Non-homogeneous concrete composite automatic heat insulation building block

A composite thermal insulation and non-homogeneous technology, applied in the direction of building materials, etc., can solve the problems of wall cracking, difficulty in automatic production, flammability, etc., and achieve the effect of low comprehensive cost, good thermal insulation effect, and dry shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

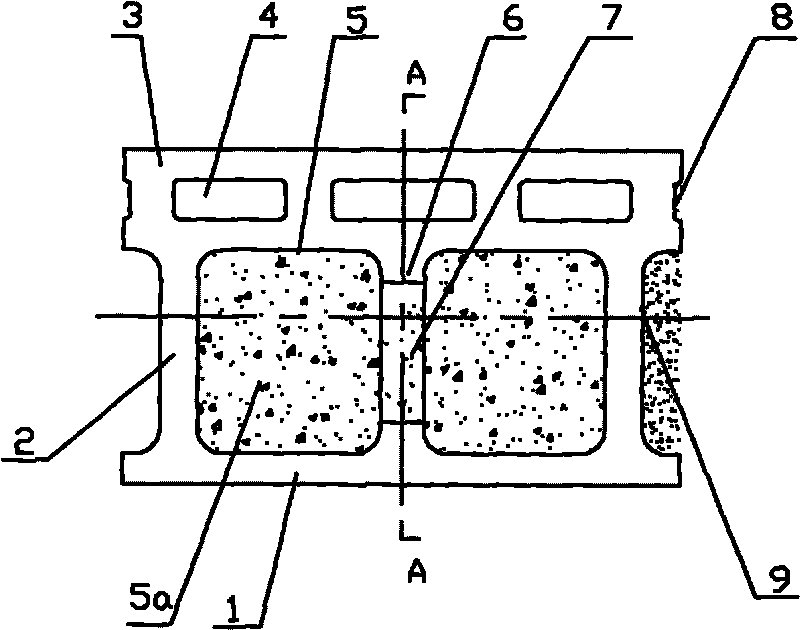

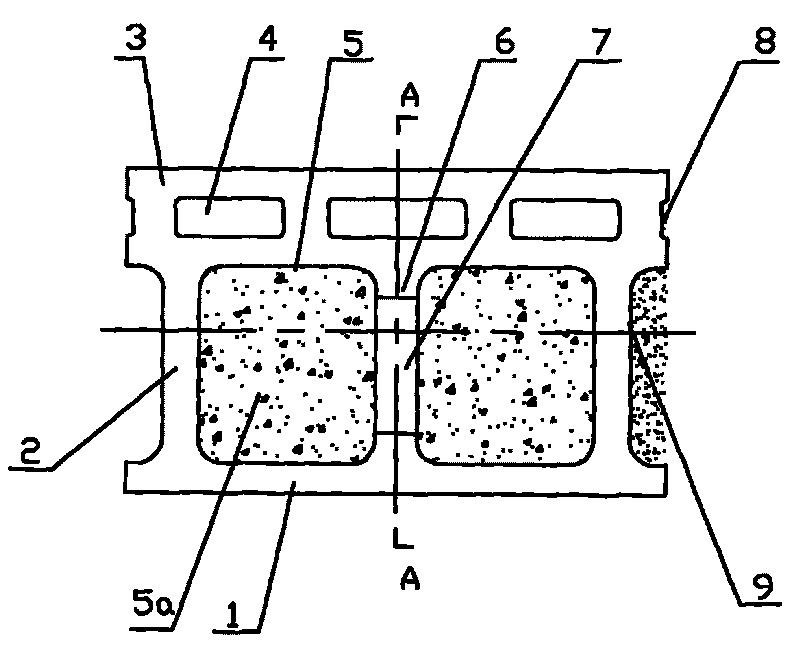

[0017] Such as figure 1 , figure 2 As shown, the non-homogeneous concrete composite thermal insulation block provided by the present invention includes a rectangular block body made of ordinary concrete through molding equipment. The middle part of the block body is provided with at least two larger rectangular heat-retaining chambers 5, which occupy most of the cross-section of the rectangular block body.

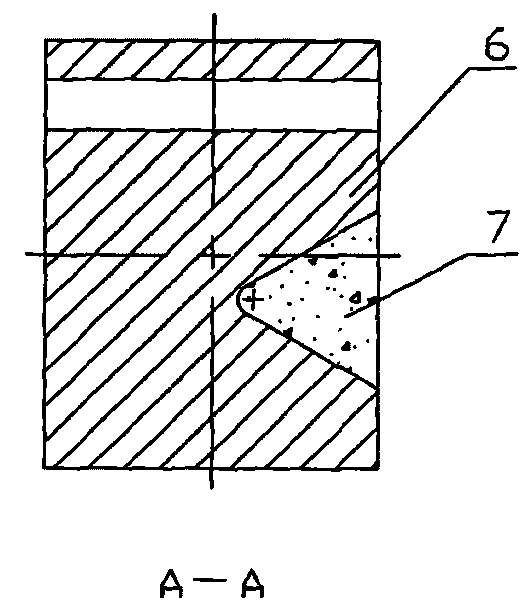

[0018] The ribs 6 formed between the two thermal insulation cavities 5 are provided with leveling grooves 7 for leveling the thermal insulation filler, so that the plastic slurry can be automatically leveled between adjacent cavities when pouring the plastic slurry. In the two thermal insulation cavities 5 and in the leveling groove 7, there are thermal insulation fillers 5a poured, and the thermal insulation fillers can be foamed concrete.

[0019] In addition, on the connecting ends on the left and right sides of the rectangular block body, that is, on the side of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com