Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

95results about How to "Surface performance is stable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of hypha/nanoparticle composite sphere material

InactiveCN104785216AHigh activityImprove stabilityOther chemical processesOrganic-compounds/hydrides/coordination-complexes catalystsFiltrationFreeze-drying

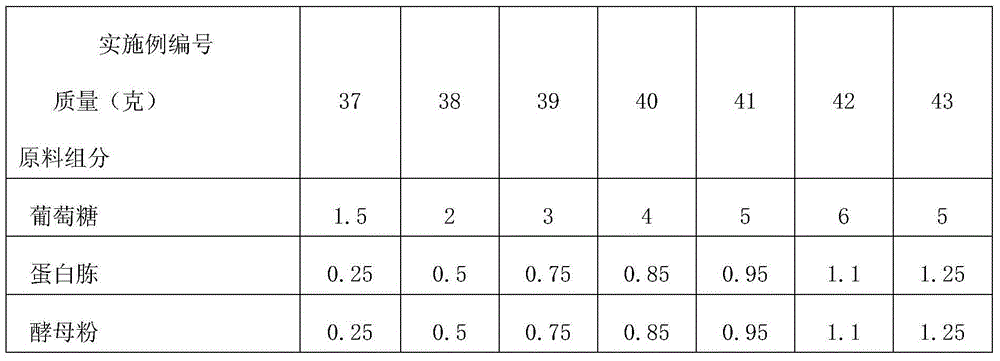

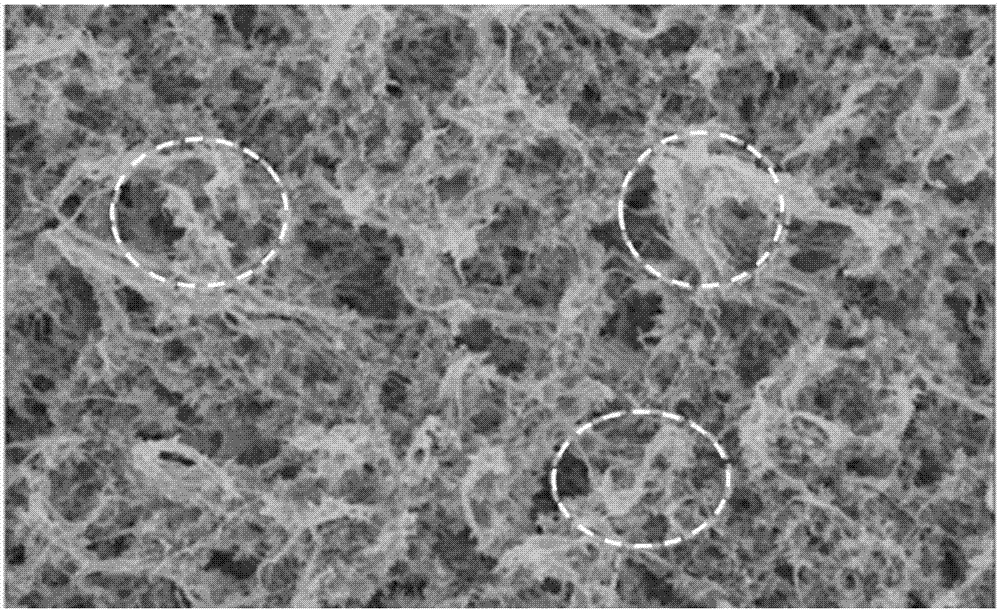

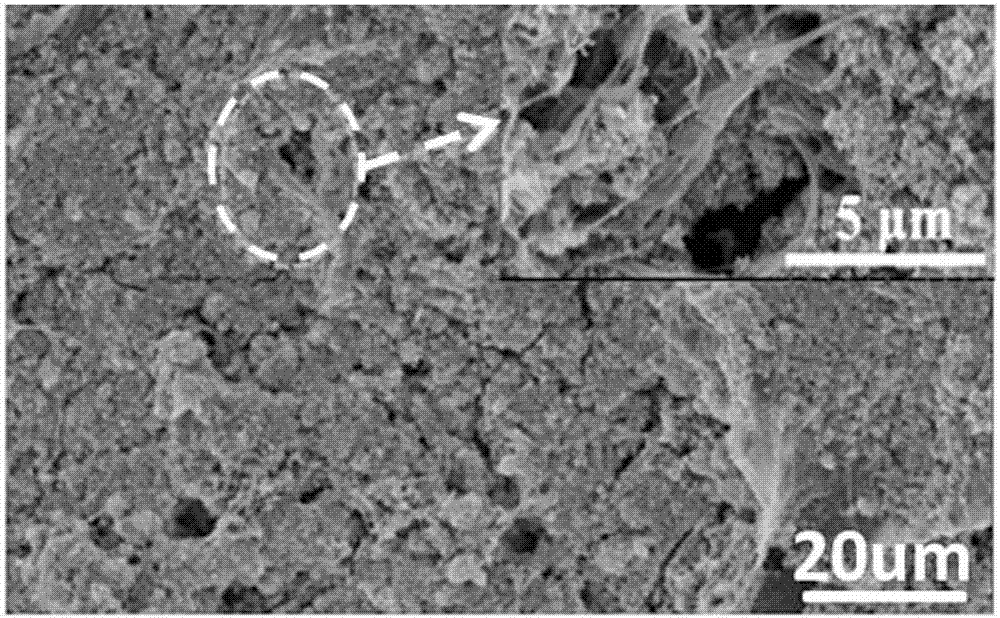

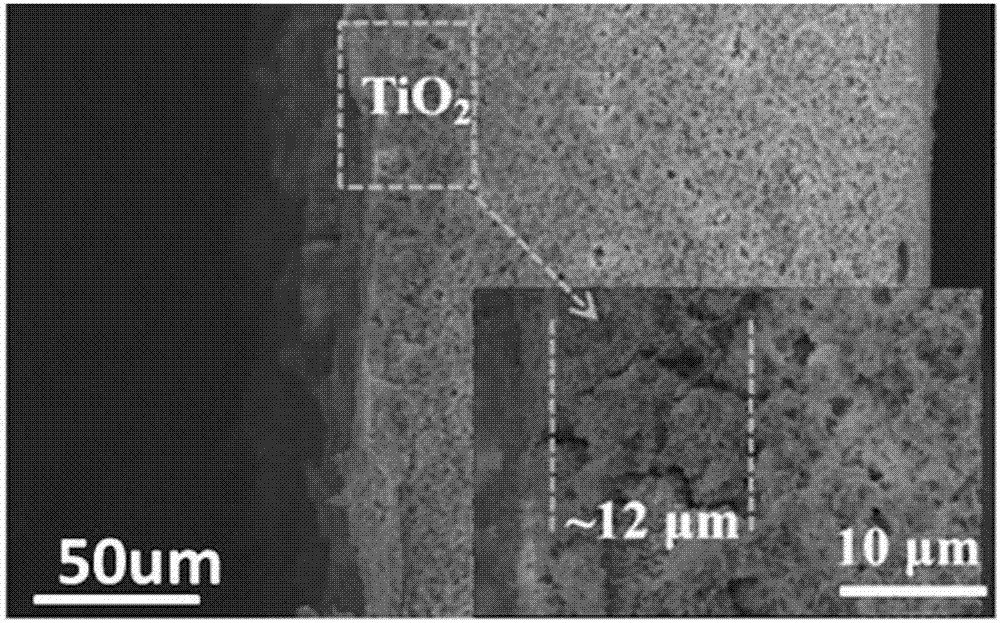

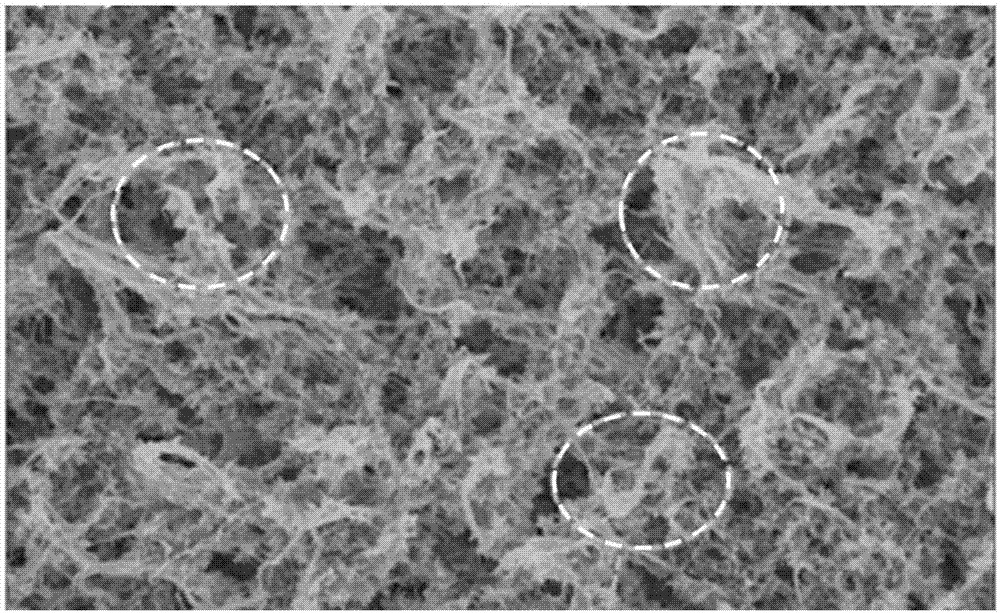

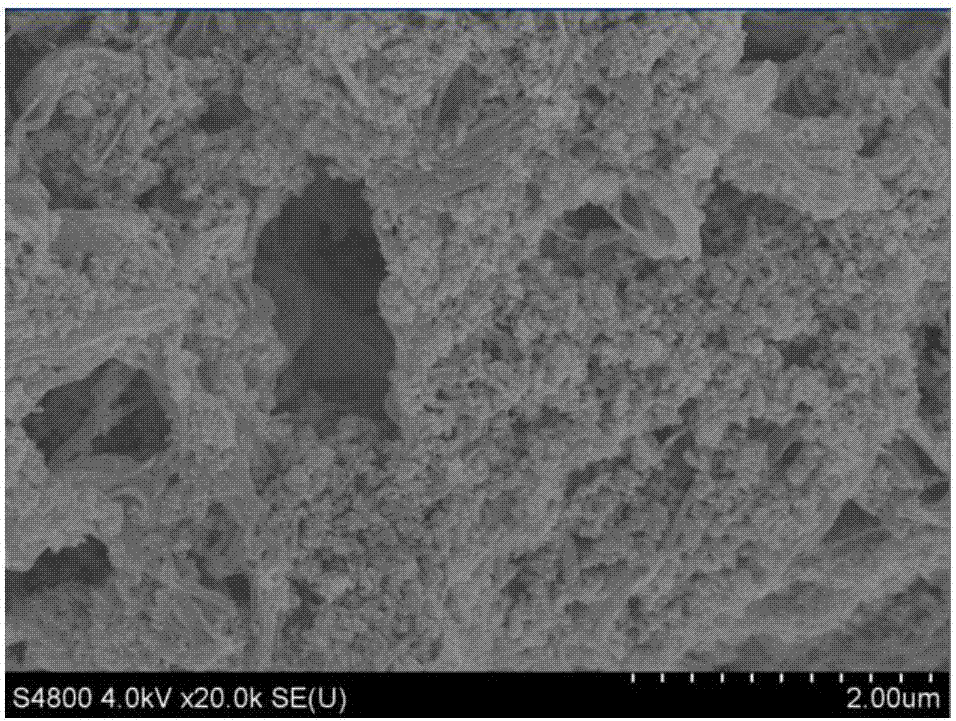

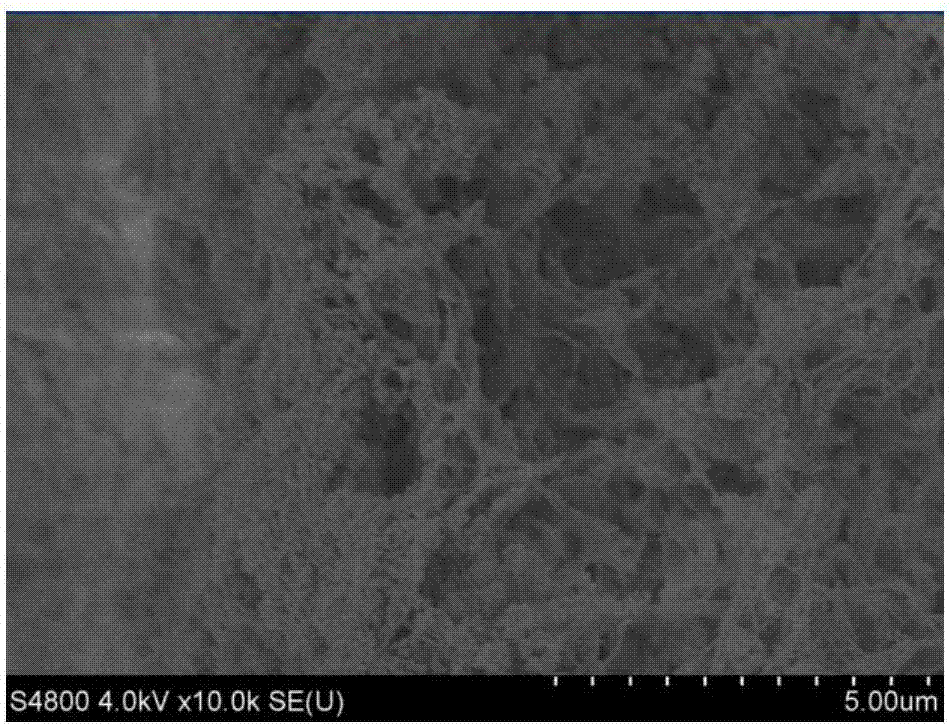

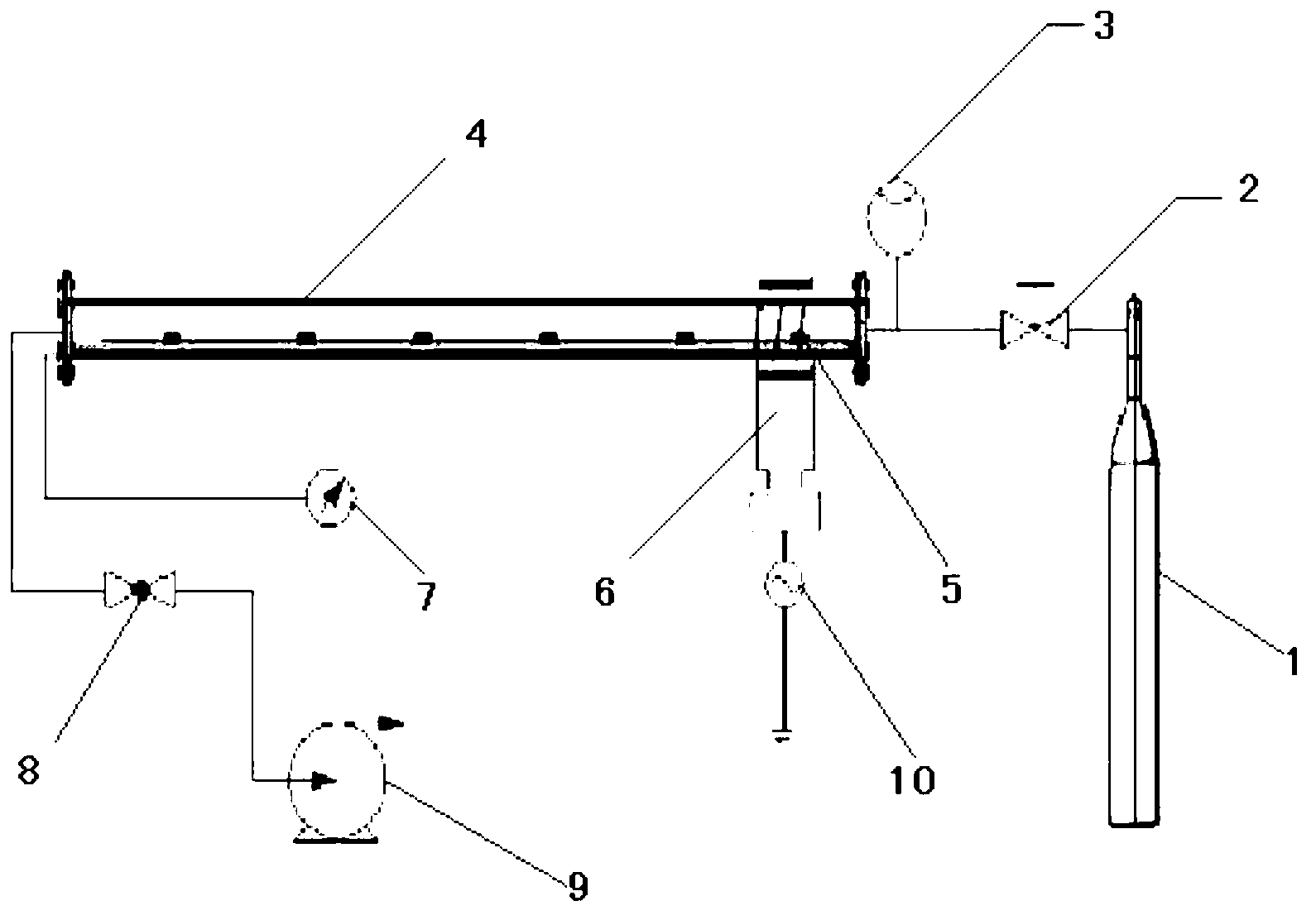

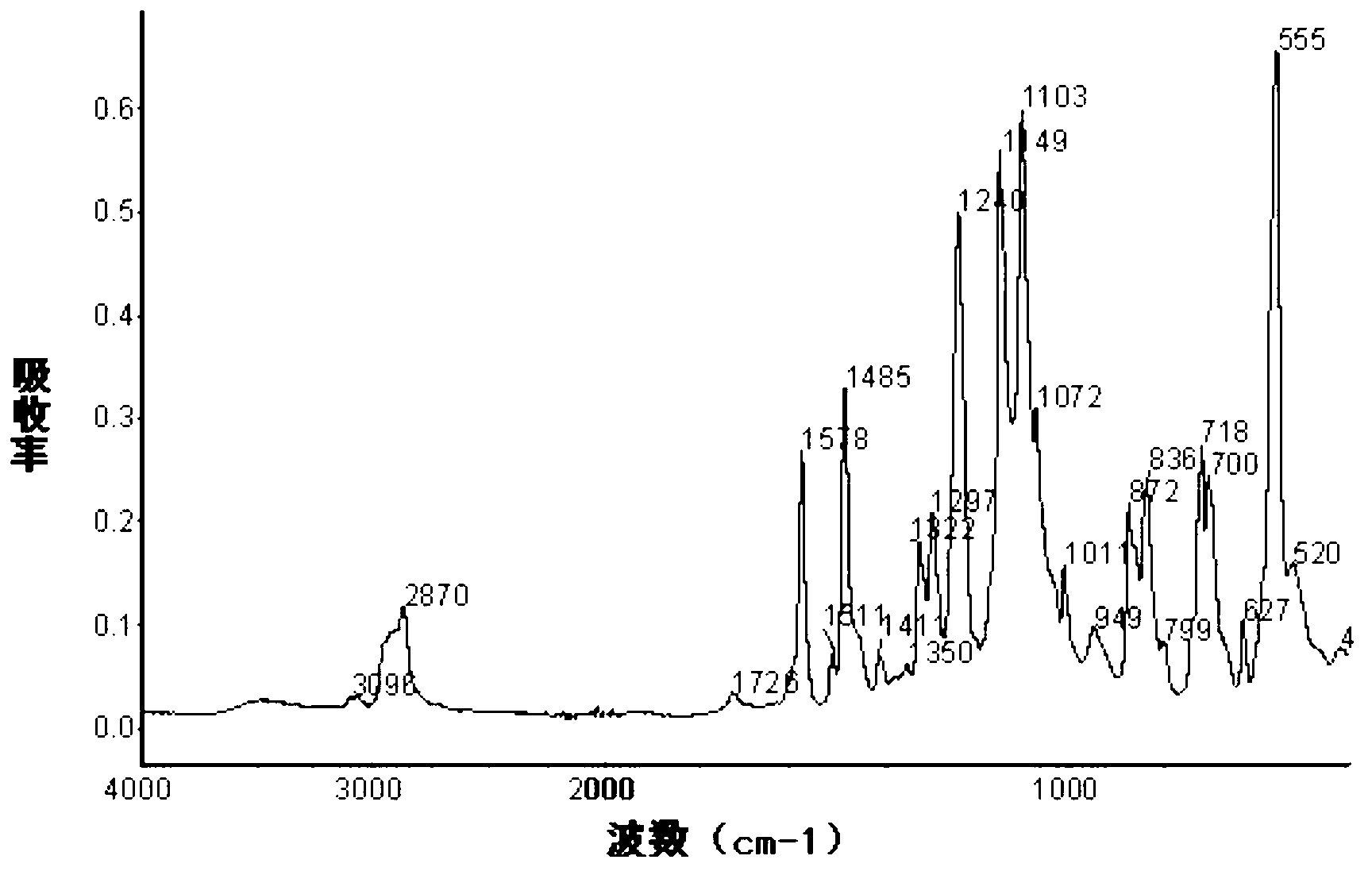

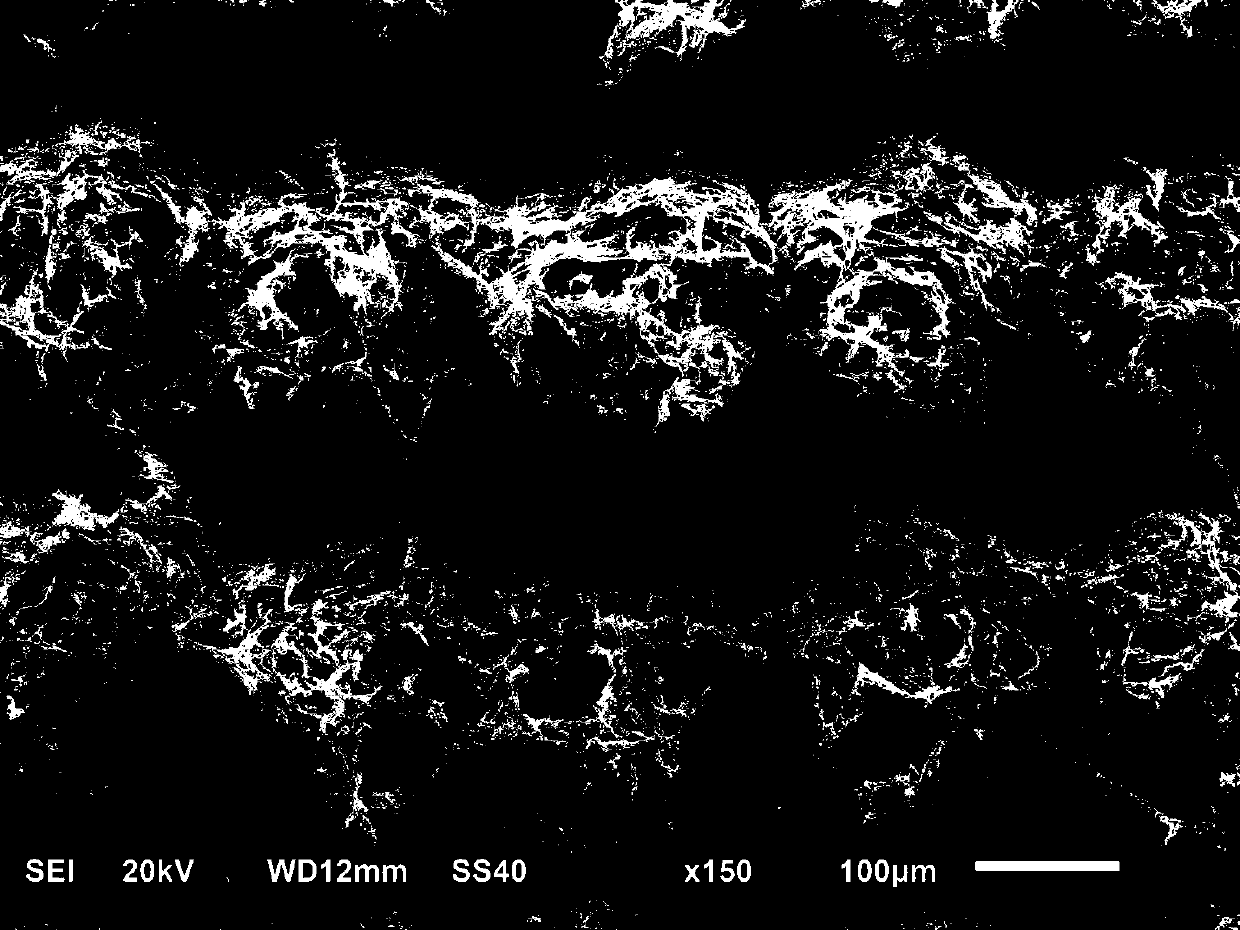

The invention discloses a preparation method of a hypha / nanoparticle composite sphere material. The preparation method is characterized by comprising steps as follows: preparing a culture medium; adding 4-20 ml of a nanoparticle aqueous solution containing 1-10 mg of nanoparticles per milliliter to the sterilized liquid culture medium, evenly mixing the mixture, inoculating the mixture with strains, culturing the mixture for 48-96 h under conditions that the temperature is 15-35 DEG C and rotating oscillation is performed at the speed of 80-200 r / min to form a hypha / nanoparticle composite sphere material, performing filtration to remove a liquid, soaking solids, namely, hypha / nanoparticle composite spheres, with a sodium hydroxide aqueous solution for 12 h, washing the spheres with deionized water until the spheres are neutral, and then performing freeze-drying to prepare the hypha / nanoparticle composite sphere material. The composite sphere material prepared with the method is applicable to fields of industrial catalysis, wastewater treatment, biomedicine and the like and has the characteristics of low cost, high activity, easiness in recovery and the like.

Owner:SOUTHWEAT UNIV OF SCI & TECH

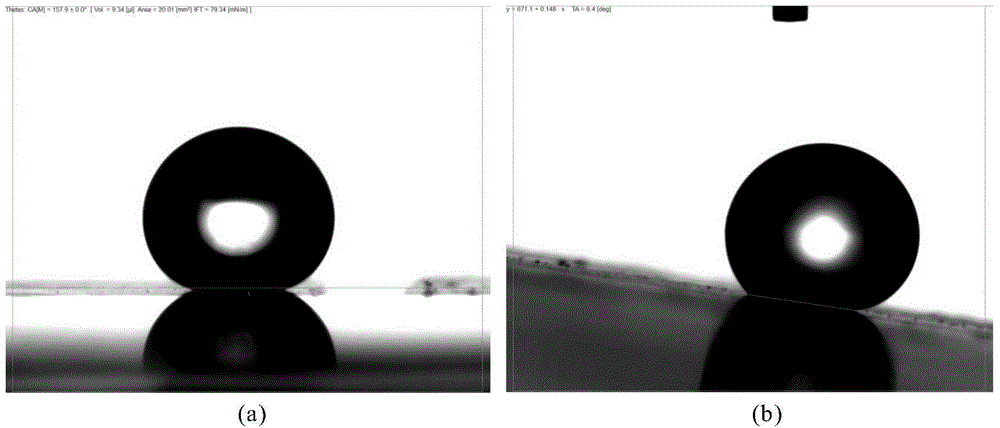

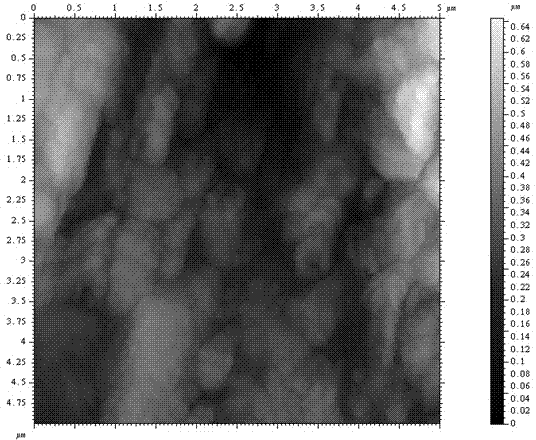

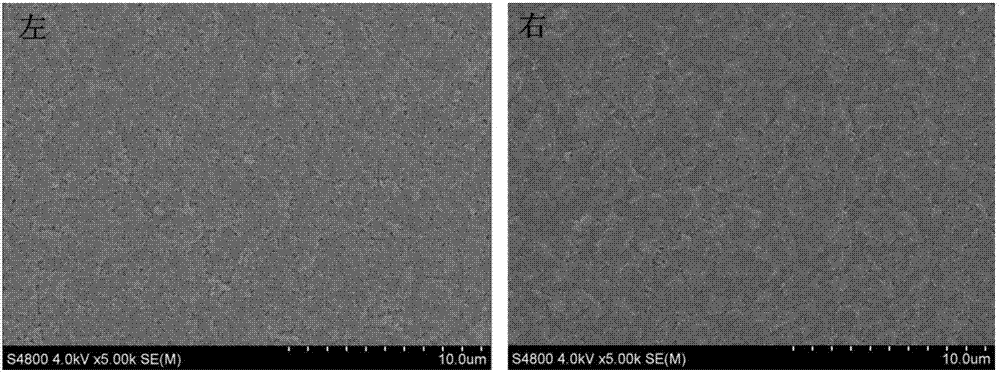

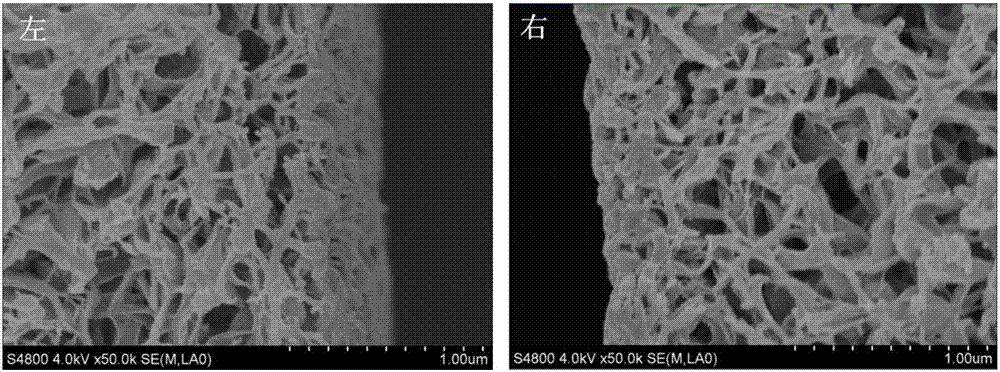

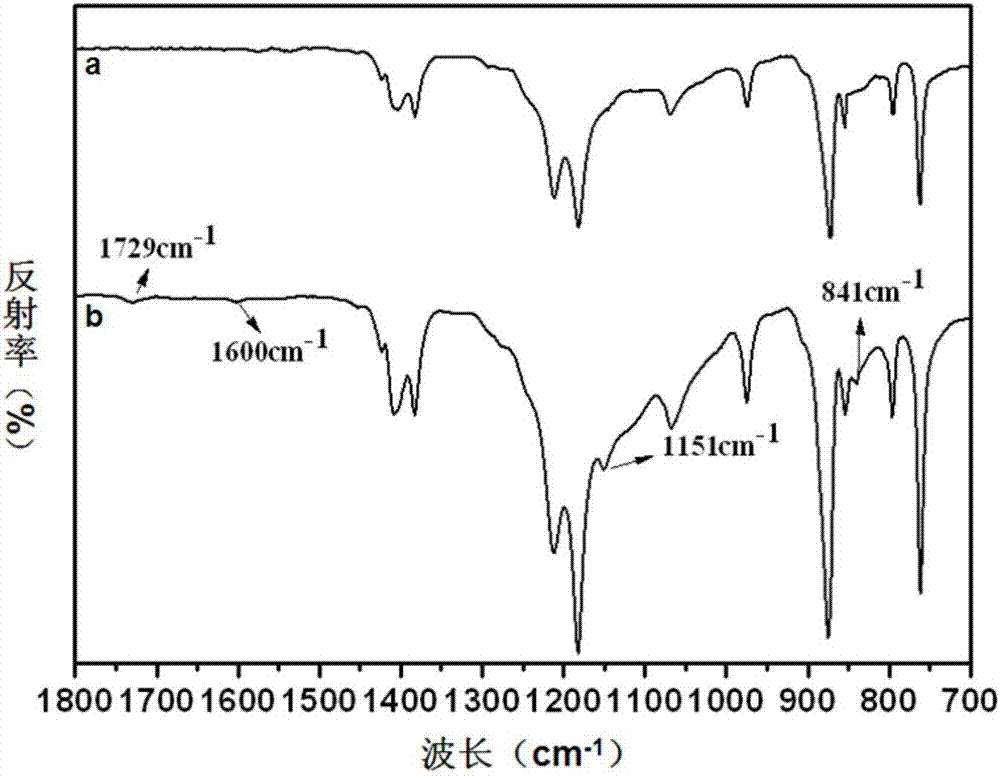

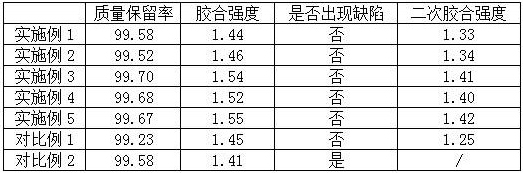

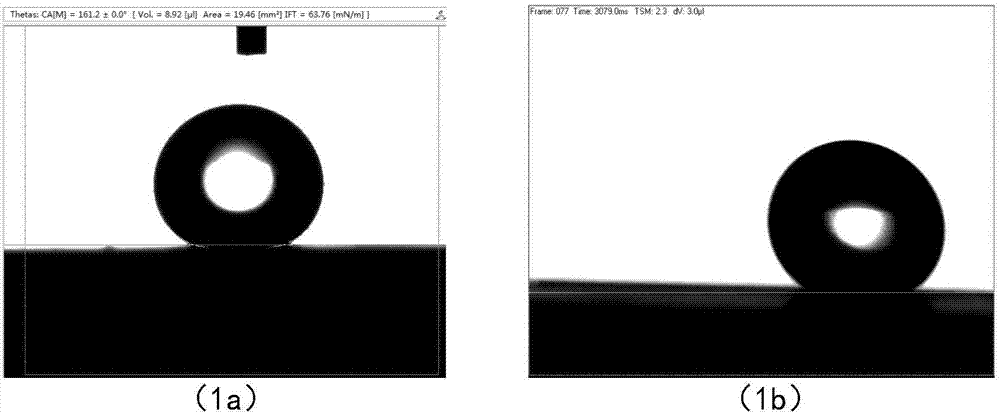

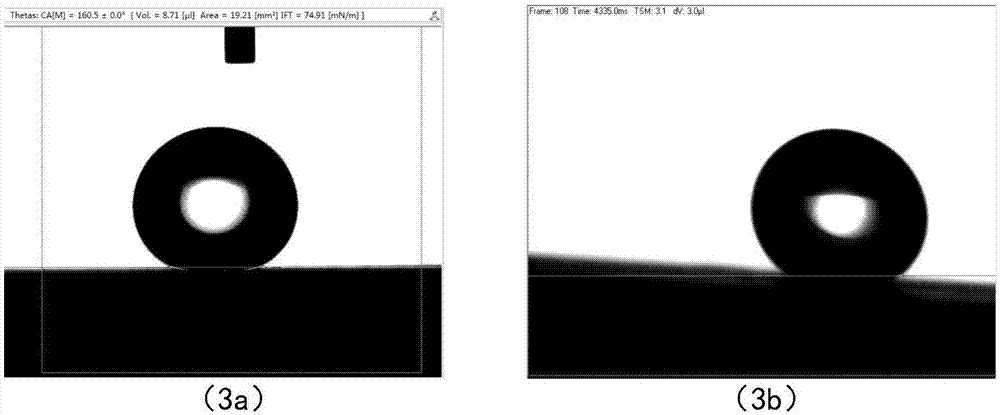

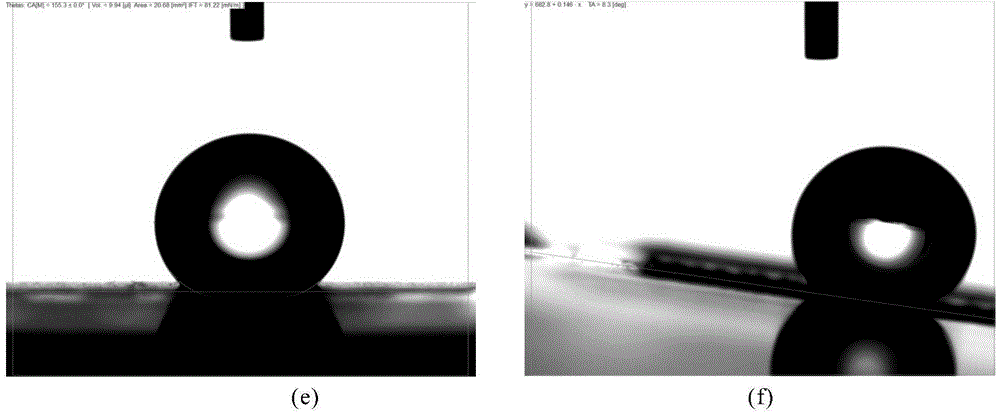

An ultra-hydrophobic polymer microporous membrane and a preparing method thereof

ActiveCN107349803ASurface performance is stableNo damage to physical and mechanical propertiesMembranesSemi-permeable membranesPolymer scienceSilanes

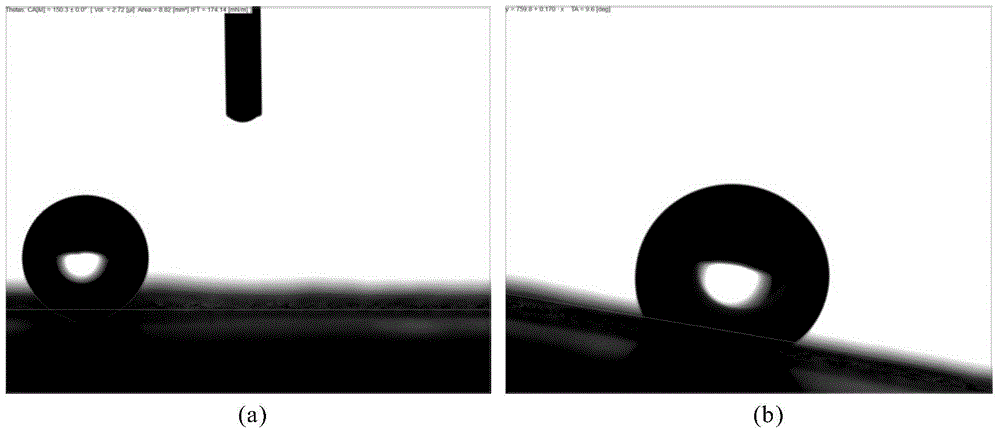

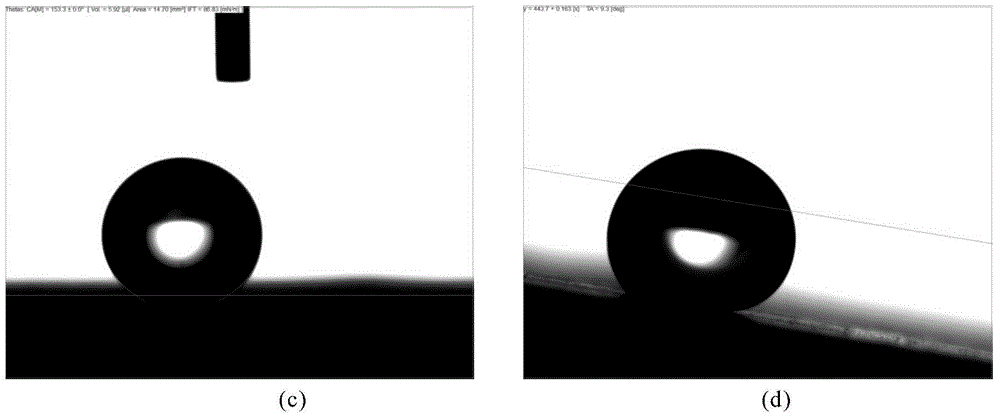

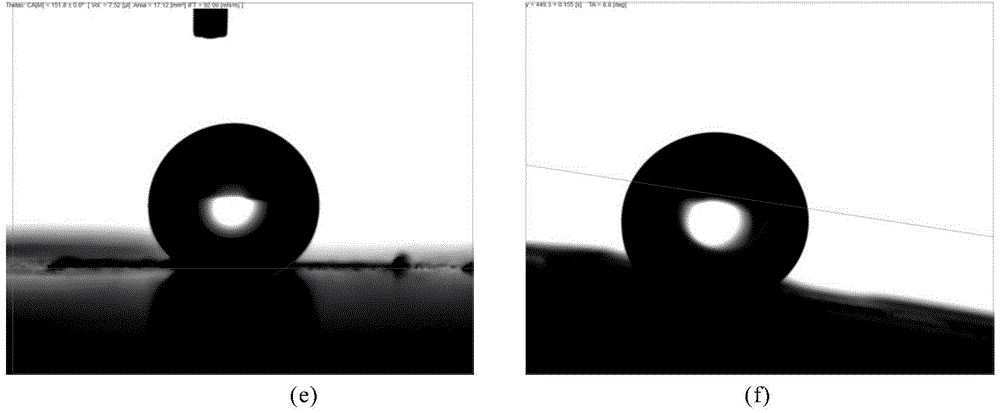

The invention relates to an ultra-hydrophobic polymer microporous membrane. The ultra-hydrophobic polymer microporous membrane includes a polymer microporous membrane and a hydrophobic coating attached to the surface of the polymer microporous membrane. The hydrophobic coating is a crosslinked layer comprising hydrophobic modified inorganic nanometer particles. The hydrophobic modified inorganic nanometer particles are prepared by subjecting inorganic nanometer particles to hydrophobic modification by utilizing multi-alkoxy silane end-capped with hydrophobic groups. The invention also relates to a preparing method of the ultra-hydrophobic polymer microporous membrane.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Aqueous rust proof coating and preparation method thereof

The invention relates to water-based antirusting paint operable with rust and the method for preparation. The water-based paint contains talcum powder, iron oxide red, phosphoric acid, CF-01 non-ionic humectant, P-19 polyacrylic sodium salt disperser, aluminium tropolyphosphate, self crosslinking acroleic acid emulsion, erinitrit and water added up to 100% (weight). The method for preparation is as following: mixing by homogenizer match said P-19 polyacrylic sodium salt disperser, CF-01 non-ionic humectant, talcum powder, iron oxide red, aluminium tropolyphosphate, and erinitrit, then sending the mixture to sand mill and sanding to prepare the serum of a fineness less than 60 micrometre, adding self crosslinking acroleic acid emulsion and phosphoric acid to the serum and mixing thoroughly, and filtering to prepare the product. It has a characteristic of no-containing of toxic and heavy metal, drying quickly, operable with rust, and corrosion-preventive property nice.

Owner:SHANGHAI HUAYI FINE CHEM CO LTD

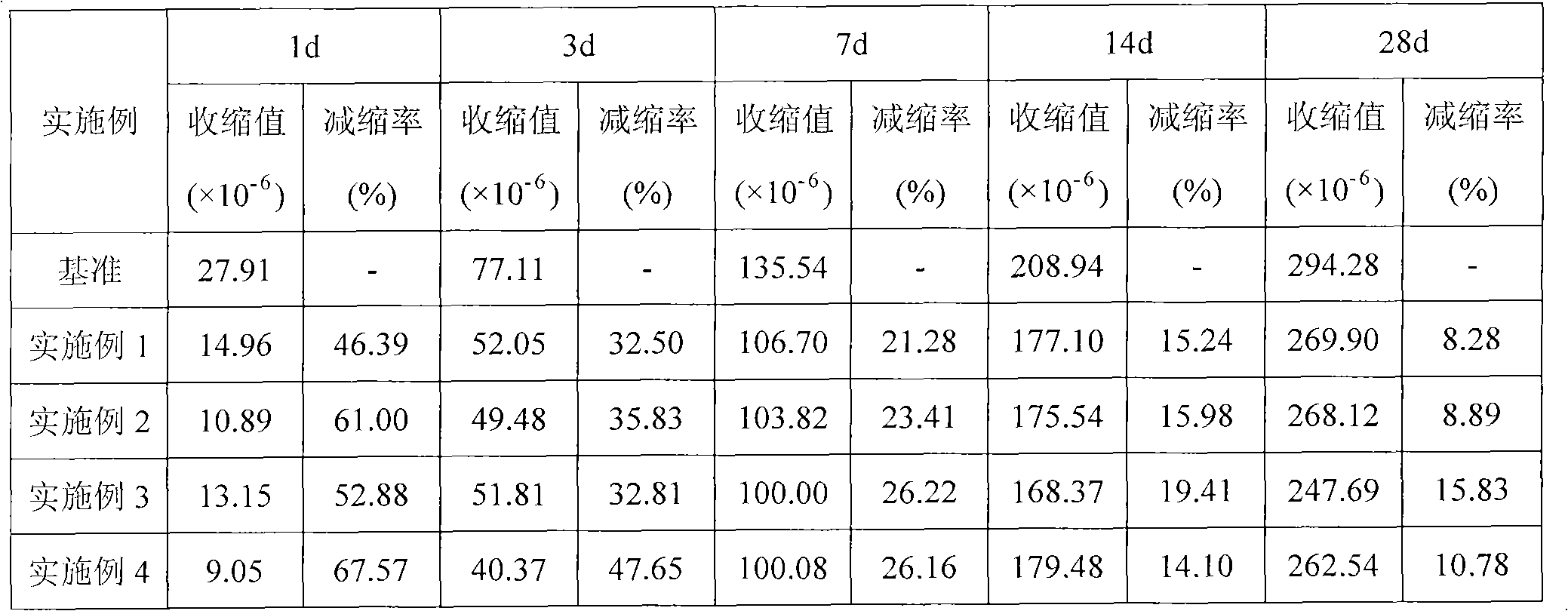

Multifunctional anti-leakage shrinkage type concrete surface layer reinforcer

The invention relates to a multifunctional anti-leakage shrinkage type concrete surface layer reinforcer which is prepared from the following components in percentage by weight: 10-20 percent of high polymer, 1-7 percent of film forming aided compound, 5-10 percent of surface layer active agent compound, 1-4 percent of leakage aided compound, 1.5-4.5 percent of active compound and the balance of water. The invention has good concrete surface layer enhancement effect, can obviously reduce the shrinkage of surface layer concrete, obviously improves the carbonization resistance and the medium leakage resistance of surface layer concrete, has convenient construction and obvious economic benefit and can be widely applied to the strengthening treatment operations on the surface layers of cement and concrete pouring components, concrete components under corrosion environment conditions such as piers, dams, and the like and deformed concrete components difficult to be strengthened by adopting a conventional method.

Owner:湖州苏博特新材料有限公司

Method for preparing aluminum alloy superhydrophobic self-cleaning surface by using ultrashort pulse laser

InactiveCN104947116AExcellent superhydrophobic propertiesSimple processMetallic substrateSurface modification

The invention relates to a method for preparing an aluminum alloy superhydrophobic self-cleaning surface by using an ultrashort pulse laser, belonging to the technical field of metal substrate surface modification. The method comprises the following steps: carrying out polishing pretreatment on an aluminum alloy sample, cleaning the sample surface respectively with deionized water and anhydrous ethanol, blow-drying with cool air or drying in air, and carrying out surface treatment on the sample by using a laser processing technique after adjusting related technological parameters by an ultrashort pulse laser so as to obtain countless microstructures on the sample surface; and after finishing processing, putting the processed sample into an electrothermal drying box, and baking to obtain the aluminum alloy superhydrophobic surface with a micron-sized mastoid or porous structure on the surface, wherein the surface has the self-cleaning function and has excellent friction resistance and corrosion resistance. The preparation method has the advantages of simple technique, high efficiency, low energy consumption, low cost and environment friendliness, is convenient to operate, and can easily implement industrial application.

Owner:HUBEI UNIV OF TECH

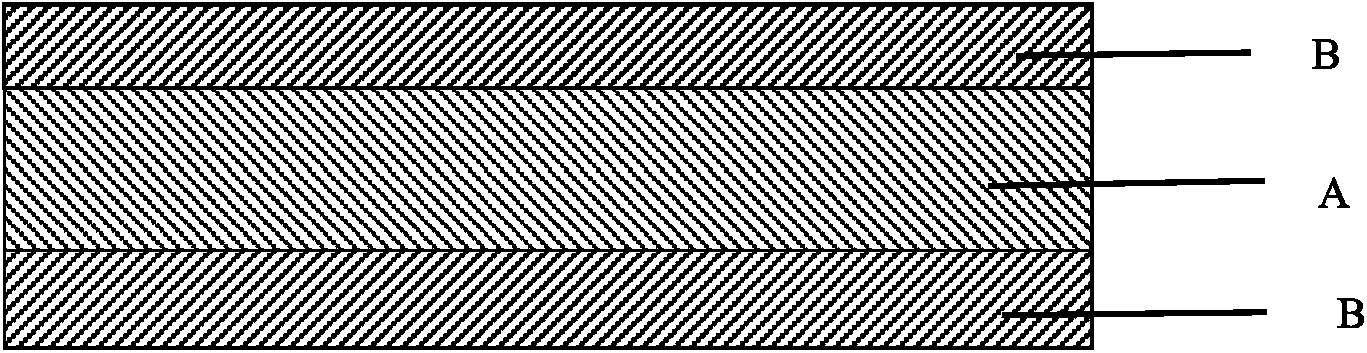

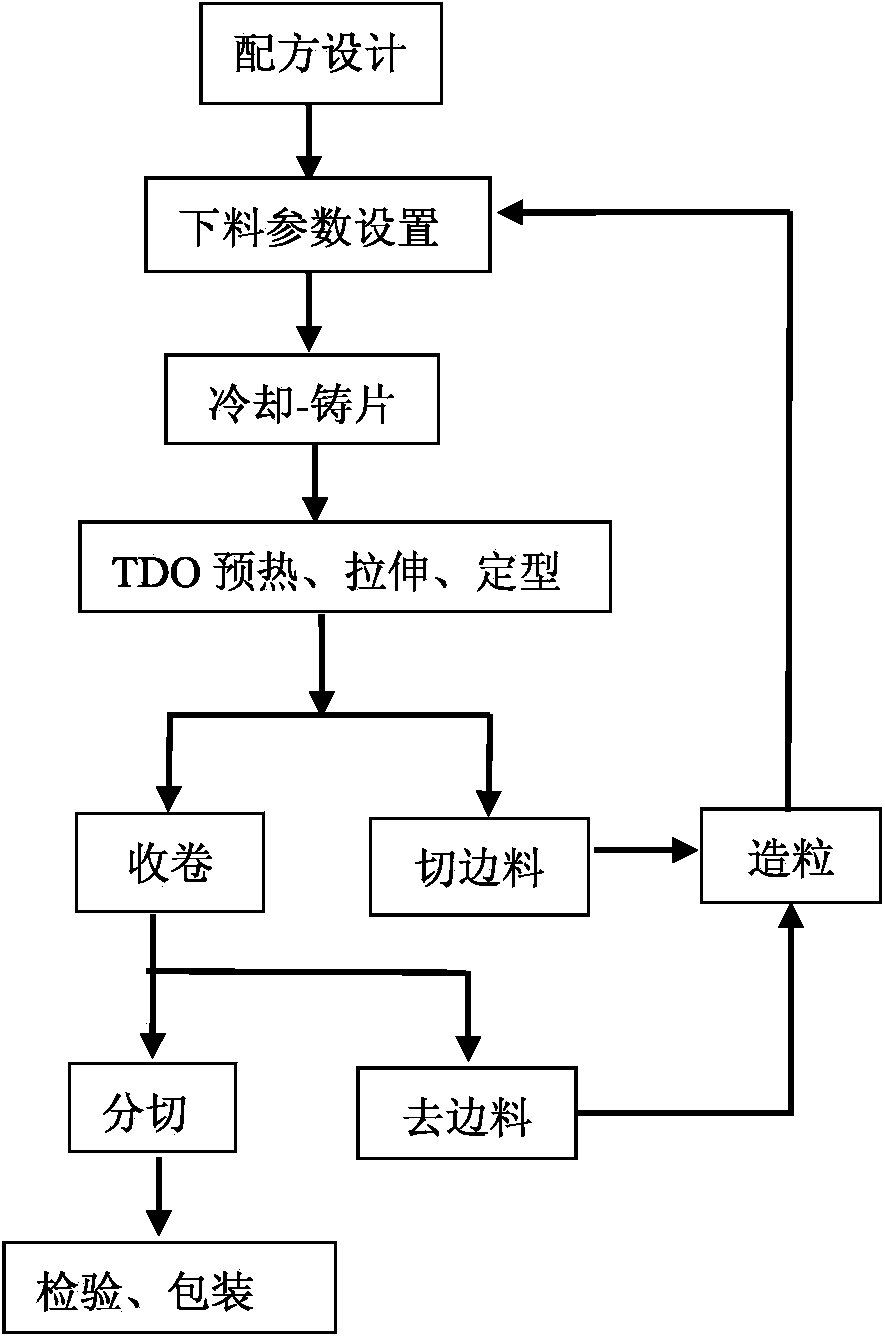

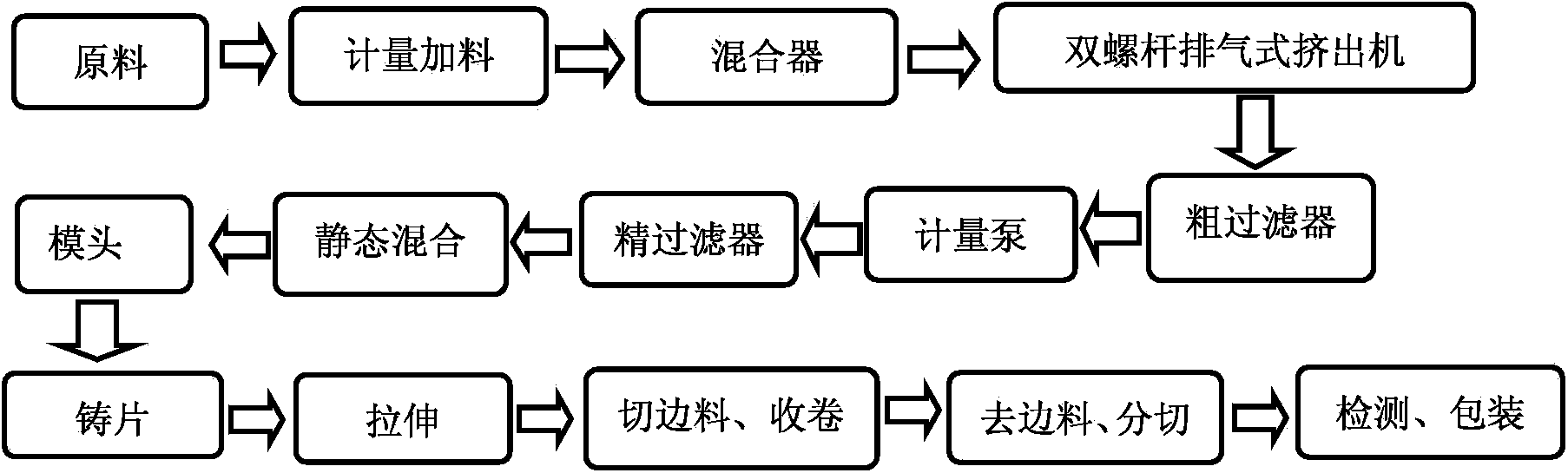

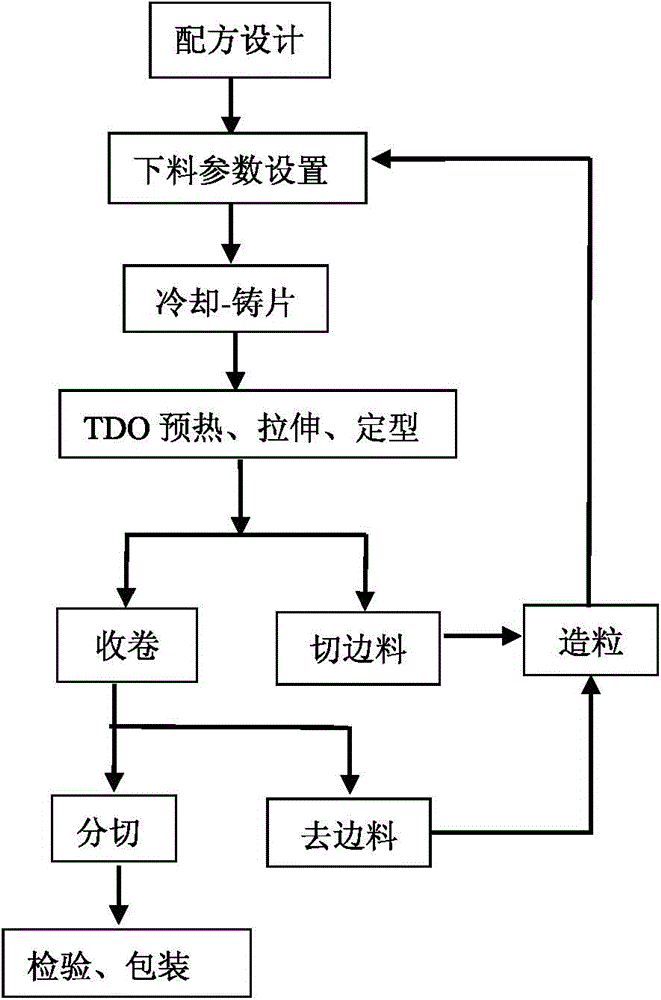

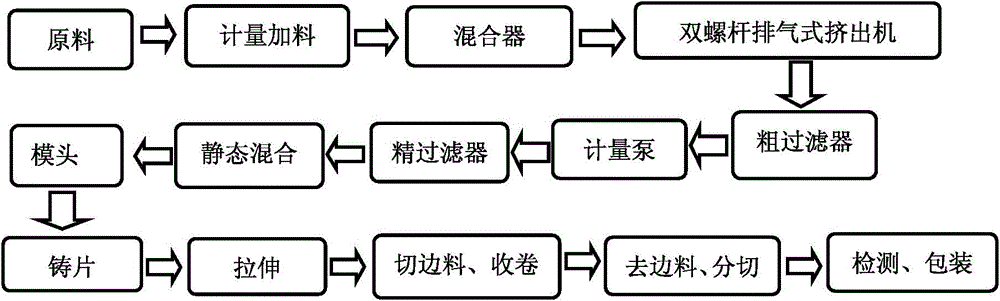

Tape-casting environment-friendly degradable heat-shrink film and manufacturing method thereof

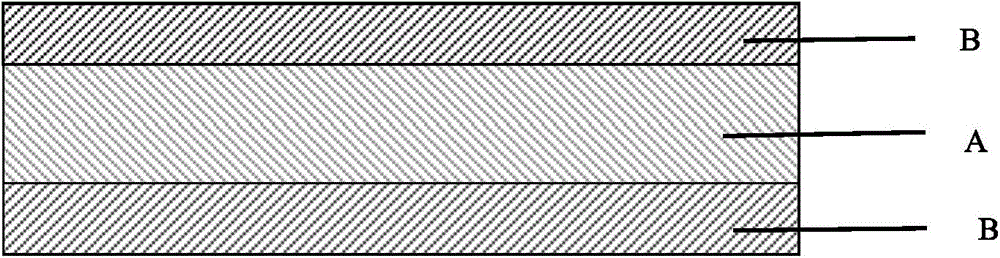

ActiveCN103625061AHigh filtration precisionGuaranteed uniformitySynthetic resin layered productsLaminationSurface layerStatic mixer

The invention relates to the field of processing and manufacturing of heat-shrink films, and in particular relates to a tape-casting environment-friendly degradable heat-shrink film and a manufacturing method thereof. The environment-friendly degradable heat-shrink film is of a three-layer (B / A / B) structure, wherein A is a base material core layer, and B is a printable surface layer; each printable surface layer comprises degradable poly lactic acid (PLA) resin, nano-silicon dioxide and processing aids. Materials of the base material core layer and the printable surface layers are put into a mold head through a double-screw exhaust type extruder, a coarse filter, a metering pump, a fine filter and a static mixer respectively, converge at the mold head and are extruded; the extruded materials are attached to a quenching roller and are quickly cooled to form a casting sheet; the casting sheet is preheated in transverse stretching equipment, and is transversely and uniformly stretched for four times, set and cooled to obtain the degradable heat-shrink film.

Owner:河南银金达新材料股份有限公司

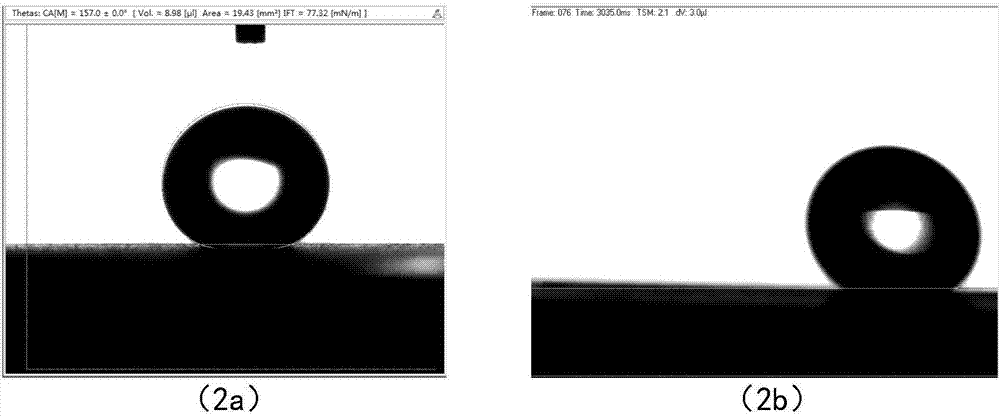

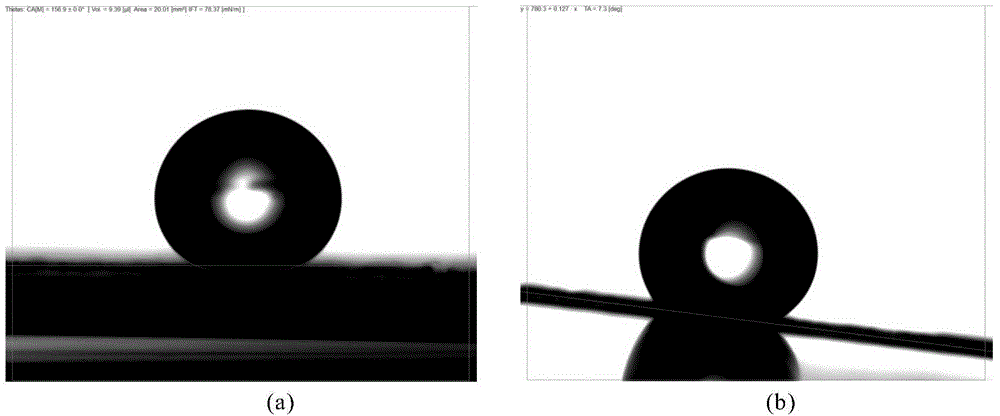

An ultra-hydrophilic polymer microporous membrane and a preparing method thereof

ActiveCN107349797ASurface performance is stableNo damage to physical and mechanical propertiesMembranesSemi-permeable membranesHydrophilic coatingHydrophilic polymers

The invention relates to an ultra-hydrophilic polymer microporous membrane. The ultra-hydrophilic polymer microporous membrane includes a polymer microporous membrane and a hydrophilic coating attached to the surface of the polymer microporous membrane. The hydrophilic coating is a crosslinked layer comprising hydrophilic modified inorganic nanometer particles. The hydrophilic modified inorganic nanometer particles are prepared by subjecting inorganic nanometer particles to hydrophilic modification by utilizing multi-alkoxy silane end-capped with hydrophilic groups. The invention also relates to a preparing method of the ultra-hydrophilic polymer microporous membrane.

Owner:NINGBO SHUIYI FILM TECH DEV CO LTD +1

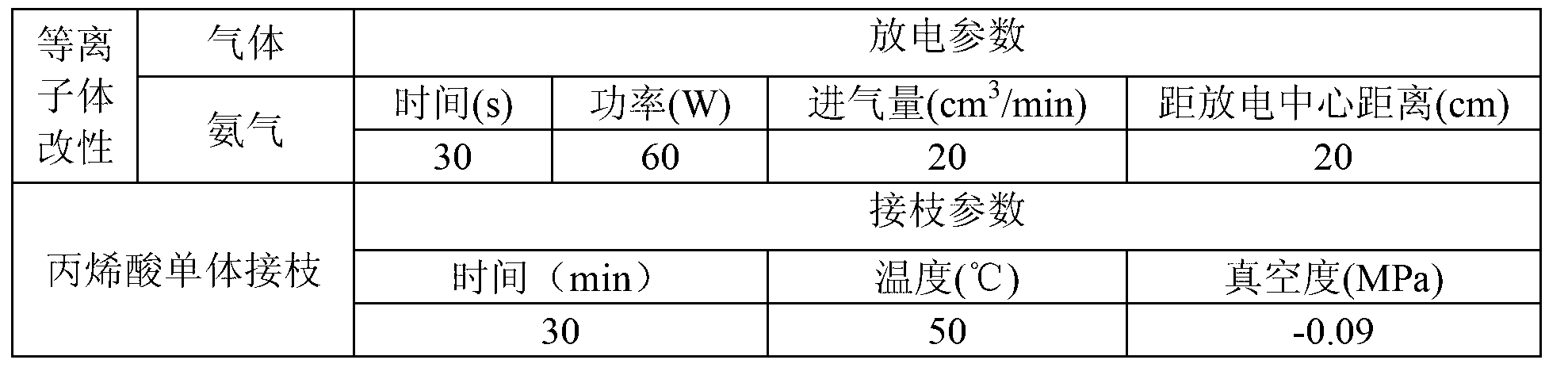

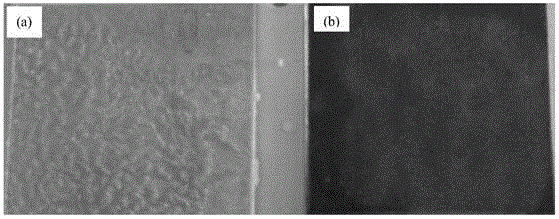

Preparation method of amphoteric polyether sulphone separation membrane

InactiveCN103263863AEasy to prepareMild preparation conditionsSemi-permeable membranesUltrafiltrationCarboxylic group

The invention discloses a preparation method of an amphoteric polyether sulphone separation membrane. The preparation method specifically comprises the following steps of: 1, taking a polyether sulphone flat ultrafiltration membrane, and removing an additive contained in the polyether sulphone flat ultrafiltration membrane to obtain a clean polyether sulphone flat ultrafiltration membrane; 2, performing plasma modification on the polyether sulphone ultrafiltration membrane obtained in the step 1 by using a controllable low-temperature plasma discharge device to obtain a modified polyether sulphone ultrafiltration membrane; and 3, taking an acrylic monomer, and grafting the modified polyether sulphone ultrafiltration membrane with the acrylic monomer to obtain the amphoteric polyether sulphone separation membrane. The polyether sulphone separation membrane prepared by the preparation method is an amphoteric membrane of which the surface contains amine groups and carboxyl, and the surface hydrophilicity is enhanced, so that the pollution resistance of the membrane is improved; and while the retention rate is increased, the pure water flux is greatly improved, so that the filtration efficiency is improved.

Owner:XI'AN POLYTECHNIC UNIVERSITY

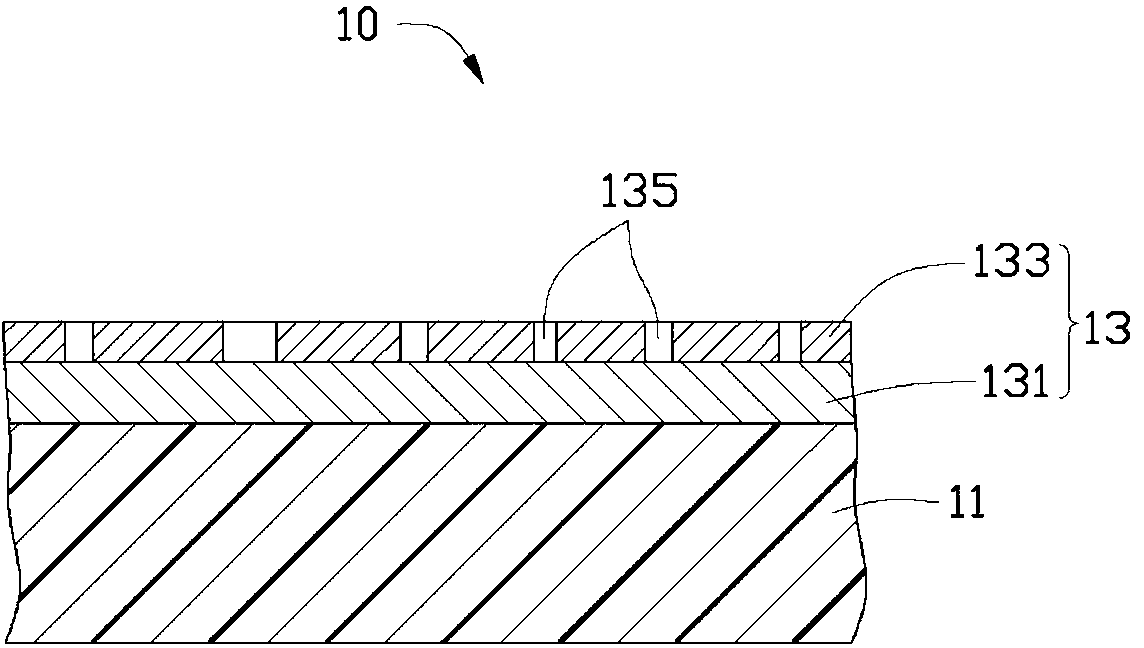

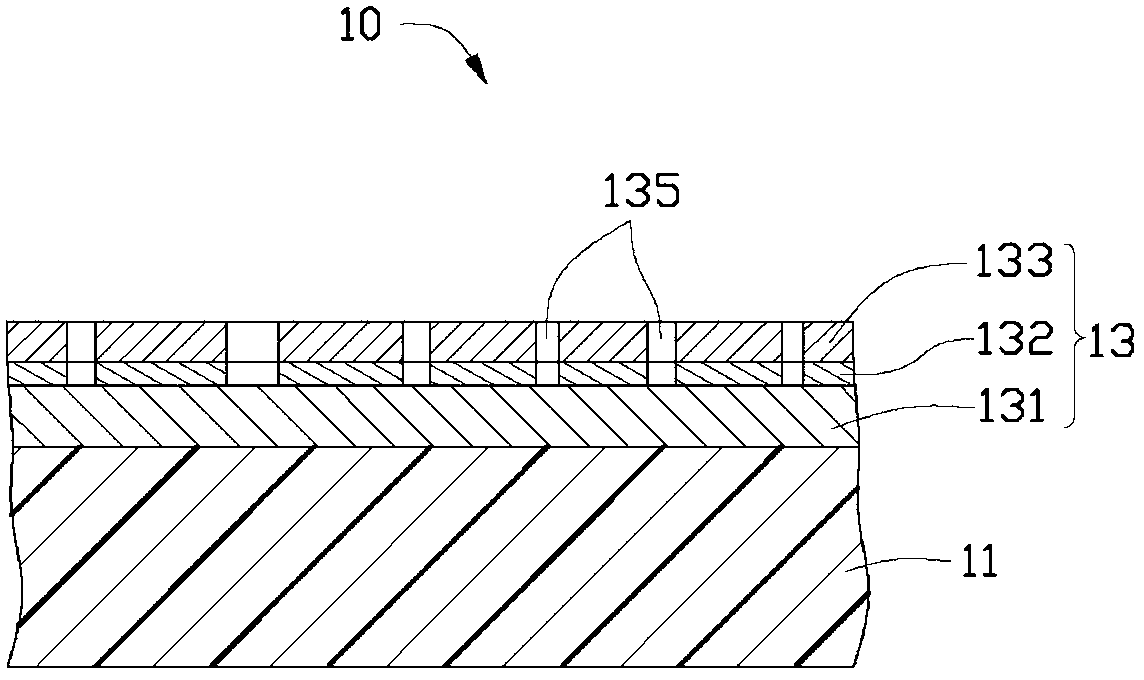

Coated part and preparation method thereof

InactiveCN103132014ARich color combinationsColorfulVacuum evaporation coatingSputtering coatingComputer scienceOpen hole

Owner:SHENZHEN FUTAIHONG PRECISION IND CO LTD

Method for preparing titanium alloy super-hydrophobic anti-frost surface using short pulse laser

ActiveCN104985328AExcellent superhydrophobic propertiesSimple processWelding/soldering/cutting articlesLaser beam welding apparatusTitanium alloyMetallic substrate

The invention relates to a method for preparing titanium alloy super-hydrophobic anti-frost surface using short pulse laser, and belongs to the technical field of surface modification on metal base material. The method comprises preprocessing (polishing) a titanium alloy sample, washing the surface of the sample in an ultrasonic cleaner using deionized water, drying the sample through cold air or airing the sample after the sample is cleaned up, treating the surface of the sample through a short pulse laser after related parameters are adjusted (the laser processing technology), making countless microstructures in the surface of the sample, putting the processed sample into an electrothermal drying box to be roasted after the sample is processed, to obtain the titanium alloy super-hydrophobic anti-frost surface. The surface has micron order papilla structures or crack structures, so the surface is excellent in super-hydrophobic performance and anti-frost performance. The method is simple in technology, convenient to carry out, high in efficiency, low in energy consumption, low in cost and environmental friendly, so the method can be easily applied to industrial application.

Owner:WUHAN JINDUN LASER TECH CO LTD

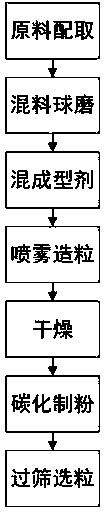

Production method of interphase carbon-coated graphite negative electrode material

The invention provides a production method of an interphase carbon-coated graphite negative electrode material. The production method is characterized in that natural graphite or artificial graphite with median particle diameter being 10 to 30 micrometers is adopted as a raw material A, interphase carbon microspheres are adopted as a raw material B, and nano-grade micro powder asphalt is adopted as a raw material C. The raw material A is carbonized at the temperature of 1200 to 1500 DEG C or is graphitized at the temperature of 2800 to 3200 DEG C. The raw material B is crushed into nano powder with median particle diameter being less than or equal to 80nm by utilizing a nano crushing method. The raw material A and the raw material B are mixed in a ratio of 100 / (3-10) to be primarily coated and modified, the raw material C is added into the mixture of the raw material A and the raw material B according to a ratio of (A+B) / C being equal to 100 / (5-10) to be secondarily coated and modified, and finally the mixture is secondarily and thermally treated at the temperature of 1200 to 1500 DEG C or 2800 to 3200 DEG C. The production method has the advantages that the conductivity is good, the capacity is high, the cycling performance is good, the service life is long, and compatibility with electrolyte is good.

Owner:大连宏光锂业有限责任公司

High-temperature resisting anti-corrosion aluminum alloy section for automobile engine and preparation method of high-temperature resisting anti-corrosion aluminum alloy section

InactiveCN108642354AImprove mechanical propertiesImprove high temperature resistanceMetallic material coating processesImpurityMaterials science

The invention discloses a high-temperature resisting anti-corrosion aluminum alloy section for an automobile engine and a preparation method of the high-temperature resisting anti-corrosion aluminum alloy section. An aluminum alloy base body comprises the following components: Cu, Mn, Cr, Zr, B, Be, Mg, Zn, Si, Fe, Ti, Ni, V, La, Eu and Er and the balance Al and unavoidable impurities. Raw materials of a coating include, by weight, 25-40 parts of TiC, 15-25 parts of NiO and 10-20 parts of TiO2. According to the high-temperature resisting anti-corrosion aluminum alloy section for the automobileengine and the preparation method of the high-temperature resisting anti-corrosion aluminum alloy section, the aluminum alloy section has good mechanical performance and excellent high-temperature resistance and anti-corrosion performance and is long in service life, and the performance of the automobile engine is effectively improved.

Owner:铜陵康达铝合金制品有限责任公司

Method for surface nano-crystallization and structure stabilization of metal material

InactiveCN104278137ASurface performance is stableFast preparationMaterial nanotechnologyVacuum evaporation coatingHigh energySteel ball

The invention discloses a method for surface nano-crystallization and structure stabilization of a metal material and belongs to the technical field of surface treatment of materials. The method disclosed by the invention comprises the following steps: by taking the metal material as an object, firstly performing stress relief annealing pretreatment to remove internal stress left by a previous machining process; then putting into a surface mechanical grinding device under vacuum conditions, and repeatedly hitting the surface of the material at high frequency by utilizing a large number of steel balls to perform surface nano-crystallization treatment; further performing pressure relief annealing treatment to remove the internal stress produced in the mechanical grinding treatment; and finally performing high-energy ion injection on the material after surface nano-crystallization to obtain the metal material with a stable surface nano-layer. According to the method disclosed by the invention, the surface mechanical grinding is combined with the high-energy ion injection, so that the nano-layer can be prepared on the surface of the metal material, the nano-layer has good stability in the subsequent cold and hot processing, and thus the stability of the mechanical properties of the surface of the material can be kept; in addition, the method disclosed by the invention is simple in process, low in investment, high in efficiency, low in energy consumption, pollution-free and easy to realize industrial production.

Owner:KUNMING UNIV OF SCI & TECH

Method for manufacturing plastic carrier belt

The invention relates to a method for manufacturing a plastic carrier belt. The method comprises the following steps of (1) sheet manufacturing, wherein the sheet manufacturing step comprises forming of two kinds of particles through prilling, drying and extruding, and one kind of plastic particles forms a middle layer of the sheet, and the other kind of plastic particles forms an upper surface layer and a lower surface layer of the sheet; (2) sheet slitting, wherein the sheet obtained through co-extrusion of three layers is slit by a tool on an extruding machine to form strip-shaped sheets; (3) pocket forming, wherein the slit sheets are arranged on a punch press, the sheets are punched through a forming device, a row of positioning round holes is formed at one side in the length direction of the sheets, a row of pocket type loading holes is formed at the other side in the length direction of the sheets, the sheets are stretched and formed, and the carrier belt is obtained. The method has the pertinence according to different characteristics of raw materials on the layers, the materials are different in layers, the optimum performance of the materials on each layer can make good for deficiency, the performance is stable, the optimum performance of the materials can be fully developed, and therefore on the premise of ensuring the needed performance of the carrier belt, the production cost is reduced.

Owner:ZHEJIANG JIEMEI ELECTRONICS & TECH

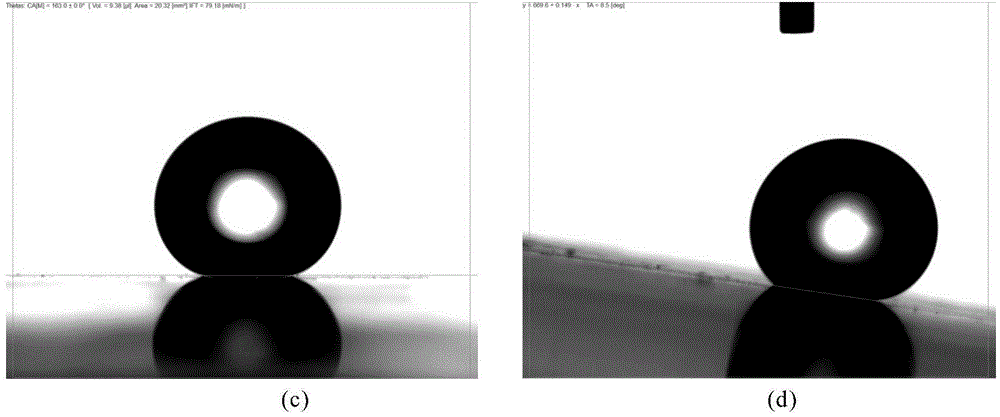

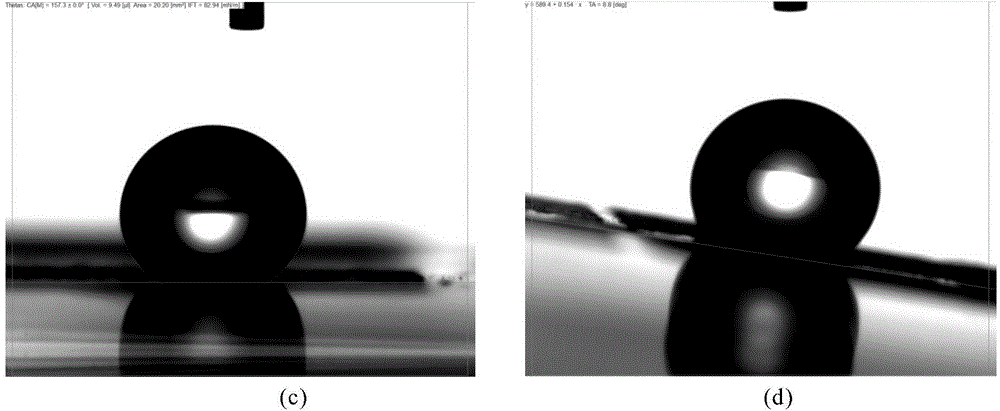

A modified polymer microporous membrane and a preparing method thereof

ActiveCN107349808ASurface performance is stableMild conditionsSemi-permeable membranesMembranesPrepolymerFunctional monomer

The invention relates to a modified polymer microporous membrane. The modified polymer microporous membrane includes a polymer microporous membrane and a crosslinked layer attached to the surface of the polymer microporous membrane. The crosslinked layer is formed by subjecting the surface of the polymer microporous membrane to crosslinking modification by utilizing a siloxane prepolymer solution. The siloxane prepolymer solution includes a prepolymer and an inert organic solvent. The prepolymer is a copolymer prepared by polymerizing multi-alkoxy silane and a functional monomer. The invention also relates to a preparing method of the modified polymer microporous membrane.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Method for preparing zinc alloy super-hydrophobic and self-cleaning surface by using ultra-short pulse laser

The present invention relates to a method for preparing a zinc alloy super-hydrophobic and self-cleaning surface by using ultra-short pulse laser, and belongs to the technical field of metal substrate surface modification. According to the method, a zinc alloy sample is subjected to polishing pretreatment, the sample surface is washed respectively with deionized water and dehydrated alcohol, blow drying or air drying is performed, a laser processing technology is utilized, ultra-short pulse laser is used to adjust the relevant process parameters, the sample is subjected to a surface treatment, countless micro structures are processed on the sample surface, and after completing the processing, the processed sample is placed into an electric heating drying box to bake so as to obtain the zinc alloy super-hydrophobic surface having the micron-scale granular or papillary structure, wherein the surface has characteristics of self-cleaning function, excellent friction resistance, and excellent corrosion resistance. The preparation method of the present invention has characteristics of simple process, convenient operation, high efficiency, low energy consumption, low cost, green environmental protection, and easy industrial application achieving.

Owner:金顿激光科技(佛山)有限公司

Environmentally friendly degradable heat-shrinkable film formed by tape casting and manufacturing method thereof

ActiveCN103625061BWith surface roughnessGood printabilitySynthetic resin layered productsLaminationSurface layerStatic mixer

The invention relates to the field of processing and manufacturing of heat-shrink films, and in particular relates to a tape-casting environment-friendly degradable heat-shrink film and a manufacturing method thereof. The environment-friendly degradable heat-shrink film is of a three-layer (B / A / B) structure, wherein A is a base material core layer, and B is a printable surface layer; each printable surface layer comprises degradable poly lactic acid (PLA) resin, nano-silicon dioxide and processing aids. Materials of the base material core layer and the printable surface layers are put into a mold head through a double-screw exhaust type extruder, a coarse filter, a metering pump, a fine filter and a static mixer respectively, converge at the mold head and are extruded; the extruded materials are attached to a quenching roller and are quickly cooled to form a casting sheet; the casting sheet is preheated in transverse stretching equipment, and is transversely and uniformly stretched for four times, set and cooled to obtain the degradable heat-shrink film.

Owner:河南银金达新材料股份有限公司

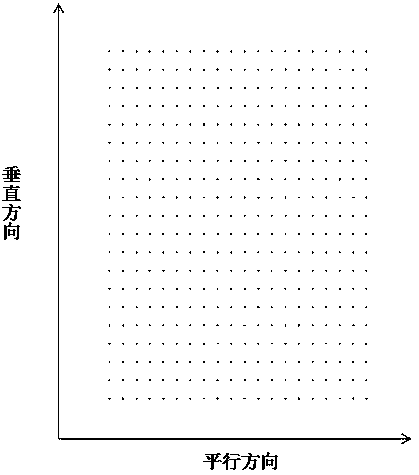

Preparation method of bionic rice leaf surface lattice anisotropy super-hydrophobic surface material

InactiveCN110900687AAvoid harmImprove machining accuracyMetal working apparatusLight spotPolytetrafluoroethylene

The invention relates to a preparation method of a bionic rice leaf surface lattice anisotropy super-hydrophobic surface material. The method sequentially comprises steps of (1) slicing a polytetrafluoroethylene high polymer material, sequentially putting the sliced polytetrafluoroethylene high polymer material into methylbenzene, absolute ethyl alcohol and the deionized water, respectively carrying out ultrasonic cleaning for 5-15 minutes, and drying at 40-90 DEG C; (2) drawing a bionic rice leaf surface lattice anisotropic structure graph by using Marking Mate software; (3) setting process parameters of laser equipment, setting the light spot diameter to be 0.1-0.5 mm, setting the engraving speed to be 10-100mm / s, setting the engraving mode to be horizontal and bidirectional, setting thepower to be 1%-10% and setting the engraving frequency to be 1-10 times, placing a treated base material on a laser equipment sample table, and completing laser engraving of the bionic rice leaf lattice anisotropic structure graph so as to obtain the bionic rice leaf lattice anisotropic structure graph. The method is advantaged in that the method is simple, the structure preparation method is rapid, environmental pollution is avoided, the prepared anisotropic super-hydrophobic surface is of a hierarchical structure similar to rice leaf surfaces, the anisotropic wettability is shown, and the method is suitable for industrial batch production.

Owner:HUBEI POLYTECHNIC UNIV

Multi-layer coated co-extrusion profile and production method thereof

PendingCN113771451AImprove physical strengthIncreased load-bearing capacitySynthetic resin layered productsWood layered productsElastomerAdhesive cement

The invention provides a multi-layer coated co-extrusion profile and a production method thereof. The co-extrusion profile comprises a rigid core and a coating layer coating the periphery of the rigid core in a co-extrusion mode, wherein the coating layer comprises an inner coating layer and an outer coating layer, the inner coating layer is prepared from a polyolefin wood-plastic material which takes polyolefin, unsaturated carboxylic acid modified polyolefin and plant fiber powder as main components, the outer coating layer is made of one of a thermoplastic elastomer, a thermoplastic engineering plastic, an ionic polymerization resin and an ionic polymerization resin reinforced polyolefin plastic, a first adhesive layer is also arranged between the rigid core and the inner coating layer, and an adhesive selected by the first adhesive layer is unsaturated carboxylic acid modified polyolefin hot melt glue or polyurethane hot melt glue. According to the invention, through the arrangement of the multi-layer structure, the profile has the physical strength of the core material, the wood-like effect and corrosion resistance of the wood-plastic layer and the wear resistance of the co-extrusion surface layer at the same time.

Owner:ANHUI SENTAI WPC GRP CO LTD

Artists' canvas with-ethylene copolymer coating and without filler and its producing process

InactiveCN1858336AEasy to useImprove compactnessSpecial artistic techniquesTextiles and paperCoated surfaceCoated membrane

The present invention belongs to the field of drawing article technology, and is especially one kind of artists' canvas with coating of vinyl acetate-ethylene copolymer and no filler suitable for oil painting, propylene drawing, gouache and decoration and its production process. The artists' canvas producing process includes compounding the coating materials for the bottom layer, the middle layer and facing layer; painting the bottom coating and stoving; painting 1-3 middle coating and stoving; and painting 1 or 2 facing coating and stoving to obtain the product. The artists' canvas has fine smooth and homogeneous coating, improved use performance, no oil permeation, high water resistance, and other advantages.

Owner:宋健 +2

Method for preparing silicone rubber super-hydrophobic self-cleaning surface with pulse laser

InactiveCN107039131AImprove processing efficiencySimple processInsulatorsLaser beam welding apparatusMicro nanoMature technology

The invention relates to a method for preparing a silicone rubber super-hydrophobic self-cleaning surface with a pulse laser. The pulse layer is used to perform laser scanning on the surface of a silicone rubber sample, a micro nano structure is formed on the surface of the silicone rubber sample, and the super-hydrophobic self-cleaning surface is prepared. The laser preparation method adopted in the invention has the advantages of simple process and mature technology, and only changes the structure of the surface layer of the silicone rubber without changing its body composition, structure and characteristics. Compared with a method adopting the use of chemical reagents on the surface modification of silicone rubber, the method provided by the invention is higher in laser processing efficiency, lower in energy consumption, lower in cost and greener. With the method of the present invention, it is possible to obtain a super-hydrophobic silicone rubber surface within a wide range of process conditions and has a very important effect on practical applications. The method is simple in process, safe and reliable, and suitable for processing silicone rubber products of various shapes and specifications and products covered by silicone rubber. The prepared super-hydrophobic silicone rubber is stable in surface performance and particularly suitable for large-scale industrial production.

Owner:HUBEI UNIV OF TECH

Art canvas with non-filler polyvinyl built coating and its production process

InactiveCN1869328AEasy to useImprove compactnessSpecial artistic techniquesTextiles and paperFilling materialsWadding

The invention relates to a no-filling material polyvinyl alcohol coating layer art canvas and the producing technology. It uses polyvinyl alcohol as main raw material to make bottom, middle and covering coating material. Coating bottom layer on the bottom canvas, drying; coating middle coating layers, drying; coating covering layers, drying; and the product would be gain. The invention improves the softness, compactness and mechanical strength of the coating film, and would not cause loose by the alteration of temperature and humidity.

Owner:宋健 +2

Method for preparing aluminum alloy super-hydrophobic and self-cleaning surface by using ultra-short pulse laser

The present invention relates to a method for preparing an aluminum alloy super-hydrophobic and self-cleaning surface by using ultra-short pulse laser, and belongs to the technical field of metal substrate surface modification. According to the method, an aluminum alloy sample is subjected to polishing pretreatment, the sample surface is cleaned respectively with deionized water and dehydrated alcohol, then blow drying with cold wind or air drying is performed, a laser processing technology is utilized, short pulse laser is used to adjust the relevant process parameters, the sample is subjected to a surface treatment, countless micro structures are processed on the sample surface, and after completing the processing, the processed sample is placed into an electric heating drying box to bake so as to obtain the aluminum alloy super-hydrophobic and self-cleaning surface having the micron-scale papillary structure, wherein the surface has characteristics of good super-hydrophobicity and excellent self-cleaning function. The preparation method of the present invention has characteristics of simple process, convenient operation, high efficiency, low energy consumption, low cost, green environmental protection, and easy industrial application achieving.

Owner:金顿激光科技(佛山)有限公司

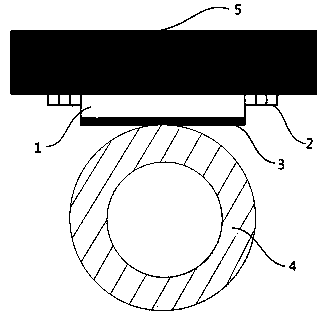

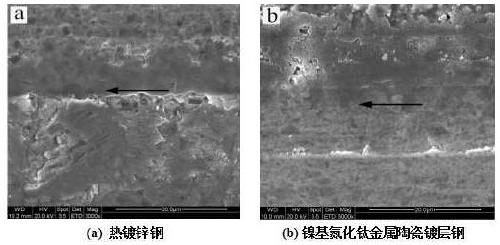

Nickel-based titanium nitride metal ceramic coating material and preparation method and application thereof

InactiveCN109536816AHigh bonding strengthImprove wear resistanceHeat inorganic powder coatingTitanium nitrideCarbonization

The invention discloses a nickel-based titanium nitride metal ceramic coating material and preparation method and application thereof. The preparation method comprises the following steps that S1, mixing and ball milling, carrying out ball milling on a mixed raw material and a ball milling solvent; the mixed raw materials are calculated according to the mass ratio of 60%-85% of a titanium nitride,10-30% of nickel and 0.5-10% of carbon; S2, mixed forming agent, after the ball milling is finished, adding the mixed forming agent into the ball mill to carry out rolling ball milling, and a mixed material liquid is obtained; S3, spray granulation, carrying out spray granulation on the mixed material liquid in the step S2, so as to obtain mixed materials; S4, carbonizing to prepare the powder, drying the mixed material granules in the step S3, then carrying out carbonization and solid solution reaction in a high-temperature carbonization furnace to obtain (Ti, Ni) (C,N) solid solution powder; S5, screening particles, the (Ti, Ni) (C,N) solid solution powder is sieved by a mesh sieve, so as to obtain the nickel-based titanium nitride metal ceramic coating material with the average grain diameter of 60-100 microns. The nickel-based titanium nitride metal ceramic coating material prepared by the preparation method has high wear resistance and strong corrosion resistance.

Owner:GUANGDONG POWER GRID CO LTD +1

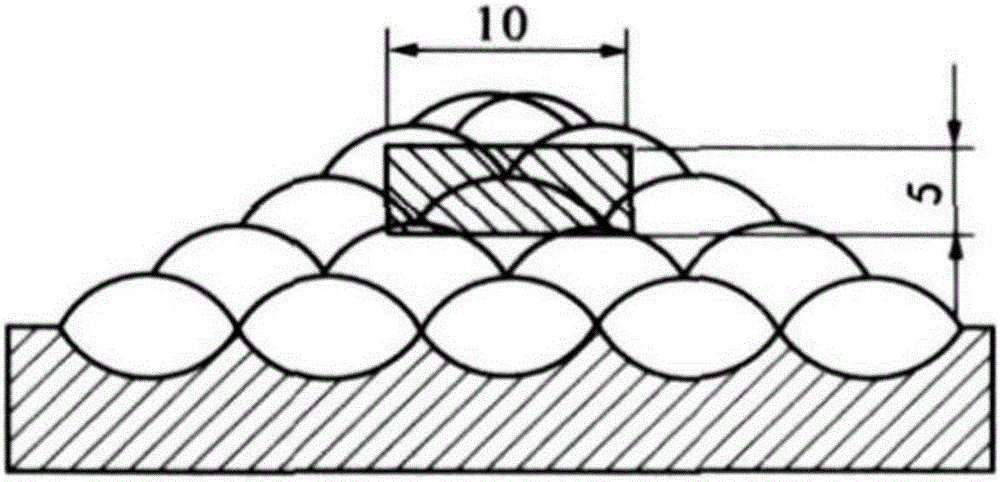

Welding wire, preparation method thereof and method for reinforcing hot-working die material surface by using welding wire

ActiveCN105728979AImprove high temperature stabilityImprove mechanical propertiesWelding/cutting media/materialsSoldering mediaNiobiumManganese

The invention discloses a welding wire, a preparation method thereof and a method for reinforcing the hot-working die material surface by using the welding wire. The welding wire comprises, by mass, 85.2-89% of iron elements, 5.71-6.98% of chromium elements, 0.86-1.52% of carbon elements, 1.16-1.63% of manganese elements, 0.56-0.84% of vanadium elements, 0.55-1.0% of niobium elements, 1.39-1.63% of molybdenum elements, 0.5-1.1% of silicon elements and 0.08-0.1% of nitrogen elements. Through the improvement on the predesigned components and proportion of the welding wire, especially components and proportion of alloy powder forming a welding wire drawing material, the welding wire is particularly applicable to reinforcement of the hot-working die material working surface, and the high-temperature working performance of the hot-working die surface is improved.

Owner:HUAZHONG UNIV OF SCI & TECH

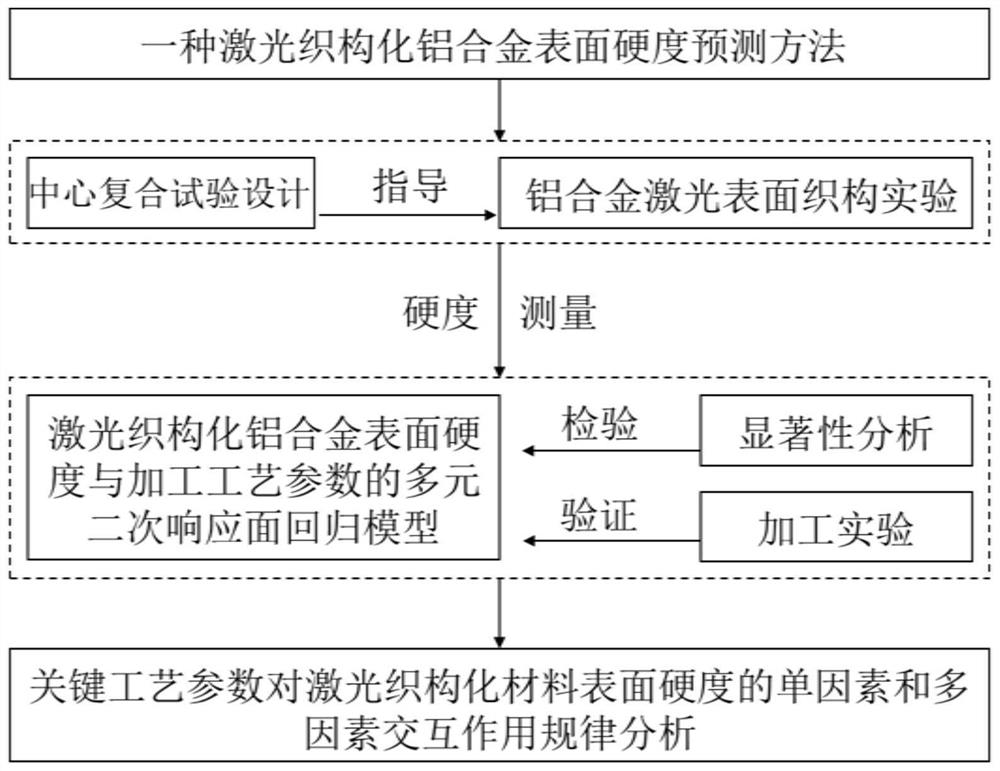

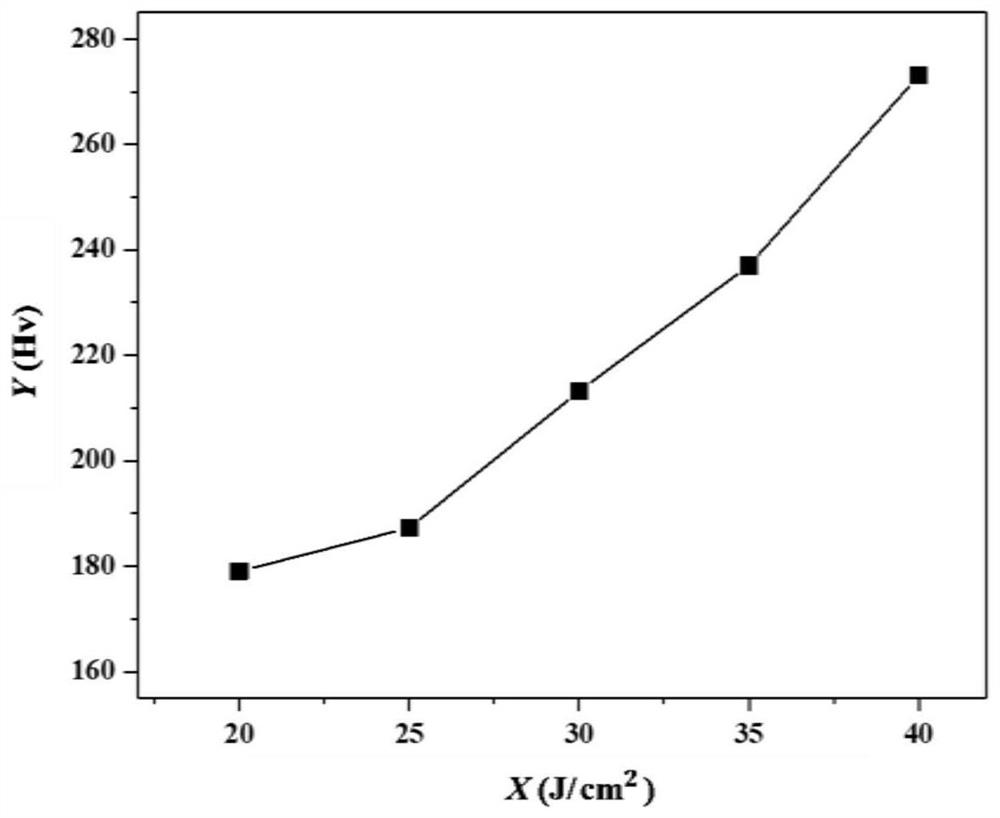

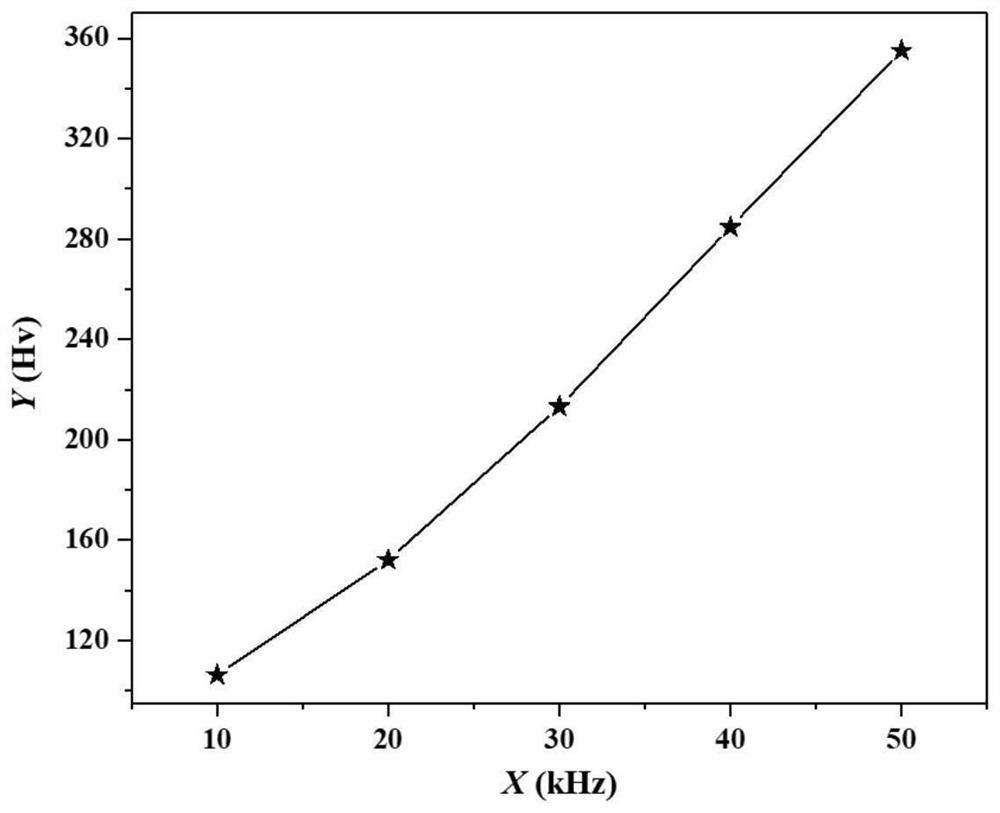

Method for predicting surface hardness of laser textured aluminum alloy

ActiveCN112199632AImprove surface performanceSurface performance is stableInvestigating material hardnessLaser beam welding apparatusLaser processingHardness

The invention discloses a method for predicting the surface hardness of laser textured aluminum alloy, belongs to the technical field of high-performance surface non-traditional machining, and relatesto a method for predicting the surface hardness of the laser textured aluminum alloy. According to the method, a laser surface texture processing experiment is carried out based on a central composite experiment design method, a hardness prediction model is established by using a response surface method according to an aluminum alloy laser texture surface hardness measurement value, an aluminum alloy laser texture surface hardness value is predicted, and an influence rule of key process parameters on the hardness of a laser textured material is obtained; and the interaction between the process parameters are determined. The method can accurately and reliably predict the surface hardness of the laser textured aluminum alloy, can be effectively applied to manufacturing high-performance laser surface textures by selecting proper laser processing technological parameters, and has important practical application significance for improving the surface service performance of the laser textured aluminum alloy.

Owner:DALIAN UNIV OF TECH

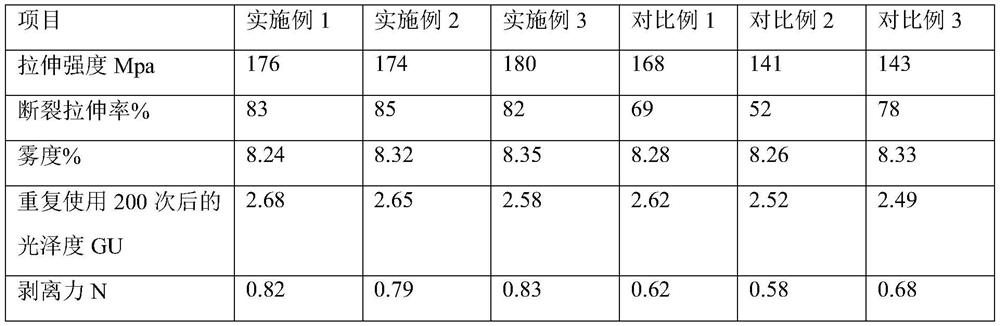

Matte release film produced by EB curing

InactiveCN112940640AEasy to peelImprove adhesionCoatingsFilm/foil adhesive release linersPolymer sciencePolymer chemistry

The invention relates to the technical field of new materials, and concretely relates to a matte release film produced by EB curing. The matte release film produced by EB curing is characterized by comprising a base material and a release layer which coats the base material, and the thickness of the release layer is 35-280 nm; and the functional release agent is prepared from, by weight, 12 to 15 parts of an acrylate modified polysiloxane prepolymer, 13 to 18 parts of a reactive diluent, 20 to 35 parts of natural latex, 6 to 10 parts of an emulsifier, 4 to 8 parts of a stabilizer and 5 to 10 parts of an oxygen trapping agent. A PU fabric produced by using the matte release film disclosed by the invention is good in surface smoothness, good in strength, and free of brittleness and breakage after repeated use; the surface effect of the PU fabric is stable, and the glossiness is not changed after the PU fabric is continuously produced and repeatedly used for more than 200 times; and the temperature resistance is good, the high temperature of about 150 DEG C can be resisted, the durability is good, and the repeated use frequency is 5-10 times that of release paper.

Owner:南京盛凯新材料有限公司

Stainless steel surface treatment method capable of improving anti-corrosion capacity

InactiveCN107740036AQuality improvementImprove bindingSolid state diffusion coatingSurface layerAfter treatment

The invention discloses a stainless steel surface treatment method capable of improving the anti-corrosion capacity. The stainless steel surface treatment method comprises the following steps that a steel sample with the size being 15*15*10 mm is cut to serve as a base material, and AlN is selected to serve as a source electrode material; the steel sample is subjected to abrasive paper grinding and mechanical polishing many times and then sequentially cleaned and dried; and aluminum diffusion treatment is conducted through a double-layer glow plasma surface alloying vacuum furnace, a stainlesssteel cylinder serves as an auxiliary cathode, the base material and the AlN are placed in the auxiliary cathode, surface treatment begins to be conducted, and the sample is cooled to be the indoor temperature with a furnace after treatment. According to the stainless steel surface treatment method capable of improving the anti-corrosion capacity, operation is easy, the implementation process isenvironmentally friendly and free of pollution, and the combining force between a diffusion layer and a base body is increased; AlN is selected to serve as the source electrode material and can generate N2 in a reaction, other oxidation reactions are avoided, and the cleanliness of the surface layer of steel is improved; and an anti-corrosion aluminium oxide surface layer can be formed on the surface of the stainless steel with the passage of time, after an oxidation film is formed on the surface, further infiltration of oxygen atoms can be effectively prevented, and the overall surface performance is stable.

Owner:江苏徐钢钢铁集团有限公司

Packaging box sticky folded surface processing method

InactiveCN101224644AExcellent adhesionHigh quality sticky effectContainer making machineryAdhesiveEngineering

The invention provides a bonding surface disposal method of a packing box. The surface of the bonding position of the packing box is disposed by a low-temperature plasma before the bonding is achieved by an adhesive. The method can effectively reinforce the bonding of the packing box, gains the bonding effect with high quality, and is safe and protects the environment.

Owner:SHENZHEN NINE STARS PRINTING & PACKAGING GRP

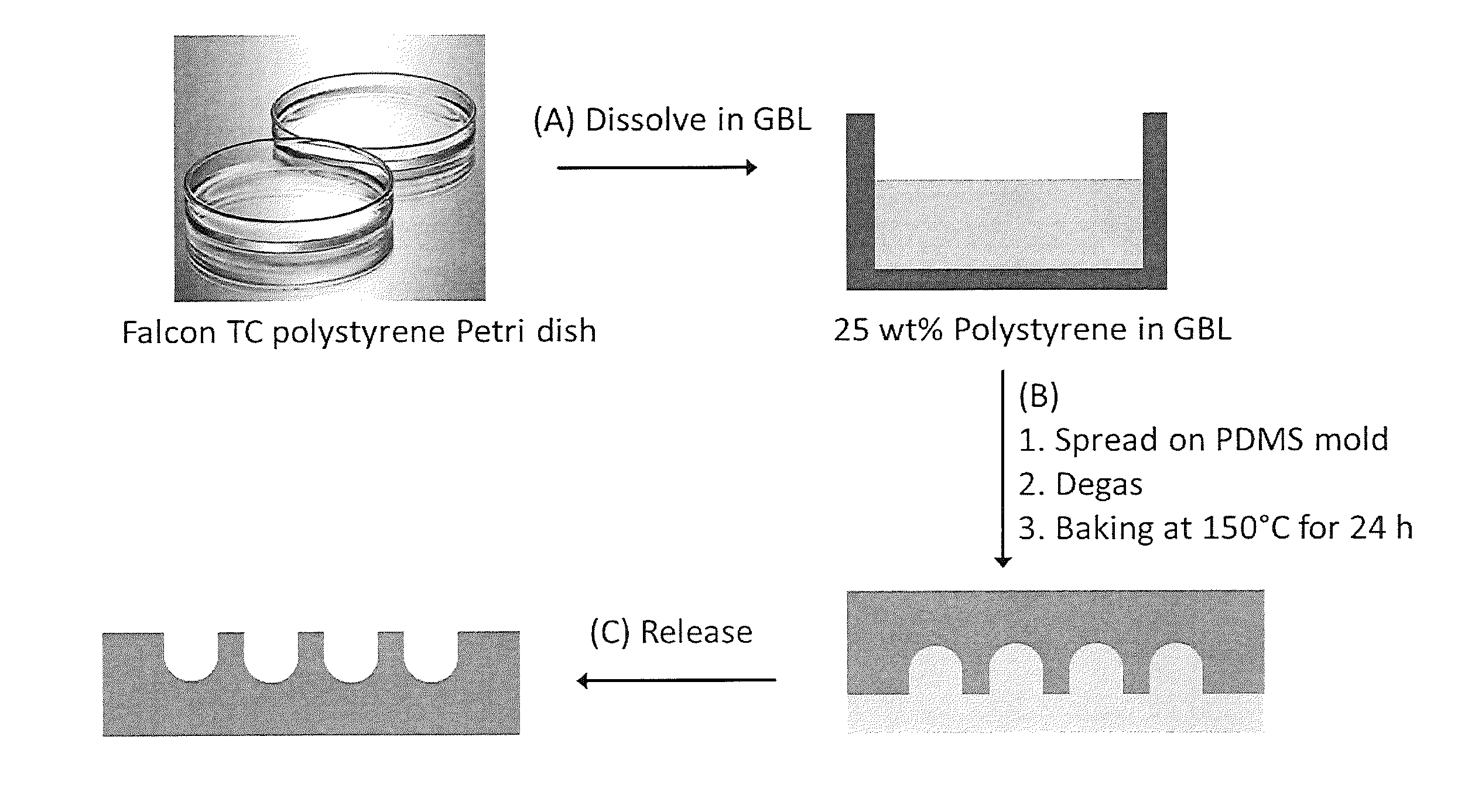

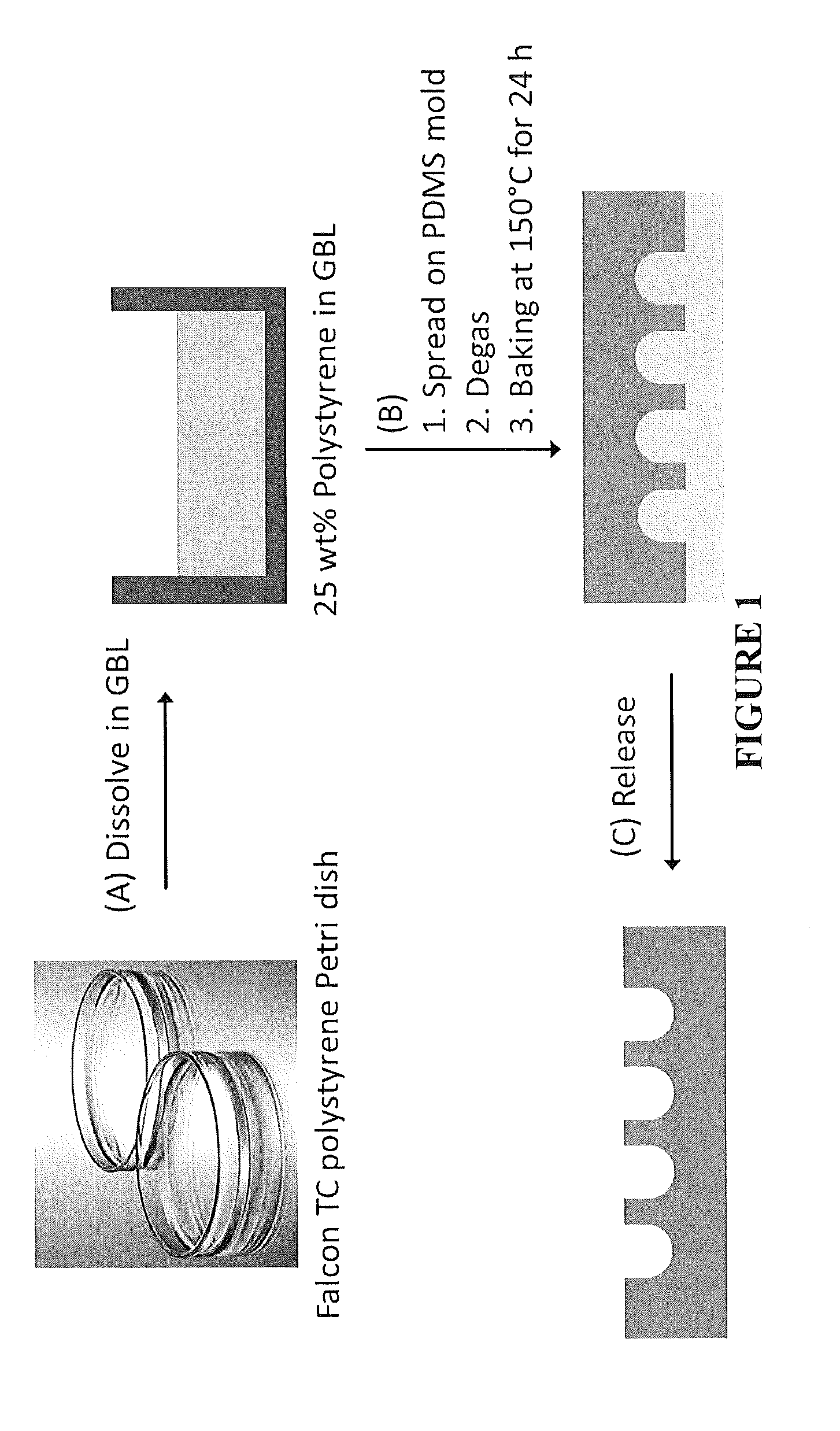

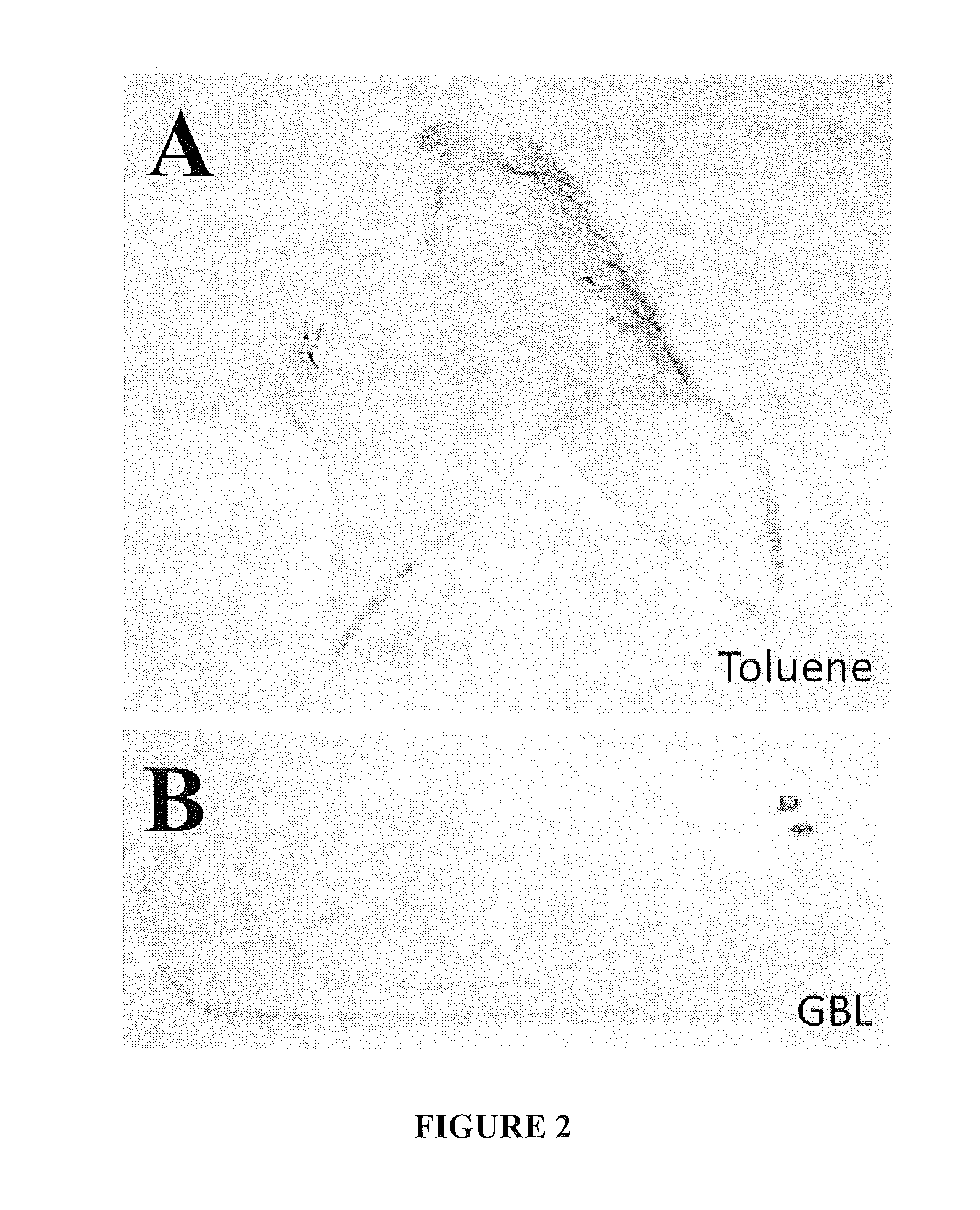

Micromolding of polystyrene by soft lithography

InactiveUS20130066031A1High resolutionWide applicabilityNanoinformaticsPhotomechanical apparatusPolyesterElastomer

A method of making such is carried out by (a) providing a reverse template for said article, said template comprising an elastomeric polymer such as PDMS; (b) providing a solution comprising a polymer dissolved in a first solvent; wherein said polymer is selected from the group consisting of polystyrene, poly(methyl methacrylate), epoxy, and aliphatic polyesters; and wherein said solvent comprises a lactone; (c) depositing said solution on said template; (e) removing said solvent from said template to form said article from said polymer on said template; and then (f) separating said template from said article.

Owner:THE UNIV OF NORTH CAROLINA AT CHAPEL HILL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com