Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

128results about How to "Promotes hydration process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Foam cement insulation material for exterior wall and preparation method thereof

InactiveCN102942380AShorten the setting timeStrong synergistic effect is obviousCeramicwareSilica fumePortland cement

The invention belongs to the technical field of insulation material for building, and particularly relates to a foam cement insulation material for exterior wall and a preparation method thereof. The foam cement insulation material for exterior wall is prepared from raw materials comprising ordinary portland cement, sulphoaluminate cement, fly ash, silica fume, an expansive agent, a coagulating enhancer, a tackifier, a water-reducing agent, a waterproofing agent, a foaming agent, a foam stabilizer, fiber and water. The preparation method comprises the following steps: (1) first conducting dry mixing on ordinary portland cement, sulphoaluminate cement, fly ash, silica fume and the expansive agent, adding coagulating enhancer, tackifier, water-reducing agent, waterproofing agent, foam stabilizer, water and fiber, and stirring to obtain a slurry; and (2) adding the foaming agent in the slurry, and filling the foamed slurry into a mold. The foam cement insulation material for exterior wall has good fire resistance, long service life, good insulation property, light weight, high strength, low water absorption and good crack resistance.

Owner:刘巧玲

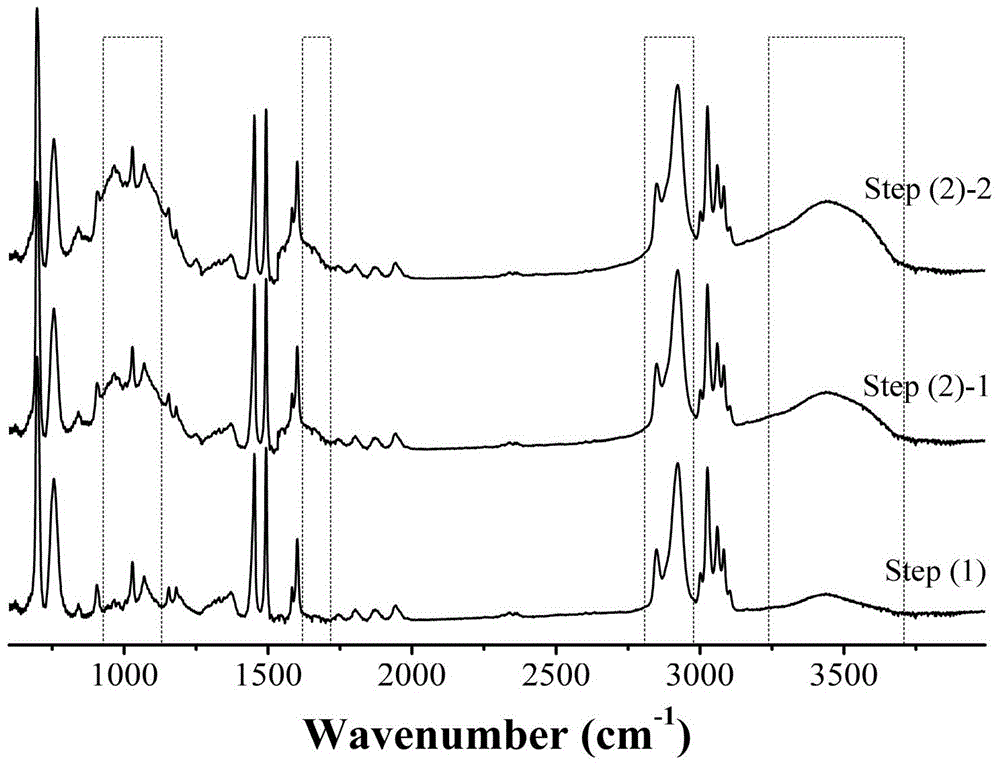

Preparation method for cement auxiliary-grinding strengthener of polyethylene glycol amine ester carboxylic acid system

The invention belongs to the technical field of cement auxiliary-grinding agents, and in particular to a preparation method for a cement auxiliary-grinding strengthener of a polyethylene glycol amine ester carboxylic acid system. The preparation method comprises the following steps: (1) performing esterification reaction on alcohol amines and unsaturated carboxylate in a molar mass ratio to obtain esterification monomers which contain polar groups, such as hydroxyl and carboxyl; (2) adding unsaturated large monomers and water into a reaction container, stirring, heating and dissolving, respectively adding an initiator, the esterification monomers and a chain transfer agent dropwise, preserving the heat after the reaction is performed for a certain period of time, and adjusting the pH of a solution to be neutral after the reaction is completed so as to prepare the cement auxiliary-grinding strengthener of the polyethylene glycol amine ester carboxylic acid system. The cement auxiliary-grinding strengthener fully plays the action mechanism of the polar functional groups, such as the hydroxyl and the carboxyl, on cement; when the using amount is 0.01 to 0.1 percent of the mass of the cement, the yield each grinding machine per hour is improved by 12 to 25 percent, the 3-day strength of the cement can be increased by 2 to 5 MPa, the 28-day strength of the cement can be increased by 4 to 8 MPa, and the aims of stable performance and remarkable effects of auxiliary grinding and strengthening are fulfilled.

Owner:KZJ NEW MATERIALS GROUP CO LTD

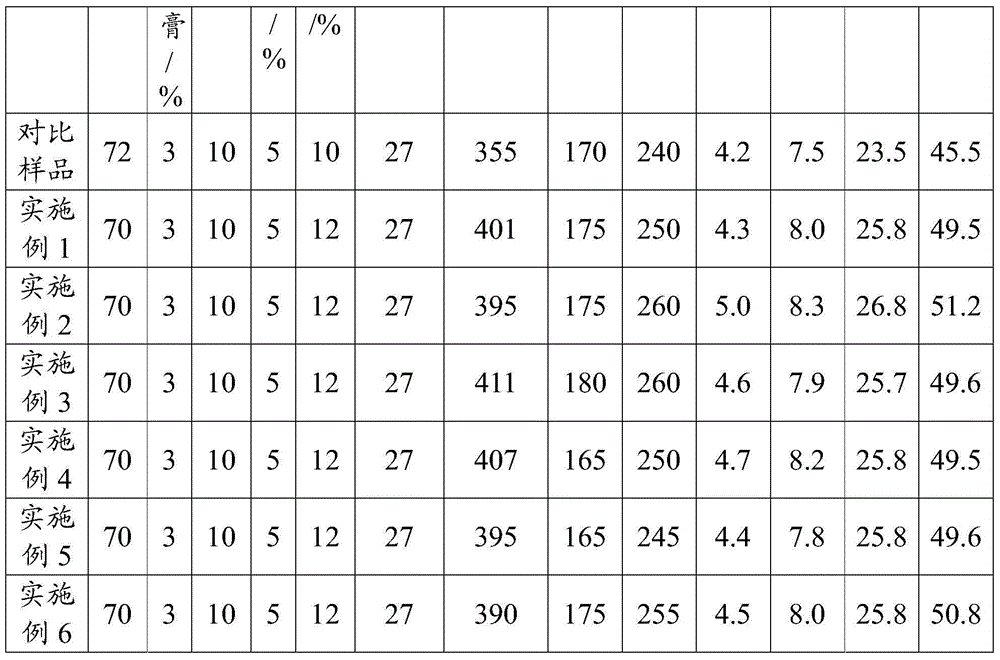

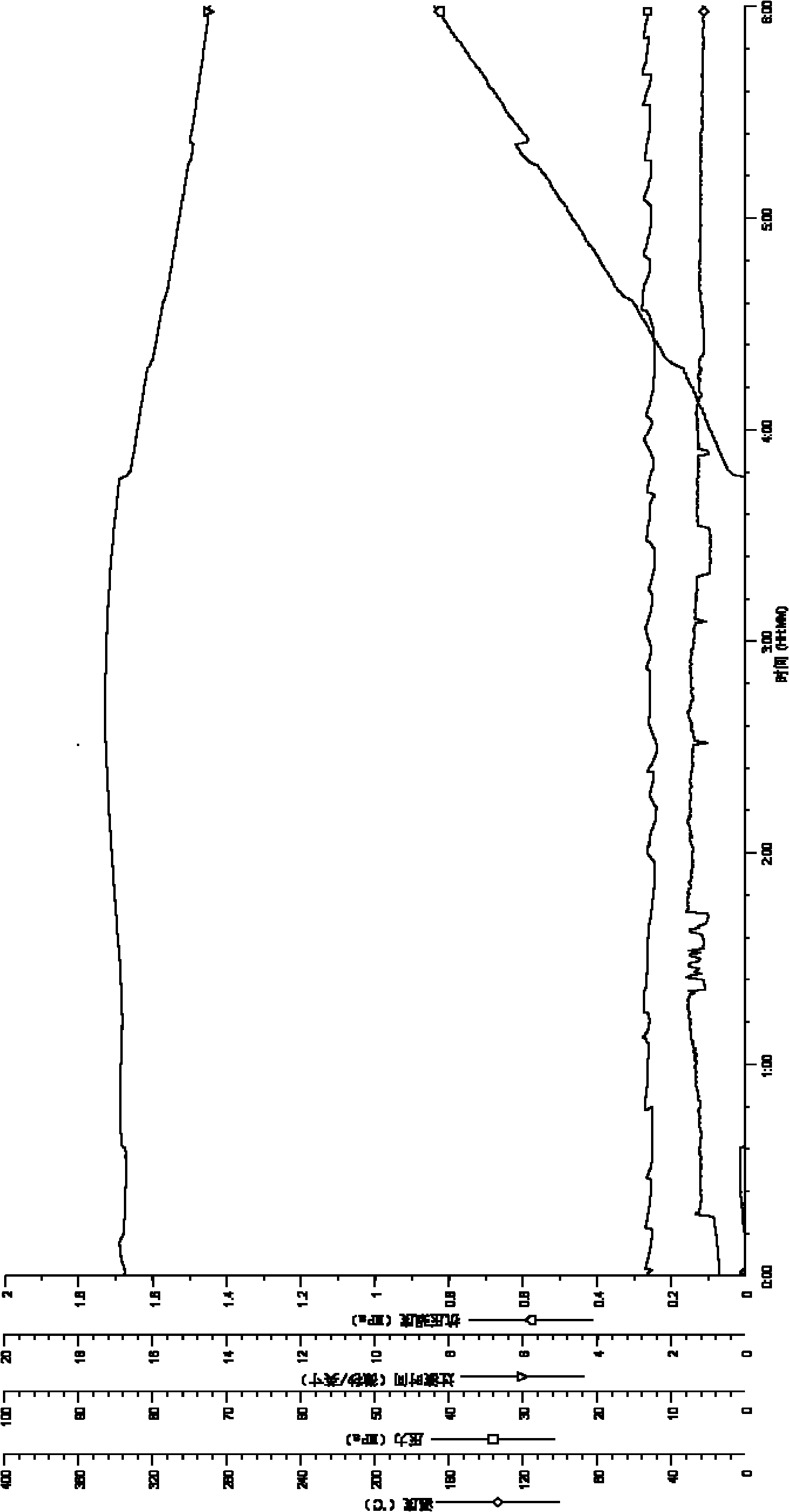

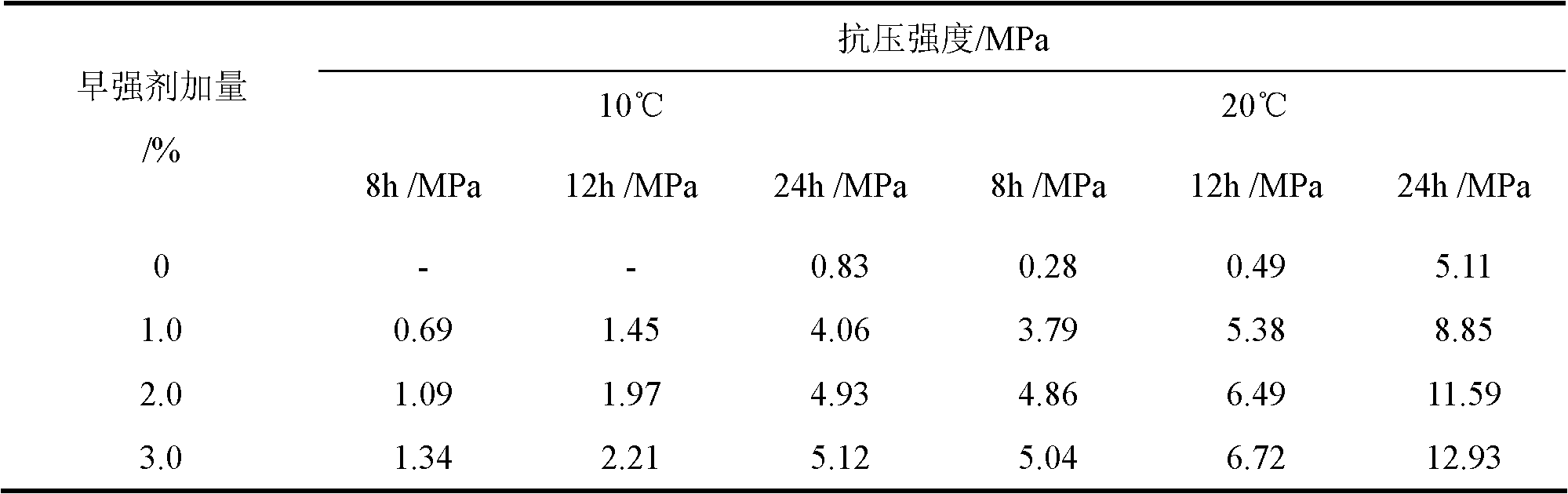

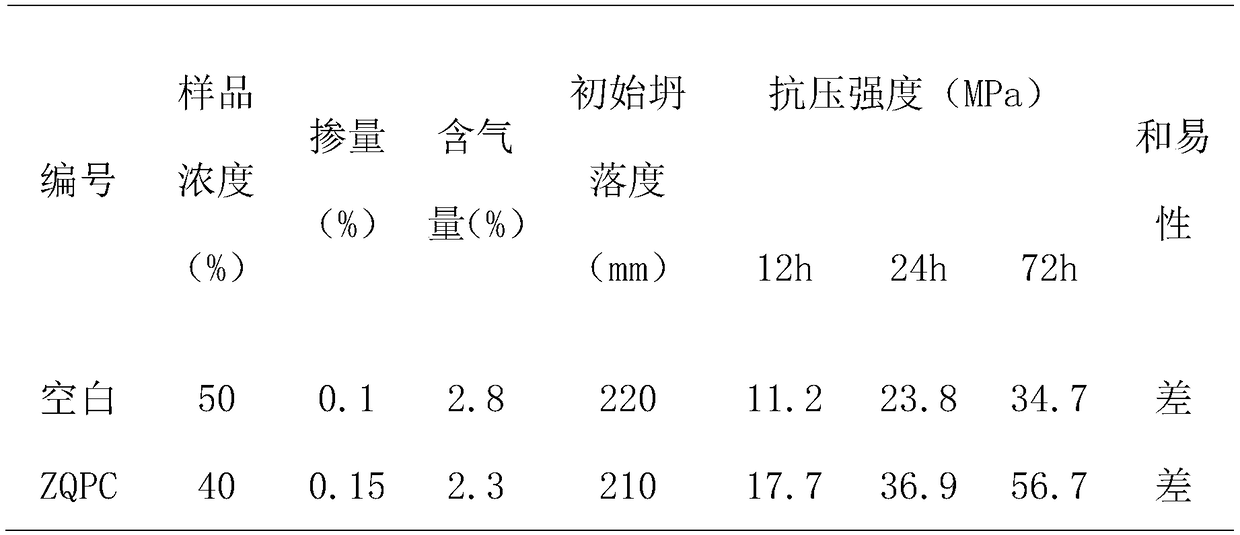

Deepwater cementing low-temperature early strength agent

InactiveCN101864285APromotes hydration processImprove compactnessDrilling compositionTriisopropanolamineCement paste

The invention relates to a deepwater cementing low-temperature early strength agent. The low-temperature early strength agent comprises the following components in percentage by weight: 33 to 66 percent of alkali metal bromides, 6 to 16 percent of sodium metaaluminate, 15 to 35 percent of alkali metal hydroxides, 8 to 15 percent of silicon dioxide and 0.8 to 1.5 percent of alcamines organics, wherein the alkali metal bromides are a mixture of one, two or more of NaBr, KBr and LiBr; the alkali metal hydroxides are NaOH, KOH or a mixture of the NaOH and KOH; and the alcamines organics are triethanolamine, triisopropanolamine or a mixture of the triethanolamine and triisopropanolamine. The deepwater cementing low-temperature early strength agent has small influence on rheological behaviour of cement paste at low temperature, can prompt the cement paste to be solidified rapidly at low temperature and reach higher early strength, shortens the thickening time of the cement paste at lower temperature and can well meet the requirements of the cementing construction of a surface casing under the conditions of low temperature, shallow gas and the like.

Owner:SOUTHWEST PETROLEUM UNIV

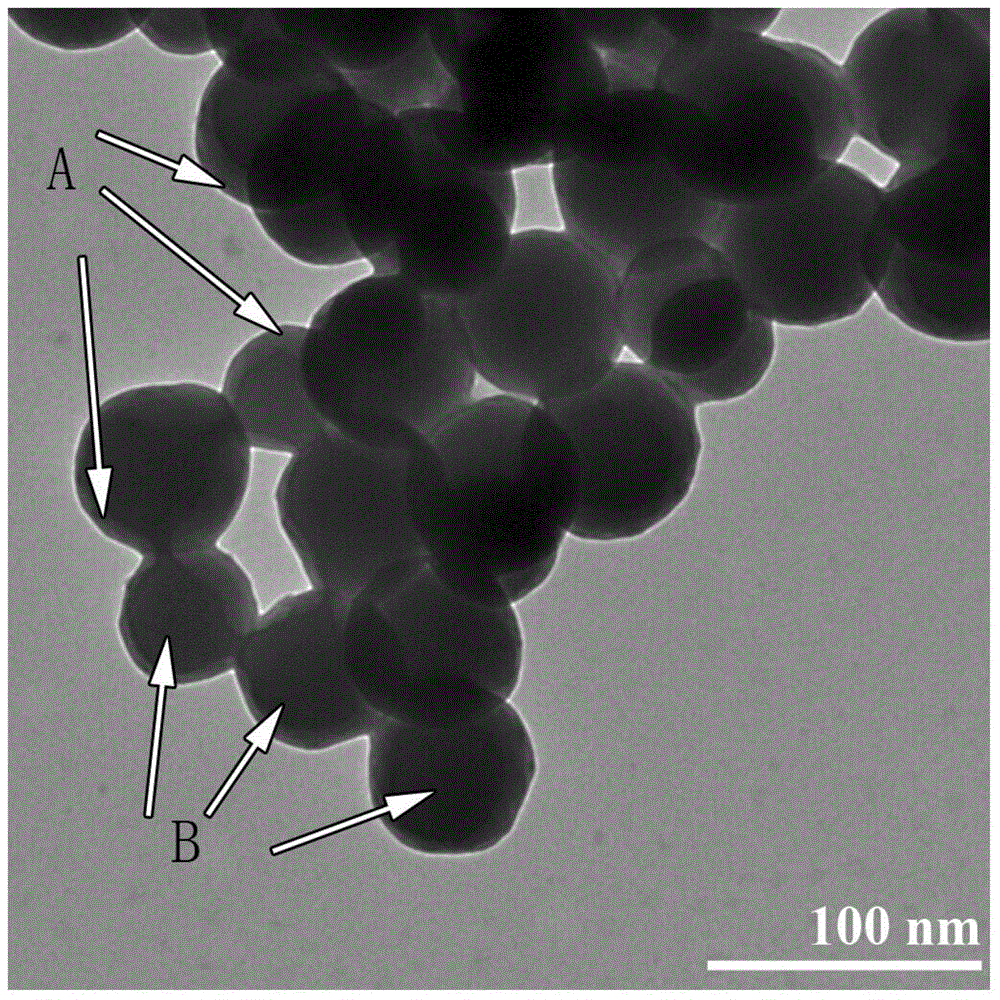

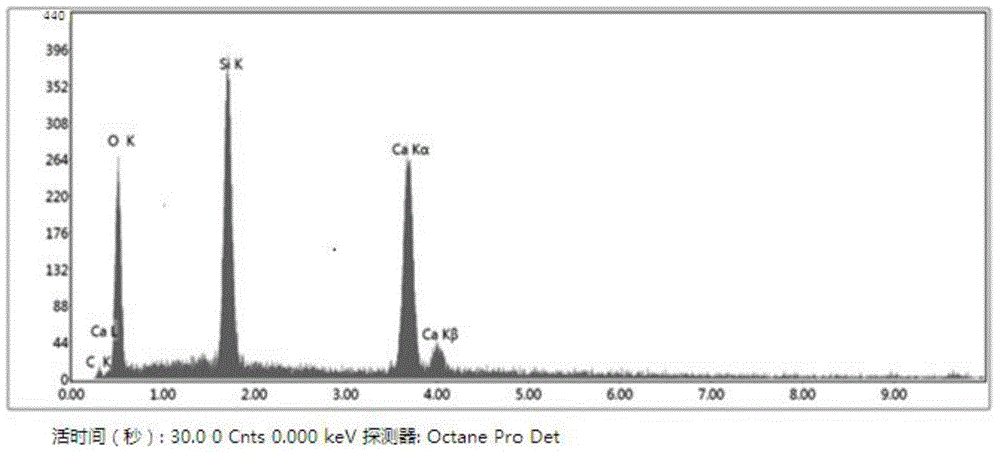

Additive capable of improving bending strength and tensile strength of cement base material and its preparation method

The invention discloses an additive capable of improving bending strength and tensile strength of a cement base material. The additive is an aqueous dispersion of organic-inorganic hybrid particles with core-shell structures. Each organic-inorganic hybrid particle is composed of inner and outer layers, wherein the inner layer is an organic polymer core; the outer layer is an inorganic composite oxide or an inorganic composite oxide covalently connected with an organic functional group; the inorganic composite oxide is a silicon-calcium composite oxide or a silicon-magnesium composite oxide or a silicon-calcium-magnesium composite oxide; and the outer layer is in covalent connection with an electronegative organic polyelectrolyte internally. Compared to the mixing amount of a polymer or polymer fiber in a pure polymer-modified cement base material or a polymer fiber-modified cement base material, the mixing amount of the additive in the cement base material can be greatly reduced; and the additive can more obviously improve the splitting tensile and bending resistant performances of the cement base material in comparison with a traditional polymer emulsion in the same mixing amount. Therefore, the additive overcomes the disadvantage that the high polymer mixing amount of the traditional polymer modified cement base material affects the compressive strength of the cement base material, and can effectively improve the bending strength and tensile strength (or splitting tensile strength) of the cement base material.

Owner:JIANGSU SOBUTE NEW MATERIALS

Magnesium oxychloride fiber light wallboard

InactiveCN103979921AAvoid the phenomenon of moisture absorption and return to halogenHigh strengthSolid waste managementCompressive resistanceSlag

The invention provides a magnesium oxychloride fiber light wallboard, and relates to the wallboard field in the construction materials. The wallboard is composed of the following components in parts by weight: 40 to 60 parts of magnesium chloride water solution, 20 to 30 parts of magnesium oxide, 0.1 part of fly ash, 0.2 part of slag, 0.5 part of construction waste, 0.1 part of waste ceramic, 2 parts of short glass fiber, 2 parts of straw, 2 parts of saw dust, 3 parts of perlite, and 0 to 2 parts of modifier. The formula of the wallboard comprises industrial and agricultural wastes such as fly ash, slag, mineral slag, construction wastes, broken ceramics, straws, and saw dust, thus the wastes are fully recycled and reutilized, and moreover the using amount of sands and stones is reduced, so the destroy on mountain and river bed is avoided, resources are saved, and environment is protected. The prepared magnesium oxychloride fiber light wallboard has the advantages of good water resisting property, high compressive strength, good freeze resisting performance, good acid / alkali resistant property, no halogen appearance, no scumming, and no deformation.

Owner:四川省元程中博能源开发有限公司

Foamed cement heat insulating material for exterior wall and preparation method thereof

The invention relates to a foamed cement heat insulating material for an exterior wall. The foamed cement heat insulating material is prepared by using the following raw materials in parts by weight: 150-250 parts of sulphoaluminate cement, 0-0.5 part of water reducing agent, 2-5 parts of waterproof agent, 7-13 part of foaming agent, 0.5-3 parts of foam stabilizer, 0.5-3 parts of fiber and 60-135 parts of water. The foamed cement heat insulating material for the exterior wall has the advantages of high economy and practicability, light weight, high strength, good heat insulating performance, high waterproof, fireproof and anti-freezing performance and long service life.

Owner:薛一冰

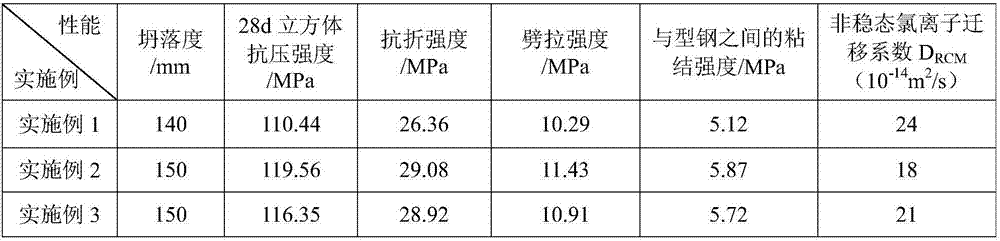

Ultrahigh strength high-performance fiber concrete at C160 strength grade and preparation method thereof

ActiveCN107382205APrevent pulling outImprove energy consumptionSolid waste managementModified carbonCarbon nanotube

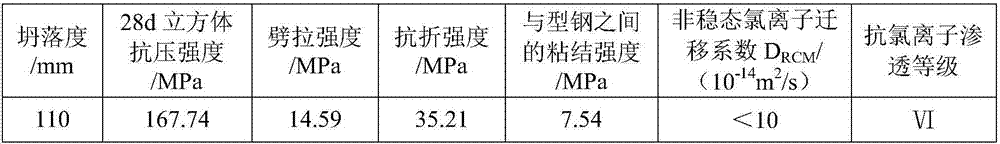

The invention discloses an ultrahigh strength high-performance fiber concrete at C160 strength grade and a preparation method thereof. The concrete comprises the following components in parts by weight: 485 parts of cement, 82 parts of water, 1000 parts of macadam, 750 parts of fine aggregate, 70 parts of coal ash, 73 parts of rice hull ash, 102 parts of silica fume, 14.0 parts of water reducer, 9.5 parts of excitant, 1.6 parts of cellulosic fiber, 40 parts of hydroxy modified carbon nano tube dispersion liquid, 37 parts of graphene oxide dispersion liquid and 2.6 parts of de-foaming agent. The prepared concrete has higher toughness, durability, higher bonding strength with profile steel, compressive strength reaching up to 167.74MPa, breaking strength reaching up to 35.21MPa, splitting strength reaching up to 14.59MPa, bonding strength with profile steel reaching up to 7.54MPa and chloride penetration resistance grade at VI-grade. When the ultrahigh strength high-performance fiber concrete is applied to a profile steel concrete combined structure, the cooperative working property between the profile steel and the concrete is effectively exerted and the defects of poor bonding property of the profile steel and the concrete and incapability of fully utilizing the respective mechanical properties of the profile steel and the concrete can be overcome.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Alkali-activated and nano-enhanced early strength type ultra-high performance concrete and preparation method thereof

The invention discloses a preparation method of alkali-activated and nano-enhanced early strength type ultra-high performance concrete. The concrete is characterized in that the formula comprises theproduction raw materials in parts by mass: 650-720 parts of Portland cement, 95-130 parts of silica fume, 165-185 parts of mineral powder, 5-10 parts of nano silicon dioxide, 1050-1075 parts of quartzsand, 96-128 parts of straight steel fibers, 24-32 parts of torsional steel fibers, 13.725-15.54 parts of water glass with modulus of 1.2-1.3, 13.75-18.13 parts of a water reducing agent and 154.7-202 parts of water. The method has the advantage that the liquidity and early strength of the ultra-high performance concrete are remarkably improved.

Owner:成都宏基建材股份有限公司

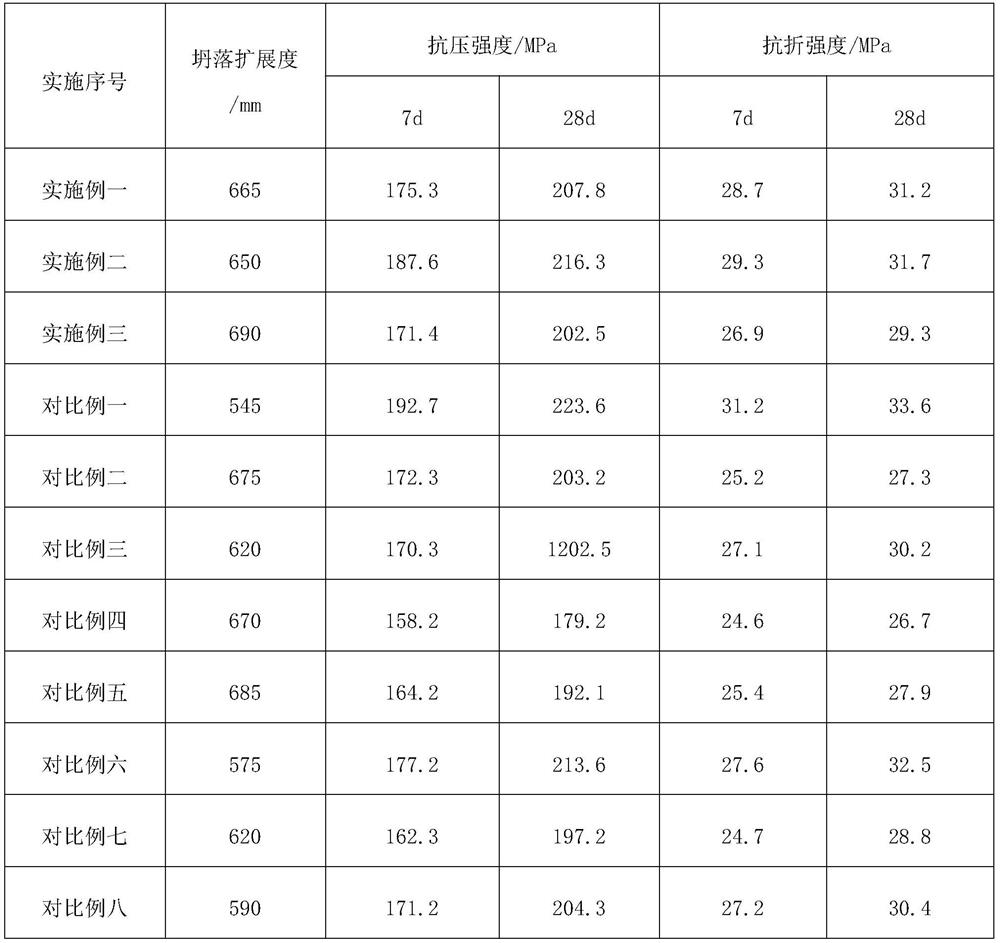

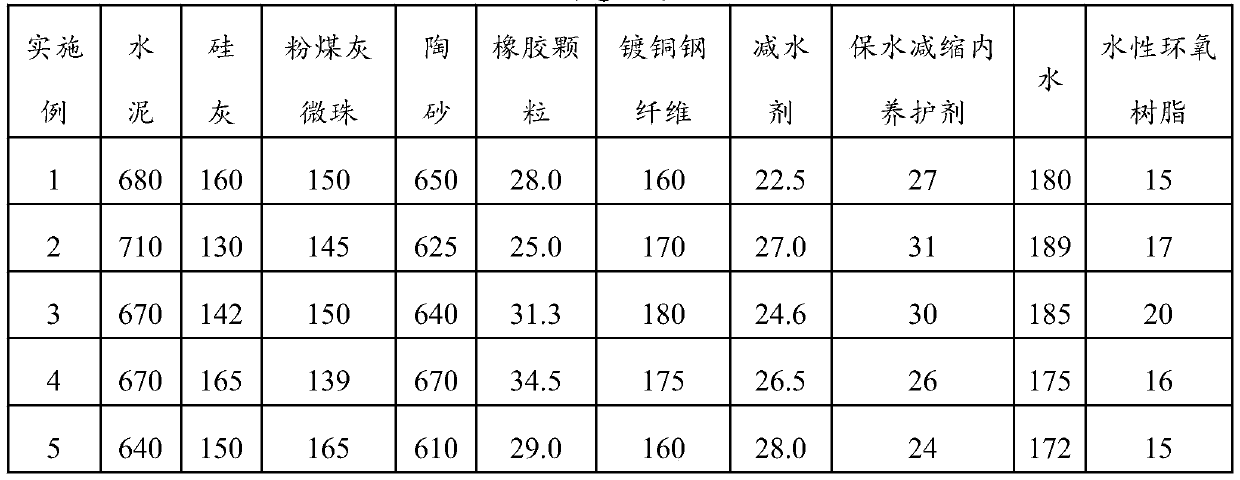

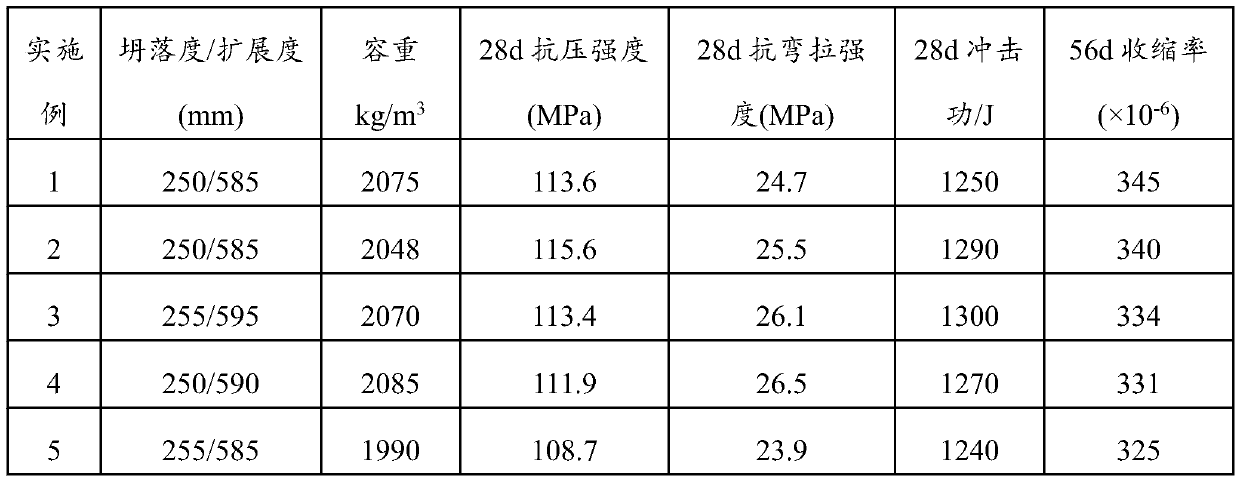

Modified rubber particle lightweight ultra-high performance concrete and preparation method thereof

The invention discloses modified rubber particle lightweight ultra-high performance concrete and a preparation method thereof. The concrete is prepared from cement, fly ash microbeads, silica fume, pottery sand, rubber particles, copper-plated steel fibers, waterborne epoxy resin, a water-retaining shrinkage-reducing internal curing agent, a water reducing agent and water as main raw materials, wherein the rubber particles are prepared by crushing waste tires and then modifying the crushed waste tires. The modified rubber particle lightweight ultra-high performance concrete has the advantagesof light weight, high strength, high impact toughness, abrasion resistance and good volume stability, and has practical application value.

Owner:CHINA STATE CONSTR READY MIXED CONCRETE CO LTD +1

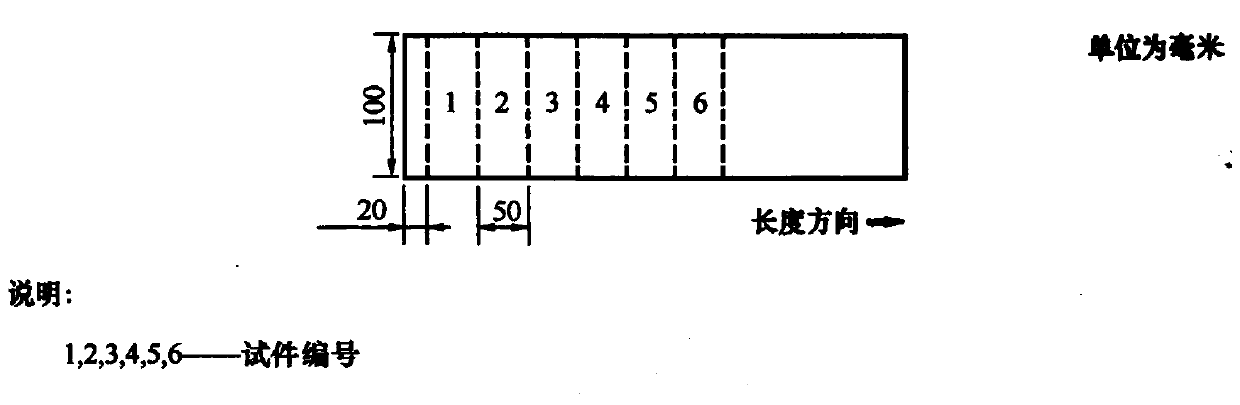

Coarse-aggregate-containing C240-strength-grade ultrahigh-performance fiber concrete and preparation method

ActiveCN107285708AImprove toughnessImprove deformation abilitySolid waste managementModified carbonCellulose fiber

The invention discloses coarse-aggregate-containing C240-strength-grade ultrahigh-performance fiber concrete and a preparation method. The concrete is composed of, by mass, 578 parts of cement, 62 parts of water, 880 parts of rubble, 800 parts of fine aggregate, 70 parts of coal ash, 60 parts of rice husk ash, 154 parts of silicon ash, 16.5 parts of water reducer, 11.5 parts of excitant, 1.7 parts of cellulosic fiber, 90 parts of steel fiber, 51 parts of hydroxyl modified carbon nanotube dispersion, 54 parts of oxidized graphene dispersion and 2.9 parts of defoamer. The concrete prepared by the method has high toughness and durability and has high binding strength with section steel, compressive strength reaches 249.65MPa, bending strength reaches 50.88MPa, splitting tensile strength reaches 24.78MPa, the binding strength with the section steel reaches 10.54MPa, and chlorion anti-permeation grade reaches VI grade. When the concrete is used in a section steel and concrete combined structure, cooperative working performance between the section steel and the concrete can be brought into play effectively, and the defects that the section steel and the concrete are poor in binding performance and respective mechanical performance of the section steel and the concrete cannot be brought into full play are made up.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Amphoteric early-strength polycarboxylate superplasticizer mother solution for C30 concrete

The invention provides an amphoteric early-strength polycarboxylate superplasticizer mother solution for C30 concrete. The polycarboxylate superplasticizer mother solution comprises, by weight, 330-339 parts of polyether macromonomers with the molecular weight being 4000, 22-25 parts of acrylic acid, 11-18 parts of quaternary ammonium and quaternary phosphorus cation micromonomers, 2-5 parts of 27.5% industrial-grade hydrogen peroxide, 3-6 parts of unsaturated sulfonate, 2-4 parts of phosphate functional monomers, 4-8 parts of amide micromonomers, 0.4-1 part of reducing agent, 6-12 parts of caustic soda liquid, 0.4-0.8 part of chain transfer agent and the balance water, wherein the total weight of the components is 1000 parts. The mass fraction of the polycarboxylate superplasticizer mother solution is 40%, and the acid-ether ratio of the mother solution is controlled to be 3.7-4.1. Compared with relatively-low-molecular-weight polyether macromonomers such as polyether macromonomers with the molecular weight being 2400 used by existing common polycarboxylate superplasticizers, the polyether macromonomers with the molecular weight being 4000 and used by the polycarboxylate superplasticizer mother solution have cost advantages and can meet the production requirements of low cost and high effectiveness.

Owner:HUBEI UNIV OF TECH

High anti-penetration concrete mixing material for tunnel shield tube plate and its preparation method

InactiveCN101007715AMeet the needs of the actual production processMeet the needs of impermeabilitySolid waste managementSlagWollastonite

The invention discloses a blending material and making method of shield-driven gilled tube concrete, which comprises the following parts: 25%-40% mineral slag, 40%-50% coal ash, 15%-25% wollastonite and 3%-6% functional regulating component, wherein the functional regulating component is composed of 36-40% reinforcer, 48-51% waterproofing agent and 10-15% flexibilizer.

Owner:WUHAN UNIV OF TECH

Inorganic grouting blocking material

The invention discloses an inorganic grouting blocking material, and belongs to the technical field of blocking materials. The inorganic grouting blocking material is prepared from, by mass, 75-90 parts of portland cement clinker, 3-10 parts of slag, 5-15 parts of sulphoaluminate cement, 0.5-4 parts of bentonite, 0.05-0.2 part of hydroxyethyl cellulose ester, 0.25-0.5 part of a water reducing agent, 0.005-0.1 part of lithium carbonate and 0.05-0.5 part of defoaming agent. The blocking material is mainly suitable for grouting leakage blocking of rock and soil layers, is particularly suitable for grouting leakage blocking projects for water burst in dam foundations and other parts, and has the advantages of being good in blocking effect, high in post-blocking strength, good in bonding aggregation performance and not capable of dispersing underground.

Owner:JIAHUA SPECIAL CEMENT

Nano cement-based crystal-nucleated early strength agent and preparation method and application thereof

ActiveCN110304857AAchieve the goal of early strengthGood compatibilityNanotechnologyAlkali–aggregate reaction

The invention provides a nano cement-based crystal-nucleated early strength agent and a preparation method and application thereof. The nano cement-based crystal-nucleated early strength agent mainlycomprises, by weight, 20-35 parts of cement, 1-3 parts of a dispersant, 0.5-1 part of a retarder, and 64.5-79.5 parts of water. Nano cement is used to provide a crystal nucleus for hydrating of the cement-based material herein, the crystal nucleus induces rapid hydration of the cement-based material; after the nano cement is added to the cement-based material, pore structure and induced nucleatingcan be improved to arrive at early strength; in addition, no harmful ions are introduced, the early strength agent herein is well compatible with cement and never causes alkali-aggregate reaction, scumming and the like.

Owner:WUHAN UNIV OF TECH

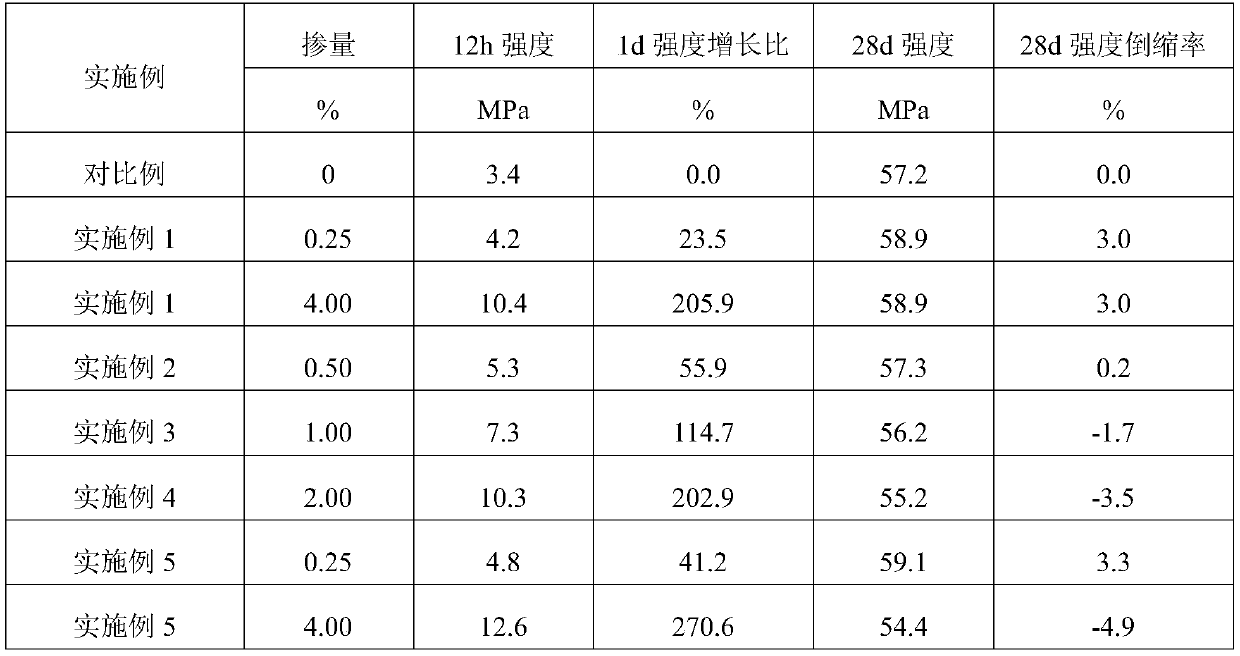

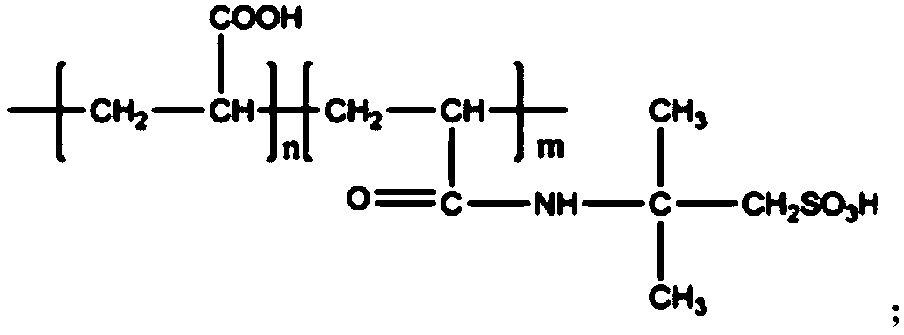

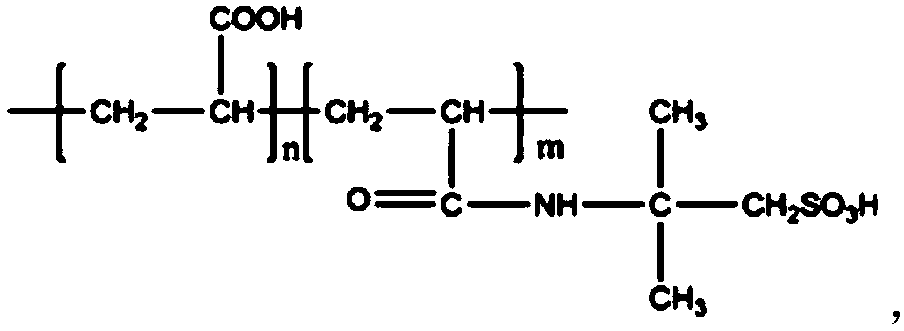

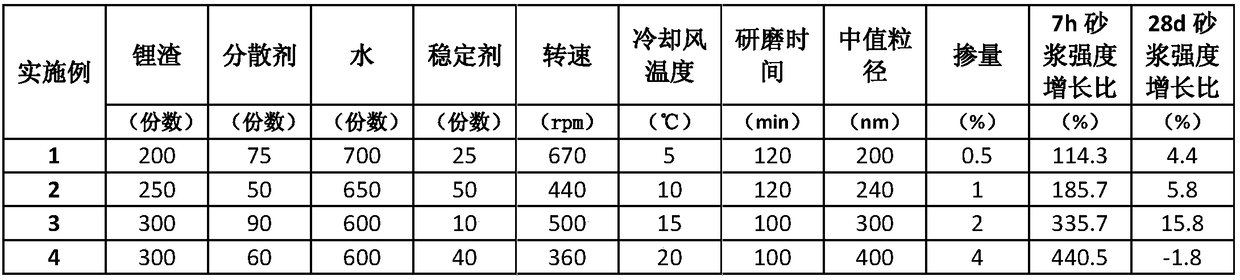

Early strength agent using nanometer lithium slag for sulphoaluminate cement and preparation method thereof

The invention relates to an early strength agent using nanometer lithium slag for sulphoaluminate cement and a preparation method thereof. The early strength agent is prepared from the following raw materials and components in percentage by mass: 20 to 30% of lithium slag, 5 to 9% of dispersant, 1 to 5% of stabilizer, and 60 to 70% of deionized water. The preparation method comprises the followingsteps of adding the lithium slag, the dispersant, the stabilizer and the deionized water into a planetary ball mill according to a ratio, adding zirconium oxide grinding balls, and performing ball grinding, so as to obtain the early strength agent using the nanometer lithium slag for sulphoaluminate cement, wherein the medium particle size is 200 to 400nm. The early strength agent using the nanometer lithium slag is doped into the sulphoaluminate cement according to the doping amount of 0.5 to 4.0%, the 7d strength of the mortar of the sulphoaluminate cement can be increased by 110 to 140%, and the later strength can avoid shrinkage. The preparation method has the advantages that the technology process is simple, and the technology parameters are easy to control; the used lithium slag isindustrial waste, so that the cost is low, and the preparation method is suitable for environment protection.

Owner:WUHAN UNIV OF TECH

Soil curing agent doped with sludge incineration ash and preparation method thereof

The invention provides a soil curing agent doped with sludge incineration ash. The soil curing agent is prepared from the following materials in parts by weight: 0-30% of sludge incineration ash, 5-10% of gypsum, 40-55% of slag powder and 20-30% of cement; when the curing agent is used for reinforcing a high-soft soil foundation, the dosage ratio of the curing agent to soft soil is 10%-30%; when the curing agent is used for roadbed reinforcement, the dosage ratio of the curing agent to soil is 4-15%. According to the soil curing agent doped with the sludge incineration ash, multiple solid wastes are synergistically matched, chlorine salt and sulfate components in the sludge incineration ash serve as exciting agents, strength is provided for the soil body, the curing agent is an environment-friendly curing agent integrating multiple solid wastes, and on the premise that the same curing effect as cement is achieved, the cost is lower than cement; besides, development of the soil curing agent finds a way for disposal and utilization of sludge incineration ash, and meanwhile, various solid wastes can be consumed, so that resource and energy conservation and waste utilization and new material development are realized.

Owner:SHANGHAI RES INST OF BUILDING SCI CO LTD +2

Super-early-strength type ultra-high performance concrete and preparation method thereof

PendingCN113480277AIncreased durabilityExtended working hoursArchitectural engineeringStructural engineering

The invention discloses super-early-strength type ultra-high performance concrete and a preparation method thereof, and belongs to the technical field of building materials. The super-early-strength type ultra-high performance concrete is prepared from the following components in parts by weight: 50 to 100 parts of cement, 10 to 30 parts of silica fume, 5 to 20 parts of fly ash, 80 to 150 parts of aggregate, 0.1 to 2 parts of slaked lime, 5 to 25 parts of steel fiber, 1 to 5 parts of a water reducing agent, 0.05 to 0.5 part of a retarder, 0.01 to 0.2 part of a coagulant and 10 to 30 parts of water. The super-early-strength type ultra-high performance concrete has the characteristics of super early strength, ultrahigh later strength, ultrahigh durability, controllable setting time, excellent working performance and the like, and has important practical value in various emergency repair projects and winter construction projects. The invention further discloses a preparation method of the super-early-strength type ultra-high performance concrete, wherein the preparation method is simple, easy to operate, easy to control preparation conditions and low in requirement for production equipment, and is easy to achieve industrial production .

Owner:华新超可隆新型建材科技(黄石)有限公司 +1

Rapid hardening early strength type composite repair mortar

The invention belongs to the technical field of building materials, and provides rapid hardening early strength type composite repair mortar. The rapid hardening early strength type composite repair mortar comprises, by weight, 5%-10% of water, 20%-30% of cement, 1%-5% of silica fume, 1%-5% of fly ash, 50%-70% of quartz sand, 0.4%-0.5% of composite early strength agents, 0.06%-0.1% of water reducing agents, 1%-5% of gelatin powder and 0.06%-0.8% of hybrid fibers. The composite early strength agents comprise components A and components B, the components A are nanometer calcium carbonate whiskers, the components B are mixtures of triisopropanolamine and aluminum sulfate, the quartz sand comprises coarse sand, medium sand and fine sand, and the hybrid fibers include basalt fibers and polypropylene fibers. The rapid hardening early strength type composite repair mortar has the advantage that the problems of strength decreasing, high dry shrinkage and low bonding strength of repair mortar in the prior art can be solved by the aid of the rapid hardening early strength type composite repair mortar.

Owner:长春昌驰新材料科技有限公司

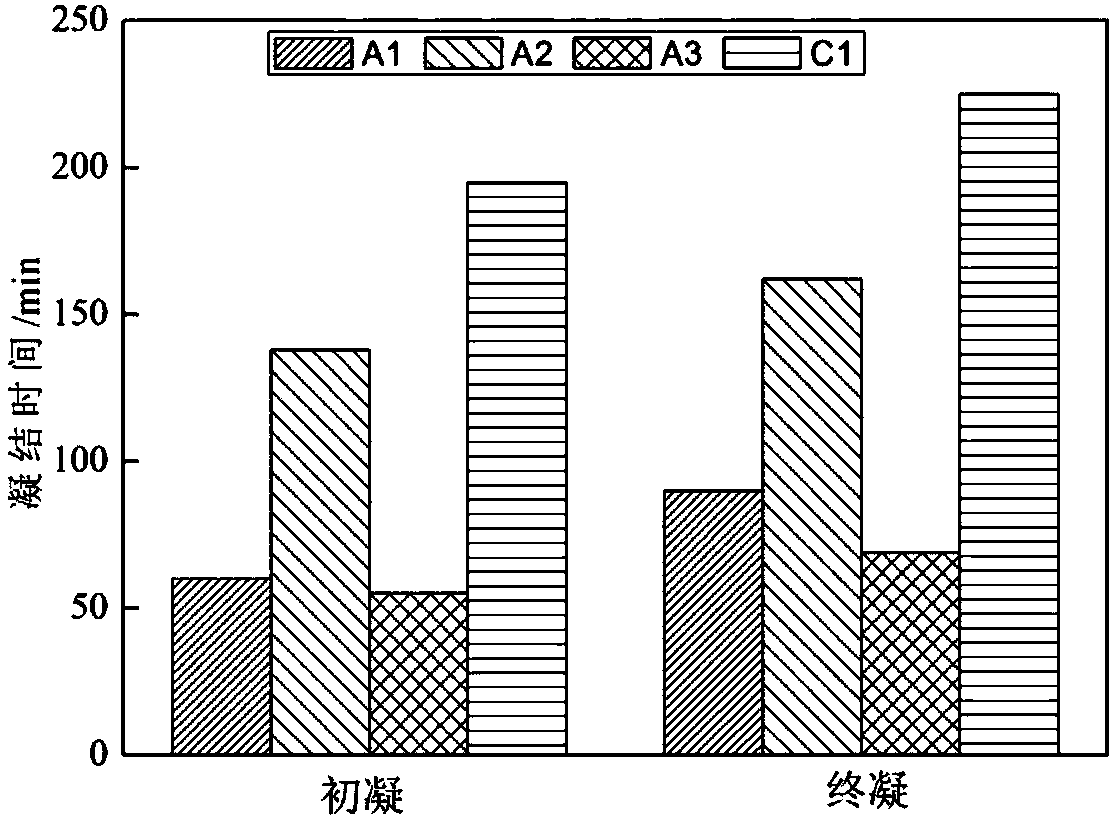

Quick-setting early-strength grouting material

InactiveCN105565745AShorten the setting timeControllable clotting timeSolid waste managementSlagDefoaming Agents

The invention discloses a quick-setting early-strength grouting material, and belongs to the technical field of grouting materials. The quick-setting early-strength grouting material comprises the following raw materials in percentage by mass: 75 to 90 parts of potland clinker, 3 to 10 parts of mineral slag, 5 to 15 parts of sulphate aluminium cement, 1 to 5 parts of silica fume, 0.5 to 4 parts of bentonite, 0.05 to 0.2 part of hydroxyethyl cellulose, 0.25 to 0.5 part of water reducing agent, 0.005 to 0.1 part of lithium carbonate, and 0.05 to 0.5 part of defoaming agent. The grouting material disclosed by the invention is mainly applied to grouting leakage plugging of a rock-soil layer, and in particular to the grouting leakage plugging engineering of water burst at the positions of a dam foundation and the like, and has the advantages of short setting time, high early strength, high construction performance, and good plugging performance.

Owner:JIAHUA SPECIAL CEMENT

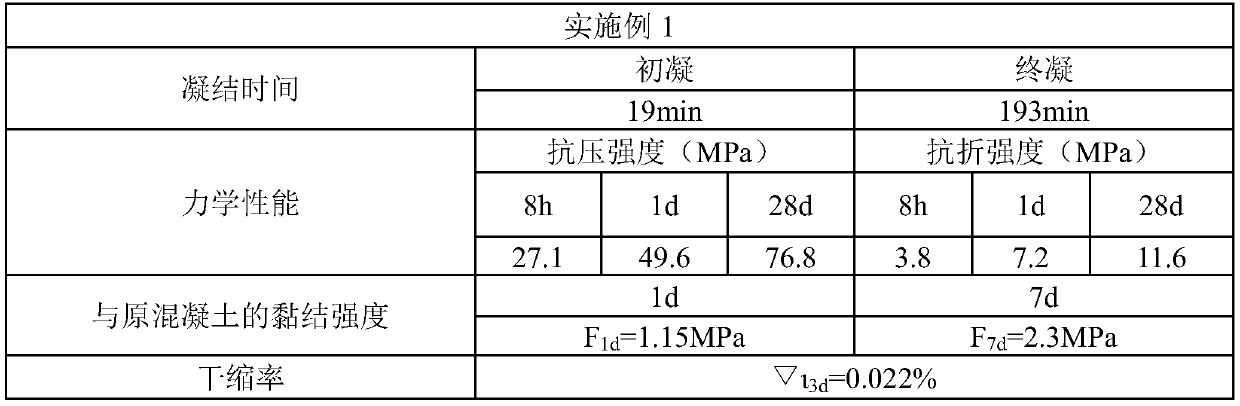

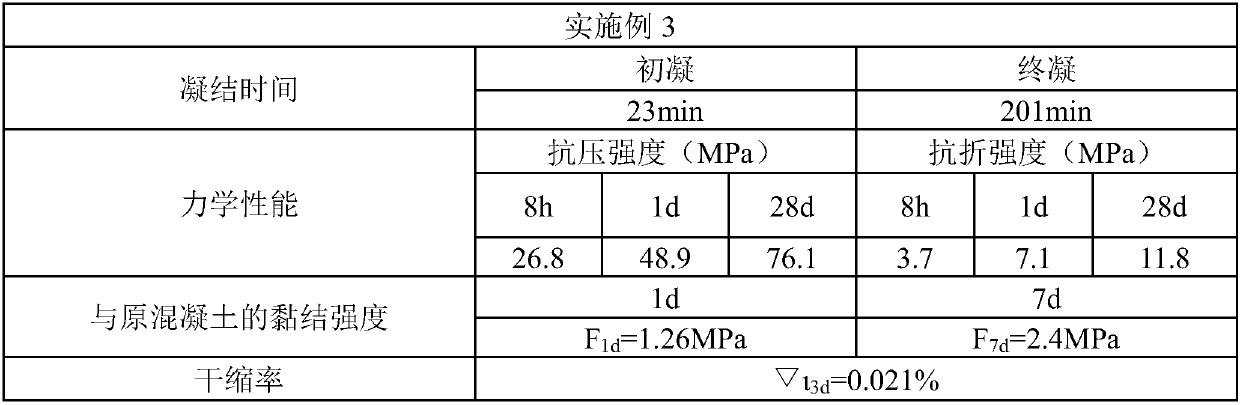

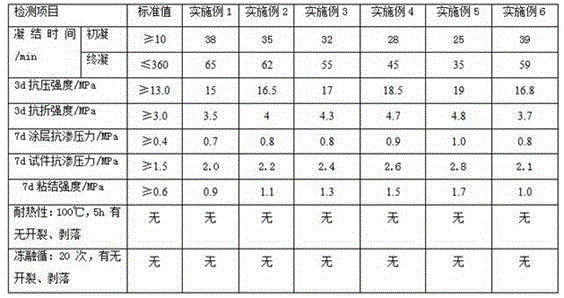

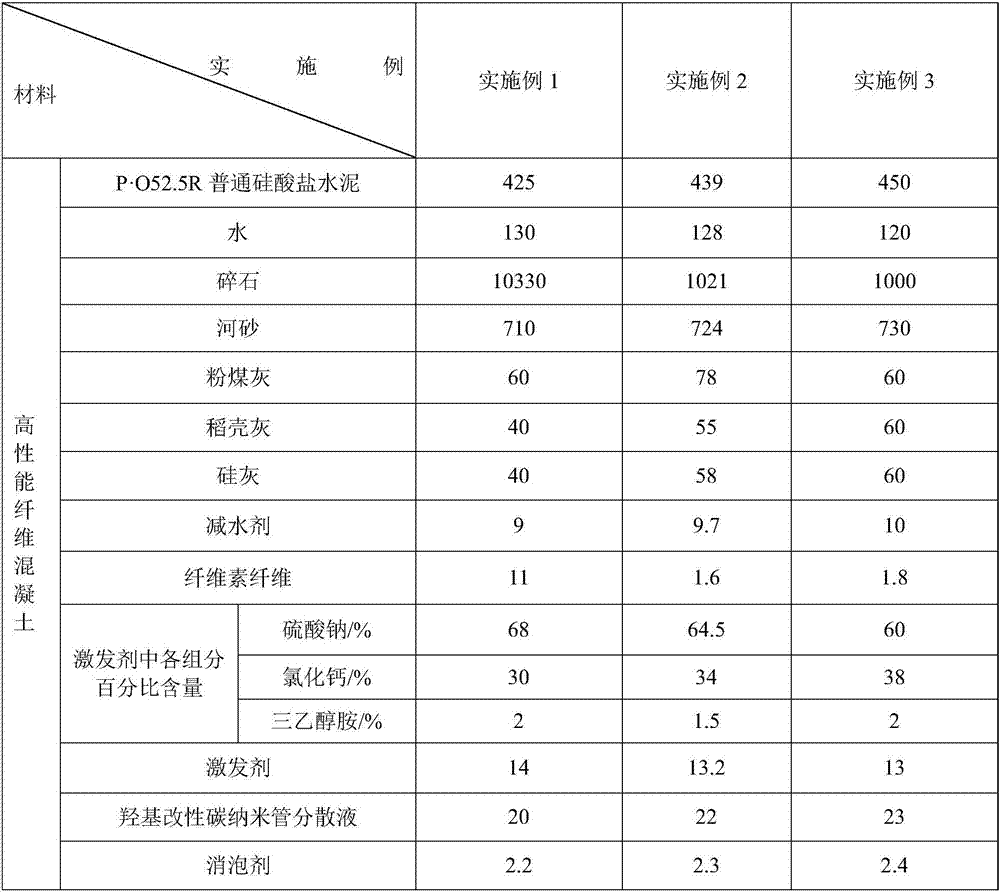

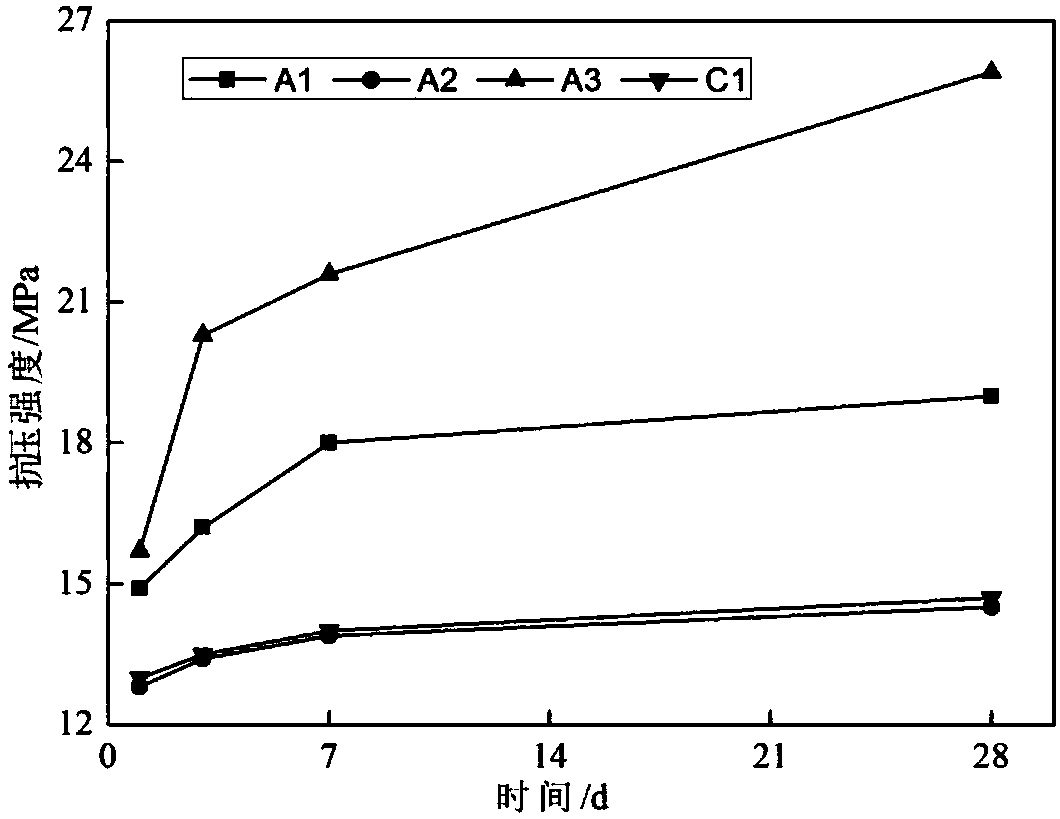

High-performance fiber concrete with C110 strength grade and preparation method thereof

The invention discloses high-performance fiber concrete with a C110 strength grade and a preparation method thereof. The concrete is prepared from the following components in parts by mass: 425 to 450 parts of cement, 120 to 130 parts of water, 710 to 730 parts of river sand, 1000 to 1030 parts of crushed stones, 60 to 90 parts of fly ash, 40 to 60 parts of rich husk ash, 40 to 60 parts of silicon ash, 9 to 10 parts of a water reducing agent, 13 to 14 parts of an exciting agent, 1.1 to 1.8 parts of cellulose fibers, 20 to 23 parts of a hydroxyl-modified carbon nanotube dispersion solution and 2.2 to 2.4 parts of a de-foaming agent. The concrete prepared by the preparation method has relatively high toughness and excellent durability and has relatively high bonding strength with section steel. The high-performance fiber concrete is used in a section steel concrete composite structure and can effectively express cooperative work performance between the section steel and the concrete; the disadvantages that the bonding performance of the section steel and the concrete is poor and respective mechanical properties of the section steel and the concrete cannot be sufficiently expressed are overcome.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

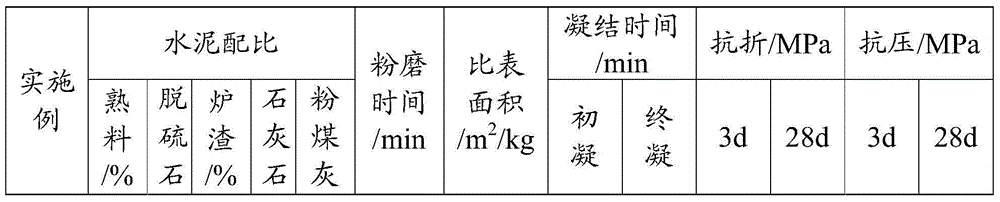

Liquid grinding aid capable of promoting coagulating, and preparation method thereof

The invention discloses a liquid grinding aid capable of promoting coagulating, and a preparation method thereof, and belongs to the technical field of cement additive. The liquid grinding aid capableof promoting coagulating is prepared from, by mass, aluminum sulfate of 5% to 15%, magnesium sulfate of 5% to 10%, modified alcohol amine small organic molecules of 40% to 50%, sodium lignosulfonateof 3% to 10%, calcium formate of 1.5% to 3%, and balance deionized water. According to the preparation method, aluminum sulfate and magnesium sulfate are mixed as a coagulating promoting main component, so that cement hydration process is accelerated; chemical imbalance caused by high content aluminium ions is capable of realizing dissolving of gypsum and C3A easily, promoting early stage generation of a large amount of ettringite, and realizing rapid coagulation; the modified alcohol amine small organic molecules are taken as a grinding aid enhancing component, and is high in stability; the preparation technology is simple; reaction is relatively mild; the liquid grinding aid is capable of promoting cement early stage rapid coagulation, and at the same time, early stage strength is ensured, later stage strength increasing is not influenced, and the adaptability on cement is excellent.

Owner:安徽海螺材料科技股份有限公司 +1

Preparation method of alkali excitation enhanced sulphoaluminate cement based material

InactiveCN108358572AShorten the setting timeImprove the problem of slow strength growthHydration reactionCALCIUM HYDROXIDE SOLUTION

The invention discloses a preparation method of an alkali excitation activated enhanced sulphoaluminate cement based material. The method comprises the following steps of (1) mixing sulphoaluminate cement and fly ash to be used as a gelling material; (2) dissolving calcium hydroxide into water to be prepared into a calcium hydroxide water solution; (3) adding the gelling material into the calciumhydroxide water solution; performing stirring. Various ingredients are contained; the sulphoaluminate cement is used as a base material; the fly ash is used as a modification agent; the calcium hydroxide solution is used as a modification regulating agent for preparing the modified sulphoaluminate cement. The prepared sulphoaluminate cement based material has the advantages that the initial curingand final curing time of the cement can be effectively shortened; the generation of hydration products of ettringite can be obviously promoted; the secondary hydration reaction of the fly ash is obviously promoted; the low long-term stage intensity increase of the sulphoaluminate cement is effectively solved; the economic cost is reduced; good economic benefits are realized.

Owner:WUHAN UNIV OF SCI & TECH

Self-compacting UHPC containing microbeads, and preparation method thereof

The invention provides a self-compacting UHPC containing microbeads, and a preparation method thereof. The UHPC comprises, by weight, 500-790 parts of cement, 245 parts of silica fume, 205 parts of metakaolin, 100-255 parts of the microbeads, 980 parts of sands, 180 parts of steel fibers, 30-35 parts of a water reducer and 238.5 parts of water. The preparation method comprises the following steps:the cement, silica fume, metakaolin and microbeads are taken, and are stirred and mixed to obtain a primary powder; the sands are added to the primary powder, and stirring is performed to reach uniformity in order to obtain a secondary powder; the water reducer is uniformly mixed with 75% of the water, the obtained solution is added to the secondary powder, and stirring is performed to reach uniformity in order to obtain a primary slurry; the remaining water is added to the primary slurry, stirring is performed, the steel fibers are added, and stirring is performed to reach uniformity in order to obtain a mortar; and the mortar is added into a mold, undergoes forming curing, and is demolded to obtain the self-compacting UHPC containing microbeads. The obtained UHPC has the advantages of high strength, good mechanical properties and good durability.

Owner:湖南恒盛瑞通新型建材有限公司

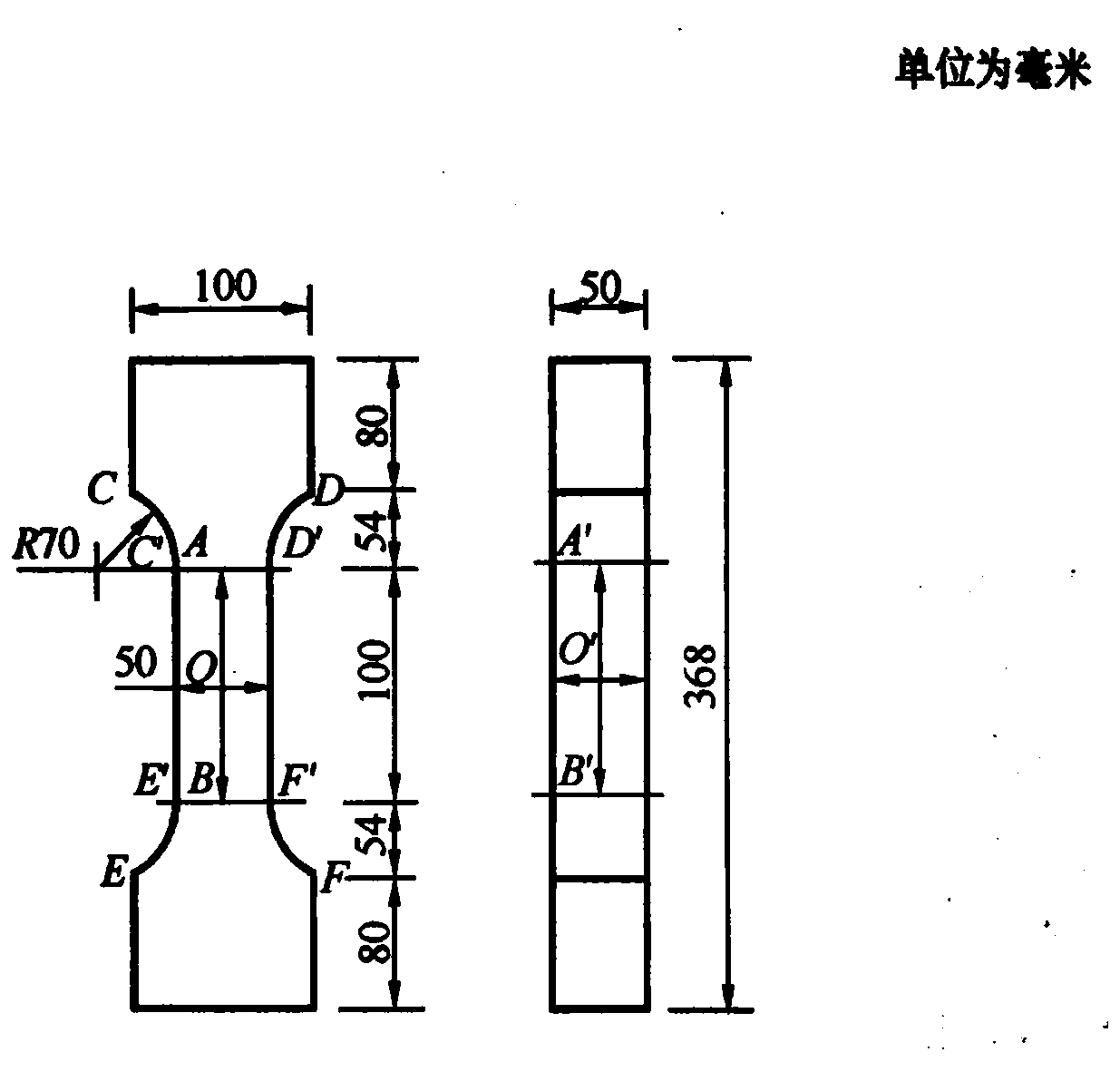

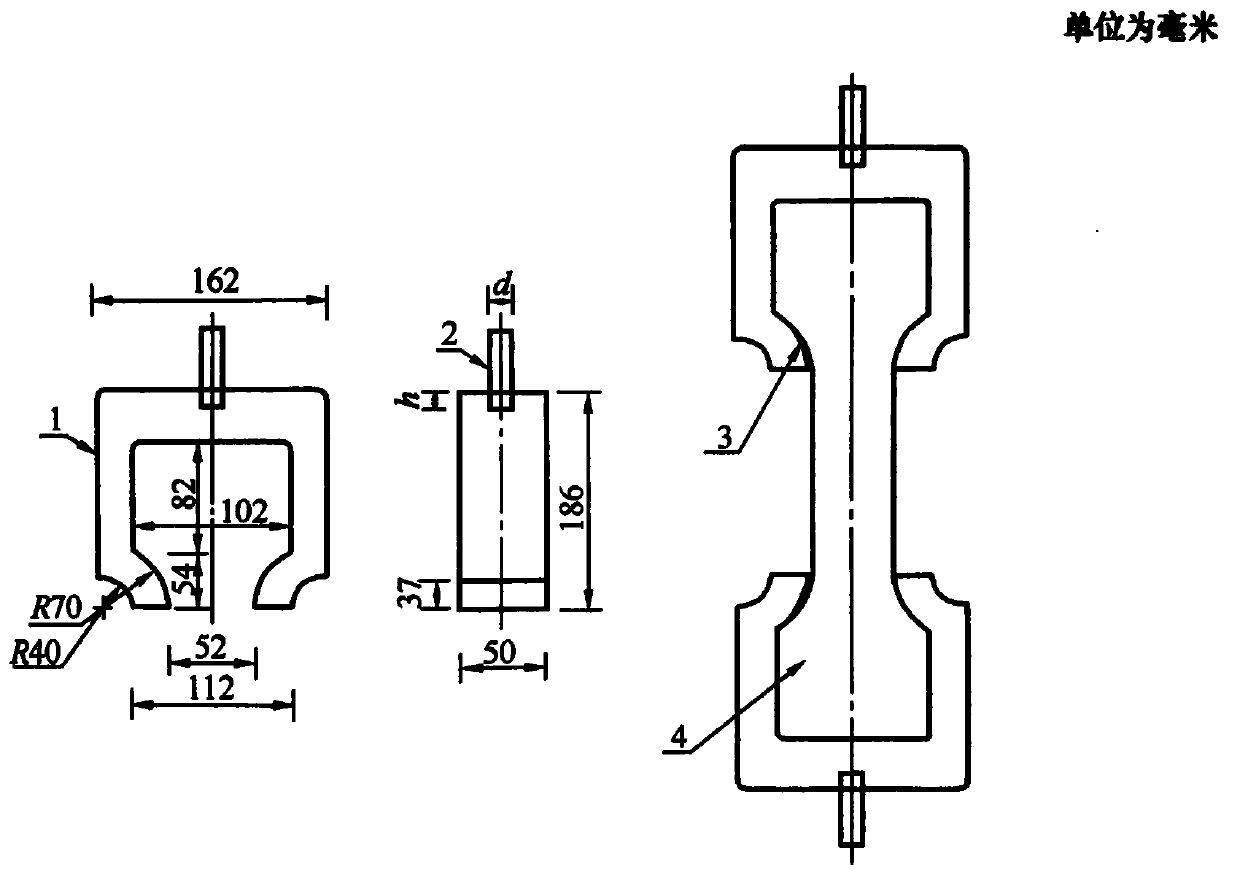

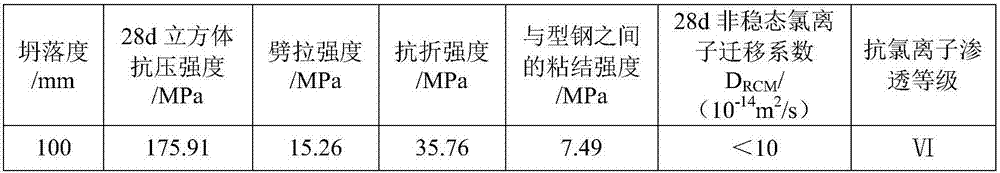

Ultrahigh-strength and high-performance fiber concrete with C170 strength grade and preparation method thereof

ActiveCN107352912AOvercoming brittlenessOvercome crackingSolid waste managementModified carbonFlexural strength

The invention discloses ultrahigh-strength and high-performance fiber concrete with a C170 strength grade and a preparation method thereof. The concrete is prepared from the following components in parts by mass: 497 parts of cement, 74 parts of water, 1000 parts of crushed stones, 760 parts of fine aggregate, 80 parts of fly ash, 75 parts of rich husk ash, 111 parts of silicon ash, 14.4 parts of a water reducing agent, 10 parts of an exciting agent, 1.6 parts of cellulose fibers, 41 parts of a hydroxyl-modified carbon nanotube dispersion solution, 42 parts of a graphene oxide dispersion solution and 2.6 parts of a de-foaming agent. The concrete prepared by the preparation method has relatively high toughness and excellent durability and has relatively high bonding strength with section steel; the compression strength reaches 175.91MPa, the flexural strength reaches 35.76MPa, the splitting tensile strength reaches 15.26MPa, the bonding strength with the section steel reaches 7.49MPa and a chloride ion anti-leakage grade reaches a grade VI. The ultrahigh-strength and high-performance fiber concrete is used in a section steel concrete composite structure and can effectively express cooperative work performance between the section steel and the concrete; the disadvantages that the bonding performance of the section steel and the concrete is poor and respective mechanical properties of the section steel and the concrete cannot be sufficiently expressed are overcome.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Novel polycarboxylic acid high-performance nano seed crystal early-strength water reduction complex agent and preparation method thereof

The invention discloses a novel polycarboxylic acid high-performance nano seed crystal early-strength water reduction complex agent and a preparation method thereof. The novel polycarboxylic acid high-performance nano seed crystal early-strength water reduction complex agent comprises the following raw materials in percentage by weight: 5.5 to 12.5 percent of a base material, 4.5 to 10 percent ofsoluble calcium salt, 4 to 9 percent of soluble silicate, 2.5 to 5 percent of a stabilizer, 0.07 to 0.12 percent of a surfactant containing a functional monomer, 0.2 to 0.3 percent of a dispersant, 0.02 to 0.04 percent of a de-foaming agent and the balance of water, wherein the calcium-silicon ratio is 1 to 1.6. A polycarboxylic acid water reduction agent and a strong crystal nucleus are used forassisting and promoting the generation of C-S-H gel in cement hydration and a cement hydration progress is accelerated, so that the early strength of concrete is obviously improved and the long-term strength is not decreased; the stabilizer, the surfactant and the dispersant cooperatively act on the surface of the crystal nucleus, so that the state of an obtained complex agent solution is uniformand stable; a preparation technology of the complex agent has a simple process; the obtained solution is uniform and stable, has no sediment and has factors which easily reduce the durability of a concrete structure, such as low alkali, no triethanolamine, no chlorine and no sulfate; and a prefabricated part production process does not need high-temperature autoclave curing and energy saving and emission reduction are facilitated.

Owner:SHANXI SUNWAY INTION TRADE CO LTD

High-toughness and high-cohesiveness C250 ultrahigh-strength hybrid fiber concrete and preparation method thereof

ActiveCN113024189AHigh tensile strengthHigh elastic modulusSolid waste managementPolymer sciencePolyvinyl alcohol

The invention discloses high-toughness and high-cohesiveness C250 ultrahigh-strength hybrid fiber concrete and a preparation method thereof. The ultrahigh-strength hybrid fiber concrete is prepared from cement, sand, gravel, fly ash, straw ash, silica fume, nano silicon, water, a water reducing agent, an exciting agent, a defoaming agent, a shrinkage reducing agent, ramie fibers, basalt fibers, CaCO3 whiskers, a carboxyl modified polyvinyl alcohol polymer and nano titanium / graphene oxide dispersion liquid according to the mixing ratio of (550-560): (760-770): (830-840): (65-70): (103- 108): (125-135): (5.4-5.6): (70-75): (20-21): (16-17): (3-3.3): (14.5-15): (7.5-8): (13.3-13.6): (21-21.5): (22-23.5): (42-46). The materials are evenly mixed at intervals through a layered stirring method, and discharging, forming and curing are conducted. The mechanical property and durability of the concrete and the bonding property between the concrete and the profile steel are obviously improved.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Cube spar based stucco gypsum for internal insulation system and method of manufacturing the same

InactiveCN101367639AImprove volume stabilityImprove workabilitySolid waste managementFiberCrack resistance

The invention relates to an anhydrite base render plaster for an inner heat preservation system and a preparation method thereof. The anhydrite base render plaster for an inner heat preservation system mainly comprises 70 percent to 90 percent of the anhydrite, 0.1 percent to 5 percent of excitant, 5 percent to 20 percent of inorganic activity material, 2 percent to 5 percent of cement, 0.05 percent to 0.2 percent of macromolecule water retention agent and 0.05 percent to 0.3 percent of fibers. The anhydrite hydration activity is complexly excited through adopting calcining powder grinding activation technology and excitant technology, cementation material water resisting property and durability are improved by adopting the inorganic activity material and the anhydrite hydration complementation, and the intensity and cracking resistance of the anhydrite base render plaster are raised by adopting comprehensive measures such as fiber toughness increasing, and the like. The preparation method comprises that the anhydrite after calcined and ground into power is mixed with other raw materials and is evenly agitated. The anhydrite base render plaster for an inner heat preservation system has good workability and application property, long operational time, high bending resistance and compression resistance intensity, good volume stability and exceptional cracking resistance, and is mainly used for the render plaster of the inner heat preservation system of a building outer wall.

Owner:CHONGQING UNIV

Method for improving hydration activity of waste glass powder

The invention discloses a method for improving the hydration activity of waste glass powder. The method comprises the following steps: carrying out cleaning, airing, preliminary crushing and jaw crushing on waste glass having different colors and kinds, collected from salvage stations, and carrying out ball milling by a ball mill for 60-120 min to obtain the waste glass powder; carrying out dry screening, wet screening and a settlement process on the waste glass powder to obtain waste glass powder with the particle size range of 10-75 [mu]m and the particle specific surface area being greater than 400 m<2> / kg; and adding cement and a composite exciter to the waste glass powder, carrying out mixing milling treatment for 30 min, adding water, pouring the obtained mixture into a cement neat paste stirrer, and stirring the mixture for 2-3 min to obtain a composite gelling material. The composite gelling material prepared in the invention is a waste glass recycled product, waste glass has a high utilization rate, wide sources and easiness in obtaining, and the composite gelling material has the advantages of quickness in setting, quickness in hardening, high early stage strength, and great increase of the later strength.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

High-performance fiber concrete at C60 strength grade and preparation method thereof

ActiveCN107445548APrevent pulling outImprove energy consumptionSolid waste managementFiberUltimate tensile strength

The invention discloses high-performance fiber concrete at a C60 strength grade and a preparation method thereof. The concrete comprises the following components in parts by mass: 360-380 parts of cement, 145-160 parts of water, 700-720 parts of river sand, 1020-1040 parts of gravel, 80-125 parts of fly ash, 40-60 parts of rice hull ash, 6-7.5 parts of a water reducing agent, 9-10 parts of a shrinkage reducing agent, 12.5-14 parts of an excitant, 1.1-1.8 parts of cellulosic fibers, 16-20 parts of a carboxyl butadiene styrene polymer an 1.7-1.8 parts of an antifoaming agent. The prepared concrete has high toughness and excellent durability, has high bonding strength with section steel, can effectively achieve the cooperative working performance between the section steel and the concrete when applied to a section steel and concrete combined structure, and overcomes the defects that the adhesive property between the section steel and the concrete is poor and respective mechanical properties of the two cannot be fully achieved.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

High-damping concrete and preparation method thereof

The invention relates to high-damping concrete. The high-damping concrete comprises the following components in parts by mass: 140-150 parts of cement, 260-280 parts of natural river sand, 5-8 parts of rubber powder, 12-15 parts of silica fume, 400-420 parts of gravels, 0.58-2.16 parts of polypropylene fibers, 0.8-1 parts of a water reducing agent and 80-90 parts of water, wherein the granularityof the gravels is less than 40mm; the high-damping concrete is formed by fully mixing and curing the components. The invention further provides a technical scheme of the preparation method of the high-damping concrete. According to the invention, the polypropylene fiber with toughening and internal curing effects, the rubber powder with viscoelasticity, the silica fume with physical filling effectand the like are added, and the components cooperate with one another to improve the performance of the concrete, so that the concrete has high damping ratio.

Owner:YANGTZE UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com