Graphene/silicon dioxide/nano zero-valent iron composite as well as preparation method and application thereof

A nano-zero-valent iron and silicon dioxide technology, applied in chemical instruments and methods, water/sludge/sewage treatment, other chemical processes, etc., can solve the problems of limiting the application of graphene, losing specific surface area, etc., and achieve abundant reserves , Improve the specific surface area and stability, and prevent the effect of agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

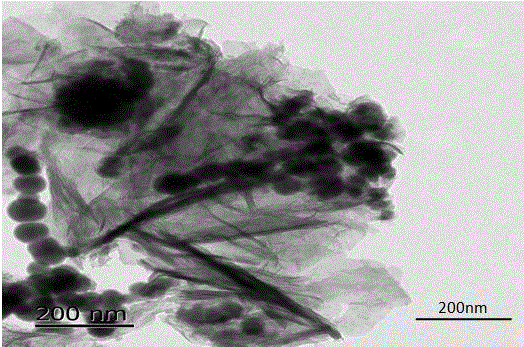

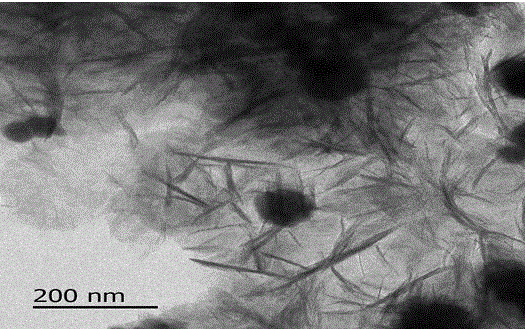

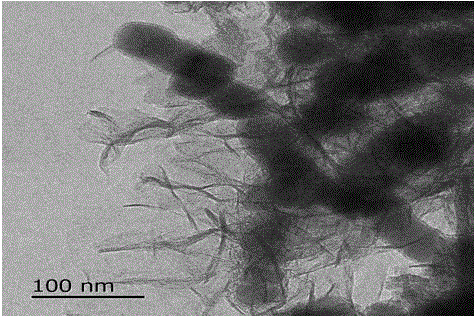

Image

Examples

Embodiment 1

[0040] (1) Add 0.3g of graphite oxide solid, 1.5g of cetyltrimethylammonium bromide and 0.9g of sodium hydroxide into water, and obtain modified graphene oxide with a concentration of 0.3g / L after ultrasonic treatment at 180W for 2h suspension;

[0041]Graphite oxide in this example is prepared by the improved Hummers method. The specific steps are: slowly add 120ml of concentrated sulfuric acid to a 1000mL beaker and place it in a mixture of ice and water, stir it slowly with an electric stirrer, and when the temperature drops When the temperature reaches about 5°C, add 5g of graphite and 2.5g of sodium nitrate, stir for 30 minutes and slowly add 15g of potassium permanganate, keep the temperature of the reaction system not higher than 15°C during the process, and continue the reaction for 90 minutes; place the beaker at 35°C In a constant temperature water bath, when the temperature of the system rises to 35°C, continue to stir for 30 minutes; continuously and slowly add 230...

Embodiment 2

[0047] (1) Add 0.2g of graphite oxide solid, 1.0g of cetyltrimethylammonium bromide and 0.6g of sodium hydroxide into water, and obtain modified graphene oxide with a concentration of 0.2g / L after ultrasonic treatment at 190W for 2h suspension;

[0048] (2) After the modified graphene oxide suspension obtained in step (1) is magnetically stirred for 2h, add 14mL tetraethyl orthosilicate, and the mass ratio of graphene oxide and tetraethyl orthosilicate is 1:13; continue Stir for 36 hours, and keep the temperature at 40°C. After fully reacting, the product is centrifugally washed with deionized water until the product does not contain bromide ions, and the graphene oxide / silica solid is obtained after drying;

[0049] (3) The solid obtained in step (2) is put into a tube furnace and fed with nitrogen for calcination, the nitrogen flow is controlled at 40mL / min, the tube furnace calcination temperature is 550°C, and the calcination time is 180min to obtain graphene / di Silica so...

Embodiment 3

[0054] (1) Add 0.4g of graphite oxide solid, 2g of cetyltrimethylammonium bromide and 1.2g of sodium hydroxide into water, and obtain a modified graphene oxide suspension with a concentration of 0.4g / L after ultrasonic treatment at 200W for 2h liquid;

[0055] (2) After the modified graphene oxide suspension obtained in step (1) is magnetically stirred for 2h, add 20mL tetraethyl orthosilicate, and the mass ratio of graphene oxide and tetraethyl orthosilicate is 1:17; continue Stir for 40 hours, and keep the temperature at 40°C. After fully reacting, the product is centrifugally washed with deionized water until the product does not contain bromide ions, and the graphene oxide / silica solid is obtained after drying;

[0056] (3) put the solid obtained in step (2) into a tube furnace and feed nitrogen for calcination, the nitrogen flow rate is controlled at 60mL / min, the tube furnace calcination temperature is 550°C, and the calcination time is 180min to obtain graphene / di Sili...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com