Nanometer cerium oxide hydrate-based arsenic removing material, preparation method thereof and application in arsenic removing

A cerium oxide and hydration technology, applied in the field of nano-hydrated cerium oxide-based adsorption materials and their preparation, can solve problems such as excessive arsenic in water, and achieve the effects of wide applicable pH range, stable performance and high adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

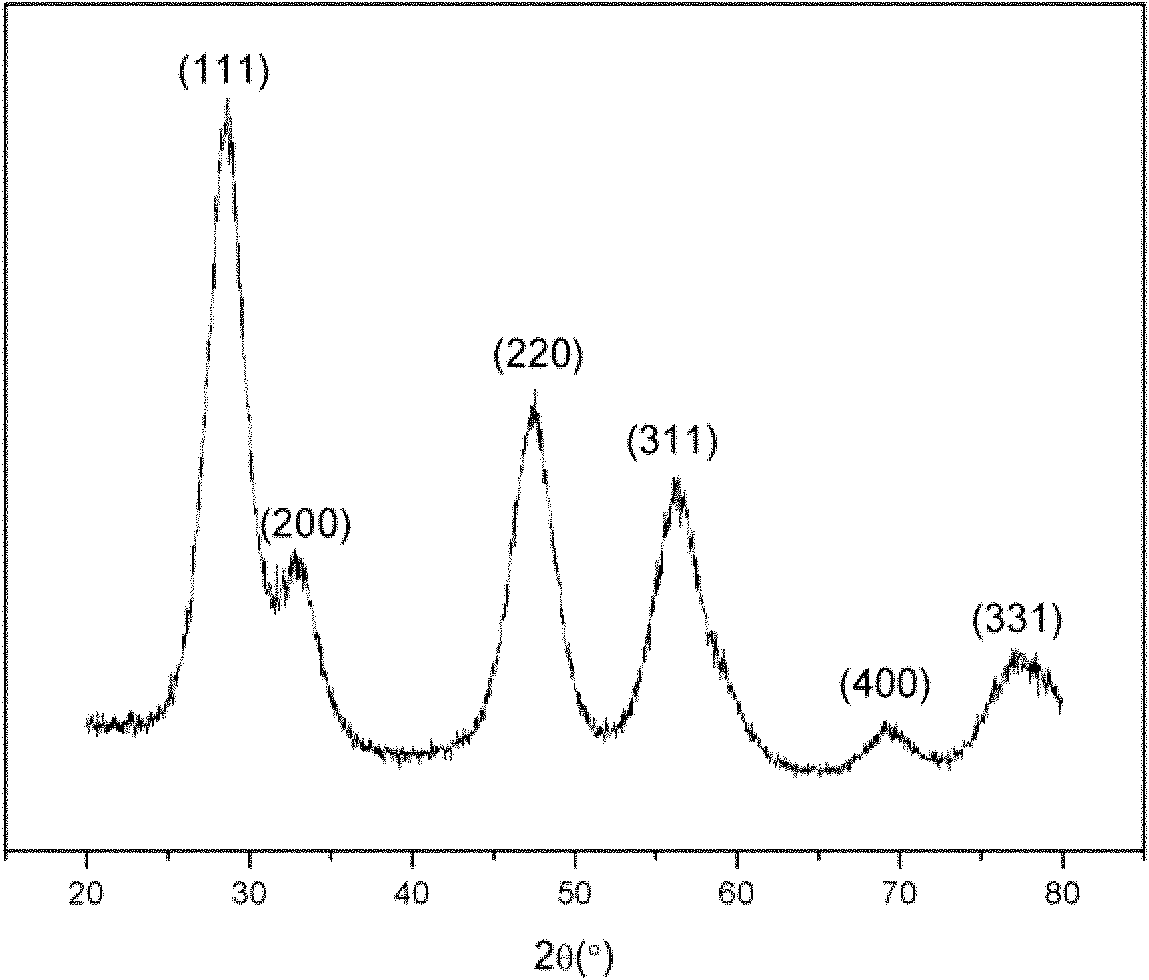

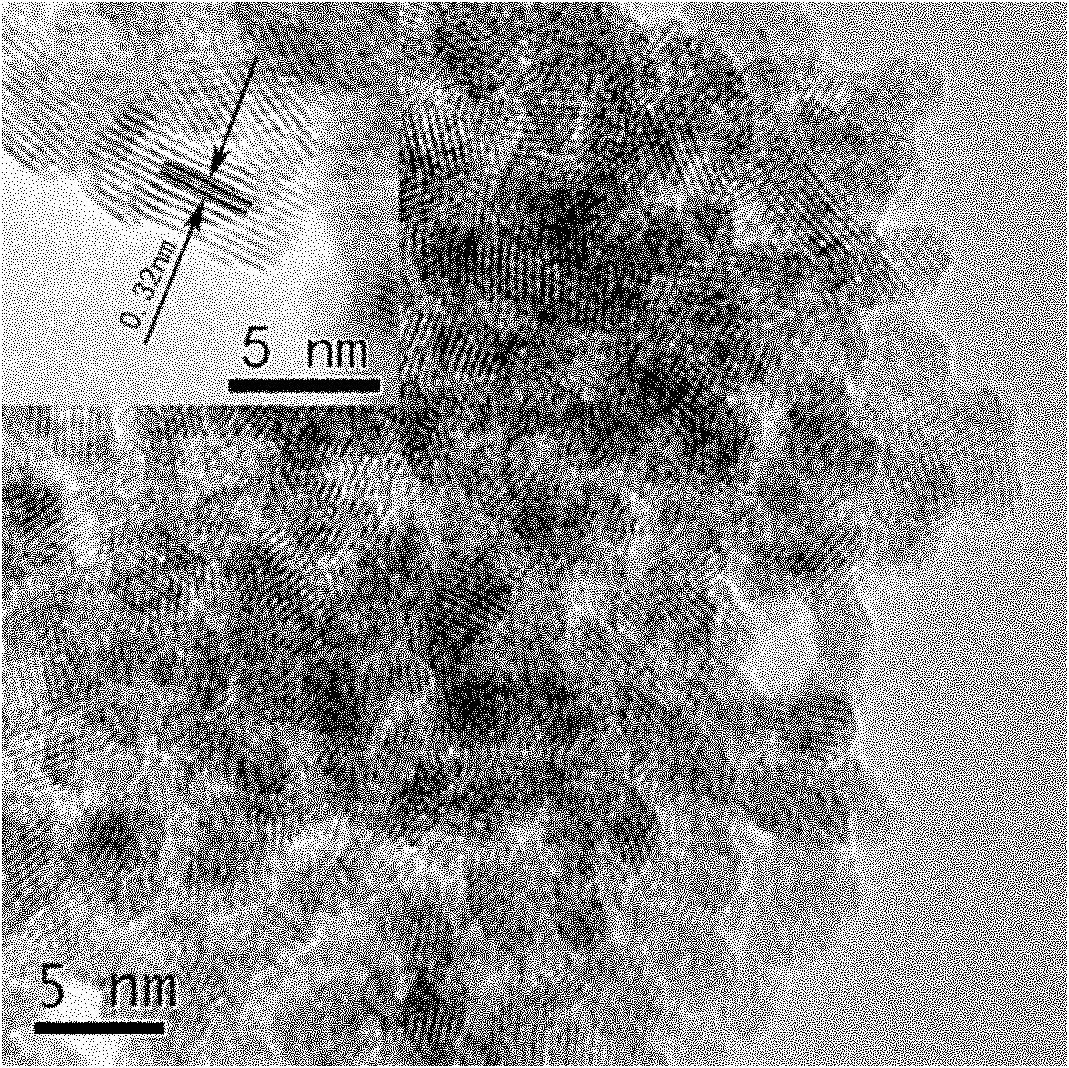

[0033] Dissolve 2.17g of cerium nitrate hexahydrate in 200ml of absolute ethanol solution, add 0.8g of sodium hydroxide after stirring for 10 minutes, then stir for 20 minutes, the precipitate turns from dark brown to bright yellow. The obtained precipitate was washed to neutrality with secondary deionized water, then soaked in absolute ethanol, stirred to remove water, and then dried at 100° C. for 10 hours to obtain arsenic-removing nano-hydrated cerium oxide material. From figure 1 As can be seen from the shown XRD result, what the present invention makes is hydrated cerium oxide, and particle diameter is about 4nm, and figure 2 The high-resolution TEM results shown are consistent.

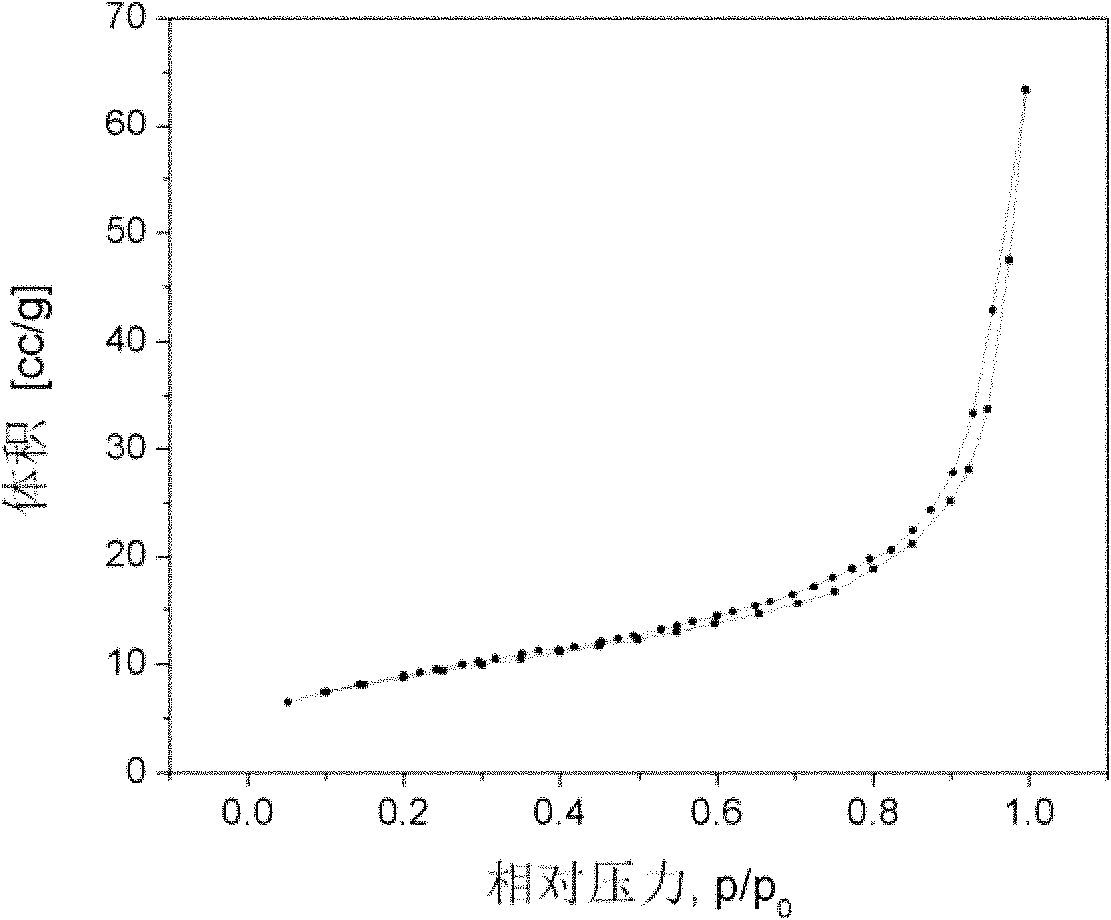

[0034] image 3 It is the nitrogen adsorption-desorption curve of the nano hydrated cerium oxide prepared by the present invention, and the specific surface area obtained by the test is 198m 2 / g.

[0035] The obtained nano-hydrated cerium oxide was used to make the arsenic adsorption isot...

Embodiment 2

[0038] Dissolve 2.17g of cerium nitrate hexahydrate in 200ml of absolute ethanol solution, add 0.8g of sodium hydroxide after stirring for 10 minutes, then stir for 20 minutes, the precipitate turns from dark brown to bright yellow. Wash the obtained precipitate with deionized water to neutrality, soak the precipitate in absolute ethanol, stir to remove water, and dry at 100° C. for 10 hours to obtain a cerium-based arsenic-removing material. The cerium-based arsenic-removing material was ultrasonically dispersed in 200 mL of deionized water, and the glass fiber cloth was soaked in it for about 1 minute, then taken out, and dried at 100°C for 3 hours to obtain the glass fiber cloth loaded with cerium oxide, and the obtained glass fiber cloth loaded with cerium oxide The cloth is impregnated several times to obtain the glass fiber cloth loaded with cerium oxide for many times. Weighing the glass fiber cloth before and after loading can calculate the loading capacity of the mate...

Embodiment 3

[0046] Soak activated alumina (spherical, diameter 3-5mm) in different concentrations of cerium nitrate aqueous solution (0.1M, 0.2M, 0.5M, 2M) for 5 hours, remove activated alumina and dry at 60°C for 12 hours, 450 ℃ for 1 hour to obtain activated alumina loaded with cerium oxide.

[0047] Table 2. Loading capacity and specific surface area of activated alumina loaded with cerium oxide

[0048] al 2 o 3

0.1M

0.2M

0.5M

2M

load (%)

0

4.8

7.6

13.7

15.6

Specific surface area (m 2 / g)

231.7

215.4

210.8

180.8

146.7

[0049] The sample with 15.6% loading of cerium oxide in this example is used for dynamic penetration test, and the activated alumina loaded with cerium oxide is filled into a glass tube (Φ10×150cm), the flow rate is controlled at 2ml / min, and the initial arsenic The concentration is 60ppb. The effluent was collected at regular intervals, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Saturated adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com