Oil shale ash and fly ash co-doped mineral aggregate concrete and preparation method thereof

A technology for oil shale ash and fly ash is applied in the field of oil shale ash and fly ash compound ore concrete and its preparation, which can solve environmental hazards and restrict the utilization of oil shale slag and fly ash. rate, reduction of concrete strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

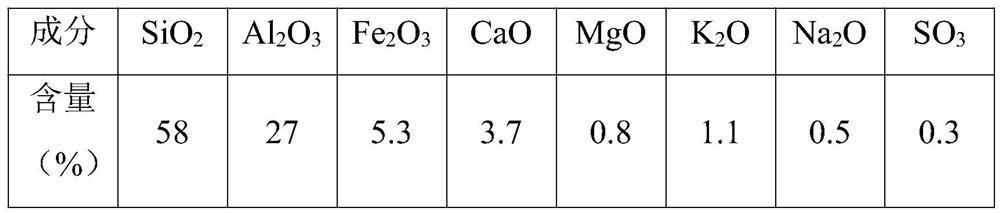

[0036] The amount of raw material for oil shale gray residue and fumifying gas-doped ore concrete is as follows:

[0037] P.O42.5 140 silicate cement, 60 parts of oil shale gray (an average particle size ≤ 20 μm), 100 fly ash, 715 pieces of quartz sand (particle size 20 ~ 200), 1180 gravel, base Osmest agent (NA 2 O) 6 copies of the polycarboxylic acid water decrease (water reduction rate of ≥ 25%), 155 parts of water.

[0038] Preparation method of oil shale gray residue and flour gray mixed ore concrete:

[0039] (1) First, the oil shale gray residue, alkali-activator, and water reducer are added to the cement mixer, add water, stir for 30 min, and make the oil shale ash slag and alkali activator for sufficient reaction;

[0040] (2) Add fly ash and cement, stir for 30 min, so that fly ash and cement are sufficiently reacted with the mixture in step (1);

[0041] (3) Add quartz sand and gravel, stirred for 10 min, mix all raw materials, and produce oil shaft ash and fly ash. Con...

Embodiment 2

[0043] The amount of raw material for oil shale gray residue and fumifying gas-doped ore concrete is as follows:

[0044] P.O42.5 Silicate cement 130 parts, oil shale ash residue (an average particle size ≤ 20 μm), 90 fly ash, quartz sand (particle size 20 ~ 200 mesh) 715 parts, 1100 gravel, base Osmest agent (NA 2 O) 5 copies of the polycarboxylic acid water decrease (water reduction rate of ≥ 25%), and 170 water.

[0045] Preparation method of oil shale gray residue and flour gray mixed ore concrete:

[0046](1) First addition of the oil shaft ash, the alkali-activator, and the water reducer, stir well, add water, stir for 20 min, and mix the oil shale ash and alkali activator.

[0047] (2) Add fly ash and cement, stir for 40min, so that the fly ash and cement are sufficiently reacted with the mixture in step (1);

[0048] (3) Add quartz sand and gravel, stirred for 10 min, mix all raw materials, and produce oil shaft ash and fly ash. Concrete.

Embodiment 3

[0050] P.O42.5 150 silicate cement, 50 parts of oil shale ash residue (average particle size ≤ 20 μm), 110 fly ash, quartz sand (particle size 20 ~ 200 mesh) 750 parts, 1200 gravel, base Excitation agent (K 2 O) 8 copies of the polycarboxylic acid water-water reduction agent (water moisture ratio ≥ 25%), 150 water.

[0051] Preparation method of oil shale gray residue and flour gray mixed ore concrete:

[0052] (1) First addition of oil shaft ash, alkali-activator and water reduction, mix well, add water, stir for 40min, and stir the oil shale ash slag and alkali activator.

[0053] (2) Add fly ash and cement, stir for 20 min, so that fly ash and cement are sufficiently reacted with the mixture in step (1);

[0054] (3) Add quartz sand and gravel, stir for 15 min, mix all the raw materials, and the oil shale gray slag and fly gray-blended oyster reflection.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com