High-damping concrete and preparation method thereof

A technology of concrete and high damping, applied in the field of building materials, can solve the problem that the compressive strength of concrete and the damping ratio cannot have both, and achieve the effect of low price, promoting the hydration process and improving the damping performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The present invention also designs the preparation method of above-mentioned high damping concrete, comprises the following steps:

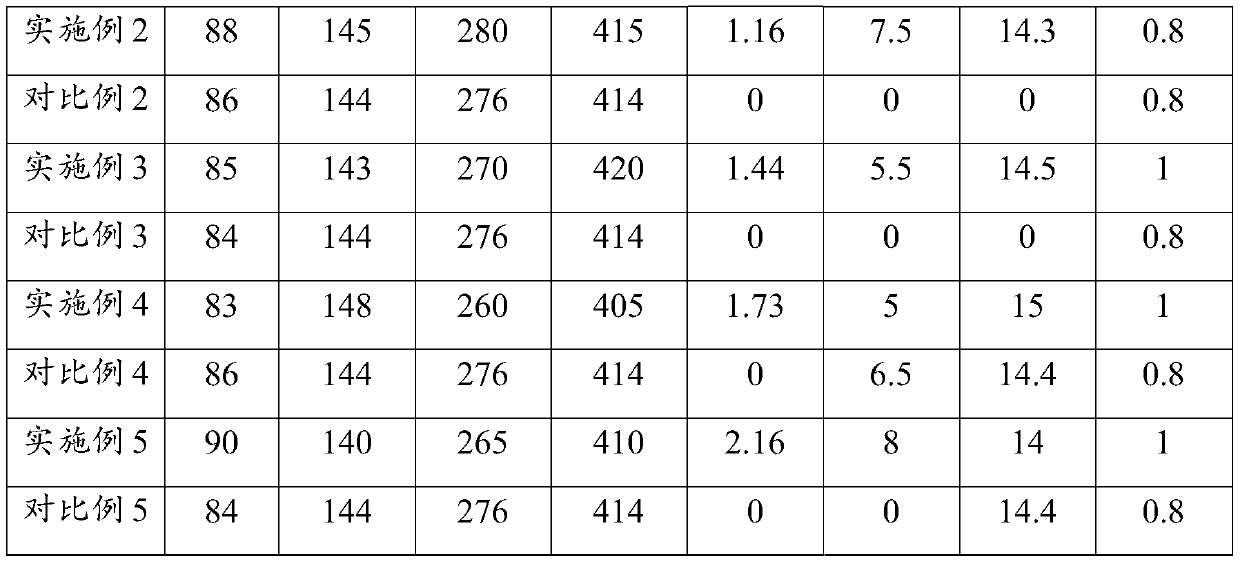

[0035] 1) Weigh each raw material component in proportion, each component and its mass weight part include: 140-150 parts of cement, 260-280 parts of natural river sand, 5-8 parts of rubber powder, 12-12 parts of micro-silica fume 15 parts, 400-420 parts of gravel, 0.58-2.16 parts of polypropylene fiber, 0.8-1 part of water reducer, 80-90 parts of water, the particle size of the gravel is below 40mm;

[0036] 2) Add the cement and polypropylene fiber in the raw material in step 1) and stir evenly until the polypropylene fiber in the mixture has no obvious agglomeration phenomenon, then add the rubber powder and microsilica powder in the raw material in step 1) and stir for 2 to 3 minutes, then Add the natural river sand and gravel in the raw materials in step 1), stir for 2-3 minutes, and finally add the water and water reducing agent in t...

Embodiment

[0039] The present invention adopts the method designed in the present invention to prepare the high-damping concrete of multiple embodiments by adopting different component distribution ratios, and the preparation steps are as follows:

[0040] 1) Weigh each component raw material in proportion, clean the mold and apply a layer of release agent;

[0041] 2) Put the weighed cement and polypropylene fiber into a forced mixer, and stir until the polypropylene fiber is evenly dispersed in the cement without obvious agglomeration;

[0042] 3) Add the weighed rubber powder and silica fume in sequence, and stir for 2-3 minutes;

[0043] 4) Add the weighed natural river sand and gravel in sequence, and stir for 2-3 minutes;

[0044] 5) Add weighed water and water reducer in sequence, and continue to stir for 3 minutes to obtain a concrete mixture;

[0045] 6) Put the obtained concrete mixture into the mold that has been coated with the release agent, place the mold on the vibrating...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com