Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

394 results about "Arsenic pollution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

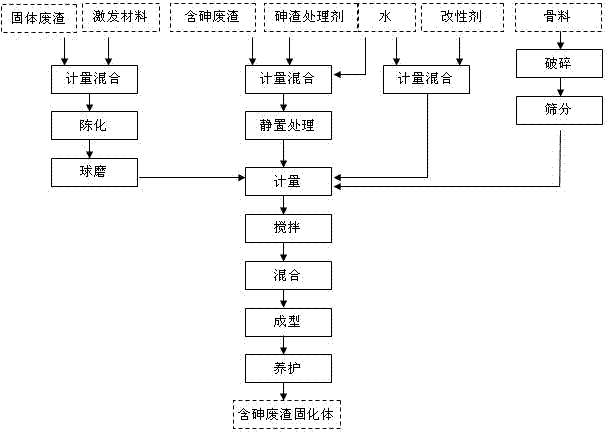

Arsenic-containing waste slag solidified body and preparation method thereof

InactiveCN102249609ASimple curing processLow costSolid waste managementSolid waste disposalArsenic pollutionSlag

The invention relates to an arsenic-containing waste slag solidified body and a preparation method thereof, and belongs to the technical field of environmental protection. The preparation method comprises the following steps of: treating arsenic-containing waste slag, mixing the treated arsenic-containing waste slag and a curing agent prepared from industrial waste slag and a mineral activated material, a modifying agent, aggregates, water and the like, and stirring, forming and curing the mixed materials to obtain the solidified body with high strength and low arsenic leaching rate. Comparedwith the prior art, the solidification process is simple, low in cost, safe and reliable, and solves the problem of arsenic pollution of the arsenic-containing waste slag.

Owner:KUNMING UNIV OF SCI & TECH +1

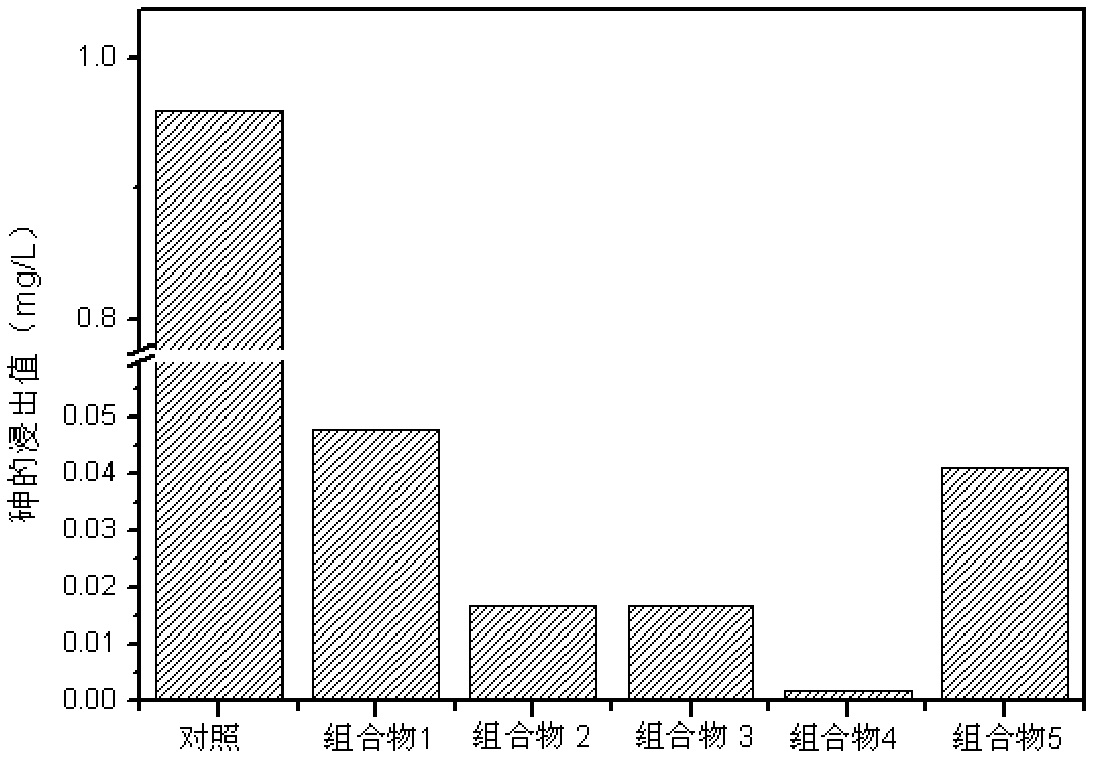

Multicomponent composite flocculating setting agent and use in arsenic contamination water treatment

ActiveCN101503239AEfficient removalGood arsenic removal effectWater/sewage treatment by flocculation/precipitationArsenic pollutionEarth surface

The invention belongs to the technical field of river water body pollution control and in particular relates to a multiple-element compound flocculating settling agent and the application of the multiple-element compounded flocculating settling agent in arsenic pollution water body treatment. The multiple-element compounded flocculating settling agent is prepared by compounding malysite, aluminium salt, hypermanganate, polyacrylamide and aqueous solution. The multiple-element compounded flocculating settling agent can be applied in the arsenic pollution water body treatment to remove arsenic in the arsenic pollutant water body. The concentration of the arsenic in the treated water can meet or is superior to the specified requirement of three types of water on the arsenic concentration in the national earth surface water environment quality standard (less than 0.05 mg / L). The invention also can be used for removing heavy metals such as copper, chromium, cadmium, lead and the like in water by sedimentation. The multiple-element compounded flocculating settling agent can be used together with a multiple-element compounded metal oxide arsenic removal setting agent in static or flowing arsenic pollution water body treatment for removing the arsenic in the water body polluted by arsenic.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

Multiple element composite metal oxidate arsenic removal settling agent and use method thereof

The invention belongs to the material field for removing the arsenic in water by settlement, more particularly relates to polyelement composite metal oxide arsenic removal settlement agent and an application method thereof based on iron oxide, manganese oxide, and aluminum oxide. The invention uses an ectopic preparation method or situ preparation method for preparing and obtaining polyelement composite metal oxide arsenic removal settlement agent which comprises hydrated iron oxide, hydroxyl-hydrated ferric hydroxide, hydrated aluminum oxide, hydroxyl-hydrated alumina, hydrated manganese oxide and the like. The polyelement composite metal oxide arsenic removal settlement agent can be used for removing the arsenic pollutants in water bodies such as lakes, reservoirs, rivers, groundwater, drinking water, industrial waste water, and the like; in addition, the settlement agent can also be used for removing the heavy metals such as copper, chromium, cadmium, lead, and the like, and the pollutants such as iron, manganese, phosphates, and the like in water by settlement.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

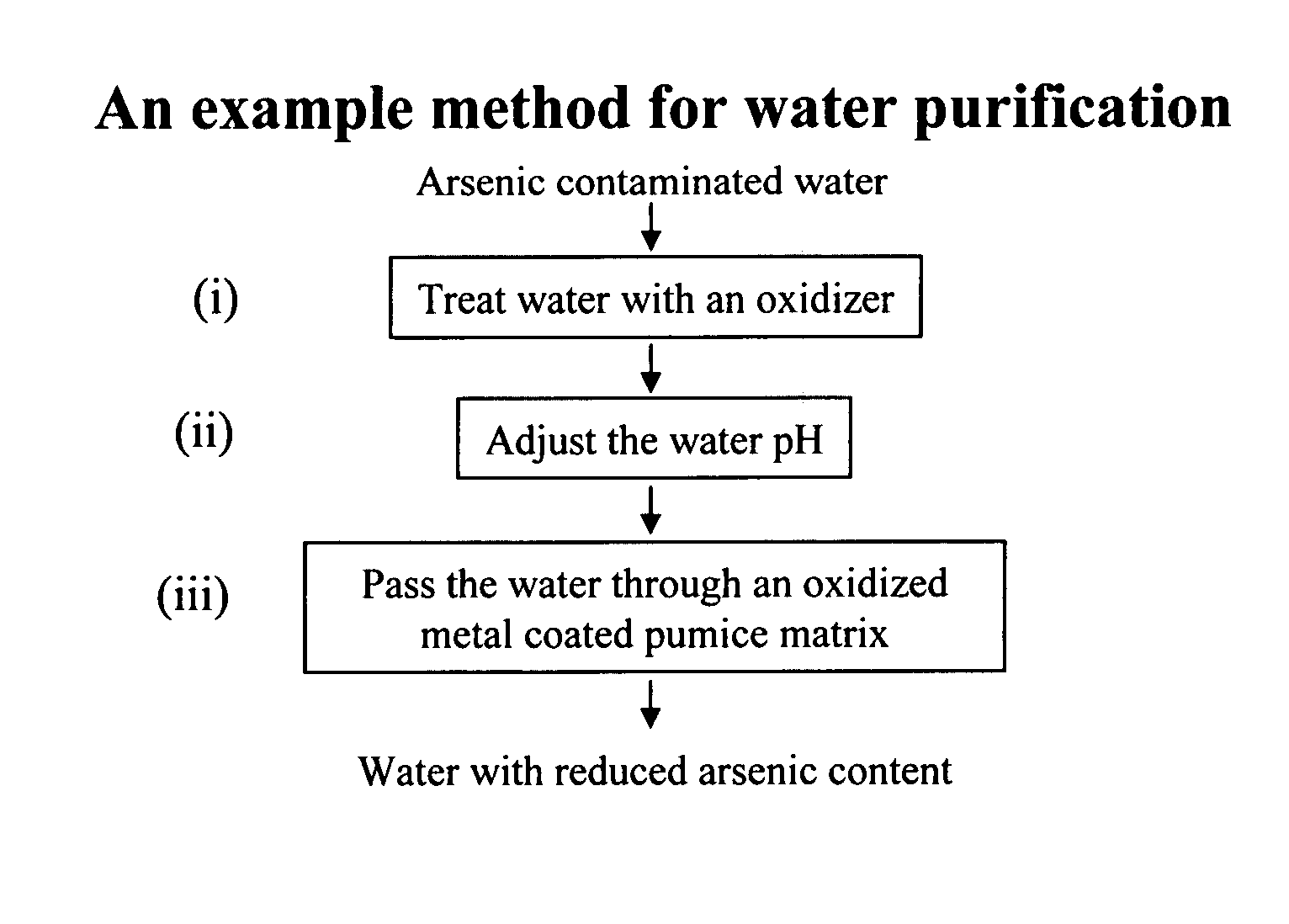

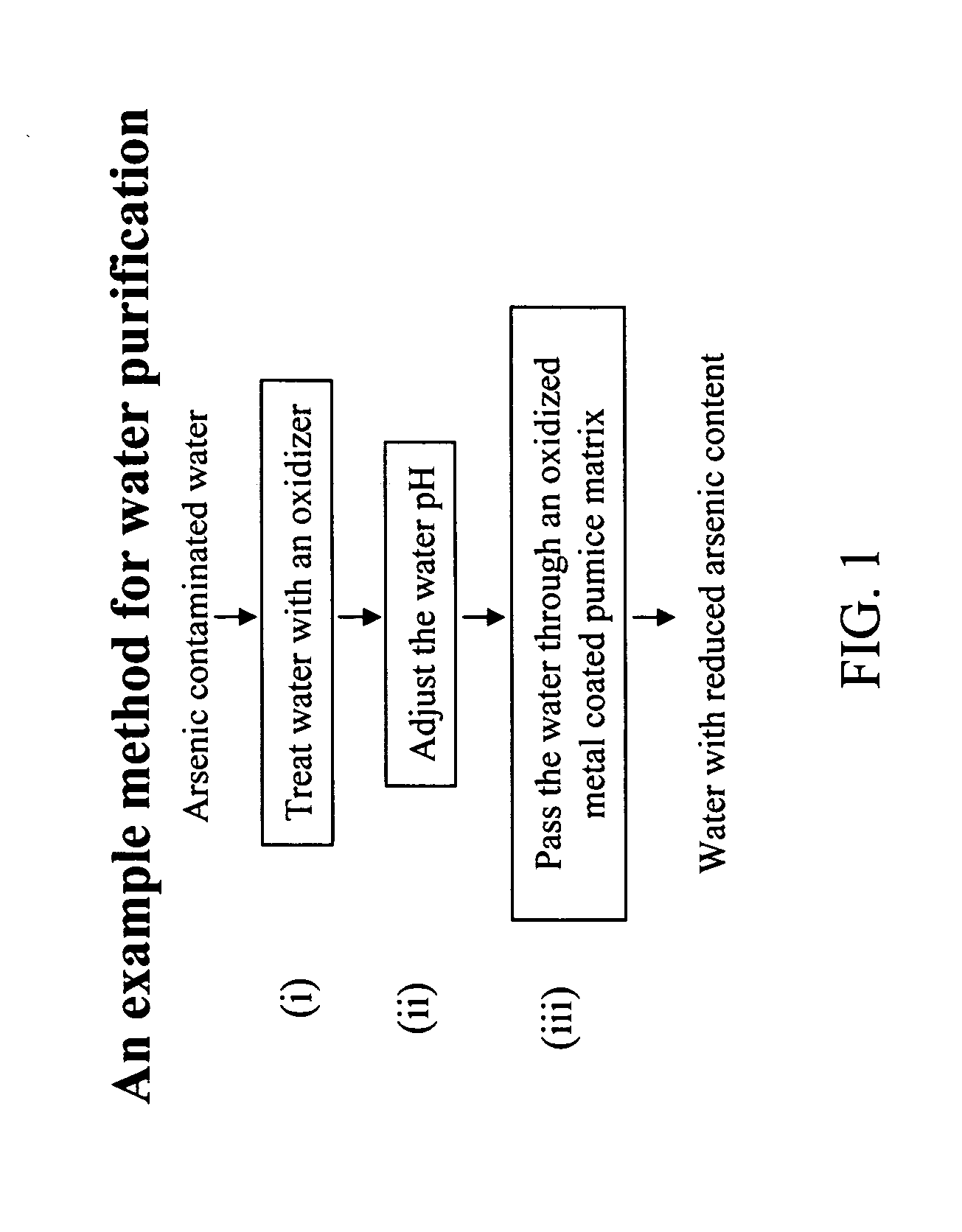

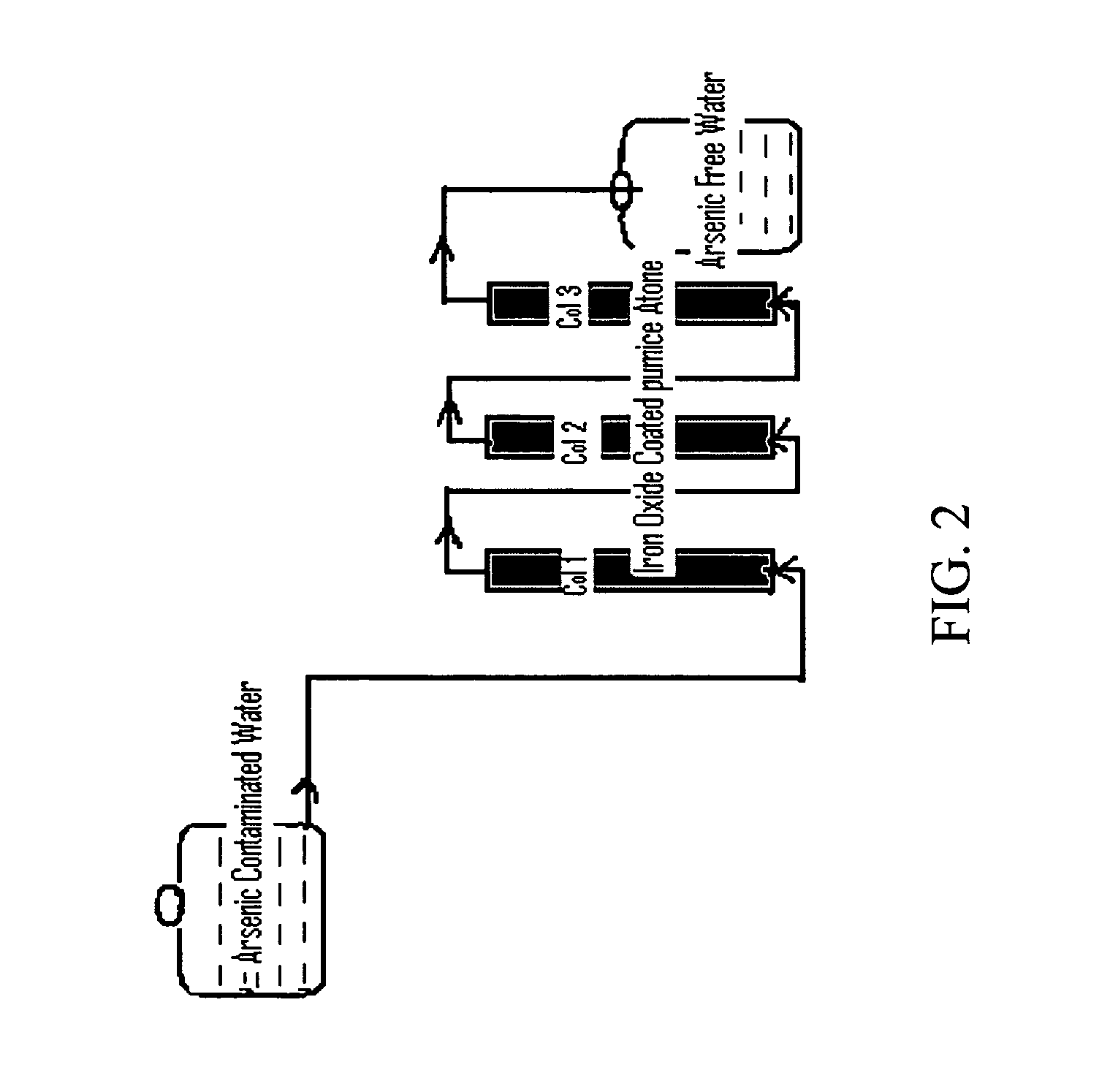

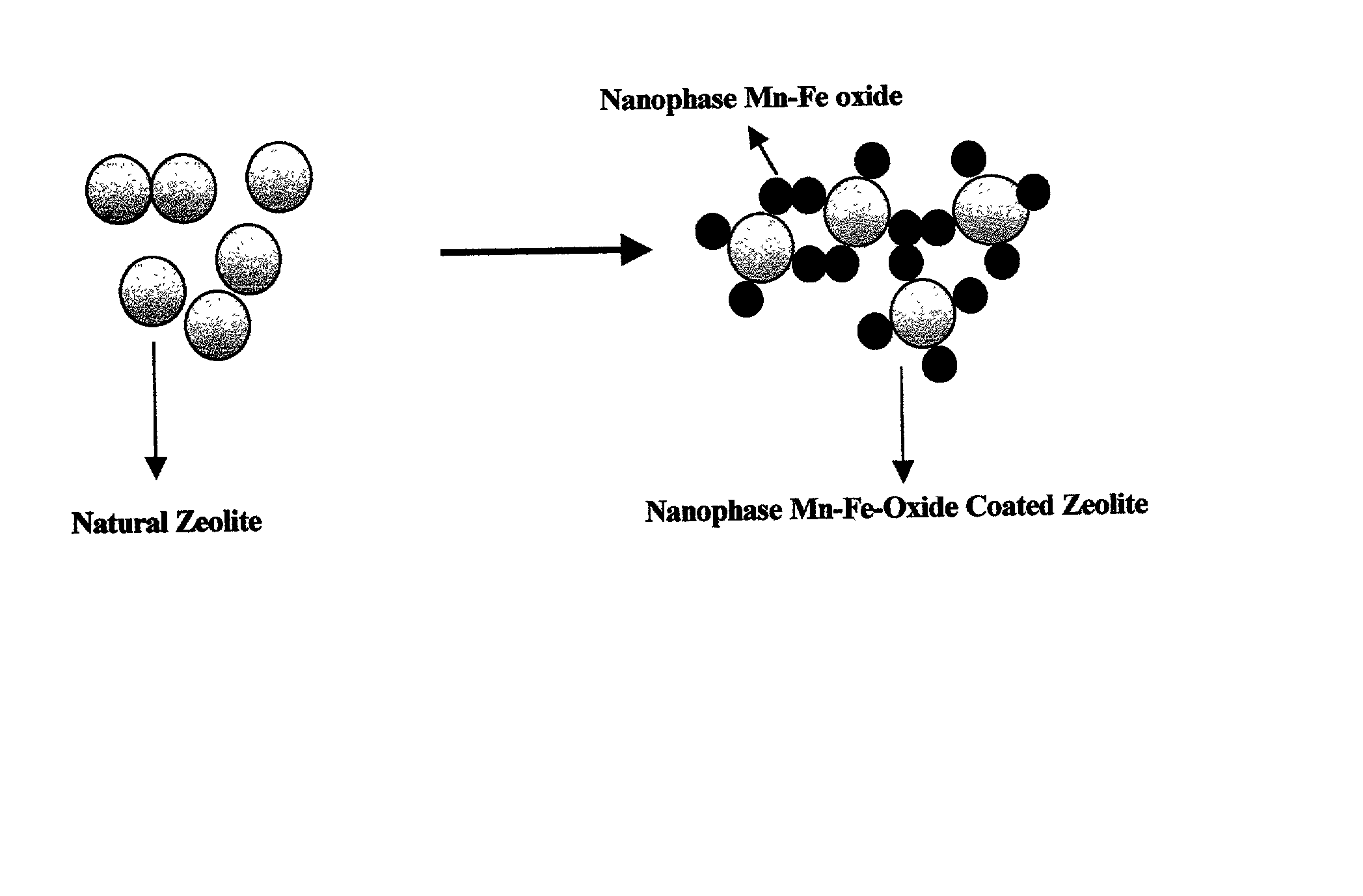

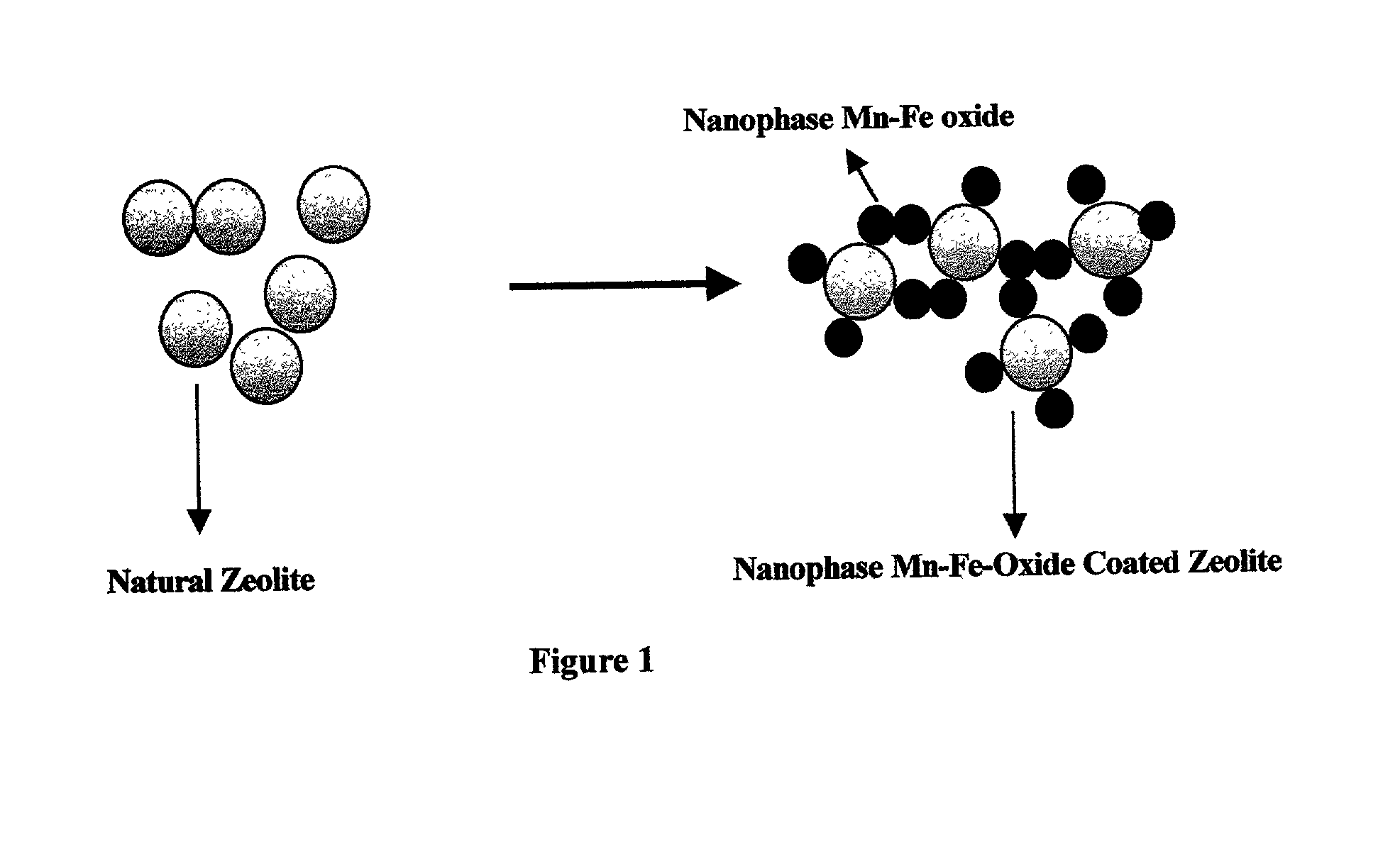

Removal of arsenic from water with oxidized metal coated pumice

InactiveUS20070017871A1Cheap disposalWithout environmental riskWater contaminantsSolid sorbent liquid separationContaminationMetal

The current invention is concerned with methods and compositions for the removal of arsenic contamination from water. A method for binding As to oxidized metal coated pumice and method for making the same are disclosed. Water filters comprising oxidized metal coated pumice, such as oxidized iron coated pumice, are also provided.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

Remediation agent for treating arsenic contaminated soil and usage of remediation agent

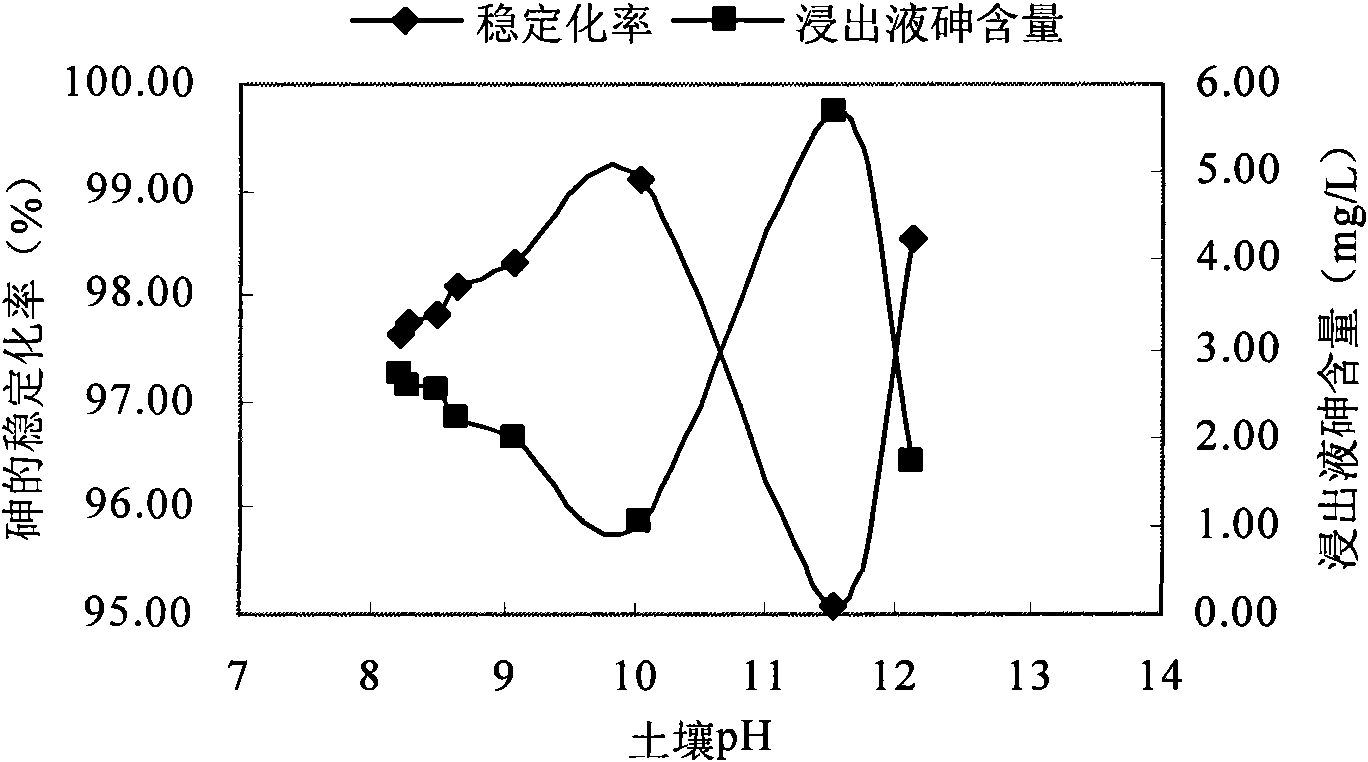

ActiveCN102764759AWide range of raw materialsEasy to obtainContaminated soil reclamationArsenateArsenic pollution

The invention discloses a remediation agent for treating arsenic contaminated soil and a usage of the remediation agent. The remediation agent comprises the following raw materials by mass: 5-30% of oxidant, 30-70% of iron-based compound and 10-60% of mineral material. The raw materials are respectively ground into materials with particle size not smaller than 200 meshes and are mixed uniformly according to the proportion. The usage of the remediation agent for treating the arsenic contaminated soil comprises the following steps that: the arsenic content and the leaching toxicity of the to-be-treated contaminated soil are detected; the remediation agent with different ratios according to the degree of contamination is paved on the surface of the to-be-treated soil; the soil is turned over and uniformly mixed to form the mixed soil; the water content in the mixed soil is kept not to be less than 25% by adding water; a moisturizing material is covered on the mixed soil; and the mixed soil is cured for at least 5 days in order to allow the remediation agent in the mixed soil to be reacted with unstable arsenic in the heavy metal contaminated soil; and the generated insoluble arsenate sediment is stabilized, so that the cured soil can meet the environment protection requirements.

Owner:YONKER ENVIRONMENTAL PROTECTION

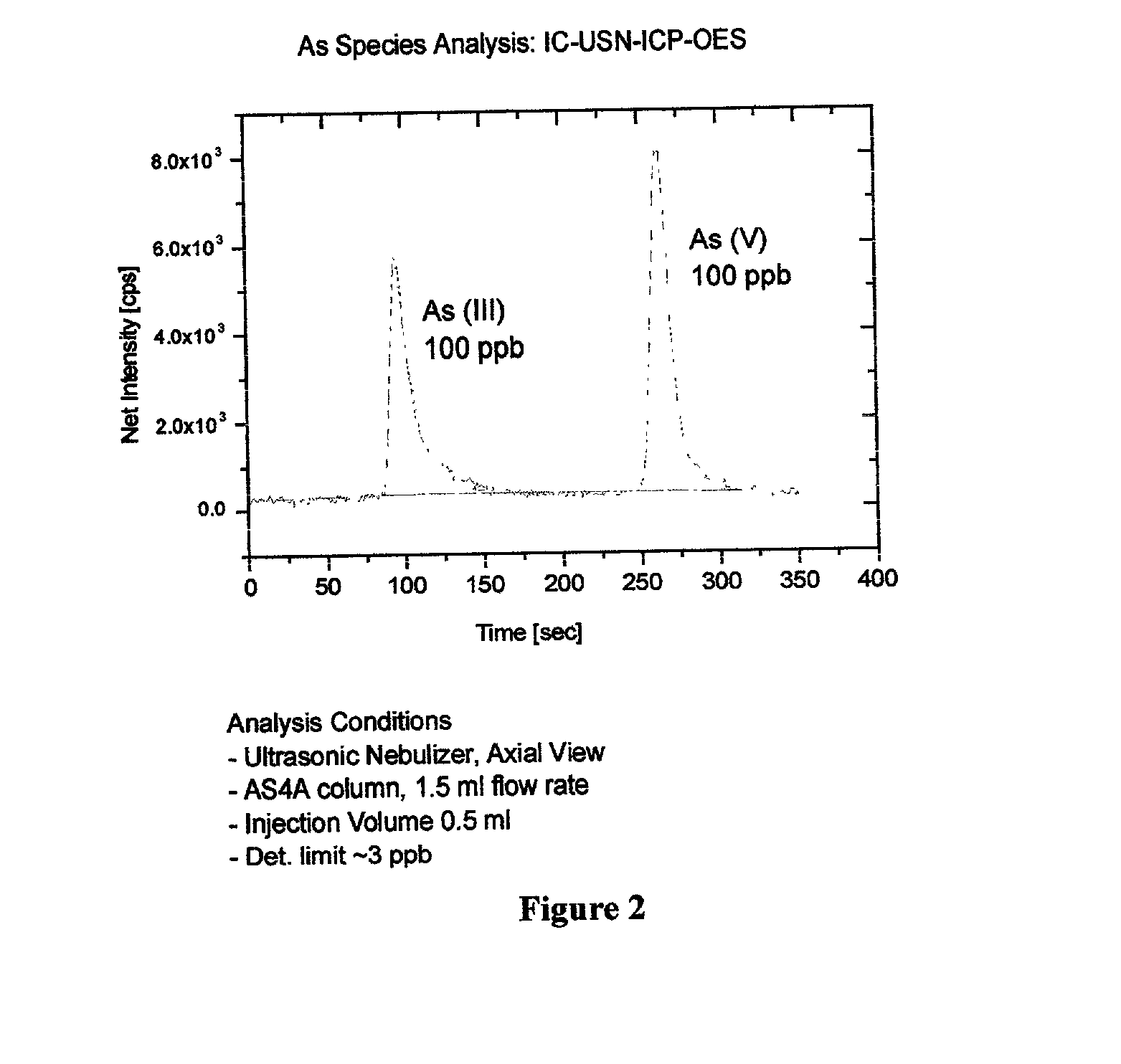

Absorbent for arsenic species and method of treating arsenic-contaminated waters

InactiveUS20030116504A1Maintain aestheticsReduce the amount requiredSolid sorbent liquid separationWater/sewage treatment by neutralisationArsenic pollutionPotable water

The present invention is directed to an adsorbent for removing arsenic species from ground water and / or surface water systems. Such adsorbent removes both As(III) and As(V), thereby providing potable water. Also provided is a method and / or device (e.g., filter) for removing arsenic species from contaminated waters utilizing such adsorbent.

Owner:CHK GROUP

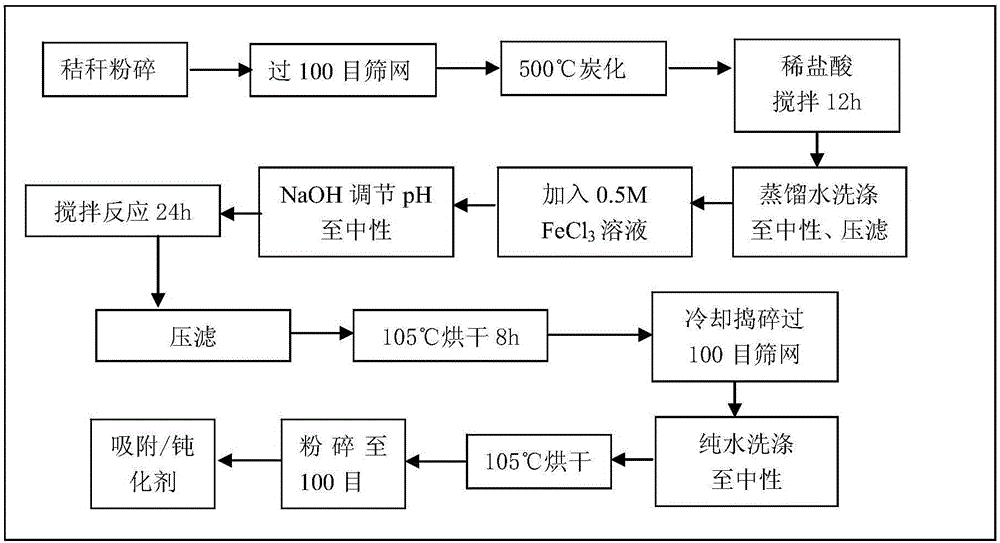

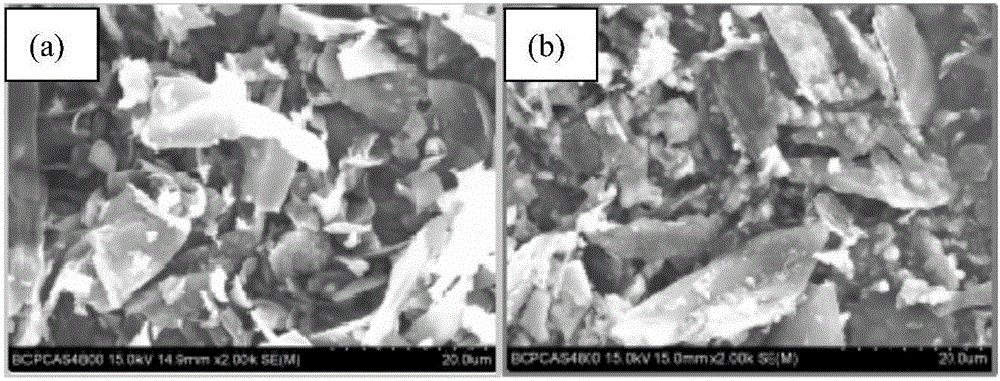

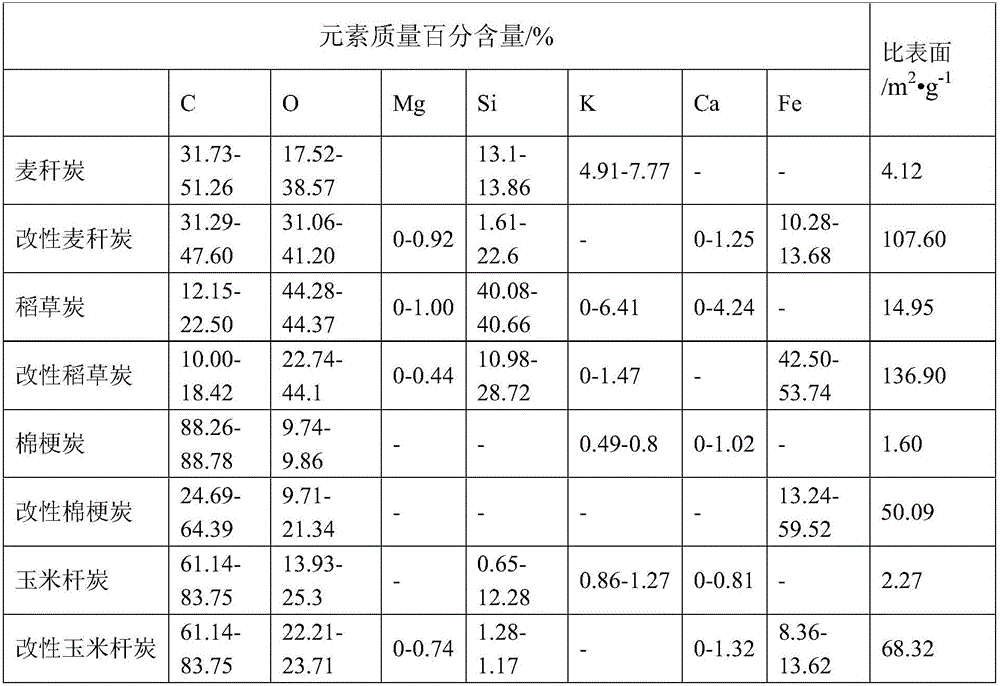

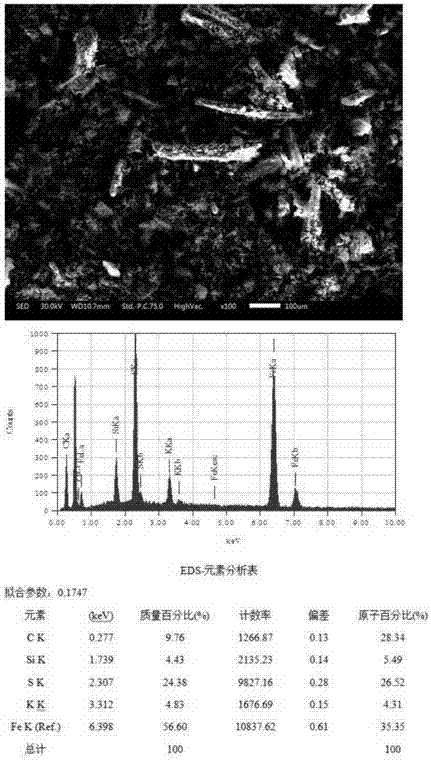

Modified biomass charcoal for treating arsenic pollution as well as preparation method and application of modified biomass charcoal

InactiveCN105944668AImprove stabilityLow carbonization temperatureOther chemical processesWater contaminantsArsenic pollutionFood safety

The invention provides modified biomass charcoal for treating arsenic pollution as well as a preparation method and an application of the modified biomass charcoal. The preparation method of the modified biomass charcoal comprises steps as follows: (1) biomass raw materials are charred, and the biomass charcoal is obtained; (2) the biomass charcoal is subjected to a reaction with a hydrochloric acid solution, solid-liquid separation is performed, a solid substance is obtained, is washed till the pH is neutral and then is dried, and the pretreated biomass charcoal is obtained; (3) the pretreated biomass charcoal and a FeCl3 solution are subjected to a reaction under the condition that the solution pH is neutral, solid-liquid separation is performed after the reaction, and mud cake is obtained; (4) the mud cake is dried and then washed till the pH is neutral, solid-liquid separation is performed, an obtained solid is dried for a second time, and the modified biomass charcoal is obtained. The modified biomass charcoal has large specific surface area and high iron content; the preparation method is simple and easy to operate; the modified biomass charcoal can be applied to treatment of arsenic waste and passivation of arsenic in farmland soil, and food safety is guaranteed.

Owner:INST OF ENVIRONMENT & SUSTAINABLE DEV IN AGRI CHINESE ACADEMY OF AGRI SCI

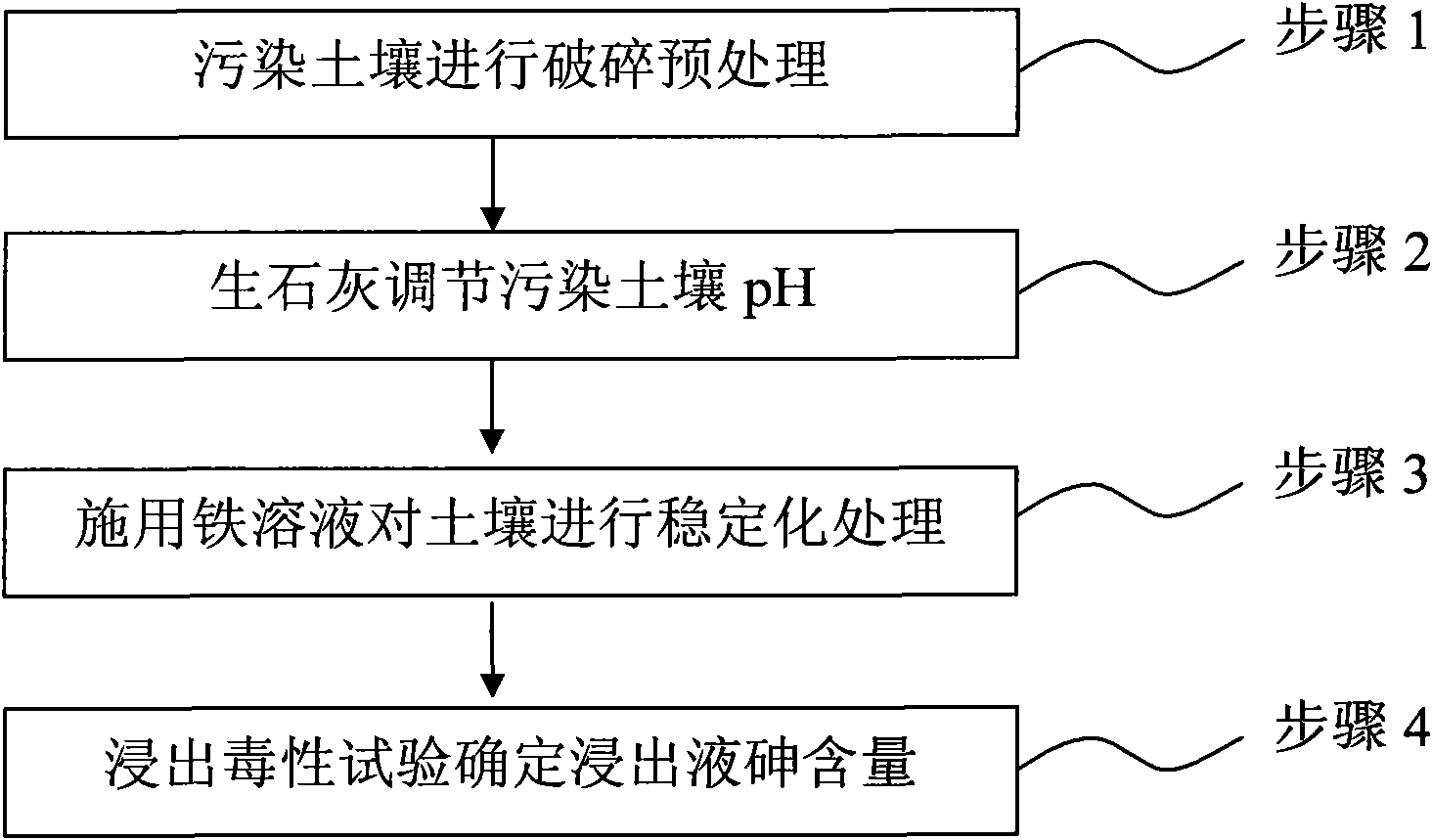

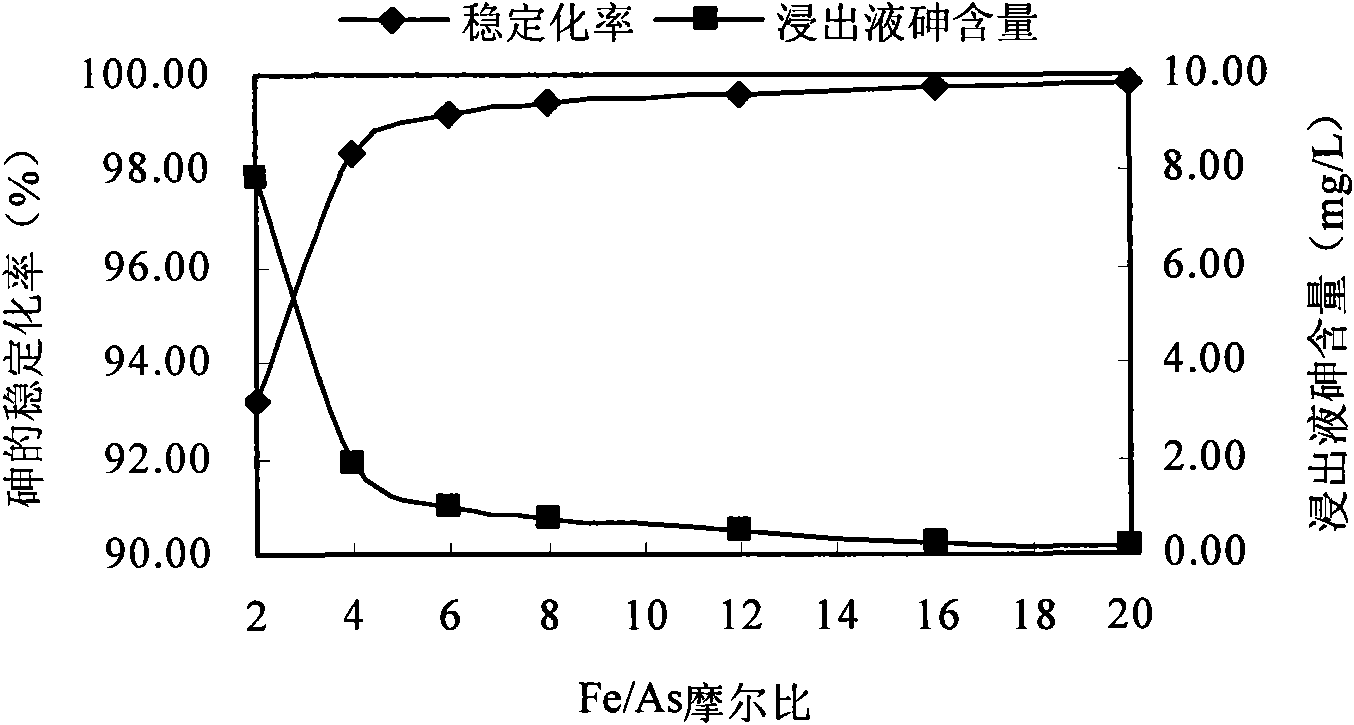

Method for remedying arsenic polluted soil

InactiveCN101879521AEasy to handleSimple operation and managementContaminated soil reclamationArsenateArsenic pollution

The invention discloses a method for remedying arsenic polluted soil. The method comprises a step of adding iron salt solution into the arsenic polluted soil so that the iron salt solution is reacted with arsenic in the soil to form arsenate FeAsO3 or FeAsO4 of iron. Before the iron salt solution is added, the method also comprises a step of crushing the arsenic polluted soil and steps of adjusting the pH of the arsenic polluted soil and measuring the arsenic content of the arsenic polluted soil. The method can quickly and efficiently treat the arsenic polluted soil, has simple operation and management and is suitable for major unexpected arsenic pollution remediation.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

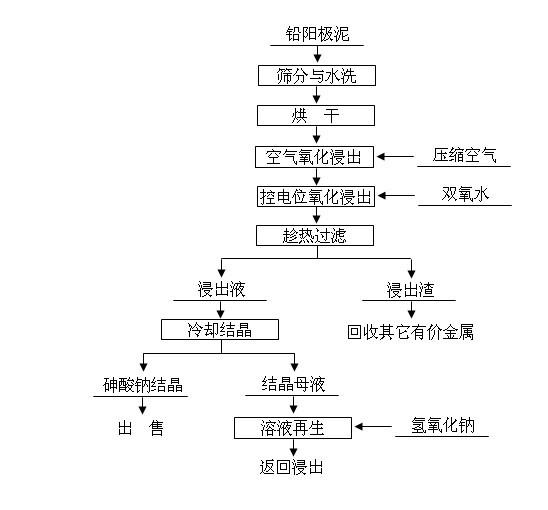

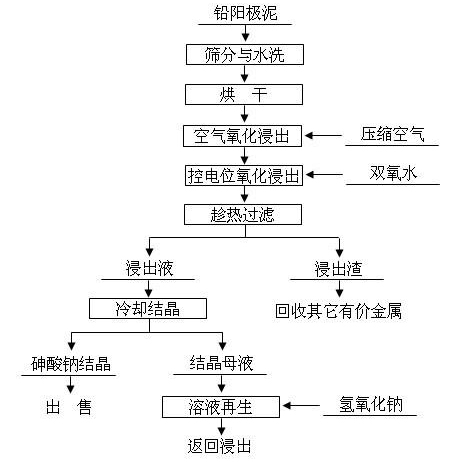

Method for removing and recovering arsenic from lead anode slime

ActiveCN101928838AHigh removal rateAvoid secondary pollutionProcess efficiency improvementArsenic pollutionSodium hydroxide

The invention discloses a method for removing and recovering arsenic from lead anode slime, which comprises the following steps of: performing screening, hot water washing and baking on the lead anode slime, performing oxidation leaching by controlling potential in sodium hydroxide solution, oxidizing the arsenic by using compressed air and hydrogen peroxide as oxidants respectively, adding the oxidized arsenic into alkaline leachate, and ensuring metals such as bismuth, lead, stibium and copper are oxidized and then enter alkaline leaching residue together with noble metals; and after alkaline oxidization leaching process is finished, filtering while hot, performing cooling crystallization on the leachate to generate sodium arsenate crystals, supplementing certain sodium hydroxide to crystallization mother liquor, returning the crystallization mother liquor to the leaching process, and separating and recovering the arsenic and other valuable metals from the lead anode slime. The arsenic leaching rate is over 98.0 percent and the secondary arsenic pollution is free; and the method has the advantages of low requirement on equipment materials, safe operation, low labor intensity, short treatment time and good operating environment.

Owner:YONGZHOU FUJIA NON FERROUS METALS

Arsenic pollution soil stabilizer and method for repairing contaminated soil

The invention discloses an arsenic pollution soil stabilizer and a method for repairing contaminated soil, belonging to the technical field of arsenic pollution soil remediation and repair. The method for repairing contaminated soil is characterized by comprising the following steps of: preparing a stabilizer by taking low-cost montmorillonite, calcium oxide, magnesium carbonate and scrap iron as raw materials, adding the stabilizer into the arsenic contaminated soil according to a certain ratio, uniformly mixing, adding a certain amount of water, stirring, and culturing for a certain time to achieve the aim of repairing the arsenic contaminated soil. The arsenic pollution soil stabilizer has the characteristics that the finished product comprises the following components by weight based on the 100kg of dry basis: 30-40kg of montmorillonite, 20-30kg of calcium oxide, 20-30kg of magnesium carbonate and 10-20kg of scrap iron. The arsenic pollution soil stabilizer can effectively solve the problem that the arsenic pollution soil is polluted, has the characteristics of low cost, high repair efficiency, easy operation method and the like and is suitable for repairing the arsenic pollution soil.

Owner:CECEP L&T ENVIRONMENTAL TECH

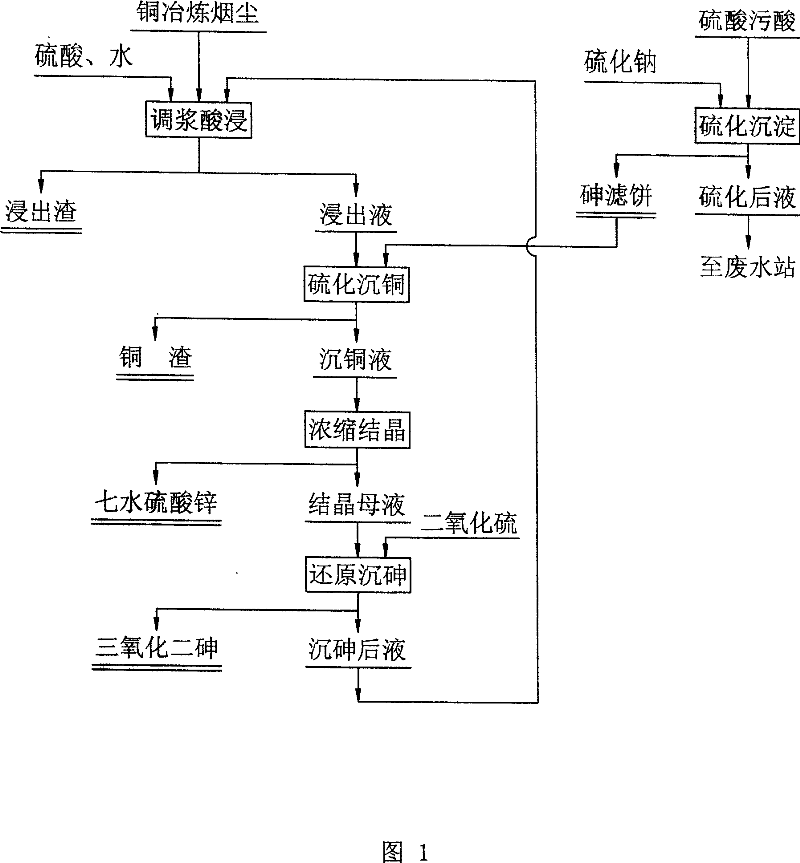

Method for treating arsenic pollution of copper smelt industry

InactiveCN101037725AAchieve separationProcess efficiency improvementWater/sewage treatment by oxidationArsenic pollutionZINC SULFATE HEPTAHYDRATE

The invention provides a method for controling arsenic pollution in the copper metallurgy industry, is characterized in that arsenic acid filtering case is added as vulcanized agent in sulphuric acid extract of copper metallurgy smoke to precipitate copper, copper slag and the solution containing copper are obtain by separation; the solution containing copper is contracted to 60-100 g / l of arsenical concentration and then cooled to the room temperature, heptahydrate zinc sulphate and crystal mother liquor are obtained after separation; sulfur dioxide is added to crystal mother liquor, thereby arsenic is dissolved out in the form of arsenic trioxide, arsenic trioxide and the solution after precipitating arsenic are obtained after separation, the solution after precipitating arsenic is back to smoke extract. The separature of the main component such as copper, arsenic, zinc and cadmium is performed in sulphuric acid extract of copper metallurgy smoke and arsenic acid filtering case with an objective for controling arsenic pollution economically and effectively, while provided with an advantage for further recycling valent metal synthetically.

Owner:朱永文

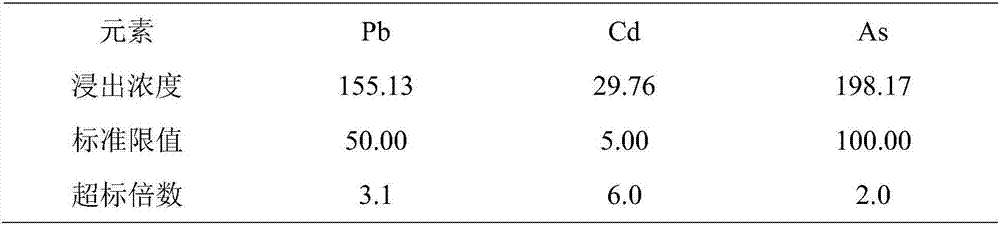

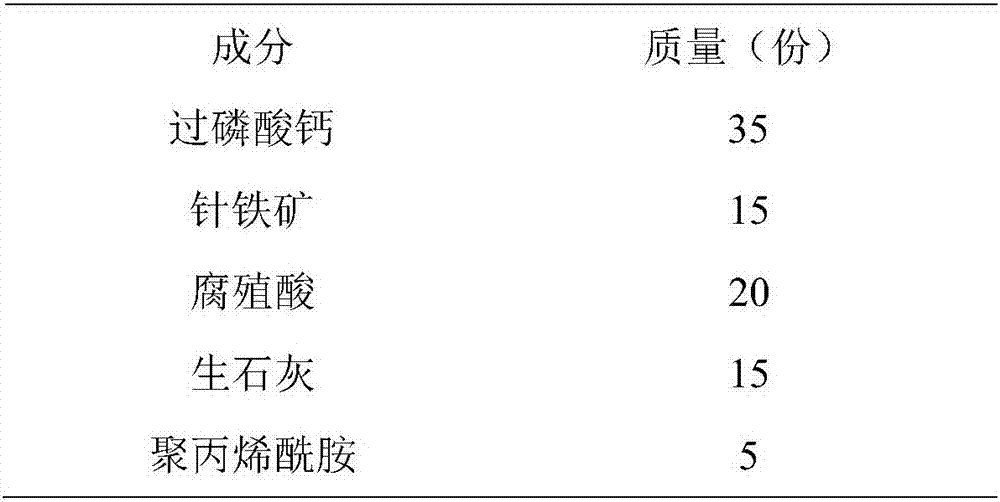

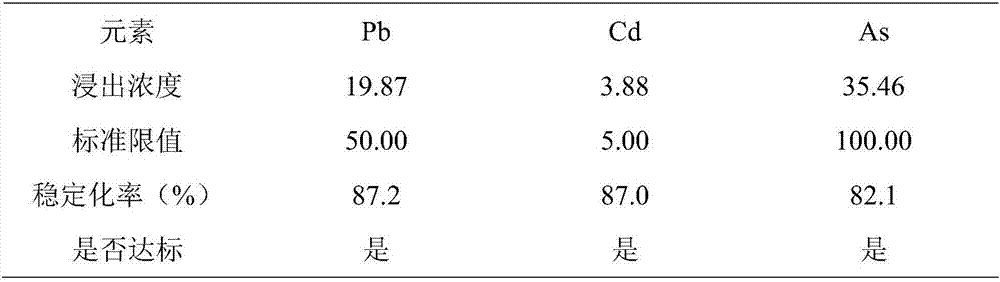

Composite stabilizer for repairing lead, cadmium and arsenic pollution in acid soil

ActiveCN106978191AImprove stabilityThe amount of medicine added is lessOrganic fertilisersSoil conditioning compositionsArsenic pollutionDissolution

The invention discloses a composite stabilizer for repairing lead, cadmium and arsenic pollution in acid soil. The composite stabilizer comprises the following components: calcium superphosphate, goethite, humic acid, quick lime, polyacrylamide and the like. The composite stabilizer is used for repairing heavy metal polluted soil, arsenic, lead and cadmium can be fixed and stabilized simultaneously, the use amount is small, a soil structure is not affected, the soil repairing effect is good, and re-dissolution of heavy metal can be prevented.

Owner:HUNAN XISI ECOLOGY TECH

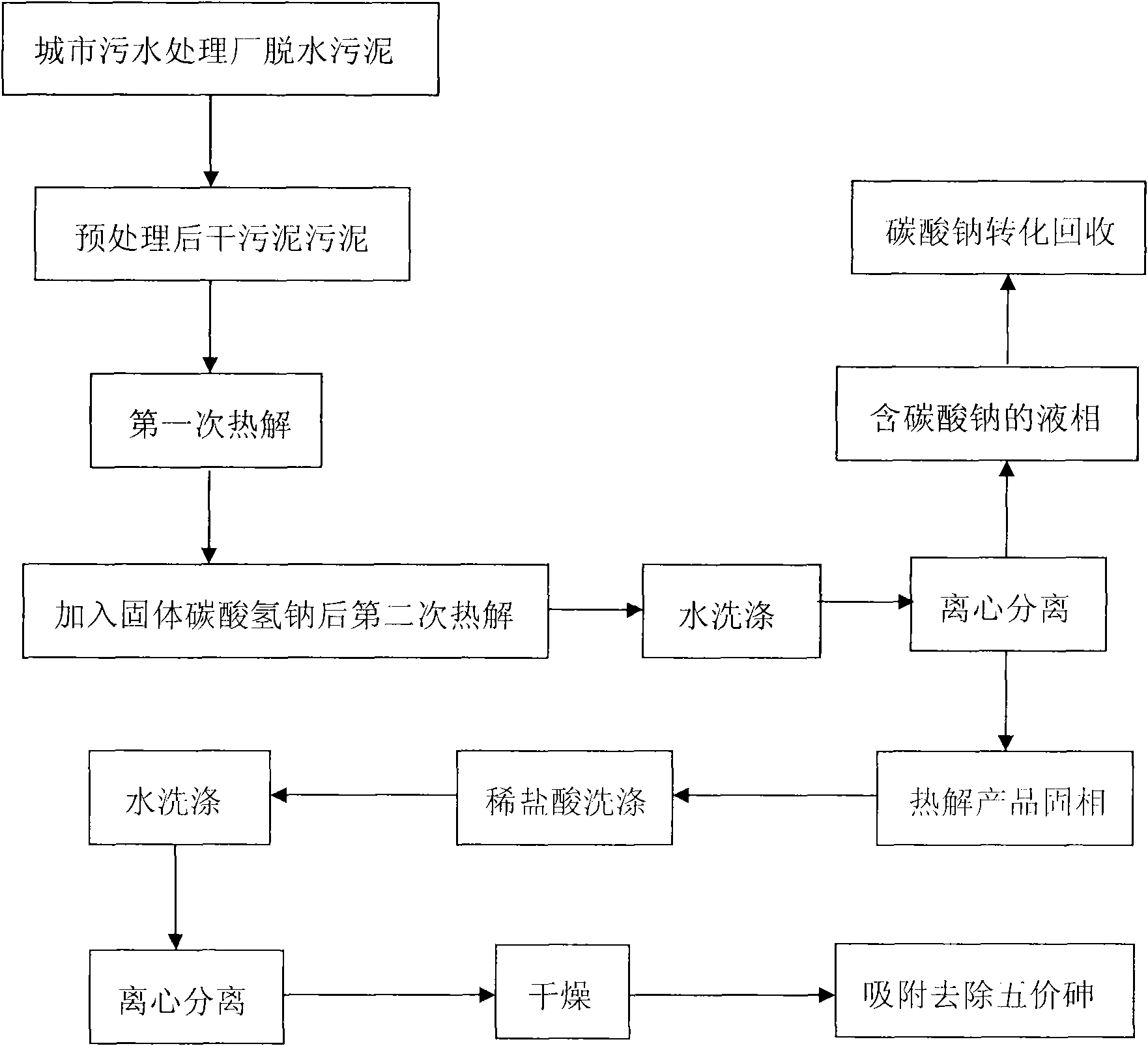

Preparation method of sludge absorber and applications thereof

InactiveCN101559354ARealize resource utilizationLow costOther chemical processesMultistage water/sewage treatmentSodium bicarbonateSludge

The invention belongs to the technical field of sludge recycling treatment in solid and waste treatment, in particular to a preparation method of a sludge absorber and applications thereof. The technical steps are as follows: firstly carrying out first thermolysis in the protective gas atmosphere under the temperature of 400 to 600 DEG C; then adding solid sodium bicarbonate for mixing evenly into the products from the first sludge thermolysis with the mass ratio range of the sodium bicarbonate and the sludge of 0.1 to 3; carrying out second thermolysis to solid mixture in the nitrogen atmosphere under the temperature of 400 to 800 DEG C; then carrying out cleaning and drying to the mixture from the second thermolysis with water and diluted acid respectively; and finally obtaining the product of sludge absorber. The absorber has good effect when being applied to absorption and removal of heavy metal and pentavalent arsenic in water. The invention realizes recycling utilization of sludge, namely, solid waste, and the prepared product is application to treatment of water polluted by arsenic, therefore, the invention has the advantages of high utilization rate and low cost and the like.

Owner:TONGJI UNIV

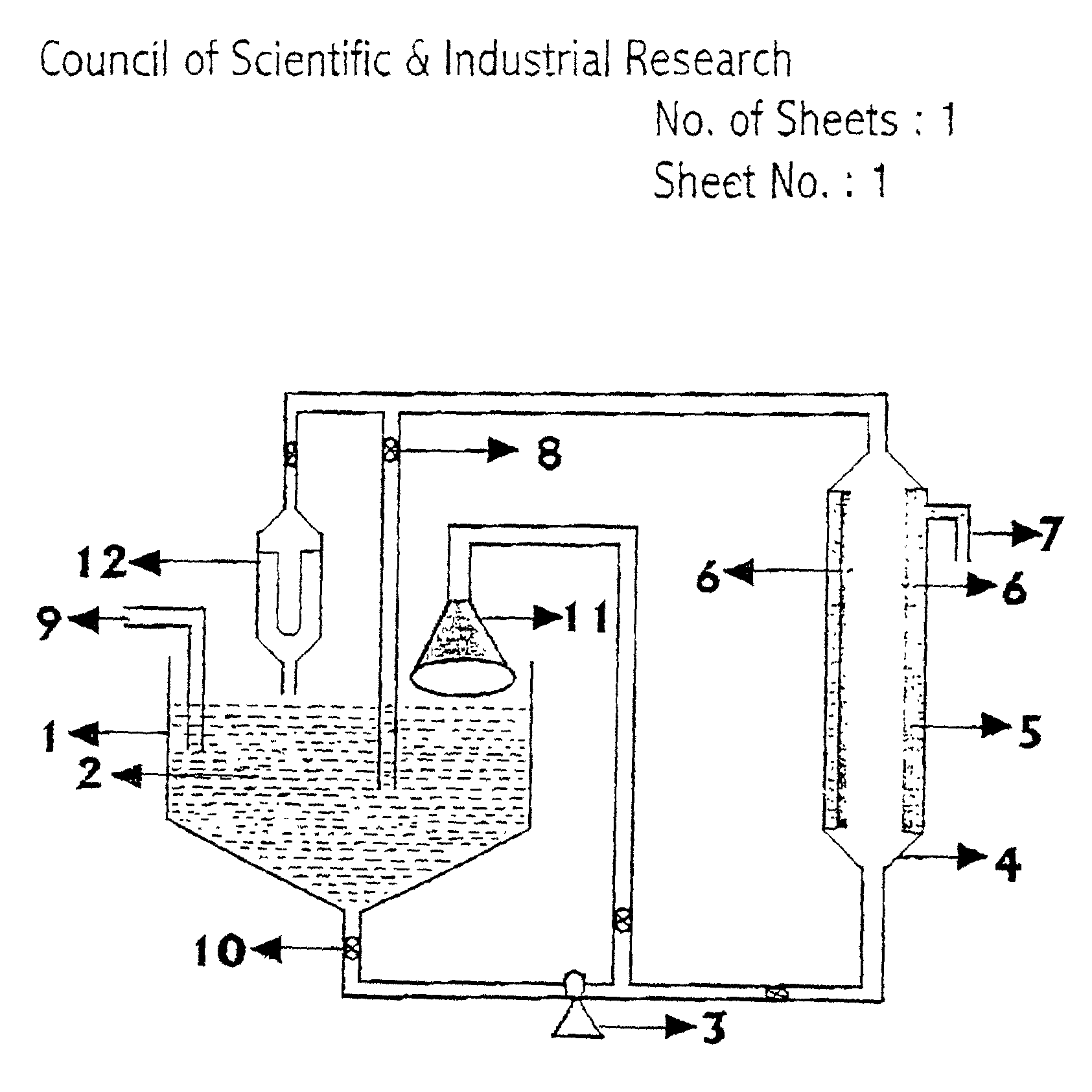

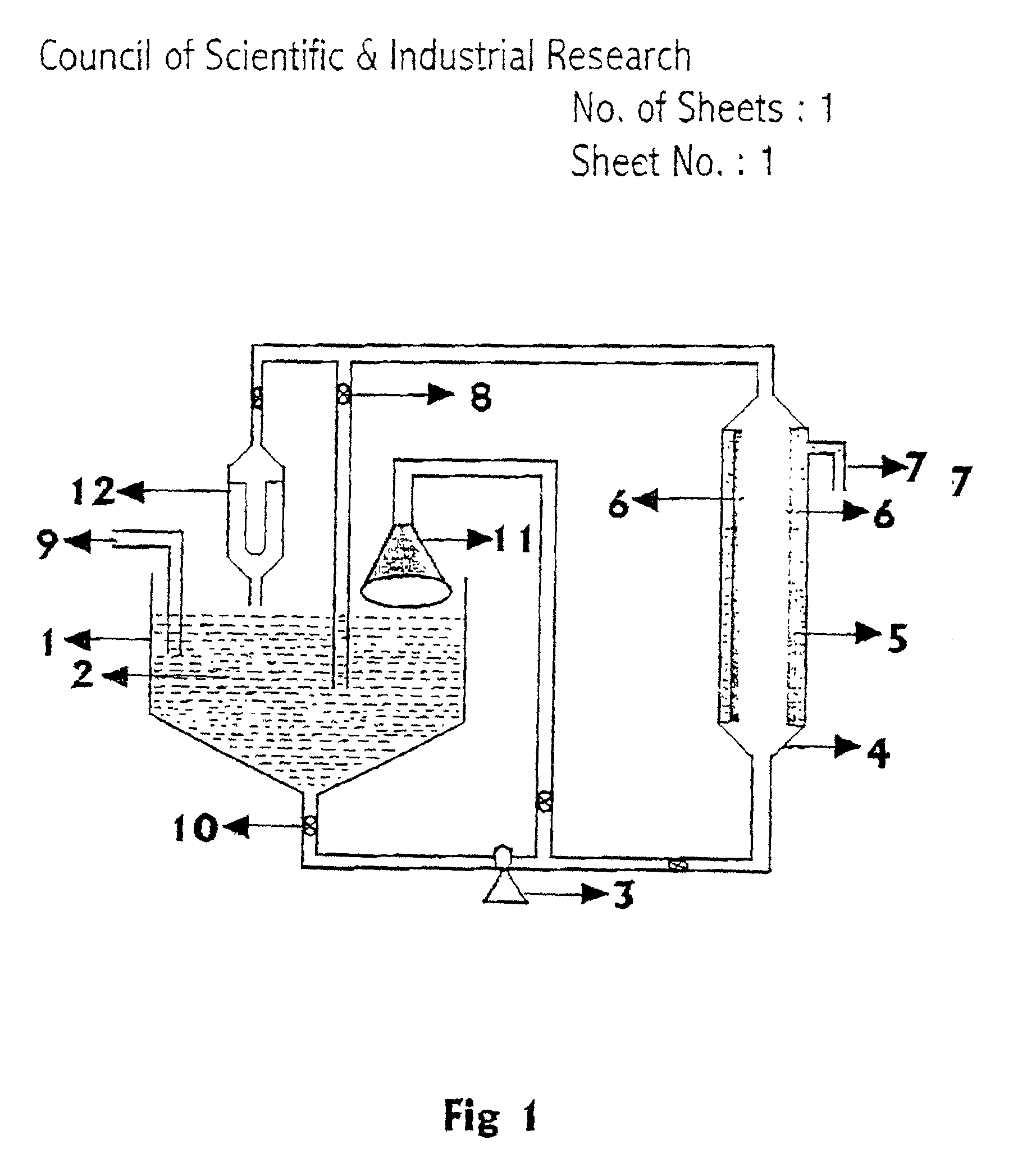

Process for the preparation of arsenic free water, apparatus therefor, method for the manufacture of porous ceramics for use in pressure filtration to produce arsenic free water

InactiveUS20030183579A1Low production costSimple preparation techniqueOther chemical processesWater contaminantsFiltrationGroundwater

The present invention relates to a process for the preparation of arsenic free water and an apparatus therefor. The present invention also relates to a porous ceramic useful for pressure filtration in order to produce arsenic free water. The present invention particularly relates to a process for preparing arsenic free (<10 ppb) water from arsenic contaminated ground water and apparatus therefor.

Owner:COUNCIL OF SCI & IND RES

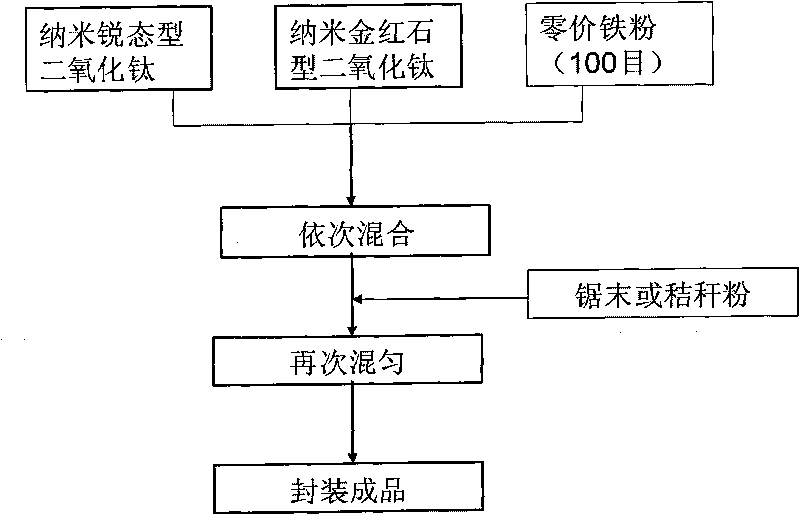

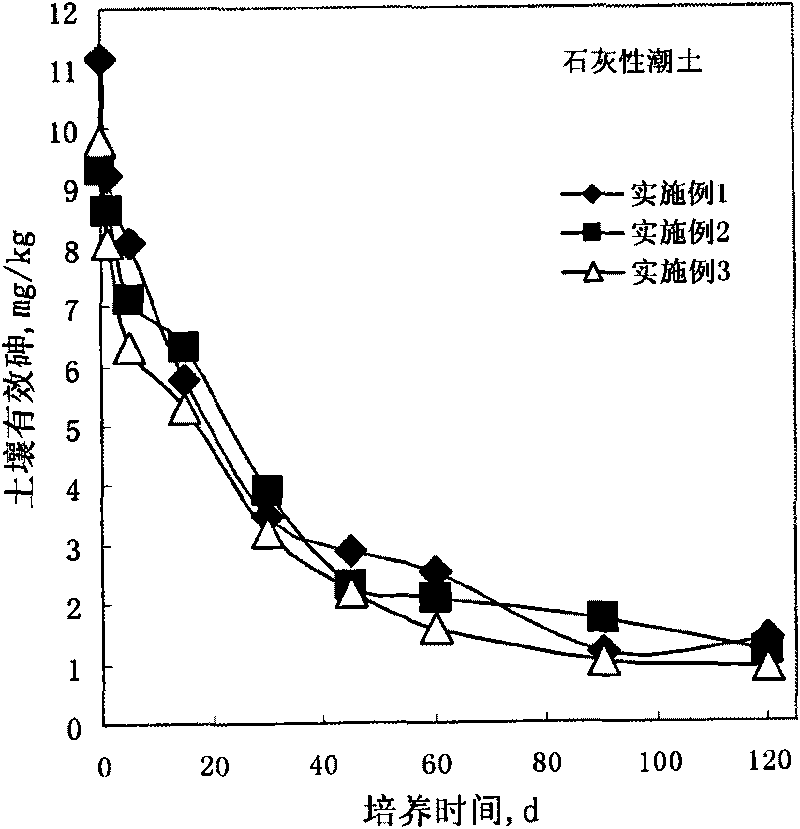

Chemical fixing material suitable for arsenic in soil and application thereof

The invention belongs to the technical field of remediation of pollution of arsenic in soil, arsenic in sediment and arsenic in tailings, also relates to the technical field of agriculture environmental protection, in particular to a chemical fixing material suitable for remediation of pollution of arsenic in soil, arsenic in sediment and arsenic in tailings, and a preparation method and application thereof. The chemical fixing material prepared can effectively fix the arsenic in arsenic-polluted soil, arsenic-polluted sediment, arsenic-polluted tailings and the like, reduce the bioavailability of the arsenic, and inhibit crops from absorbing and accumulating the arsenic. The chemical fixing material for the arsenic is characterized in that: 200kg of dry basis of a finished product comprises the following compositions by weight: 120 to 145kg of nano-grade anatase titanium dioxide, 30 to 40kg of nano-grade rutile titanium dioxide, and 20 to 30kg of zero-valent iron powder (of which 90 percent passes through a 100-mesh sieve); and 0 to 10kg of tree saw dust or stalk powder is added or not added so as to prepare the chemical fixing material. The invention also discloses the preparation method and the application of the material.

Owner:广西聚缘农业有限公司

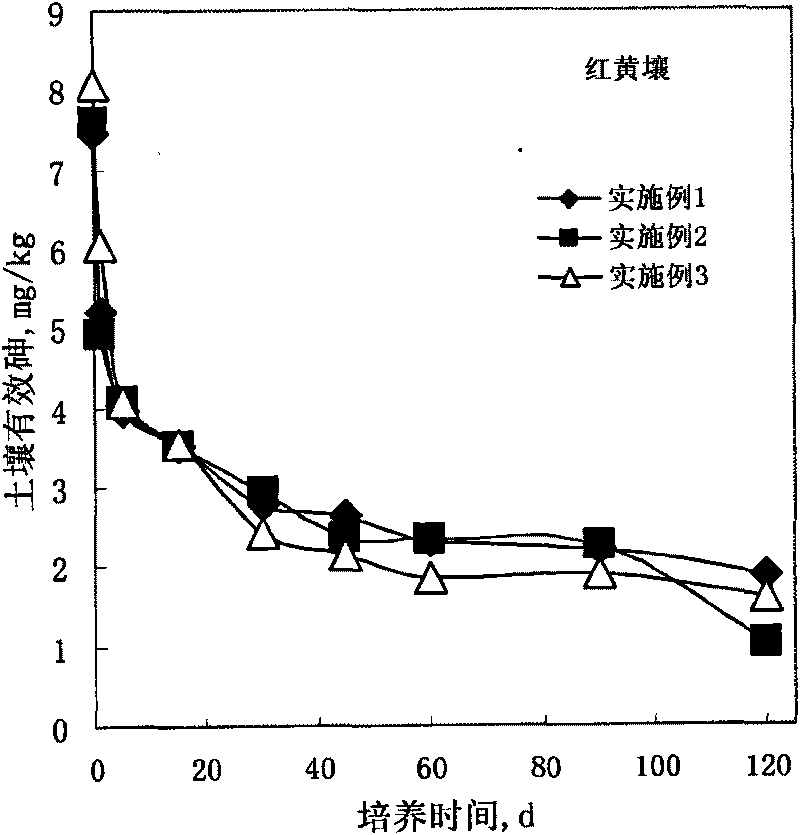

Arsenic-polluted soil passivator, preparation method and method for controlling arsenic-polluted soil

ActiveCN107254313AEasy to fixReduced Arsenic AvailabilityContaminated soil reclamationOrganic fertilisersSoil fertilityPollution

The invention discloses an arsenic-polluted soil passivator, a preparation method and a method for controlling arsenic-polluted soil. The passivator takes rice straw, ferrous sulfate heptahydrate and hydrogen peroxide as raw materials. The preparation method of the passivator comprises the following steps: cleaning and grinding the rice straw, soaking the rice straw into a FeSO4.7H2O solution, adding H2O2 with the concentration of 30 percent according to a ratio, uniformly mixing, filtering, drying, charring the raw materials in a muffle at 300 to 400 DEG C, so as to obtain the passivator. The passivator is wide in raw material sources, low in cost and simple in preparation method, does not cause secondary pollution, efficiently utilizes the adsorption property of the rice straw, ensures that iron base is loaded on the rice straw, ensures that the iron base is polyhydroxylated through the adding of the hydrogen peroxide, is more convenient for the fixing of arsenic, improves the use effect of the passivator, and is further beneficial to the improvement of soil fertility through biological carbon component.

Owner:CENT SOUTH UNIV

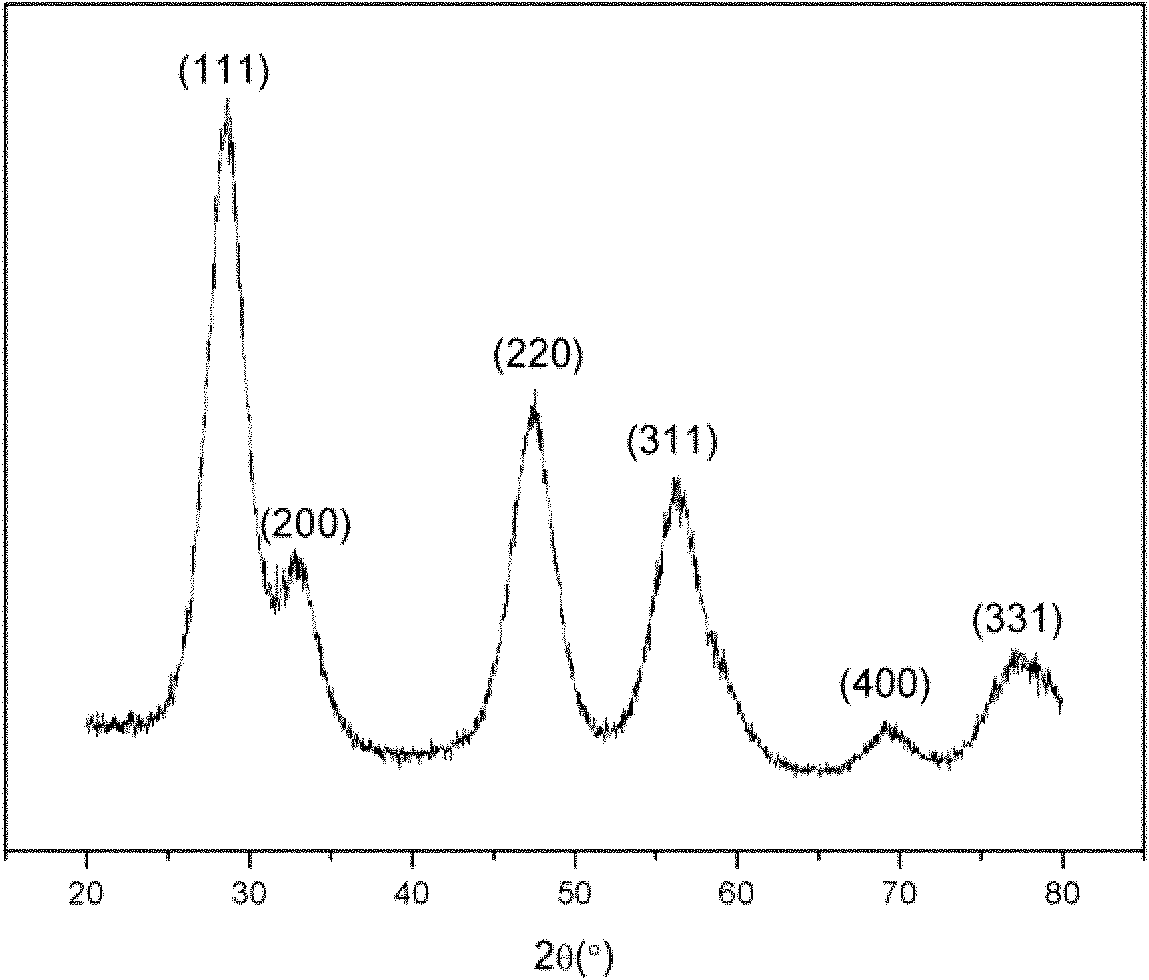

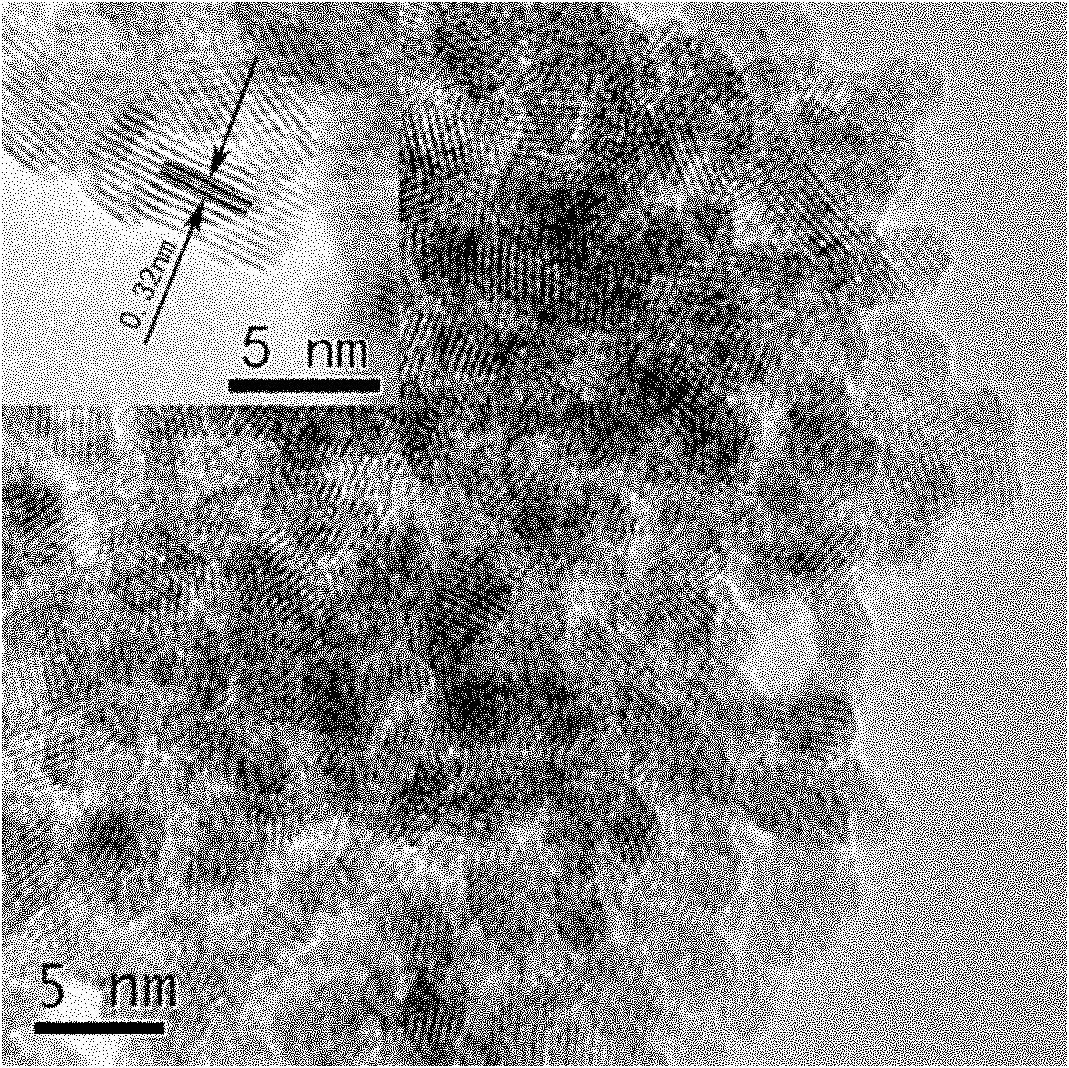

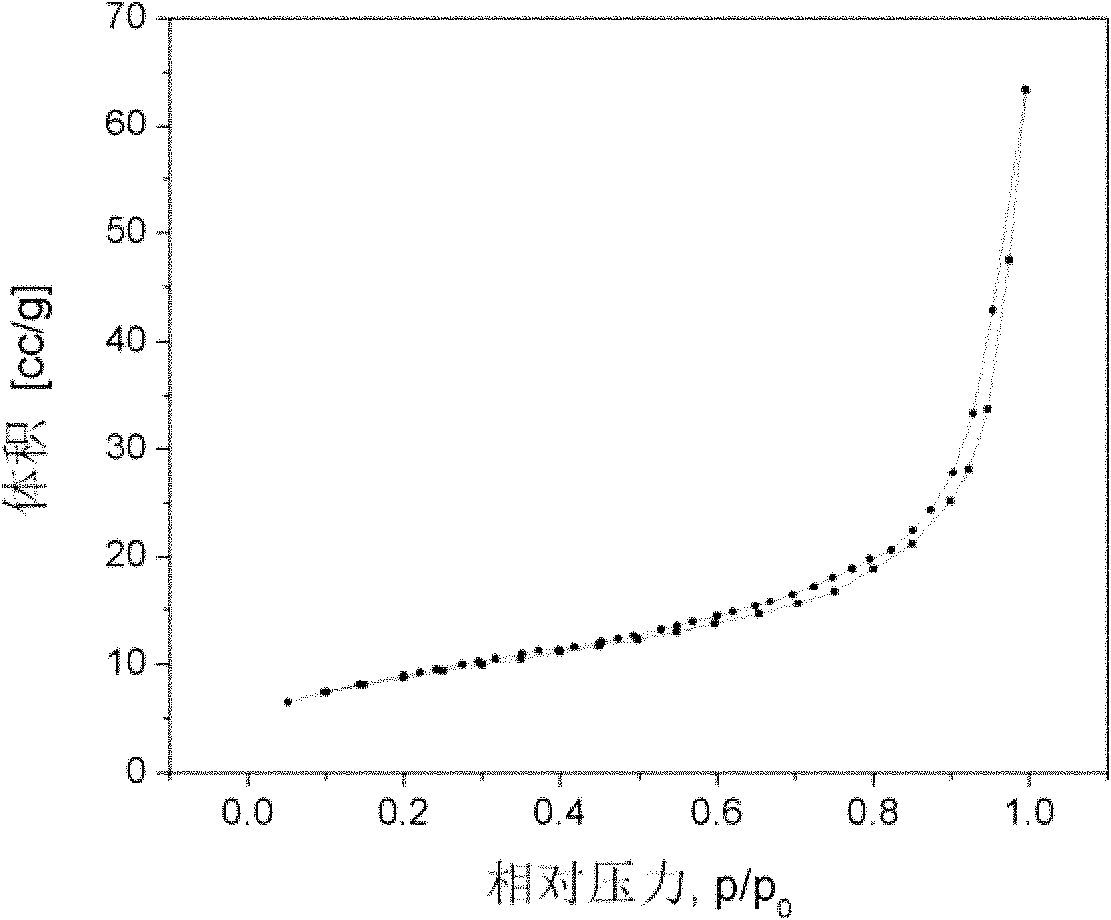

Nanometer cerium oxide hydrate-based arsenic removing material, preparation method thereof and application in arsenic removing

InactiveCN102600790ASimple preparation processEasy to operateOther chemical processesAlkali metal oxides/hydroxidesHydration reactionArsenic pollution

The invention belongs to the inorganic non-metal nanometer material preparation and the environmental friendliness field of water purification, in particular relates to a nanometer cerium oxide hydrate-based adsorbing material with a high specific surface area, a preparation method of the adsorbing material and application in removing arsenic. By using the nanometer cerium oxide hydrate-based adsorbing material, trivalent arsenic and pentavalent arsenic in the water can be removed at one step and the current problem that the content of arsenic in water exceeds the standard can be effectively solved. The cerium oxide hydrate-based adsorbing material is obtained by the steps of depositing a cerium salt (or a mixture of a cerium salt and other metal salt) by an alkali in water (or a non-aqueous solvent) and drying the product. The preparation method is simple in process; the obtained cerium oxide hydrate-based adsorbing material is large in specific surface area, strong in arsenic removing ability, wide in pH applicable range and stable in performance, and the arsenic pollution in a natural water area can be simply and efficiently removed by loading the adsorbing material with no need of pre-treatment, so as to provide a novel arsenic removing material for purification of arsenic-containing sewage and environment friendliness.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

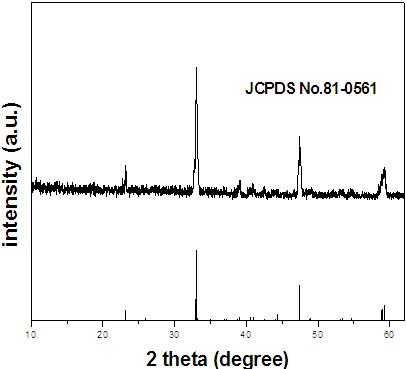

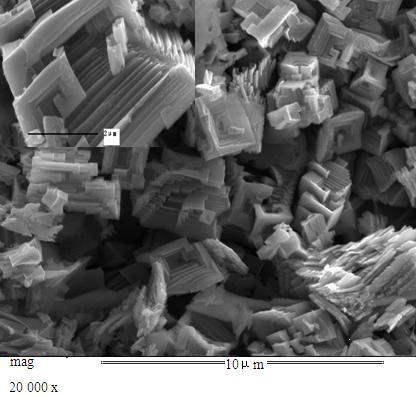

Calcium titanate photocatalyst for removing arsenic by photocatalysis

InactiveCN101829556AGood photocatalytic oxidation activityImprove adsorption capacityWater/sewage treatment by irradiationWater contaminantsArsenic pollutionPhysical chemistry

The invention provides a method for preparing a novel photocatalyst CaTiO3 for processing an arsenic polluted water body, which belongs to a photocatalysis technology in environmental management. The calcium titanate with a lamellar microstructure is obtained for the first time by adopting a product obtained by fully hydrolyzing tetra-n-butyl titanate as a titanium source. In addition, the photocatalyst can effectively optically catalyze and oxidize As (III) and greatly adsorb and remove As (V) generated by oxidization and prevents secondary pollution of the water body caused by a flocculant added after the photocatalyst adopting TiO2 as a main component oxidizes the As (III) in the prior art. Finally, the method for preparing the photocatalyst is simple and easy and is beneficial to popularization at a large scale.

Owner:FUZHOU UNIV

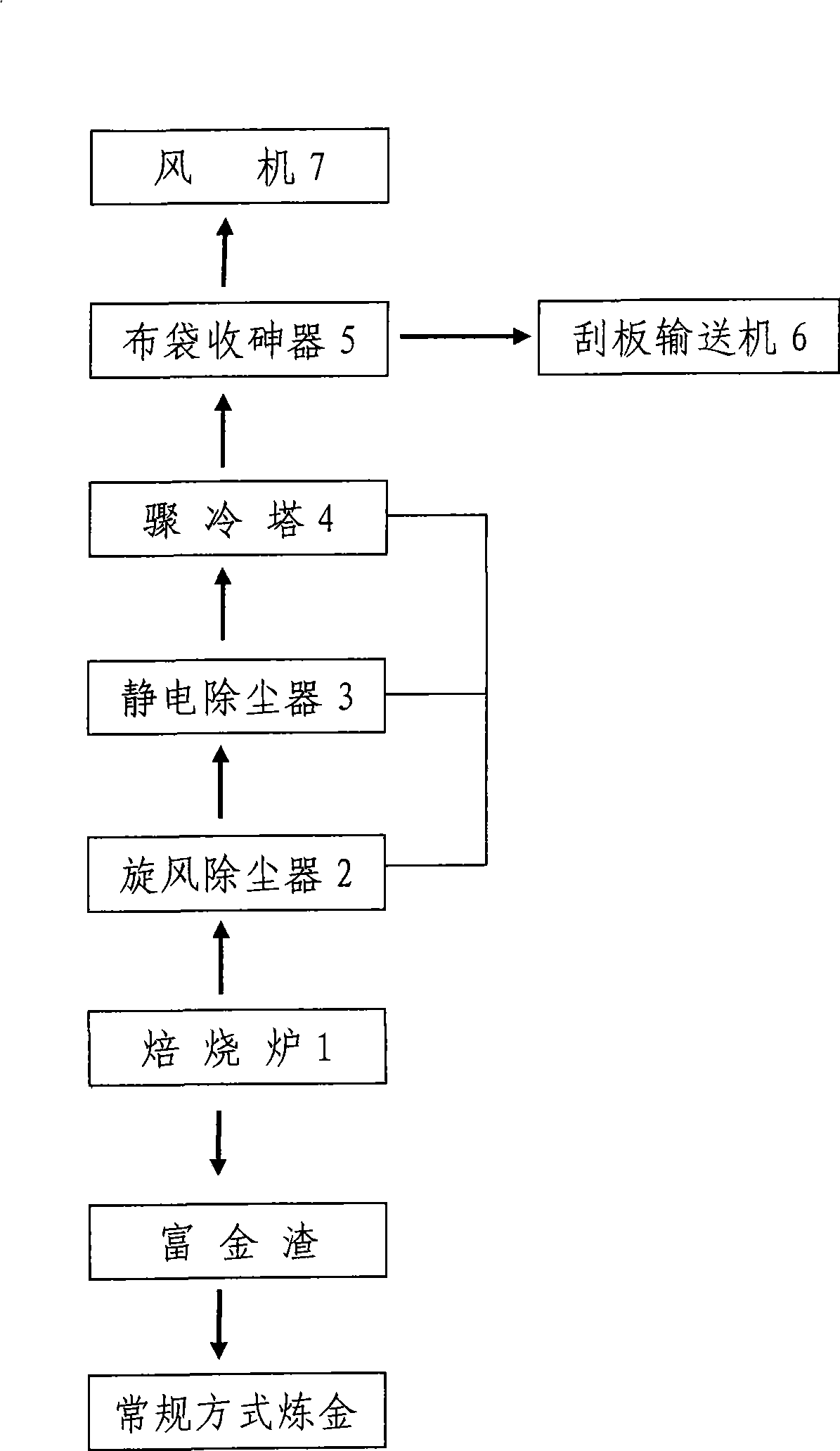

Method for extracting arsenic trioxide from roasting dust of arsenic-containing gold concentrate powder

ActiveCN101412538AHigh purityThe process is easy to controlArsenic compoundsArsenic pollutionCyclonic spray scrubber

The invention discloses a method for extracting arsenic trioxide from gold concentrate powder roasted fume containing arsenic. The method adopts a staged gradually-heating purification process and a quenching extraction process. The purification process is to volatilize impurities with low melting points in materials under the condition of different temperatures. The purified materials are insulated at a temperature of between 500 and 550 DEG C for more than 150 minutes, so that the arsenic is oxidized into arsenic trioxide gas; the gas is purified through a cyclone dust collector and an electrostatic precipitator in sequence; the purified high-temperature arsenic trioxide gas directly enters a quenching tower of which the temperature is between 120 and 140 DEG C to be crystallized into arsenic trioxide microparticles; and powdery arsenic trioxide collected by a bag arsenic collector is outputted via a scraper conveyor. The method has the advantages that the process procedure is arranged reasonably, controllably and stably, and the rate of extracting the arsenic trioxide from fume is high, and the purity of the extracted arsenic product is high, and the method well solves the problem of arsenic pollution in the gold smelting industry.

Owner:JIANGSU KANGJIE ENVIRONMENT ENG

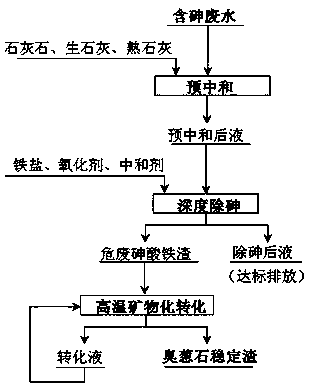

Harmless arsenic solidifying method for industrial wastewater containing arsenic

PendingCN109761390ASimple processHigh arsenic removalWater contaminantsMultistage water/sewage treatmentArsenateArsenic pollution

The invention discloses a harmless arsenic solidifying method for industrial wastewater containing arsenic, and belongs to the field of arsenic pollution control. The harmless arsenic solidifying method includes the steps: the industrial wastewater containing the arsenic is subjected to pre-neutralization treatment; iron salt and an oxidant are added to a solution after pre-neutralization to solidify the arsenic into iron arsenate precipitation arsenic slag, and a neutralizer is used for controlling the process pH; and the iron arsenate precipitation arsenic slag is transformed into scoroditestabilization slag in a high-temperature aqueous solution by high-temperature mineralization. According to the harmless arsenic solidifying method for the industrial wastewater containing arsenic, standardized discharge of the industrial wastewater containing the arsenic can be realized, meanwhile, the arsenic is solidified into the scorodite stabilization slag, the technological process is simple, and the efficiency of arsenic removing and solidifying is high.

Owner:KUNMING UNIV OF SCI & TECH

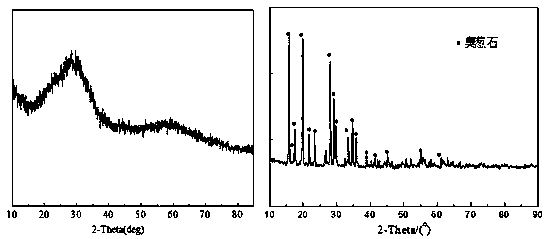

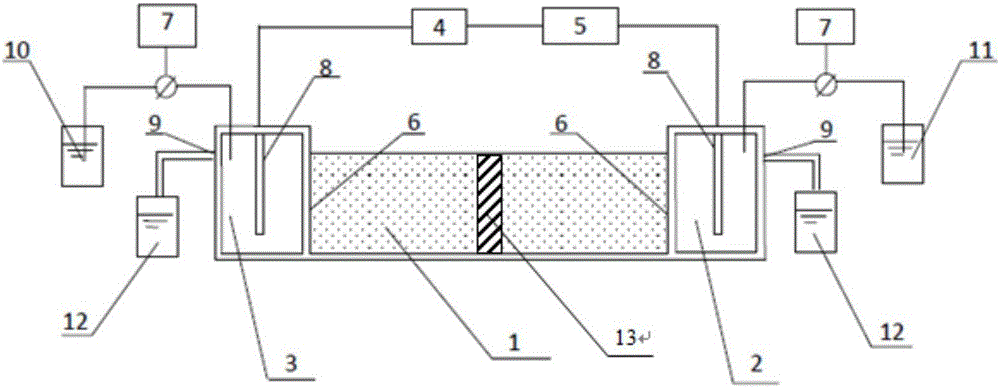

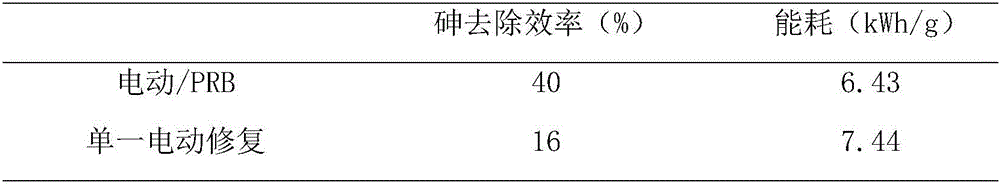

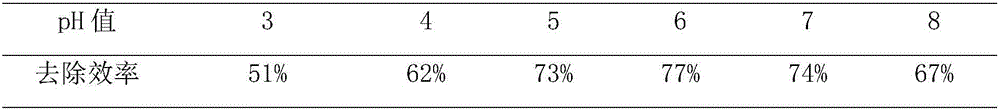

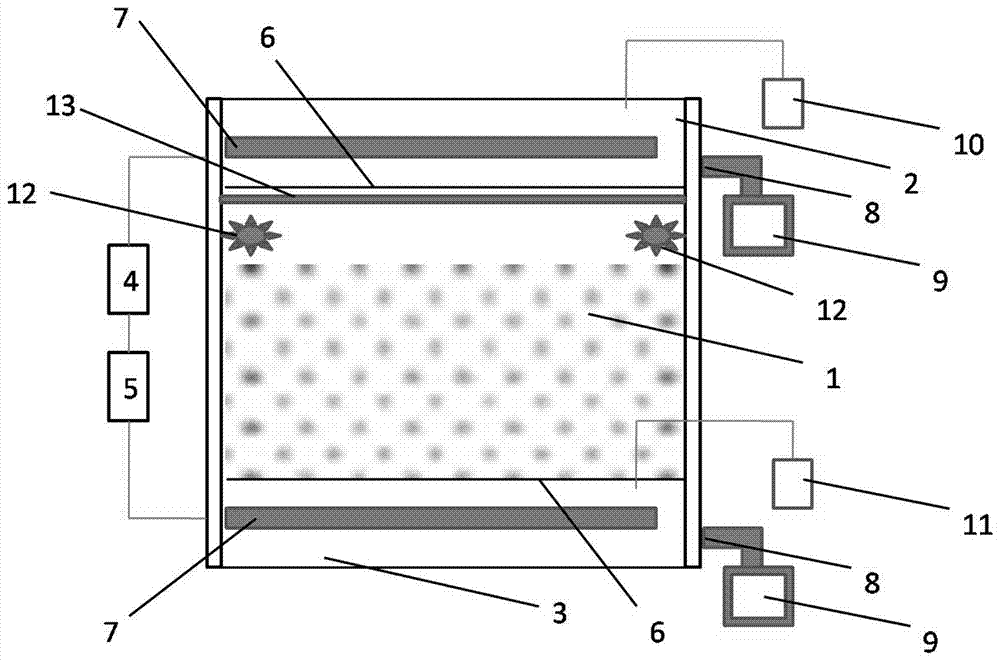

Method for in-situ repairing of contaminated soil in arsenic slag field

The invention discloses a method for in-situ repairing of contaminated soil in an arsenic slag field. The method comprises the following steps that naturally-aired arsenic slag field arsenic contaminated soil is crushed and screened; the above soil is mixed with deionized water, the water content of the soil is 25%-45%, and stirring is conducted for achieving balancing; and joint repairing is conducted on the above balanced soil through the electric-PRB technology through an electrolyte and a strengthening reagent under the condition of pH being 5-7, wherein the medium of PRB is Fe0. According to the method, the electric repairing technology is utilized for being in joint usage with PRB, the advantages of the electric technology and the PRB technology can be combined, the removing efficiency of arsenic in the soil is improved, and the repairing time is short; a soil layer is not disturbed, and the method is suitable for soil with low permeability; and meanwhile, the arsenic can be recycled, secondary pollution can be effectively reduced, the subsequent treatment workload is reduced, and the economic benefits are increased.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

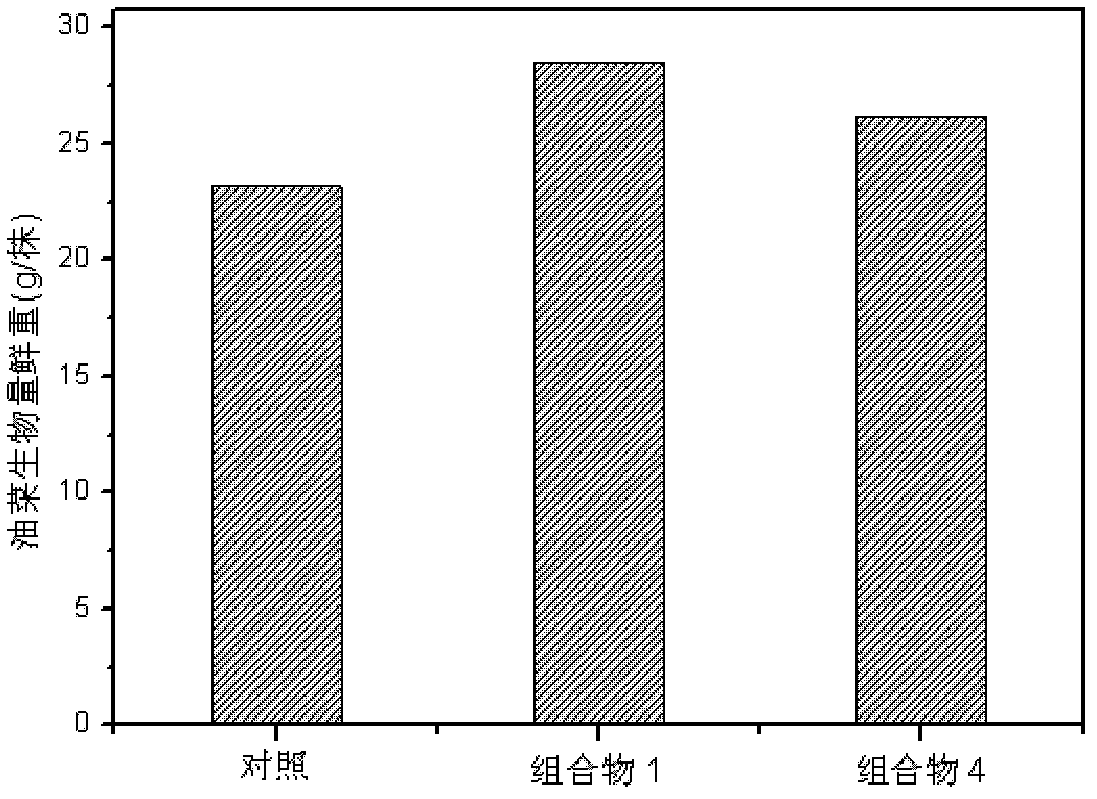

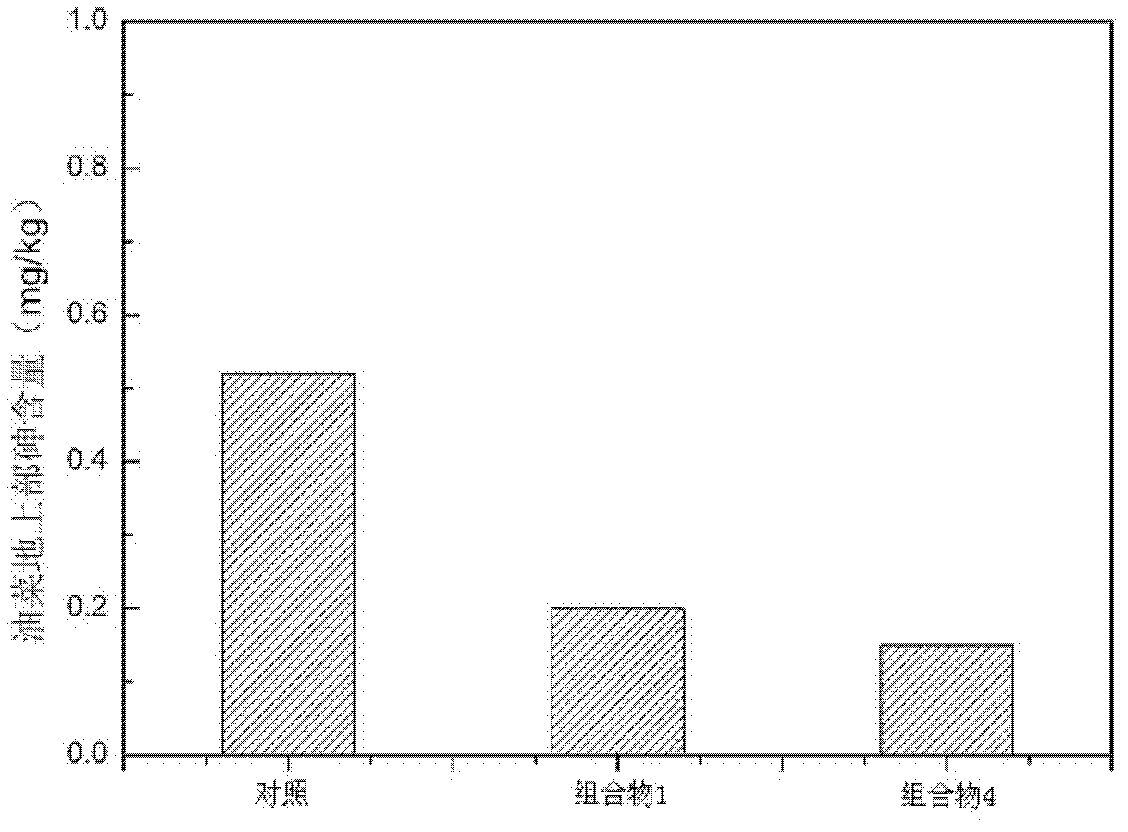

Composition used for treating soil arsenic pollution, and application method thereof

InactiveCN102513350AWide variety of sourcesLow costContaminated soil reclamationArsenic pollutionMetallic sulfide

The invention belongs to the field of soil arsenic pollution treatment. Specifically, the invention relates to a composition used for treating soil arsenic pollution, and an application method thereof. The composition provided by the invention comprises components of, by weight: 20-30% of a pH regulating agent, 10-40% of aluminum oxide, 10-40% of elementary iron, and 15-30% of metal sulfide. The prepared composition is added to arsenic-polluted soil with a dosage of 0.5-4% by weight. With the composition provided by the invention, arsenic in soil can be fixed, and bioavailability of arsenic in soil is substantially reduced. Therefore, arsenic absorption of crops can be inhibited, and crop growth can be promoted. The composition is advantaged in rich raw material, low price, simple preparation method, and simple application method. With the method, large-scale production can easily be realized. The method is suitable for large-range popularization.

Owner:盛世绍普(天津)环保科技有限公司

Method for repairing arsenic-polluted soil

The invention discloses a method for repairing arsenic-polluted soil. The method is divided into the following steps that 1, the soil is submerged, and the arsenic content is detected; 2, arsenic ions are enriched; 3, the surface of the soil is tiled with arsenic-polluted soil repairing agents by 3-5 cm; 4, lighting and repairing are conducted; and 5, a power source is turned off, and a solidified repairing agent layer on the surface of the soil is removed. According to the provided method for repairing the arsenic-polluted soil, arsenic is enriched to the surface layer of the soil through an electrochemical method, the soil repairing difficulty is greatly lowered, and the using amount of the soil repairing agents is saved; the repairing agent repairing process and the photochemical repairing process are conducted at the same time, and As (III) in the soil is removed to a great extent; and stable-state arsenic after repairing can be removed together with the solidified repairing agents, so that the removing rate of the arsenic in the soil is ensured, and the problem of arsenic pollution in the soil is fundamentally solved.

Owner:ZHENGZHOU UNIVERSITY OF AERONAUTICS

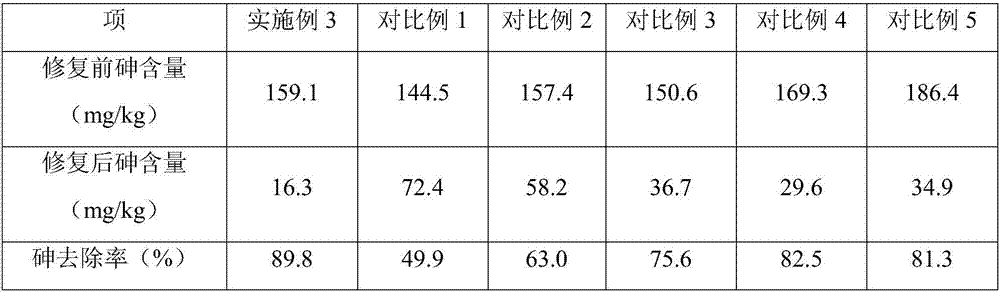

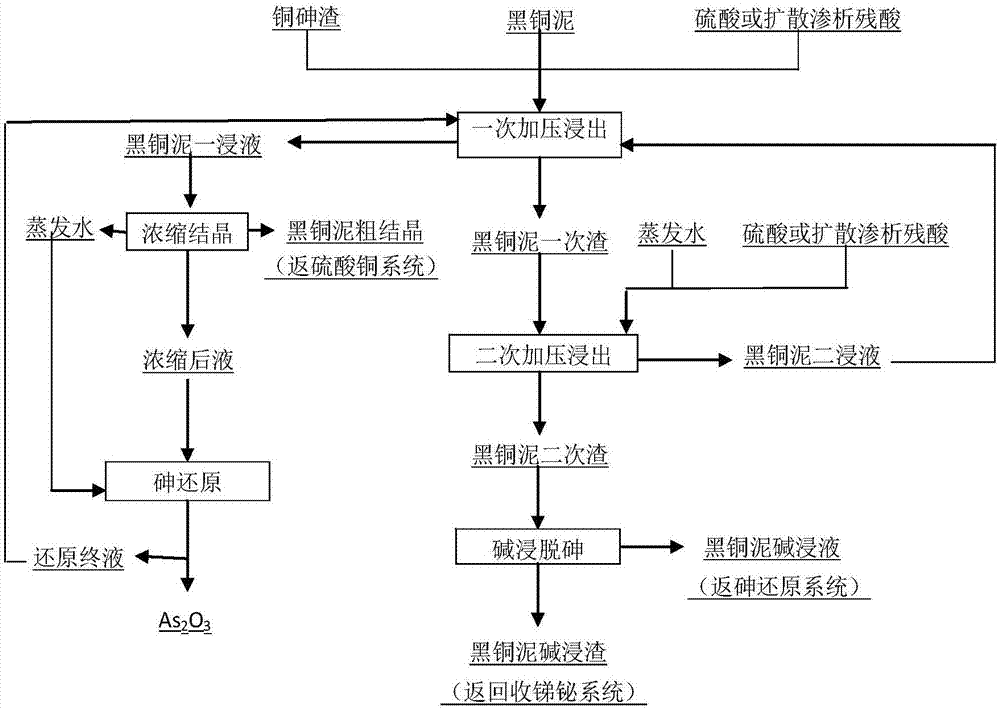

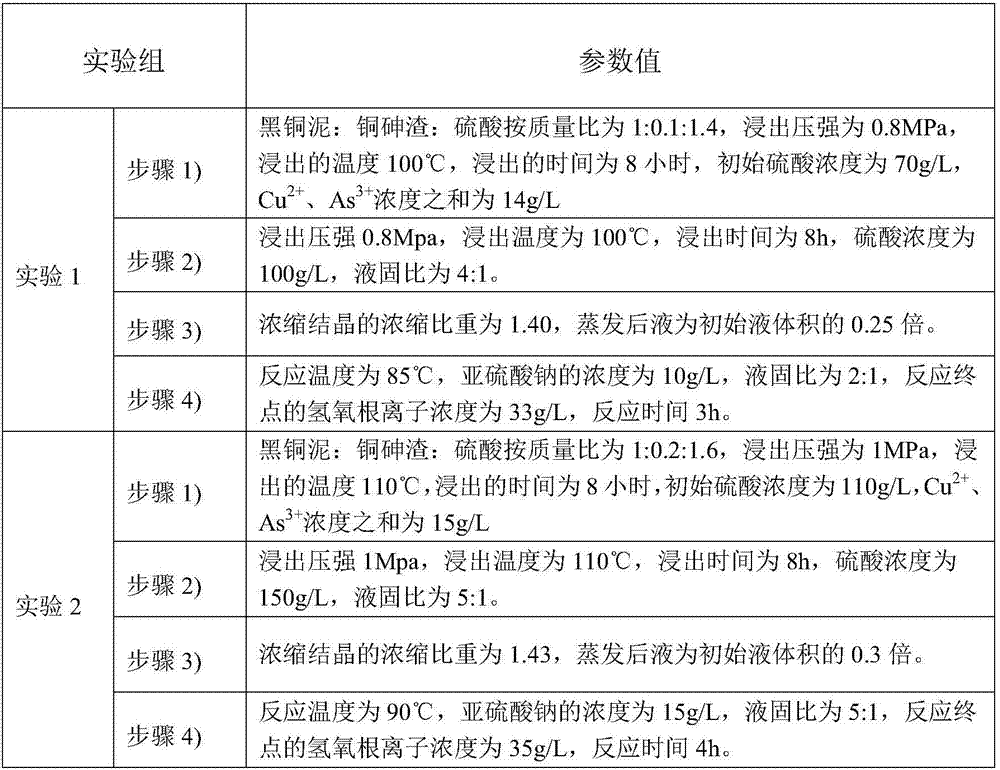

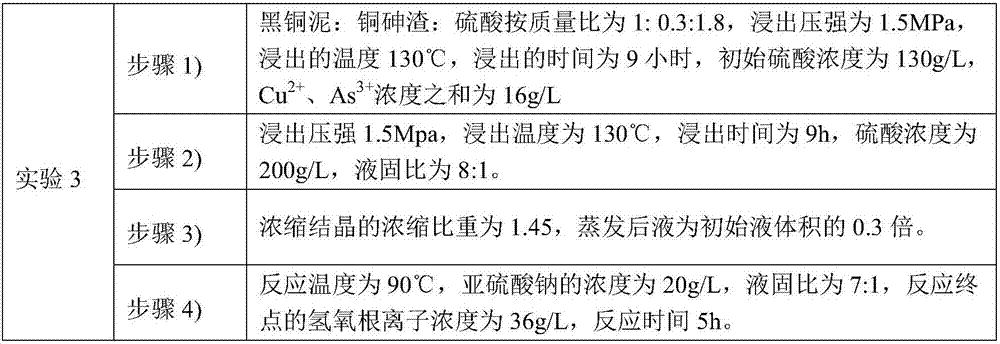

Method for resourcefully utilizing black copper mud by copper electrolysis

ActiveCN107385215AEfficient separationSolve the open circuit processing problemProcess efficiency improvementPregnant leach solutionArsenic pollution

The invention discloses a method for resourcefully utilizing black copper mud by copper electrolysis. The method comprises the steps: (1) primary pressure leaching of black copper mud; (2) secondary pressure leaching of black copper mud; (3) condensation crystallization; (4) alkali leaching and arsenic removal; (5) arsenic reduction. The method adopts primary pressure leaching, secondary pressure leaching, alkali leaching and arsenic removal of secondary leaching residues, condensation crystallization of primary leaching liquid, merging concentrated liquid with secondary leaching arsenic and alkali leaching liquid to reduce and move arsenic as a trunk process to process the black copper mud, therefore realizing effective separation of copper, arsenic, antimony and bismuth, and solving the problem of opening treatment of the black copper mud. Valuable elements such as copper, antimony, bismuth, nickel and arsenic in the black copper mud are effectively and comprehensively recovered, arsenic pollution governance realizes resourceful utilization, and the severe secondary pollution of hazardous solid wastes is avoided.

Owner:JIANGXI COPPER

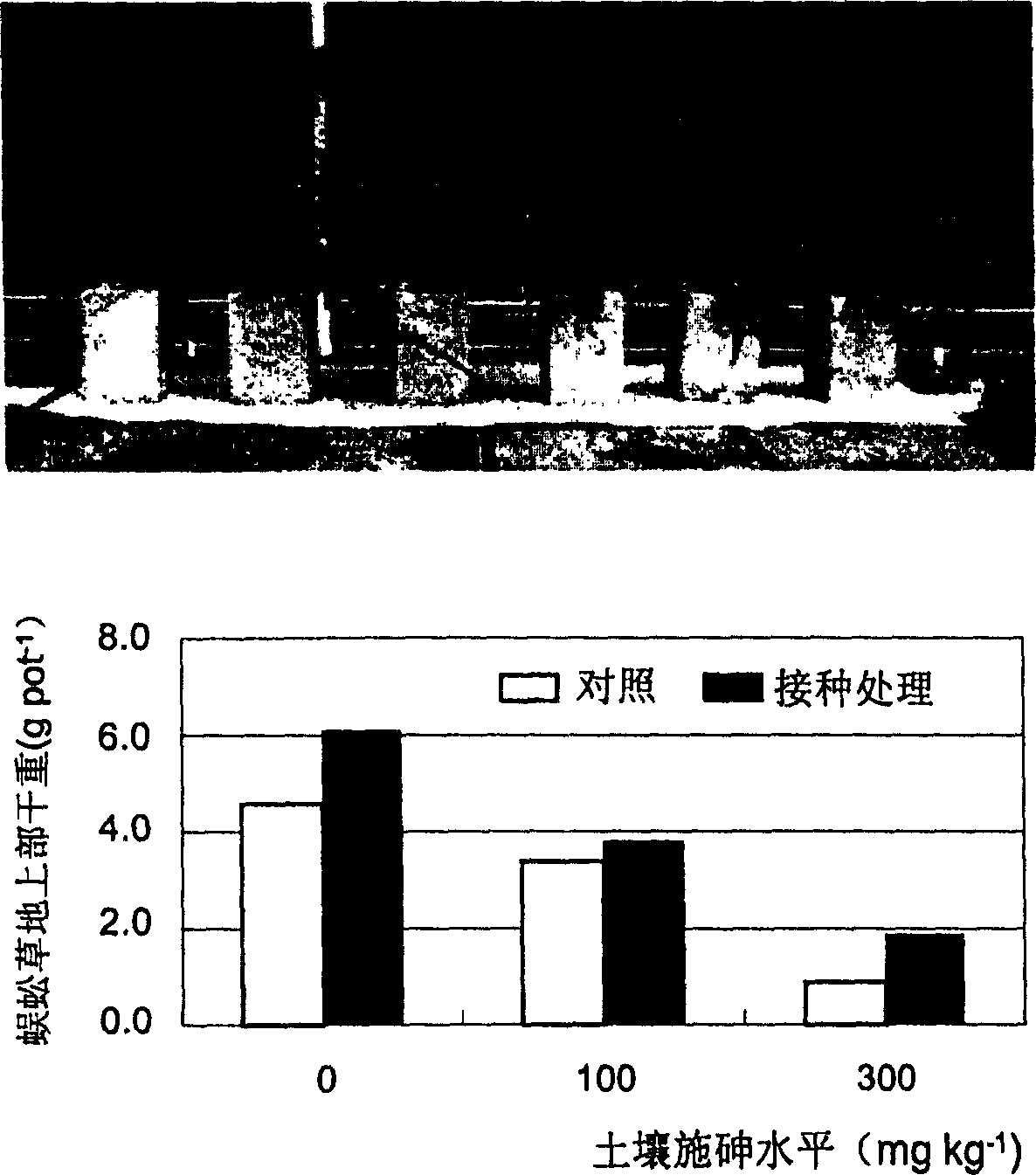

Method for promoting plant restoration efficiency of arsenic polluted soil

InactiveCN1633834APromote absorptionImprove mineral nutrition (especially phosphorus nutrition) statusFungiSymbiotic/parasitic combinationsPteridophyteArbuscular mycorrhizal fungi

The invention relates to a method for plant restoring soil of arsenic contamination, which is realized through inoculating arbuscular mycorrhizal fungi to centipedefern, a kind of pteridophyte, thus producing fungus root, the method comprises the steps of, (1) collecting raw pteridophyte material, obtaining spores of pteridophytes, cultivating young plant sprout, (2) producing fungus roots from pteridophyte, (3) transplanting the adult strain of young sprouts to arsenic contaminated soil. The invention can be applied to aid the arsenic super rich centipedefern to adapt to arsenic contamination environment.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI +1

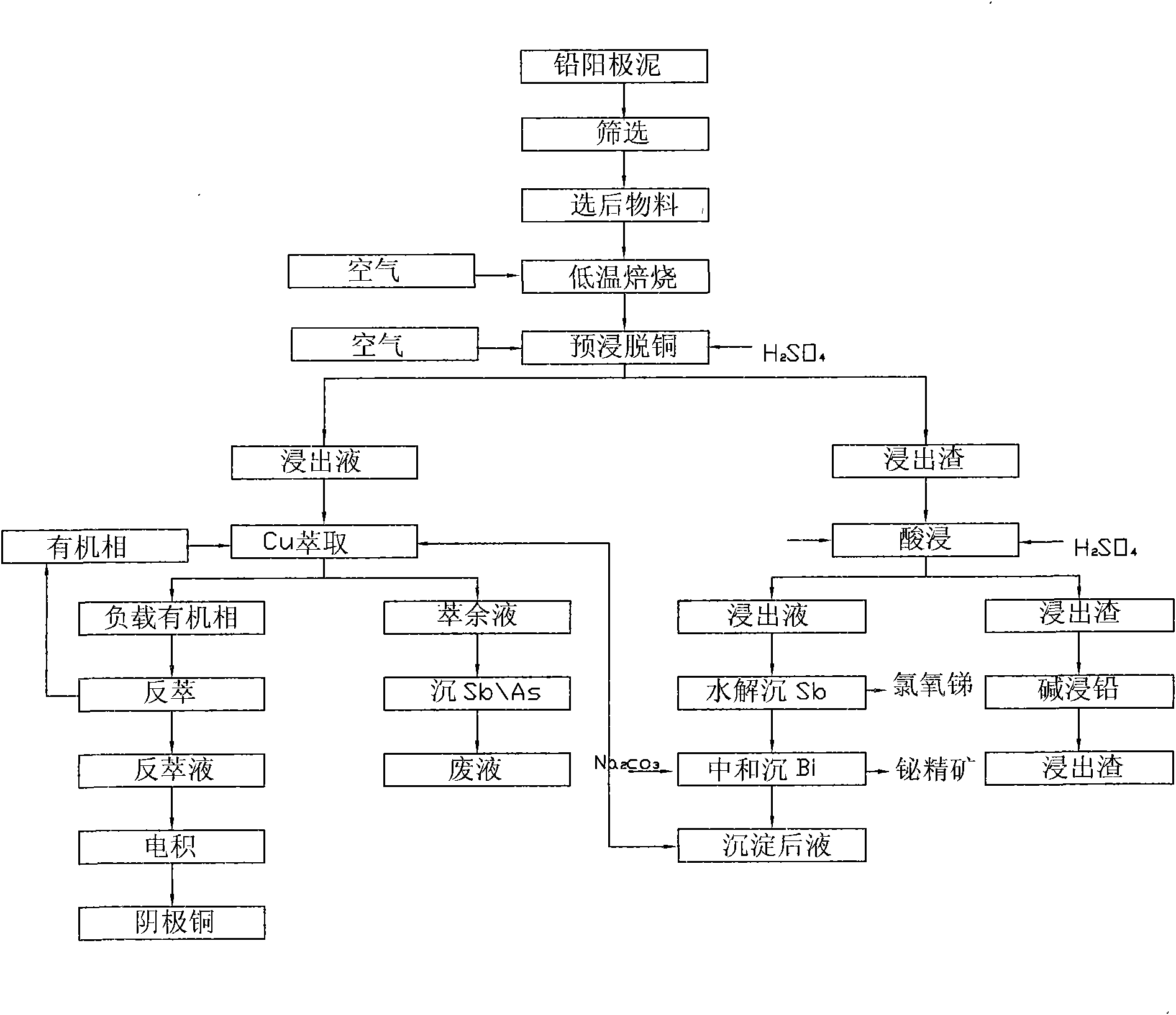

Method for recycling multiple precious metals from anode mud

InactiveCN101597690AAddressing Arsenic PollutionAddressing Adaptive IssuesPhotography auxillary processesProcess efficiency improvementArsenic pollutionAntimony

The invention discloses a method for recycling multiple precious metals from anode mud, comprising a step of smelting and filtering the anode mud in a smelting furnace, cooling the smelted material and then preliminarily immersing and removing copper to obtain extract and leached mud, conveying the leached mud to acid leaching tank to obtain extract and leached mud again, conveying the extract to the hydrolysis tank to process neutralization precipitation, conveying the leached mud to alkaline leaching lead tank, processing smelting method to the processed leached mud. The extract is conveyed to copper extraction tank to process back extract by the organic substances of organic box. Copper-contained material and extract residual are obtained after extraction. The copper-contained material is conveyed to the load organic box to process back extract; after the back extract, the material part is conveyed to the organic box to reprocess; the rest back extract liquid is conveyed to the electrodeposition tank to process electrodeposition to obtain cathode copper. The extract residual liquid obtained from copper extraction box is conveyed to a sedimentation tank to settle; and the waste liquid is conveyed to waste water treatment system to treat. The invention uses wet leaching method to separate precious metals, combines the advantages of fire and wet production and solves the problems of arsenic pollution, long production process, bad raw material applicability, long production period and lower comprehensive recovery in the fire smelting. The recycling yield of gold, silver, copper, antimony, bismuth, arsenic and lead reaches up to 95%.

Owner:永兴县元泰应用材料有限公司

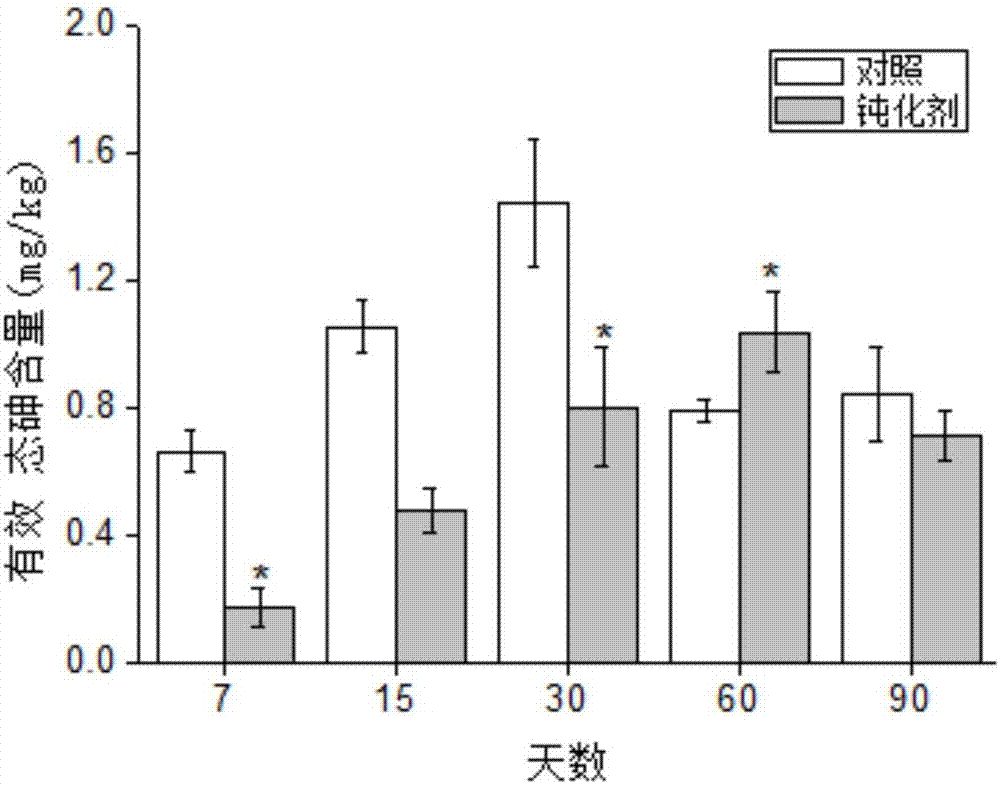

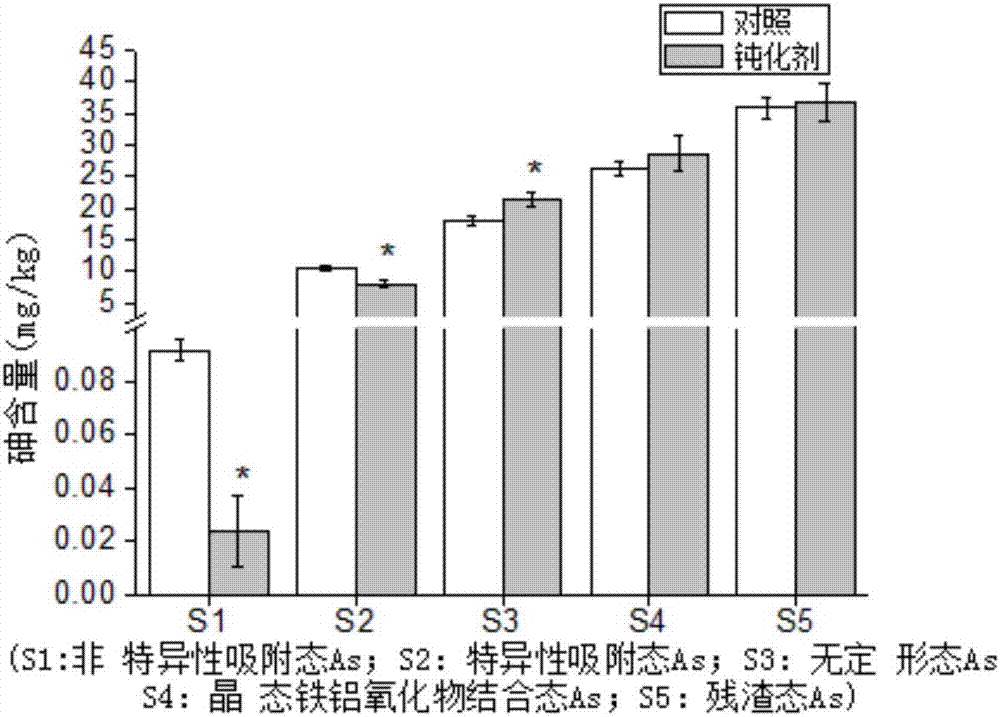

Remediation method of arsenic (As)-contaminated soil

The invention provides a remediation method of arsenic (As)-contaminated soil, and belongs to a treatment method of As-contaminated soil. The remediation method is technically characterized by comprising the following steps: taking low-cost red mud as a raw material to prepare an activated red mud stabilizer by a ferric salt and ferrous salt activation method; and adding the activated red mud stabilizer to the As-contaminated soil according to a certain proportion, evenly mixing, maintaining a certain water content, and culturing for a certain time so as to finally achieve the purpose of remediation of the As-contaminated soil. The remediation method has the advantages of low investment and maintenance cost, small engineering amount, simple operation management procedure, high treatment efficiency and capability of effectively solving the pollution problem of the existing As-contaminated soil, thus providing an effective solution to the As-contaminated soil treatment problem and having very important realistic significance.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

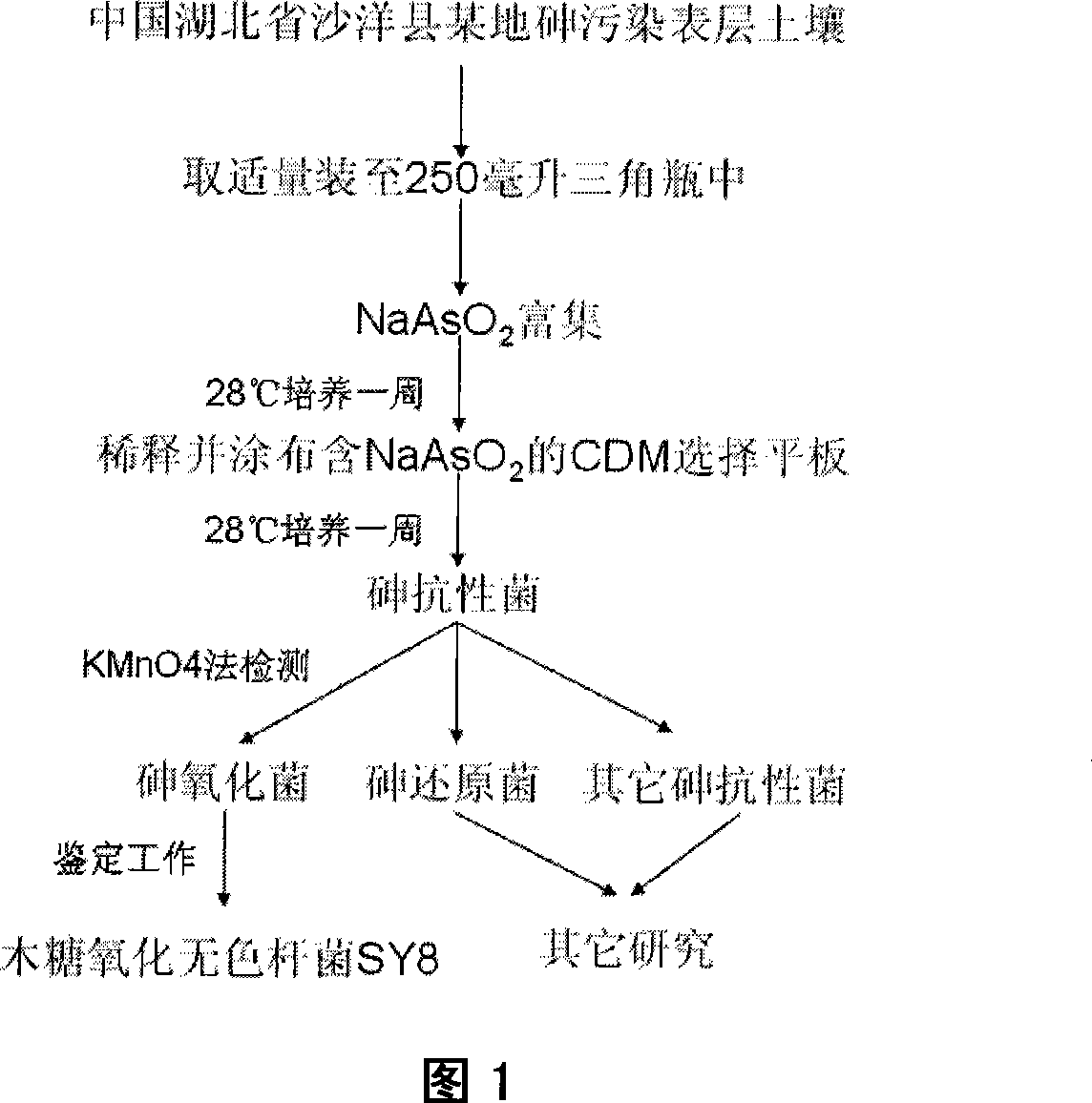

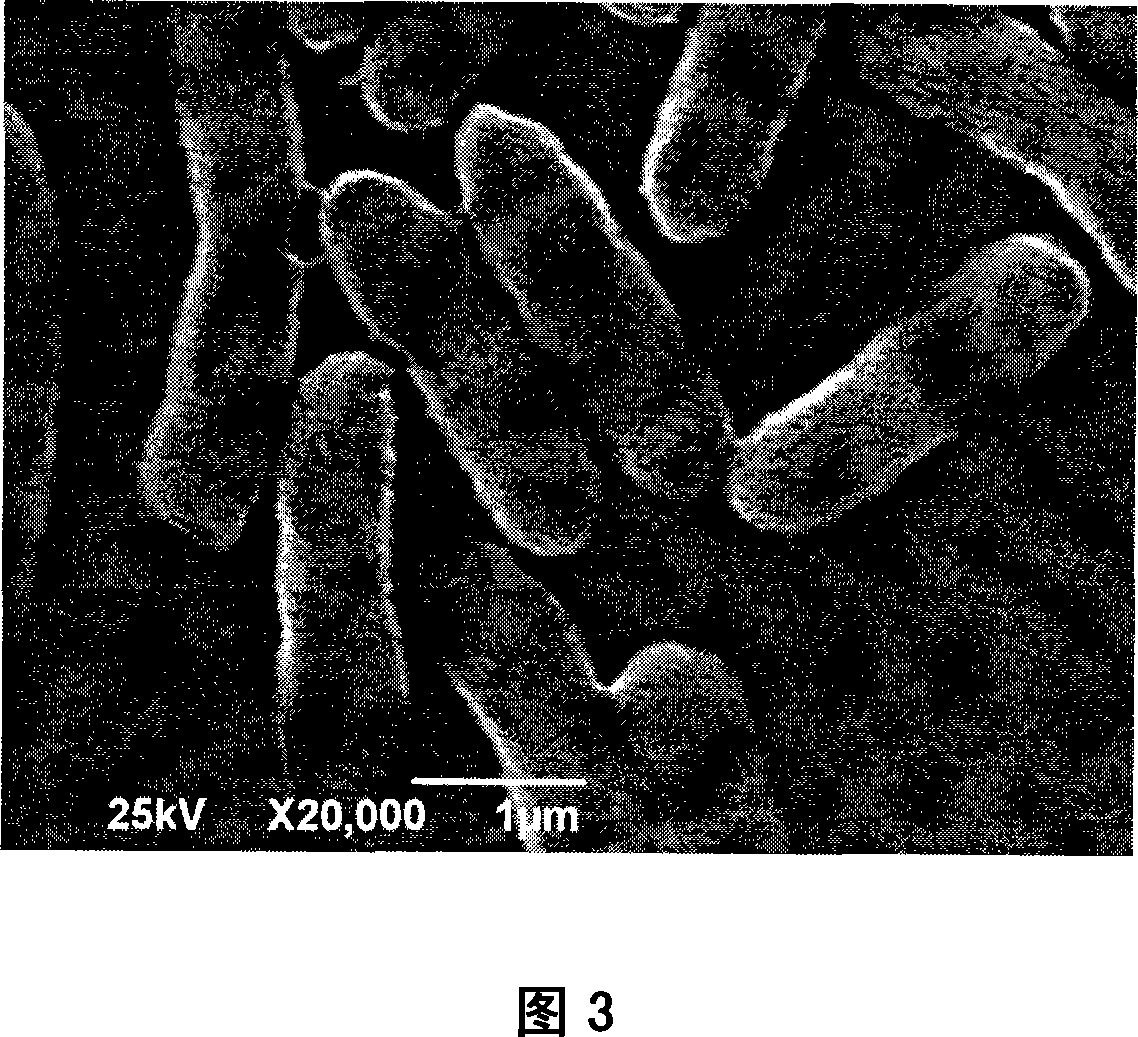

Xylose oxidation achromatous bacillus SY8 for purifying arsenic contamination and usage thereof

InactiveCN101063097AHarm reductionHighly toxicBacteriaContaminated soil reclamationBacteroidesMicroorganism

The invention discloses a wood sugar oxidation achromobacter SY8 and appliance in purifying arsenic contamination aspect in environmental microbiology technical domain, which is characterized by the following: separating a wood sugar oxidation achromobacter SY8 from arsenic contamination soil; possessing oxidation for inorganic tervalence arsenic; oxidizing inorganic tervalence arsenic to inorganic pentavalent arsenic in arsenic environmental pollution; decreasing toxicity of arsenic in environment; decreasing adsorbing removing property of arsenic; setting the preserved number as CCTCC NO: M207048. This strain possesses better applying prospect in arsenic pollution aspect.

Owner:HUAZHONG AGRI UNIV

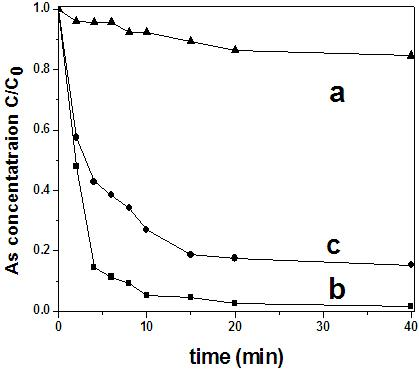

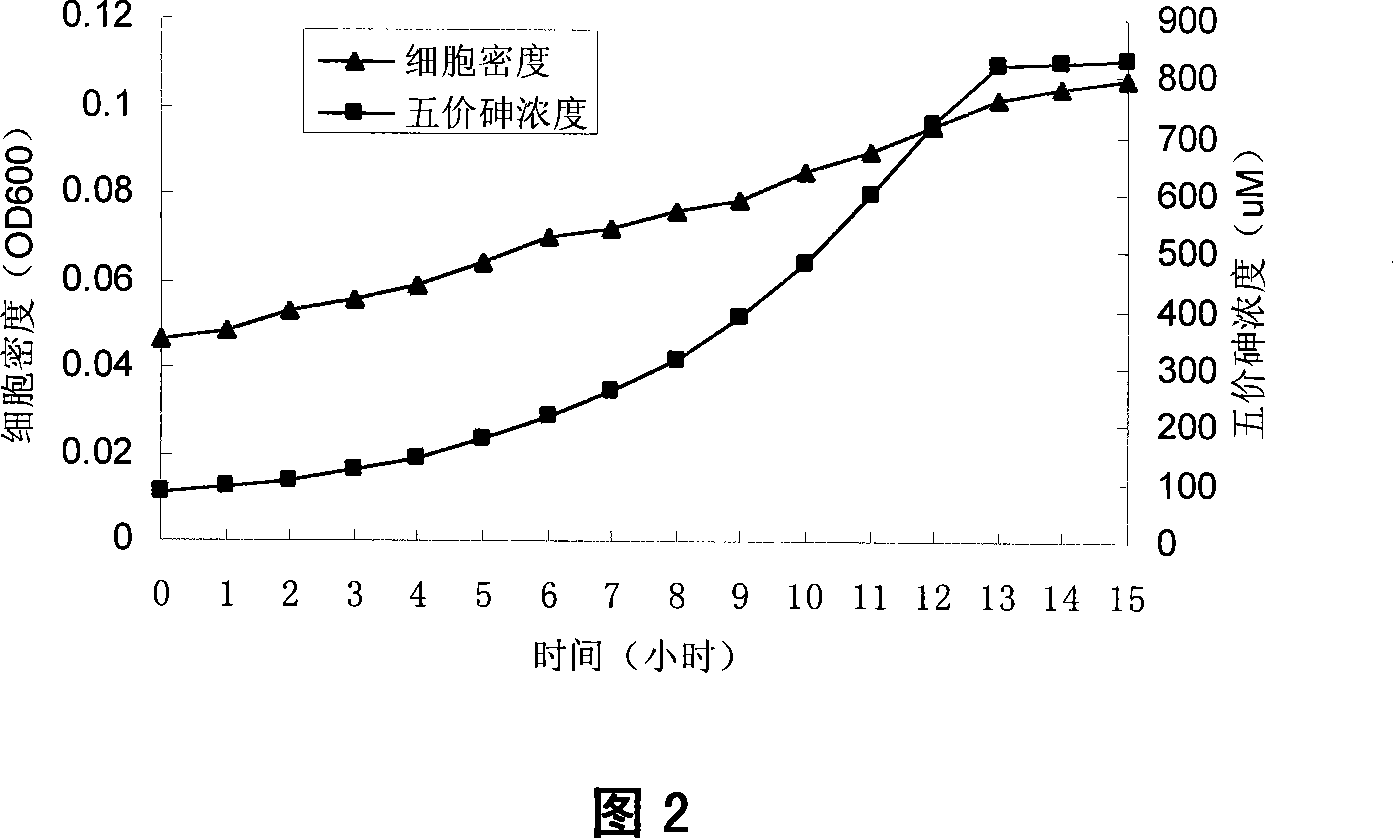

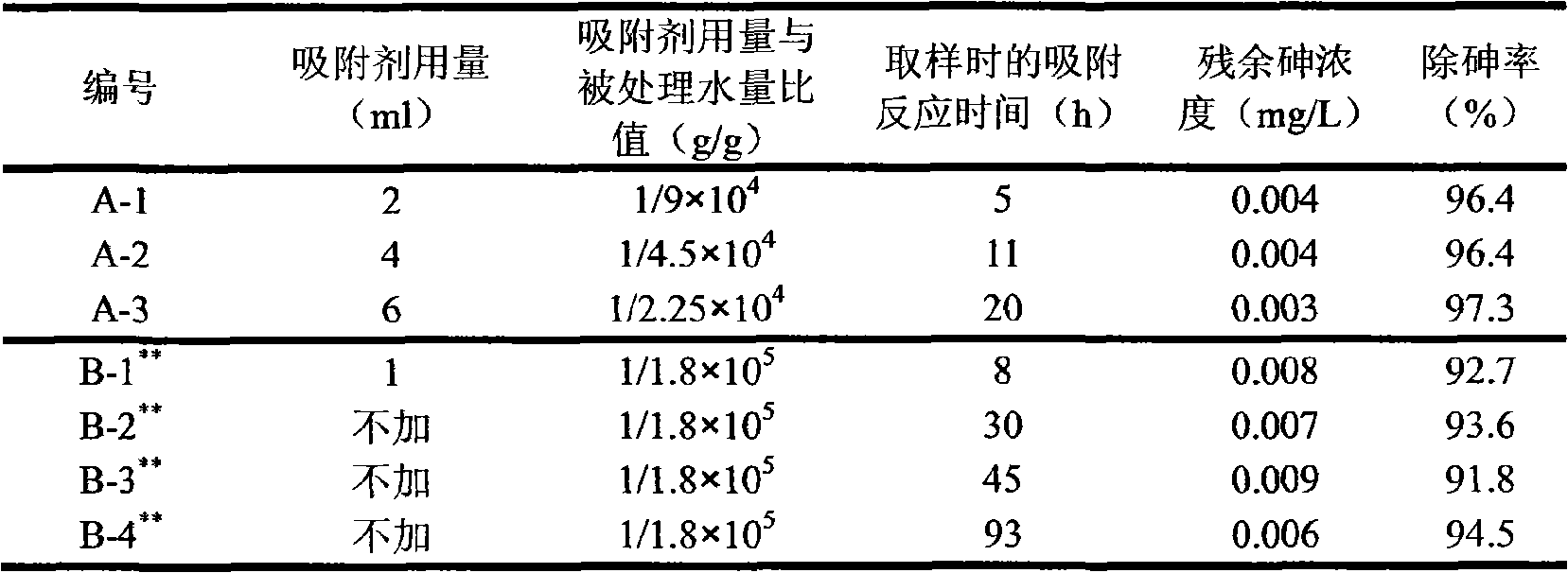

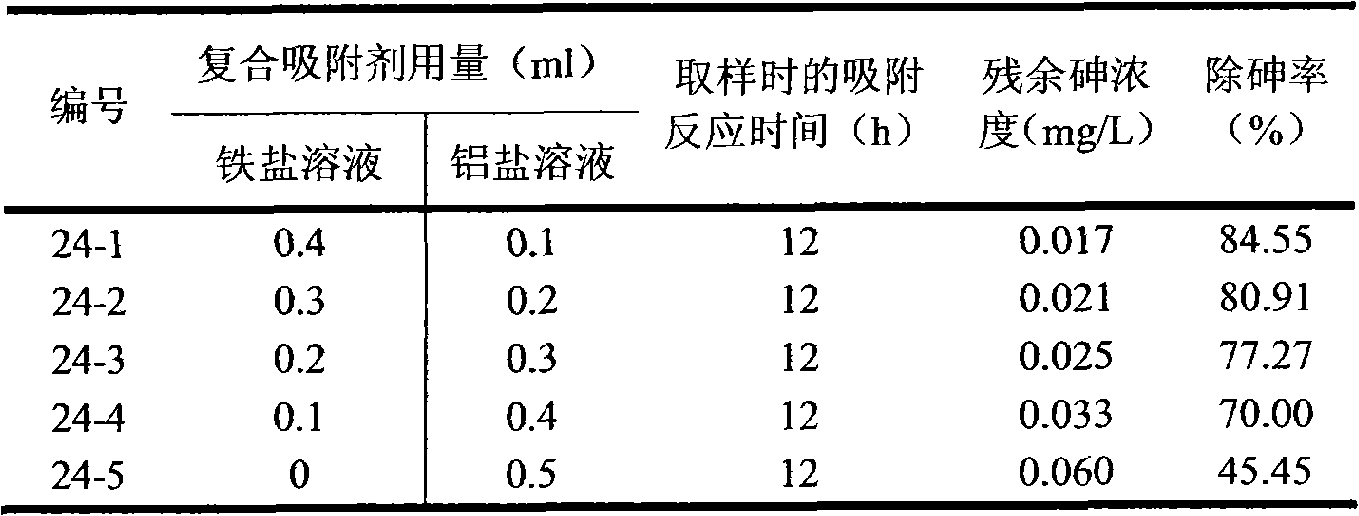

Liquid adsorbent and method for controlling arsenic pollution of lake water

InactiveCN101601989ALarge specific surface areaImprove adsorption capacityOther chemical processesWater/sewage treatment by sorptionIron saltsArsenic pollution

The invention provides a liquid adsorbent and a method for controlling arsenic pollution of lake water, which relates to large-scale treatment of arsenic-polluted water. The adsorbent is reserve liquid formed by compounding iron salts FeCl3 or Fe2(SO4)3 or adding an appropriate amount of aluminum salts AlCl3 or Al2(SO4)3 with tap water or deionized water, and the mass concentration of the adsorbent is 100 to 600 g / L. The adsorbent in use is diluted by 10 to 30 times and then sprayed on the arsenic-polluted water. The adsorbent has the advantages of safety, low price, high arsenic removal efficiency and easy operation. A Yangzonghai arsenic-polluted water sample treated with the invention is detected through graphite furnace atomic absorption spectrometry and atomic fluorescence spectrometry, and detection results show that the arsenic removal rate of the invention can be greater than 92.7 percent, and the invention can reduce arsenic concentration from 0.110-0.130 mg / L to 0.003-0.008 mg / L which is lower than 0.050 mg / L specified by the national drinking water health standard (GB5749-2006) and 0.010 mg / L specified by the WHO drinking water quality standard.

Owner:YUNNAN UNIV

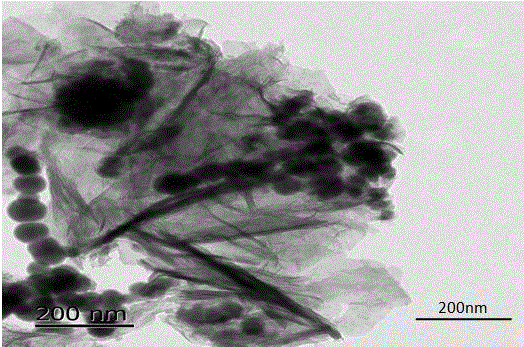

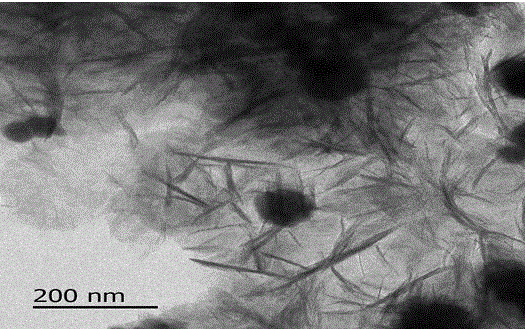

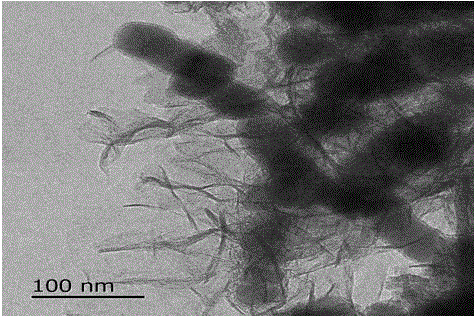

Graphene/silicon dioxide/nano zero-valent iron composite as well as preparation method and application thereof

ActiveCN105457597ARich reservesLow priceOther chemical processesWater/sewage treatment by sorptionArsenic pollutionSilicic acid

The invention discloses a graphene / silicon dioxide / nano zero-valent iron composite as well as a preparation method and application thereof. The preparation method comprises the following steps: after the graphene oxide is subjected to ultrasonic dispersion, adding tetraethyl orthosilicate, drying after magnetic stirring is carried out completely, introducing nitrogen in a tubular furnace for calcination, adding deionized water into the solids obtained through calcination, after ultrasonic dispersion, introducing nitrogen and adding ferrous sulfate heptahydrate, after uniform stirring, and adding a reducing agent for reducing so as to obtain black flocculent precipitates after complete reaction, washing, carrying out suction filtration, drying, grinding and screening through a sieve so as to obtain the graphene / silicon dioxide / nano zero-valent iron composite. The graphene / silicon dioxide / nano zero-valent iron composite prepared according to the preparation method can be applied to the field of water pollution control as an adsorbent, particularly adsorption removal of arsenic pollutants in waste water, and has the advantages of simple and convenient preparation process, high adsorption speed and the like, and in addition, the required raw materials are wide in source, low in cost and high in practical application value.

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com