Aerated concrete block produced through using specially-made mineral waste residue and tailings steel slag and production method of aerated concrete block

A technology of air-entrained concrete and steel slag, applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve problems such as environmental pollution and resource waste, and achieve the effect of high strength and small drying shrinkage value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

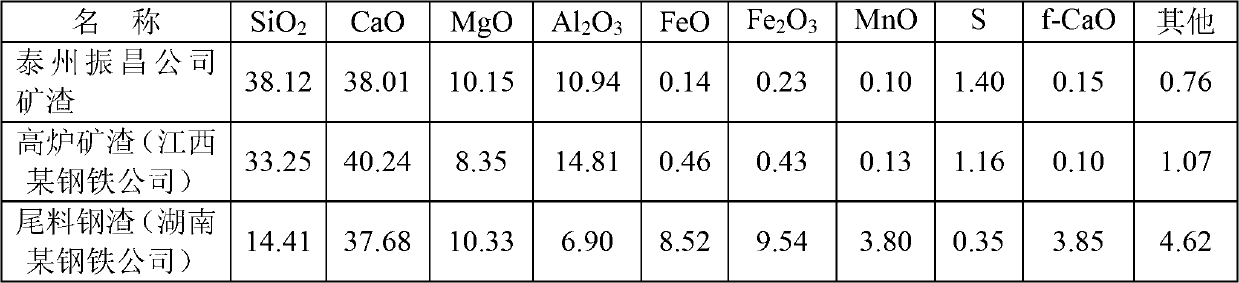

[0032] Embodiment 1: a kind of aerated concrete block that utilizes special slag and tailings steel slag to produce, it is characterized in that the raw material component and weight percentage of described aerated concrete block are:

[0033]

[0034]

[0035] Add 1% of its total weight of additive A to the above substances, gas-generating aluminum powder with a purity of 0.05% of the above substances’ total weight ≥ 98%, and water of 0.5 times the total weight of the above substances; wherein the additive A is composed of sodium lignosulfonate, Ethylene glycol and sodium hydroxide are mixed in a weight ratio of 3:3:4;

[0036] Wherein: the tailing steel slag is made of the hot stewed steel slag of Jiangxi Xinyu Iron and Steel Company through conventional crushing, screening and magnetic separation processes, and the selected particle size is ≤ 20mm, the moisture content is 10% to 15%, and the composition requirement is : TFe≤16%, MFe≤2%, f-CaO≤4%, f-MgO≤0.2% tailing st...

Embodiment 2

[0052] An aerated concrete block produced by using special slag and tailing steel slag, characterized in that the raw material components and weight percentages of the aerated concrete block are:

[0053]

[0054]

[0055] Add 1% of its total weight of additive A to the above substances, gas-generating aluminum powder with a purity of 0.05% of the above substances’ total weight ≥ 98%, and water of 0.55 times the total weight of the above substances; wherein the additive A is composed of triethanolamine, Sodium lignosulfonate and sodium hydroxide are mixed in a weight ratio of 1:5:4;

[0056] The tailing steel slag is the hot stewed steel slag from Hunan Xiangtan Iron and Steel Company. %, MFe≤2%, f-CaO≤4%, f-MgO≤0.2% tailing steel slag;

[0057] The modified material is composed of quartz sand and volcanic ash in a weight ratio of 1:2.

[0058] Adopt the material described in embodiment 2 and the method for proportioning production air-entrained concrete block, it is c...

Embodiment 3

[0072] An aerated concrete block produced by using special slag and tailing steel slag, characterized in that the raw material components and weight percentages of the aerated concrete block are:

[0073]

[0074]

[0075] Add 1% of its total weight of additive A to the above substances, gas-produced aluminum powder with a purity of 0.05% of the above substances’ total weight ≥ 98%, and 0.6 times the water of the above substances’ total weight; wherein the additive A is made of lignosulfonic acid Sodium, ethylene glycol, and sodium sulfate are mixed in a weight ratio of 3:2:5;

[0076] The tailing steel slag is the hot stewed steel slag of Hunan Lianyuan Iron and Steel Company, after conventional crushing, screening, magnetic separation and other processes, the selected particle size is ≤ 20mm, the moisture content is 10% to 15%, and the composition requirement is: TFe ≤16%, MFe≤2%, f-CaO≤4%, f-MgO≤0.2% tailing steel slag;

[0077] The modified material is composed of c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com