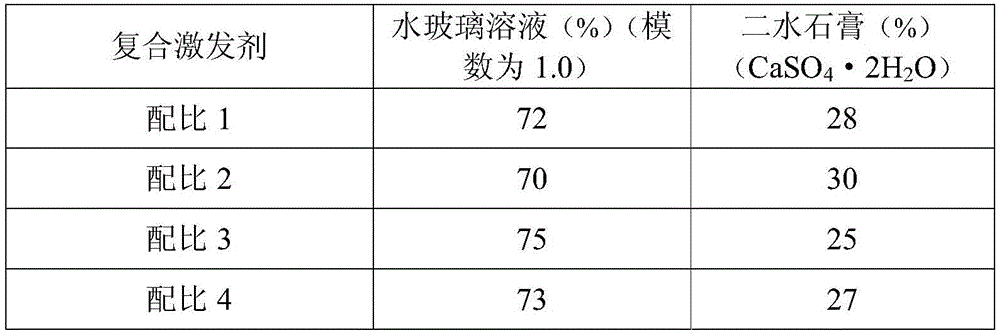

Method for improving hydration activity of waste glass powder

The invention discloses a method for improving the hydration activity of waste glass powder. The method comprises the following steps: carrying out cleaning, airing, preliminary crushing and jaw crushing on waste glass having different colors and kinds, collected from salvage stations, and carrying out ball milling by a ball mill for 60-120 min to obtain the waste glass powder; carrying out dry screening, wet screening and a settlement process on the waste glass powder to obtain waste glass powder with the particle size range of 10-75 [mu]m and the particle specific surface area being greater than 400 m<2> / kg; and adding cement and a composite exciter to the waste glass powder, carrying out mixing milling treatment for 30 min, adding water, pouring the obtained mixture into a cement neat paste stirrer, and stirring the mixture for 2-3 min to obtain a composite gelling material. The composite gelling material prepared in the invention is a waste glass recycled product, waste glass has a high utilization rate, wide sources and easiness in obtaining, and the composite gelling material has the advantages of quickness in setting, quickness in hardening, high early stage strength, and great increase of the later strength.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

P*S*A grade retarded cement and preparation method thereof as well as concrete road

The invention provides P*S*A grade retarded cement, and belongs to P*S*A grade retarded cement. The retarded cement comprises the following raw materials by weight percentage: 51% to 59% of Portland cement clinker, 32% to 37% of granulated blast furnace slag powder, 4% to 6% of fly ash and 4% to 6% of desulfurized gypsum. The invention also provides a preparation method of the P*S*A grade retardedcement, and the method comprises the following steps: mixing and grinding the Portland cement clinker, the fly ash, the granulated blast furnace slag powder and the desulfurization gypsum, or grinding after mixing. The P*S*A grade retarded cement prepared with the preparation method is long in retarded time.

Owner:山东永正水泥有限公司 +1

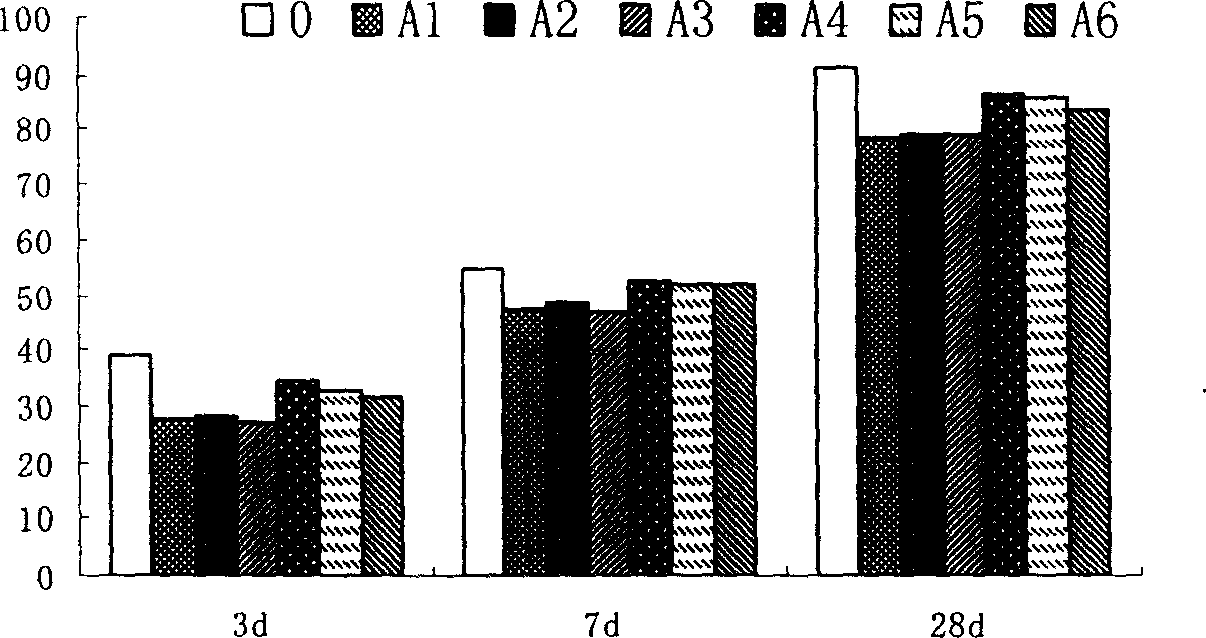

Method for preparing low-clinker and high-phosphorus-slag cement composite cementitious material

InactiveCN106977122ALow early strengthImprove the shortcomings of low early strength and long setting timeCement productionMetakaolinGypsum

The invention discloses a method for preparing a low-clinker and high-phosphorus-slag cement composite cementitious material. The method comprises the following steps: weighing 15-25% by mass of clinker, 40% by mass of phosphorus slag, 5-15% by mass of metakaolin, and 30% by mass of compound admixture consisting of steel slag, fly ash, limestone and gypsum according to a mass ratio of 5 to 10 to 10 to 5; and mechanically mixing, adding water according to a water cement ratio of 0.5 after uniformly mixing, and stirring for 2min to obtain the low-clinker and high-phosphorus-slag cement composite cementitious material. By adding the metakaolin, the problems that the low-clinker and high-phosphorus-slag cement composite cementitious material has lower early strength and longer setting time are solved, and the optimum added quantity of the metakaolin is obtained and is between 5% and 15%. The preparation method provided by the invention is simple, the clinker quantity can be reduced, other industrial wastes such as phosphorus slag can be more fully utilized, the environmental pollution is reduced and the energy saving and emission reduction are realized.

Owner:WUHAN UNIV OF TECH

Grinding aid for improving adaptability of high-aluminum clinker cement admixture

The invention discloses a grinding aid for improving the adaptability of a high-alumina clinker cement admixture, and solves the technical problems that a grinding aid in the prior art causes lowadaptability of high-alumina clinker cement to the admixture and reduces the early strength of the high-alumina clinker cement. The grinding aid comprises: 3%-20% of dimer glycerol; 10%-27% of monoethanol diisopropanolamine; 2%-7% of hydroxyethylidene diphosphonic acid; 0.1%-0.25% of polyacrylamide; and the balance of water. Compared with a traditional grinding aid, the grinding aid for improving the adaptability of the high-aluminum clinker cement admixture has higher admixture adaptability, the fluidity of neat paste is improved by 20 mm or above, the slump of C30 and C25 concrete is improved by 15 mm or above, and the expansion degree is improved by 15 mm or above; and the formula of the grinding aid is optimized to improve the 28-day strength of the high-alumina clinker cement concrete.

Owner:华润水泥技术研发(广西)有限公司

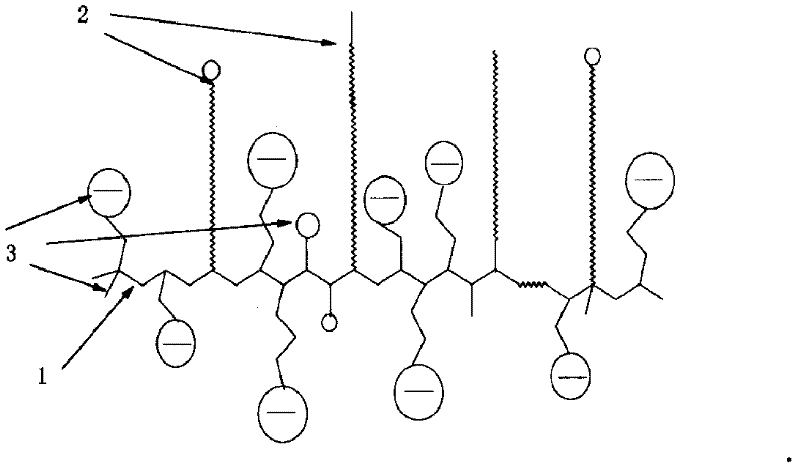

Concrete water-reducing agent and application thereof

The invention discloses a concrete water-reducing agent and the application of the concrete water-reducing agent. The concrete water-reducing agent comprises the components by weight ratio: 58-80 parts of polycarboxylate high-performance water-reducing agent and 20-42 parts of compound containing hydroxyl and carboxyl. According to the concrete water-reducing agent, the advantages of the polycarboxylate high-performance water-reducing agent can be developed and the adaptability of the polycarboxylate high-performance water-reducing agent can be improved, in addition, the dosage is reduced, resources are saved, energy consumption is reduced and the comprehensive application cost of the polycarboxylate high-performance water-reducing agent can be lowered.

Owner:TIANJIN BINHAI NEW AREA JINYU XINAO TECH DEV

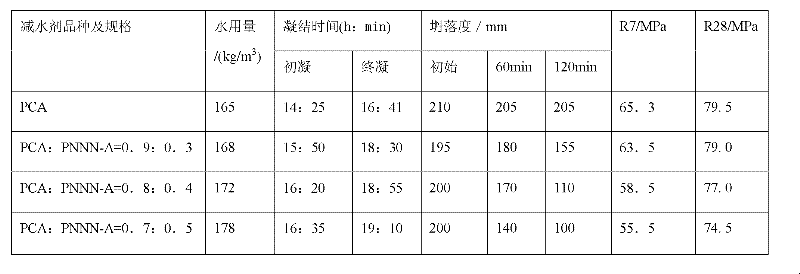

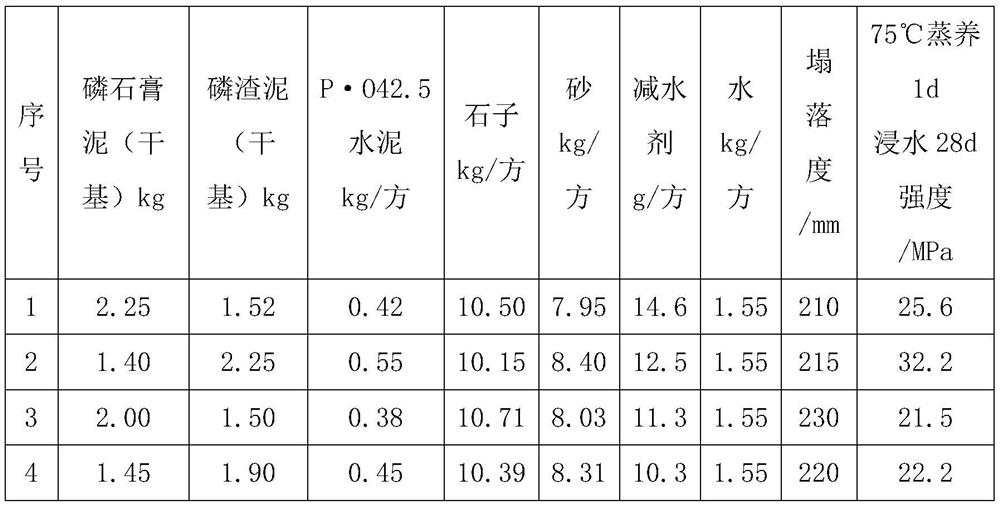

Supersulfide phosphogypsum phosphorus slag cement concrete product and preparation method thereof

InactiveCN111848093AHigh strengthEliminate weakeningSolid waste managementEnvironmental engineeringPhosphogypsum

The invention discloses a supersulfide phosphogypsum phosphorus slag cement concrete product and a preparation method thereof. The supersulfide phosphogypsum phosphorus slag cement concrete product comprises the following raw material components: phosphogypsum, phosphorus slag, silicate cement, sand, stones, a water reducing agent and water. Through early-stage wet grinding of the phosphogypsum and the phosphorus slag, the strength of the material in each stage is greatly improved, the production process is simple, the cost is low, a large amount of industrial solid waste can be used, and environmental protection is facilitated.

Owner:JIANGSU EFFUL SCIENCE AND TECHNOLOGY CO LTD

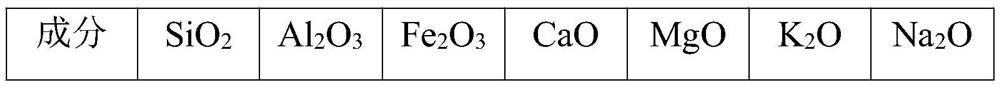

Early strengthening flyash three-slag road forndation material

InactiveCN1483694AImprove frost resistanceHigh strengthRoadwaysSolid waste managementSlagCrushed stone

The present invention relates to an early-strength flyash three-slag road bed material, said road bed material composition includes 10%-30% of flyash, 5%-15% of slaked lime, 60%-84.5% of broken stone and 0.5%-1% of early-strength agent, and adds the water whose added quantity is 37% of the above-mentioned total weight, and the early strength agent is formed from two portions of high calcium lime and one portion of sodium sulfate, the flyash, slaked lime and broken stone are dry material, and the total content of SiO2 and Al2O3 in the flyash is greater than 70%, and the total content of active calcium oxide and magnesium oxide in the slaked lime is greater than 30%.

Owner:SHANGHAI JINGAN NEW BUILDING MATERIAL SCI INST

Cementing materials for filling, slurry and preparing and filling processes

InactiveCN1238292CReduce manufacturing costLess investmentSolid waste managementMaterial fill-upSlurrySulfur containing

A gelatining material similar to cream for filling underground working surface is preapred from the Ca-contained non-crystal and microcrystal material, alkali and / or sulfur contained exciting material, active material, aggregate and regulator. A filling slurry is prepared from said gelatining material, filling aggregate, fine particles, regulator and water through heating to at least 18 deg.C and proportional mixing.

Owner:CHINA UNIV OF MINING & TECH (BEIJING) +2

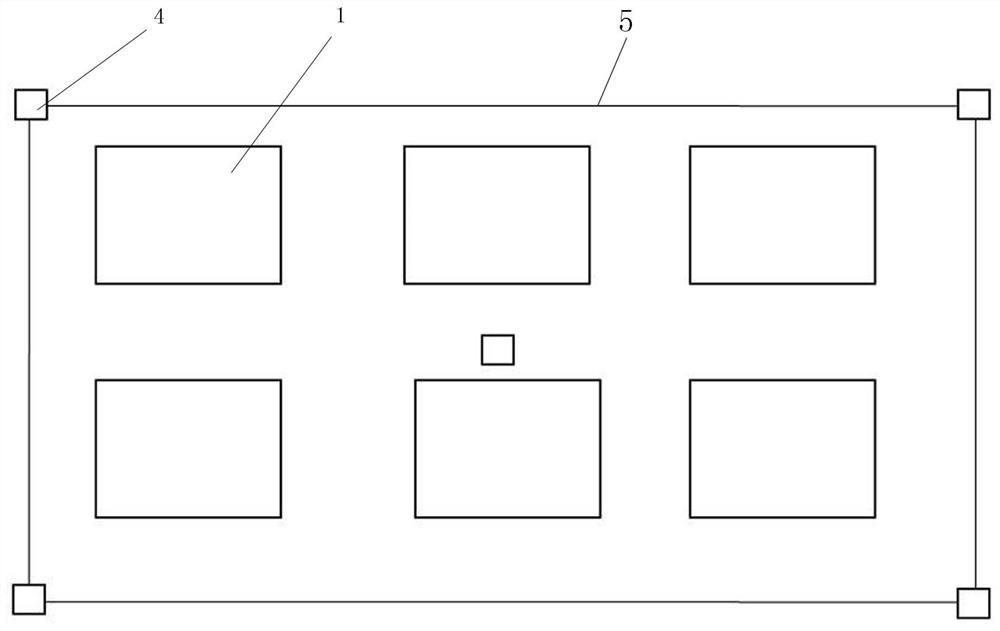

Full-automatic steam curing equipment and method for precast concrete component

InactiveCN113084985AEasy to operateSkilledPreparing sample for investigationAuxillary shaping apparatusTemperature controlEconomic benefits

The invention relates to the field of precast concrete components, in particular to full-automatic steam curing equipment and method for a precast concrete component. The full-automatic steam curing equipment comprises a steam curing cover, an automatic steam curing temperature controller and an electric heating boiler, wherein four steam curing stages are arranged in the automatic steam curing temperature controller and include the static stopping stage, the temperature rising stage, the constant temperature stage and the temperature lowering stage. During steam curing, parameters in the four steam curing stages are set respectively. By means of the full-automatic steam curing equipment and method for the precast concrete component, the steam-cured precast concrete component can smoothly reach the strength required by form removal, corner cracks are obviously reduced, the quality of the small precast component is improved, remarkable technical achievements and economic benefits are obtained, and the equipment and method are well accepted by owners.

Owner:CHINA RAILWAY SIXTH GRP TAIYUAN RAILWAY CONSTR +2

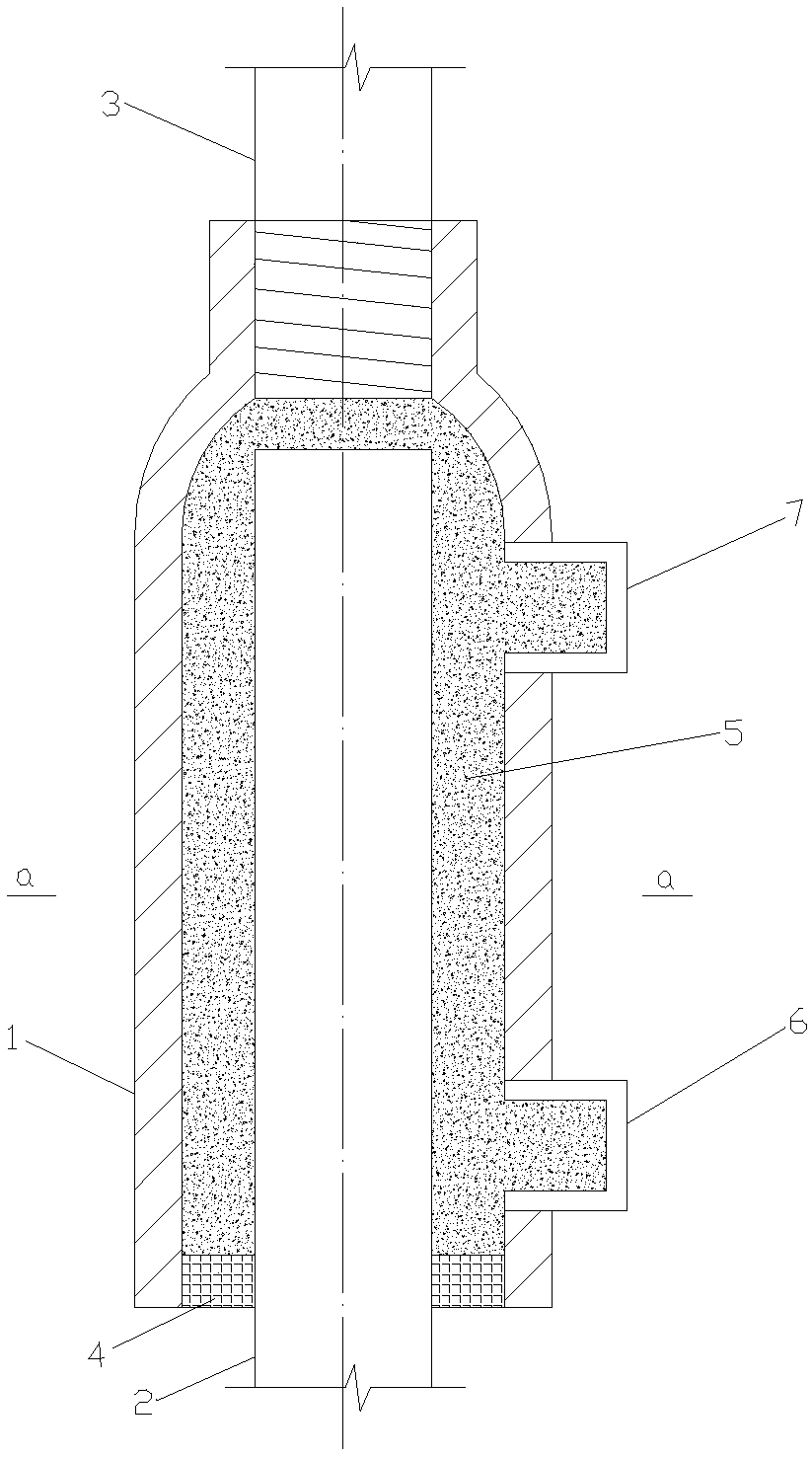

Fabricated building sleeve connecting grouting material based on phosphorus and magnesium materials and construction method of grouting material

InactiveCN108947463AHigh strengthControllable solidification timeBuilding reinforcementsFreeze thawingMagnesium phosphate

The invention discloses a fabricated building sleeve connecting grouting material based on phosphorus and magnesium materials and a construction method of the grouting material. The grouting materialis prepared from the following raw materials in parts by weight: 80-120 parts of magnesium phosphate cement, 3-16 parts of an additive, 10-25 parts of an admixture and 0-130 parts of aggregates. The phosphorus-magnesium grouting material has good corrosion resistance and freeze thawing resistance, good durability and fluidity, low contractibility, good steel adhesion, strong self-compaction property and environment temperature adaptability, is easy for pouring and can be used for construction at any time; an oxide film can be formed on the surface of the grouting material, has very good associativity and high bonding strength and has good attachment property with sleeves and steel bars; the grouting material can be mixed on site and convenient to construct, the construction procedure is simplified, the grouting material can be condensed and hardened after 10-30 minutes of the grouting, the compressive strength of the phosphorus-magnesium grouting material can reach over 40MPa after 1.5hours of the grouting, and the phosphorus-magnesium grouting material basically does not need to be maintained, so that the construction efficiency is improved, the construction period is greatly shortened, and the cost is saved.

Owner:GUIZHOU PHOSPHORUS MAGNESIUM MATERIAL CO LTD

Downward parallel middle-deep hole sublevel fill stoping mining method for steep and medium-thick hard-to-mine ore body

PendingCN110985114AImprove early strengthHigh compressive strengthMaterial fill-upSlagMining engineering

The invention provides a downward parallel middle-deep hole sublevel fill stoping mining method for a steep and medium-thick hard-to-mine ore body, and belongs to the technical field of mining. The ore body is divided into a plurality of sublevels according to the middle sublevel, stope rooms and stope pillars are divided in the ore body direction, the middle sublevel is divided in the inclined direction of the ore body, sublevel rock drilling roadways are arranged along veins, artificial false roofs and false bottoms are constructed in the sublevel rock drilling roadways in advance, and middle-deep hole stoping ore blocks are adopted from top to bottom. After the stope rooms are mined, the stope rooms are filled with filling materials. After the stope pillars are mined, the stope pillarsare filled with full tailings and / or barren rock powder. The content of particles with the particle size being less than or equal to 30[mu]m in the full tailings for the filling materials accounts for75-77%; the content of the particles with the particle size being less than or equal to 35[mu]m in slag accounts for 86-88%; and an activator is prepared from glauberite and green vitriol with a weight ratio of 1 to (0.5-0.7). According to the downward parallel middle-deep hole sublevel fill stoping mining method, safe, efficient and low-cost mining of the ore body can be realized, continuous mining in an area can be realized, and the sublevel fill stoping mining method is mainly suitable for a gold mine with an inclination of 50-90 degrees and a horizontal thickness of 4-10 m.

Owner:中国黄金集团石湖矿业有限公司

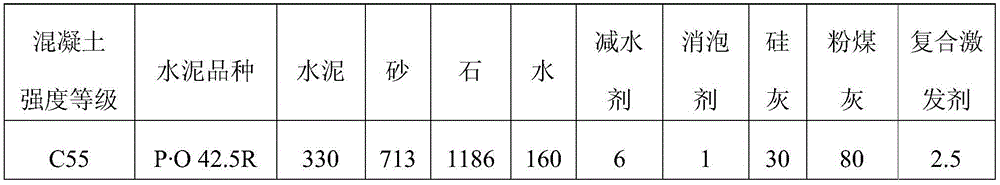

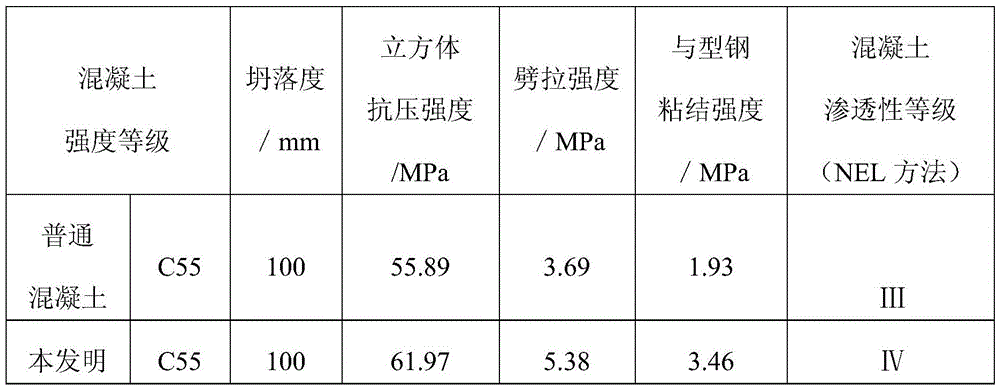

Concrete of strength grade C55 for profile steel reinforced concrete structure

The invention discloses a concrete of strength grade C55 for a profile steel reinforced concrete structure. The concrete contains the ingredients: cement, fine aggregates, coarse aggregates, water, an efficient water reducing agent, an antifoamer, silica fume, fly ash and a composite excitant, wherein the ratio (kg / m<3>) of the cement to the fine aggregates to the coarse aggregates to the water to the efficient water reducing agent to the antifoamer to the silica fume to the fly ash to the composite excitant is 330: 713: 1186: 160: 6: 1: 30: 80: 2.5. A preparation method of the concrete comprises the steps of firstly, uniformly mixing the polycarboxylic acid efficient water reducing agent and the composite excitant with the weighed water so as to obtain a mixture, sequentially adding the fine aggregates and 1 / 3 the total weight of the mixture into a stirrer according to a weight ratio, carrying out stirring, adding the coarse aggregates and 1 / 3 the total weight of the mixture into the stirrer, carrying out stirring, adding the cement, the silica fume and the fly ash into the stirrer, carrying out stirring, adding the antifoamer and the remaining mixture into the stirrer, carrying out stirring, and carrying out discharging. The concrete can be used for remarkably improving the bonding property between profile steel and the concrete in a state of nature, and respective mechanical properties and mutual cooperated working performance of two kinds of materials, i.e., the steel and the concrete are effectively exerted, so that the bearing capacity and use performance of structural elements are substantially improved, and the durability of structures is improved.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Method for production of acid from phosphogypsum by utilizing electrolytic-aluminium waste cathode carbon blocks

ActiveCN109279582ALow early strengthDetrimental effects favor inhibitionSulfur compoundsCement productionDecompositionPhosphogypsum

The invention discloses a method for applying electrolytic-aluminium waste cathode carbon blocks in combined production of sulfuric acid and cement from phosphogypsum. The method comprises the following steps: smashing the phosphogypsum, carrying out drying and dehydrating so as to obtain hemihydrate gypsum, crushing the electrolytic-aluminium waste cathode carbon blocks into a powder material, mixing the powder material with the hemihydrate gypsum, clay and bauxite, carrying out on-line drying, after completion of drying, carrying out integrated grinding so as to obtain a phosphogypsum cementraw material, preheating the raw material, delivering the preheated raw material into a hollow rotary kiln for decomposition and calcination, subjecting generated SO2-containing gas to gas-solid separation, carrying out dedusting and purifying, then delivering obtained gas into a sulfuric acid system so as to prepare a finished sulfuric acid product, subjecting the raw material to high-temperature calcination so as to obtain a cement clinker, blending the cement clinker with certain amounts of coal cinder and fly ash, and carrying out grinding with a ball mill so as to obtain the cement. Themethod provided by the invention realizes reutilization of the electrolytic-aluminium waste cathode carbon blocks and the phosphogypsum, eliminates the influence of wastes on the environment, saves the cost of occupied land, seepage prevention treatment and the like for waste residue storage at the same time, and has significant economic and environmental benefits.

Owner:山东汇泰再生资源有限公司

Concrete with strength grade C30 for steel reinforced concrete composite structure

InactiveCN105621995AIncreased durabilityImprove work performanceSolid waste managementNatural stateSuperplasticizer

The invention discloses concrete with a strength grade C30 for a steel reinforced concrete composite structure. The mixture ratio of cement to fine aggregate to coarse aggregate to water to an efficient slushing agent to an antifoaming agent to silica fume to coal ash to a composite catalyst (kg / m<3>) is 270:742:1124:140:4:1:20:60:2. A preparation method of the concrete comprises the steps that the polycarboxylate-type efficient slushing agent and the composite catalyst are firstly stirred into the weighed water evenly to obtain a mixture, 1 / 3 of the total quantity of the fine aggregate and the mixture is sequentially added to a stirrer according to the weight ratio, stirring is carried out, 1 / 3 of the total quantity of the coarse aggregate and the mixture is added, and stirring is carried out; the cement, the silica fume and the coal ash are added, and stirring is carried out; the antifoaming agent and the residual mixture are added, and stirring and discharging are carried out. By means of the concrete, the bonding performance between profile steel and the concrete can be remarkably improved in a natural state, the respective mechanical properties and the cooperative working property of the steel and the concrete can be effectively achieved, and therefore the bearing capacity and use performance of a structural member are greatly improved, and the durability of the structure is improved.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Composite antifreezing agent of concrete for rush-repair engineering

The invention relates to the technical field of concrete admixtures, in particular to a composite antifreezing agent of concrete for rush-repair engineering. The composite antifreezing agent is prepared from, by weight, 10-20 parts of diatomite, 3-10 parts of tributyl phosphate, 2-8 parts of sodium hexametaphosphate, 3-6 parts of sodium sulfate, 2-10 parts of oxidized graphene, 5-12 parts of dicyclohexyl carbodiimide, 1-5 parts of alkyl organic amine, 0.2-1 part of triterpenoid saponis, 2-5 parts of initiator, 6-12 parts of acrylamide, 0.2-1 part of surfactant, 2-8 parts of calcium lignosulfonate, 3-8 parts of aminosulfonate, 8-10 parts of sodium gluconate, 0.2-2 parts of silane coupling agent, 0.1-1 part of formic acid and 20-30 parts of alcohol. The composite antifreezing agent can accelerate setting speed of the concrete at minus 20 DEG C and improve strength and durability of the concrete.

Owner:芜湖恒固混凝土材料有限公司

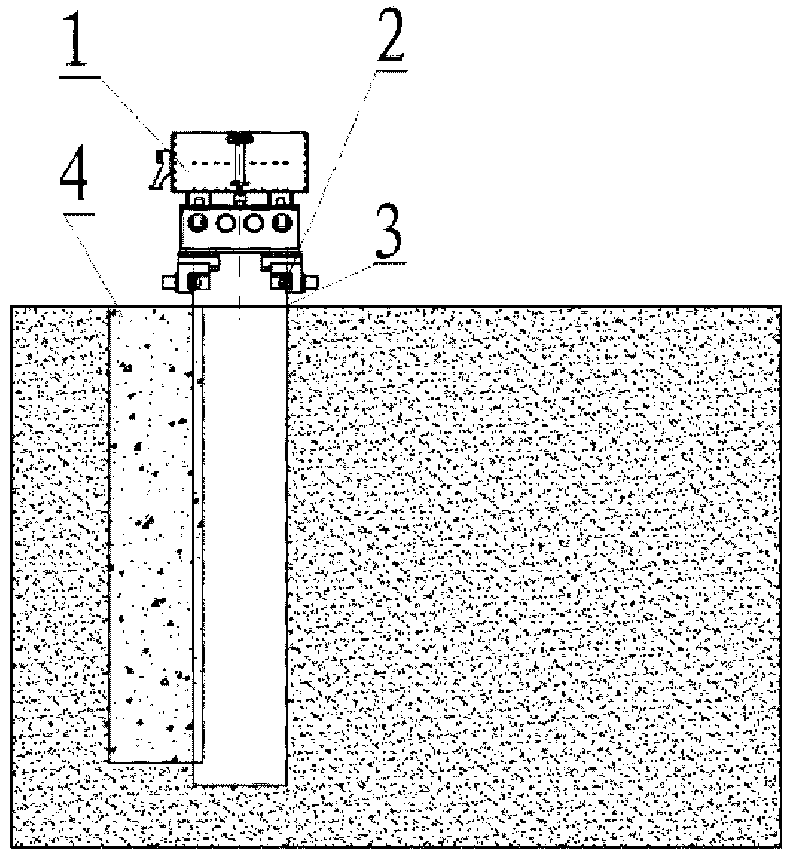

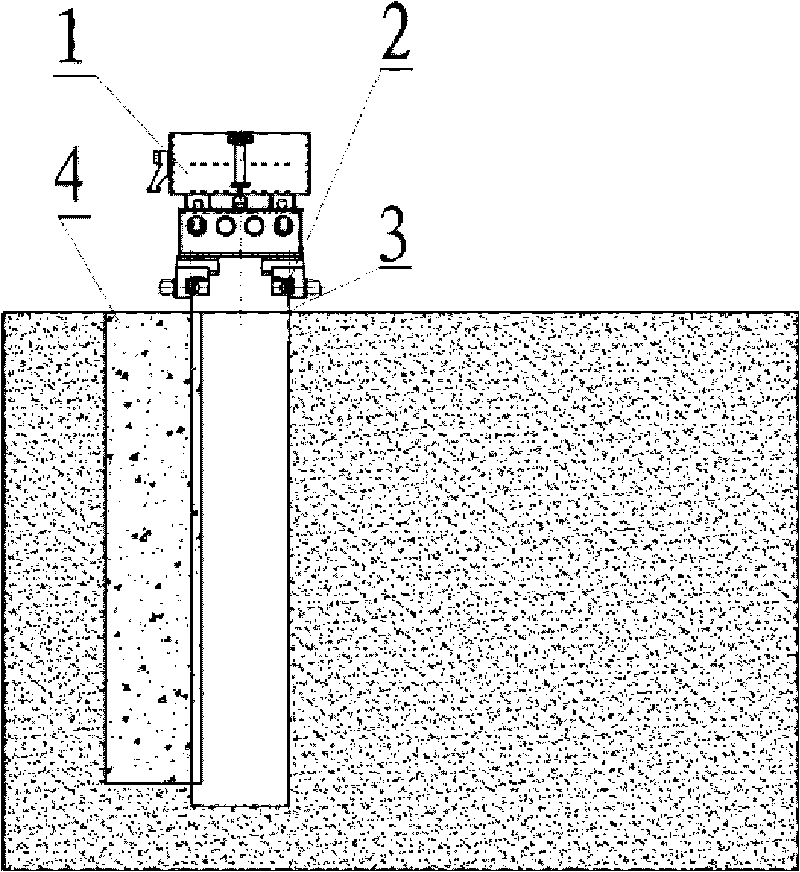

Construction method of conjoined mortar piling wall

ActiveCN101709579AProlong clotting timeLow early strengthBulkheads/pilesMaterials scienceWater seepage

The invention discloses a construction method of a conjoined mortar piling wall which is used for retaining and protecting for foundation excavation in the field of buildings. The construction method comprises the following steps of: sinking a steel sleeve to a designed elevation at a first piling position by using high-frequency hydraulic vibratory piling hammering machine along a central line of a conjoined piling wall; taking out soil in the steel sleeve; after a formed pore is qualified, putting sand soil taken out from the steel sleeve mixed with water, cement or lime into a stirrer for uniformly stirring; pouring the stirred mortar into the steel sleeve; pulling out the steel sleeve in a high frequency way to form a first mortar piling; then sinking a pipe to the designed elevation at a second piling position which is engaged with the first piling position; and repeating piling-forming construction steps to form the conjoined mortar piling wall. The construction method is applicable to constructions of water seepage prevention and earth-supporting-pile wall structure under any geological conditions, except rock strata; the close-grained mortar body pilings are formed in the frequency vibration way while pulling the steel sleeve by a piling machine; and by utilizing local materials, not only spoil and freight of construction materials can be reduced, but also construction cost can be reduced under the premise of ensuring the water seepage prevention effect.

Owner:FUJIAN YONGQIANG SOIL

Preparation method of autoclaved aerated concrete block and autoclaved aerated concrete block

The invention discloses a preparation method of an autoclaved aerated concrete block. The preparation method comprises the following steps: S1, preparing an additive A from aluminum powder paste, sodium sulfate and sodium abietate; and preparing fly ash, bagasse, juncus roemerianus powder, lime powder, gypsum powder and the additive A into ball billets, and curing to obtain lightweight aggregate; s2,preparing fly ash, ceramic tile waste, glass waste, quicklime and gypsum powder into a mixture; s3, preparing sodium hydroxide, rosin powder, triethanolamine and sodium silicate into an additive B; and S4, preparing a brick blank from the lightweight aggregate, the mixture, cement and the additive B, and maintaining the brick blank to obtain the autoclaved aerated concrete block. The invention further discloses the autoclaved aerated concrete block which is prepared by the preparation method of the autoclaved aerated concrete block. According to the autoclaved aerated concrete block, the construction waste, the household waste and the industrial waste are reasonably utilized, waste is turned into wealth, resource waste and environmental pollution are reduced, and the autoclaved aerated concrete block which is high in compressive strength and breaking strength and light in weight is prepared.

Owner:广西建工集团建筑产业投资有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com