Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

185results about How to "Fast solidification" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

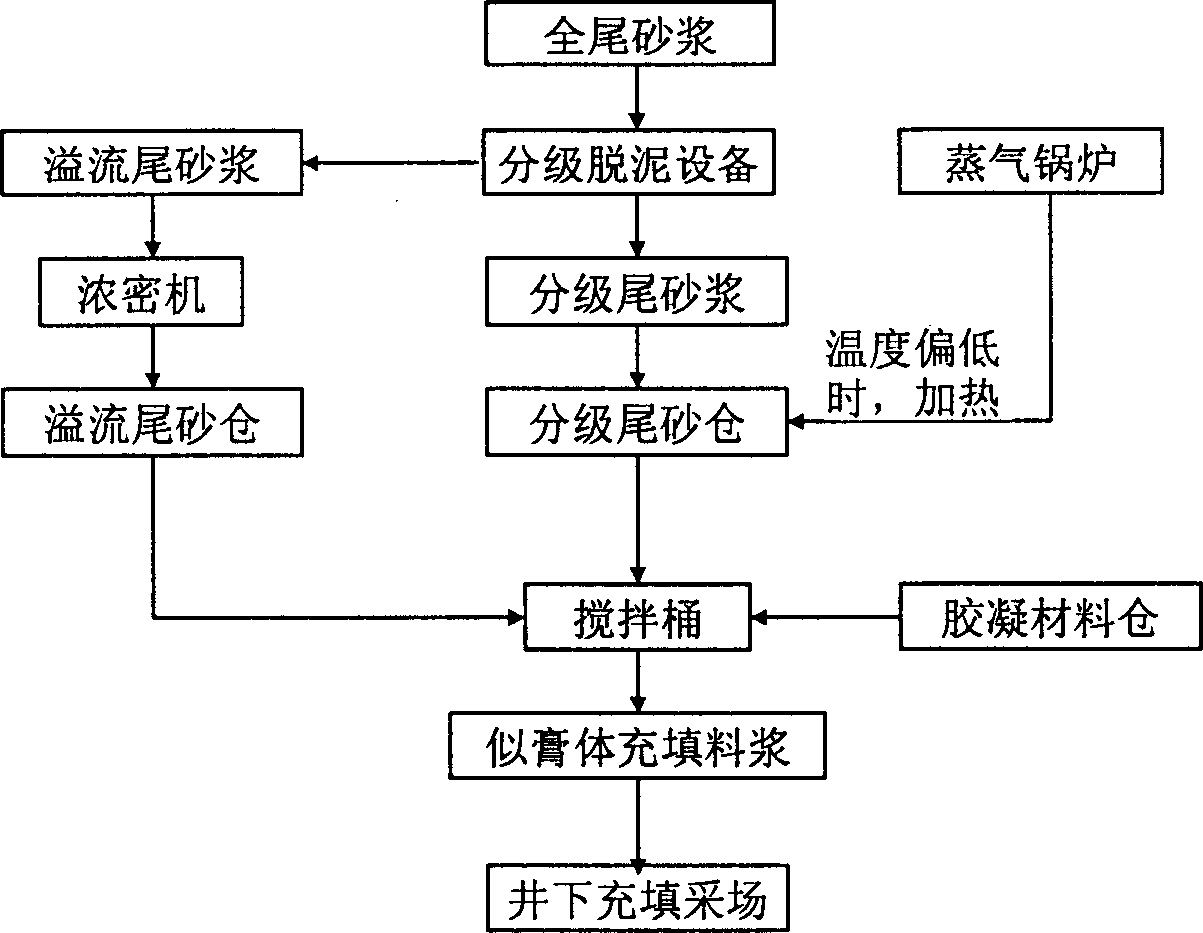

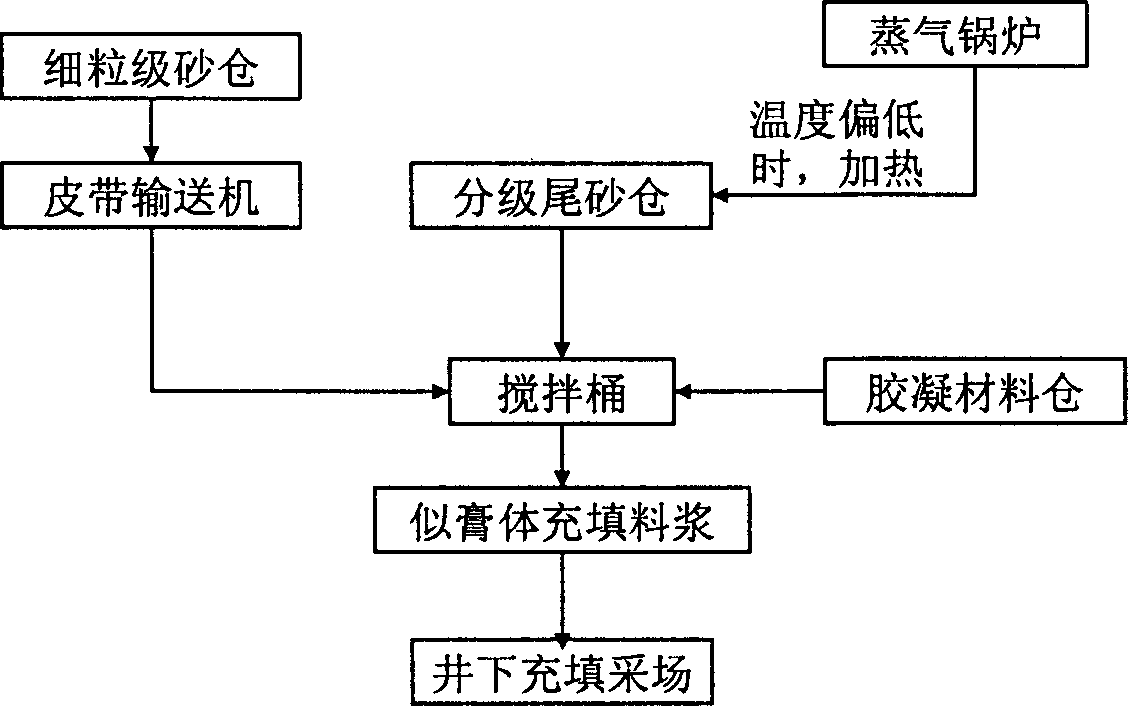

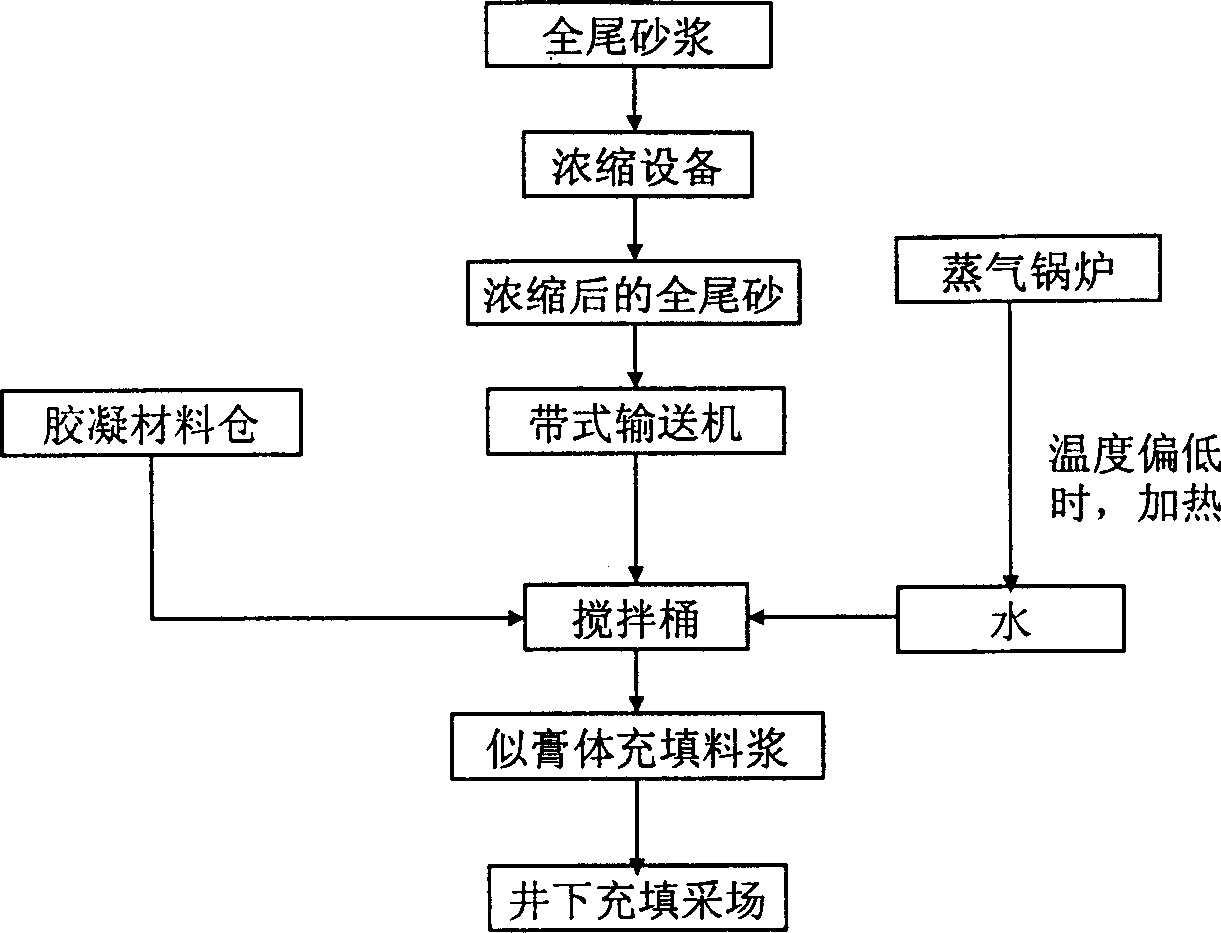

Cementing materials for filling, slurry and preparing and filling processes

InactiveCN1424275AReduce manufacturing costLess investmentSolid waste managementMaterial fill-upSlurrySulfur containing

A gelatining material similar to cream for filling underground working surface is preapred from the Ca-contained non-crystal and microcrystal material, alkali and / or sulfur contained exciting material, active material, aggregate and regulator. A filling slurry is prepared from said gelatining material, filling aggregate, fine particles, regulator and water through heating to at least 18 deg.C and proportional mixing.

Owner:CHINA UNIV OF MINING & TECH (BEIJING) +2

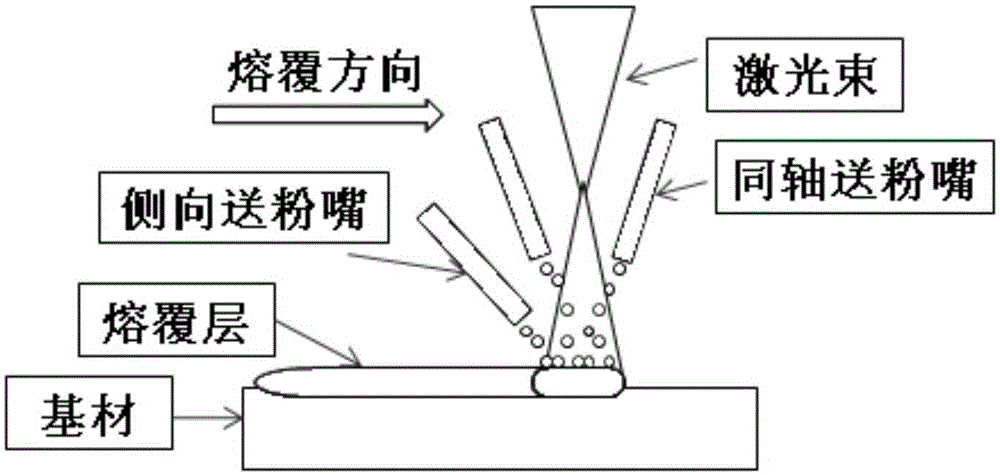

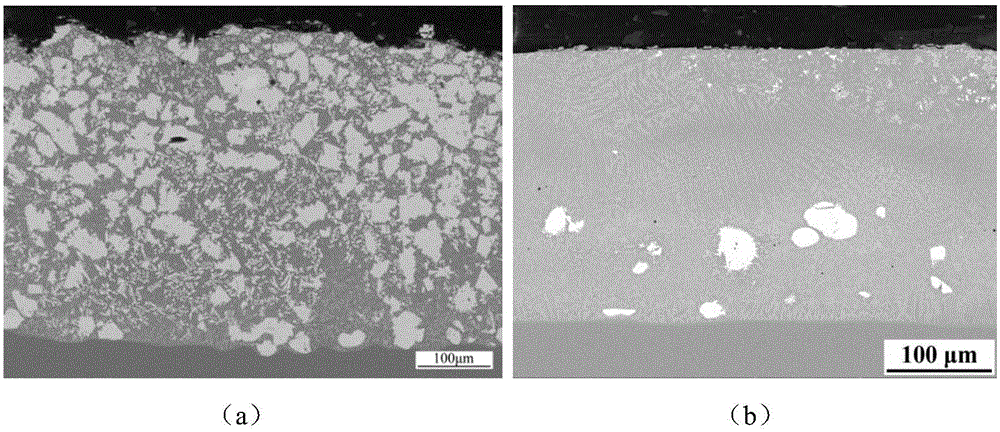

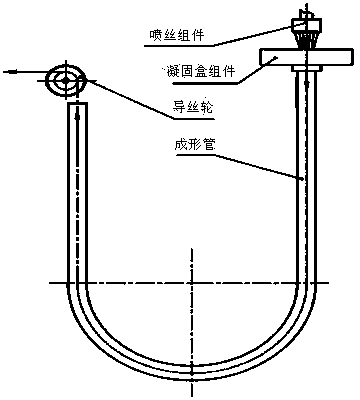

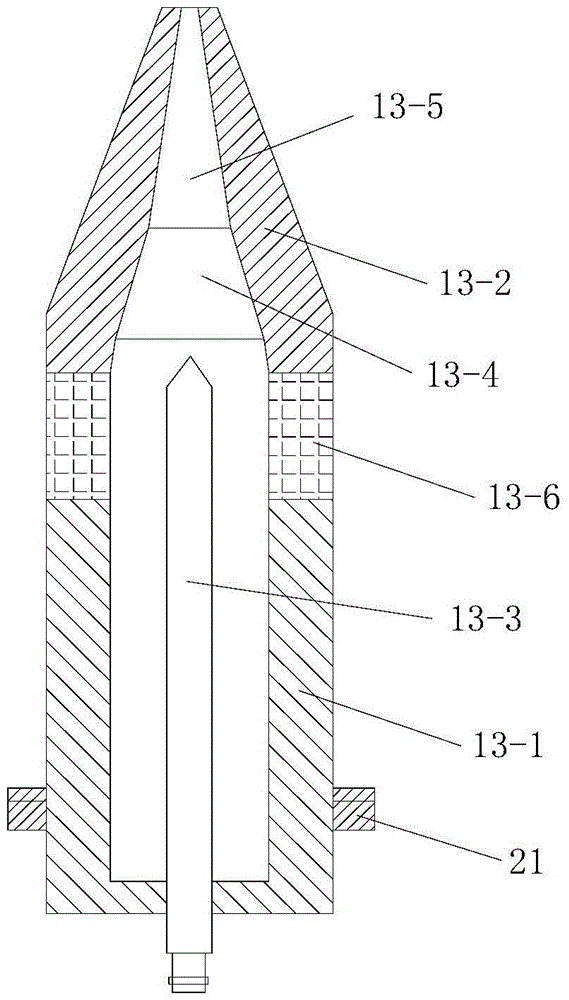

Method for preparing ceramic particle enhanced metal matrix composite coating in laser cladding mode through asynchronous powder feeding method

ActiveCN105002492AImprove performanceSimple processMetallic material coating processesDecompositionLaser scanning

The invention provides a method for preparing a ceramic particle enhanced metal matrix composite coating in a laser cladding mode through an asynchronous powder feeding method. A lateral powder feeding nozzle is fixed to one coaxial powder feeding nozzle and assembled into an asynchronous powder feeding nozzle; the lateral powder feeding nozzle is used for feeding ceramic particle enhancing phases into the portion between the middle portion and the tail portion of the side, opposite to the laser scanning direction, of a molten pool; the coaxial powder feeding nozzles are used for feeding alloy powder or metal ceramic composite powder to the center of the molten pool; a laser device is used for conducting laser cladding, and then the ceramic particle enhanced metal matrix composite coating is obtained. According to the method, the coaxial powder feeding method and the lateral powder feeding method are combined, the ceramic particle enhancing phases are fed into the low-temperature region at the rear portion of the molten pool, so that the phenomena of nonuniformity of melting decomposition, clustering and distribution of the ceramic particle enhancing phases are reduced, and the ceramic particle enhancing phases are evenly distributed in the whole coating by keeping the original appearance to the maximum extent; accordingly, the ceramic particle enhancing phases are effectively retained and evenly distributed, and the performance of the composite coating can be substantially improved.

Owner:西安合方长激光智能科技有限公司

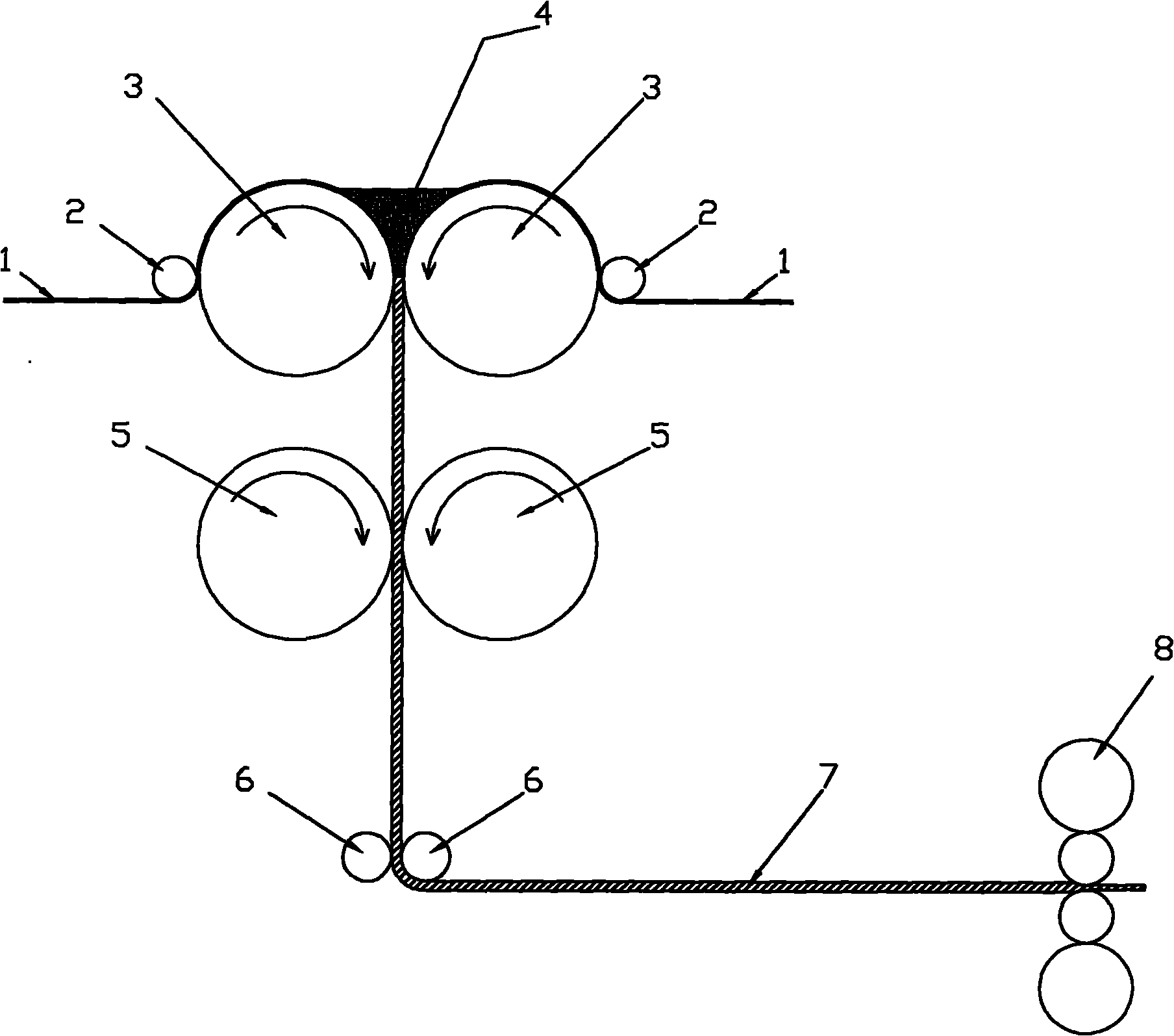

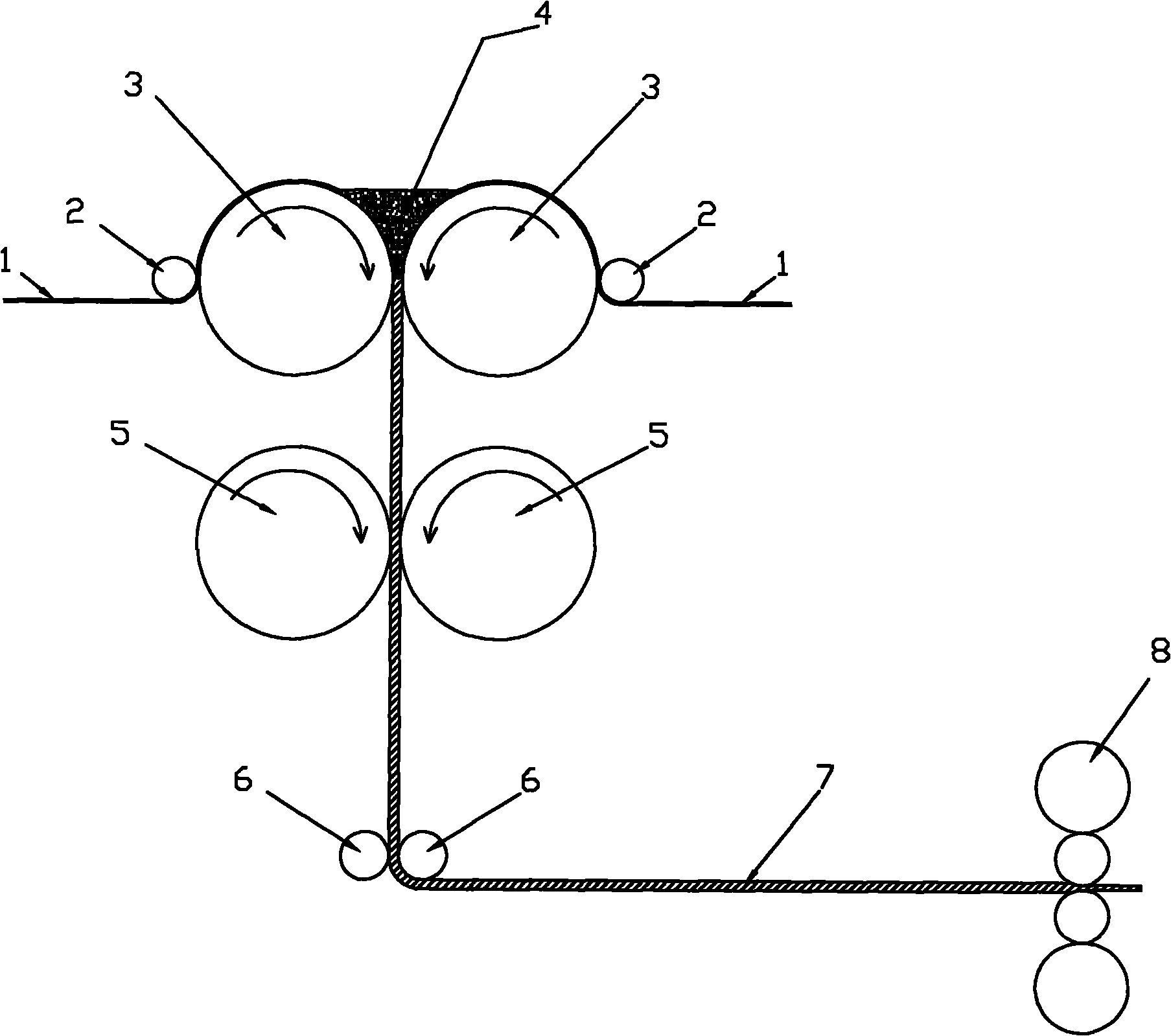

Twin-roller double-strip composite-structured thin strip continuous casting and rolling method

InactiveCN102039309ASurface quality is easy to controlImprove surface qualityMetal rolling arrangementsHigh surfaceMolten steel

The invention relates to a twin-roller double-strip composite-structured thin strip continuous casting and rolling method. In a twin-roller continuous casting process, a molten steel bath is formed jointly by two metal master strips respectively through two crystallizing rollers rotating oppositely, molten metal is crystallized and solidified on the master strips so as to from a composite casting strip under the casting-rolling effect of the crystallizing rollers, and then the finished thin strip is formed after rolling. The method disclosed by the invention guarantees high surface quality of the composite casting strip and high casting efficiency, without a cast-on problem, and can be used for casting composite-constituted and composite-structured thin strips.

Owner:BAOSHAN IRON & STEEL CO LTD

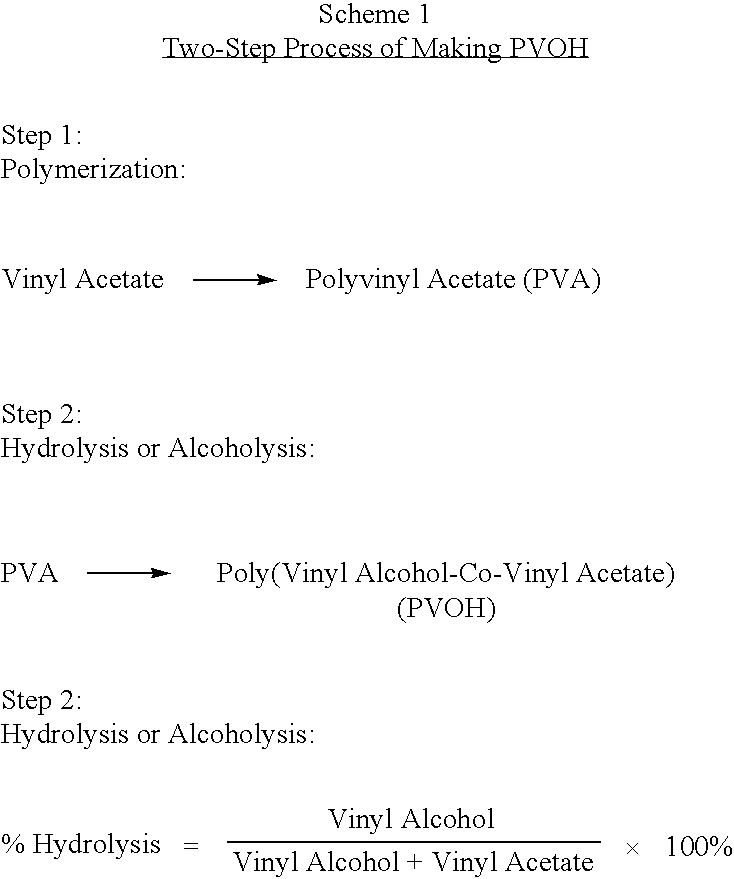

Blend compositions of an unmodified poly vinyl alcohol and a thermoplastic elastomer

InactiveUS7012116B1Good flexibilityImprove ductilityNon-fibrous pulp additionSynthetic resin layered productsPolyvinyl alcoholThermoplastic elastomer

This invention relates, in general, to blend compositions of an unmodified poly vinyl alcohol and a thermoplastic elastomer and thermoplastic film and fiber structures comprising these blend compositions. More specifically, this invention relates to substantially water-free films and fibers comprising unmodified polyvinyl alcohol and a thermoplastic elastomer.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Semi-solid die-casting aluminum alloy material and die-casting molding method using same

A semi-solid die-casting aluminum alloy material comprises 6%-9% of Si, 0-0.3% of Cu, 0.25%-0.55% of Mn, 0.2%-0.5% of Mg, 0.6%-1.2% of Fe, 0-0.15% of Ni, 0-0.15% of Zn, 0-0.15% of Pb, 0-0.05% of Sn, 0-0.2% of Ti, 0-0.15% of impurities, and the balance Al. The content of Si is controlled to be 6%-9% and the content of Fe is controlled to be 0.6%-1.2%, so that the good die-casting molding performance, corrosion resistance and demoulding effect are ensured; meanwhile, 0.25%-0.55% of Mn is added to form a MnAl6 compound, so that the harmful effect of iron is effectively weakened; also, Mn can hinder the recrystallization process of aluminum alloy, the recrystallization temperature is increased, and favorable conditions are provided for the semi-solid pulping process of alloy slurry; in addition, 0.2%-0.5% of Mg is contained properly so as to improve the tensile strength.

Owner:FUJIAN KINRUI HIGH TECH CO LTD

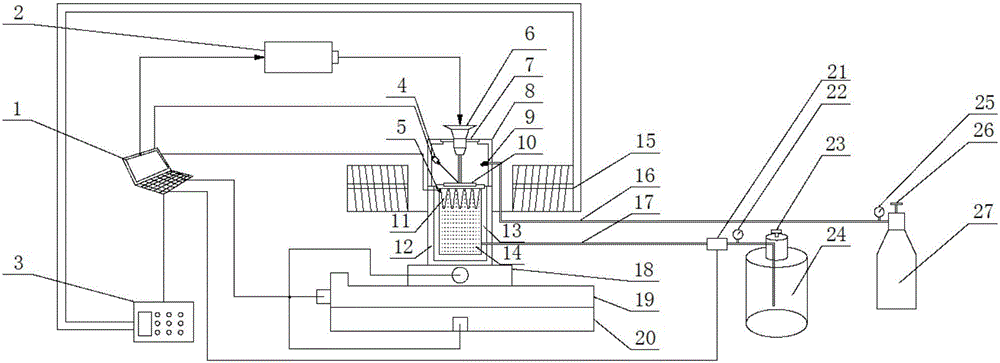

Method and device for conducting laser cladding with assistance of electromagnetic stirring in forced cooling environment

ActiveCN106757001AAvoid destructionImprove qualityMetallic material coating processesEngineeringCopper

The invention provides a method and device for conducting laser cladding with the assistance of electromagnetic stirring in a forced cooling environment. The device comprises a fiber laser, a liquid nitrogen forced cooling platform, an electromagnetic stirring platform, a temperature detection and feedback system and a computer control system. The method comprises the steps that a sample is placed on a special clamp made of red copper, the red copper clamp is forcibly cooled through liquid nitrogen, then cold is indirectly transmitted to the sample, and thus forced cooling of the sample in the laser cladding process is achieved. Meanwhile, the magnetic field intensity of the electromagnetic stirring platform is adjusted and controlled through a computer, and thus the laser cladding process with the assistance of electromagnetic stirring under forced cooling is achieved. According to the method and device for conducting laser cladding with the assistance of electromagnetic stirring in the forced cooling environment, laser cladding is conducted with the assistance of forced cooling and electromagnetic stirring to prepare a composite coating so that the good metallurgical bonding capacity of the composite coating with a matrix can be remarkably improved, a hard phase and uniform tissue distribution in the clad coating are achieved, grains are refined, and stress concentration is avoided; and defects such as cracks and pores of the laser clad coating are eliminated, and the quality of the clad coating is improved.

Owner:JIANGSU UNIV

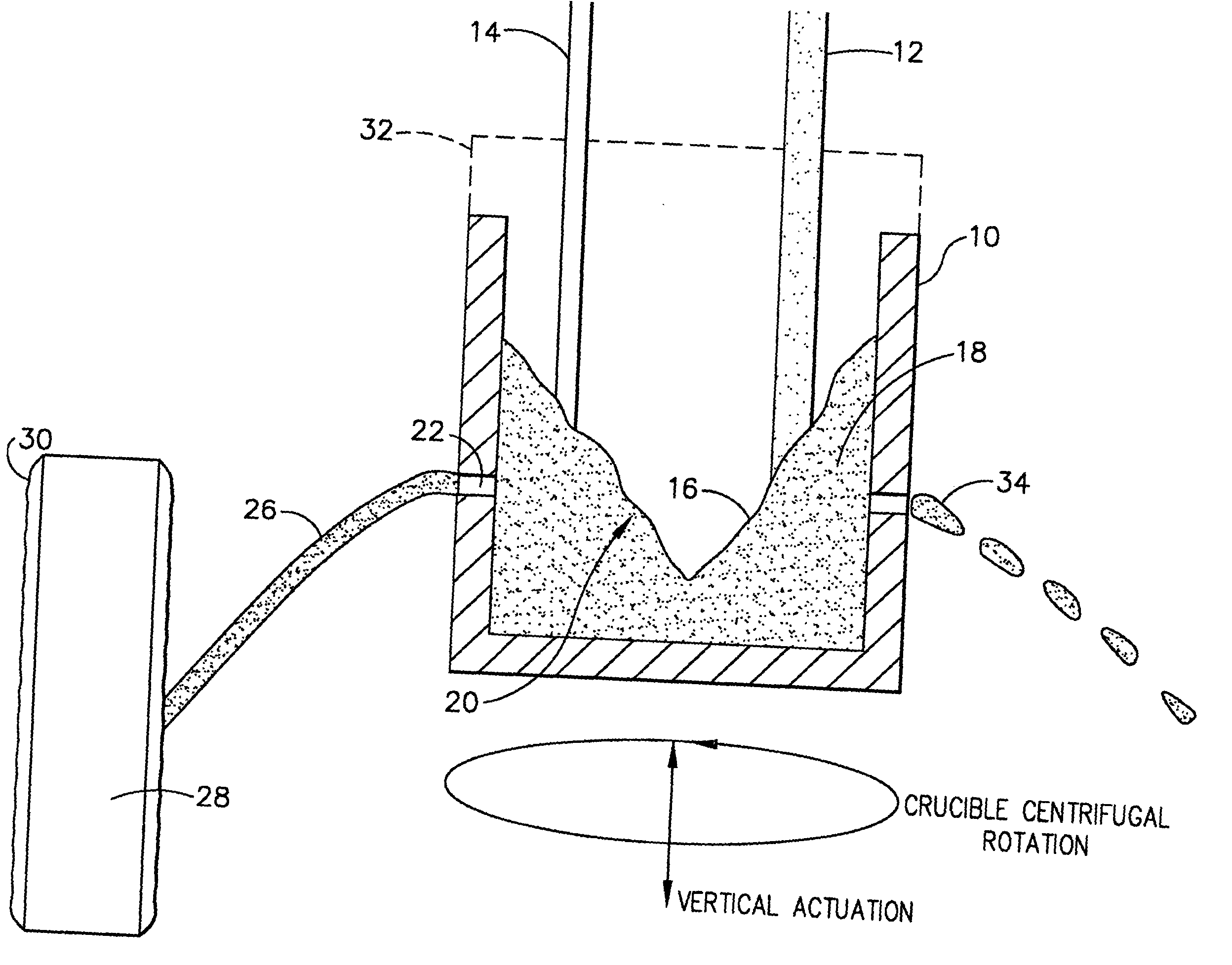

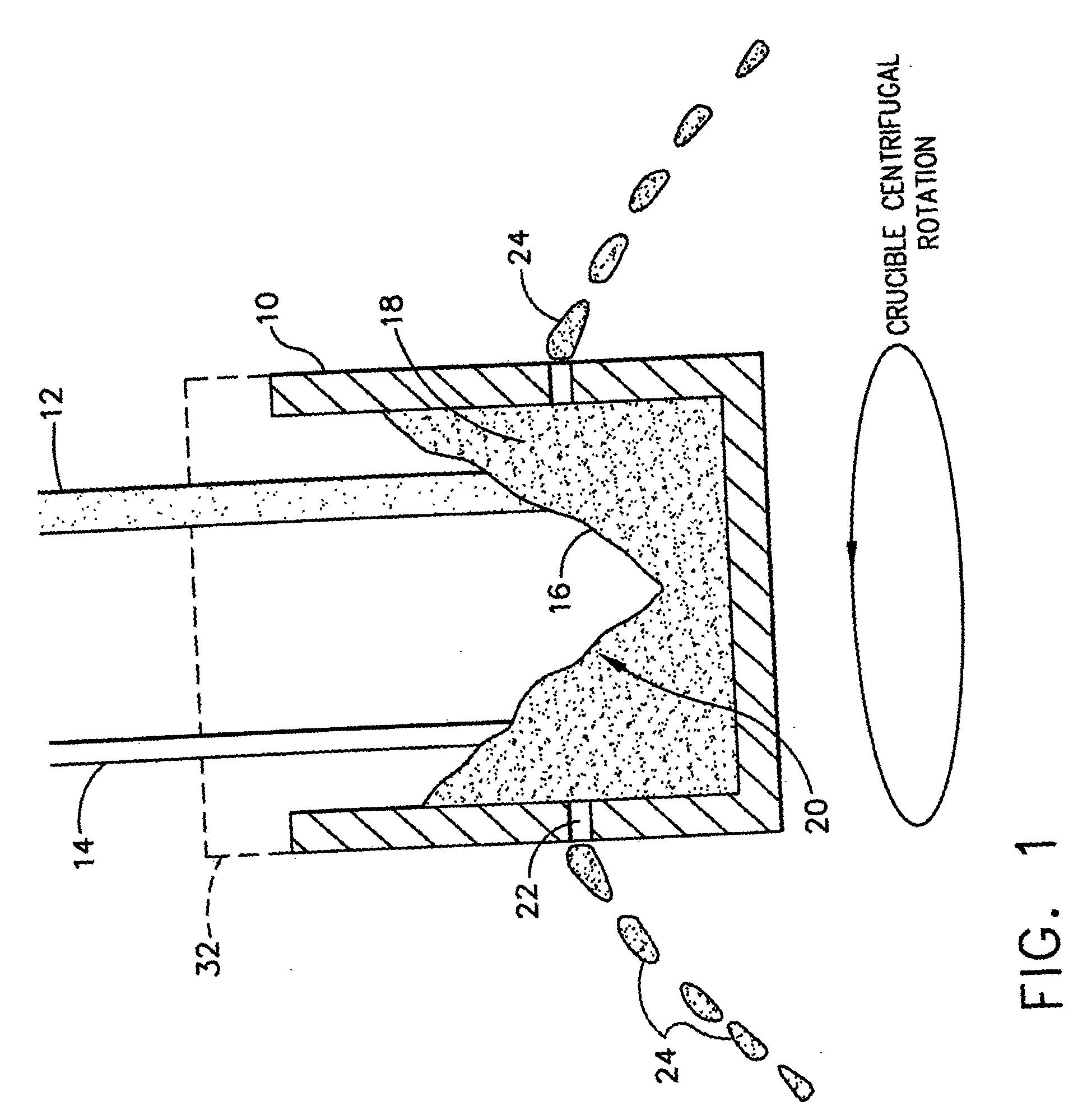

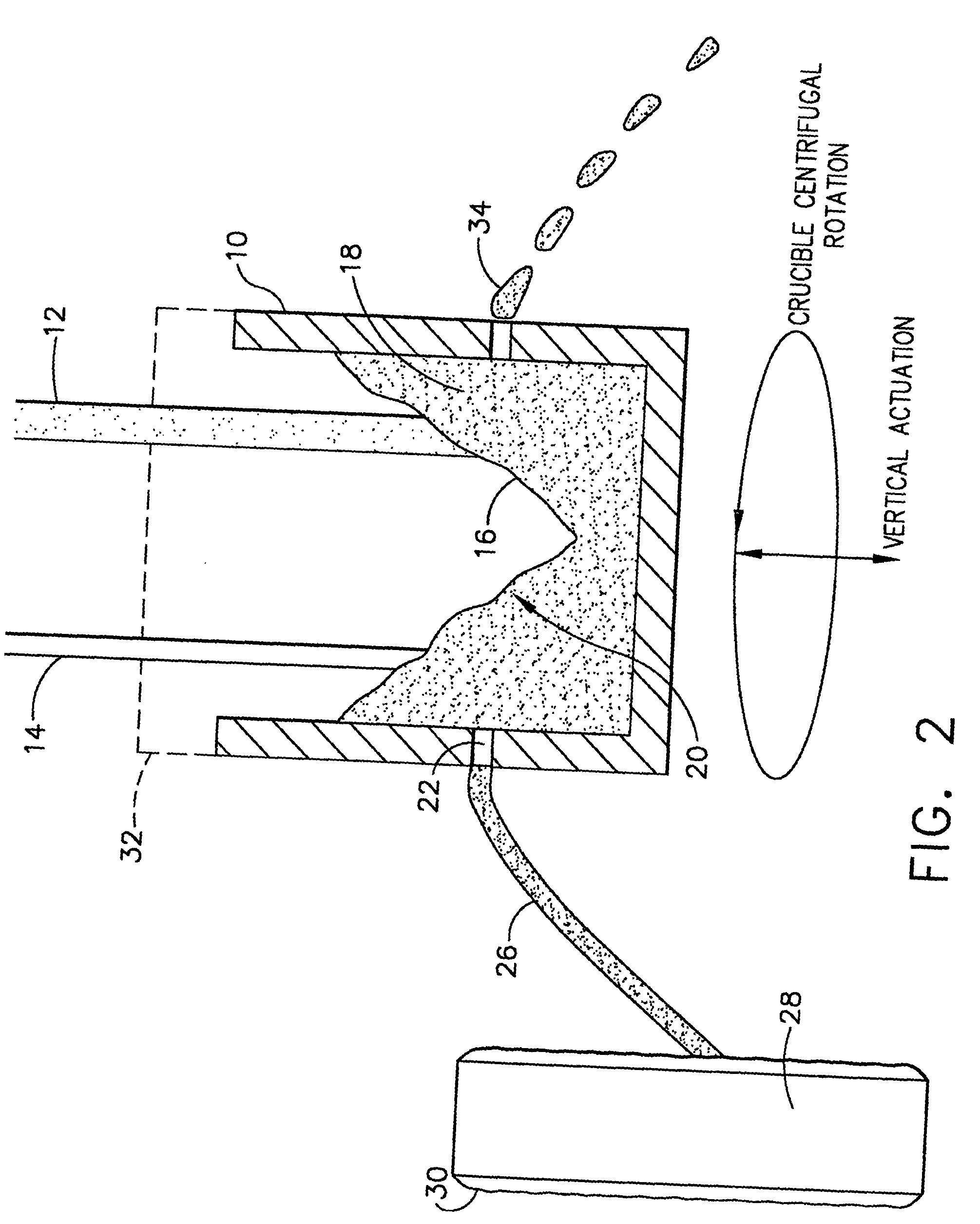

Process for producing materials reinforced with nanoparticles and articles formed thereby

A method for forming a dispersion-strengthened material containing nanoparticles that are uniformly dispersed in a matrix phase. The method includes adding nanoparticles and a molten material to a container to form a pool within the container and rotating the container to create a convection vortex in the pool. The convection vortex is sufficient to cause the nanoparticles to be incorporated into the molten material so as to yield a molten composite material, and further causes the molten composite material to be ejected from the container. The molten composite material is then cooled to form a solid composite body comprising a uniform dispersion of the nanoparticles.

Owner:GENERAL ELECTRIC CO

Method of processing soft foundation by quick low position high vacuum layering pre-compacting consolidation

The invention relates to a quick ''low level high-vacuum hierarchical precompression compaction' method for soft ground, the concretely processes are: 1) a sand layer is laid on the ground before filling, then the plastic water discharging boards are inserted vertically, a high vacuum precompression system is arranged transversely in the sand layer, and a layer of plastic air isolating film is covered; 2) the high vacuum precompressing system carries on vacuum and precompression; 3) the sand blowing high vacuum compacting system is arranged on the film transversely or vertically; 4) fills sand on the film to the set height; 5) the high vacuum precompression system carries on precompressing to the set boding rate, the system carries on the first time of vacuuming and discharge, then carries on the first time of compacting or vibration compacting the sand on the film; 6) carries on the second time or several times of 'high vacuum compacting' to the sand to the overconsolidation state. The invention is short period, low price, and the quality is controllable.

Owner:SHANGHAI HARBOUR SOFT SOIL TREATMENT ENG CO LTD

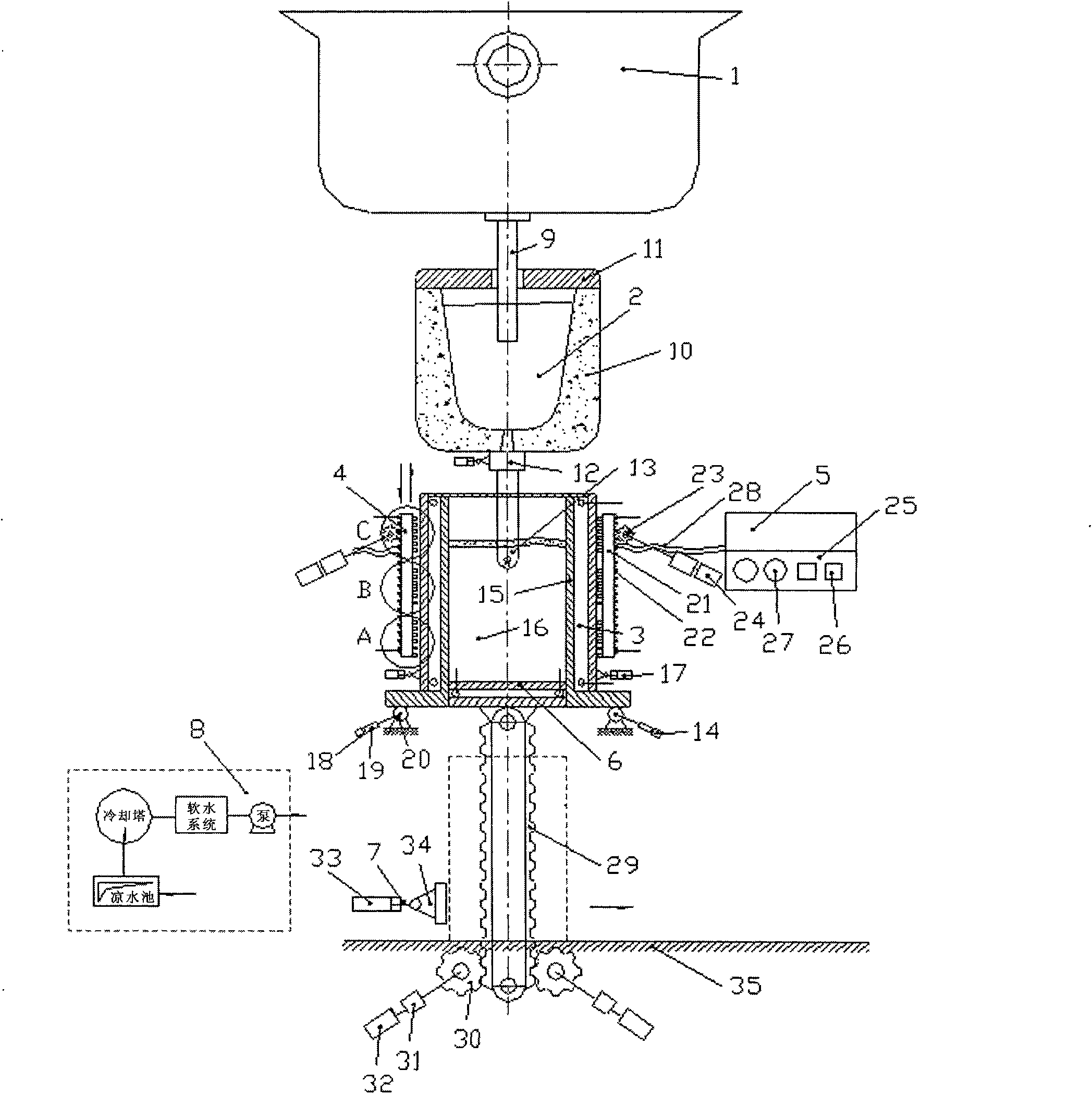

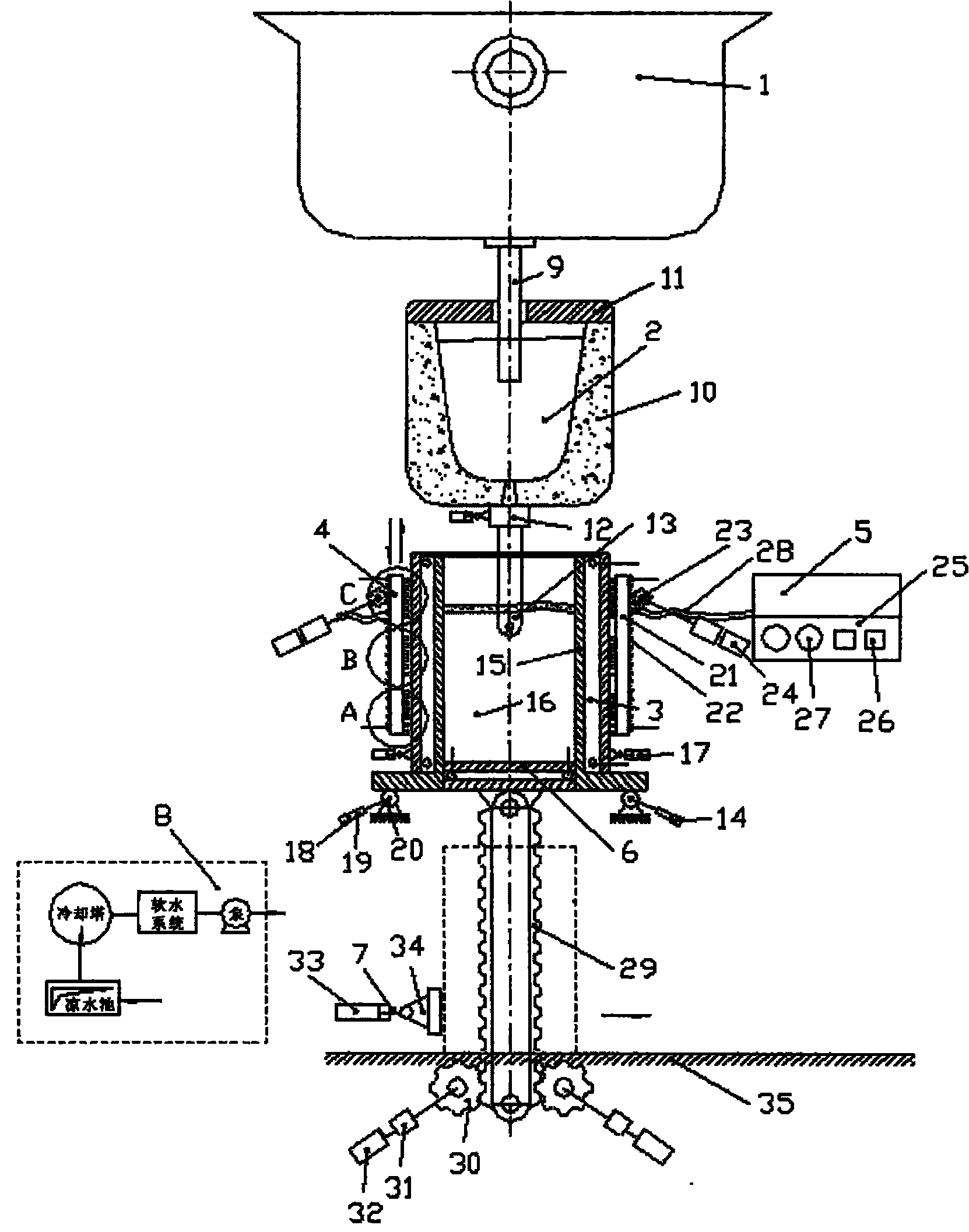

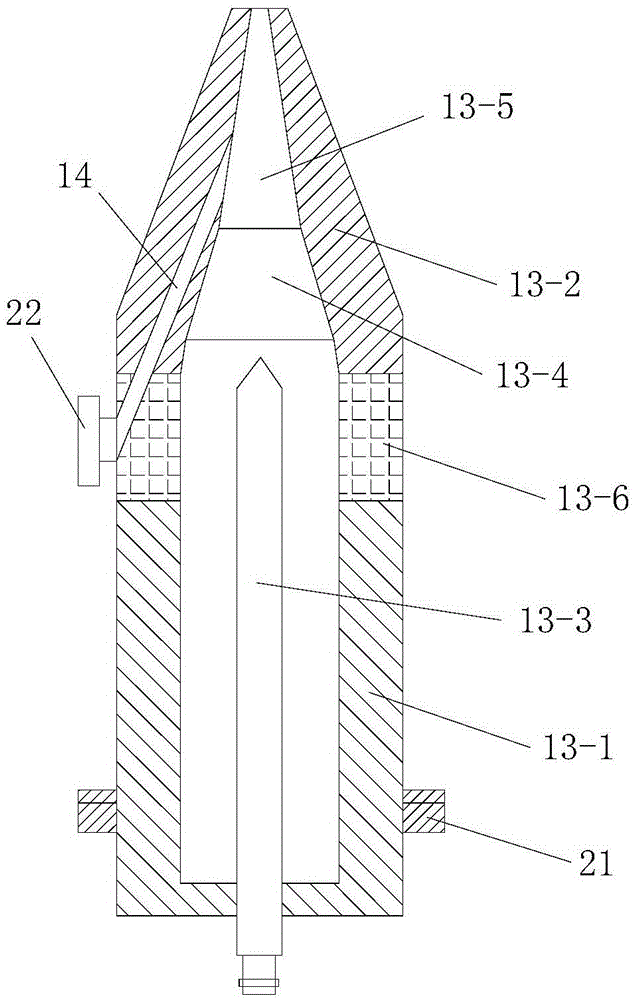

Intermediate-frequency induction and directional solidification ingot casting process and equipment utilizing same

The invention discloses an intermediate-frequency induction and directional solidification ingot casting process and equipment utilizing the same, which are used for producing extra-thick plates capable of guaranteeing internal quality of ingots and meeting requirements of the compression ratio. The intermediate-frequency induction and directional solidification ingot casting process includes that after being subjected to external refining, molten steel is delivered to an ingot casting platform by the aid of steel ladles and then used for casting, is poured into tundish through a long nozzle,and then is poured into a water-cooled crystallizer in a protected manner after flowing through a slide nozzle and an embedded nozzle; a vibration device of the crystallizer vibrates to start intermediate-frequency coils arranged outside the water-cooled crystallizer, heating of induction current and electromagnetic stirring effect are realized to control stop time, power and frequency of the induction coils at different positions of steel ingots so as to control internal quality of the steel ingots; a drawing device of a water-cooled underpan is started to draw the steel ingots from the water-cooled crystallizer, and finally the steel ingots are sent to be rolled. According to the distribution characters of an induced magnetic field in an intermediate-frequency electric induction furnace, inverted-V type segregation of the steel ingot is avoided. Gas impurity can be removed according to the electromagnetic stirring principle. Excellent feeding capacity of steel ingots is guaranteed, and the steel ingots casted by the process have compact insides and are free of segregation and low in impurity by the aid of an upper heat center utilizing induction heating. Due to better head feeding, the yield and production efficiency of steel ingots are improved.

Owner:UNIV OF SCI & TECH LIAONING

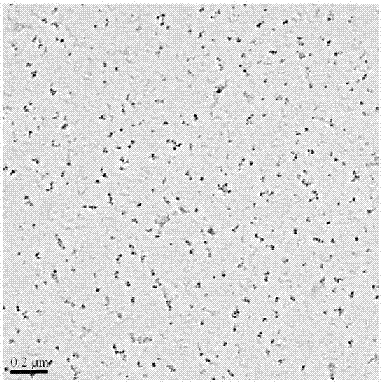

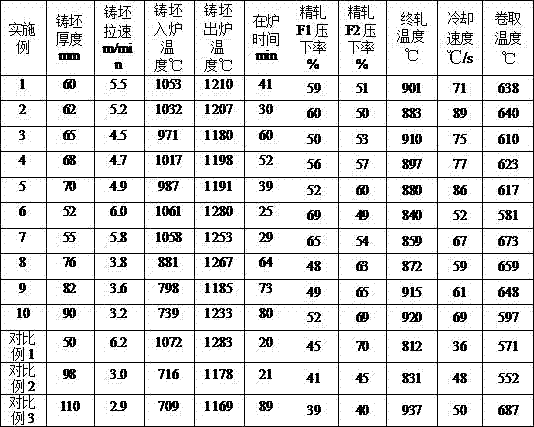

High-strength cold-roll-forming structural steel and method for producing same

InactiveCN1970811AInhibition of segregationFast solidificationTemperature control deviceMetal rolling arrangementsMolten steelHeating furnace

The invention discloses a high-strength cool-bent moulding structural steel and manufacturing method, which comprises the following parts: 0.03-0.12% C,0.08-0.50% Si,1.20-1.95% Mn,not more than 0.02% P,not more than 0.006% S, 0.05%-0.15% Mo,0.005-0.055% Als,0.03-0.07% Nb,0.08-0.15% Ti,0.01-0.05% V ,0.0008-0.004% Ca and Fe and inevitable impurity with Ceq not more than 0.42%. The making method is characterized by the following: controlling the fusing point of smolten steel over 15-30 deg.c; casting continuously; setting drawing speed of casting bland at 1.5-4.0m / min and blank thickness between 100 and 200mm; heating in the furnace directly; setting the even heating temperature at 1100-1250 deg.c, fine-rolling temperature at 940-1070 deg.c and outlet temperature at 840-920 deg.c; freezing rapidly after 0-7s; setting the coiling temperature at 500-610 deg.c with yielding strength of steel board over 700Mpa and drawing-proof strength between 750 and 950Mpa and extending rate over 17%.

Owner:ANGANG STEEL CO LTD

High-counter-pressure casting method for high-tensile and high-density aluminum silicon alloy

InactiveCN101569924AImprove micro-shrinkage feeding capacityImprove mechanical propertiesHigh densitySilicon alloy

The invention provides a high-counter-pressure casting method for a high-tensile and heavy aluminum silicon alloy, which relates to a counter-pressure casting method for the high-tensile and high-density aluminum silicon alloy. The invention solves the problem that the conventional counter-pressure casting technology cannot meet the requirement of producing castings with high mechanical properties and high density due to the limit on the density and internal quality increase of the castings. The invention has the following main steps of: regulating a counter-pressure casting machine to an operating bearing pressure of 3.0 MPa, preparing aluminum silicon alloy, controlling the temperature of the fusant after thinning and modification at 720 DEG C to 740 DEG C, and carrying out the liquid lifting, mold filling, pressurization, pressure maintaining and pressure relief of high-counter-pressure casting with the counter-pressure casting machine. The invention obviously eliminates internal pinholes, micro-shrinkage porosity and tiny cracks in the castings, and enhances the mechanical properties and density of the castings; because of small thermal resistance between the fusant and the mold wall, the setting rate of the castings accelerates, and the setting structure is obviously thinned, thereby further enhancing the mechanical properties of the castings. The method is especially suitable for the cast form of large-sized complex thin-wall parts.

Owner:HARBIN INST OF TECH

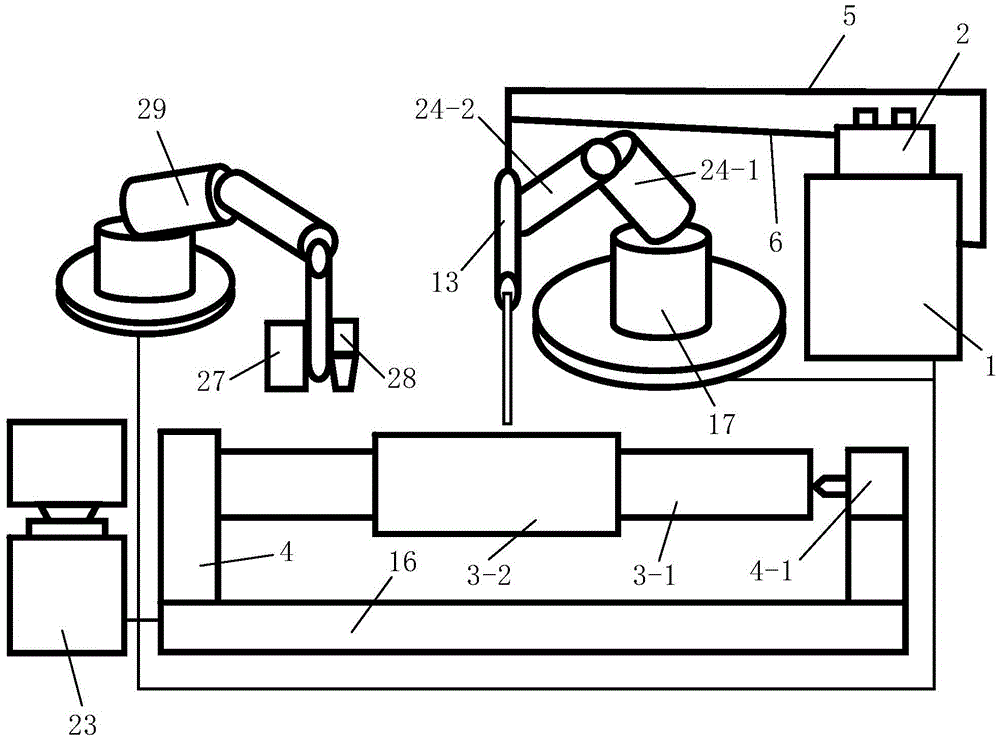

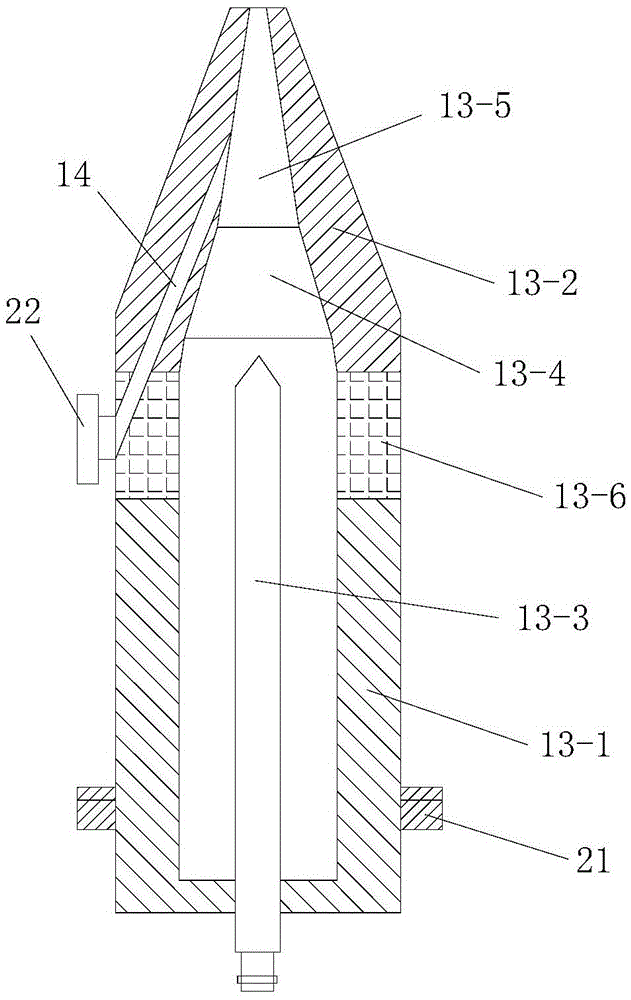

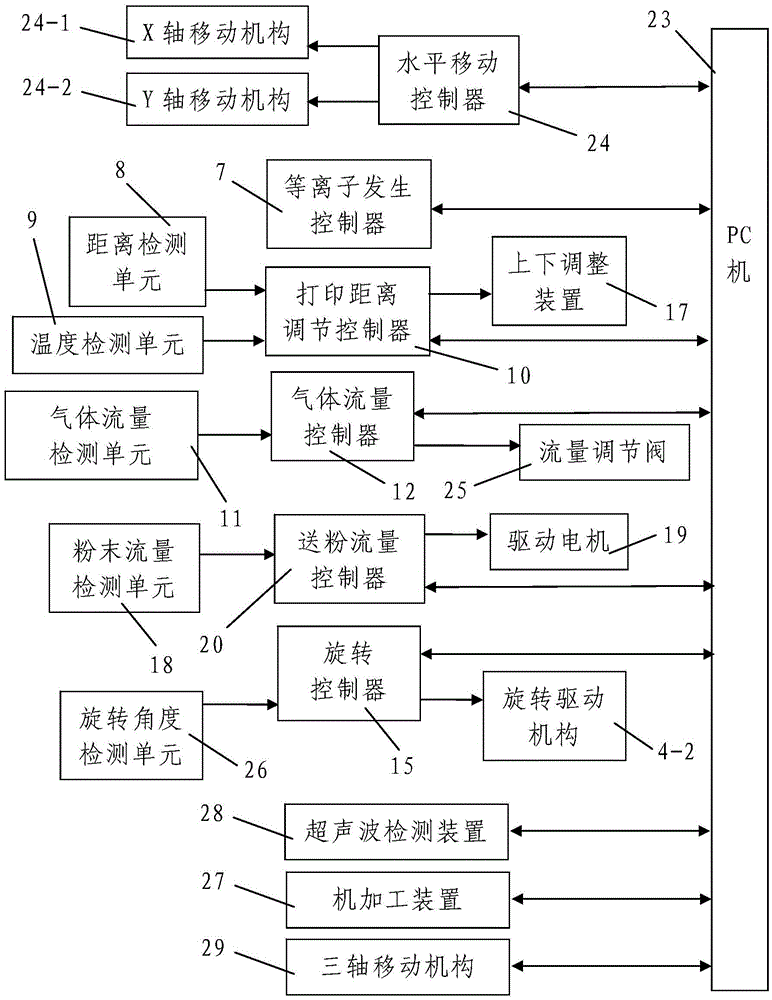

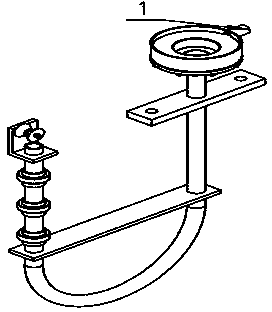

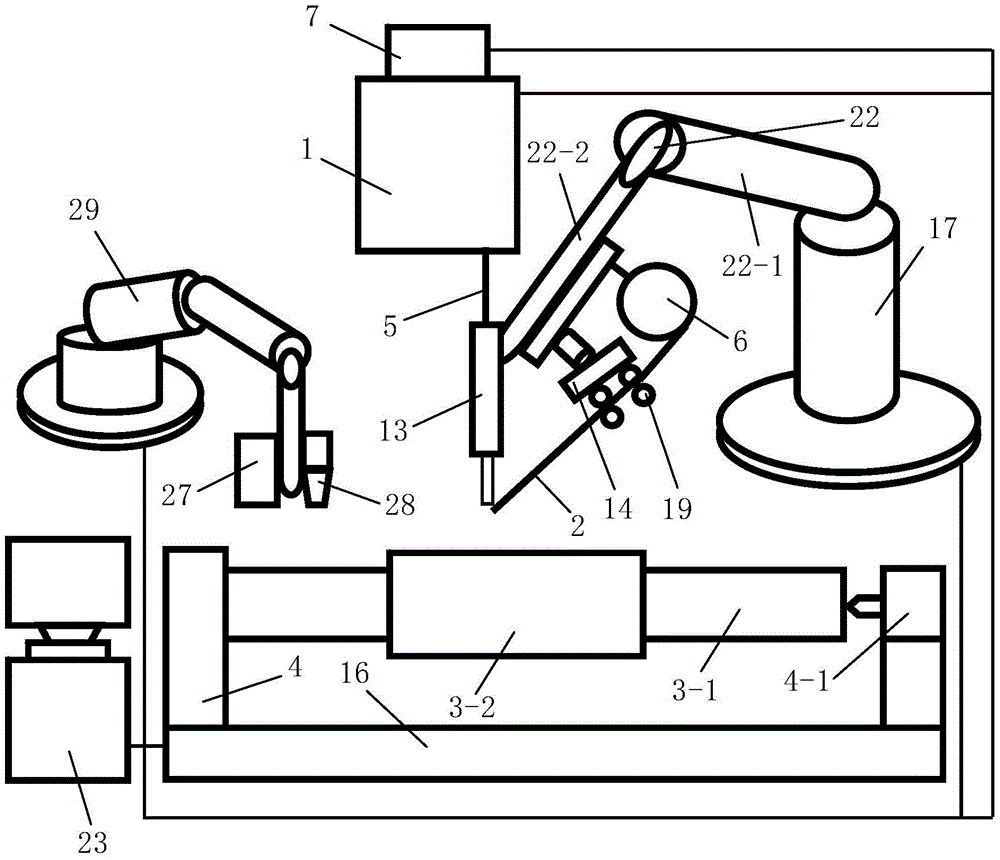

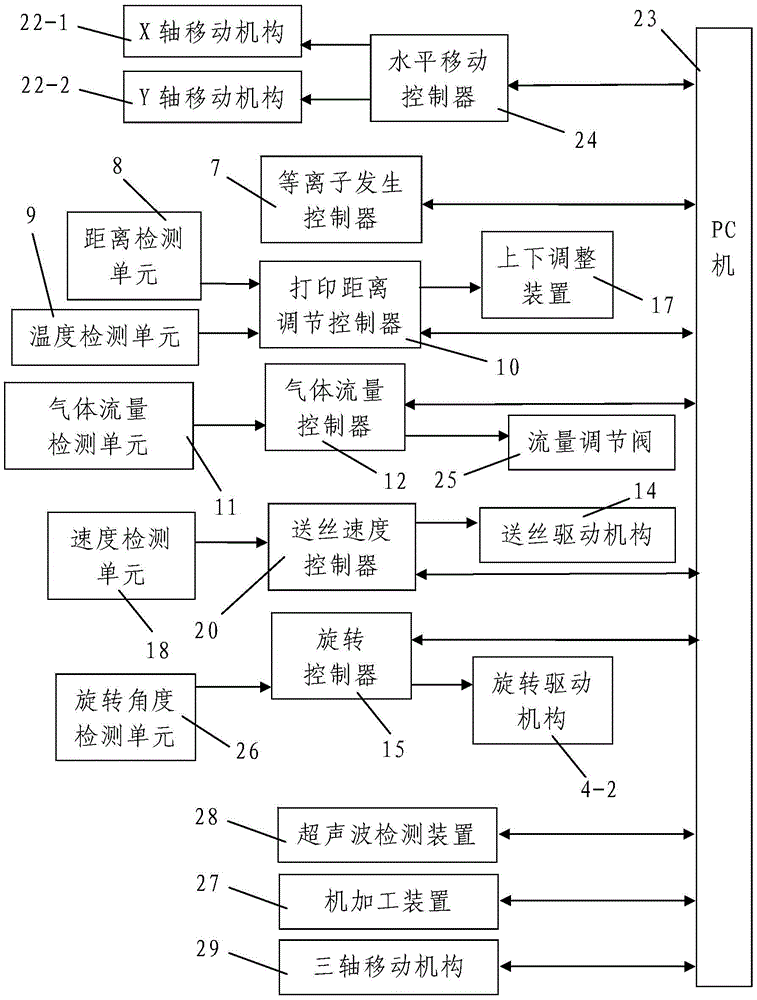

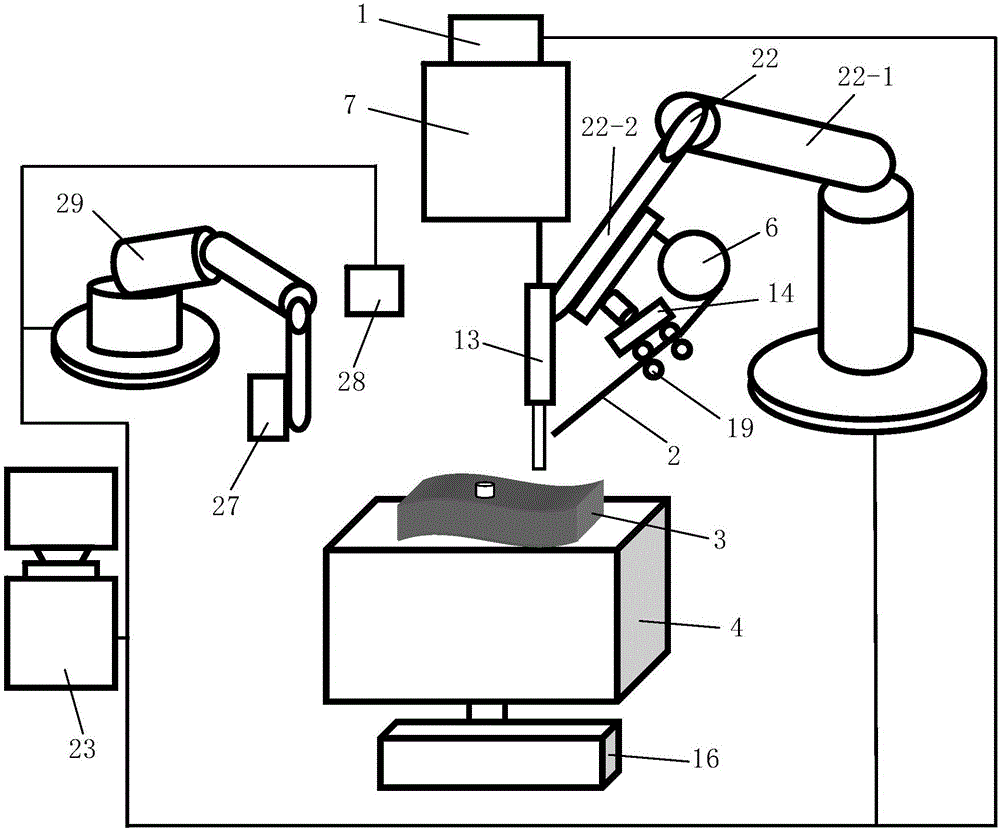

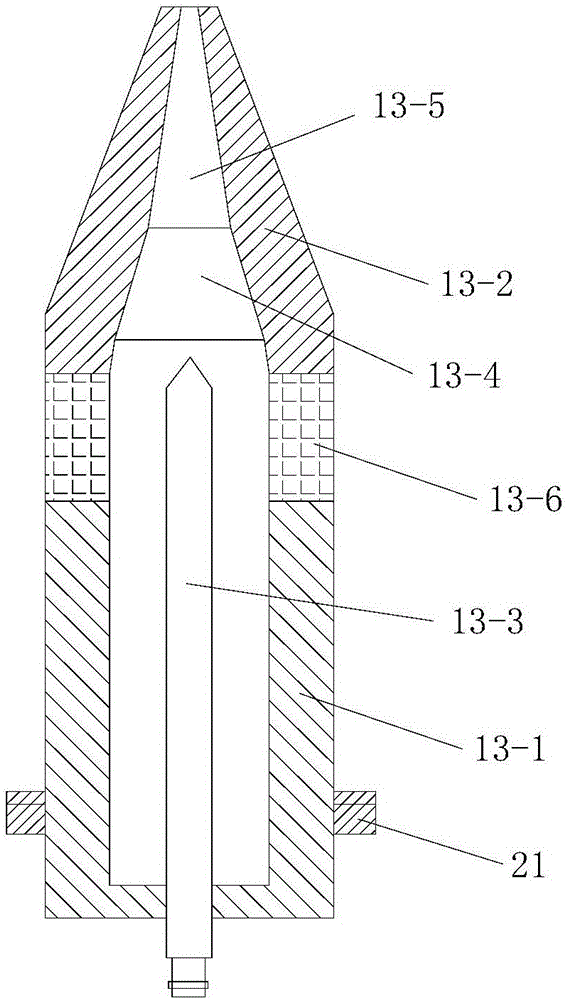

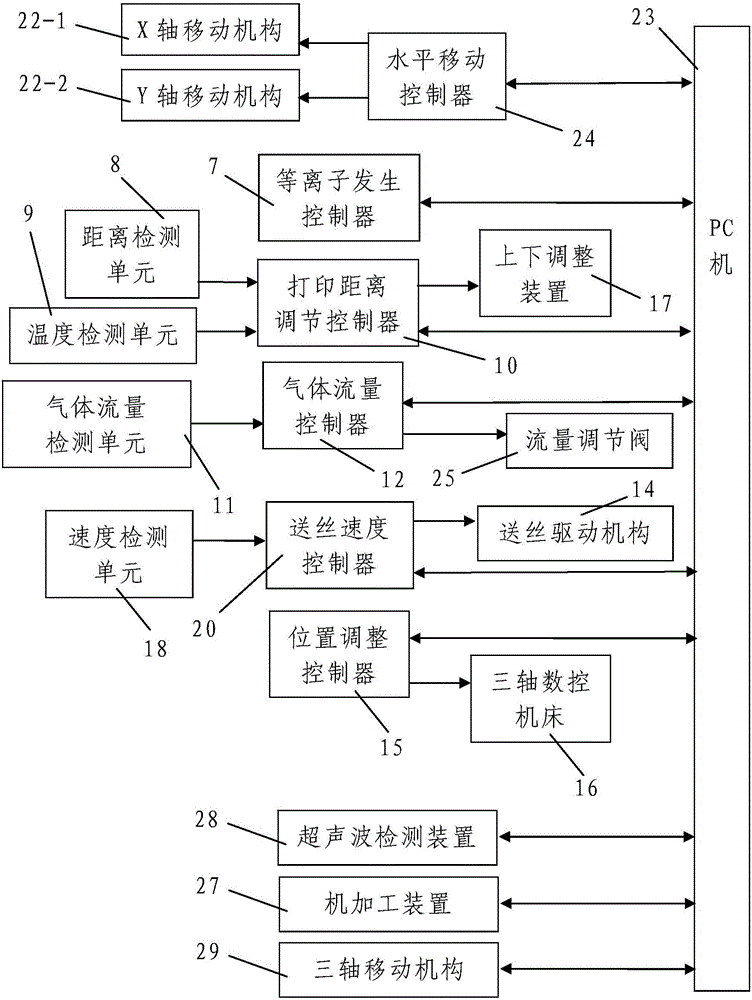

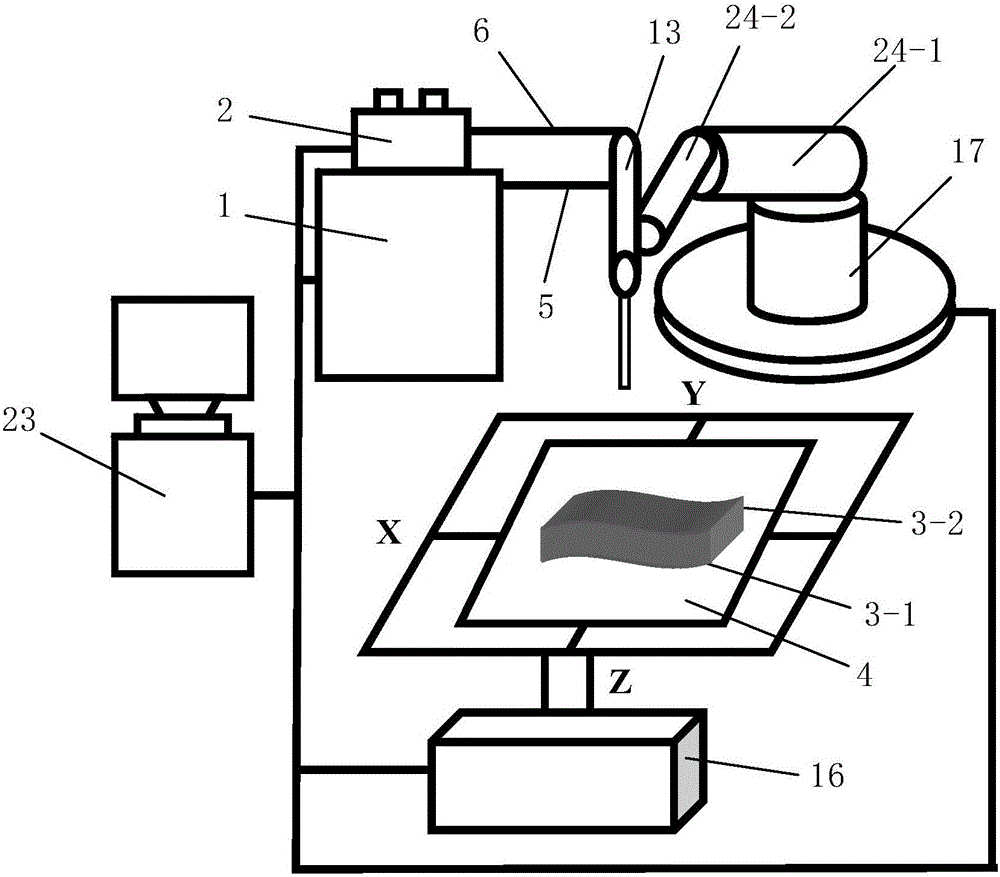

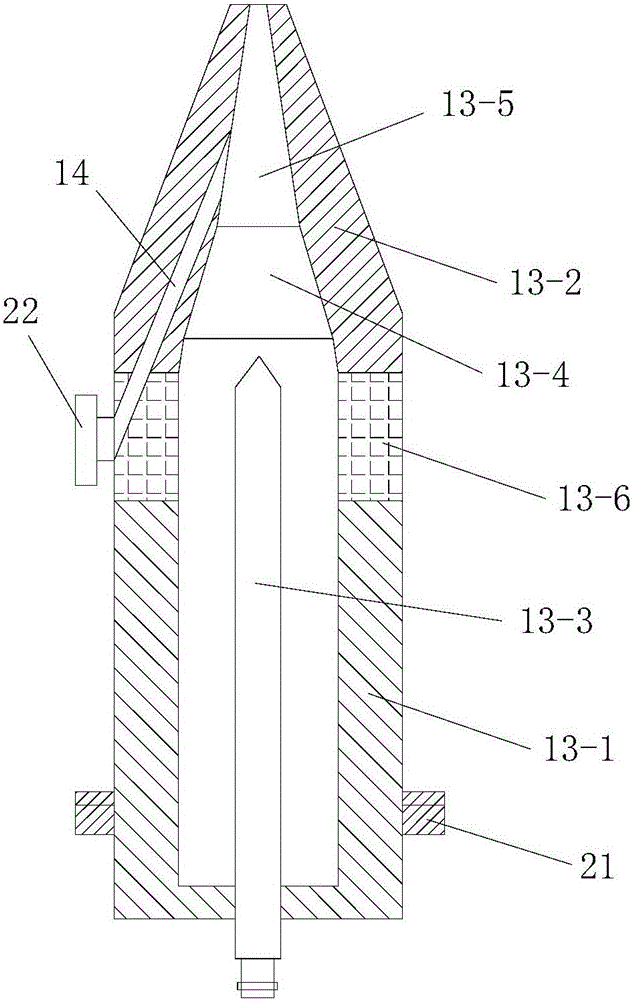

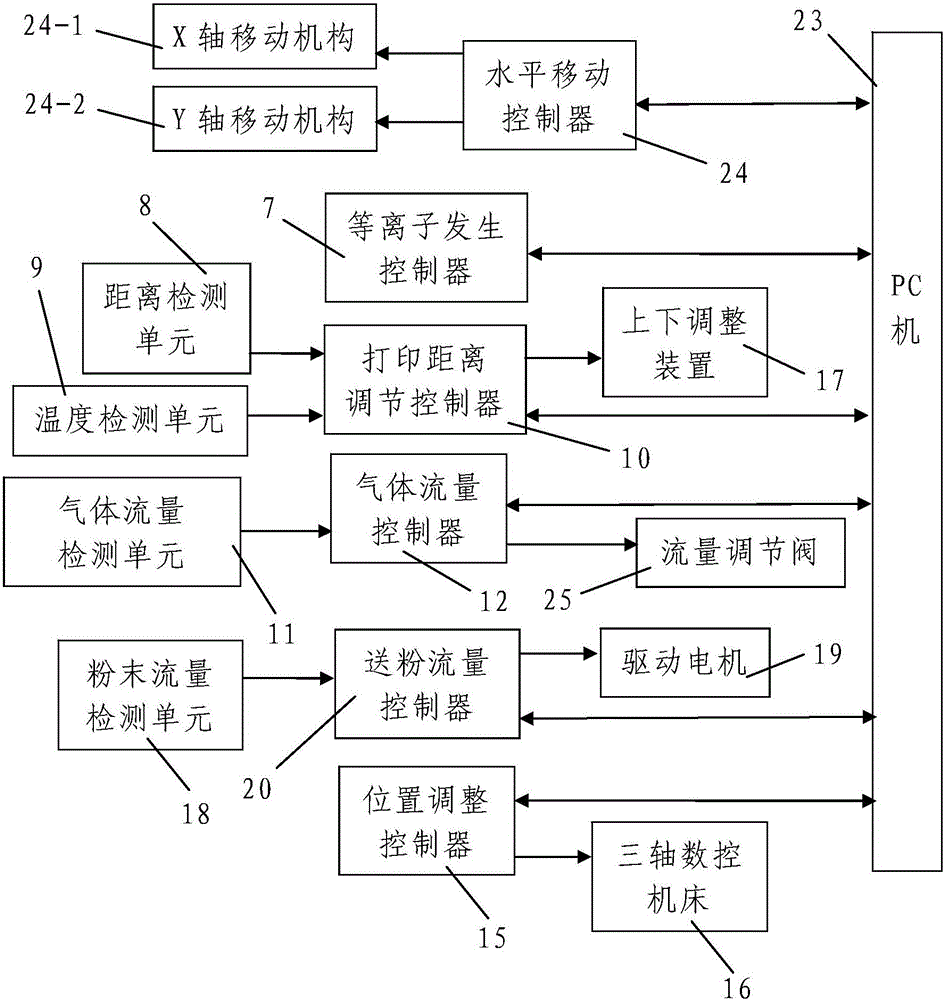

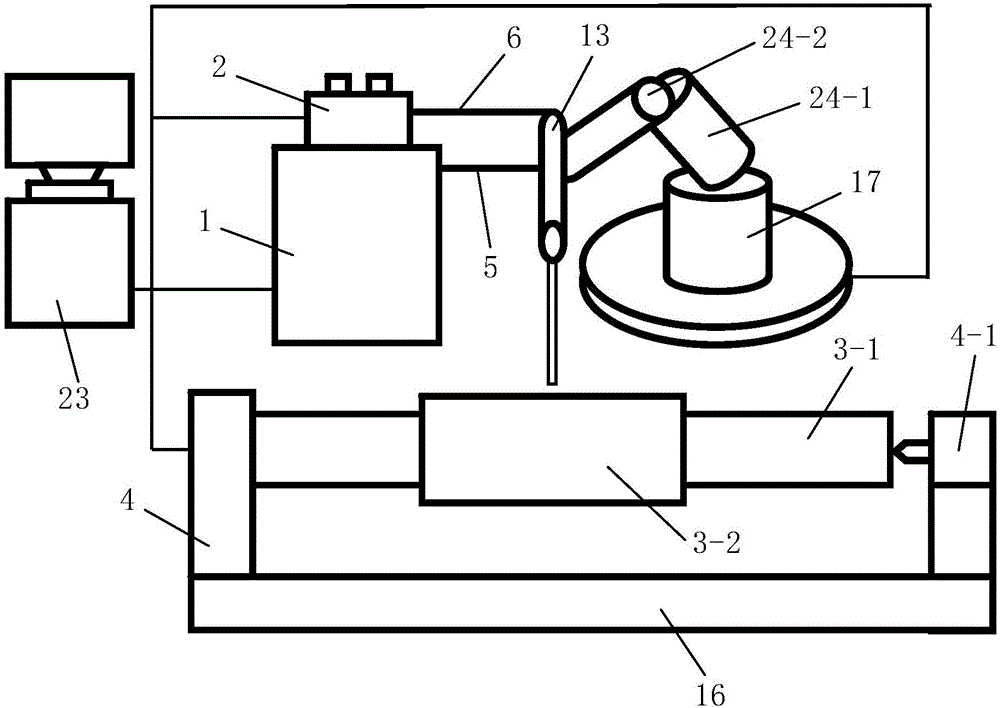

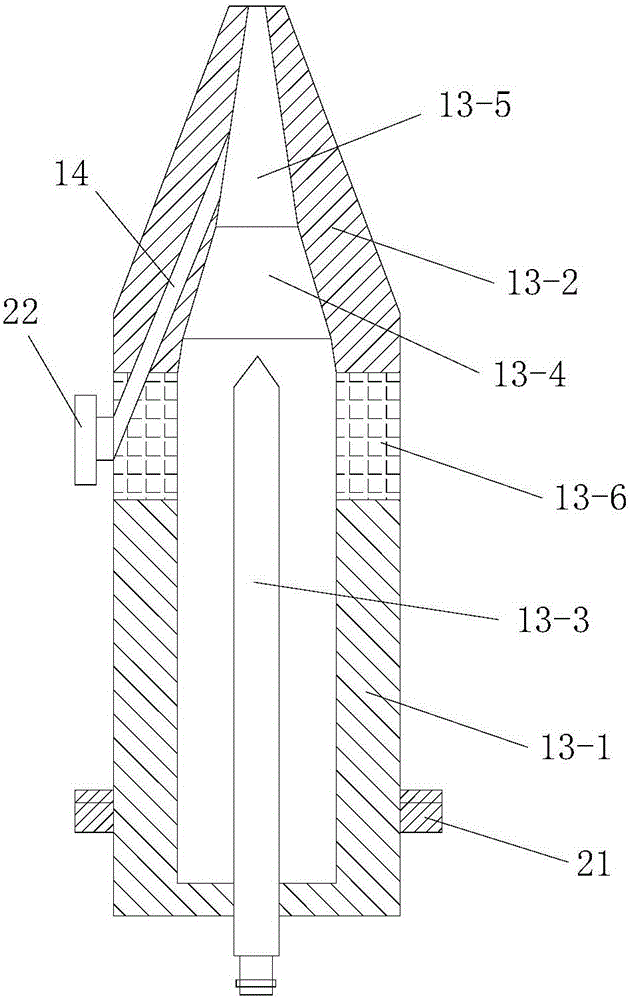

Plasma 3D printing remanufacturing equipment and method for mold

InactiveCN105642895ASimple structureReasonable designAdditive manufacturing apparatusIncreasing energy efficiencyPlasma generatorDistance detection

The invention discloses plasma 3D printing remanufacturing equipment and method for a mold. The equipment comprises a monitoring system, a plasma beam processing system, a machining device for machining a to-be-repaired mold, a horizontal printing table for accommodating the to-be-repaired mold and a temporary fixing element for fixing the to-be-repaired mold temporarily, wherein the plasma beam processing system comprises a plasma generator, a printing position adjusting device, a gas supply device and a powder feeder; the monitoring system comprises a horizontal motion controller, a temperature detection unit, a distance detection unit, a printing distance adjusting controller and a rotation controller, and the temperature detection unit and the printing distance adjusting controller constitute a temperature regulation device. The remanufacturing method comprises steps of 1, mold defect detection and 2, mold repair. The plasma 3D printing remanufacturing equipment and method for the mold have the advantages that the design is reasonable, the operation is simple, convenient and high in efficiency, the use effect is good, a molding cavity is not needed to be closed, a repair process is performed directly in an atmospheric environment, and the quality of the repaired mold is good.

Owner:SINOADDITIVE MFG EQUIP CO LTD

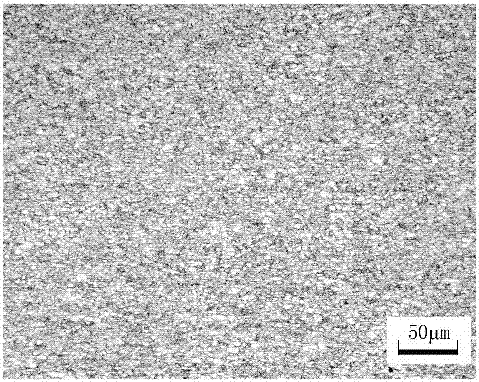

Hot rolled sheet with tensile strength equal to or higher than 800 MPa and prepared by direct rolling of sheet billet and producing method thereof

ActiveCN107190203AUniform grain sizeRefine the grain sizeMetal rolling arrangementsUltimate tensile strengthQuenching

Disclosed is a hot rolled sheet with the tensile strength equal to or higher than 800 MPa and prepared by direct rolling of a sheet billet. The hot rolled sheet comprises, by weight, 0.030-0.071% of C, 0.21-0.42% of Si, 0.5-1.5% of Mn, 0.04-0.15% of Ti, 0.12-0.41% of Mo, 0.02-0.10% of Nb, 0.13-0.35% of Cr, no more than 0.020% of P, no more than 0.010% of S and no more than 0.010% of N. A producing method includes the steps of smelting and continuous casting to form the billet, heating of the casted billet, precision rolling by seven machine frames, laminar flow cooling, and coiling. According to the hot rolled sheet with the tensile strength equal to or higher than 800 MPa and prepared by direct rolling of the sheet billet and the producing method thereof, by combining the characteristics that the solidification speed of the sheet billet continuous casting is fast and the texture is uniform, and matching with TMCP, Mo is added on the basis of the Ti-Nb composite micro-alloying, the tensile strength of a steel plate can reach 800 MPa under the condition of hot rolling, and quenching-and-tempering heat treatment can be omitted; in addition, a hot rolled material with the thickness of 0.8 mm can be produced, and a cold rolled product of the corresponding specification can be replaced directly; and according to the hot rolled sheet with the tensile strength equal to or higher than 800 MPa and prepared by direct rolling of the sheet billet and the producing method thereof, the producing process is simple, the producing efficiency is high, and the producing cost is low.

Owner:武汉钢铁有限公司

Method for preparing silicon nitride reinforced aluminium-based composite material

The invention discloses a method for preparing a silicon nitride reinforced aluminium-based composite material, which comprises the following steps: performing wet ball milling and drying on 60 to 67.5 weight percent of silicon oxide, 22.5 to 30 weight percent of carbon black, 1 to 10 weight percent of alpha-Si3N4 seed crystal, and 1 to 10 weight percent of Y2O3 to prepare mixed powder, sieving and granulating the mixed powder, and forming a blank piece through mold pressing; heating the blank piece to 1,750DEG C under the condition that the nitrogen pressure is six times of atmospheric pressure, preserving heat for 2 hours, and sintering to obtain a porous silicon nitride prefabricated body of which the relative density is between 20 and 30 percent; putting the porous silicon nitride sintered body in a die cavity of a die casting machine, and heating the die cavity to the temperature of between 500 and 700 DEG C, or firstly separately preheating the sintered body to the temperature of between 500 and 700 DEG C and then putting the preheated sintered body to the die cavity of the die casting machine; simultaneously, heating aluminium alloy to a melting state, pouring the molten aluminium alloy into the die cavity in which the prefabricated body is arranged, and pressing the molten aluminium alloy into the porous silicon nitride prefabricated body through a press machine; and finally, taking an ingot out after cooling, and performing heat treatment to obtain the silicon nitride reinforced aluminium-based composite material.

Owner:XI AN JIAOTONG UNIV

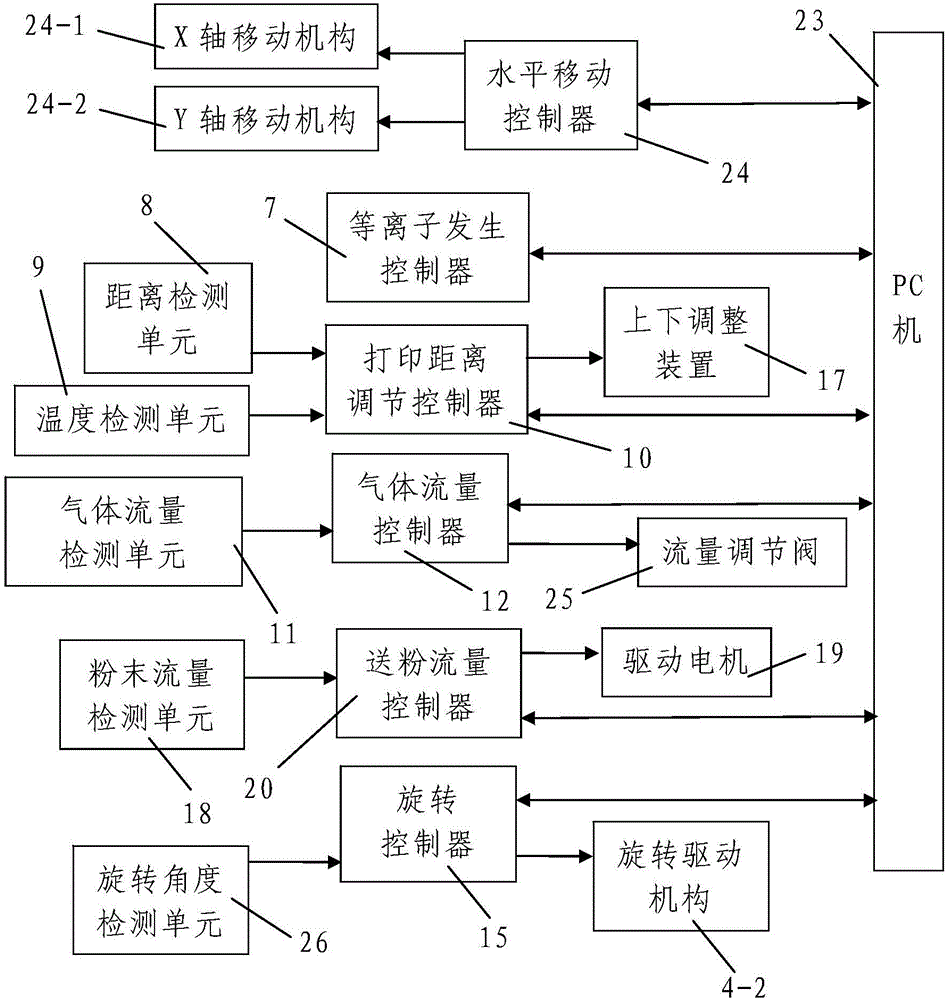

Plasma 3D printing remanufacturing equipment and method for roller

InactiveCN105543768ASimple structureReasonable designAdditive manufacturing apparatusMolten spray coatingTemperature controlDistance detection

The invention discloses plasma 3D printing remanufacturing equipment and method for a roller. The equipment comprises a monitoring system, a plasma beam processing system, a machining device for machining a to-be-repaired roller and a horizontal printing table for holding the to-be-repaired roller, wherein the plasma beam processing system comprises a plasma generator, a printing position adjustment device, a gas supply device and a powder feeder, and the printing position adjustment device comprises a horizontal moving device and a printing distance adjustment device; the monitoring system comprises a horizontal moving controller, a temperature detection unit, a distance detection unit, a printing distance adjustment controller and a rotation controller, and the temperature detection unit and the printing distance adjustment controller form a temperature control device. The remanufacturing method comprises steps as follows: 1, roller defect detection; 2, roller repair. The plasma 3D printing remanufacturing equipment is reasonable in design, simple and convenient to operate, high in efficiency and good in use effect, a forming chamber is not required to be closed, the roller is repaired directly in the atmospheric environment, and the quality of the repaired roller is good.

Owner:SINOADDITIVE MFG EQUIP CO LTD

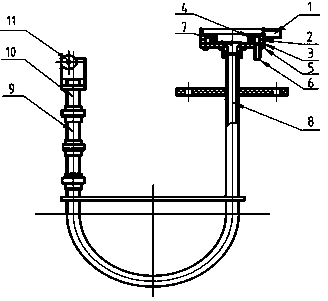

Dry spraying-wet spinning method for manufacturing aramid III fiber

ActiveCN103572390AIncrease spinning speedIncrease productivityWet spinning methodsDry spinning methodsYarnEngineering

The invention discloses a dry spraying-wet spinning method for manufacturing an aramid III fiber. The method comprises the following processing steps that A, a spinning stock solution is subjected to fine filtering and defoaming, and then extruded by a spinneret plate to form trickle; the trickle passes through an air layer and then enters a coagulating bath; B, the spinneret plate extruded trickle is coagulated in a coagulating forming device by the coagulating bath; a nascent fiber is obtained; the coagulating forming device comprises a coagulating disc and a U-shaped coagulating pipe; C, a solvent and an impurity of the coagulated and formed aramid III nascent fiber are removed by a washing technology; D, the washed fiber is oiled and dried; an aramid III fiber grey yarn is obtained; and E, the aramid III fiber grey yarn is subjected to heat treatment by heat shaping equipment; and the finished fiber is obtained. According to the method, a spinning speed and the production efficiency of the aramid III fiber are increased and improved greatly, so that the production cost of the fiber is lowered effectively; the manufactured aramid III fiber has excellent fiber performance and appearance quality and high cost performance; and the strength of the aramid III fiber is higher than that of a commercially available aramid 1414 high-strength product K129.

Owner:CHINA BLUESTAR CHENGRAND CO LTD

Plasma 3D quick-forming remanufacturing equipment and method for roller

InactiveCN105543769ASimple structureReasonable designAdditive manufacturing apparatusMolten spray coatingTemperature controlDistance detection

The invention discloses plasma 3D quick-forming remanufacturing equipment and method for a roller. The equipment comprises a monitoring system, a plasma beam processing system, a machining device for machining a to-be-repaired roller and a horizontal printing table for holding the to-be-repaired roller, wherein the plasma beam processing system comprises a plasma generator, a gas supply device, a wire feeding device for machined wires and a printing position adjustment device, and the printing position adjustment device comprises a horizontal moving device and a printing distance adjustment device; the monitoring system comprises a horizontal moving controller, a temperature detection unit, a distance detection unit, a printing distance adjustment controller and a rotation controller, and the temperature detection unit and the printing distance adjustment controller form a temperature control device. The method comprises steps as follows: 1, roller defect detection; 2, roller repair. The plasma 3D quick-forming remanufacturing equipment is reasonable in design, simple and convenient to operate, high in efficiency and good in use effect, the roller is repaired directly in the atmospheric environment, and the quality of the repaired roller is good.

Owner:SINOADDITIVE MFG EQUIP CO LTD

Copper-slag-based ferritic oxalate chemical bonded material and application thereof

The invention discloses a copper-slag-based ferritic oxalate chemical bonded material and application thereof. The material is prepared from, by weight, 300-700 parts of copper slag, 100-200 parts of oxalic acid or acid oxalate and 6-14 parts of set controlling material; the material has excellent performance of high setting rate, large cohesive force and good durability. The chemical bonded material serving as a base material for curing arsenic-containing slag can effectively cure / stabilize the arsenic-containing slag in and solve the problem of environment pollution caused by the arsenic-containing slag.

Owner:KUNMING UNIV OF SCI & TECH

High-performance initial-stage sprayed concrete for high-earth temperature tunnel and preparation method thereof

The invention discloses a high-performance initial-stage sprayed concrete for high-earth temperature tunnel. The sprayed concrete is characterized in that: raw materials and amounts of per cubic meter of concrete are as follows: cement 300-400kg, fine sand 400-500kg, a blast furnace heavy slag 700-800kg, coal ash 60-100kg, an alumina clinker 40-80kg, a basalt fiber 20-40kg, a polycarboxylic acid high performance water reducer 3-5kg, an aluminate accelerator 10-15kg, and water 180-250kg. A preparation method comprises the following steps: preparing materials; carrying out mixing and stirring; adding a coarse aggregate; adding an aluminate accelerator, and spraying and pouring the concrete. Compared with the prior art, the invention has the advantages that: the sprayed concrete for supporting the high-earth temperature tunnel can be tightly combined with surrounding rocks, so that the surrounding rocks are integrally stable, and a concrete layer can be continuously sprayed for a next step of construction. In the high-earth temperature tunnel environment, the concrete has the advantages of fast solidification speed, good heat resistance, good anti-permeability and anti-cracking performance, the intensity is not reduced, so the construction requirement is met.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

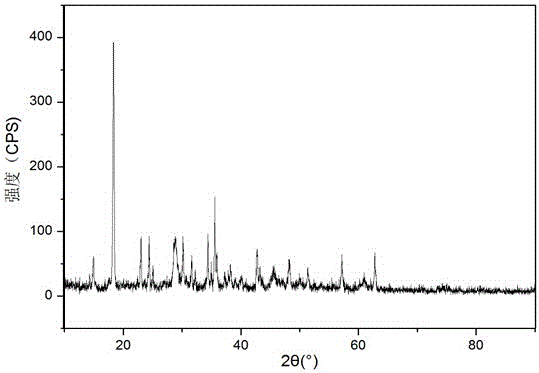

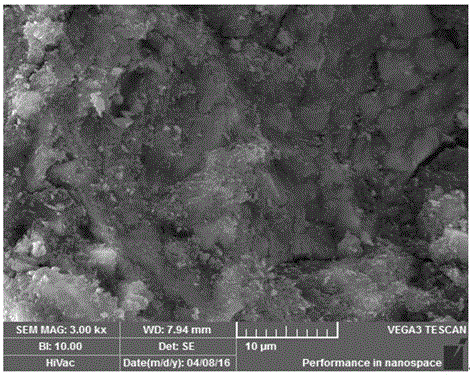

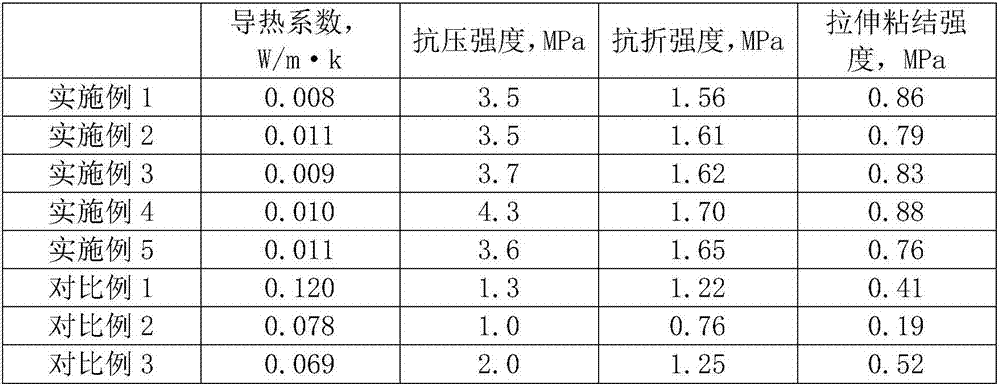

Preparation method of environment-friendly phase-changed insulated anti-cracking fast-setting spraying mortar

The invention discloses a preparation method of environment-friendly phase-changed insulated anti-cracking fast-setting spraying mortar. The preparation method comprises the following steps: mixing and stirring common silicate cement and sulfate aluminum cement into mixed cement; modifying expanded perlite by using polystyrene emulsion; adsorbing paraffin into a pore of the expanded perlite by using a reduced pressure adsorption method; coating by using cement; preparing silica-coated polyphenyl particles; preparing silica sol-modified aluminum oxide ceramic powder; uniformly mixing and stirring the prepared remaining blended cement, gypsum, aggregate coated with the blended cement, the silica-coated polyphenyl particles and the ceramic powder, continuously adding sepiolite fibers, polypropylene fibers and a thickening agent, and continuously performing uniform stirring and mixing to obtain the spraying mortar. The spraying mortar is good in thermal insulation, strong in adhesion strength and excellent in mechanical performance.

Owner:SHAOXING YISHENG MORTAR

Mold plasma 3D rapid prototyping remanufacturing device and method

InactiveCN105689715ASimple structureReasonable designAdditive manufacturing apparatusIncreasing energy efficiencyDistance detectionMonitoring system

The invention discloses a mold plasma 3D rapid prototyping remanufacturing device and method. The device comprises a monitoring system, a plasma beam processing system, a machining device used for machining a to-be-repaired mold, a level printing table used for placing the to-be-repaired mold, and a temporary fixing part used for temporarily fixing the to-be-repaired mold, wherein the plasma beam processing system comprises a plasma generator, an air supply device, a wire feeding device and a printing position adjusting device; the monitoring system comprises a horizontal motion controller, a temperature detection unit, a distance detection unit, a printing distance adjustment controller and a rotation controller; and the temperature detection unit and the printing distance adjustment controller form a temperature regulating device. The remanufacturing method comprises the steps of I, mold defect detection and II, mold repairing. According to the mold plasma 3D rapid prototyping remanufacturing device and the method, the design is reasonable, the operation is simple and convenient, the efficiency is high, the using effect is good, a sealed shaping room is not needed, the repairing process is directly carried out in the atmospheric environment, and the quality of the mold is good after repairing.

Owner:SINOADDITIVE MFG EQUIP CO LTD

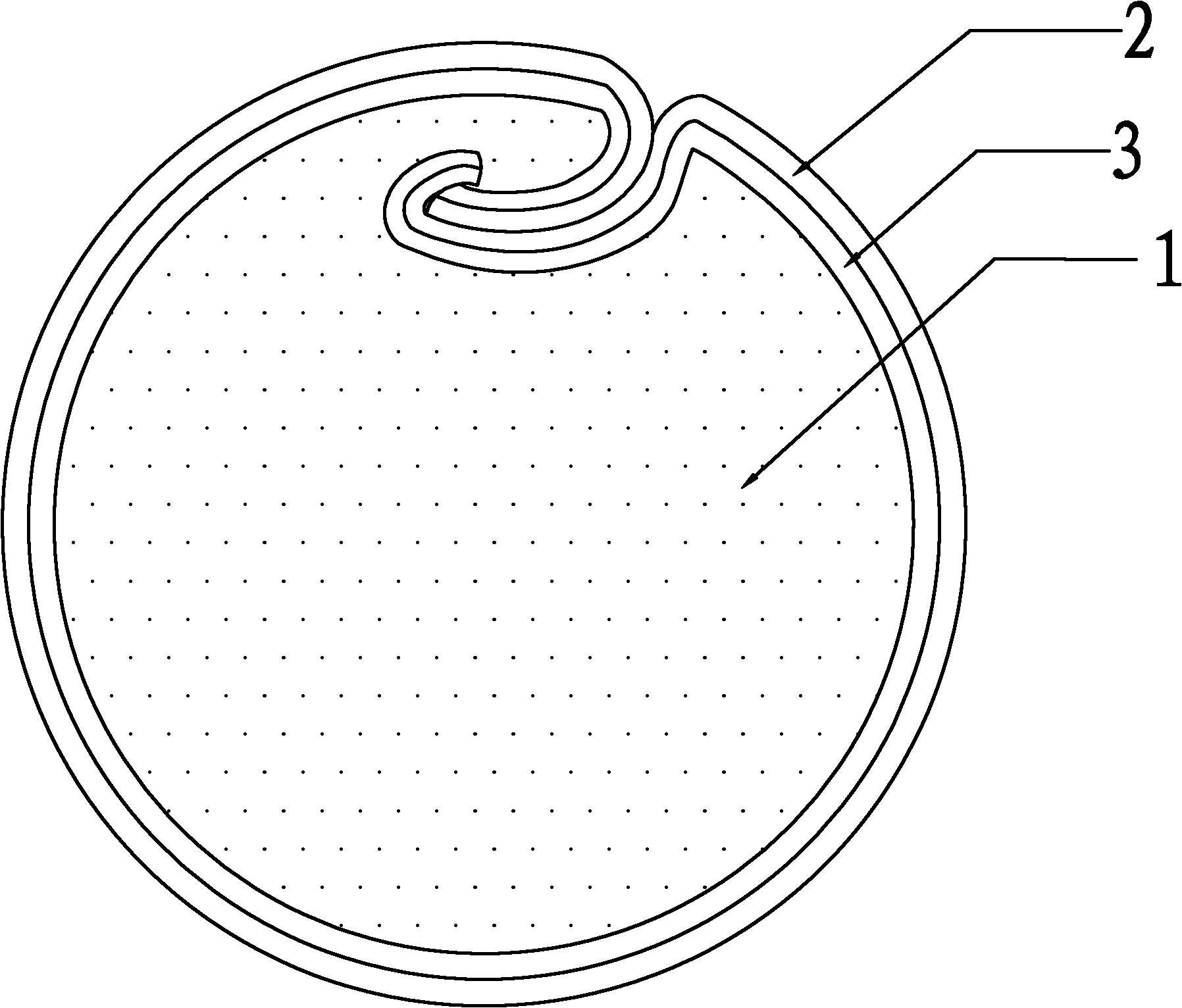

Core-spun yarn and preparation method thereof

InactiveCN102181778AGuaranteed basic strengthGuarantee the breeding effectYarnUltimate tensile strength

The invention relates to a core-spun yarn which comprises a sheath and a core material, wherein the core material is tightly filled in the sheath. The invention is characterized in that the sheath comprises an outer steel sheet layer and an inner metal layer; both sides of the sheath are folded inwards at the joints of the sheath and are extruded and fixed; the melting point of the metal layer is smaller than that of steel; and the thickness of the metal layer is 0.2mm, and the thickness of the steel sheet layer is 0.2mm. The double-layer composite sheath is adopted to lower the melting point of the surface covering layer on the premise of ensuring the basic strength of the core-spun yarn, so that the tape base can be molten within a short time in the molten iron casting process, thereby fully displaying the action of the powder inoculant, ensuring the inoculation effect of the molten iron flow and ensuring the mechanical properties of the iron castings. The invention has the advantages of firm sheath joints, tightly filled powder, regular and symmetric appearance, high working stability, high degree of automation and simple overall structure, and is convenient for maintenance and quick for operation.

Owner:SANXIANG ADVANCED MATERIALS

A casting method of an ultrafine high-nickel-content air tube

InactiveCN104525869AAvoid problemsQuality improvementFoundry mouldsFoundry coresMaterials scienceMetal

The invention discloses a casting method of an ultrafine high-nickel-content air tube. The method comprises following four steps: core preparing, moulding, pouring and sand knock-out. The method is mainly characterized in that: a pouring process of the method adopts a top pouring manner, a product is turned transversely by 90 degrees and poured, the problem that high-nickel-content tubes having a diameter of 26 mm, an inner diameter of 14 mm and a wall thickness of 4 mm are difficult to cast and mould is overcome by controlling the pouring temperature, speed and time, a process yield of the method is high, moulding operation is convenient, the consumption amount of metal liquids is small, the production cost is reduced, and requirements on the large-scale production efficiency are satisfied.

Owner:西峡飞龙特种铸造有限公司

Environment-friendly ultraviolet light resistant and high-temperature resistant paint for outer walls of buildings

InactiveCN103482905AGood liquidityExcellent anti-mildew and anti-corrosion propertiesSolventPolyaspartic acid

Environment-friendly ultraviolet light resistant and high-temperature resistant paint for outer walls of buildings comprises A compositions, B compositions and a C composition, wherein the A compositions comprise the following substances in parts by weight: 25-35 parts of polyaspartic acid ester resin, 20 parts of an aromatics mixed solvent, 8-10 parts of nano-scale ceramic powder, 2-4 parts of mica powder, 10-18 parts of diacetone alcohol, 3-8 parts of ethylene glycol monobutyl ether, 7-11 parts of a cellulose thickener solution with the mass percent of 2%, 1.0-1.4 parts of a polyphosphate dispersing agent solution with the mass percent of 10%, 1-3 parts of an emulgator, 0.1-0.3 part of sodium hydroxide, 30-50 parts of ethyl alcohol, 70-100 parts of deionized water, 140-180 parts of titanium dioxide; the B compositions comprise the following substances in parts by weight: 3-5 parts of a paint curing agent, 0.02-1 part of an initiator, 1 part of a dispersing agent, 0.6 part of a flatting agent, 0.3 part of an antifoaming agent, 0.3 part of a defoaming agent, 25 parts of a modified ammonia curing agent, 2-4 parts of tetrachloroisophthalonitrile, 3-5 parts of a dry film antiseptic; the C composition is an environment-friendly color mixed-phase inorganic pigment.

Owner:SUZHOU XIANGYUAN SPEICAL FINE CHEM

Laser-clad side guide plate and machining method thereof

ActiveCN110592580AWear-resistantHigh temperature resistantGuiding/positioning/aligning arrangementsSuperimposed coating processOxidation resistantAlloy

The invention discloses a laser-clad side guide plate and a machining method thereof. A cladding layer with a sandwich structure is machined on a common steel plate matrix through a laser cladding method, and the cladding layer is composed of three layers, that is, a bottom layer, a middle layer and a surface layer. A nickel-based high-temperature alloy system is adopted as an overall material system, the bottom layer has high toughness and is used for realizing an antifatigue function, the middle layer realizes the functions of wear resistance and self-lubricating, and the surface layer realizes the functions of ablation resistance and oxidation resistance. The three-layer structure forms a functionally-graded composite plate, and the composite plate has high-temperature resistance, oxidation resistance, wear resistance and corrosion resistance simultaneously, and has toughness to a certain extent to bear an impact force in a service process, so that the special performance requirements of wear resistance, high-temperature resistance, corrosion resistance, oxidation resistance and impact resistance which are needed in the service process of the side guide plate before the coilingof a production line for a metallurgical hot-rolled coiled plate, are met.

Owner:上海大陆天瑞激光表面工程有限公司

Method for preparing superfine spherical aluminum powder by high-pressure atomization

The invention provides a method for preparing a superfine spherical aluminum powder by high-pressure atomization. Firstly, under the protection of the mixed gas of nitrogen and helium, aluminum ingotsare heated and melted in a melting furnace to become aluminum liquid and warm is kept; then the obtained aluminum liquid is transported through an aluminum liquid catheter to an atomization chamber where the above mixed gas is used as the ambient gas, and meanwhile, the mixed gas is sprayed out through a tightly coupled gas atomization nozzle to atomize the aluminum liquid to form mist-like aluminum liquid droplets; then the liquid aluminum droplets are cooled and rapidly solidified under the cooling and protection of the ambient gas to form atomized aluminum powder; and then the mixed gas isused as a transmission medium, and the atomized aluminum powder is sent to a grading system for graded screening treatment to obtain the superfine spherical aluminum powders of different particle sizes. The method for preparing the superfine spherical aluminum powder by high-pressure atomization provided by the invention uses the mixed gas of nitrogen and helium as the atomization medium, and hasthe advantages of high atomization efficiency, high fine powder yield, uniform particle size distribution, good aluminum powder sphericity and uniform size.

Owner:WUHAN UNIV OF SCI & TECH

Mould plasma 3D printing equipment and mould plasma 3D printing method

InactiveCN105750542ASimple structureReasonable designAdditive manufacturing apparatusIncreasing energy efficiencyTemperature controlPlasma generator

The invention discloses a mould plasma 3D printing equipment and a mould plasma 3D printing equipment method. The equipment consists of a monitoring system, a plasma beam processing system, a horizontal printing table for placing a to-be-formed mould and a temporary fixing member, wherein the plasma beam processing system consists of a plasma generator, a printing position adjusting device, a gas supply device and a powder supplier; the printing position adjusting device comprises a horizontal moving device and a printing distance adjusting device; the monitoring system comprises a horizontal movement controller, a temperature detection unit, a distance detection unit and a printing distance adjustment controller; the temperature detection unit and the printing distance adjustment controller form a temperature control device. The method comprises the following steps: (I) obtaining three-dimensional stereo model and carrying out hierarchical slicing treatment; (II) scanning path filling; (III) printing path obtaining; and (IV) carrying out layer-by-layer printing from bottom to top. The equipment and the method disclosed by the invention have the advantages of reasonable design, simplicity and convenience in operation, high efficiency and good use effect; and moreover, the forming process is directly carried out in the atmospheric environment, and the formed mould has good quality.

Owner:SINOADDITIVE MFG EQUIP CO LTD

Roller plasma 3D printing equipment and method

InactiveCN105710367ASimple structureReasonable designAdditive manufacturing apparatusIncreasing energy efficiencyPlasma generatorMonitoring system

The invention discloses roller plasma 3D printing equipment and method. The equipment is composed of a monitoring system, a plasma beam machining system and a horizontal printing table; the plasma beam machining system is composed of a plasma generator, a printing position adjusting device, an air supply device and a powder feeder; the printing position adjusting device comprises a horizontal movement device and a printing distance adjusting device; and the monitoring system comprises a horizontal movement controller, a temperature detecting unit, a distance detecting unit, a printing distance adjusting controller and a rotation controller, and a temperature adjusting and control device is composed of the temperature detecting unit and the printing distance adjusting controller. The method includes the steps that (1) a three-dimensional model is obtained, and hierarchy slicing treatment is carried out; (2) filling of a scanning path is carried out; (3) a printing path is obtained; and (4) layer-by-layer printing is carried out from inside to outside. The roller plasma 3D printing equipment is reasonable in design, easy and convenient to operate, high in molding efficiency and good in using effect; the molding process is directly carried out under the atmospheric environment; and molded rollers are good in quality.

Owner:SINOADDITIVE MFG EQUIP CO LTD

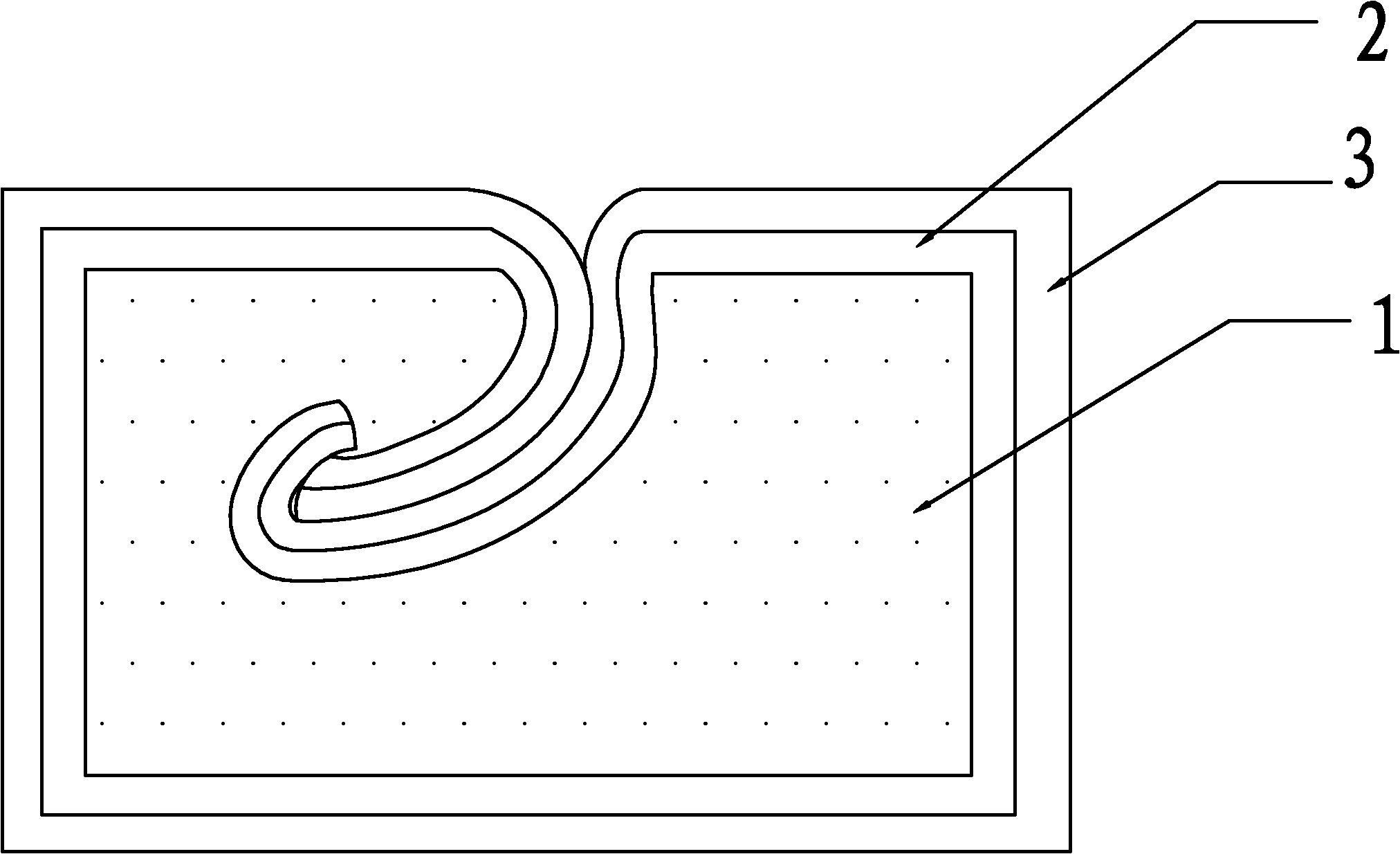

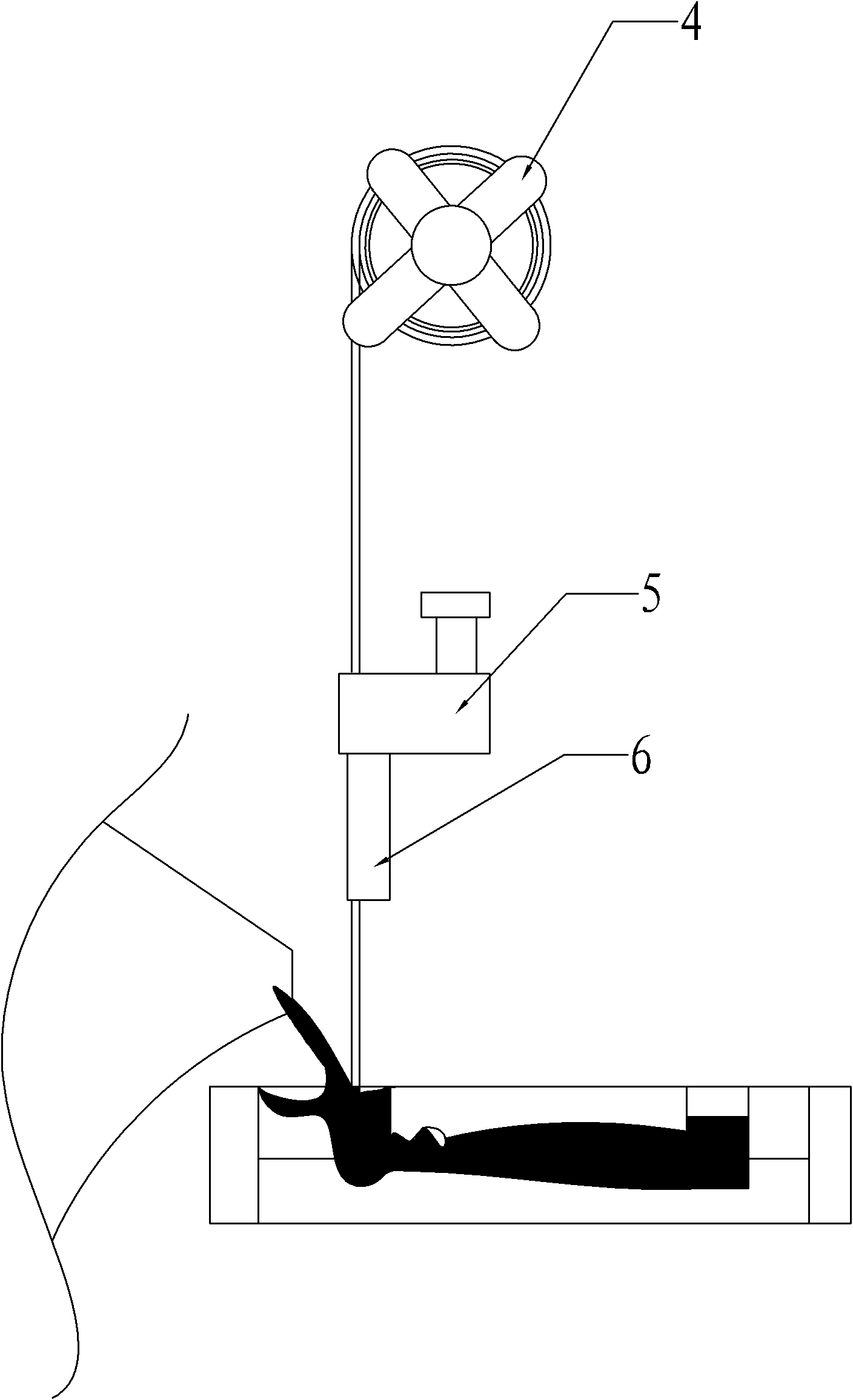

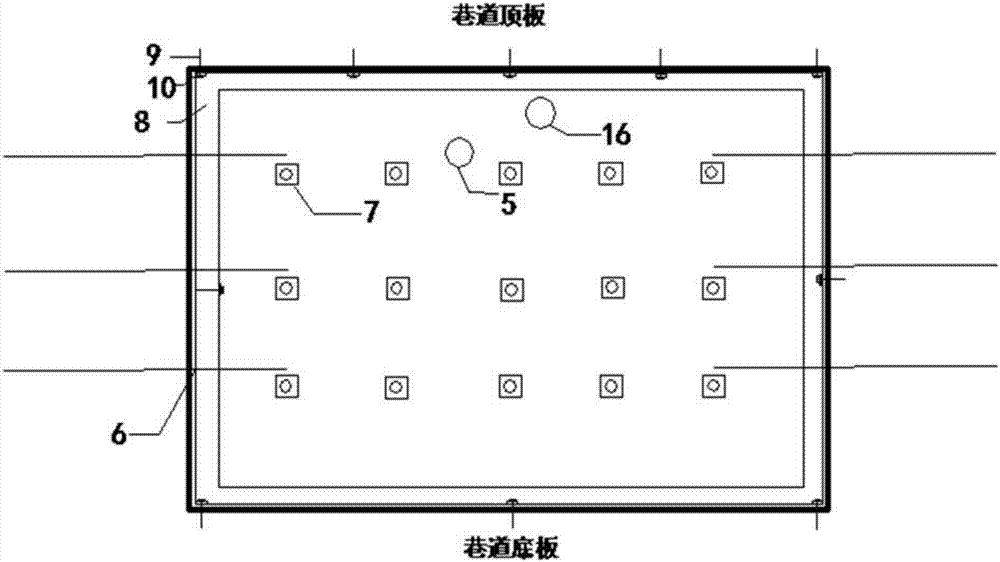

Method for constructing poured airtight walls of coal mines

The invention discloses a method for constructing poured airtight walls of coal mines. The method includes manufacturing flexible molds and suspending the flexible molds in dug grooves with corresponding sizes by expansion pipes; allowing anchor rods on two sides of each dug groove to penetrate preserved anchor rod holes in the corresponding flexible mold; carrying out pouring twice, to be more specific, injecting inorganic solidifying materials into the flexible molds by concrete pump trucks to form solidified filling bodies at first, injecting expansion roof contact materials into the molds by grouting machines to form expansion filling bodies after the inorganic solidifying materials are completely coagulated, carrying out pump pouring on wall bodies and then forming the airtight walls with reinforced concrete structures by the walls and the anchor rods. The method has the advantages that the different materials are injected into the flexible molds twice, accordingly, the strength and roof contact effects of airtight wall bodies can be guaranteed, and the wall bodies prepared by the aid of the method are simple in structure; each airtight wall only comprises the single corresponding wall body and is mechanically constructed, accordingly, the costs of the airtight walls can be reduced, and the efficiency can be improved.

Owner:SHAANXI COAL & CHEM TECH INST

Method for coagulating natural rubber fresh latex by enzymatic method

InactiveCN102002119AStable physical and chemical propertiesShort setting timeAlkaline proteaseProteinase activity

The invention discloses a method for coagulating natural rubber fresh latex by an enzymatic method, which relates to technology for coagulating the natural rubber. The method comprises the following steps of: determining the weight of natural rubber fresh latex to be coagulated and weighing protease which is 0.05 to 2 percent based on the weight of the fresh latex; dissolving the protease in water, wherein the using amount of water is 10 percent based on the weight of the fresh latex; then adding the aqueous solution of protease into the fresh latex and stirring uniformly; and standing and coagulating. In the method, the natural rubber fresh latex is coagulated according to the characteristic that papain decomposes proteins and damages the stability of the latex, and the method is easy tooperate, and has high coagulation speed and strong adaptability, and by the method, not only the fresh latex without ammonia can be coagulated, but also the fresh latex with ammonia content up to 0.2percent can be completely coagulated, and the physicochemical performance of the product is not influenced. Hydrolytic protease and alkaline protease also have the same effect.

Owner:AGRI PRODS PROCESSING RES INST CHINESE ACAD OF TROPICAL AGRI SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com