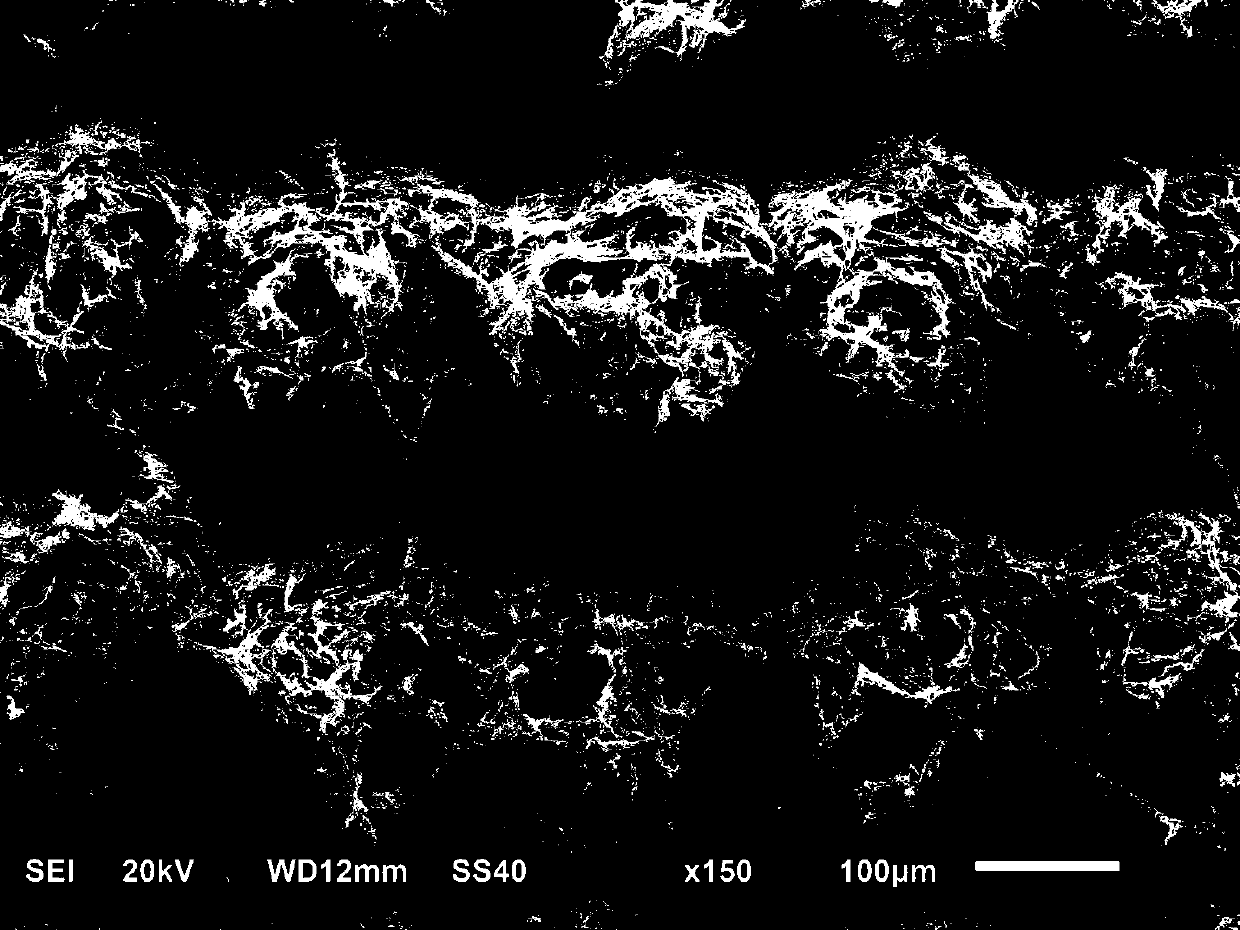

Preparation method of bionic rice leaf surface lattice anisotropy super-hydrophobic surface material

A super-hydrophobic surface and anisotropic technology, which is applied in metal processing and other fields, can solve the problems of many steps in the preparation process, the toxicity of chemical reagents, and insufficient precision control, etc., and achieve the effect of simple method, stable surface performance and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A method for preparing a bionic rice leaf surface lattice anisotropic superhydrophobic surface material, comprising the following steps in sequence:

[0030] (1) Surface pretreatment of base material

[0031] Cut the polytetrafluoroethylene polymer material with a thickness of 2mm into square pieces with a side length of 1cm×1cm, and process 4 samples at the same time, then put them in toluene, absolute ethanol and deionized water in sequence, and then use ultrasonic cleaning The machine was ultrasonically cleaned in the above solvents for 6 minutes to remove organic and inorganic pollutants on the surface of the material, and then the processed samples were placed in an oven and dried at 50°C for later use;

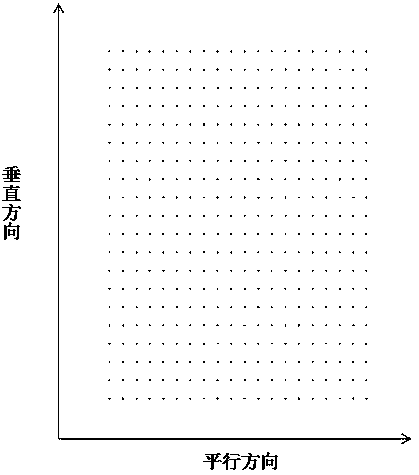

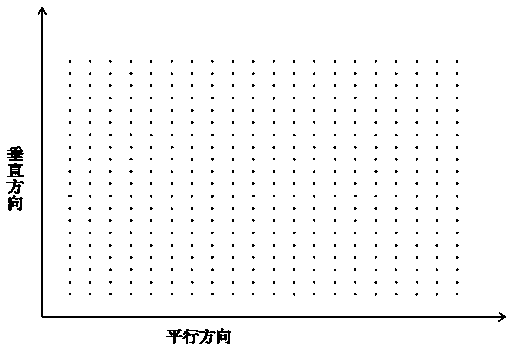

[0032] (2) Use laser equipment software to draw lattice anisotropic microstructure graphics

[0033] Use the Marking Mate drawing software of the high-speed laser marking machine to draw the dot matrix anisotropic structure, set the dot matrix spacing a in the ho...

Embodiment 2

[0039] A method for preparing a bionic rice leaf surface lattice anisotropic superhydrophobic surface material, comprising the following steps in sequence:

[0040] (1) Surface pretreatment of base material

[0041] Cut the polytetrafluoroethylene polymer material with a thickness of 4mm into square pieces with a side length of 2cm×2cm, and process 6 samples at the same time, then put them in acetone, absolute ethanol and deionized water in sequence, and then use ultrasonic cleaning The machine was ultrasonically cleaned in the above solvents for 10 minutes to remove organic and inorganic pollutants on the surface of the material, and then the processed samples were placed in an oven and dried at 60°C for later use;

[0042] (2) Use laser equipment software to draw lattice anisotropic microstructure graphics

[0043] Use the Marking Mate drawing software of the high-speed laser marking machine to draw the dot matrix anisotropic structure, set the dot matrix spacing a in the h...

Embodiment 3

[0047] A method for preparing a bionic rice leaf surface lattice anisotropic superhydrophobic surface material, comprising the following steps in sequence:

[0048] (1) Surface pretreatment of base material

[0049] Cut the polytetrafluoroethylene polymer material with a thickness of 5mm into square pieces with a side length of 4cm×4cm, and process 4 samples at the same time, and then put them in toluene, absolute ethanol and deionized water in sequence, and then use ultrasonic cleaning The machine was ultrasonically cleaned in the above solvents for 10 minutes to remove organic and inorganic pollutants on the surface of the material, and then the processed samples were placed in an oven and dried at 70°C for later use;

[0050] (2) Use laser equipment software to draw lattice anisotropic microstructure graphics

[0051] Use the Marking Mate drawing software of the high-speed laser marking machine to draw the dot matrix anisotropic structure, set the dot matrix spacing a in t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com