An ultra-hydrophilic polymer microporous membrane and a preparing method thereof

A polymer and microporous membrane technology, applied in chemical instruments and methods, membrane, membrane technology, etc., can solve problems such as multi-level micro-nano structure damage, and achieve the effects of simple process, stable surface performance and mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The invention provides a kind of preparation method of superhydrophilic polymer microporous membrane, it comprises the following steps:

[0028] S1, carrying out a copolymerization reaction of polyalkoxysilane and hydrophilic monomer in an organic solvent under the action of a catalyst to obtain a hydrophilic modified siloxane prepolymer solution;

[0029] S2, adding inorganic nanoparticles to the hydrophilic modified siloxane prepolymerization liquid to modify the inorganic nanoparticles to obtain an emulsion containing hydrophilic modified inorganic nanoparticles; and

[0030] S3, coating the emulsion containing the hydrophilic modified inorganic nanoparticles on the surface of the polymer microporous membrane to form a hydrophilic coating to obtain the superhydrophilic polymer microporous membrane.

[0031] In step S1, the temperature of the copolymerization reaction is 40°C to 100°C, preferably 50°C to 70°C. The time for the copolymerization reaction is 2 hours to ...

Embodiment 1

[0045] (1) Add 3g of hydroxyethyl methacrylate, 2g of vinyltrimethoxysilane and 0.06g of benzoyl peroxide to 100mL of dehydrated ethanol in turn, pass through industrial nitrogen, and 200r at room temperature / min Mechanical stirring for 20min. Then heat and gradually increase the temperature to 65° C., and react with mechanical stirring at 200 r / min for 36 hours in an industrial nitrogen atmosphere. Turn off the heating, and obtain a hydrophilic hydroxyethyl methacrylate / vinyltrimethoxysilane copolymer prepolymer liquid after fully cooling down.

[0046] (2) Add 5g of nano-zinc oxide particles to the hydrophilic hydroxyethyl methacrylate / vinyl trimethoxysilane copolymer pre-polymerization solution, and ultrasonically treat it for 20 minutes to obtain a nano-zinc oxide particle containing hydrophilic modification lotion.

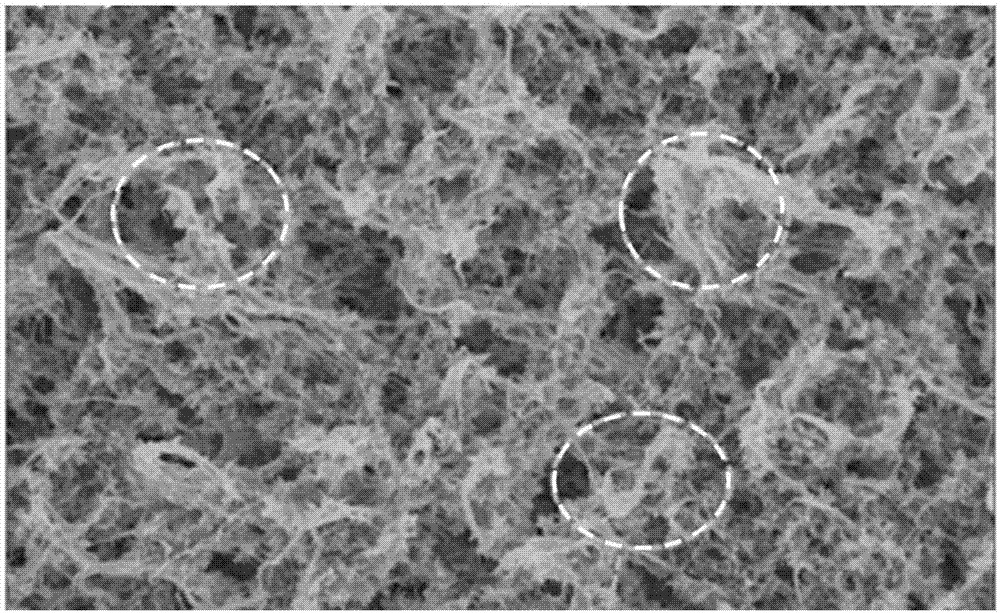

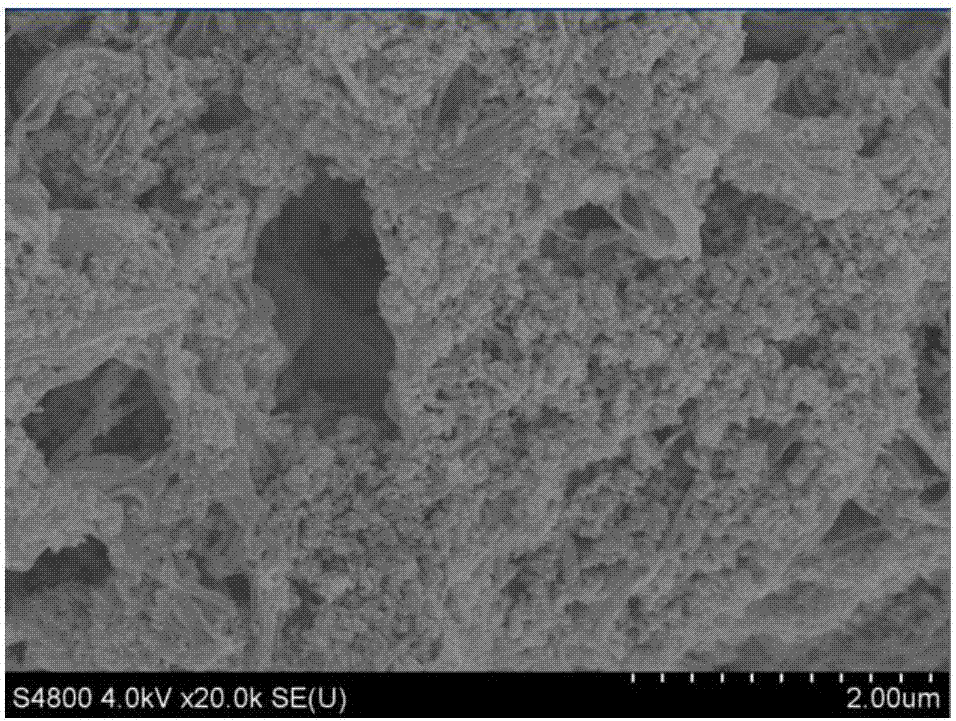

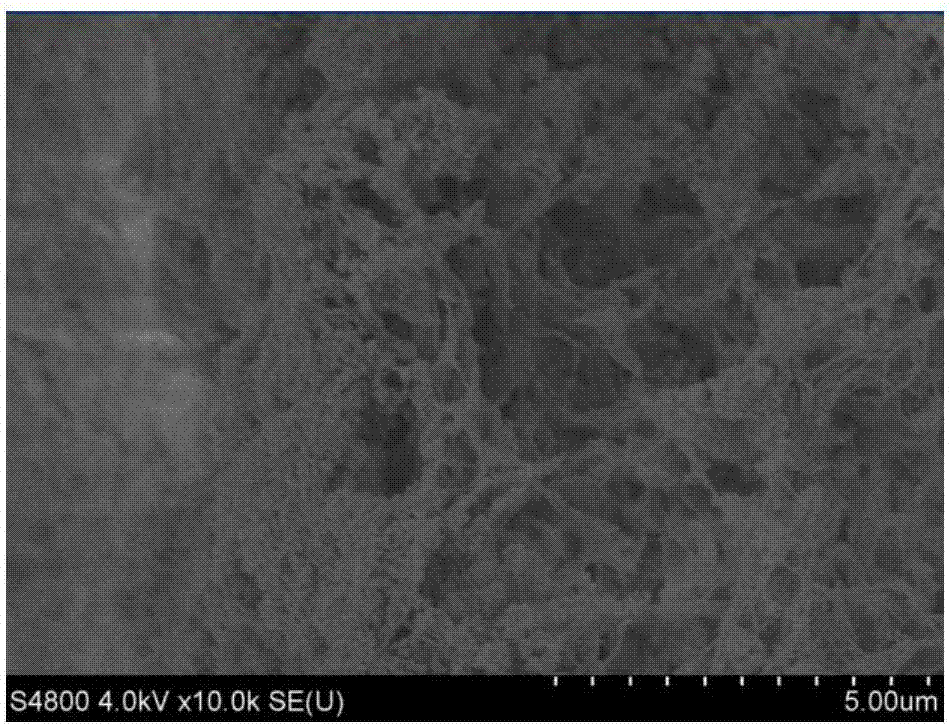

[0047] (3) The emulsion containing the hydrophilic modified nano-zinc oxide particles is evenly coated on the surface of the polyvinylidene fluoride micro...

Embodiment 2

[0050] (1) Add 4g of N-vinylpyrrolidone, 3g of vinyltriethoxysilane and 0.1g of azobisisoheptylcyanide to 100mL of absolute ethanol in sequence, feed high-purity nitrogen, and Under 250r / min mechanical stirring for 30min. Then heat and gradually increase the temperature to 80° C., and react with mechanical stirring at 250 r / min for 24 hours in an industrial nitrogen atmosphere. Turn off the heating, and obtain a hydrophilic N-vinylpyrrolidone / vinyltriethoxysilane copolymer prepolymer liquid after cooling down sufficiently.

[0051] (2) Add 6 g of nano-titanium dioxide particles to the hydrophilic N-vinylpyrrolidone / vinyltriethoxysilane copolymer prepolymerization solution, and perform ultrasonic treatment for 40 minutes to obtain an emulsion containing hydrophilic modified nano-titanium dioxide particles.

[0052] (3) The emulsion containing the hydrophilic modified nano-titanium dioxide particles is evenly coated on the surface of the polyvinylidene fluoride microporous memb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com