Method for preparing silicone rubber super-hydrophobic self-cleaning surface with pulse laser

A technology of pulsed laser and silicone rubber, which is applied in laser welding equipment, manufacturing tools, welding equipment, etc., can solve the problem that the surface structure cannot be changed, and achieve the effect of green environmental protection, high efficiency and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Experimental steps: using a pulsed laser with a wavelength of 1064nm, the surface of the silicone rubber sample is scanned by laser; the pulse width of the laser is 240ns, the energy of a single pulse is 0.5mJ, and the repetition frequency is 80kHz. The laser scan uses a galvanometer system, Make the laser beam irradiate the surface of the silicone rubber sample row by row at a speed of 1121mm / s, and the processing range of the sample is 100mm x 100mm. The galvanometer system is composed of a high-speed rotating X-Y optical scanning head, an electronic drive amplifier, an optical mirror and a field mirror. The scanning speed, scanning range and scanning path of the galvanometer system are controlled and set by a computer controller.

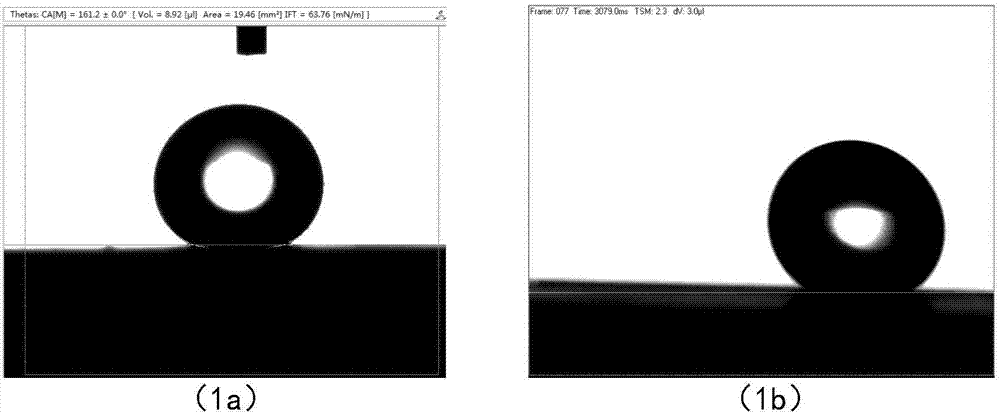

[0033] Use the optical contact angle surface interfacial tension measuring instrument to test the contact angle and rolling angle of the obtained silicone rubber superhydrophobic self-cleaning surface: use the pick-up method to measure, for...

Embodiment example 2

[0038] Experimental steps: using a pulsed laser with a laser wavelength of 1064nm, laser scanning processing is performed on the surface of the silicone rubber sample; the pulse width of the laser is 10ns, the single pulse energy is 0.07mJ, and the repetition frequency is 571kHz. The laser scanning uses a galvanometer system, Make the laser beam irradiate the surface of the silicone rubber sample row by row at a speed of 4000mm / s, and the processing range of the sample is 100mm x 100mm. The galvanometer system is composed of a high-speed rotating X-Y optical scanning head, an electronic drive amplifier, an optical mirror and a field mirror. The scanning speed, scanning range and scanning path of the galvanometer system are controlled and set by a computer controller.

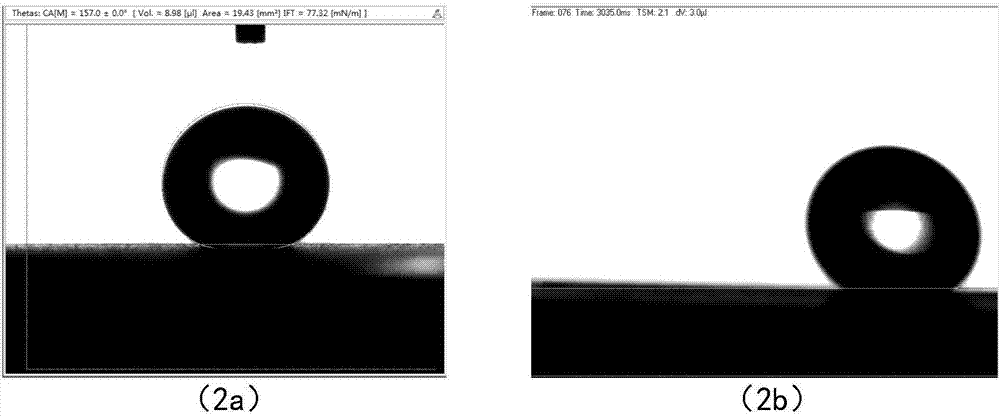

[0039] The contact angle and rolling angle of the obtained silicone rubber superhydrophobic self-cleaning surface were tested by the same test method as the above-mentioned embodiment case 1.

[0040] The superh...

Embodiment example 3

[0044] Experimental steps: using a pulsed laser with a wavelength of 1064nm, the surface of the silicone rubber sample is scanned by laser; the pulse width of the laser is 15ps, the energy of a single pulse is 0.0085mJ, and the repetition frequency is 1MHz. The laser scan uses a galvanometer system, Make the laser beam irradiate the surface of the silicone rubber sample row by row at a speed of 1500mm / s, and the processing range of the sample is 70mm x 70mm. The galvanometer system is composed of a high-speed rotating X-Y optical scanning head, an electronic drive amplifier, an optical mirror and a field mirror. The scanning speed, scanning range and scanning path of the galvanometer system are controlled and set by a computer controller.

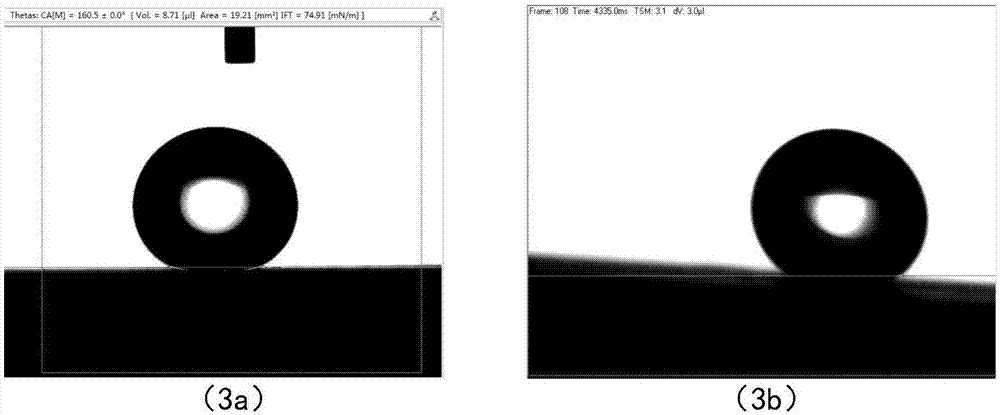

[0045] The contact angle and rolling angle of the obtained silicone rubber superhydrophobic self-cleaning surface were tested by the same test method as the above-mentioned embodiment case 1.

[0046] The superhydrophobic self-cleaning surf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com