Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

193results about How to "Small drying shrinkage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hydration heat inhibited concrete expanding material as well as preparation method and applications thereof

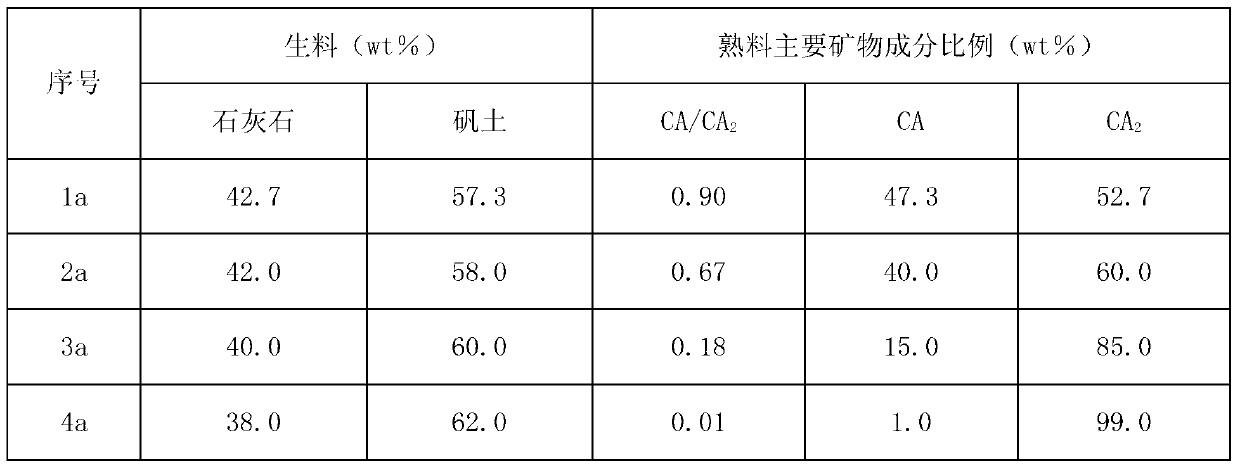

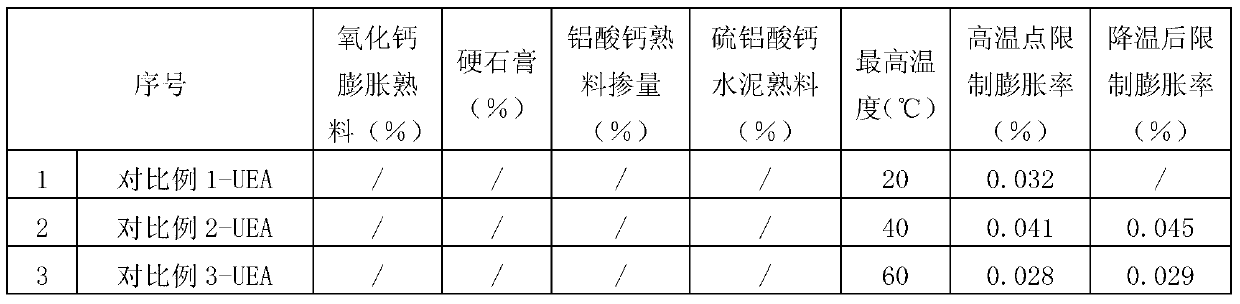

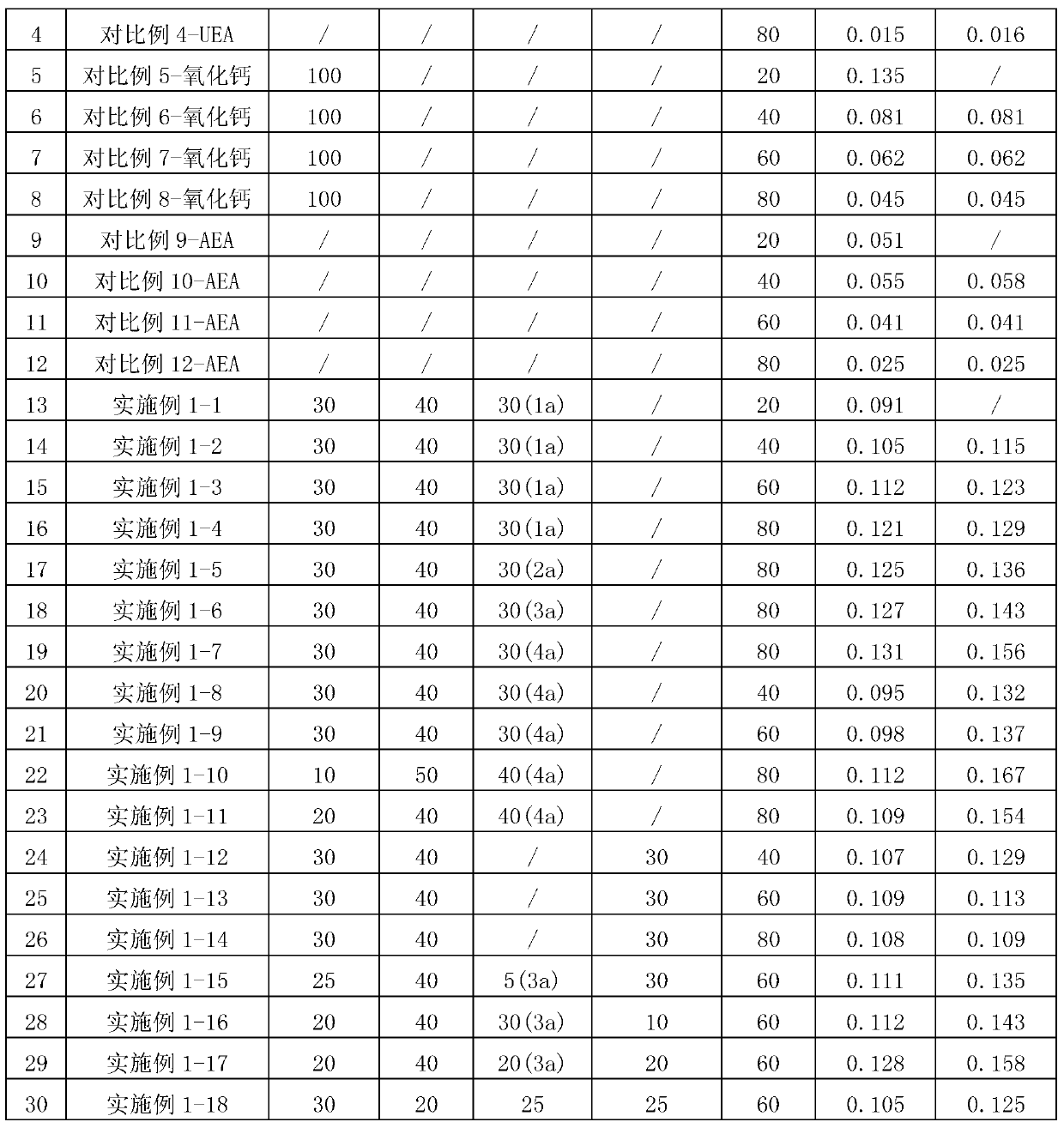

The invention discloses a hydration heat inhibited concrete expanding material as well as a preparation method and applications thereof. The hydration heat inhibited concrete expanding material is implemented by complexly using first two or three of an expanding agent, a hydration heat inhibitor and an inner curing agent. The hydration heat inhibited concrete expanding material disclosed by the invention fully plays the superimposed effect of the three types of materials, so that the dry shrinkage resistance and cold shrinkage resistance of concrete can be maximized. Experiments prove that concrete with the hydration heat inhibited concrete expanding material disclosed by the invention produces a large expansion in the temperature-fall period, thereby considerably improving the temperature shrinkage (caused by hydration heat) resistance of the concrete; the temperature rise of concrete can be effectively reduced; high relative humidity can be kept in the concrete for a long time, thereby providing a good hydration reaction environment for the expanding agent, and reducing dry shrinkage.

Owner:CHINA BUILDING MATERIALS ACAD

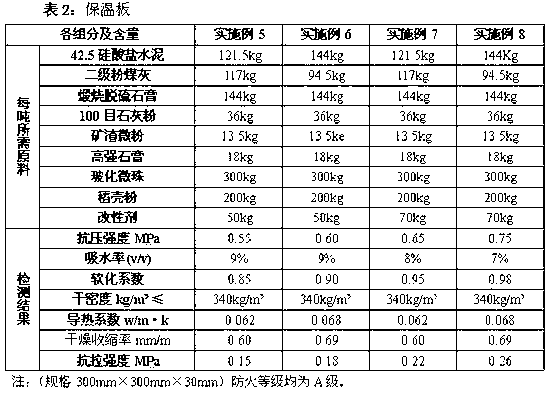

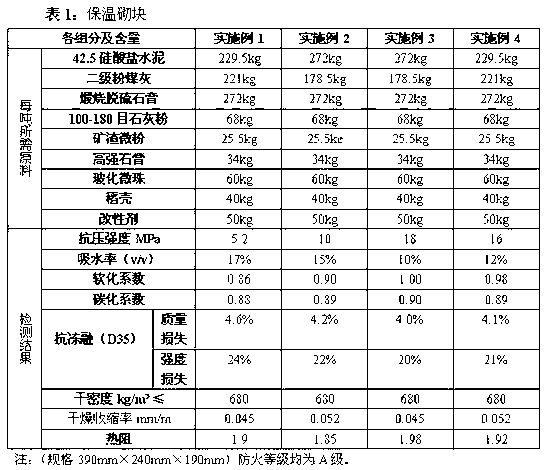

Building exterior wall thermal insulation material and preparation process thereof

The invention discloses a building exterior wall thermal insulation material. The building exterior wall thermal insulation material is formed by mixing a binding material, thermal insulation lightweight aggregate and a property-modifying additive according to the weight ratio of (40-85): (10-55):5. The building exterior wall thermal insulation material disclosed by the invention can be manufactured into wall thermal insulation mortar, thermal insulation blocks and thermal insulation boards, can be applied to different parts of a building, so as to ensure that the energy conservation index of the building meets the national mandatory standard, the fire rating can reach level A, and the drying shrinkage is low. A preparation process of the building exterior wall thermal insulation material is energy-saving, meanwhile, the recycling problem of industrial waste gypsum is solved, and the pollution of the industrial waste gypsum to the environment is avoided.

Owner:李奕

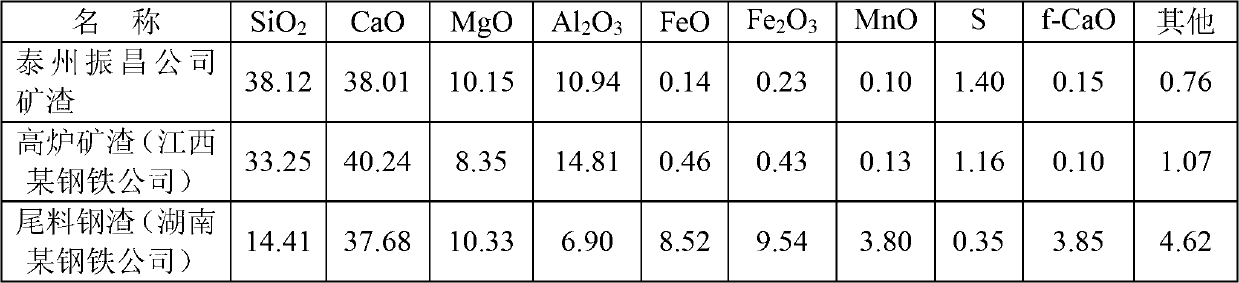

Aerated concrete block produced through using specially-made mineral waste residue and tailings steel slag and production method of aerated concrete block

The invention provides an aerated concrete block produced through using specially-made mineral waste residue and tailings steel slag and a production method of the aerated concrete block. The aerated concrete block is produced through the following steps: adding an additive A, an additive B and water in components as follows: 40 to 50% of specially-made mineral waste residue obtained in a such way that cinder is obtained through the production process of recycling steel slag discharged from Taizhou Zhenchang Industrial Waste Residue Comprehensive Utilization LTD and metallurgical and chemicalferrous waste residue, and then is water-quenched, 35 to 45% of tailings steel slag, 2 to 4% of cement clinker, 1 to 3% of gypsum, and 8 to 12% of modified wood, wherein the grain size of the specially-made mineral waste residue is less than or equal to 5 mm, the grain size of the tailings steel slag is less than or equal to 20 mm, the additive A accounts for 1% of the total weight of the components, the additive B accounts for 0.05% of the total weight of the components, and water accounts for 0.5 to 0.6 times of the total weight of the components; and conducting mixing, heating, air-entrapping, steaming and pressing, and curing in sequence. The aerated concrete block produced by adopting the production method is high in strength, and small in drying shrinkage value, and can meet the block standards of the A3.5 grade and the B09 grade in the JC1062-2007 foam concrete block standard.

Owner:TAIZHOU ZHENCHANG IND RESIDUE COMPREHENSIVE UTILIZATION +1

Quick setting and rapid hardening non-shrinkage anti-disturbance self-compacting concrete and preparation method thereof

The invention relates to quick setting and rapid hardening non-shrinkage anti-disturbance self-compacting concrete and a preparation method thereof. Raw materials contain the following ingredient (by weight): 100-450 parts of cement, 20-70 parts of gypsum, 150-450 parts of fine aggregate, 200-600 parts of crude aggregate, 10-30 parts of fly ash, 10-50 parts of heavy calcium powder, 10-50 parts of silica fume, 10-50 parts of slag powder, 10-50 parts of quartz powder, 1-5 parts of a water reducer, 0.1-0.8 part of cellulose ether, 0.05-1.0 part of a retarder, 0.1-1.0 part of a coagulation accelerator, 0.5-2.0 parts of an antifoaming agent, 0.5-2.05 parts of an early strength agent, 0.5-5.0 parts of an expanding agent, 1.0-5.0 parts of a shrinkage reducing agent, 0.2-1.0 part of anti-crack fiber, and 50-200 parts of water. Through an optimum mixture ratio and by the use of a polycarboxylate superplasticizer, the early strength agent and other additives, properties such as early strength, disturbance rejection, crack resistance, durability, self-compaction and the like of concrete are greatly enhanced, and disadvantages of low early strength, long time interval of initial set and final set and the like of common concrete are solved.

Owner:张彬

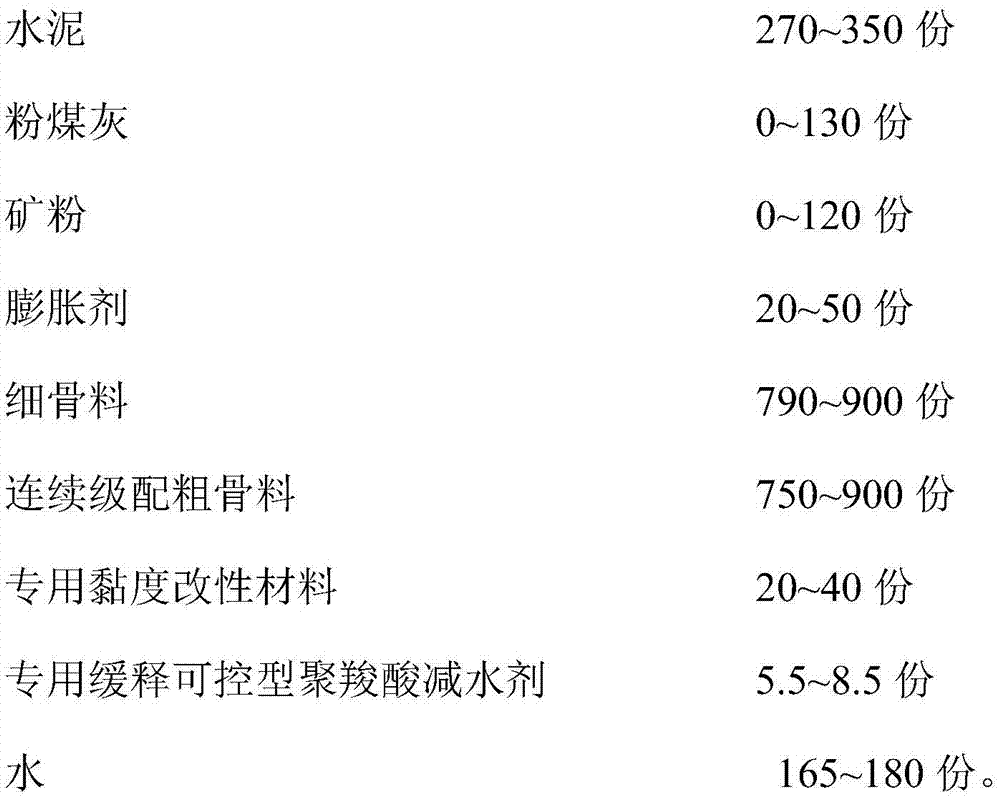

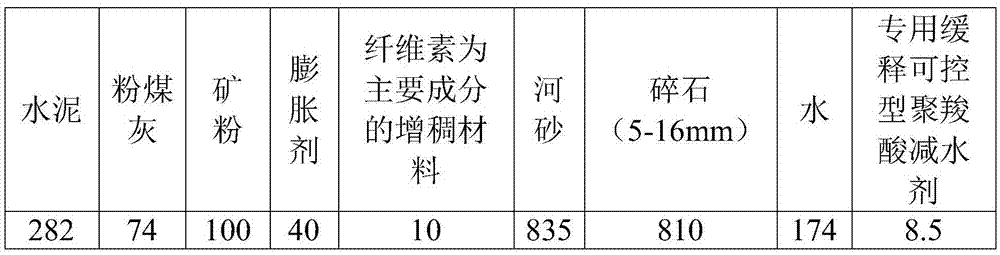

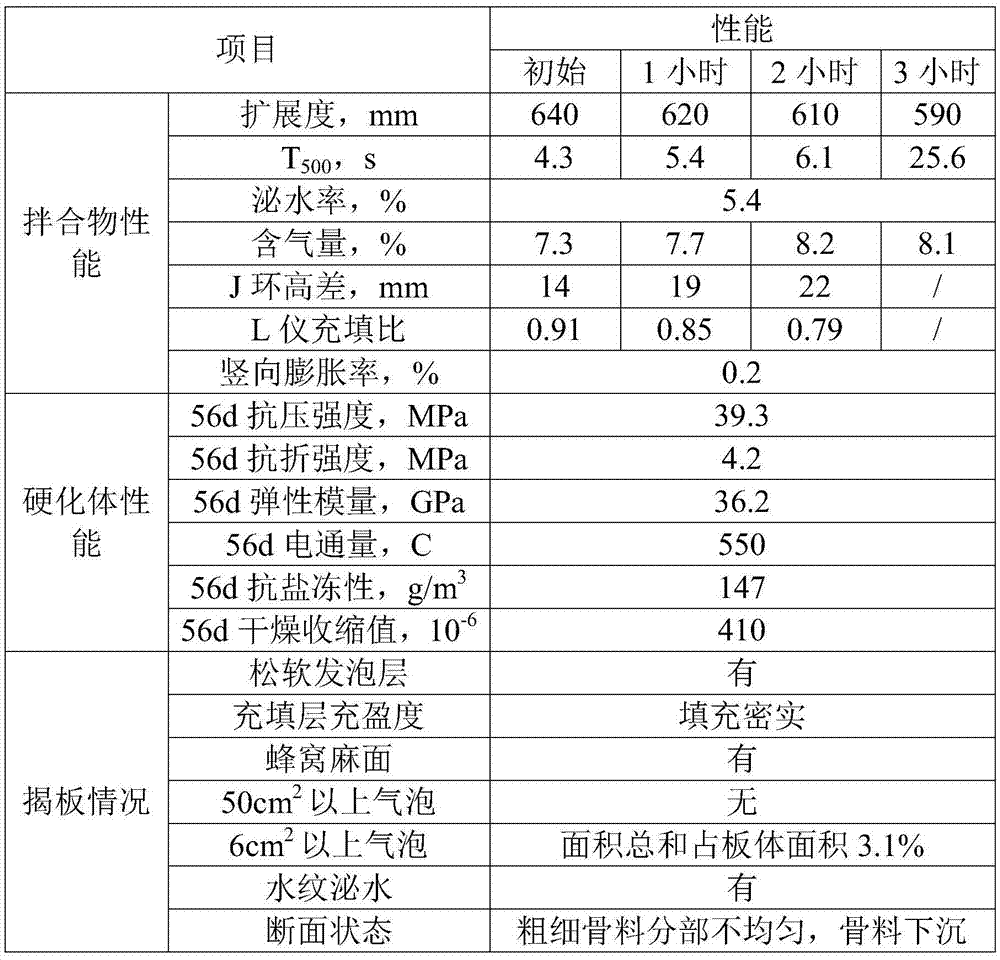

Self-compacting concrete for CRTS III plate-type ballastless track filling layer and preparation method for self-compacting concrete

The present invention discloses a self-compacting concrete for CRTS III plate-type ballastless track filling layer. The concrete is prepared from the following raw materials in parts by weight: 270-350 parts of cement, 0-130 parts of coal fly ash, 0-120 parts of mineral powder, 20-50 parts of an expanding agent, 790-900 parts of fine aggregate, 750-900 parts of continuous gradation coarse aggregate, 20-40 parts specific viscosity modified materials, 5.5-8.5 parts of a specific sustained release controllable polycarboxylic acid water reducing agent and 165-180 parts of water. According to the invention, the specific viscosity modified materials and specific sustained release controllable polycarboxylic acid water reducing agent are used in combination to prepare the specific self-compacting concrete for filling layer with good flowability, strong volume stability, low sensitivity for water consumption, small thixotropic time change, low shrinkage and good longevity, thereby reducing theconstruction difficulty of the CRTS III plate-type filling layer and prolonging the sevice life of the ballastless track structure.

Owner:CHINA TIESIJU CIVIL ENG GRP CO LTD +1

Method for preparing micro expanded inorganic heat insulation mortar

ActiveCN102010166AWide variety of sourcesLow priceSolid waste managementCeramicwareMethyl celluloseEther

The invention discloses a method for preparing micro expanded inorganic heat insulation mortar. Materials such as common silicate cement, desulfuration ash, calcium carbonate powder, re-dispersible latex powder, hydroxypropyl methyl cellulose ether, wood fiber, polypropylene fiber, surfactant, foam stabilizer, water, vitrified micro bubbles and the like are adopted; and the mortar is obtained by adopting the steps of stirring, mixing, shaping, curing and the like. The method has the advantages of low cost, early micro expansion, low later linear shrinkage rate, fire resistance, durability and the like, is easy to construct, and achieves good effect of preparing the I-type building heat insulation mortar by using the III-class vitrified micro bubbles.

Owner:CHONGQING SIBEIKEN ENERGY SAVING TECH DEV +1

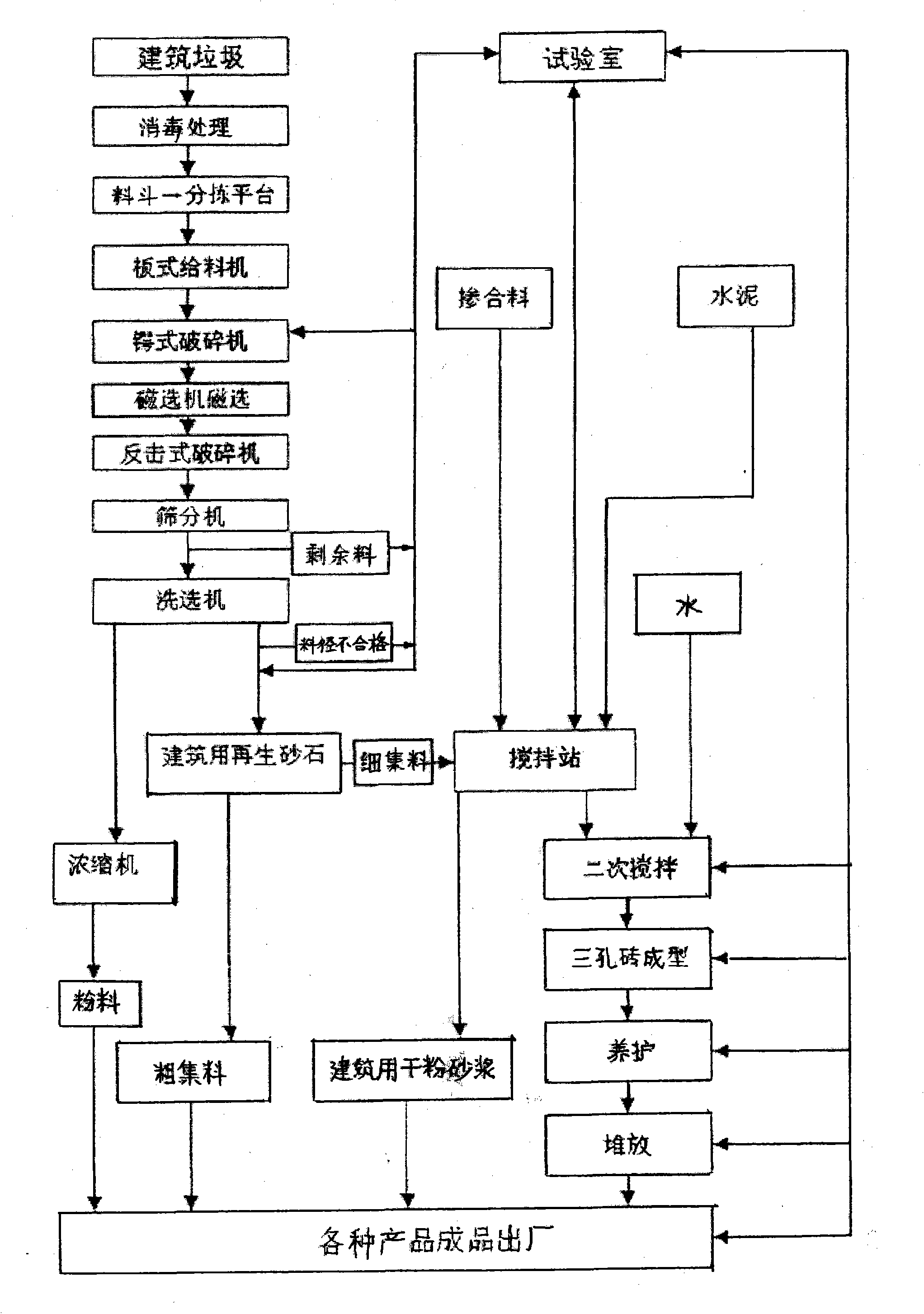

Method for comprehensively treating construction waste

The invention relates to a method for comprehensively treating construction waste, which comprises the following steps of: 1. disinfecting the construction waste to be treated by adopting a chlorine dioxide disinfectant; 2. loading the construction waste obtained from the step 1 to a hopper and conveying to a sorting platform to sort out impurities; 3. feeding the sorted construction waste to an edge-type crusher through a plate feeder to crush initially; 4. feeding the initially crushed construction waste to a hopper of an impact crusher after magnetic separation by a magnetic separator and crushing the construction waste finally by the impact crusher; 5. screening and peeling out sandstone materials from concrete and feeding the sandstone materials after being washed by a washer to a coarse aggregate bin, wherein the aggregate separated from the washed fine powder washed is used as raw materials of dry mortar or ready mixed mortar or three-hole brick of concrete. The invention ensures that the construction waste resources are utilized comprehensively, and the ordering management, the resource management and the harmless treatment of the construction waste are achieved, thereby achieving the purposes of saving land and reducing secondary pollution.

Owner:YUNNAN CONSTR ENG GRP +2

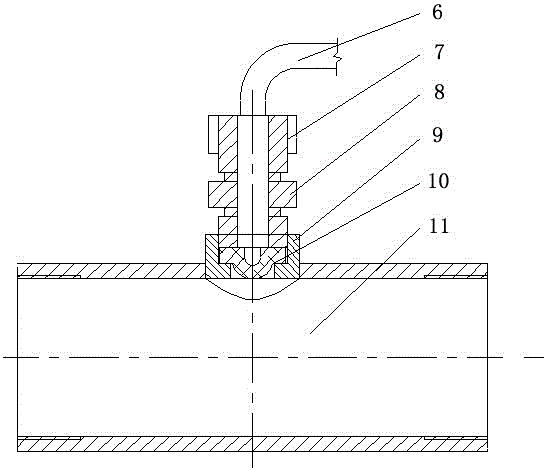

Method for backfilling of tunnel construction through TBM method and equipment for method

InactiveCN105804770AIncrease perfusionGood continuitySolid waste managementUnderground chambersTunnel constructionGrout

The invention relates to a backfilling method for tunnel construction through a TBM method and equipment for the backfilling method.The backfilling method that TBM pea gravel backfilling and grouting has many technical defects, the time limit for a project cannot be guaranteed, and backfilling quality is quite unstable.According to the backfilling method, backfilling is carried out at 360 degrees in a whole cavity segment between the duct piece outer wall and the surrounding rock wall of a TBM prefabricated lining structure, a bottom arch is backfilled with mortar and quick-setting mortar, arches on the two sides are backfilled with pea gravel grout, and a top arch is backfilled with composite mortar; in other way, the bottom arch is backfilled with mortar and quick-setting mortar, the arches on the two sides are backfilled with fine aggregate concrete and quick-setting fine aggregate concrete, and the top arch is backfilled with composite mortar.The technical advantages of mortar backfilling and fine aggregate concrete backfilling are fully utilized, pea gravel grouting and backfilling are replaced partially or completely, the technical defects of pea gravel grouting and backfilling are overcome, and particularly under the condition of unfavorable geology, the backfilling work efficiency is improved, and engineering quality is guaranteed.

Owner:刘文涛

Inorganic particle foam concrete composite insulation board

The invention discloses an inorganic particle foam concrete composite insulation board and a production method thereof. The composite insulation board mainly comprises cement, water, hydrophobic vitreous beads, a cement foaming agent, and one or several of coal ash, quartz tailing powder, siliceous slag and micro silicon powder. The composite insulation board of the present invention has the following excellent performances: fire protection, energy saving, insulation, durability and environmental protection.

Owner:HUAXIA SILICATE PRODS NANTONG CITY +2

Fiber reinforced modified foam cement thermal insulation board and preparation process thereof

InactiveCN107226657ALow water absorptionHigh strengthHeat proofingCeramicwarePolymer scienceThermal insulation

The invention discloses a fiber reinforced modified foam cement thermal insulation board and a preparation process thereof. The fiber reinforced modified foam cement thermal insulation board uses a modified foam cement thermal insulation board as a thermal insulation core material, wherein alkali-resistant fiberglass cloth is attached to the upper surface and the lower surface of the modified foam cement thermal insulation board, polymer glue is applied onto the upper surface and the lower surface of the foam cement thermal insulation board through spray coating, roller coating, dip coating or scraping so as to integrate the alkali fiberglass cloth with the modified foam cement thermal insulation board to prepare a novel light cement-based inorganic thermal insulation board. The novel light cement-based inorganic thermal insulation board has the advantages of high strength, high toughness, low water absorption rate, low heat conduction coefficient, good thermal insulation effect, small drying shrinkage value, high adhesiveness, high integrity, good anti-vibration and anti-impact performance, A-level fire-proof performance, long service life as a building and the like. A used polycarboxylate superplasticizer modified graphene can disperse in cement paste uniformly and steadily, so that the problems of agglomeration, non-thorough disperse and the like in an existing graphene adding manner are solved.

Owner:CHONGQING CITY HUTH BUILDING MATERIALS LIMITED

Straw fiber reinforcement air-entrained concrete and preparation method thereof

ActiveCN103193448ASmall drying shrinkageImprove crack resistanceCeramicwareShrinkage crackingWaste treatment

The invention discloses straw fiber reinforcement air-entrained concrete which comprises a base material, an aluminum powder paste, a straw fiber, an additive and water, wherein the doping amount of the aluminum powder paste accounts for 0.06%-0.09% of the dry weight of the base material; the doping amount of the additive accounts for 0.5%-0.8% of the dry weight of the base material; the doping amount of the straw fiber accounts for 2%-10% of the dry weight of the base material; and the mass ratio of the water and the base material is 0.52-0.60, The invention also discloses a preparation method of the straw fiber reinforcement air-entrained concrete. The straw fiber reinforcement air-entrained concrete disclosed by the invention reduces the shrinkage cracking and production cost of air-entrained concrete and solves the problems of straw resource waste, ceramic waste treatment and environmental pollution to a certain degree.

Owner:SOUTH CHINA UNIV OF TECH

Method for improving ceramic mold precision with vacuum freeze-drying technology

ActiveCN104529497ASmall drying shrinkageHigh strengthCeramic shaping apparatusSolid phasesFreeze dry

The invention discloses a method for improving ceramic mold precision with a vacuum freeze-drying technology, and relates to the technical field of precision casting. According to the invention, a water-based ceramic slurry containing solid-phase fiber is first prepared based on a gel injection molding technology; the water-based ceramic slurry is cast into a resin mold; when a ceramic mold blank is completely gel-solidified, the blank is placed into a vacuum freeze-drying machine and is subjected to pre-freezing; after a period of time, water in the ceramic mold blank is completely crystallized, vacuuming is carried out, and material temperature is controlled, such that water is directly sublimated from ice into vapor, and is pumped away. When the ceramic mold is thoroughly dried, compared to a ceramic mold blank without fiber, the ceramic mold provided by the invention has lower drying shrinkage, improved strength, and higher precision.

Owner:XI AN JIAOTONG UNIV +1

Reinforced cement foaming board and preparation method thereof

InactiveCN103172327AGuaranteed carbonization indexStrength does not shrinkCeramic shaping apparatusCeramicwareFiberPolymer science

The invention relates to a reinforced cement foaming board and a preparation method thereof. The reinforced cement foaming board comprises the following components in percentage by weight: 27.00-35.50% of water, 28.0-61.0% of Portland cement, 0-32.70% of coal ash at grade I or a mixture of coal ash and recycled filler, 0-2.00% of wollastonite powder, 0.10-0.30% of fiber, 0.37-0.65% of ammonium stearate, 1.00-2.00% of a mixture of 10 parts of calcium sulphate and 1 part of calcium formate, 0.10-0.20% of naphthalenesulfonate formaldehyde condensation compound, 0.90-1.20% of hydrogen peroxide and reinforcement net. The reinforced cement foaming board provided by the invention has the advantages of low apparent density, low heat conductivity coefficient, good noise reduction effect, high strength, no crack and shock resistance.

Owner:上海中驰建筑工程有限公司

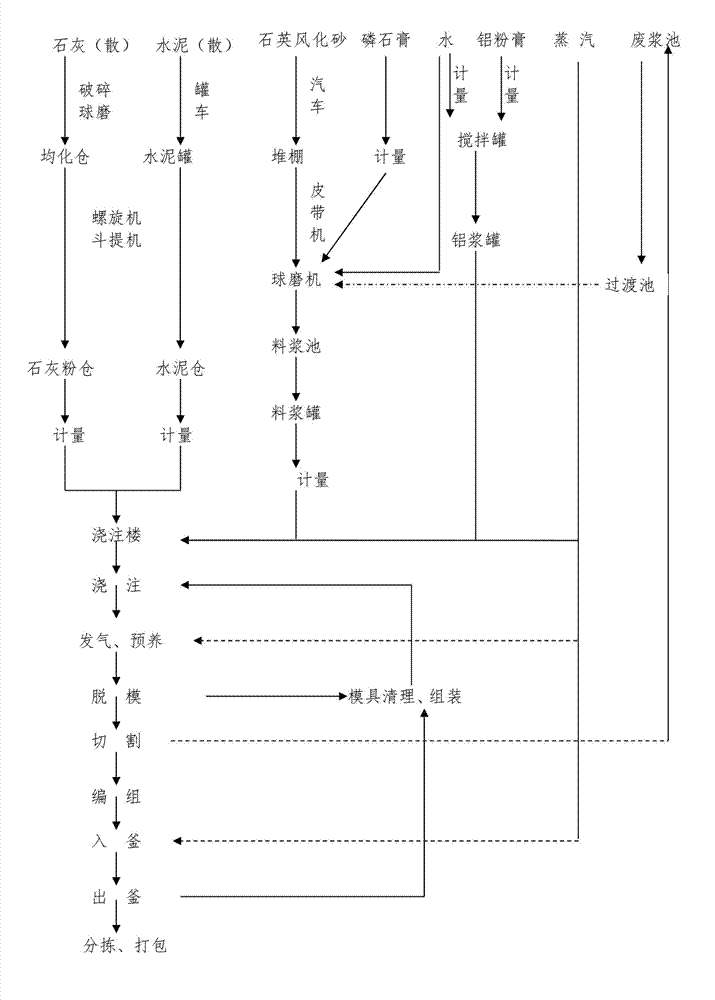

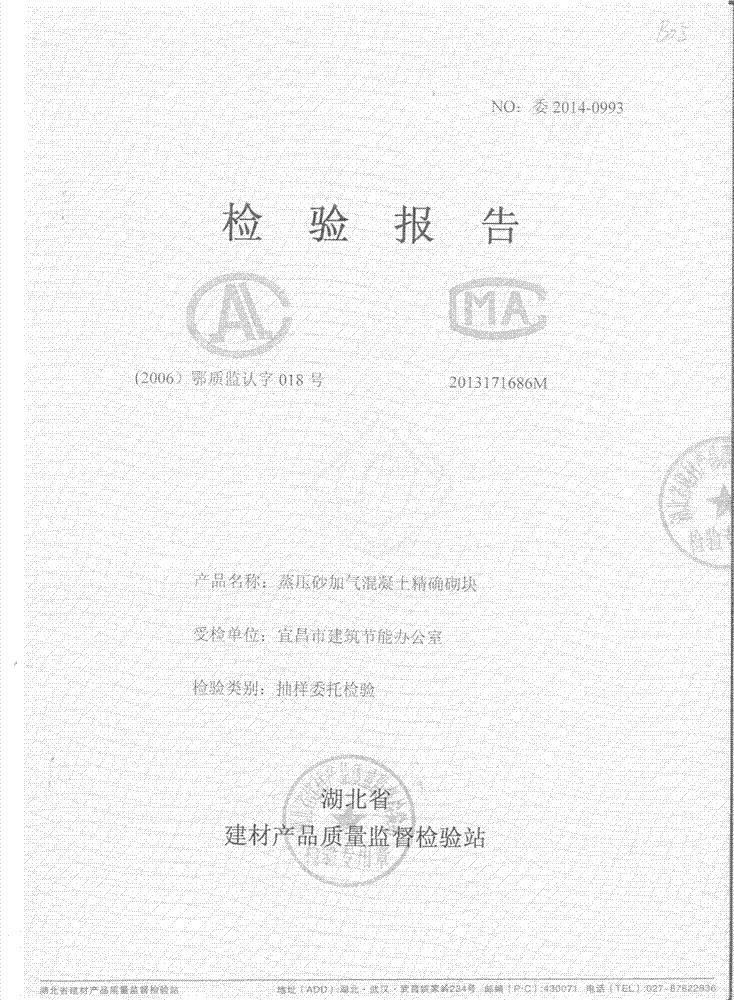

A2.0 B04 grade autoclaved aerated concrete block prepared from quartz eroded sand and preparation method thereof

ActiveCN104774031AAlleviate the problem of comprehensive utilizationInhibits digestive reactionsCeramicwareEngineeringPhosphogypsum

The invention discloses an A2.0 B04 grade autoclaved aerated concrete block prepared from quartz eroded sand. The A2.0 B04 grade high-performance autoclaved aerated concrete block is prepared from quartz eroded sand, cement, quick lime, industrial waste phosphogypsum, aluminum paste and water. The dry density of the concrete block is 415kg / m<3>, the cube crushing strength average value is 2.1 MPa, the single unit minimum value is 1.9 MPa, the ratio of splitting tensile is 0.19, the frost quality loss is 3.7%, the frost strength is 1.7 MPa, the heat conductivity coefficient (dry state) is 0.116 W / (m.K), the dry shrinkage value (standard value) is 0.22 mm / m and the percent of pass is greater than 98%. The raw material processing method is reasonable, the formula calculation is scientific, the production process is simple and the production waste can be recycled. The concrete block is a novel energy-saving and environmentally-friendly wall material and is suitable for industrial process.

Owner:HUBEI YITONG CONSTR ENG CO LTD

Aerated concrete block and preparation method thereof

InactiveCN107216102AHigh compressive strengthGood heat and sound insulationCeramic shaping apparatusCeramicwareBenzoic acidSlag

The invention discloses an aerated concrete block and a preparation method thereof, and relates to the technical field of building materials. The aerated concrete block is prepared from the following raw materials: modified pulverized fuel ash, slag Portland cement, kaolin, polypropylene fibers, baryta feldspar powder, aerated aluminum powder, heulandite powder, tetrachloroisophthalonitrile emulsion, benzoic acid, ethyl paraben, dimethyl sulfoxide, an early strength agent, a water reducing agent, a water addition agent, a foaming agent and a foam stabilizer. The preparation method comprises the steps of firstly, evenly stirring and mixing the raw materials to prepare slurry, then carrying out pouring, initial curing treatment, cutting and autoclaved curing on the slurry to obtain the aerated concrete block. The aerated concrete block is high in compression strength, good in heat resistance and sound insulation, small in drying shrinkage value, excellent in water resistance, simple to prepare, wide in raw material sources, and low in cost, thus being suitable for being popularized and used.

Owner:肥西县碧涛建材有限公司

Flame-retardant high-temperature-resistant concrete and preparation method thereof

The invention discloses flame-retardant high-temperature-resistant concrete and a preparation method thereof. The flame-retardant high-temperature-resistant concrete is prepared from the following components in parts by weight: 30 to 40 parts of cement, 12 to 30 parts of clay clinker, 18 to 30 parts of water, 8 to 15 parts of magnesia, 2 to 3 parts of a water reducer, 5 to 10 parts of alumina, 1 to 2 parts of a modifier, 1 to 2 parts of graphene, 1 to 2 parts of a flame retardant agent, 0.1 to 0.4 part of hexenyl distearamide, and 0.05 to 0.3 part of polyethylene glycol. The used materials are simple and easy to obtained, the process is easy to control, the production cost is low, and the preparation method adapts to mass production; the ratio is reasonable, and the water reducer, the modifier and the flame retardant agent are formed through compounding, so that the compressive strength of the flame-retardant high-temperature-resistant concrete is significantly enhanced, the dry shrinkage rate is significantly decreased, and the water absorption rate per volume is decreased significantly; and in addition, the preparation method of the flame-retardant high-temperature-resistant concrete is simple and feasible, has no special requirements on equipment, and is simple to operate.

Owner:WUHAN YUANJING READY MIXED CONCRETE CO LTD

Novel thermal-insulation material for building external wall

The invention discloses a novel thermal-insulation material for a building external wall, which comprises the following components in parts by weight: 5-10 parts of coal ash, 6-12 parts of styrene resin, 4-10 parts of inorganic fiber, 8-12 parts of butyl acetate, 5-10 parts of aluminate refractory cement, 7-13 parts of calcium oxide, 3-8 parts of hollow glass micro-beads and 1-2 parts of gypsum powder. The novel thermal-insulation material for the building external wall has the advantages that all the raw material components are approximately neutral, cause little pollution to surroundings, are non-toxic, odorless, pollution-free, green and environment-friendly; the drying shrinkage ratio is small, the drying time is short, and the construction time is greatly shortened; and the dosage is small, the construction cost is low, the cost is greatly saved in the using process, and the using method is simple.

Owner:QINGDAO HAIFALI GRAIN & OIL MACHINERY

Lightweight high-strength press molding block, and production method thereof

InactiveCN102358688AGuaranteed StrengthSmall drying shrinkageCeramic shaping apparatusSlagEconomic benefits

The present invention discloses a lightweight high-strength press molding block and a production method thereof. The block is prepared through carrying out treatments of material preparing, mixing and stirring, pressing formation and autoclave curing for a digested mixed material and a lightweight coarse aggregate, wherein the pile volume content range of the digested mixed material is 50-60%, the pile volume content range of the lightweight coarse aggregate is 40-50%. The digested mixed material is prepared from a fine aggregate material and a cementing material, wherein the fine aggregate material is a mixture comprising one or more than two selected from fly ash, slag, coal slag, coal gangue, shale, and has a particle size less than 3 mm, the cementing material is a mixture comprising one or more than two selected from quick lime, cement and carbide slag. The produced block provided by the present invention has characteristics of small density, high strength, good insulation property, simple production method, waste utilization and environmental protection, and provides significant social and economic benefits.

Owner:ANHUI KEDA IND CO LTD

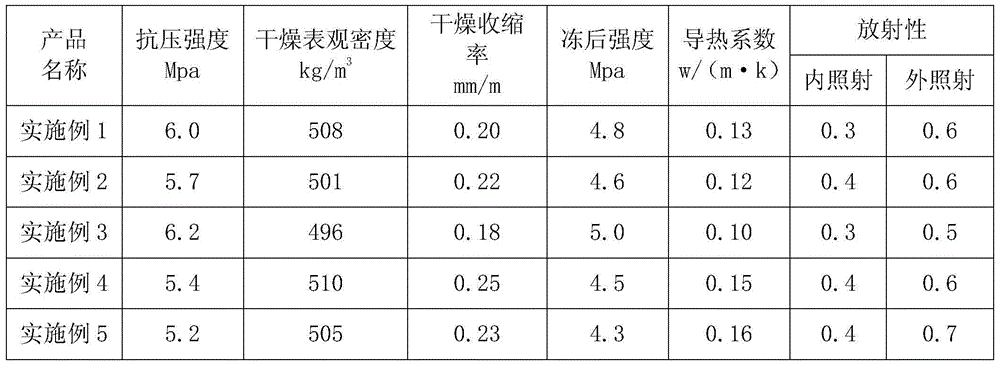

A3.5 B05 grade autoclaved aerated concrete block made of quartz weathered sand, and making method thereof

ActiveCN104844106AInhibits digestive reactionsResolve fast digestionCeramicwareIndustrial wasteAluminium

The invention provides an A3.5 B05 grade autoclaved aerated concrete block made of quartz weathered sand. The high-performance A3.5 B05 grade autoclaved aerated concrete block is made by using the quartz weathered sand, cement, quicklime, industrial waste phosphogypsum, aluminum powder paste and water as raw materials. The dry density of the block is 509kg / m<3>, the average cubic compressive strength of the block is 3.6MPa, the single component minimum of the block is 3.2Mpa, the split-to-compression ratio is 0.20, the mass loss after freezing is 2.8%, the strength after freezing is 3.1Mpa, the heat conduction coefficient (dry state) is 0.1251W / (m.K), the drying shrinkage value (standard process) is 0.32mm / m, and the qualified rate is greater than 98%. The method has the advantages of reasonable treatment of raw materials, scientific formula calculation, concise production flow, recycling of production wastes. The block is a novel energy saving and environmental protection wall material, and can be industrially produced.

Owner:HUBEI YITONG CONSTR ENG CO LTD

Method for preparing ceramsite by using Xianfeng diatomite

InactiveCN102515822AEasy to operateIncrease contentCeramicwareExpanded clay aggregateUltimate tensile strength

The invention discloses a method for preparing ceramsite by using Xianfeng diatomite. The method comprises steps of: crushing a naturally dried raw material Xianfeng diatomite; mixing the raw material with water in a ratio of 100:60-70 and stirring uniformly; air-drying the mixture to a water content of 40-50%; moulding; air-drying naturally; and finally sintering to obtain high strength diatomite ceramsite. The method of the invention is simply operated, has good effect; and the ceramsite prepared by the method has good strength, reduced water absorption, strong durability and wide application scope.

Owner:KUNMING UNIV OF SCI & TECH

Cement plastering mortar

InactiveCN102126845AImprove crack resistanceExtended hydration timeSolid waste managementCrack resistanceCement mortar

The invention discloses cement plastering mortar, which comprises cement, medium and fine sand, a water-retaining thickener, polymer emulsion powder, an anti-cracking agent, an expanding agent and an internal curing agent. After the internal curing agent is mixed into the common cement plastering mortar, numerous 'miniature reservoirs' are established in the cement mortar; therefore, when the mortar lacks of water, the water in the internal curing agent can be slowly released for the continuous hydration of the cement and the expanding agent until the water is exhausted. Longer hydration time is provided for the expanding agent to generate more expanded crystals, namely ettringite. A drying shrinkage value of the cement mortar is reduced, and the crack resistance of the plastering mortar is improved.

Owner:NANJING EFFUL

Foamed concrete and preparation method thereof

InactiveCN108947398AImprove mechanical propertiesImprove thermal insulation performanceCeramicwareFoam concreteGlass fiber

The invention discloses foamed concrete and a preparation method thereof. The foamed concrete contains aerogel powder, foamed concrete and fibers, wherein the aerogel powder contains an internal hydrophobic layer and a surface hydrophilic layer, and the thickness of the surface hydrophilic layer is 0.1-100 microns; and a fiber felt is one or more of a glass fiber felt, a basalt fiber felt, an aluminum oxide fiber felt, a carbon fiber felt and a polyvinyl chloride fiber felt. According to the preparation method, the fibers are compounded with the foamed concrete, the fibers are uniformly distributed in the foamed concrete, and the foamed concrete still remains a nano-porous structure; and compared with existing foamed concrete in the market, the foamed concrete has relatively excellent mechanical property and heat insulation property, the fracture resistance and pressure resistance of the foamed concrete can be remarkably improved, the foamed concrete can be endowed with certain flexibility, and the drying shrinkage value of the foamed concrete can be decreased.

Owner:苏州郎旭志远科技有限公司

Cement mortar for constructional engineering

The invention discloses a cement mortar for constructional engineering. The cement mortar comprises a cement, yellow ground, a water-retaining and thickening agent, a plastic swelling agent, a concrete swelling agent and an internal curing agent. Because the plastic swelling agent forms a large amount of fine and uniform bubbles in the mortar, the plastic mortar swells; after the internal curing agent is mixed, innumberable mini-impounding reservoirs are built in the cement mortar; and when the mortar is in lack of water, the water in the internal curing agent can be slowly released so as to ensure the concrete and the swelling agent to continuously hydrate until the water is used up. Thus, long hydration time is provided for the swelling agent, and more swell crystal ettringites are generated, thereby reducing the dry shrinkage value of the cement mortar.

Owner:NANJING EFFUL

Method for comprehensive treatment of building garbage

InactiveCN107540254AOrderly managementSave landSolid waste managementCeramic materials productionBrickResource utilization

The present invention relates to a method for comprehensive treatment of building garbage. The method comprises: a, disinfecting building garbage to be treated with an agent; b, loading the building garbage obtained in the step a into a material hopper, transporting to a sorting platform, and sorting out debris; c, feeding the sorted building garbage into a jaw crusher through a plate type material feeder, and carrying out primary crushing; d, carrying out magnetic separation on the building garbage obtained in the step c with a magnetic separation machine, feeding into the material hopper ofan impact crusher, and carrying out final crushing with the impact crusher; and e, carrying out screening and peeling on the building garbage obtained in the step d by using a screening machine so asto obtain the sand and stone aggregate in concrete, feeding into a cleaning separation machine, carrying out cleaning separation, feeding into a coarse aggregate bin, and separating to obtain fine powder, wherein the fine aggregate separated by the cleaning separation is used as the raw material for dry powder mortar or pre-mixed mortar or concrete three-hole brick. According to the present invention, with the method, the building garbage resources can be subjected to comprehensive utilization, such that the building garbage can achieve ordered management, resource utilization and harmless treatment, and the purposes of land saving and secondary pollution reducing can be achieved.

Owner:王志凤

Ferronickel slag magnesium phosphate binding material and application thereof

InactiveCN106630924AHigh yieldGuaranteed physical and mechanical propertiesSolid waste managementPorosityMagnesium phosphate

The invention discloses a ferronickel slag magnesium phosphate binding material and application thereof. The binding material is prepared from 6-12 parts of ferronickel slag, 12-25 parts of dead burned magnesia, 3-12 parts of phosphate and 1-10 parts of retarder. The ferronickel slag magnesium phosphate binding material is used in structural members requiring high strength in early age period and rush-repair work. The ferronickel slag magnesium phosphate binding material has the advantages of achieving rapid hardening and early strengthening, and being high in strength and small in shrinkage deformation, the interior structure is more compact, the porosity is low, and the durability including water tolerance is improved. Moreover, according to the ferronickel slag magnesium phosphate binding material, innocent treatment of the ferronickel slag is achieved, high-efficiency resource utilization of industrial waste residues is promoted, and on the premise that the mechanical properties of the binding material is guaranteed, the consumption of dead burned magnesia is reduced, the consumption of a non-renewable resource, namely magnesite, and energy loss are reduced, the production cost of the magnesium phosphate binding material is decreased, and therefore, economic benefits and environmental benefits are remarkable.

Owner:HOHAI UNIV

Aerated concrete block produced by dump-leached slags

ActiveCN103819217AGood weather resistanceHigh strengthSolid waste managementCeramicwareSlagSuperplasticizer

The invention relates to an aerated concrete block produced by dump-leached slags. The block comprises the following raw materials in parts by weight: 200 to 500 parts of dump-leached slags, 80 to 150 parts of quick lime, 50 to 200 parts of cement, 3 to 10 parts of gypsum, 0.4 to 1.2 parts of aluminium powder and 8 to 15 parts of superplasticizer, wherein the dump-leached slags are waste residues formed after silicate minerals are processed by acid. The aerated concrete block has the advantages of light weight, high strength, heat preservation, heat insulation and the like, utilizes wastes, is environmental-friendly, saves resources and is a green building material with excellent performance.

Owner:广西建筑材料科学研究设计院有限公司 +1

Flexible putty of rubber powder and preparation method thereof

InactiveCN101709170ASmall drying shrinkageImprove workabilityFilling pastesCelluloseCrack resistance

The invention relates to a flexible putty of rubber powder and a preparation method thereof, which belong to the technical field of building materials. The flexible putty of the rubber powder mainly comprising the following materials in percentage by weight: 20 to 30 percent of cement, 20 to 30 percent of quartz flour, 1.5 to 3.5 percent of re-dispersible latex powder, 0.2 to 0.8 percent of cellulose ether, 20 to 40 percent of surface modified rubber powder, 0.2 to 0.5 percent of defoaming agent, and 5 to 25 percent of calcium carbonate. The flexible putty is added into the rubber powdered which is obtained by crushing waste tires mechanically and performing surface modification, so the prepared flexible putty not only fulfills the aim of comprehensively using the waste tires but also has the characteristics of good crack resistance, high flexibility, good bonding strength and the like. Besides, the flexible putty is powdered, is convenient to package and transport, is easy to use, and can be suitable for manual batch scraping.

Owner:JIANGNAN UNIV

Environmentally friendly heat-insulation fireproof mortar and preparation method thereof

InactiveCN105272343AReduce the impactMeet the requirements of sustainable developmentCeramicwareFiberThermal insulation

The invention discloses environmentally friendly heat-insulation fireproof mortar and a preparation method thereof. The heat-insulation fireproof mortar is prepared from, by weight, 30 parts of ordinary Portland cement, 10 parts of pulverized fuel ash, 25 parts of construction waste, 25 parts of vitrified micro beads, 4 parts of gypsum powder, 0.5 part of plant fiber, 2.5 parts of sodium silicate; 1.5 parts of foaming agent and 1.5 parts of redispersable latex powder. The environmentally friendly heat-insulation fireproof mortar is good in bonding performance, can enhance the bonding strength of a heat-insulation material and a wall to the great degree, has superior fireproof performance and certain heat absorption effect, accordingly enhances the fireproof performance of a wall heat insulation system, has strong anti-aging capability and enhances the durability of the heat insulation system. All performance indexes of the mortar meet the performance requirements of Heat-insulation Mortar for Buildings GB / T 20473-2006.

Owner:TIANYUAN CONSTR GROUP

Gypsum-based heat-insulation mortar and preparation method thereof

The invention discloses gypsum-based heat-insulation mortar and a preparation method thereof. The gypsum-based heat-insulation mortar is prepared from the following ingredients in parts by weight: 15to 25 parts of Portland cement, 30 to 40 parts of building plaster, 10 to 20 parts of glass bead, 10 to 30 parts of converter steel slag, 10 to 20 parts of coal ash, 5 to 15 parts of nano silicon dioxide powder, 15 to 25 parts of ash calcium powder, 5 to 10 parts of modified pulpified starch, 2 to 8 parts of dispersible latex powder, 5 to 15 parts of cellulose ether, 3 to 8 parts of crack-resistant fiber, 5 to 15 parts of modified talcum powder, 4 to 10 parts of binder, 0.3 to 0.7 part of air entraining agent, 0.2 to 0.6 part of water repellent, 0.1 to 0.5 part of water reducing agent and 40 to 60 parts of water. The gypsum-based heat-insulation mortar disclosed by the invention has the advantages of high strength, good heat insulation, small drying shrinkage, no easiness in cracking and the like. The gypsum-based heat-insulation mortar can meet a requirement of building industry to mortar performance indexes and can be widely applied to projects of heat insulation and the like of outer walls and inner walls of buildings.

Owner:HEFEI OAKS NEW BUILDING MATERIAL CO LTD

Novel high-toughness fiber reinforced cement-based composite material and preparation method thereof

The invention discloses a novel high-toughness fiber reinforced cement-based composite material and a preparation method thereof. The composite material is prepared from, by weight, 10-20 parts of composite reinforcing fiber, 30-50 parts of portland cement, 15-25 parts of fly ash, 4-10 parts of fine sand, 1-5 parts of dispersing agent, 2-5 parts of water reducing agent, 0.5-3.5 parts of tougheningagent and 12-18 parts of water. According to the composite material, the toughness and crack resistance of the material are improved, the composite reinforcing fiber is uniformly distributed by the dispersing agent, the mechanical properties are changed, the ability of the material to resist deformation is greatly improved, and the probability of occurrence of cracking and fracture of concrete isreduced.

Owner:合肥市闵葵电力工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com