Copper-slag-based ferritic oxalate chemical bonded material and application thereof

A technology for oxalate chemistry and bonding materials, which is applied in the field of copper slag-based iron-based oxalate chemical bonding materials, and achieves the concept of reducing waste and pollution, reducing production costs, and achieving good effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Example 1: The raw material composition of the copper slag-based iron-based oxalate chemical bonding material is 400 g of copper slag, 100 g of oxalic acid, and 8 g of desulfurized gypsum. The copper slag is ground to a particle size of 200 mesh sieve and the balance is not more than 10%;

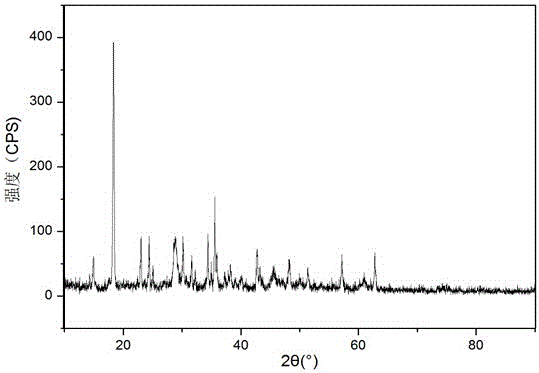

[0025] The above-mentioned copper slag-based iron-based oxalate chemical bonding material is used as a pouring material. Mix 600 g of copper-based iron-based oxalate chemical bonding material with 120 g of water at room temperature and then cast it into shape. The solidification time is 30 minutes , demoulded after 1 day, and its mechanical properties were tested when it was maintained in the natural environment for 3d, 7d, and 28d. The compressive strengths of 3d, 7d, and 28d were 19.2Mpa, 32.4Mpa, and 42.1Mpa respectively; XRD phase analysis was performed on the material , see the result figure 1 , it can be seen from the figure that the material contains ferrous oxalate, calcium o...

Embodiment 2

[0026] Example 2: The raw material composition of the copper slag-based iron-based oxalate chemical bonding material is 300 g of copper slag, 100 g of oxalic acid, and 6 g of desulfurized gypsum. The copper slag is ground to a particle size requirement of 200 mesh sieve and the balance is not more than 10%;

[0027] The above-mentioned copper slag-based iron-based oxalate chemical bonding material is used as a pouring material. Mix 600 g of the copper-slag-based iron-based oxalate chemical bonding material with 120 g of water at room temperature and then cast it into shape. The solidification time is 26 minutes. After 1 day, it was removed from the mold, and its mechanical properties were tested when it was maintained in the natural environment for 3d, 7d, and 28d. The compressive strengths of 3d, 7d, and 28d were 16.5Mpa, 21.4Mpa, and 31.5Mpa, respectively.

Embodiment 3

[0028] Example 3: The raw materials of the copper slag-based iron-based oxalate chemical bonding material are composed of 600 g of copper slag, 150 g of oxalic acid, and 12 g of desulfurized gypsum. The copper slag is ground to a particle size of 200 mesh sieve and the balance is not more than 10%;

[0029] The above-mentioned copper slag-based iron-based oxalate chemical bonding material is used as a pouring material. Mix 600 g of copper-based iron-based oxalate chemical bonding material with 120 g of water at room temperature and then cast it into shape. The solidification time is 36 minutes. , demoulded after 1 day, and its mechanical properties were tested when it was maintained in the natural environment for 3d, 7d, and 28d. The compressive strengths of 3d, 7d, and 28d were 18.7Mpa, 24.9Mpa, and 37.3 Mpa, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com