Ultrahigh strength high-performance fiber concrete at C160 strength grade and preparation method thereof

A technology of high-performance fibers and strength grades, applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve the problems of unfavorable dispersion of graphene oxide, loss of concrete strength, unstable dispersion, etc., and achieve the purpose of inhibiting plasticity Shrinkage, improve crack resistance, promote the effect of hydration process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

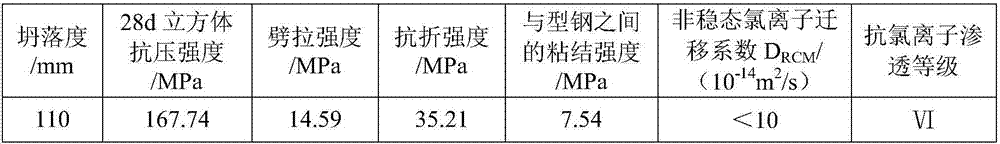

Examples

preparation example Construction

[0051] The preparation method of the ultra-high-strength high-performance fiber concrete of the C160 intensity grade of the present invention comprises the following steps:

[0052] 1) 9.5 parts by mass of activator and 2.6 parts of defoamer are dissolved in water with a total water content of 25%, which is recorded as aqueous solution 1, 14.0 parts of water reducer, 40 parts of hydroxyl modified carbon nanotube dispersion and 37 parts of graphene oxide dispersions are added to an aqueous solution with a total water content of 50%, which is denoted as aqueous solution 2;

[0053] 2) Weigh 750 parts of river sand and quartz sand with a mass ratio of 8:2, 1000 parts of gravel and 1.6 parts of cellulose fiber and add them to the mixer in turn, and stir evenly for 2-3 minutes;

[0054] 3) Then, add 485 parts of cement, 70 parts of fly ash, 73 parts of rice husk ash, and 102 parts of silica fume in sequence, and then add the aqueous solution 1 prepared in step 1) into the mixer, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com