Inorganic grouting blocking material

A plugging material and grouting technology, which is applied in the field of plugging materials, can solve the problems of low strength and limited use of plugging materials, and achieve the effects of improving resistance to groundwater erosion, prolonging service life, and promoting hydration process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

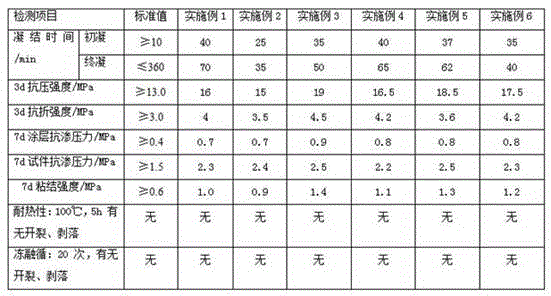

Examples

Embodiment 1

[0020] An inorganic grouting plugging material, comprising the following raw materials in parts by weight: 75 parts of Portland cement clinker; 3 parts of slag; 5 parts of sulphoaluminate cement; 0.5 parts of bentonite; 0.05 parts of hydroxyethyl cellulose ether 0.25 parts of water reducing agent; 0.005 parts of lithium carbonate; 0.05 parts of defoamer.

Embodiment 2

[0022] An inorganic grouting plugging material, comprising the following raw materials in parts by weight: 90 parts of Portland cement clinker; 5 parts of slag; 10 parts of sulphoaluminate cement; 2 parts of bentonite; 0.2 parts of hydroxyethyl cellulose ether parts; 0.5 parts of water reducing agent; 0.1 parts of lithium carbonate; 0.5 parts of defoaming agent.

[0023] In this embodiment, the specific surface area of the slag is 400 kg / m3; the sulphoaluminate cement is sulphoaluminate cement with a strength grade of 42.5.

Embodiment 3

[0025] An inorganic grouting plugging material, comprising the following raw materials in parts by weight: 80 parts of Portland cement clinker; 10 parts of slag; 15 parts of sulphoaluminate cement; 4 parts of bentonite; 0.1 parts of hydroxyethyl cellulose ether 0.35 parts of water reducing agent; 0.01 parts of lithium carbonate; 0.35 parts of defoamer.

[0026] In this example, the specific surface area of the slag is 800kg / m3; the sulphoaluminate cement is sulphoaluminate cement with a strength grade of 52.5; the bentonite is sodium-based bentonite, the water absorption is greater than 300%, and the sieve residue of 80 μm is less than 8%. ; The viscosity of hydroxyethyl cellulose ether is 50000mPa·s; the water reducing agent is polycarboxylate water reducing agent, and the water reducing rate is 25%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com