Cement clinker and hydraulic engineering cement for impervious wall of dam and application thereof

A technology of cement clinker and anti-seepage wall, applied in the field of hydraulic cement and cement clinker, can solve problems such as being unfavorable for the secondary construction of dam anti-seepage wall and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

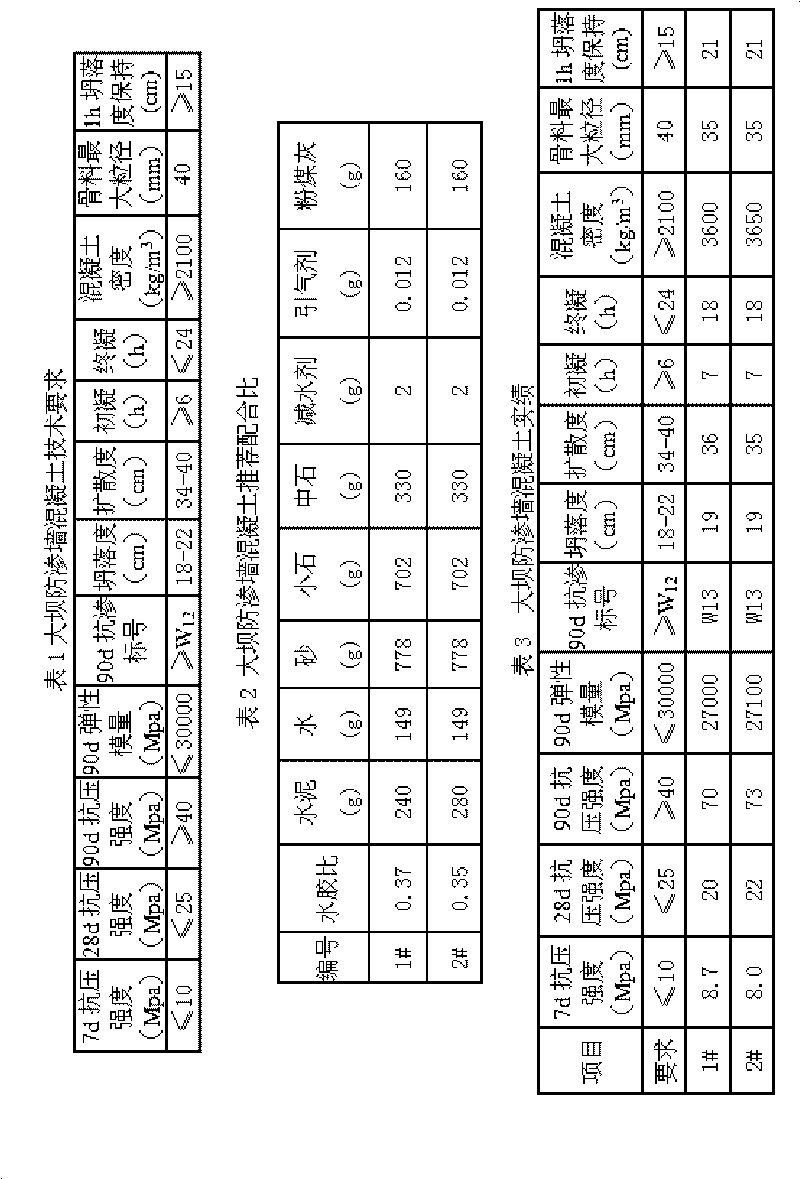

[0046] The cement of the present invention is used as the hydraulic cement of the dam cutoff wall, and the chemical composition of the cement clinker used is 24% of silicon dioxide, 4.4% of aluminum oxide, 5.1% of ferric oxide, 61% of calcium oxide, and magnesia 3.4%; sulfur trioxide 1.3%, other unavoidable impurities 0.8%. The mineral composition is: C 3 S 29%, C 2 S 51%, C 3 A 2.0%, C 4 AF 15%, unavoidable impurities 1%. Mix 95% of cement clinker and 5.0% of dihydrate gypsum with the above components, and grind to make cement with required specific surface area for testing.

[0047] Table 2 shows the recommended mix ratio of concrete for the cut-off wall of the dam, in which the specific surface area of 1# cement used is 220m 2 / kg, the specific surface area of 2# cement is 205m 2 / kg. The water reducer is a polycarboxylate or naphthalene water reducer commonly used in the hydraulic concrete market, and the air-entraining agent is a commonly used air-entraining ag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com