Welding wire, preparation method thereof and method for reinforcing hot-working die material surface by using welding wire

A technology of hot work die and welding wire, applied in welding/cutting medium/material, welding equipment, manufacturing tools, etc., can solve the problems of decarburization and softening of carbon alloyed steel, insufficient performance, etc., to improve the microstructure and properties, high temperature mechanical properties Good, improve the effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

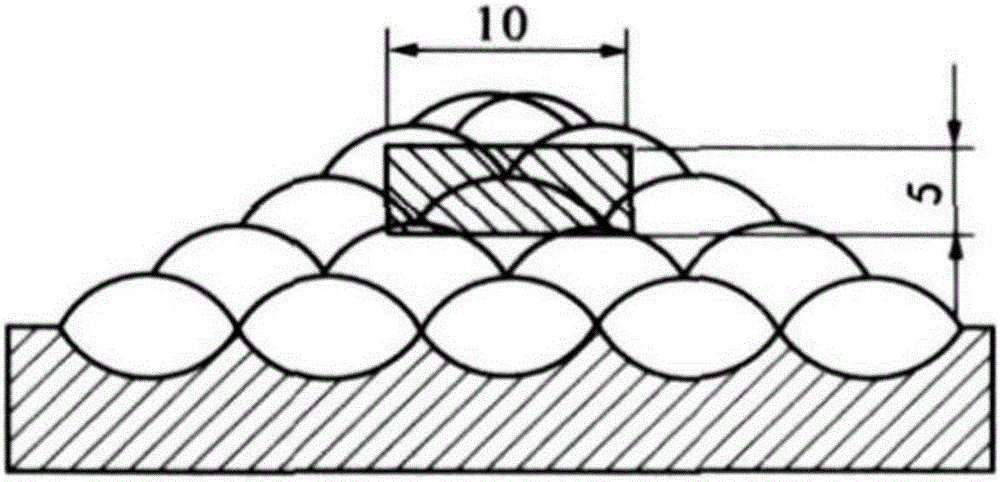

Image

Examples

Embodiment 1

[0035] The welding wire in this embodiment satisfies: the welding wire includes iron element accounting for 85.2%-89% of the welding wire mass, and includes chromium element accounting for 5.71%-6.98% of the welding wire mass, 0.86%-1.52% carbon element, 1.16% ~1.63% manganese, 0.56%~0.84% vanadium, 0.55%~1.0% niobium, 1.39%~1.63% molybdenum, 0.5%~1.1% silicon and 0.08%~0.1% nitrogen element.

[0036] The alloy powder used in this embodiment consists of 46wt% high-carbon ferrochromium, 6.5wt% electrolytic manganese, 4wt% ferrosilicon, 13.5wt% molybdenum iron, 4.5wt% chromium nitride, which account for the total mass of the alloy powder. Composition of iron powder; the above ratio is based on the composition of commonly used hot work die steel H13 steel, optimized and obtained by adding nitrides. In the specific preparation process of alloy powder, the powders of various components are firstly weighed according to the above ratio, and then these powders are sieved (the mesh ...

Embodiment 2

[0043] Similar to Example 1, the welding wire suitable for strengthening the surface of the hot work mold material can also adopt the following proportions: the welding wire includes chromium element accounting for 5.95% of the welding wire mass, 1.11% carbon element, and 1.2% manganese element, 0.6% vanadium element, 0.6% niobium element, 1.50% molybdenum element, 0.6% silicon element and 0.08%-0.1% nitrogen element, and the balance is iron element.

Embodiment 3

[0045] Similar to Example 1, the welding wire suitable for strengthening the surface of the hot-working mold material can also adopt the following proportions: the welding wire includes 5.71% of chromium, 1.4% of carbon, and 1.2% of manganese that account for the weight of the welding wire element, 0.8% vanadium element, 0.6% niobium element, 1.5% molybdenum element, 0.8% silicon element and 0.08% nitrogen element, and the balance is iron element.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com