Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

130results about How to "Stem shrink" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Non-homogeneous concrete composite automatic heat insulation building block

InactiveCN101694117AImprove insulation effectHigh void rateConstruction materialThermal engineeringBrick

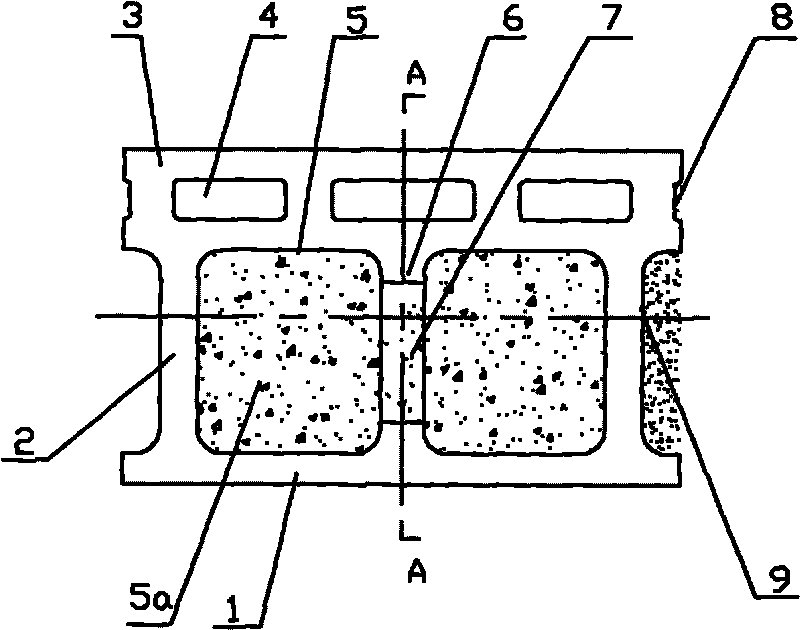

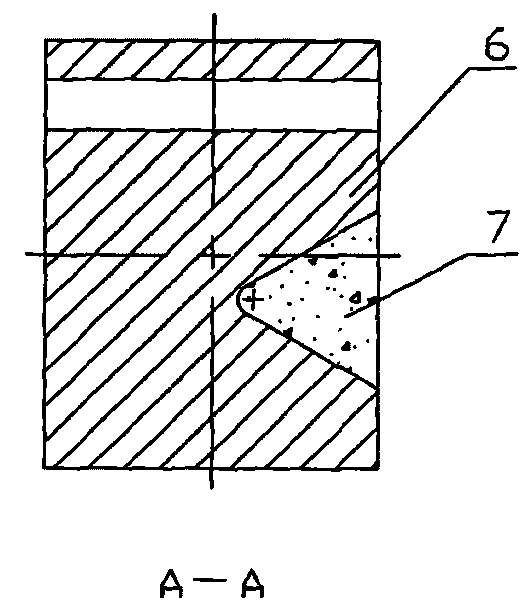

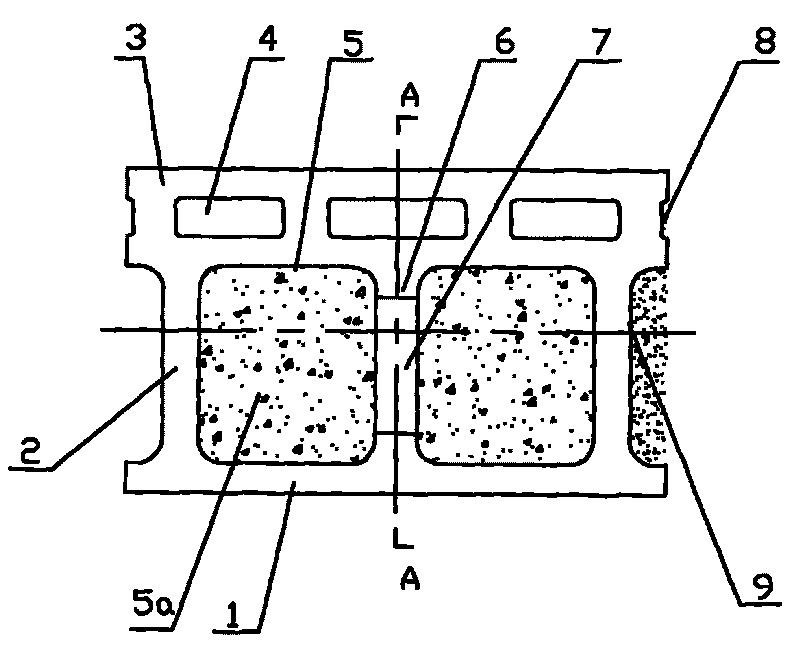

The invention relates to a composite heat insulation building block which comprises a rectangular building block body, and is characterized in that one side of the rectangular building block body is provided with a group of parallel thermal insulation water-proof chamber (4); the middle part of the rectangular building block is provided with at least one heat insulation chamber (5) which is internally provided with heat insulation fillers (5a); the middle part of the rectangular building block is provided with two parallel heat insulation chambers (5); a leveling groove (7) used for leveling the heat insulation fillers are arranged on a rib plate (6) formed between the heat insulation chambers (5); and the connecting ends at two sides of the rectangular building block are respectively provided with an opening slit building groove (9) and an opening slit building groove (8). The composite heat insulation building block has the advantages of high void content (more than 60%), good heat insulation effect and high strength, and the produced composite heat insulation building brick has light weight, high strength, low water absorption rate, small air shrinkage rate, and good thermal engineering performance, and can meet the design requirement that building energy conservation rate can reach 65%.

Owner:金波

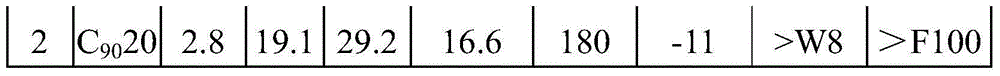

Anti-erosion low calcium portland cement and preparation method thereof

ActiveCN105347707AImprove corrosion resistanceErosion defensePortland cementUltimate tensile strength

The invention discloses anti-erosion low calcium portland cement and a preparation method thereof. The anti-erosion low calcium portland cement comprises clinker and gypsum according to a weight ratio of 96.5: 3.5 to 94.5: 5.5. Minerals of the cement comprises, by weight, 35.03-49.51% of C3S, 25.13-39.00% of C2S, 0.21-8.84% of C3A, 8.2-19.2% of C4AF and 1.71-9.24% of MgO. The cement has good anti-erosion performances, can effectively prevent seawater erosion of concrete engineering, has small dry shrinkage and good anti-cracking ability, improves a service life of oceanographic engineering, and has high early strength. Compared with the existing low-heat portland cement, the anti-erosion low calcium portland cement is conducive to shortening of a concrete work form stripping period and processing progress.

Owner:CHINA BUILDING MATERIALS ACAD

Environment-friendly type building water-proof heat-insulating mortar and its production method

InactiveCN1544381AEasy to operateDecreased insulation performance without heat preservationClimate change adaptationHeat proofingPolymer scienceEmulsion

The invention discloses an environment-friendly type construction water resistant thermal insulating mortar prepared from cement, polymer emulsion powder, discarded polyphenylacetylene, polypropylene fiber, alta-mud, water-based silane / siloxane emulsion, quartz sand and water with right weight ratio through finite process. The mortar has fine thermal insulation property, chemical-resisting, waterproof and barrier properties.

Owner:TONGJI UNIV

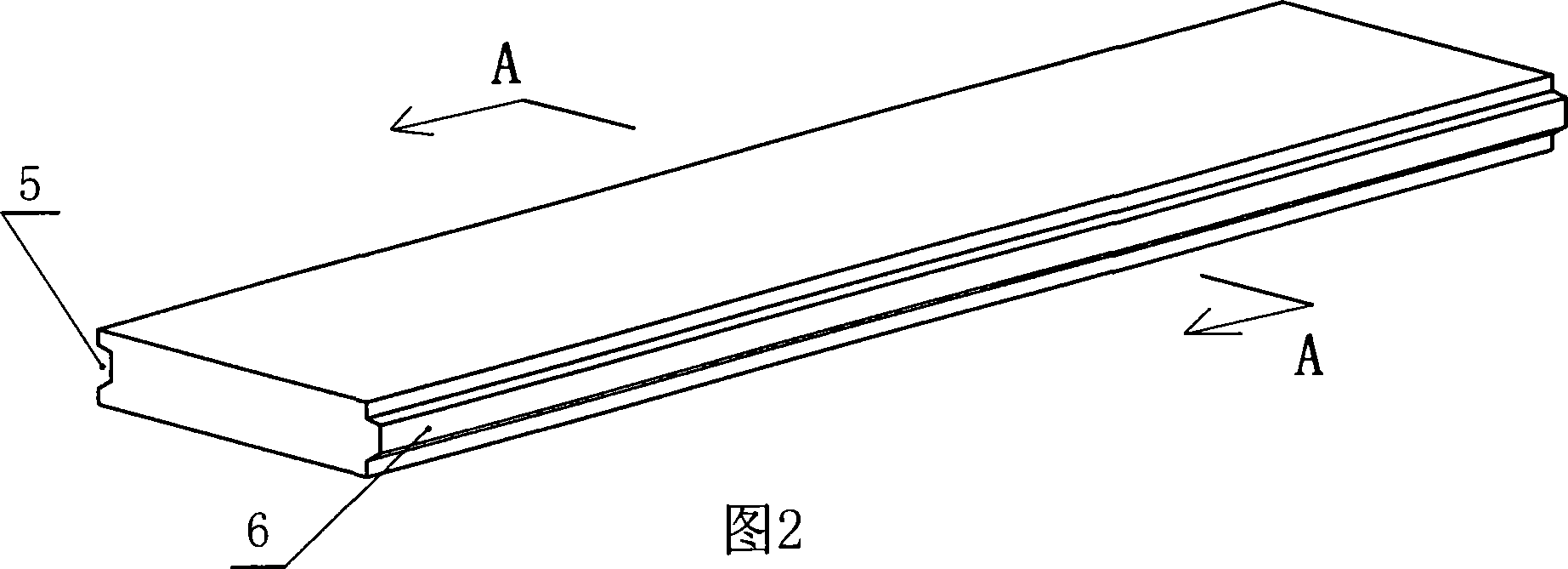

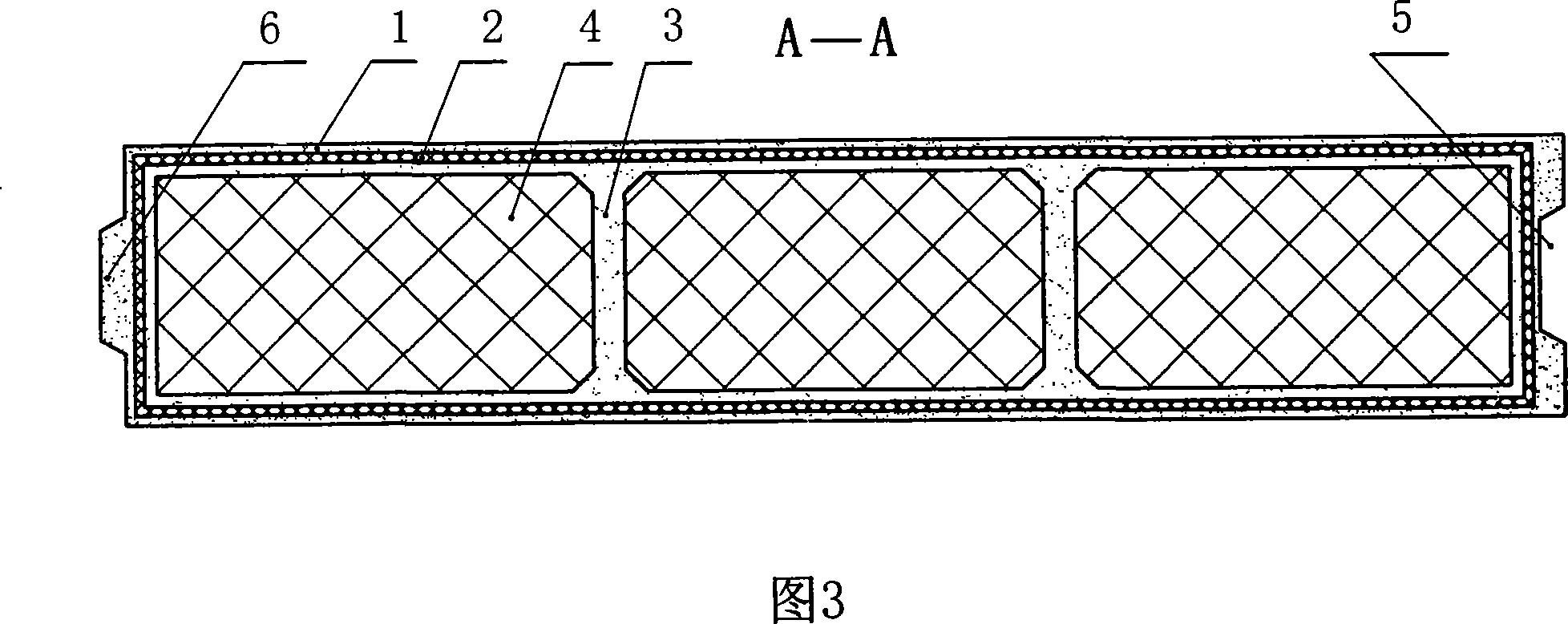

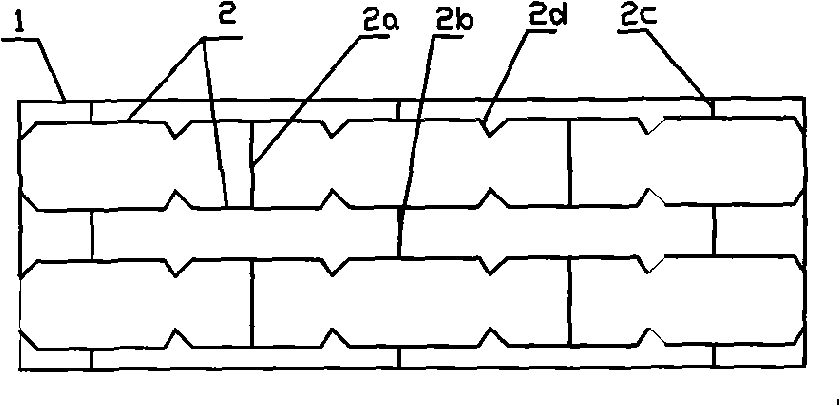

Compact composite light internal and external wall plate

InactiveCN101050658AImprove surface strengthGuaranteed not to deformSolid waste managementBuilding componentsPolystyreneSlurry

The present invention relates to a compact composite light-weight internal and external wall panel. It includes slurry material layer of external layer. Said slurry material layer is made up by using (by weight portion) 100 portions of quick-hardening early-strength sulphoaluminate cement, 0-35 portions of fly-ash, 0-10 portions of building glue and 0.2 portions as raw material through the processes of mixing, adding water and making slurry. It the slurry material layer interior a plastic-coated glass fiber mesh fabric is filled, and the slurry material layer interior is covered with a foamed plastic layer, said foamed plastic layer is a high-foamed polystyrene foam plastic plate. In the foamed plastic layer several through holes are set, in every through hole a column slurry material body is injected, and two sides of said panel body are equipped with tongue and slot mortise.

Owner:周胜利

High-flexibility and low-shrinkage fiber reinforced cement-based composite material

The invention belongs to the technical field of building materials, and in particular relates to a high-flexibility and low-shrinkage fiber reinforced cement-based composite material. The composite material is prepared by mixing cement, coal ash, silicon powder, gypsum, an expanding agent, a water reducing agent, a shrinkage reducing agent, a defoaming agent, a thickening agent, fine sand, fibers and water, wherein the total mass percentage of the cement, the coal ash, the silicon powder, the gypsum, the expanding agent, the water reducing agent, the shrinkage reducing agent, the defoaming agent, the thickening agent, the fine sand and the fibers is 77-85 percent, and the mass percentage of the water is 15-23 percent. The fiber reinforced cement-based composite material has the performance characteristics of low shrinkage, high flexibility, small crack width, quickness in condensation and early strength and is high in compressive strength and good in synergism with other materials.

Owner:TSINGHUA UNIV

Multifunctional anti-leakage shrinkage type concrete surface layer reinforcer

The invention relates to a multifunctional anti-leakage shrinkage type concrete surface layer reinforcer which is prepared from the following components in percentage by weight: 10-20 percent of high polymer, 1-7 percent of film forming aided compound, 5-10 percent of surface layer active agent compound, 1-4 percent of leakage aided compound, 1.5-4.5 percent of active compound and the balance of water. The invention has good concrete surface layer enhancement effect, can obviously reduce the shrinkage of surface layer concrete, obviously improves the carbonization resistance and the medium leakage resistance of surface layer concrete, has convenient construction and obvious economic benefit and can be widely applied to the strengthening treatment operations on the surface layers of cement and concrete pouring components, concrete components under corrosion environment conditions such as piers, dams, and the like and deformed concrete components difficult to be strengthened by adopting a conventional method.

Owner:湖州苏博特新材料有限公司

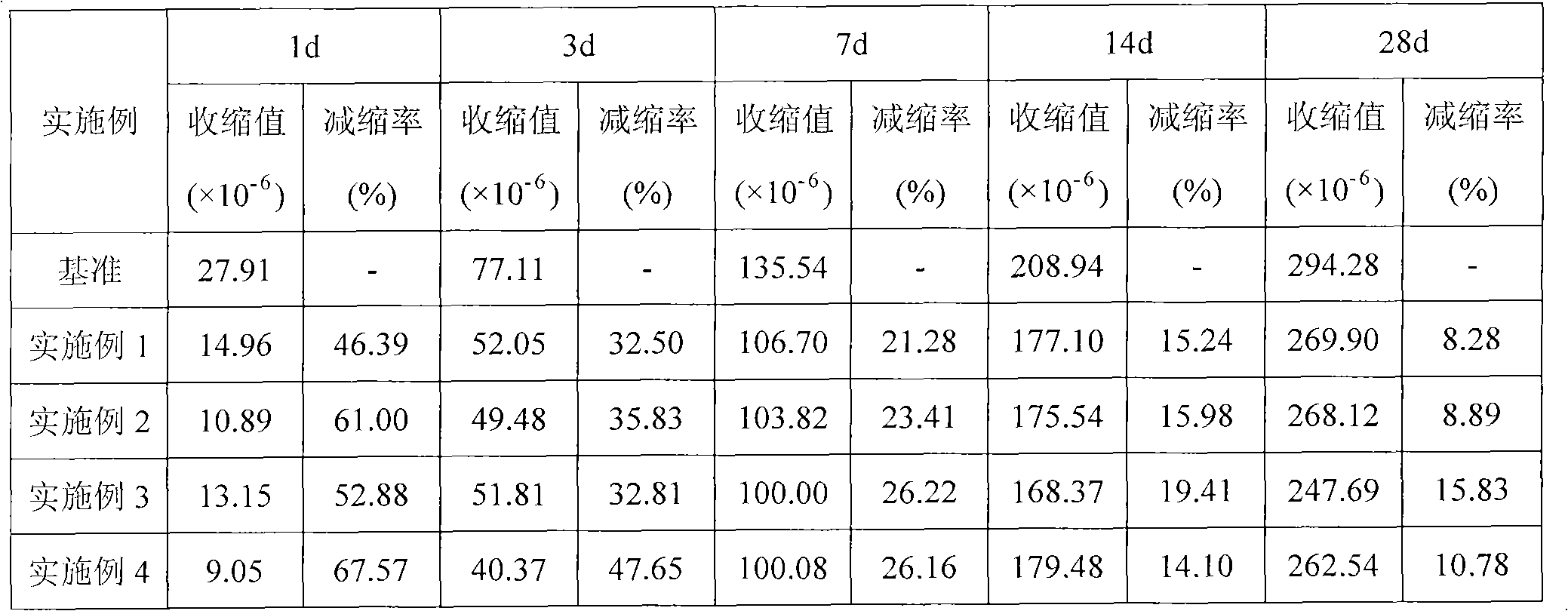

Concrete admixture for hydroelectric engineering and its application

This invention relates to a hydropower project used concrete admixture and its applications. The mixture mixed by grinding slag powder and grinding limestone powder, with the ratio of 4:6 to 7:3. Under the project design requirements to adjust the ratio of limestone powder, can gain varying activity of concrete admixture. With 30% to 70% of the amount used, not to increase consumption of concrete and can reduce concrete shrinkage. Iron (Fe-Mn) Slag from steel smelting industrial waste, sources is rich, is conducive to environmental protection; Using this invention, hydropower construction can make full use of the geographical situation to produce admixture, can reduce the long-distance transport of fly ash, economic benefits and reduce the adverse effects of supply and transportation of fly ash.

Owner:HUANENG LANCANG RIVER HYDROPOWER +2

Design method of ceramsite foam concrete

The invention provides a design method of ceramsite foam concrete, and relates to mixing proportion design and manufacturing of ceramsite foam concrete for producing the ceramsite foam concrete meeting requirements of related specifications. According to the method, the mixing proportion of the ceramsite foam concrete is determined on the basis of a volumetric method, and the density degree of the ceramsite foam concrete can be accurately controlled, so that the ceramsite foam concrete satisfies the required strength and has favorable use value. The method comprises the following steps: determining that the ceramsite mixing amount ranges from 40% to 60%; then determining the consumption of a cementing material according to the designed dry density of the ceramsite foam concrete; designing a workability testing method of newly mixed ceramsite foam concrete for judging an appropriate water-cement ratio; and designing a density control method of the ceramsite foam concrete for controlling the actual dry density of the ceramsite foam concrete to be in the vicinity of the designed dry density. The method can heavily utilize solid wastes (such as desulfurized gypsum, fly ash, sludge and refuse incineration ash, an animal protein foaming agent is prepared from animal hoofs and horns or animal hairs), has the characteristics of waste utilization, environment friendliness, energy saving and high efficiency, and conforms to requirements of sustainable development.

Owner:TONGJI UNIV

Polymer dry mixed mortar

The dry mixed polymer mortar consists of quartzite 60-65 wt%, cement 20-25 wt%, limestone powder 8-12 wt%, amylase 3-3.5 wt%, thixotropic bentonite lubricant 1-3 wt%, organic silicon compound 1.5-2.0wt%, hydrophobic agent 0.15-0.20 wt%, methyl cellulose 0.20-0.30 wt% and cellulose fiber 0.30-0.60 wt%. It is one kind of green furnishing and decorating material and has the features of light weight, high strength, high adhesion, being fireproof, etc.

Owner:王胜怀

Building rubbish pavement base material and preparation method thereof

The invention relates to a building rubbish pavement base material and a preparation method thereof. The pavement base material is prepared from the components in parts by mass: 95 to 96 parts of building rubbish recycled aggregate, 4 to 5 parts of binding material, 9.4 to 12.2 parts of water relative to the sum of the components i.e. the building rubbish recycled aggregate and the binding material, and 3.5 to 5.5 parts of alkali-activator relative to the mass of water. The pavement base material provided by the invention adopts building rubbish and industrial waste residues as main raw materials, and the material has the advantages of high strength, dry shrinkage, long construction working time and the like. By applying the building rubbish pavement base material provided by the inventionin a large scale, not only can considerable economic benefit be produced, but also a huge environmental protection benefit can be produced.

Owner:HUNAN YUNZHONG REGENERATION TECH CO LTD

Straw fiber reinforcement air-entrained concrete and preparation method thereof

ActiveCN103193448ASmall drying shrinkageImprove crack resistanceCeramicwareShrinkage crackingWaste treatment

The invention discloses straw fiber reinforcement air-entrained concrete which comprises a base material, an aluminum powder paste, a straw fiber, an additive and water, wherein the doping amount of the aluminum powder paste accounts for 0.06%-0.09% of the dry weight of the base material; the doping amount of the additive accounts for 0.5%-0.8% of the dry weight of the base material; the doping amount of the straw fiber accounts for 2%-10% of the dry weight of the base material; and the mass ratio of the water and the base material is 0.52-0.60, The invention also discloses a preparation method of the straw fiber reinforcement air-entrained concrete. The straw fiber reinforcement air-entrained concrete disclosed by the invention reduces the shrinkage cracking and production cost of air-entrained concrete and solves the problems of straw resource waste, ceramic waste treatment and environmental pollution to a certain degree.

Owner:SOUTH CHINA UNIV OF TECH

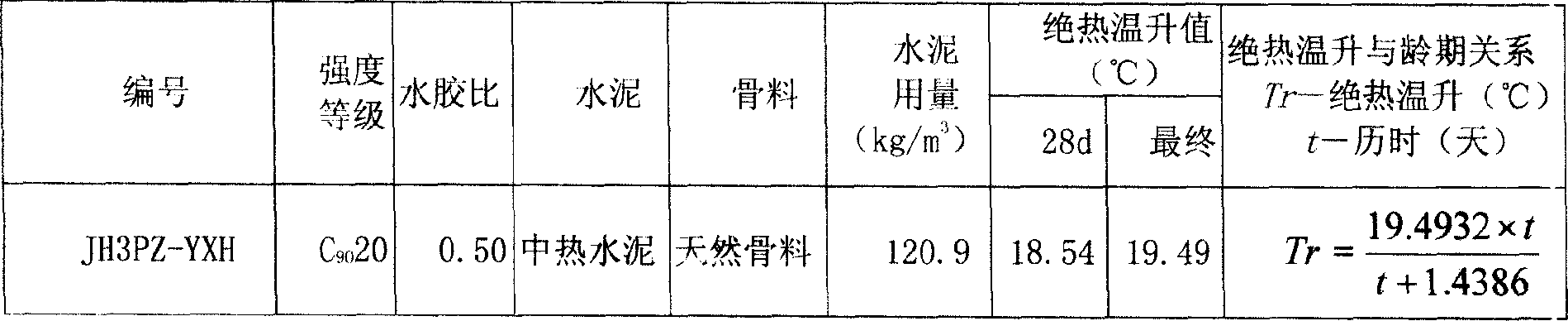

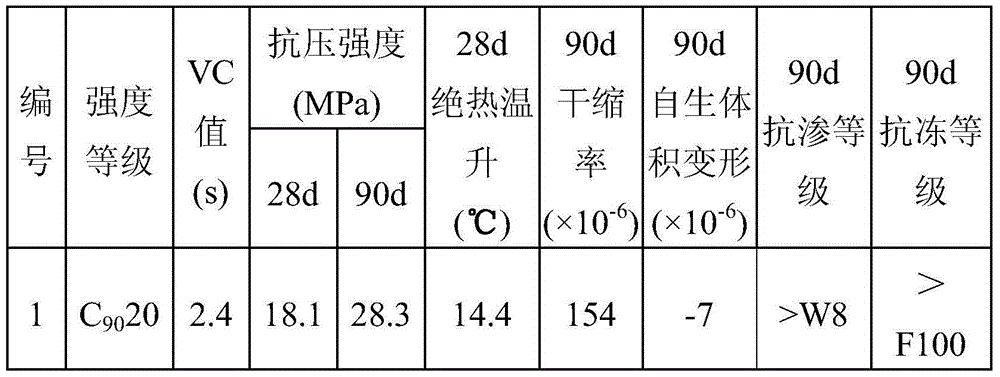

Four-graded roller compacted concrete suitable for water power hydraulic engineering and preparation method thereof

InactiveCN104402352AIncrease dosageReduce dosageSolid waste managementRoller-compacted concreteTemperature control

The invention provides four-graded roller compacted concrete suitable for water power hydraulic engineering, the four-graded roller compacted concrete per cubic meter comprises the following components: 49kg-64kg of cement, 78kg-92kg of fly ash, 70kg-71kg of water, 630kg-700kg of sand, 1520kg-1610kg of gravel, 0.98kg-1.42kg of a high efficiency water reducing agent and 0.07kg-0.14kg of an air entraining agent, the mass ratio of super large stone (80mm-120mm): large stone (40mm-80mm): middle stone (20mm-40m m): small stone (5mm-20mm) is 20:30:30:20. The four-graded roller compacted concrete is low in cementitious material use amount and low in adiabatic temperature rise, has good working performance, mechanical performance and durability, and can simplify the temperature control measures, improve the construction progress, and reduce cost.

Owner:CHANGJIANG RIVER SCI RES INST CHANGJIANG WATER RESOURCES COMMISSION

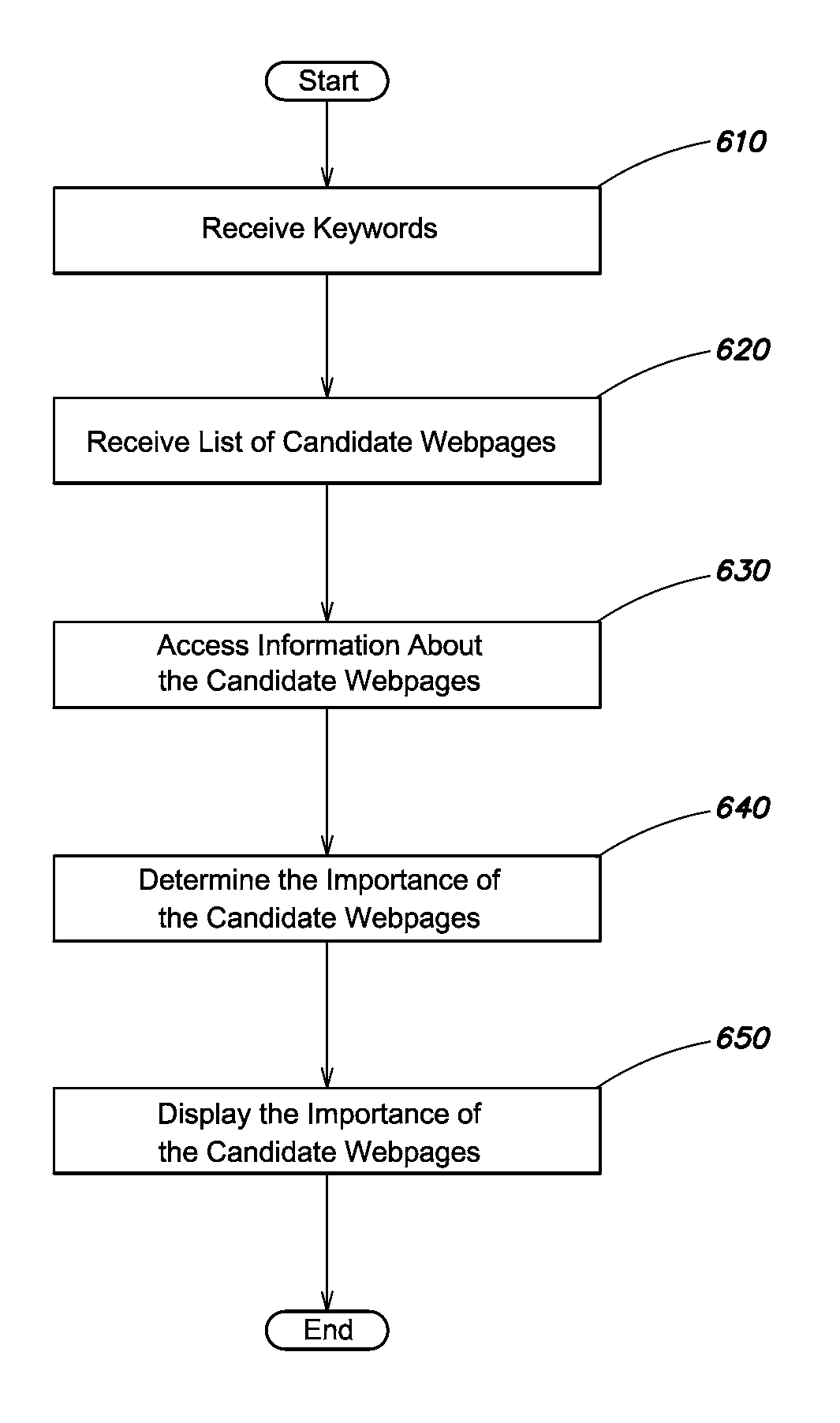

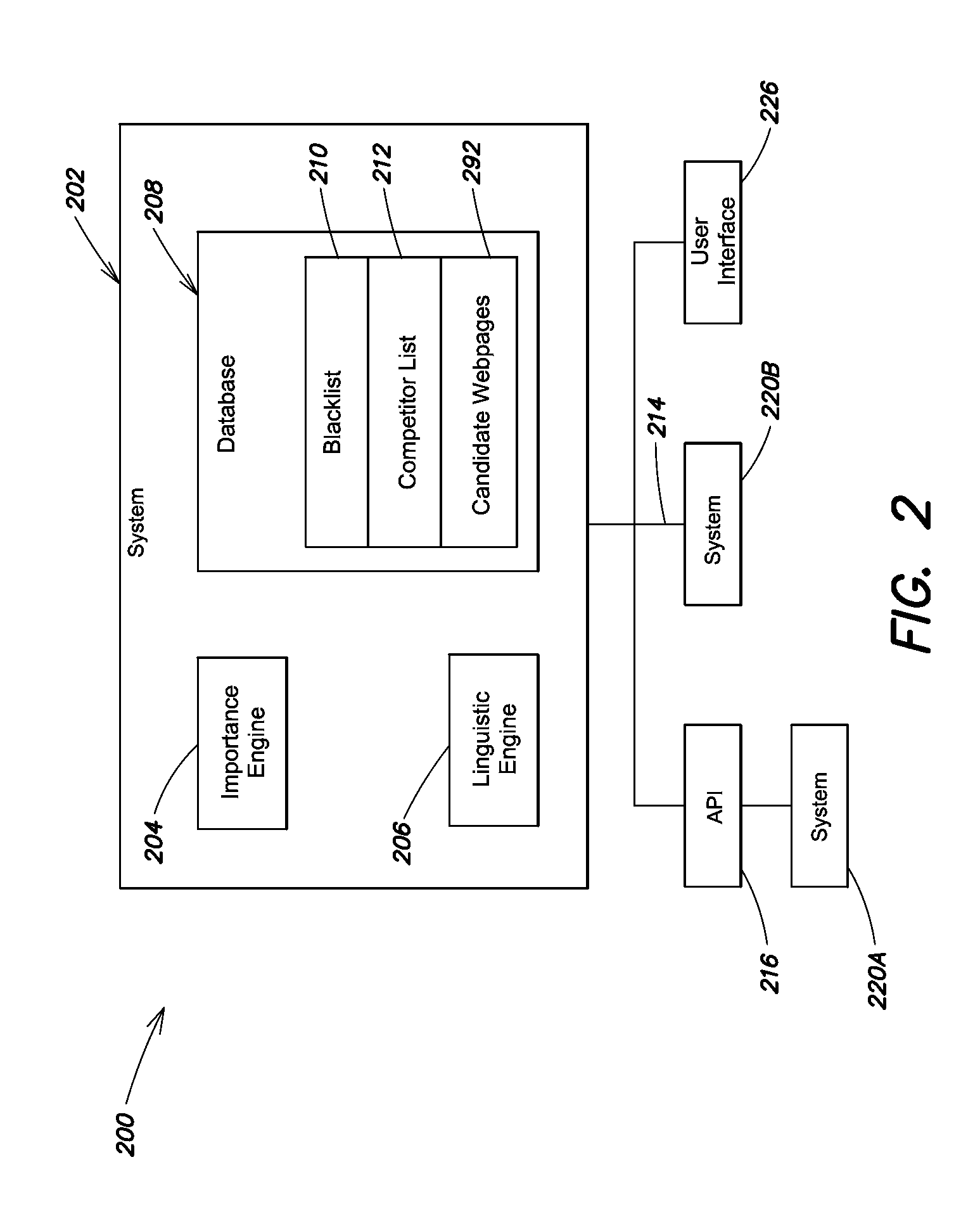

Method and system for evaluating link-hosting webpages

InactiveUS20120066359A1Accurate valueImprove accuracyWeb data indexingDigital computer detailsWeb pageUser interface

A method for valuing a link-hosting webpage is provided. The method includes the act of receiving, on a computer system, at least one keyword. The method also includes the act of receiving, on a computer system, at least one identifier of a webpage, the webpage having been previously identified as a link-hosting webpage. The method also includes the act of accessing information about the webpage over a computer network. The method also includes the act of determining an importance of the webpage based on the at least one keyword and the information about the webpage. The method also includes the act of displaying the importance on a computer-based user interface.

Owner:THE SEARCH AGENCY

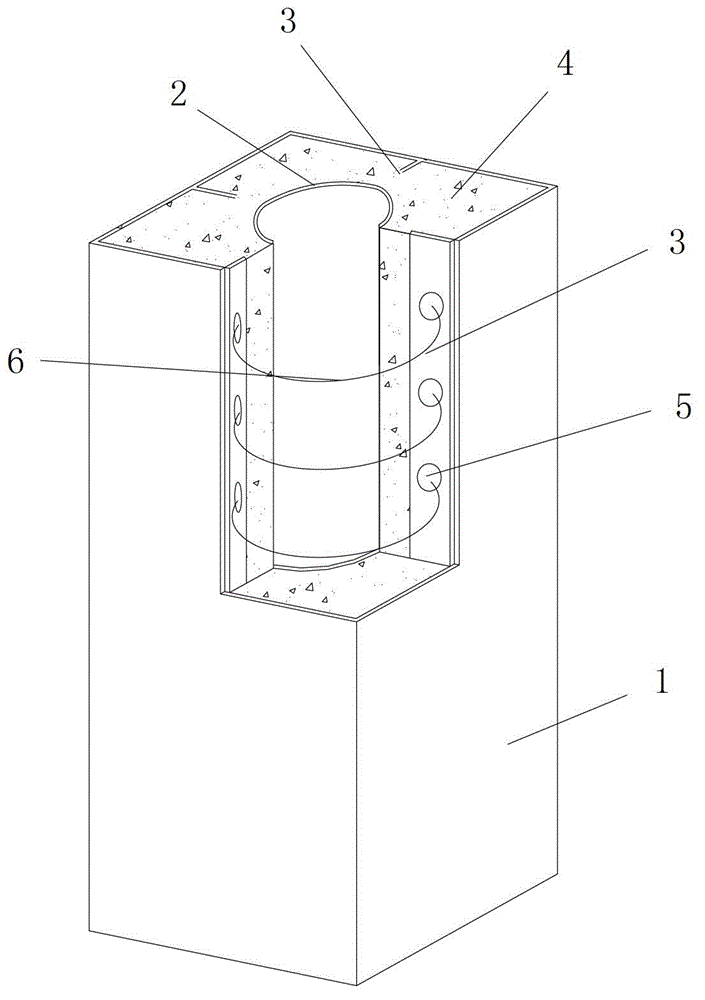

SCS (structure cabling system) encased structure based on PBL (planetary boundary layer) stiffening ribs

InactiveCN102979251ALight structureImprove seismic performanceArched girdersStrutsMechanical propertyStructure based

The invention discloses an SCS (structure cabling system) encased structure based on PBL (planetary boundary layer) stiffening ribs. The SCS encased structure comprises an outer steel tube, an inner steel tube, a plurality of PBL stiffening ribs arranged between the outer steel tube and the inner steel tube, and a concrete structure which is poured and molded by concrete filled inside a cavity between the outer steel tube and the inner steel tube, wherein the outer steel tube, the inner steel tube and the plurality of PBL stiffening ribs are equal in longitudinal length; the plurality of PBL stiffening ribs are arranged along the peripheral direction of the inner steel tube; the inner lateral wall of each PBL stiffening rib and the inner lateral wall of the inner steel tube are fastened and connected into a whole, and the outer lateral wall and the outer lateral wall of the outer steel tube are fastened and connected into a whole. The SCS encased structure is simple in structure, reasonable in design, convenient to construct, low in construction cost, excellent in mechanical property, and good in using effect, and the problems of large dead load of the existing encased structure, poor connection performance of the outer steel tube and the internal concrete, and small hoop effect of the outer steel tube on the internal concrete can be effectively solved.

Owner:CHANGAN UNIV

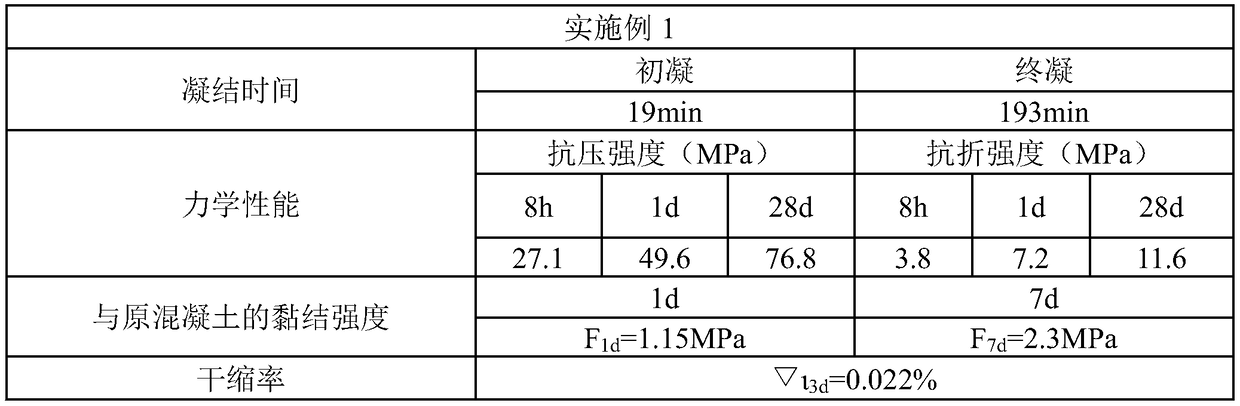

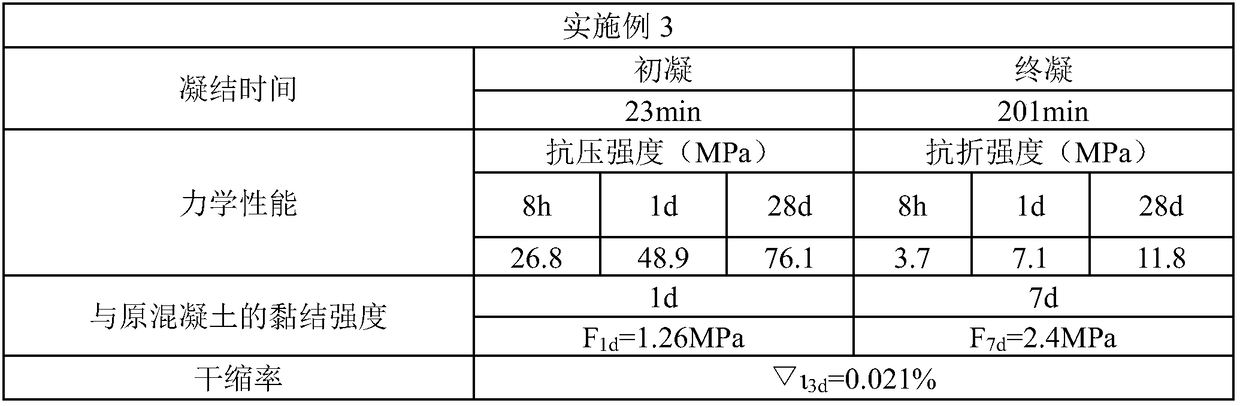

Fast hardening early strength type composite repair mortar

The invention belongs to the technical field of a building material, and provides fast hardening early strength type composite repair mortar. The mortar is prepared from the following ingredients in percentage by weight: 5 to 10 percent of water, 20 to 30 percent of cement, 1 to 5 percent of silicon ash, 1 to 5 percent of fly ash, 50 to 70 percent of quartz sand, 0.4 to 0.5 percent of compound early strength agents, 0.06 to 0.1 percent of water reducing agents, 1 to 5 percent of rubber powder and 0.06 to 0.8 percent of hybrid fiber, wherein the composite early strength agent is prepared from an ingredient A and an ingredient B; the ingredient A is lithium carbonate; the ingredient B is a mixture of triethanolamine and aluminum sulfate; the quartz sand consists of coarse sand, medium sand and fine sand; and the hybrid fiber consists of basalt fiber and polypropylene fiber. The fast hardening early strength type composite repair mortar solves the problems of reduced strength, high dry shrinkage rate and low bonding strength of the repair mortar in the prior art.

Owner:JILIN JIANZHU UNIVERSITY

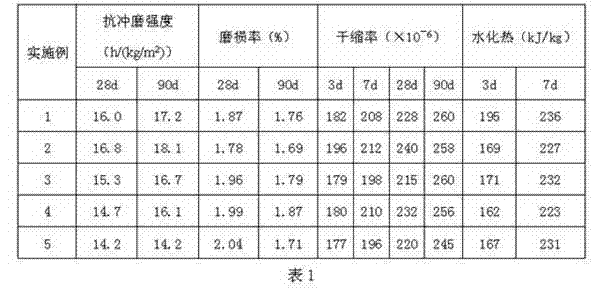

Abrasion resistant low-heat portland cement

ActiveCN102161583AReduce heat of hydrationImprove drying shrinkageSolid waste managementSuperplasticizerWater flow

The invention relates to abrasion resistant low-heat portland cement which is prepared from a low-heat portland cement clinker, an abrasion resistant mixed material and a proper amount of gypsum. The abrasion resistant low-heat portland cement comprises the following components by weight percent: 85-98% of the low-heat portland cement clinker, 2-10% of the abrasion resistant mixed material and 1-10% of the gypsum, wherein the abrasion resistant mixed material is mainly prepared from active micro-silicon powder, ultrafine low calcium coal ash and a proper amount of superplasticizer. The abrasion resistant low-heat portland cement provided by the invention has no crazing phenomenon, abrasion loss caused by the fact that concrete pushes or laminates substances is reduced, and the resistance to concrete damage generated by acting on sand inclusion and stone water flow is improved; and the abrasion resistant low-heatportland cement has the characteristics of low hydration heat, small dry shrinkage, good durability and excellent abrasion resistance, and the concrete is prepared just according to concrete design requirement so as to meet the abrasion resistant requirement on engineering parts with high concrete abrasion resistant requirement in the water and electricity fields such as diversion tunnels, spillway tunnels, dams, airfield runways and the like.

Owner:JIAHUA SPECIAL CEMENT

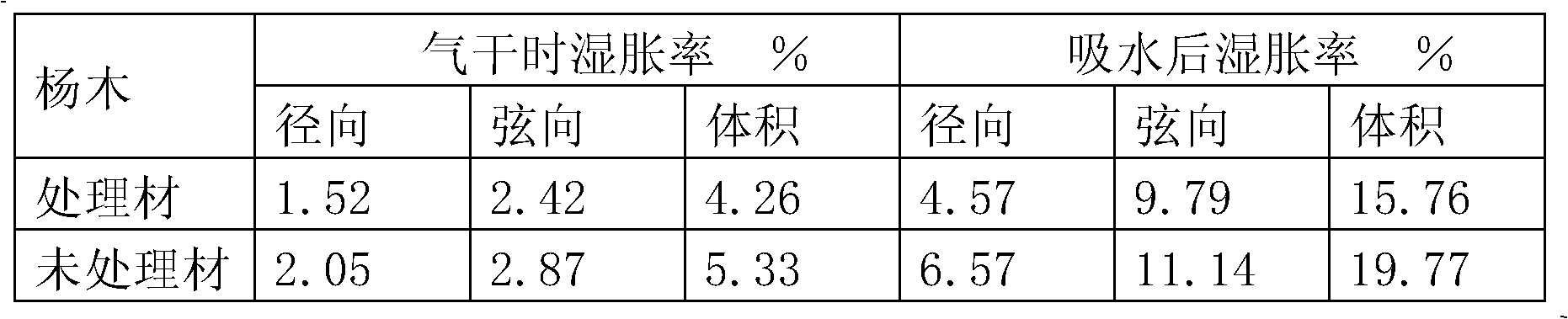

Pretreatment technology of atmospheric superheated steam for improving wood dimension stability

ActiveCN102431067ASmall moisture gradientPromote softeningWood treatment detailsWood dampingCore temperaturePulp and paper industry

The invention discloses a pretreatment technology of atmospheric superheated steam for improving wood dimension stability, comprising the step of finishing the pretreatment process through controlling numerical values of a wood inlet stack temperature, a wood outlet stack temperature and a wood core temperature as well as correlations thereof. Wood to be processed is placed in a pretreatment device, and sensors for measuring the wood inlet stack temperature, the wood outlet stack temperature and the wood core temperature respectively are arranged; not less than 2 detecting points are arranged in the wood inlet stack; not less than 4 detecting points are arranged in the wood outlet stack, half of the detecting points are used for detecting the wood outlet stack temperature, and the others are used for detecting the wood core temperature. After the hot steam treatment, the growth stress of the wood provided by the invention can be released, the plate surface is smooth and non-defective, the inner moisture channels of the wood are unimpeded, and the initial moisture content is obviously reduced. No chemical pollution is existent in the whole treatment process, the strength of the wood is not reduced, the air shrinkage and wet expandability of the wood are decreased, the dimension stability is obviously improved, and the wood textures are clearer. The wood treatment technology provided by the invention has the advantages of shortened preheating time, short treatment time and good evenness.

Owner:LANDBOND FURNITURE GROUP

SCS (structure cabling system) encased structure based on longitudinal stiffening ribs

InactiveCN102979250ASimple structureReasonable designArched girdersStrutsMechanical propertyStructure based

The invention discloses an SCS (structure cabling system) encased structure based on longitudinal stiffening ribs. The SCS encased structure comprises an outer steel tube, an inner steel tube, a plurality of longitudinal stiffening ribs arranged at the inner lateral wall of the outer steel tube, and a concrete structure which is poured and molded by concrete filled inside a cavity between the outer steel tube and the inner steel tube, wherein the outer steel tube and the inner steel tube are coaxially arranged; the plurality of longitudinal stiffening ribs are arranged along the peripheral direction of the inner steel tube; the outer steel tube, the inner steel tube and the plurality of longitudinal stiffening ribs are equal in the longitudinal length, and the transverse width of each longitudinal stiffening rib is the distance between the outer steel tube and the inner steel tube at the arranged positions. The SCS encased structure is simple in structure, reasonable in design, convenient to construct, low in construction cost, excellent in mechanical property, and good in using effect, and the problems of large dead load of the existing encased structure, poor connection performance of the outer steel tube and the internal concrete, and small hoop effect of the outer steel tube on the internal concrete can be effectively solved.

Owner:CHANGAN UNIV

Coagulated stone brick and holllow building block

The present invention relates to a building wall body material-coagulating stone brick and hollow block. Its raw material composition includes 11-28% of coagulating stone, 26-40% of coal slag, 32-43% of tails sand and the rest is water. The coagulating stone is a new type building material, and can be used as a substitute for cement.

Owner:张玉成 +2

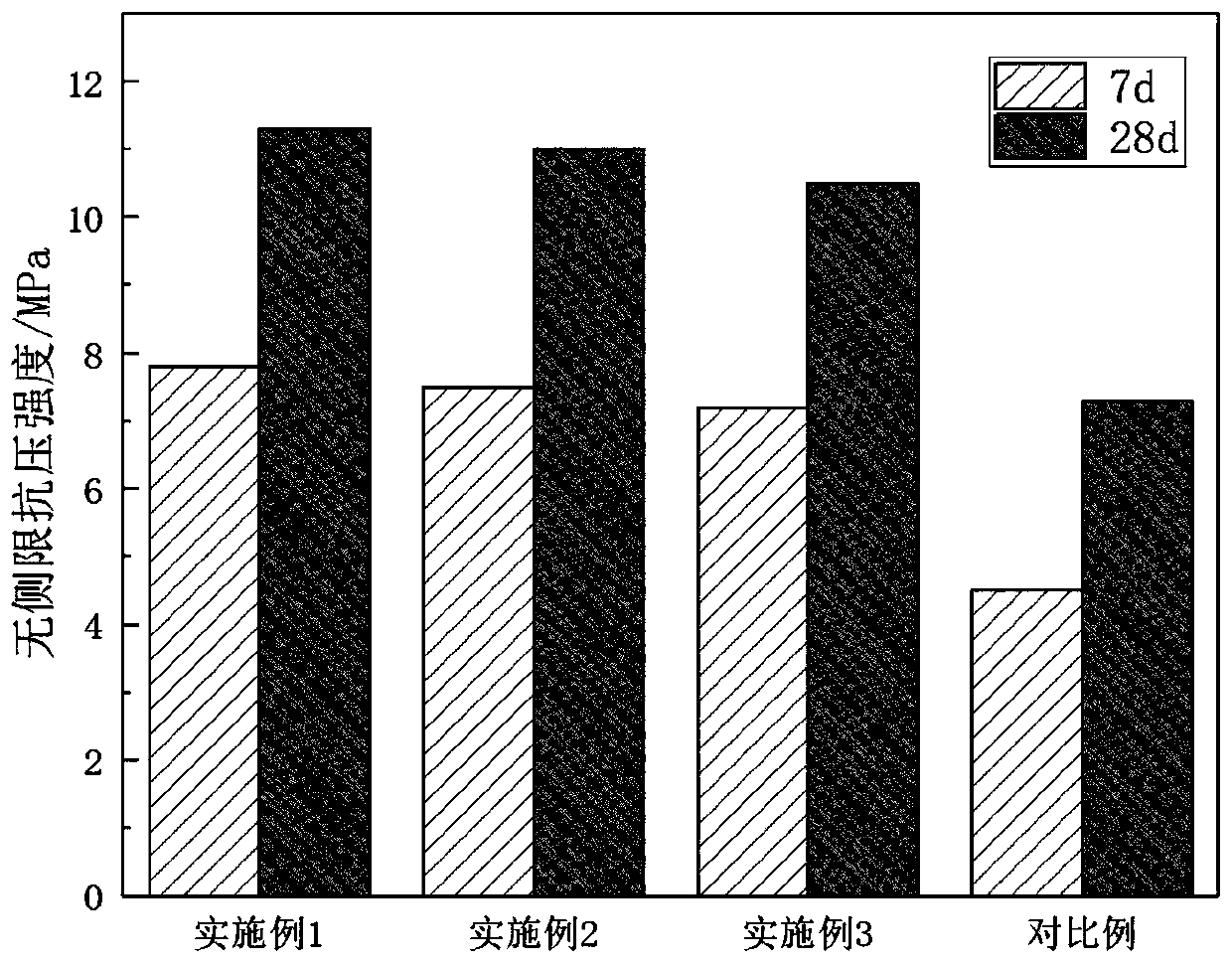

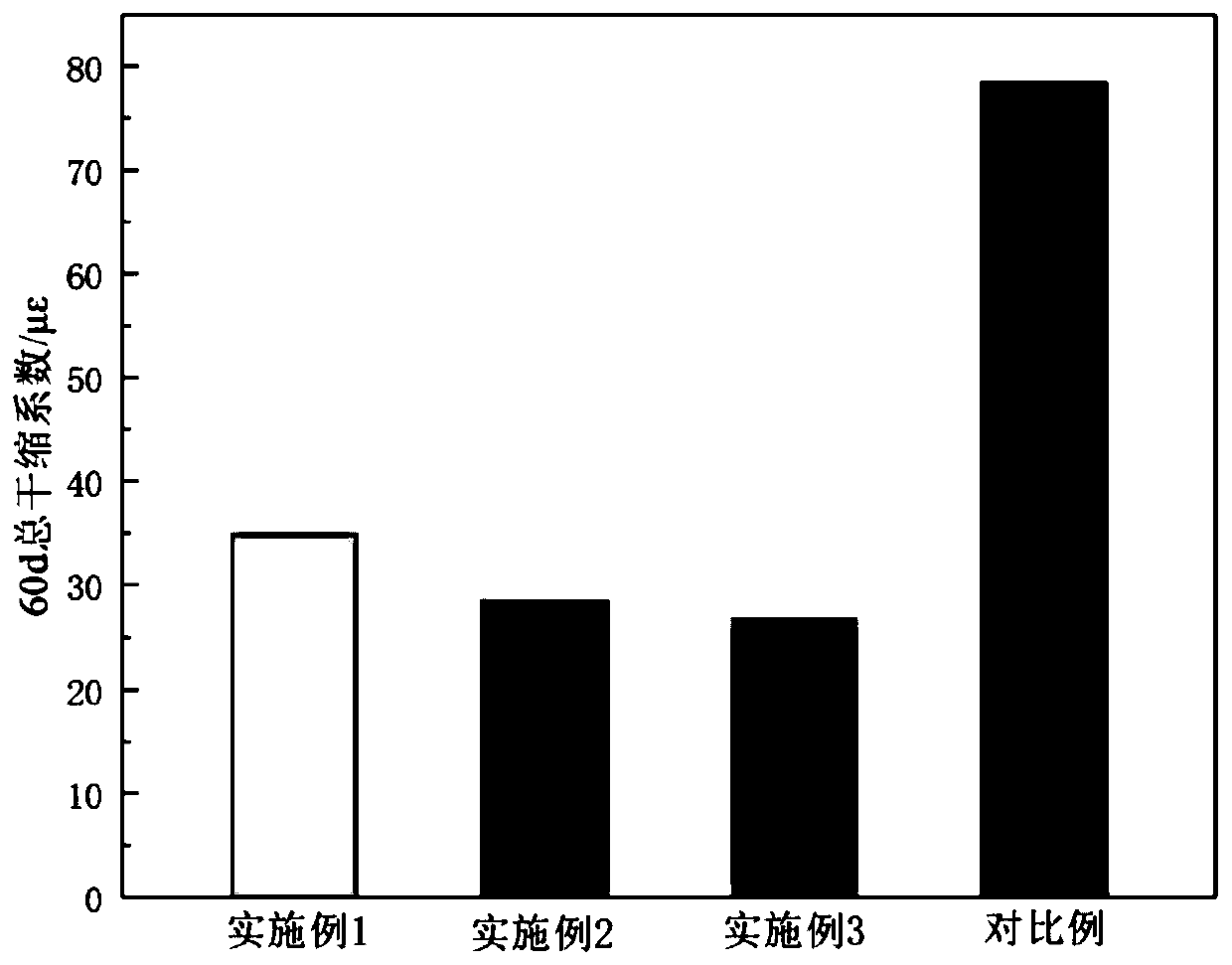

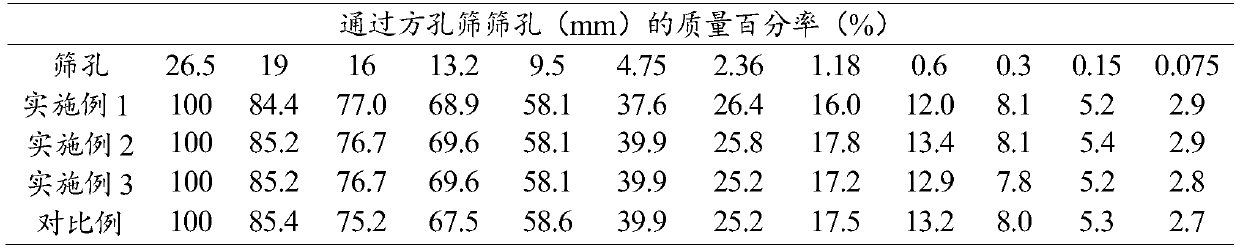

Environment-friendly low-drying-shrinkage crack-resistant casting waste sand concrete

ActiveCN105731911ASolve the technical problem of strength reductionHigh strengthSolid waste managementCrack resistanceCrushed stone

The invention discloses an environment-friendly low-drying-shrinkage crack-resistant casting waste sand concrete which is formed by mixing the following components in parts by weight: 330-370 parts of cement, 40-80 parts of rice hull ash, 700-780 parts of fine aggregate (formed by screening and mixing casting waste sand and river sand), 1080-1200 parts of coarse aggregate (macadam), 6-9 parts of shrinkage reducing agent, 3.5-5.5 parts of water reducing agent and 125-180 parts of water. The strength level of the environment-friendly low-drying-shrinkage crack-resistant casting waste sand concrete is C45-C55, the 7d drying shrinkage value is 75-100*10<-6>, the 28d drying shrinkage value is 200-250*10<-6>, the 90d drying shrinkage value is 260-300*10<-6>, and the drying shrinkage value trends to be stable; and the early crack resistance is Grade L-V. The environment-friendly low-drying-shrinkage crack-resistant casting waste sand concrete implements high-added-value recycling of the casting waste sand in concrete, and thus, has favorable environment-friendly effect. The fine aggregate, which is formed by screening and mixing the casting waste sand and river sand, effectively improves the grain size distribution of the aggregate. The rice hull ash, shrinkage reducing agent and other components are doped, thereby lowering the drying shrinkage value of the concrete and obviously enhancing the crack resistance from the angle of solid-liquid-phase optimum design.

Owner:江苏鹿晶新材料科技有限公司

Environmental protection building material and preparation method thereof

InactiveCN107098651ATo achieve the purpose of energy saving and environmental protectionImprove insulation effectChipsealCompressive strength

The invention provides an environmental protection building material and a preparation method thereof, which belong to the field of a building material. The environmental protection building material comprises the following raw materials: 10-30 parts of granite powder, 17-25 parts of alumina silicate powder, 7-13 parts of glass wool, 4-9 parts of polypropylene fiber, 21-35 parts of fine sand, 22-38 parts of broken stone, 15-21 parts of cement, 15-27 parts of waste rock wool plate, 13-21 parts of waste glass, 15-33 parts of meerschaum, 21-27 parts of bamboo charcoal, 0.3-0.7 parts of an air-entrainer, 0.4-0.6 parts of a hardener, 0.3-0.9 parts of a water reducer, and 3-11 parts of water. The preparation method comprises the following steps: 1) weighing the raw materials; 2) crushing the raw materials; 3) stirring the raw materials; and 4) performing compacting moulding, drying the material, and cooling and preserving the product. The method solves the problem that the current environmental protection building materials used for the buildings having high compressive strength, heat insulation, and environmental protection and energy saving requirements are insufficient.

Owner:HEFEI YAKELI NEW BUILDING MATERIAL CO LTD

Formula of wall heat-insulating material

InactiveCN101712541AReduce use costStem shrinkSolid waste managementCalcium carbonateFiberglass mesh

The invention relates to a wall material, in particular to a formula of a wall heat-insulating material. The formula of the wall heat-insulating material comprises the following materials: 10 to 30 percent of spherical closed cell vitrified hollow microsphere with bulk weight of 90kg / m3, 8 to 18 percent of spherical closed cell vitrified hollow microsphere with bulk weight of 130kg / m3, 15 to 35 percent of ground calcium carbonate, 30 to 50 percent of 42.5R cement, 0.5 to 3 percent of wood fiber and 0.5 to 3 percent of dispersible latex powder. During the natural maintenance of the wall heat-insulating material adopting the formula, the wall heat-insulating material overcomes the defect that the common wall heat-insulating material cannot be maintained independently, and ensures that the water absorption and discharge automatically reach certain balance, thereby solving the problems of cracking, hollow joint and dropping-off after the construction; and complicated processes, such as a process of using fiberglass mesh and the like, are not needed so as to greatly reduce the using cost.

Owner:恩施市齐进节能建材工程有限公司

High-strength coal ash calcium sulphate whisker aerated concrete block and machining method thereof

InactiveCN106242401AReduce pollutionImprove liquidityCeramic shaping apparatusCeramicwareCrack resistanceSalicylic acid

The invention discloses a high-strength coal ash calcium sulphate whisker aerated concrete block and a machining method thereof. The high-strength coal ash calcium sulphate whisker aerated concrete block is prepared from, by weight, 30-40 parts of river mud, 20-30 parts of coal ash, 3-5 parts of calcium sulphate whisker, 4-6 parts of cement, 3-5 parts of quick lime, 0.02-0.04 part of triethanolamine, 20-25 parts of crop straw, 1-1.5 parts of water glass, 0.2-0.5 part of hydroxypropyl methyl cellulose, 1-2 parts of additive, 1-2 parts of aluminum powder, 0.2-0.4 part of dodecyl salicylic acid, 0.01-0.02 part of polyoxyethylene aliphatic alcohol ether, 0.2-0.3 part of triterpenoid saponin, 0.01-0.03 part of calcium stearate and 0.02-0.04 part of benzotriazole. The aerated concrete block is small in drying shrinkage value and high in cracking resistance and water resistance, and all properties meet the national standard. Compared with existing products, the aerated concrete block has obviously higher strength.

Owner:安徽阜阳富龙建筑材料有限责任公司

Alkaline-free anti-crack concrete shrinkage reducing agent

The invention discloses an alkaline-free anti-crack concrete shrinkage reducing agent comprising the following components in percentage by weight: 35-66% of I-grade coal ash, 8-18% of polypropylene staple fiber, 2-18% of polyethylene glycol, 3-17% of methacrylic acid, 2-15% of calcium formate, 3-16% of neopentyl glycol and 0.2-0.8% of sodium dodecyl benzene sulfonate. The invention provides possibility for realizing the comprehensive improvement of an additive technology, reducing concrete shrinkage, inhibiting non-loaded cracks and improving the durability of concrete through the research on and application as a shrinkage reducing additive and creates the environment-friendly alkaline-free anti-crack concrete shrinkage reducing agent. The technology is simple in feeding way, easily-controlled in production condition, simple in process and capable of producing the alkaline-free anti-crack concrete shrinkage reducing agent which is low in alkaline content and mixing amount and capable of effectively controlling the shrinkage of concrete. The alkaline-free anti-crack concrete shrinkage reducing agent has a relatively good social benefit and a relatively high economic benefit.

Owner:HUNAN CONSTR ENG GRP COR +1

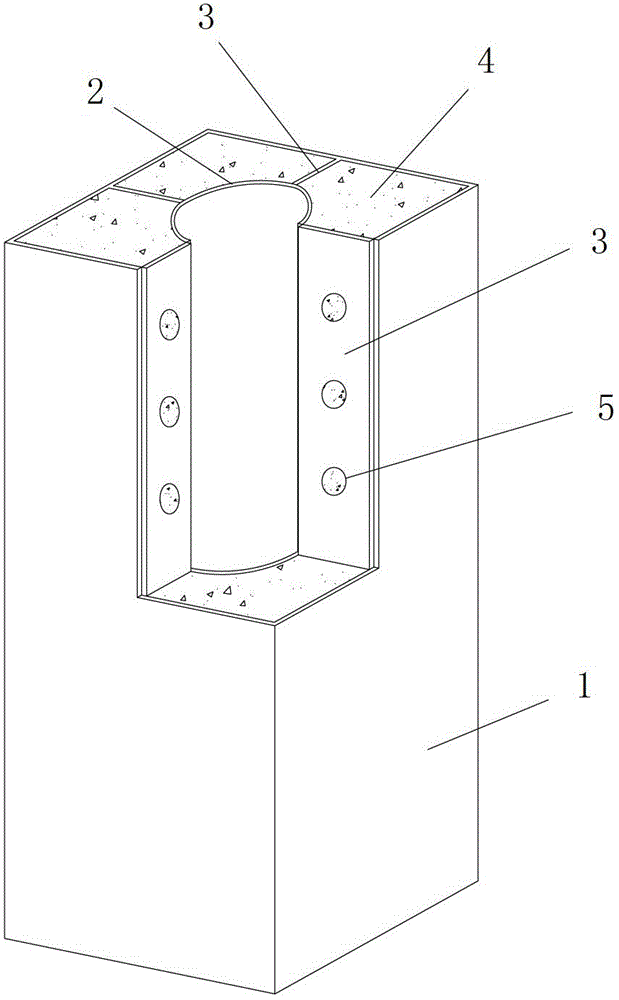

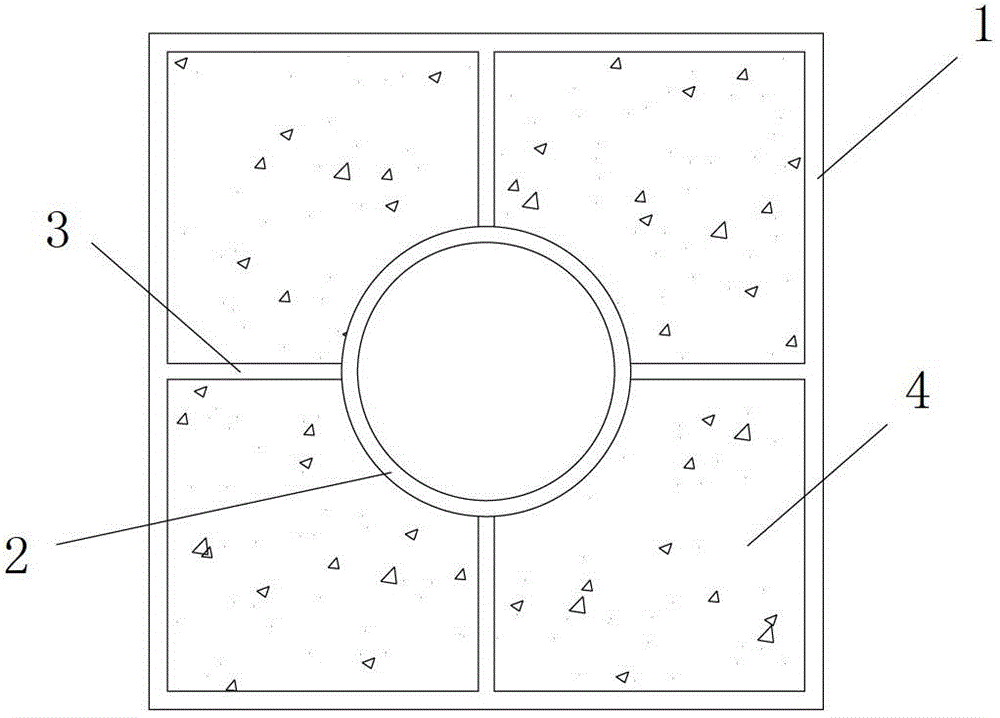

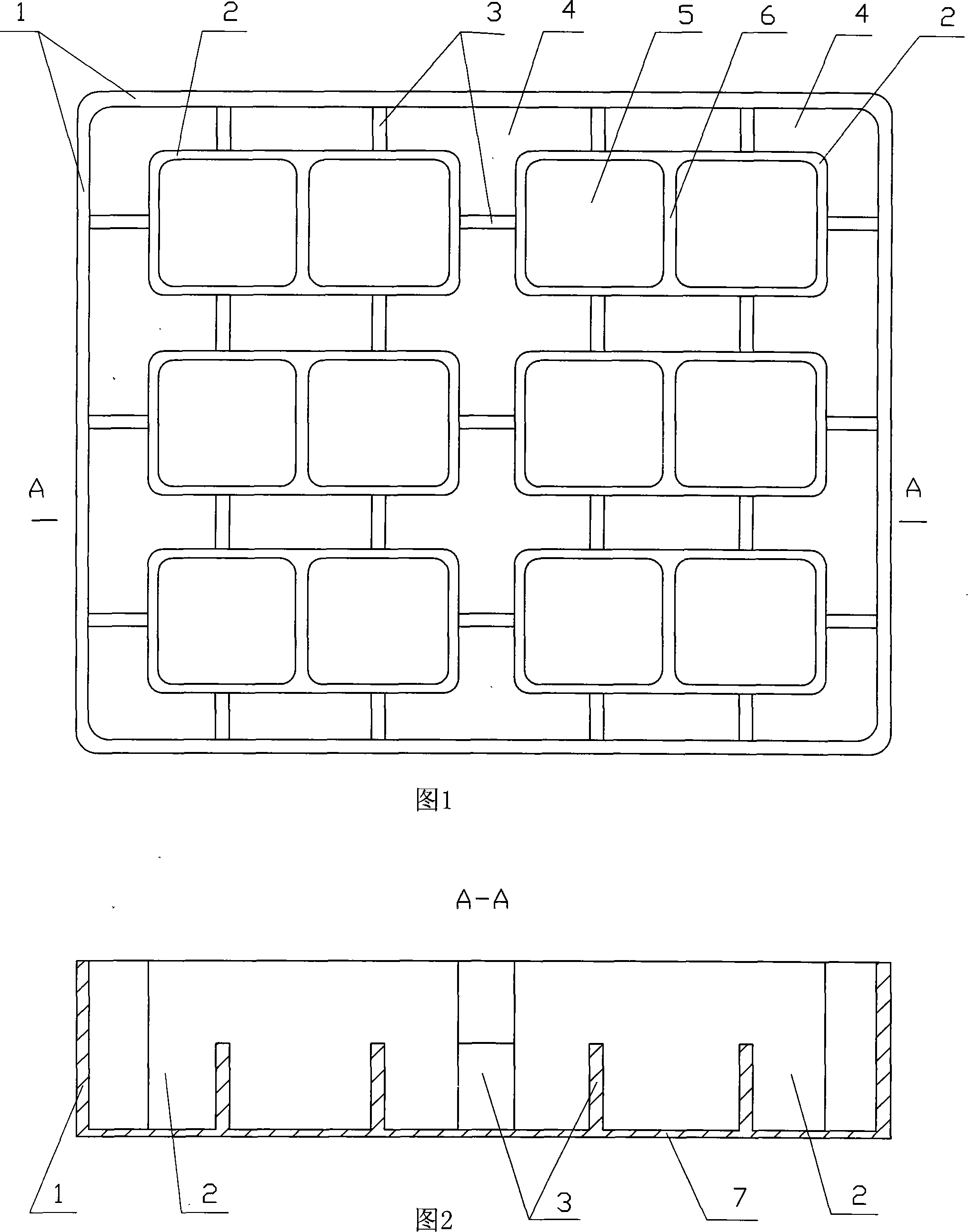

Die grid for producing composite block and casting forming method of composite block

The invention relates to a bolster for making composite blocks and is characterized in that the bolster comprises a rectangular outer surrounding frame (1), separation boards (2) are arranged in the outer surrounding frame (1), and an internal surrounding frame (5) is arranged between the separation boards (2). The invention also relates to a method for moulding the composite blocks by casting, and the following steps are adopted: 1. a foam board (3) is arranged in the internal surrounding frame (5); 2. foam concrete and hadite foam concrete are cast among the outer surrounding frame (1), the separation boards (2) and the internal surrounding frame (5); after finishing the casting, all the separation boards and the internal clapboards are taken out, and various cast materials are facilitated to fuse each other; 4. after the various materials become dry, demoulding is carried out; 5. six-side cutting is carried out on the dry blocks. The advantages of the invention are that: making composite block bolsters is simple, the method for manufacturing the composite blocks is simple, and the manufactured composite blocks have the advantages of light mass, high stiffness, low water absorption rate, small drying shrinkage and good hot work ability.

Owner:高学保

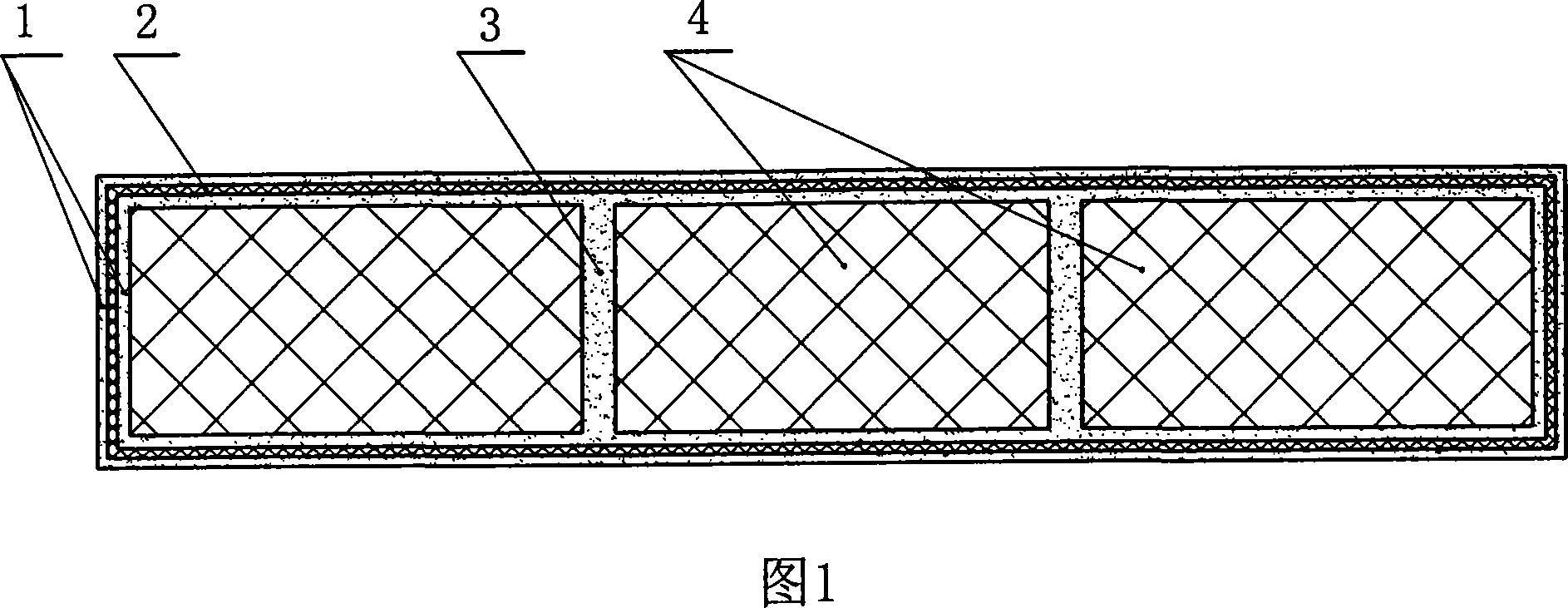

Pre-built-in template frame of composite block and method for moulding composite block

The invention relates to a pre-buried molding frame of composite block and the casting and forming method of block, characterized in that the pre-buried molding frame comprises external peripheral frame (1) and internal frame (2); connecting rib (3) is set to connect the internal frame (2) and the external peripheral frame (1); cavity (5) is set in the internal frame. The casting and forming method of composite block adopts the pre-buried molding frame mentioned above and is carried out according to following procedures. a. the mixture of foaming concrete and ceramic grain is cast in the external molding cavity between the external peripheral frame and the internal frame. b. polystyrene foaming grain is cast in the cavity in internal frame. c. after material is dried and solidified, six-face cutting is carried out with the unit of internal frame to form rectangle body of composite block. The invention comprises following merits. The pre-buried molding frame of composite block is fabricated simply and can be produced according to normal forming process for block and the material. Not only multi-layer composite heat-preservation block can satisfy wall self-heat preservation synthesis performance but also the invention is provided with simple producing method, small investment and high efficiency.

Owner:金波

Environment-friendly type building water-proof heat-insulating mortar and its production method

InactiveCN100364916CEasy to operateDecreased insulation performance without heat preservationClimate change adaptationHeat proofingWater basedThermal insulation

The invention discloses an environment-friendly type construction water resistant thermal insulating mortar prepared from cement, polymer emulsion powder, discarded polyphenylacetylene, polypropylene fiber, alta-mud, water-based silane / siloxane emulsion, quartz sand and water with right weight ratio through finite process. The mortar has fine thermal insulation property, chemical-resisting, waterproof and barrier properties.

Owner:TONGJI UNIV

Marl for repairing modern cultural relic architecture decoration

The invention discloses marl for repairing modern cultural relic architecture decoration. The marl is prepared from water, fly ash, quick lime, water-washing medium sand, activated silicon dioxide, activated calcium dioxide, silicic acid, calcium bicarbonate and titanium oxide. According to the marl disclosed by the invention, the activated silicon dioxide, the activated calcium dioxide and the water react to rapidly generate calcium silicate hydrate and the calcium silicate hydrate is subjected to hardening and dry shrinkage to form a hardened framework; the hardened framework can be used forlimiting later-period dry shrinkage of the calcium silicate hydrate generated by the fly ash, the quick lime and the water, calcium aluminate hydrate, calcium alumino-ferrite hydrate and calcium sulfoaluminate hydrate; the dry shrinkage is reduced, so that the marl can be matched with an original cultural relic very well. Moreover, the mineral characteristic value of a material formed by adoptingthe formula provided by the invention is similar with the mineral characteristic value of the original cultural relic, and the material has good compatibility with the original cultural relic. Furthermore, calcium hydroxide generated in a process is consumed in volcanic ash reaction, so that the corrosion resistance and durability of the material formed by adopting the formula provided by the invention can be effectively enhanced.

Owner:黄丽仪 +1

Full-granularity steel slag pavement base material for heavy-duty pavement

The invention discloses a full-granularity steel slag pavement base material for a heavy-load pavement The full-granularity steel slag pavement base material is prepared by adding water into a dry material and uniformly mixing, and the dry material comprises 3.4-5.0% of a cementing material and 95.0-96.6% of steel slag aggregate; the cementing material is prepared by mixing 70-90% by mass of cement and 10-30% by mass of steel slag micro-powder according to a certain ratio; and the water accounts for 5-6% of the total mass of the dry material. Excellent physical properties and potential gellingactivity of the steel slag are utilized, the base material with high strength, small cement dosage and reduced dryness can be prepared without additives, the base material is suitable for the heavy-load pavement, and the service life of the heavy-load pavement is prolonged; and an application of the full-granularity steel slag in the base material is realized, natural resources are effectively saved, the problems of environmental pollution and the like caused by improper treatment of the steel slag are reduced, the production cost is reduced, and remarkable social, economic and environmentalbenefits are achieved.

Owner:WUHAN UNIV OF TECH

Relief paint

The inorganic relief paint is compounded with quartzite, white cement, hydrated lime, heavy calcium carbonate, amylase, thixotropic bentonite lubricant, hydrophobic agent, lignocellulose fiber and methyl cellulose. After being painted, it can form coating with skin-like function to avoid bubble caused by inside water vapor and crack and powder of the outer material. It has less drying shrinkage, good weather resistance, powerful adhesion, high waterproof and penetrating performance, and other advantages, the present invention is one green wall decorating material without toxicity and pollution.

Owner:王胜怀

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com