Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

152 results about "Thermal engineering" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thermal Engineering is a specialized sub-discipline of mechanical engineering that deals with the movement of heat energy and transfer. The energy can be transformed between two mediums or transferred into other forms of energy. A thermal engineer will have knowledge of thermodynamics and the process to convert generated energy from thermal sources into chemical, mechanical, or electrical energy. Many process plants use a wide variety of machines that utilize components that use heat transfer in some way. Many plants use heat exchangers in their operations. A thermal engineer must allow the proper amount of energy to be transferred for correct use. Too much and the components could fail, too little and the system will not function at all. Thermal engineers must have an understanding of economics and the components that they will be servicing or interacting with. Some components that a thermal engineer could work with include heat exchangers, heat sinks, bi-metals strips, radiators and many more. Some systems that require a thermal engineer include; Boilers, heat pumps, water pumps, engines, and more.

Combined Energy Conversion

InactiveUS20080115817A1Solar heating energySolar heat collector controllersThermal energyThermal engineering

Means to use and combine methods of thermal engineering, plasmonics, photonics, electronics, photovoltaics, optical transfer, heat transport, light transport, catalysis and chemical reactions individually or in any combination for the enhancement or generation of solar, optical, electrical or any form of energy. The present disclosure further concerns a means to use at least a form of electromagnetic excitation or light-matter interactions in a structure or material having one or more addressable frequencies to generate the exchange of thermal, kinetic, electronic or photonic energy.

Owner:DEFRIES ANTHONY

Method or means to use or combine plasmonic, thermal, photovoltaic or optical engineering

InactiveUS20080236652A1Increase generationSolar heating energySolar heat devicesThermal engineeringChemical reaction

Means to use and combine methods of thermal engineering, plasmonics, photonics, electronics, photovoltaics, optical transfer, heat transport, light transport, catalysis and chemical reactions individually or in any combination for the enhancement or generation of solar, optical, electrical or any form of energy. The present disclosure further concerns a means to use at least a form of electromagnetic excitation or light-matter interactions in a structure or material having one or more addressable frequencies to generate the exchange of thermal, kinetic, electronic or photonic energy. The present disclosure further concerns a means to use at least a form of electromagnetic excitation or light-matter interaction, including solar or laser energy to generate localized conditions that enable initiation and spatial and temporal control of catalysis, chemical reactions, deposition, growth, synthesis, photocatalysis, photosynthesis, chemical catalysis, photochemical catalysis, photovoltaic, electrocatalysis and catalytic processes.

Owner:DEFRIES ANTHONY +1

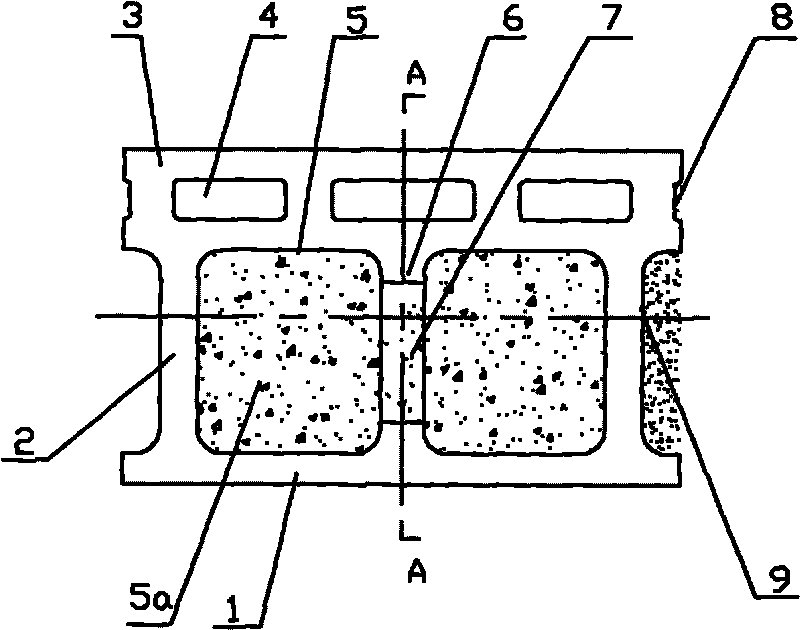

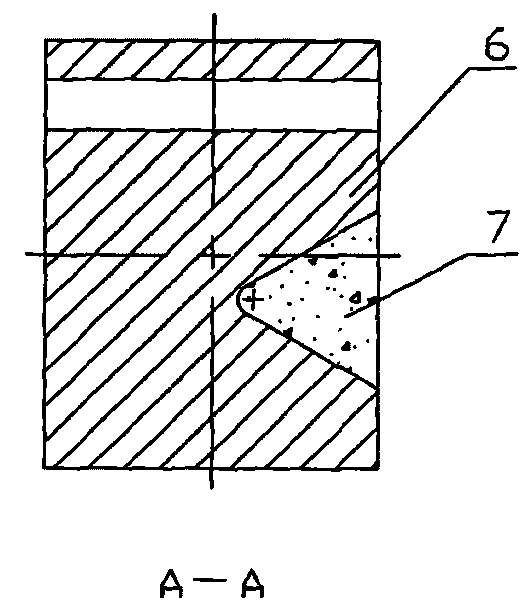

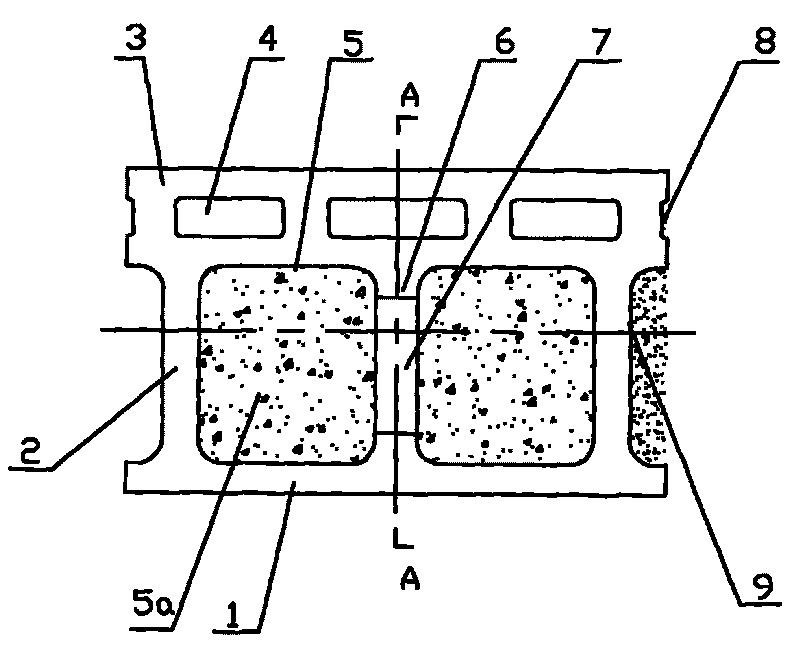

Non-homogeneous concrete composite automatic heat insulation building block

InactiveCN101694117AImprove insulation effectHigh void rateConstruction materialThermal engineeringBrick

The invention relates to a composite heat insulation building block which comprises a rectangular building block body, and is characterized in that one side of the rectangular building block body is provided with a group of parallel thermal insulation water-proof chamber (4); the middle part of the rectangular building block is provided with at least one heat insulation chamber (5) which is internally provided with heat insulation fillers (5a); the middle part of the rectangular building block is provided with two parallel heat insulation chambers (5); a leveling groove (7) used for leveling the heat insulation fillers are arranged on a rib plate (6) formed between the heat insulation chambers (5); and the connecting ends at two sides of the rectangular building block are respectively provided with an opening slit building groove (9) and an opening slit building groove (8). The composite heat insulation building block has the advantages of high void content (more than 60%), good heat insulation effect and high strength, and the produced composite heat insulation building brick has light weight, high strength, low water absorption rate, small air shrinkage rate, and good thermal engineering performance, and can meet the design requirement that building energy conservation rate can reach 65%.

Owner:金波

Refractory far infrared radiation ceramics coating

The invention provides a high temperature resistance infrared radiation pottery dope, which belongs to the thermal engineering field. The dope is a mixture of the following materials in mass share: 200 mesh zirconium dioxide 10, 200 mesh zircon quartz sand 20, 300 mesh feldspar 10, 300 mesh cerium oxide 7, 300 mesh manganese sesquioxide 15, 300 mesh manganic oxide 3, 600 mesh titanium dioxide 2, 200 mesh alumina 10, 400 mesh graphite 10, 400 mesh boron nitride 3 and 200 mesh carborundum 10. The graphite and boron nitride in the dope are of lubricating and anti-bonding functions, the carborundum is of wear resistance function, the manganic oxide, titanium dioxide and alumina are of strong infrared ray emission and the dope mad of zirconium dioxide, zircon quartz, feldspar and cerium oxide has good compact structure and strong fire-proof and the manganese sesquioxide can catalyze C, S and N for conversion. Therefore, the invention is applicable for use in dynamic furnaces such as coal dust furnace, boiling furnace and fluidized bed furnace.

Owner:颐珑达绝热材料技术(北京)有限公司

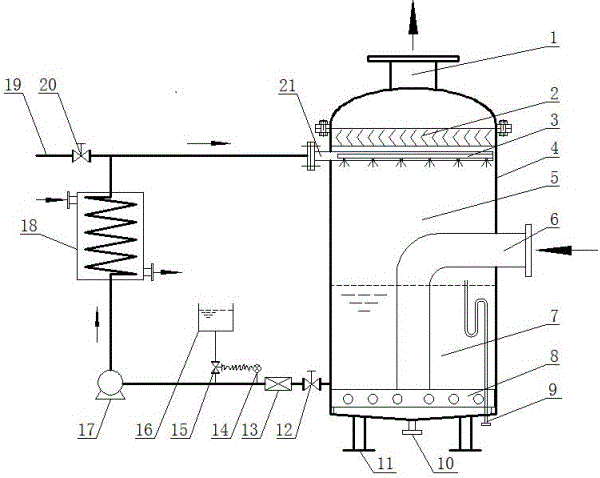

Heat supplying device for smoke purification and waste heat recovery

InactiveCN104791823AEvenly distributedReduce resistanceCombustion technology mitigationWater heatersThermal engineeringWaste heat recovery unit

The invention discloses a heat supplying device for smoke purification and waste heat recovery. The heat supplying device comprises a direct contact type waste heat recovery device and a circulating water system and is characterized in that the direct contact type waste heat recovery device comprises a bubbler, a smoke inlet pipe, an overflow pipe, a cylinder, a bubbling section, a spraying section, a sprayer, a water inlet pipe, a demister and a smoke exhaust pipe. The high temperature smoke enters cooling water in the bubble form through the bubbler and carries out direct contact type heat and mass transfer in the bubbling section; smoke discharged from the cooling water enters the spraying section and is in direct contact with the cooling water sprayed out of the sprayer again to transfer heat and mass; the cooling water absorbing heat enters the circulating water system, and a heat medium is heated through a heat exchanger in the circulating water system so as to supply heat outwards; the purified and cooled smoke is exhausted from a chimney at the upper portion of the cylinder. Two-section type direct contact of the smoke and the cooling water is adopted in the heat supplying device to transfer heat and mass, so that the smoke is fully cooled and completely purified, and the heat supplying device is suitable for smoke purification and waste heat recovery of all gas thermal engineering equipment.

Owner:ZHENGZHOU UNIV

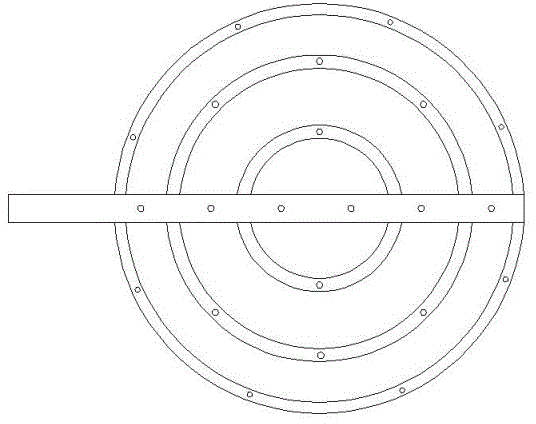

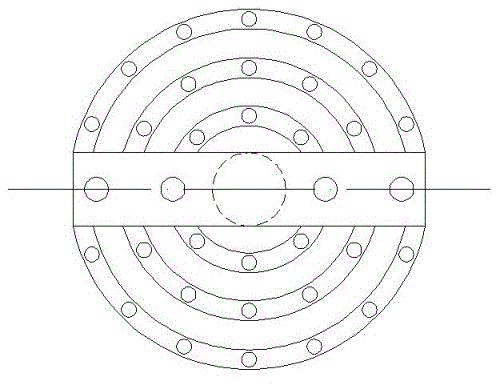

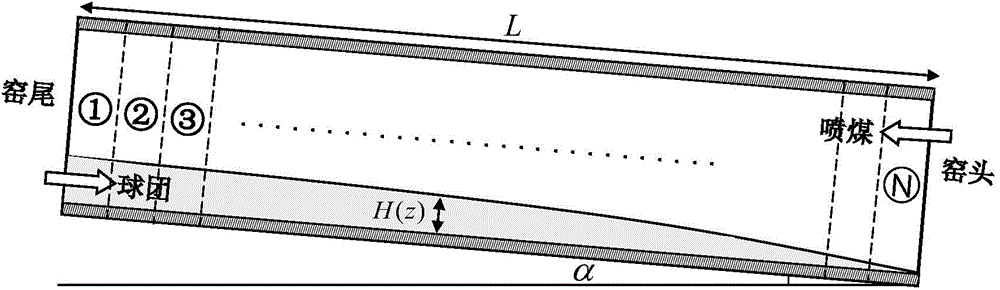

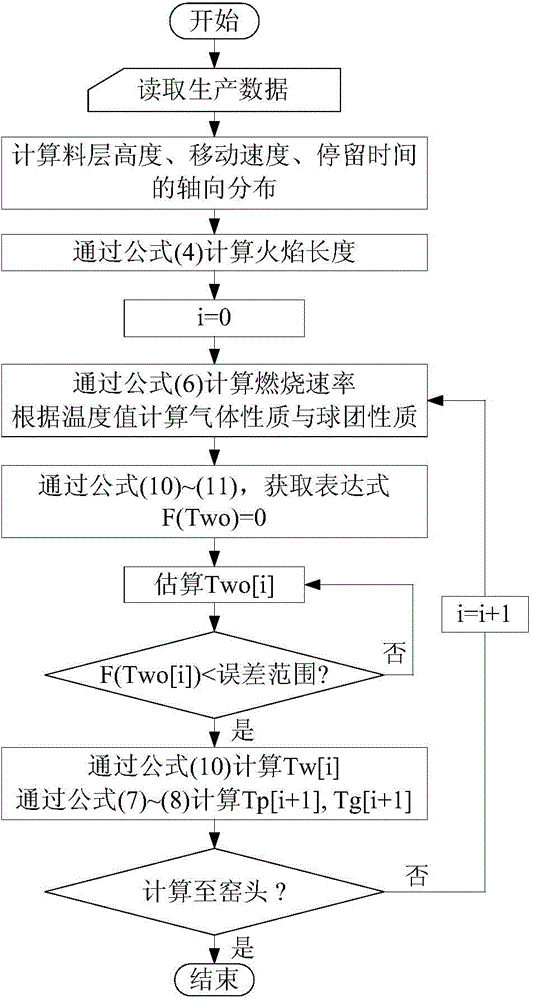

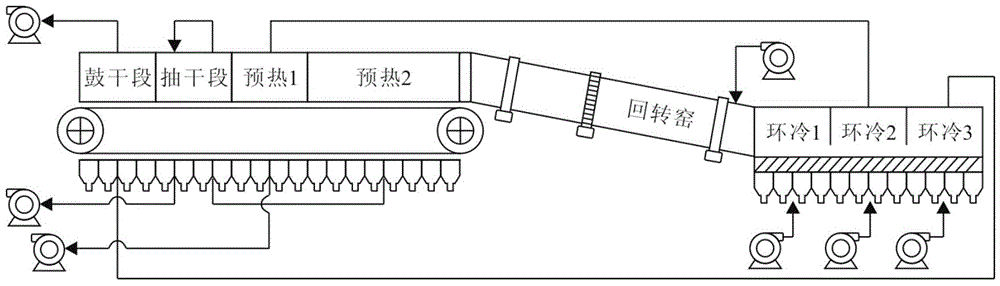

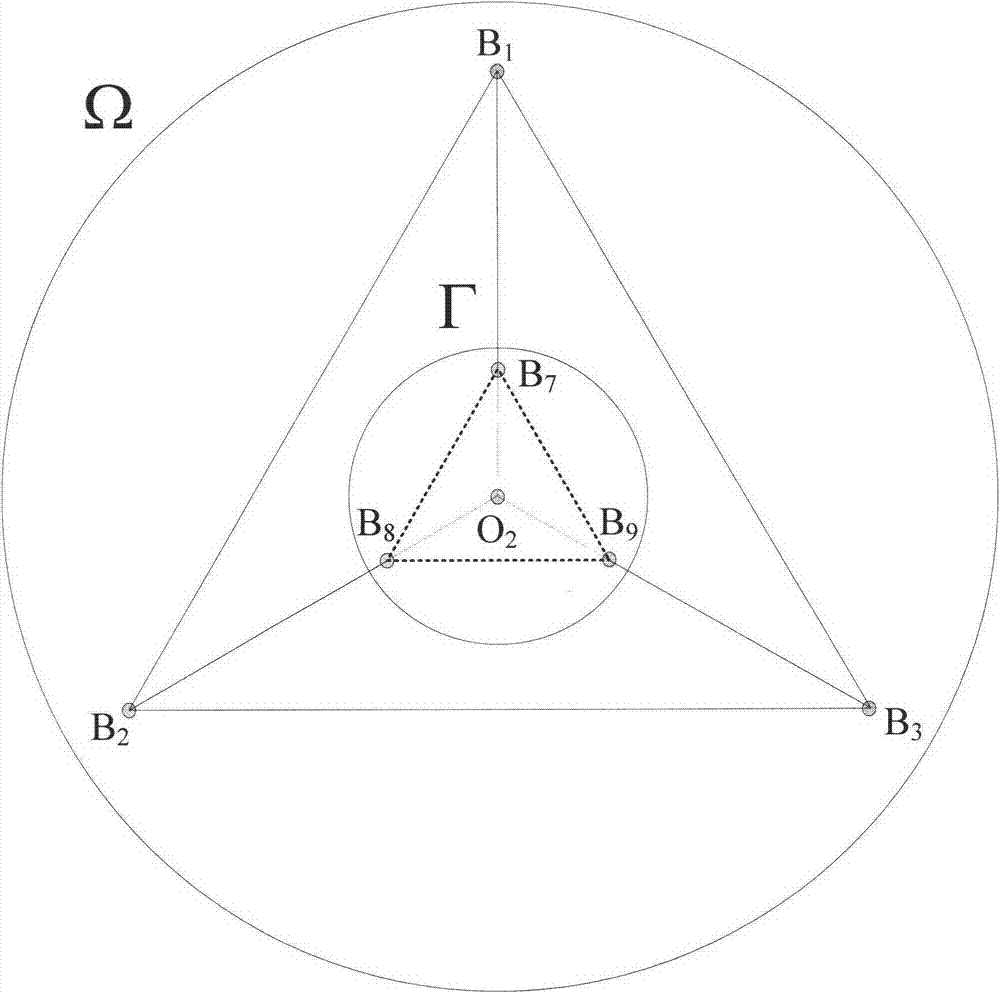

Pellet production method based on prediction of compressive strength of pellets in rotary kiln

ActiveCN104480300AHigh compressive strengthReduce porositySpecial data processing applicationsThermal engineeringHysteresis

The invention discloses a pellet production method based on prediction of compressive strength of pellets in a rotary kiln. The method comprises the following steps: 1) collecting related operation parameters of the rotary kiln; 2) establishing a motion model of the pellets in the rotary kiln; 3) measuring and calculating average residence time T of the pellets in the rotary kiln; 4) measuring flame length FL and the distribution of burning rate Rfuel of fuel in the flame length; 5) measuring the distribution of temperature of the pellets Tp along the kiln length direction z in the rotary kiln; 6) measuring a predicted value of the strength of the pellets; and 7) performing online control on process parameters of the rotary kiln according to the predicted value Qp of the compressive strength of the pellets. By using the method for online prediction of the thermal engineering state and the strength of the pellets in the rotary kiln, the transparency of the production process is increased, the control difficulty caused by information hysteresis is reduced, the risks of low finished product rate, accretion of the rotary kiln and the like caused by insufficient strength of the pellets can be reduced, and the thermal engineering operation of the rotary kiln is optimized in an online manner; and the energy consumption can be reduced and the production benefits can be improved.

Owner:CENT SOUTH UNIV

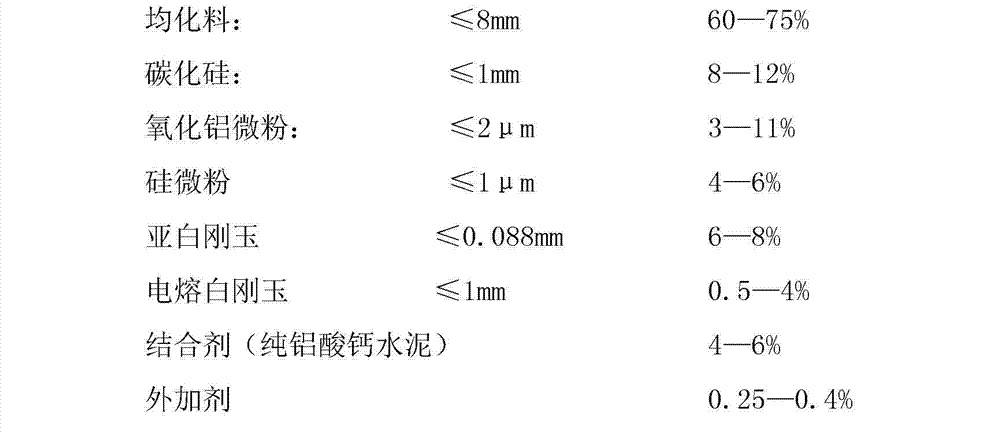

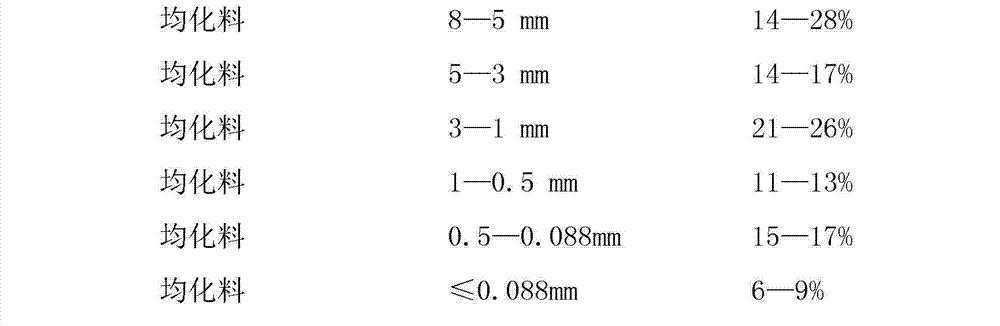

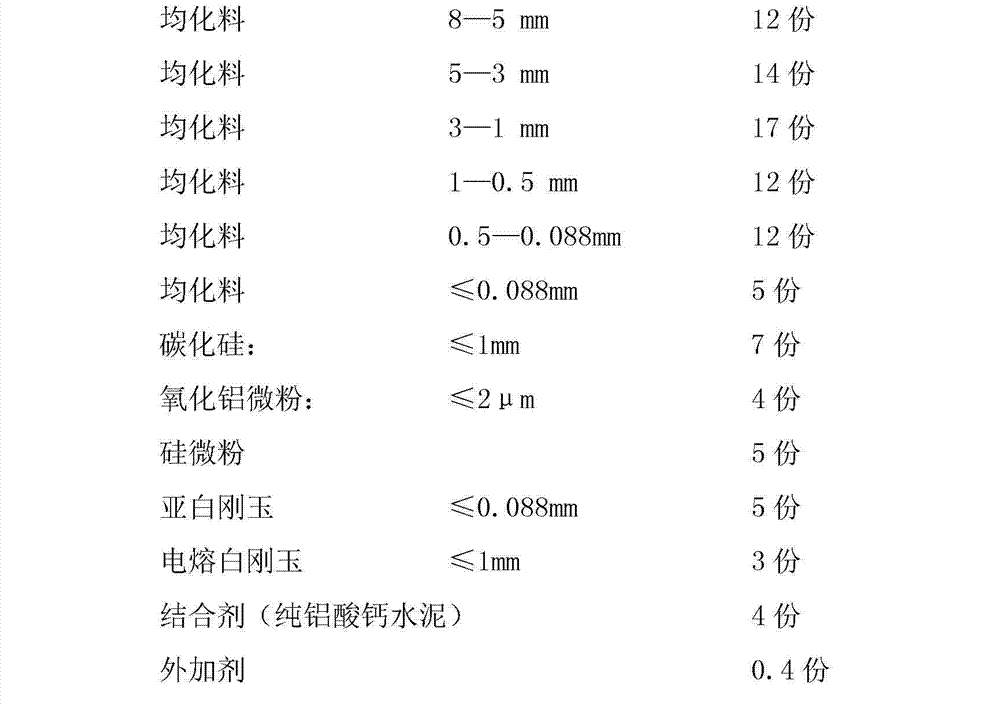

High-strength anti-stripping castable with homogeneous material as aggregate for kilneye and preparation method thereof

ActiveCN102850063AImprove thermal shock resistanceHigh mechanical strengthThermal engineeringMullite

A high-strength anti-stripping castable with a homogeneous material as an aggregate for kilneye and a preparation method thereof belong to high-temperature refractory material in the technical field of building materials. The castable comprises the following components, by weight: 60-75% of a homogeneous material, 8-12% of silicon carbide, 3-11% of an alumina micro powder, 4-6% of a silicon micro powder, 6-8% of sub-white corundum, 0-4% of white fused corundum, 4-6% of a binder pure calcium aluminate cement, and 0.25-0.4% of an admixture. The invention utilizes the characteristics of the homogeneous material that it can well form into a mullite phase at high temperature, and reduce enrichment of calcium and iron compounds. The high-strength anti-stripping castable for kilneye is prepared by using the homogeneous material as the aggregate, adding the alumina micro powder, the silicon carbide particles and micro powder, and using silicon micro powder and corundum micro powder as the matrix, pure aluminate cement as the binder, and interacted water and admixture as the additive. After casting, the pouring material provided by the present invention has excellent mechanical properties, thermal shock number up to 40 times, and excellent resistance to spalling of cement kilneye under complex thermal engineering, and is suitable for dry cement kilneye and positions with same thermal conditions.

Owner:TONGDA REFRACTORY TECH CO LTD

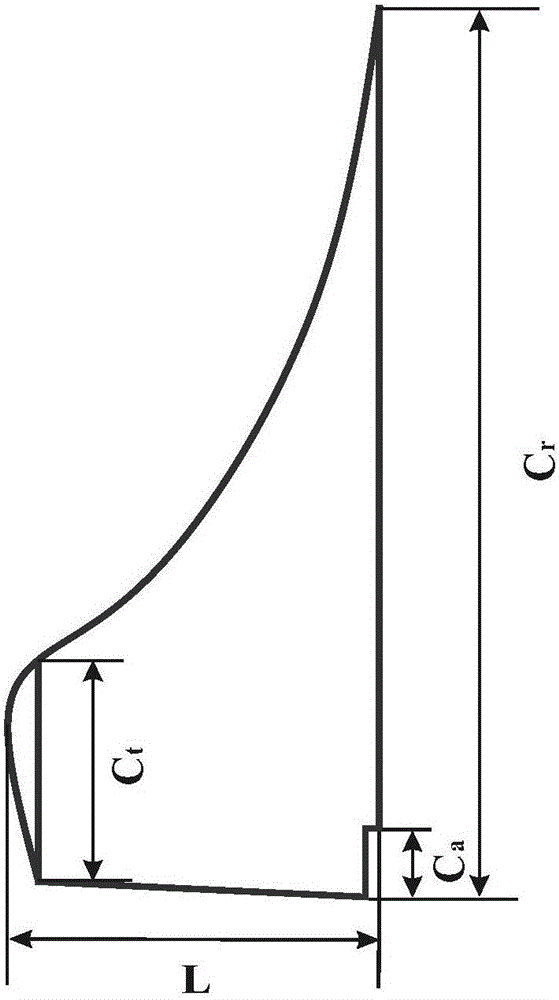

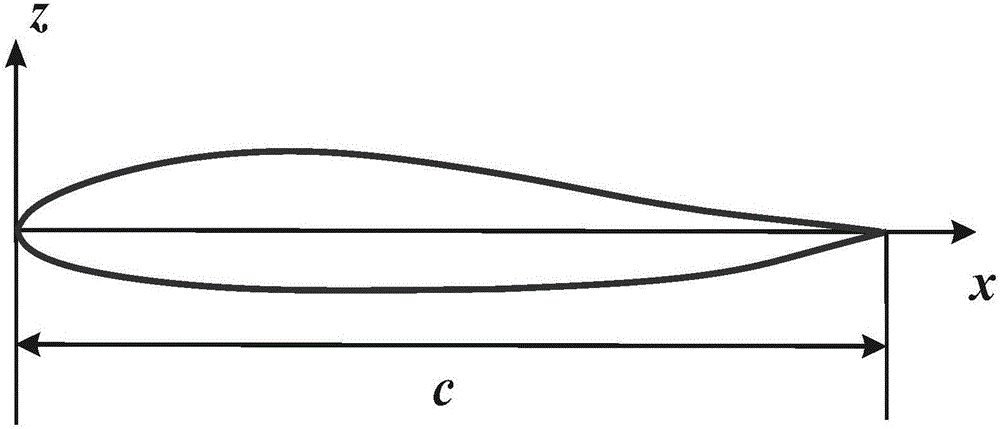

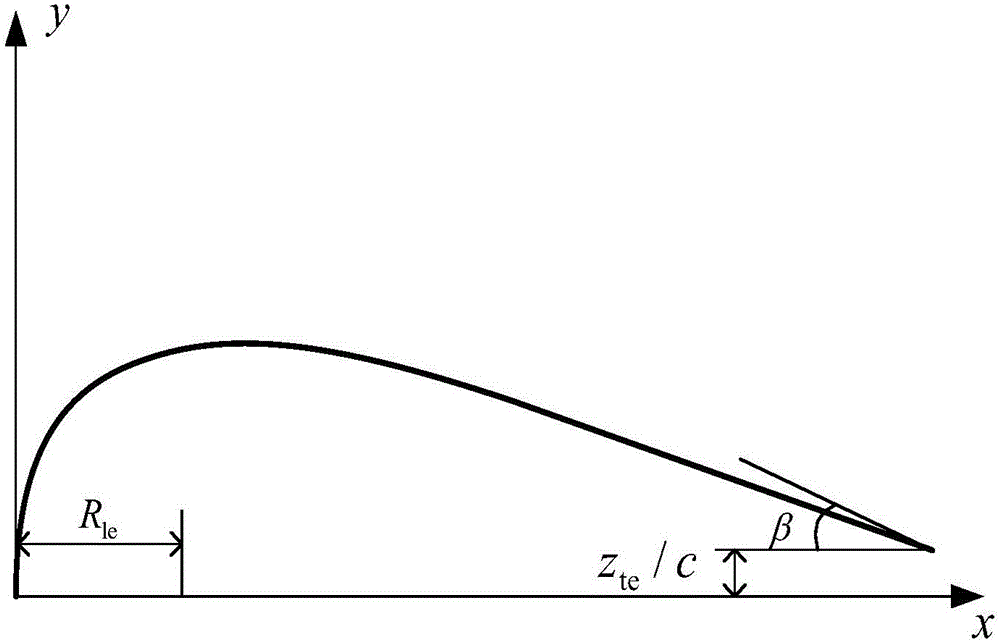

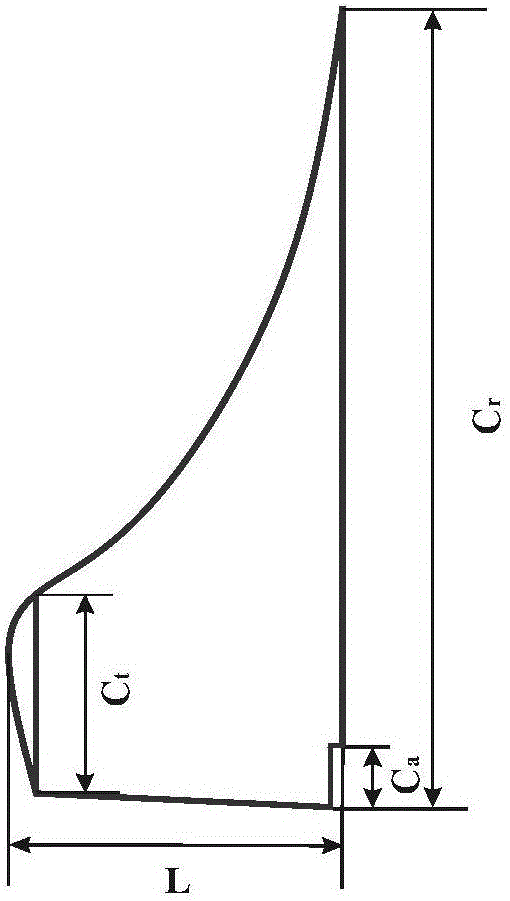

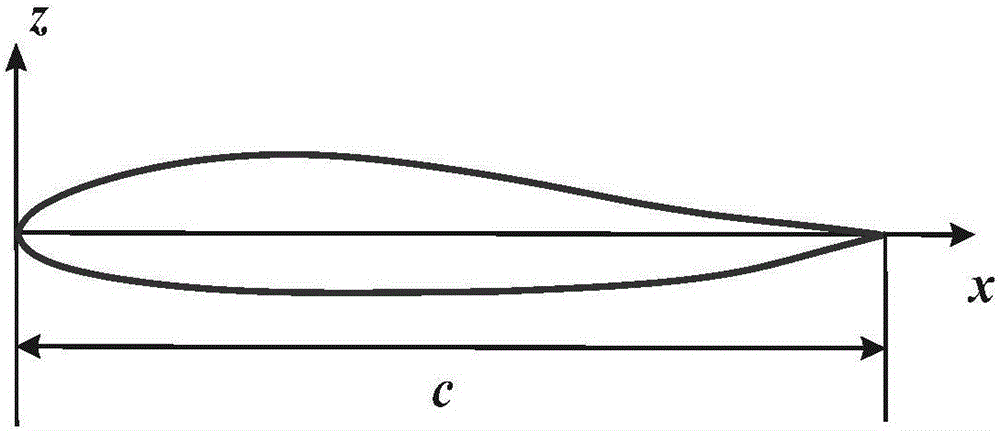

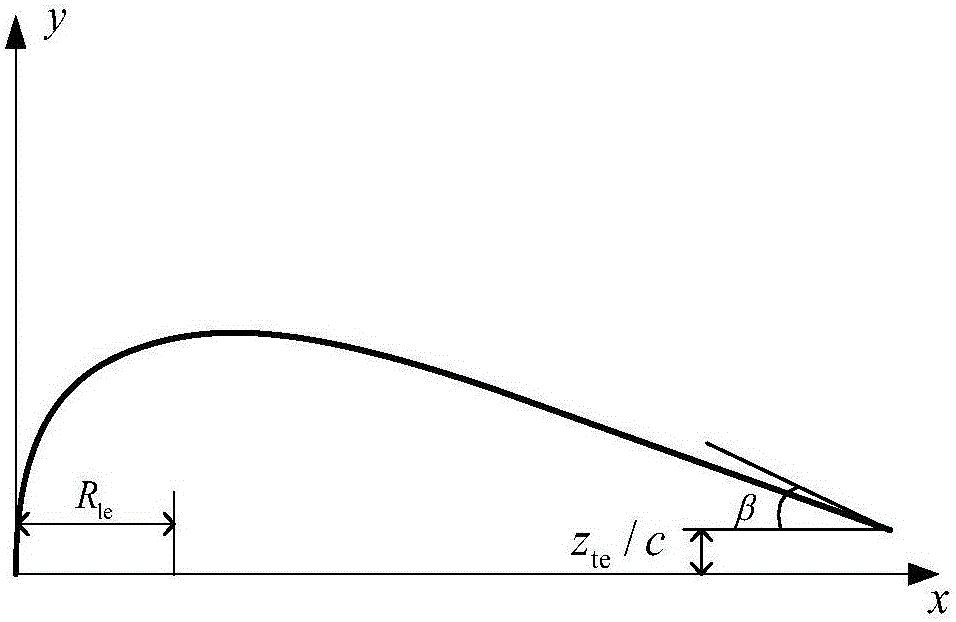

Hypersonic velocity wing robust optimization design method considering machining errors

ActiveCN106126860AEnsure safetyReduce sensitivityGeometric CADSustainable transportationThermal engineeringStagnation point

The invention discloses a hypersonic velocity wing robust optimization design method considering machining errors and belongs to the technical field of optimization design. The method comprises the following steps: fully considering geometric machining errors existing in hypersonic velocity wing design, and realizing quantitative characterization of a machining error coefficient by utilizing an interval vector under the condition that a probability density function of machining error parameters is unknown; establishing aerodynamic configuration of the hypersonic velocity wing through a parametrization method, and performing nonstructured surface mesh division; combining an interval parameter vertex method with an aerodynamic / thermal engineering algorithm, and calculating upper and lower bound of intervals of total stagnation point heating capacity and lift-drag ratio of the wings; and on the basis, establishing a multi-target interval robust optimization model, and performing optimization design on the wing shape by using a genetic algorithm. The numerical result shows that according to the method, the total stagnation point heating capacity of the designed wing is reduced under the precondition that lift-drag ratio constraint of the wing is maintained; meanwhile, a fluctuation range of the total stagnation point heating capacity is narrowed, and a new thought is provided for shape design of the hypersonic velocity wing.

Owner:BEIHANG UNIV

Method for hypersonic wing aerodynamic/thermal analysis in view of geometric uncertainty

ActiveCN106126791AFit closelyRealize Interval EnvelopeGeometric CADSustainable transportationThermal engineeringAlgorithm

The invention discloses a method for hypersonic wing aerodynamic / thermal analysis in view of geometric uncertainty. A sample point of uncertain parameters is established according to a Bernstein polynomial approximation model; an aerodynamic / thermal response value, corresponding to a wing shape, of the sample point is calculated by utilizing an aerodynamic / thermal engineering algorithm in a given flight condition; and a fitting coefficient of the polynomial approximation model is obtained by applying a least square method. Based on this, a maximum / minimum value point, about each uncertain parameter, of the aerodynamic / thermal response value is solved by utilizing the established polynomial approximation model; combination is performed to form a vector of a maximum / minimum point; and finally an interval upper bound and an interval lower bound of the aerodynamic / thermal response value are obtained, thereby realizing the hypersonic wing aerodynamic / thermal analysis in view of the geometric uncertainty. An interval boundary obtained in the method is well matched with that obtained in a Monte-Carlo method, and interval envelopment can be realized, so that a new idea is provided for overall design of the hypersonic wing shape.

Owner:BEIHANG UNIV

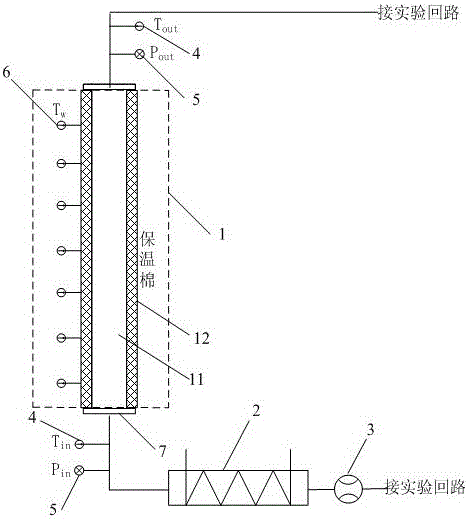

Gas-liquid two phase thermal-engineering experiment heat loss calibration method and calibration device

InactiveCN105136843AHigh precisionImprove reliabilityMaterial heat developmentThermal engineeringEngineering

The present invention discloses a gas-liquid two phase thermal-engineering experiment heat loss calibration method and calibration device, the device includes a preheater connected between an experiment section inlet and an experimental loop, a wall temperature measurement device on the experiment section outer wall and a flowmeter; the experiment section inlet and an experiment section outlet are provided with temperature measuring and pressure measuring devices, and the flowmeter is arranged between the experiment section inlet and the experimental loop, or the experiment section outlet and the experimental loop. The calibration method is as follows: first, the power of the preheater is adjusted for control of thermal-engineering experiment parameters of an introduced single-phase fluid to achieve the purpose containing two-phase formal experiment wall temperature range, a relationship formula or a relationship diagram of wall temperature experiment section and heat dissipation amount can be obtained by fitting, the wall temperature is measured in a formal two-phase thermal-engineering experiment, and the heat dissipation amount can be determined according to the relationship formula or the relationship diagram, so that experiment section heat loss amount can be determined under the conditions of gas-liquid two phase experimental conditions, and a support is provided for accurate determination of the flow working medium heat absorption amount and acquisition of reliable experimental data, and the two-phase thermal-engineering experiment accuracy and reliability can be enhanced.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

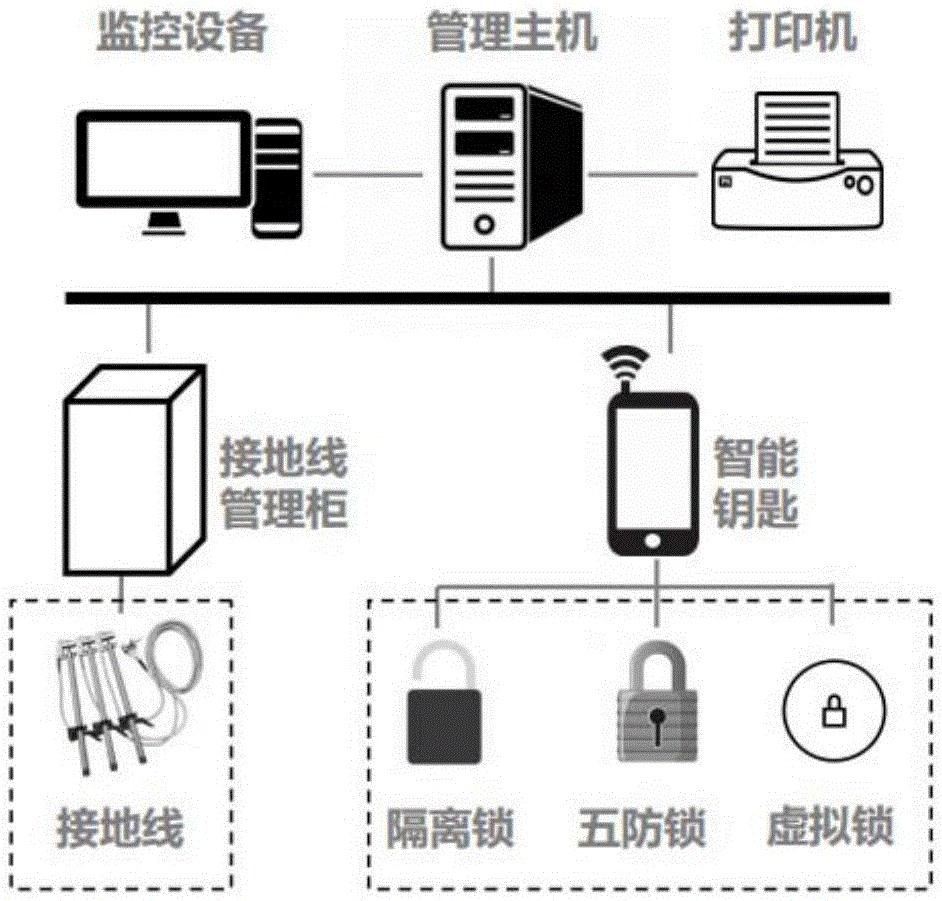

Security isolation anti-misoperation system

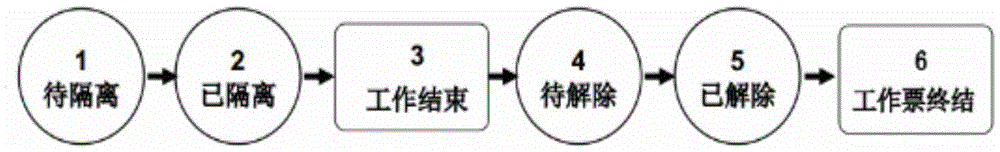

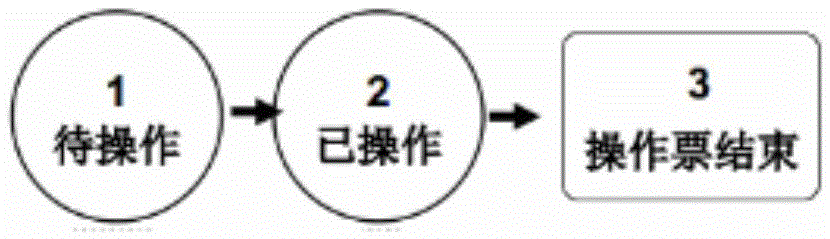

InactiveCN105550826ARealize automatic retrievalAchieving identifiabilityIndividual entry/exit registersResourcesThermal engineeringSoftware system

The invention discloses a security isolation anti-misoperation system. The anti-misoperation system comprises a hardware system and a software system; the hardware system comprises a management host, monitoring equipment, an intelligent key, a lockset, a grounding wire management cabinet and a grounding wire; the software system comprises a work ticket module, an operation ticket module, an electrical temporary grounding wire module and a thermal engineering signal compulsory single module; the management host, the intelligent key and the grounding wire management cabinet are connected with each other through a network; and the software system is operated in the management host and the intelligent key. According to the invention, the complex management link can be simplified; automatic retrieval and identification of an isolation point can be realized; the operation link can be reduced; and the security assurance of overhaul workers can be improved.

Owner:华润电力(贺州)有限公司

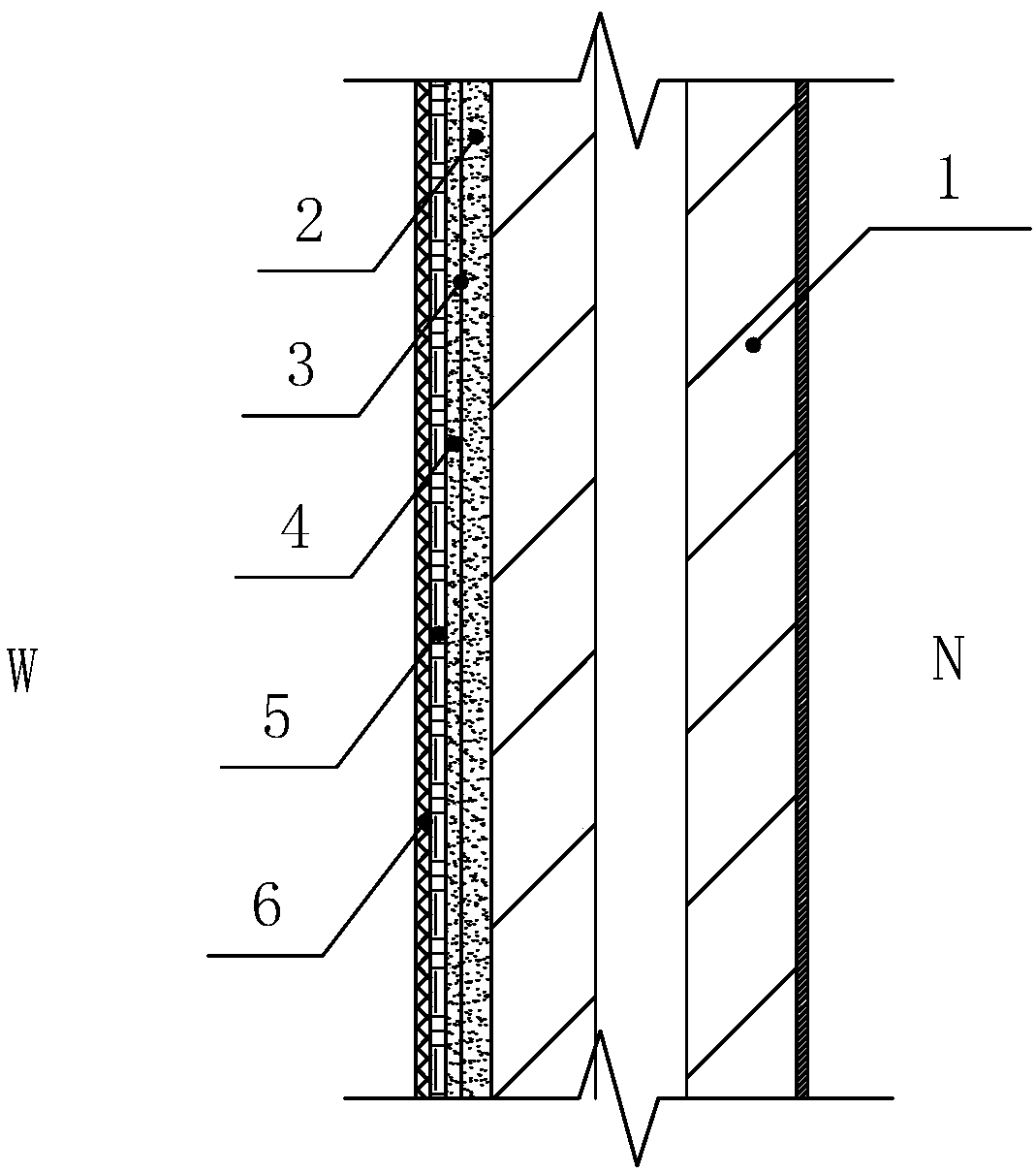

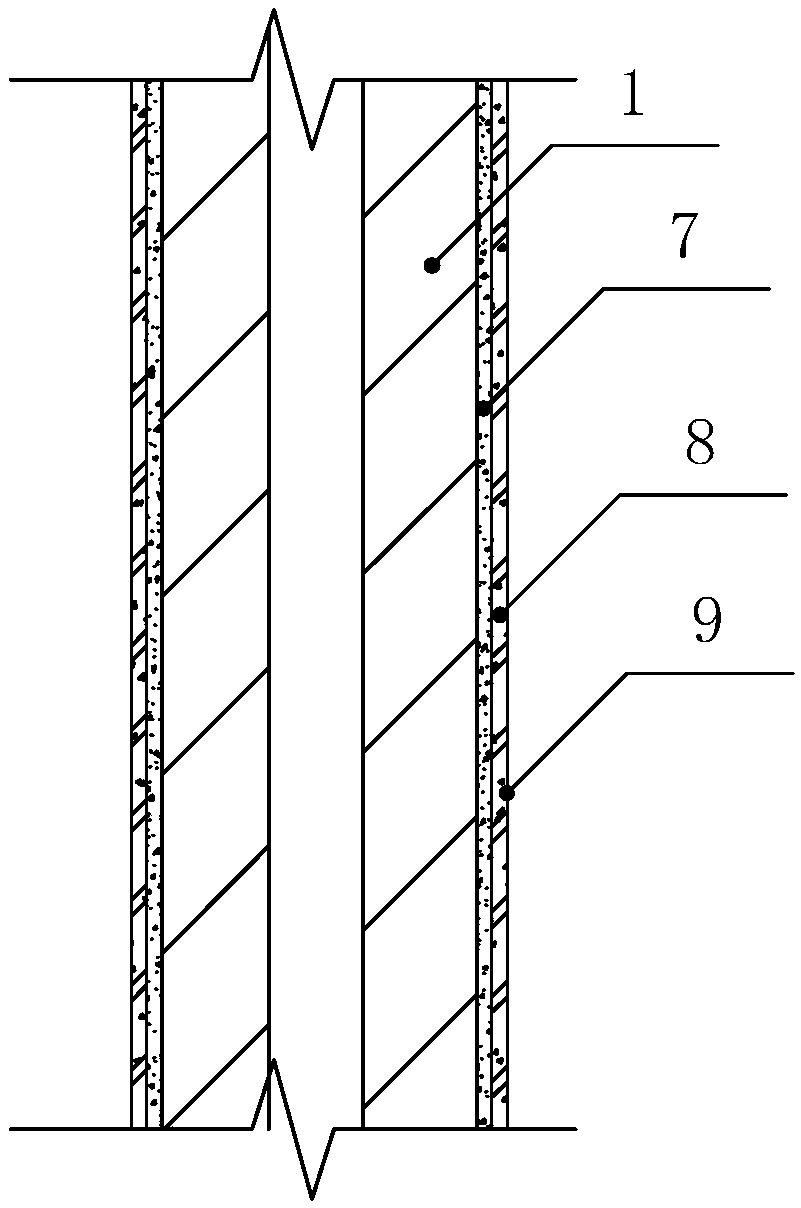

Prefabricated sandwich-type thermal-insulation wallboard, and preparing method thereof

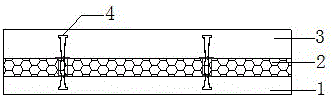

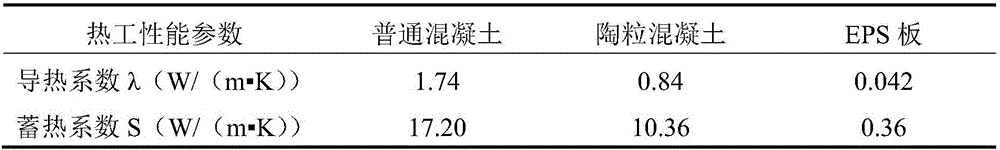

InactiveCN106168058ALight weightImprove thermal performanceCeramic shaping apparatusBuilding componentsThermal engineeringThermal insulation

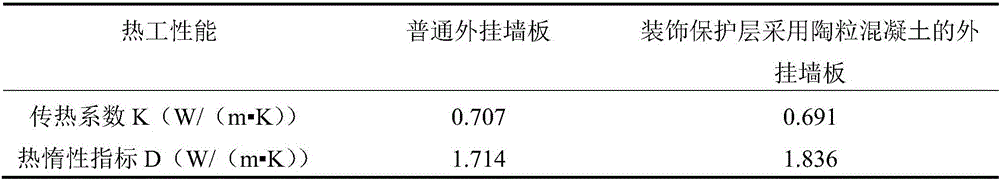

The invention discloses a prefabricated sandwich-type thermal-insulation wallboard. The prefabricated sandwich-type thermal-insulation wallboard comprises three layers including a decorative protective layer, a thermal-insulation layer, and a structure layer; the three layers are connected so as to form an integral whole via shear connectors; the structure layer is mainly used for bearing wallboard loading; the decorative protective layer is used for providing a wallboard decorative surface; and the thermal-insulation layer is used for ensuring thermal insulation performance of the prefabricated sandwich-type thermal-insulation wallboard. According to a preparation method, ceramsite concrete is used for pouring the decorative protective layer so as to reduce the self weight of the prefabricated sandwich-type thermal-insulation wallboard, and improve the thermal engineering performance of the prefabricated sandwich-type thermal-insulation wallboard; the thermal-insulation layer is prepared from EPS foam boards, and is capable of delaying transmission of heat energy among the inner and outer layers of the prefabricated sandwich-type thermal-insulation wallboard effectively as a thermal insulator in the prefabricated sandwich-type thermal-insulation wallboard; the structure layer is made from C30 concrete, and is mainly used for bearing wallboard loading. The decorative protective layer and the structure layer of conventional prefabricated external wallboard are both made from common concrete. The materials of the prefabricated sandwich-type thermal-insulation wallboard are widely available; processing and preparation are simple; performance is reliable; defects of conventional prefabricated external wallboards such as high self weight and poor thermal engineering performance are improved greatly; the prefabricated sandwich-type thermal-insulation wallboard can be taken as a prefabricated external wallboard; and application prospect is promising.

Owner:CHINA MCC17 GRP

Rough rolling temperature-measuring feedback control method

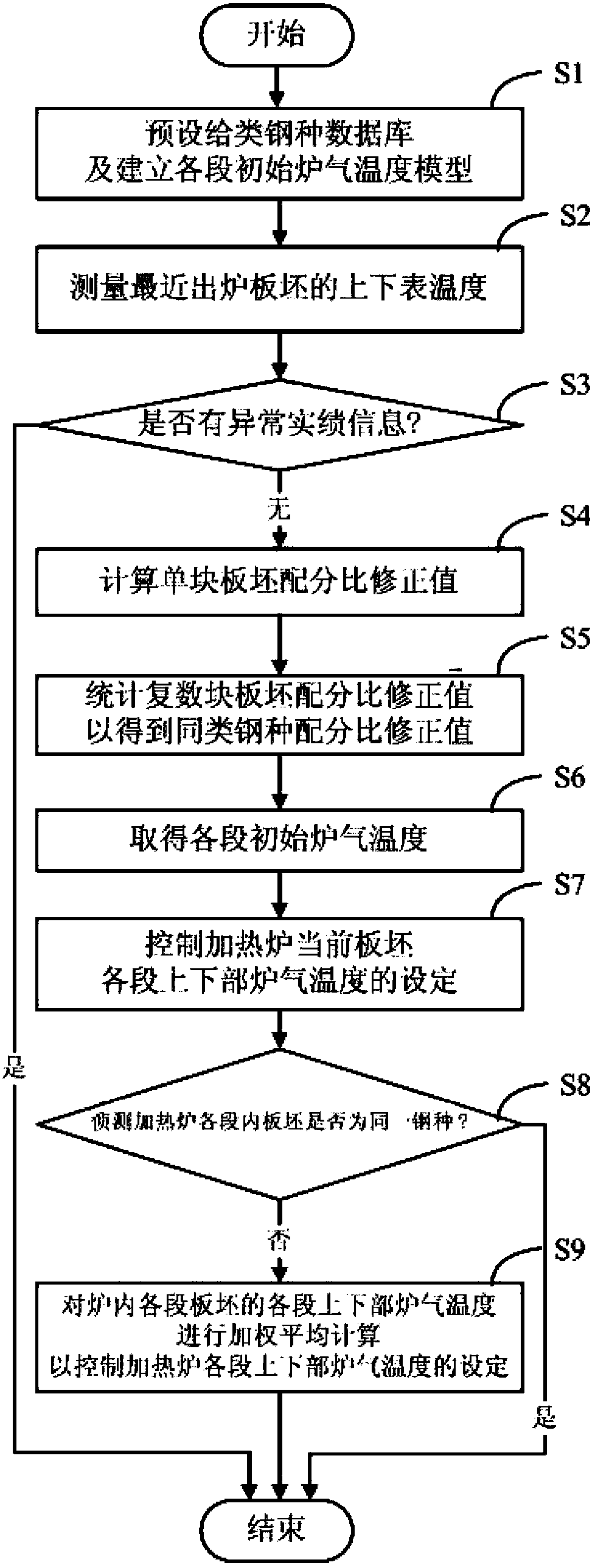

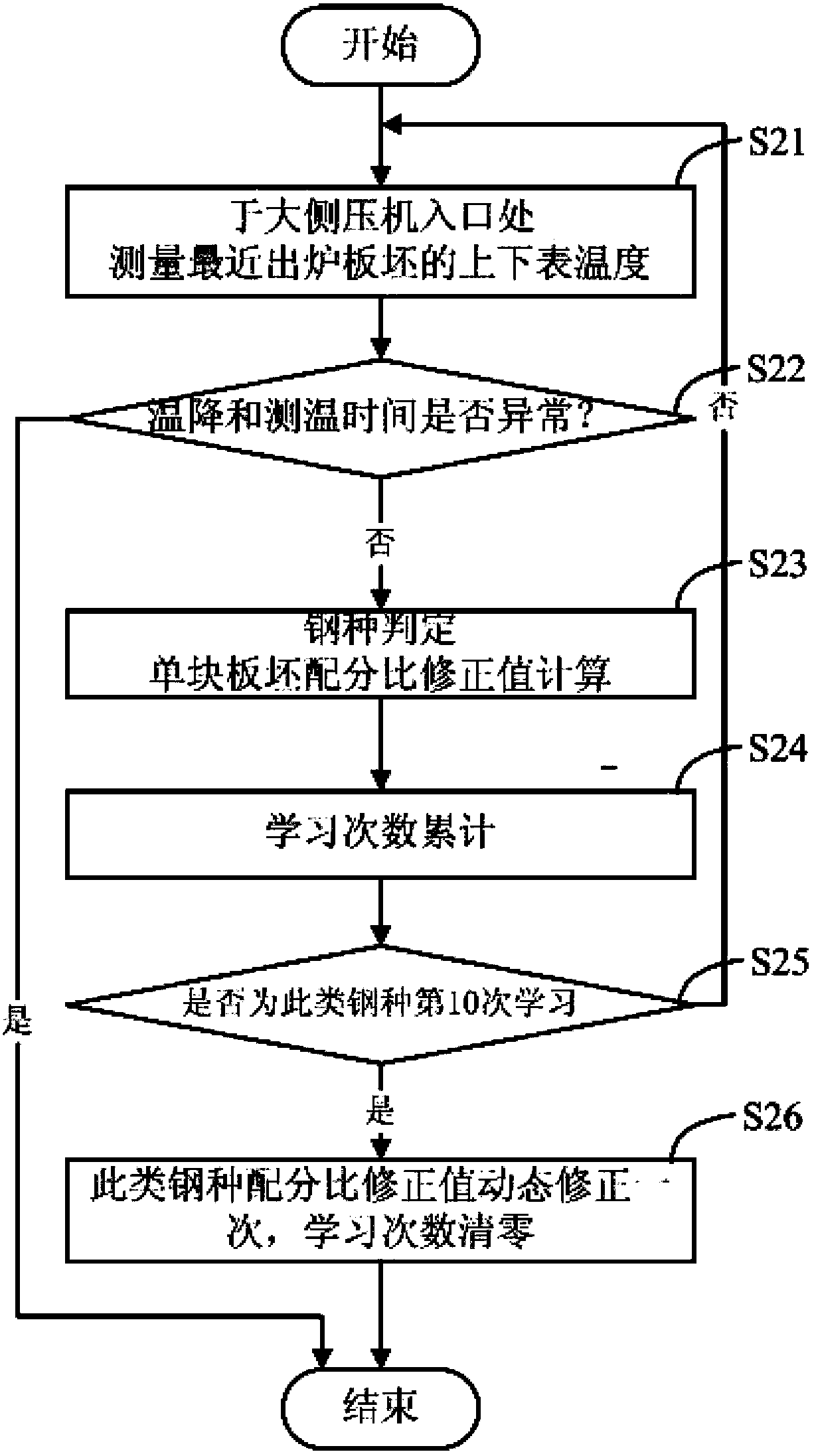

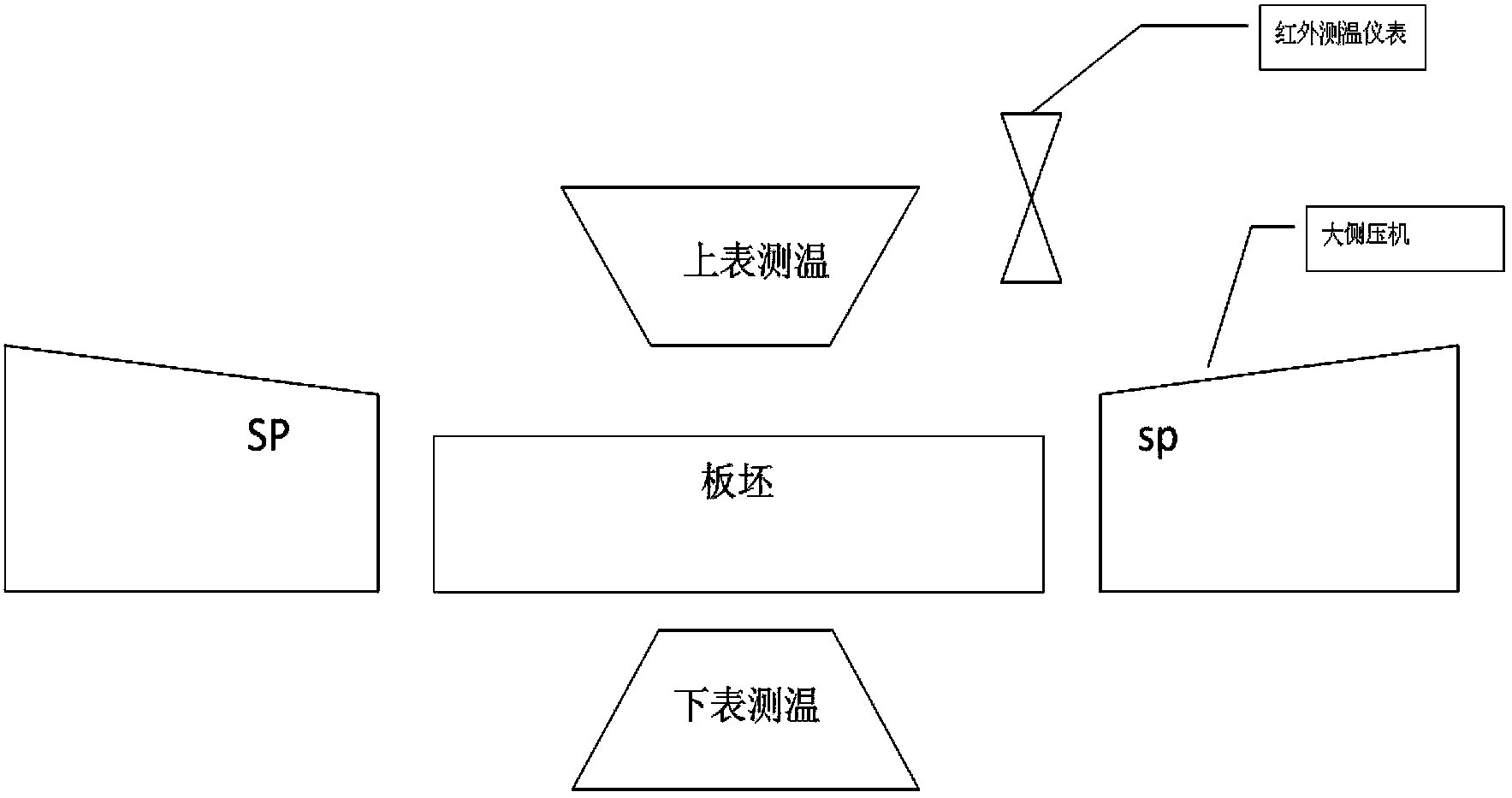

ActiveCN103447314AIncreased level of controlStable outputTemperature control deviceHeat treatment process controlThermal engineeringControl set

The invention relates to a rough rolling temperature-measuring feedback control method. The method comprises the steps of presetting a classification steel grade database and establishing an initial furnace gas temperature model of every section; measuring the upper surface temperatures and the lower surface temperatures of slabs out of a furnace recently; calculating a distribution ratio modification value of a steel grade of the same kind according to the upper surface temperatures and the lower surface temperatures which are actually measured; and controlling set values of the furnace gas temperatures of furnace gas on the upper portion and the lower portion of every section of the current slab of a heating furnace according to the distribution ratio modification value. According to the method and a system, the temperature setting upper and lower distribution ratios inside the heating furnace are dynamically amended by utilizing actual values of the upper and lower surface temperature difference of the slabs out of the furnace, and temperatures of the upper surfaces and the lower surfaces of the slabs in the heating furnace can be automatically precisely adjusted according to the actual wire rolling requirements, the control level of a rough rolling raising buckling head is remarkably improved, and the thermal engineering automatic control system simultaneously greatly reduces labor intensity of workers.

Owner:BAOSHAN IRON & STEEL CO LTD

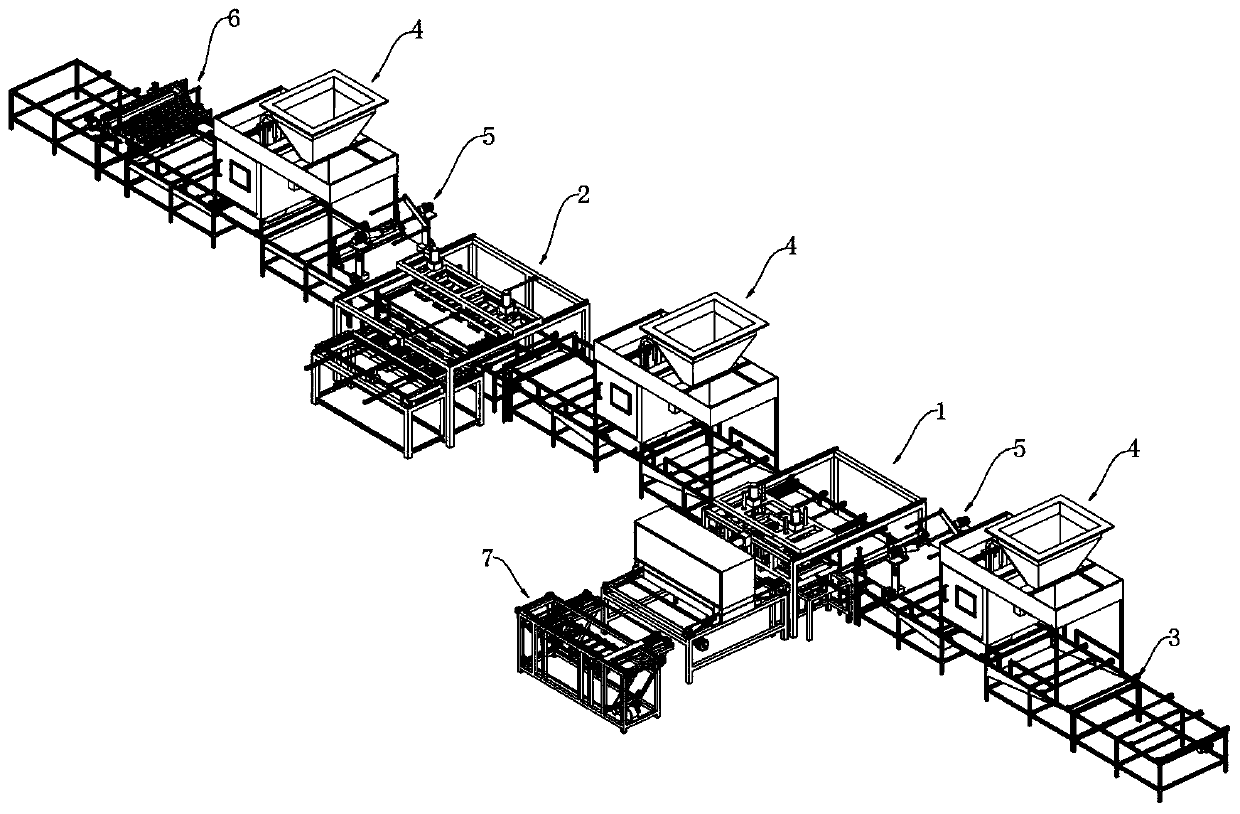

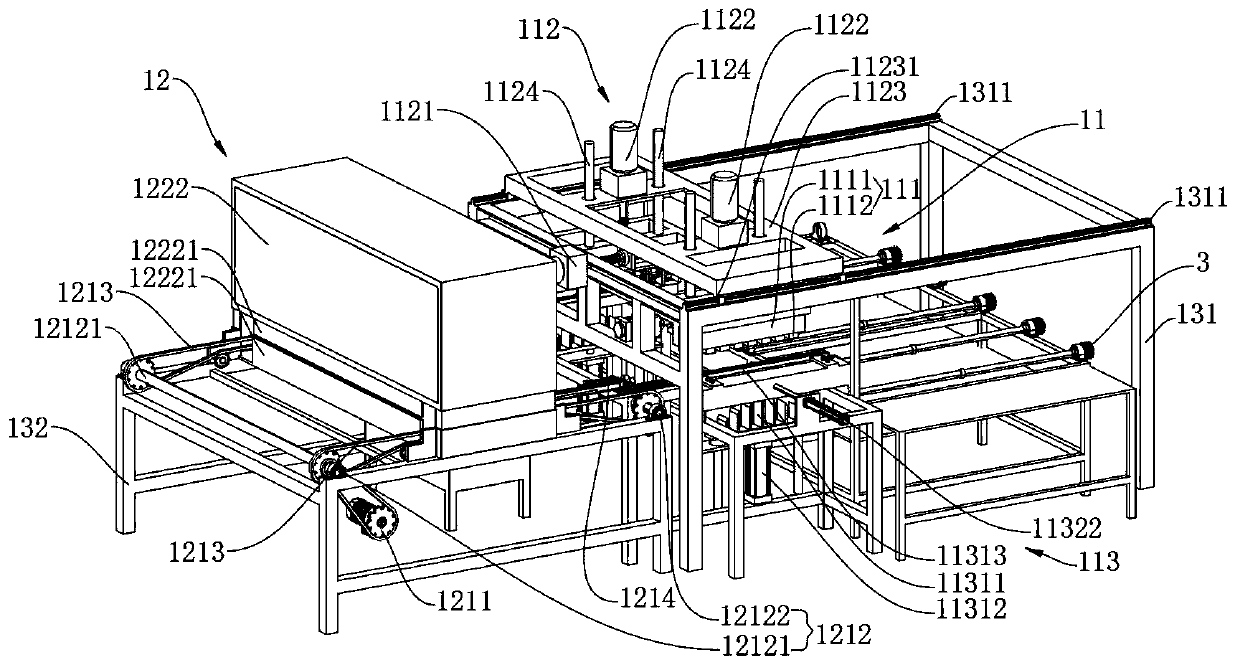

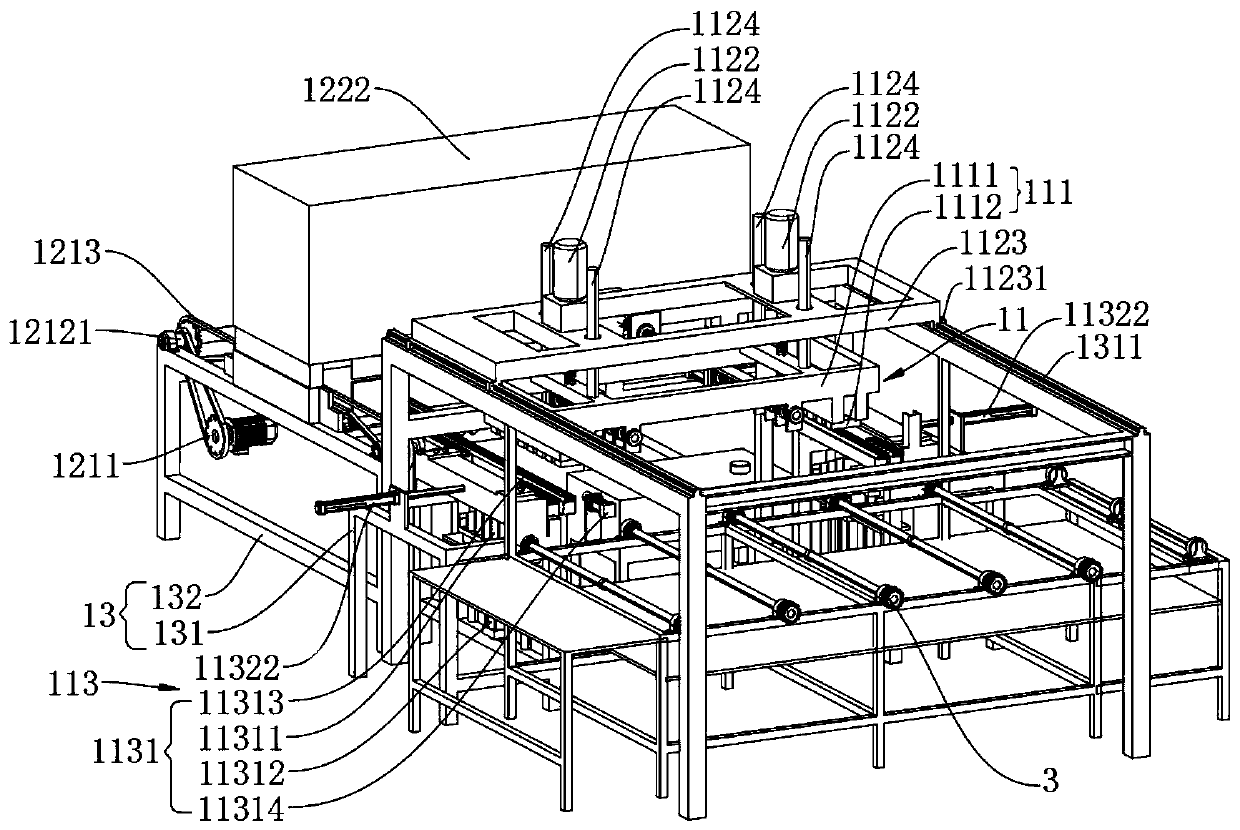

Automatic production line of partition plate

PendingCN111070400AIncrease productivityCeramic shaping plantsAuxillary shaping apparatusThermal engineeringRebar

The invention discloses an automatic production line of a partition plate. The automatic production line of the partition plate is used for forming the partition plate on a mould and comprises a hollow pipe placing device, a steel bar placing device and a conveying device, wherein the conveying device respectively conveys the mould to the hollow pipe placing device and the steel bar placing device; the hollow pipe placing device is used for placing a hollow pipe on the mould on the conveying device; and the steel bar placing device is used for placing steel bars on the mould on the conveying device. According to the automatic production line of the partition plate, the hollow pipe is placed through the hollow pipe placing device and the steel bars are placed through the steel bar placing device, so that the production machinery of the partition plate replaces thermal engineering, and the production efficiency is improved.

Owner:东莞市通顺实业有限公司

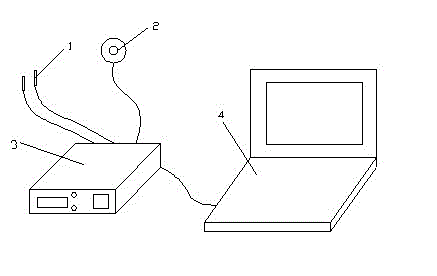

Equivalent thermal resistance detection device and detection method of thermal insulating coating

The invention discloses an equivalent thermal resistance detection device and detection method of thermal insulating coating. Thermal couplers and solar radiation sensors are both in signal connection with a detection instrument; and the detection instrument is in signal connection with a calculating terminal. The detection method comprises the following steps of: respectively adhering thermal couplers with metal sheets to the middle parts of the outer surfaces of a plurality of outer walls by using adhesive tapes; after the adhesive tapes are thoroughly dried and solidified, coating the thermal insulating coating and common paint on the outer surfaces of the outer walls respectively; enabling the outer walls to be detected to receive the sunshine radiation, and acquiring data by using the solar radiation sensors; after the solar radiation sensors constantly acquire for seven days, selecting valid data of four days and transmitting to the calculating terminal; and reckoning out the equivalent terminal resistance of the thermal insulating coating on the detected walls with the combination of calculating software. In such a mode, data can be accurately acquired to join in the calculation with the combination of an on-site thermal engineering detection method aiming at the conditions necessary for on-site detection of the thermal insulating coating, curves of output temperature are effectively analyzed, and the equivalent thermal resistance of the thermal insulating coating is reckoned.

Owner:青山绿水(江苏)检验检测有限公司 +1

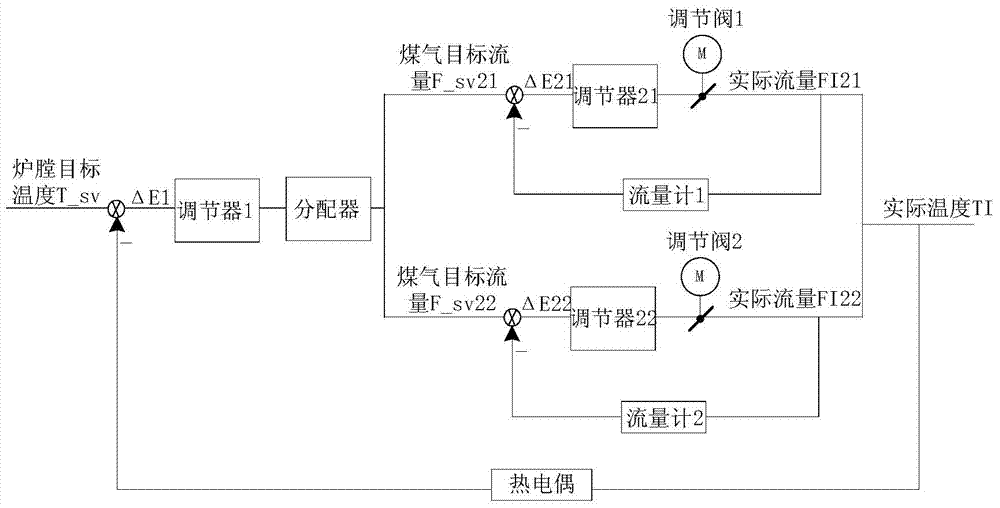

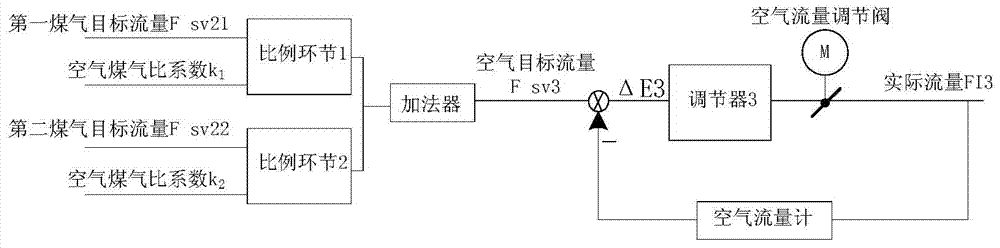

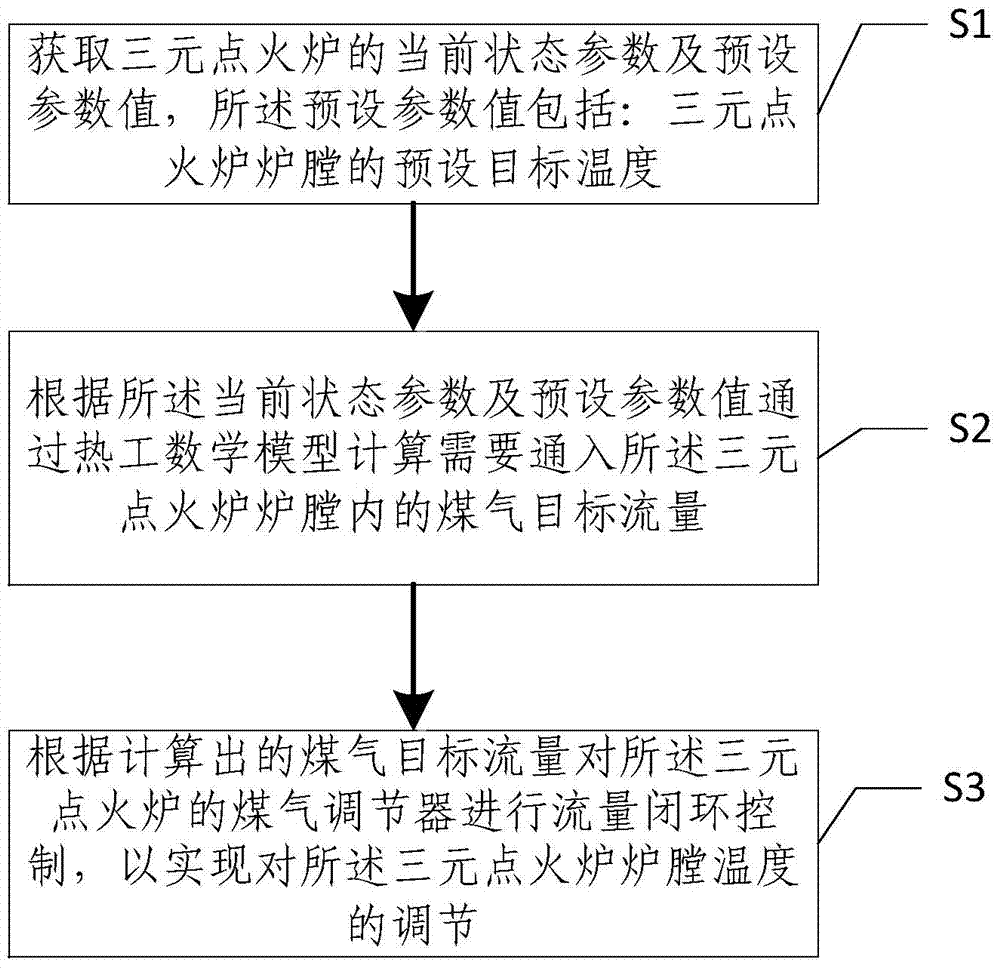

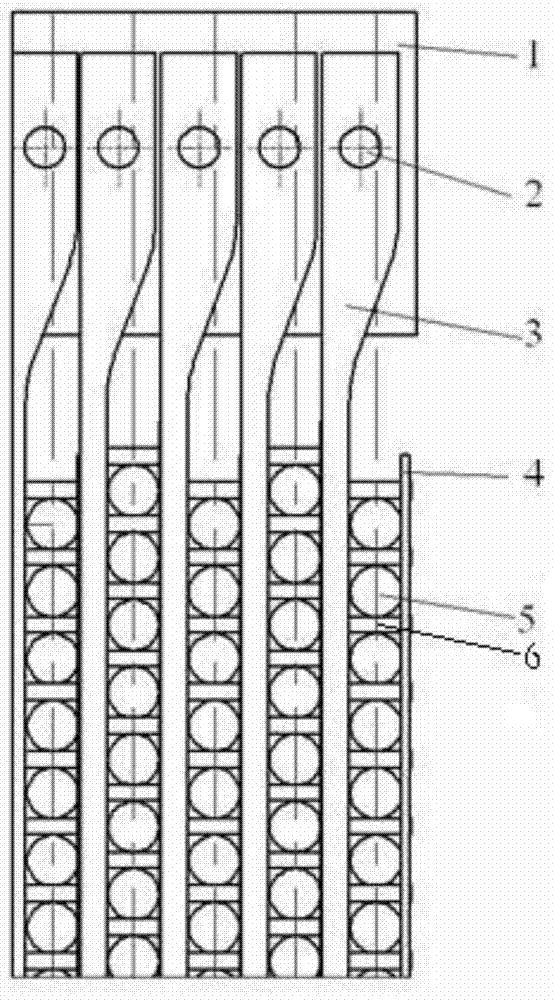

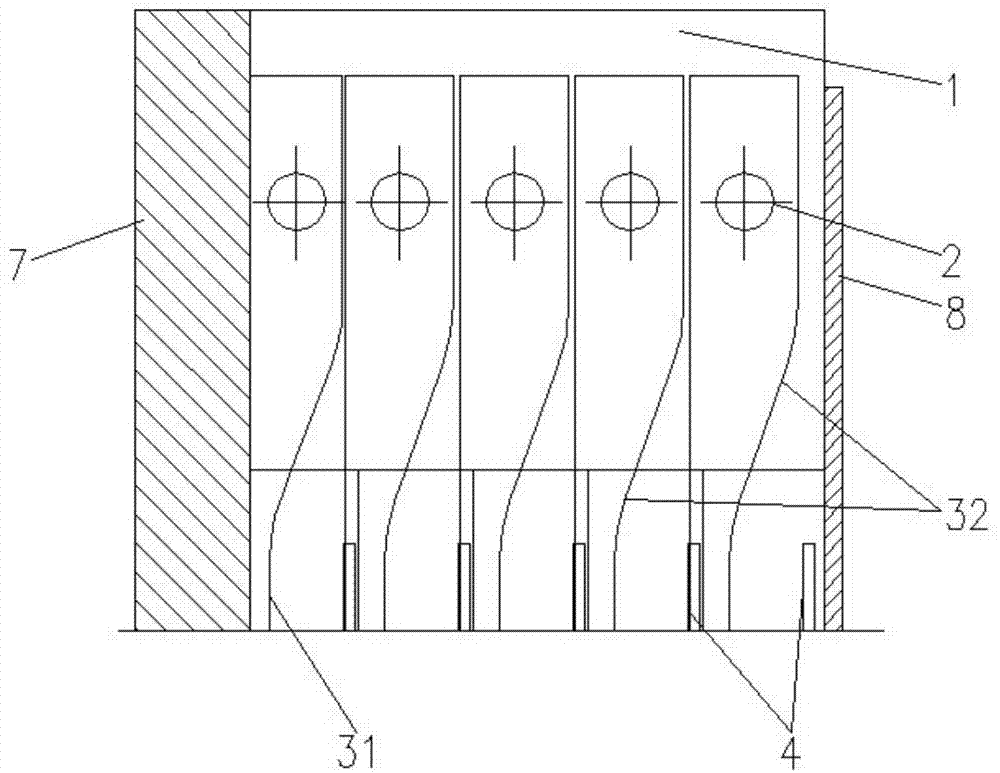

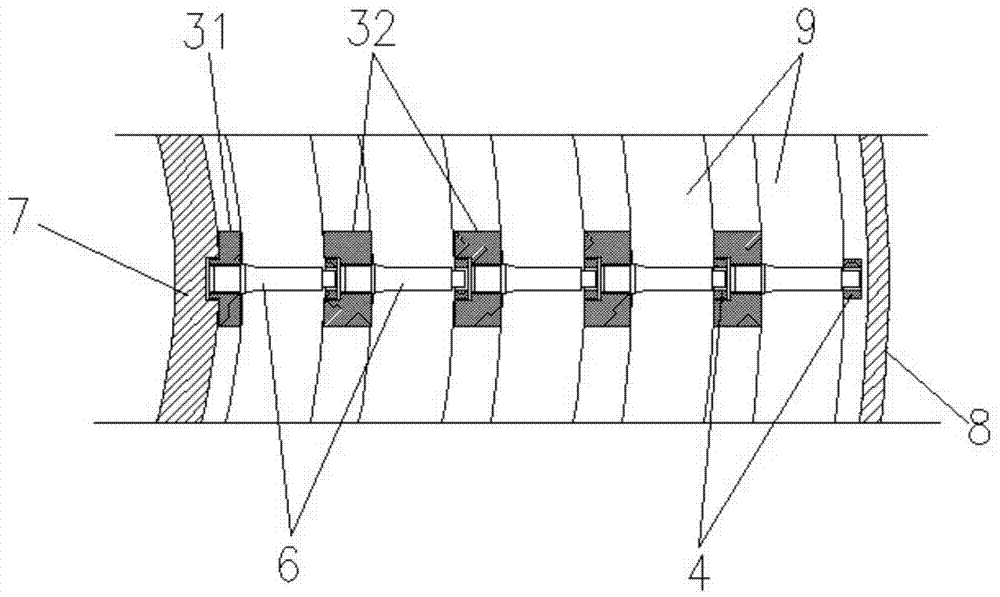

Method and device for regulating temperature of hearth of ternary ignition furnace

ActiveCN103499101AShort response timeReduce lagFuel supply regulationFurnace typesHysteresisThermal engineering

The invention discloses a method and device for regulating the temperature of a hearth of a ternary ignition furnace, and relates to the technical field of sintering and ignition. The method includes the steps of firstly, obtaining current state parameters of the ternary ignition furnace and preset parameters; secondly, calculating the target flow of coal gas which needs to enter the hearth of the ternary ignition furnace through a thermal engineering mathematical model according to the current state parameters and the preset parameters; thirdly, conducting flow closed-loop control on a coal gas regulating valve of the ternary ignition furnace according to the calculated target flow of the coal gas so that the regulation of the temperature of the hearth of the ternary ignition furnace can be achieved, wherein the preset parameters include a preset target temperature of the hearth of the ternary ignition furnace. According to the method and device, the target flow of the coal gas which needs to enter the hearth so as to enable the temperature of the hearth of the ternary ignition furnace to reach the preset target temperature is calculated through the thermal engineering mathematical model, only the closed-loop control needs to be directly conducted on the flow of the coal gas, and therefore the response time for enabling the temperature of the hearth to reach the preset target temperature is shortened, and the hysteresis is reduced.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

Clayless refractory mouldable material

InactiveCN1450025AImprove room temperature strengthImprove plasticityThermal engineeringAluminium hydroxide

The present invention relates to a clay-free plasticity refractory material, belonging to the field of refractory material. Its composition includes fire-resistant aggregate, powder material and chemical binding agent, and also contains amorphous Al2O3 fine powder, the described amorphous alumina is obtained by using industrial aluminium hydroxide through the processes of suspension heating at 600 deg.C-700 deg.C and air quenching. Said invention adopts the high-activity amorphous Al2O3 fine powder instead of raw clay to prepare plasticity refractory material, so that its plasticity is good, it is has higher normal temp. strength and excellent linear change property, its refractory aggregate and powder material can be changed for different requirements of thermal engineering equipments.

Owner:宜兴天霸非金属材料有限公司

Sleeving method for multi-layer screw-type heat exchanging tube bundles

ActiveCN104713402AAvoid scratchesAdjust the diameterHeat exchanger casingsThermal engineeringEngineering

The invention relates to the technical field for thermal engineering, and discloses a sleeving method for multi-layer screw-type heat exchanging tube bundles. The sleeving method for the multi-layer screw-type heat exchanging tube bundles comprises the following steps: first bearing strips are arranged on first layer heat exchanging tube bundles; an inner barrel is sleeved with the first layer heat exchanging tube bundles; fixing strips are arranged outside the first layer heat exchanging tube bundles; second bearing strips are arranged on second layer heat exchanging tube bundles; the first layer heat exchanging tube bundles are sleeved with the second layer heat exchanging tube bundles; the fixing strips are arranged outside the second layer heat exchanging tube bundles; other heat exchanging tube bundles are sleeved; the outer sides of outer layer heat exchanging tube bundles are sleeved with an outer barrel; the bearing strips are connected with a suspension ribbed plate arranged on the top of the inner barrel. According to the sleeving method for the multi-layer screw-type heat exchanging tube bundles, sleeving on a screw-type heat exchanging tube bundle vapor generator of flexible supporting can be smoothly achieved, the scratch on the surfaces of the tube bundles by supporting parts of the heat exchanging tube bundles can be effectively avoided, and the screw diameter accuracy of the fixed heat exchanging tube bundles is guaranteed.

Owner:TSINGHUA UNIV

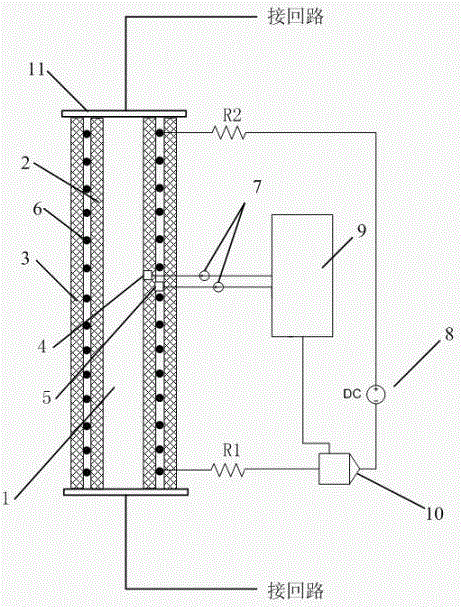

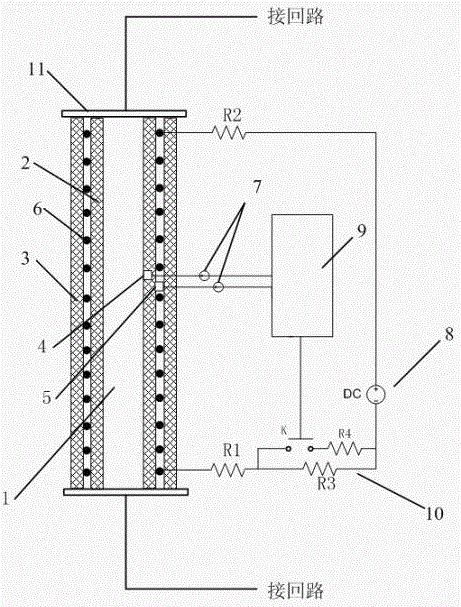

Thermal engineering experiment thermal balance environment automatic control device and control method thereof

InactiveCN106248728AAvoid getting lostAvoid differencesMaterial thermal conductivityMaterial heat developmentElectricityThermal engineering

The invention discloses an automatic control device and a control method thereof for a heat balance environment in a thermal experiment. The outer insulation layer outside the wire, the thermal compensation power supply supplying power to the thermal compensation wire, two thermocouples for collecting the temperature signal of the outer wall of the experimental pipe section and the outer wall of the inner insulation layer, and adjusting the thermal compensation according to the temperature signals collected by the two thermocouples The feedback circuit of the heating power of the wire, the thermal compensation power supply and the thermal compensation wire form a series loop, and the feedback circuit is connected to the series loop. The thermal compensation wire of the present invention adopts electric heating for thermal compensation, and the power of the thermal compensation wire can be automatically adjusted through the temperature of the outer wall of the experimental pipe section and the outer wall temperature of the inner insulation layer to achieve the thermal balance condition and realize the accurate measurement of the fluid heating power, which is further experimental data Accurate analysis provides a reliable guarantee, improving the accuracy and reliability of thermal experiments.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

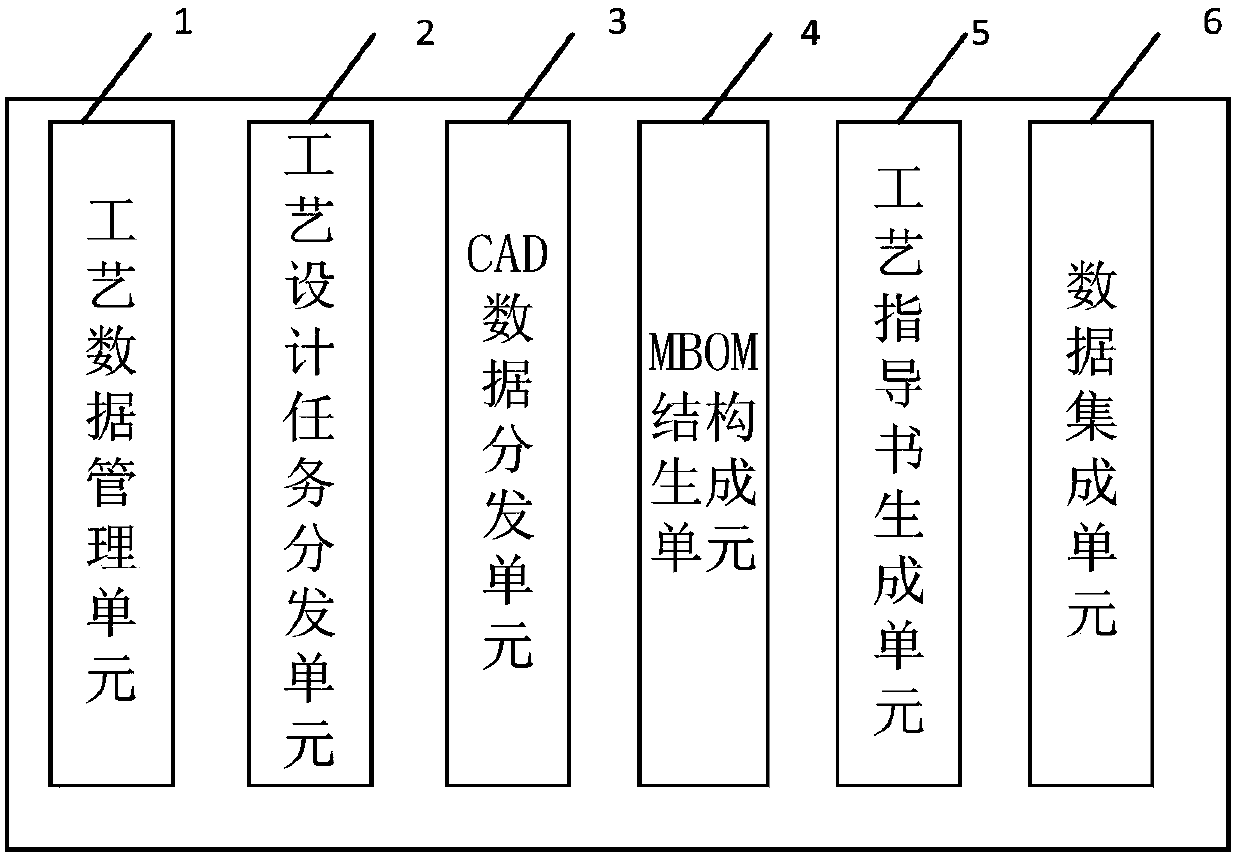

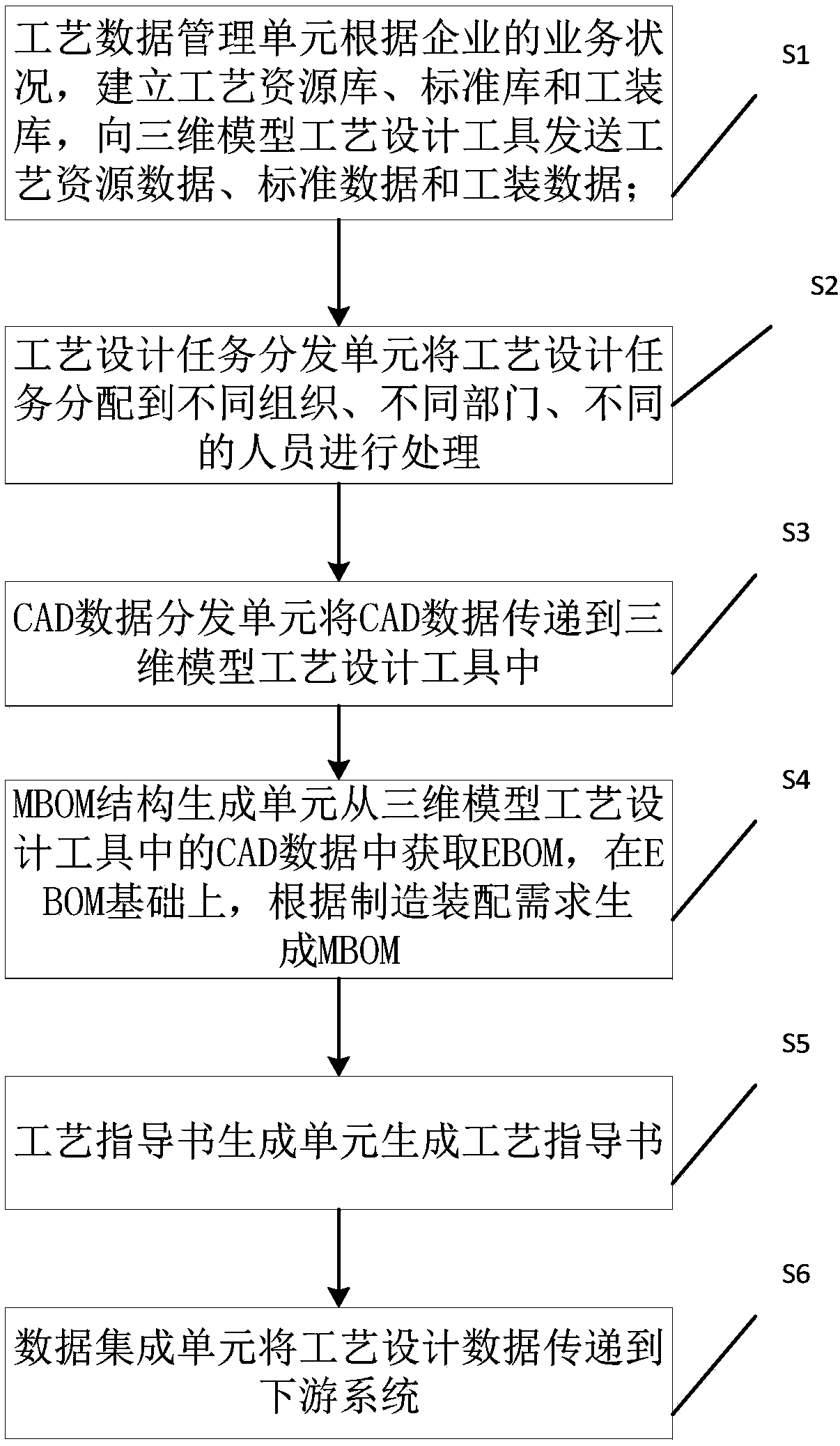

Process design collaboration management system and method based on three-dimensional model

PendingCN107729668AEasy to processConvenient to guide production and processingSpecial data processing applications3D modellingThermal engineeringBill of materials

The invention discloses a process design collaboration management system based on a three-dimensional model. The system comprises a process data management unit, a process design task distribution unit, a CAD (computer-aided design) data distribution unit, an MBOM (manufacturing bill of materials) structure generation unit, a process instruction book generation unit and a data integration unit. Digital machining, thermal engineering and assembly processes are designed and managed, process design tasks are distributed to different organizations, different departments and different staff and processed, collaborative process design and management are realized, unified management process resource bases, standard bases and tooling bases are realized, the system is integrated with a downstream system, machining information and assembly information are transmitted to the downstream system, and manufacturing of factories is conveniently instructed.

Owner:上海湃睿信息科技有限公司

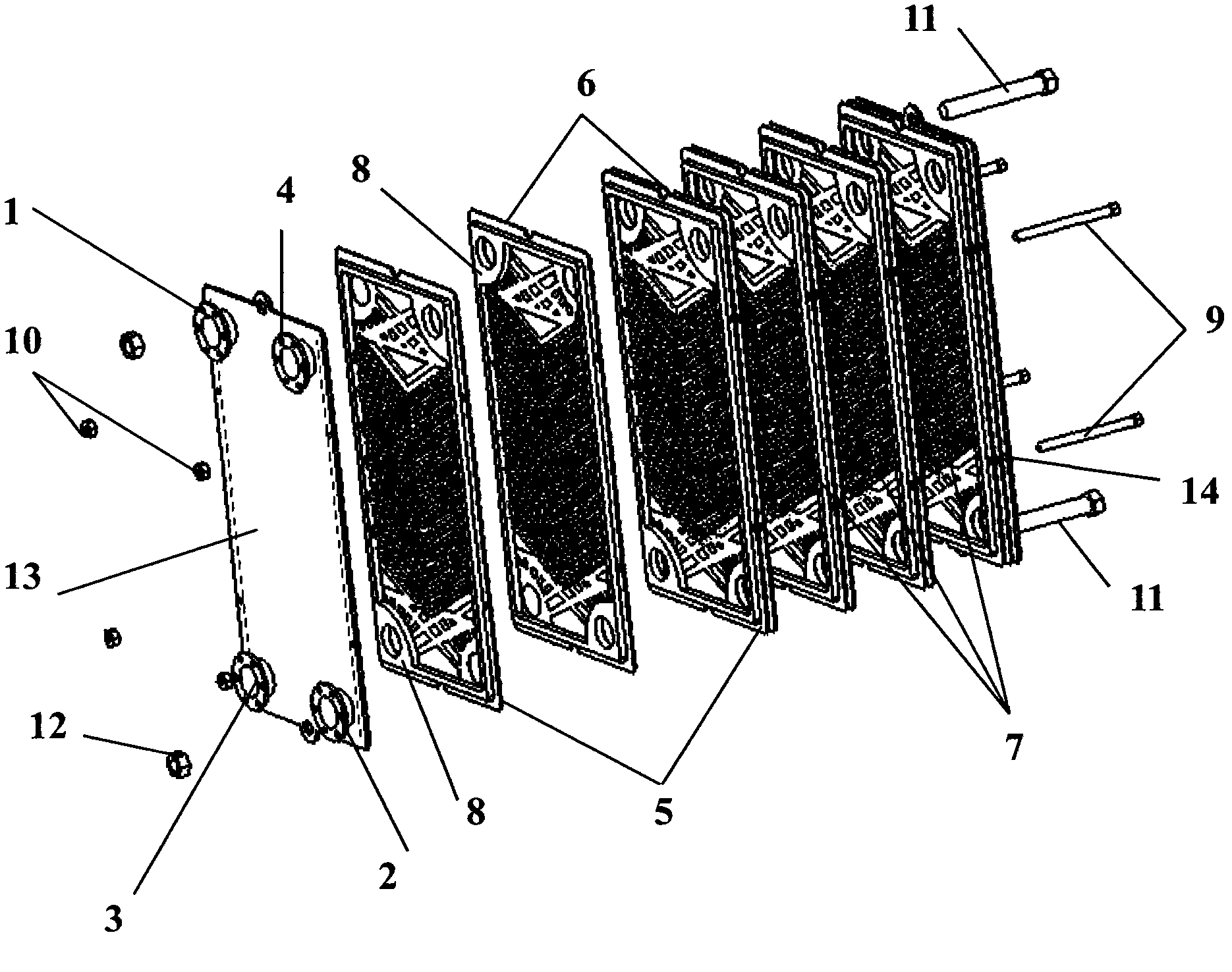

Plate type heat exchanger with pulsating heat pipes

InactiveCN102564182AImprove heat transfer efficiencyImprove heat transfer performanceIndirect heat exchangersHeat exchange apparatusThermal engineeringEnhanced heat transfer

The invention relates to a plate type heat exchanger with pulsating heat pipes. The pulsating heat pipes are arranged on heat exchange plates of the heat exchanger and are integrated with the heat exchange plates, accordingly, heat exchange efficiency of the heat exchanger is effectively improved under joint effects of forced convection heat transfer, phase-change heat transfer of the pulsating heat pipes and enhanced heat transfer of pulsating flowing, and the novel high-efficiency plate type heat exchanger with the pulsating heat pipes is formed. The plate type heat exchanger is mainly used for places relevant to heat exchange including ships, automobiles, aerospace, aviation, electronics, motors, the nuclear industry, thermal engineering, buildings, medical treatment, temperature adjustment and waste heat recovery, utilization of solar energy and terrestrial heat, and the like. The plate type heat exchanger has the advantages that heat exchange efficiency is high, pressure loss is low, the temperatures of the heat exchange plates are uniform, scaling cannot be caused easily, and the like.

Owner:纪玉龙

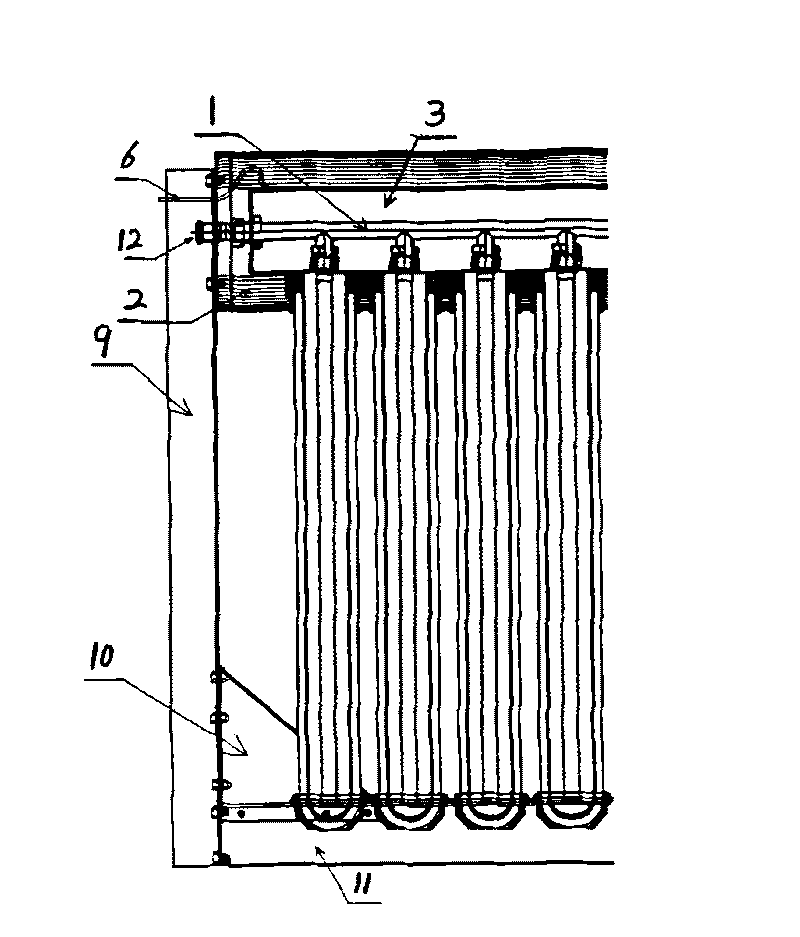

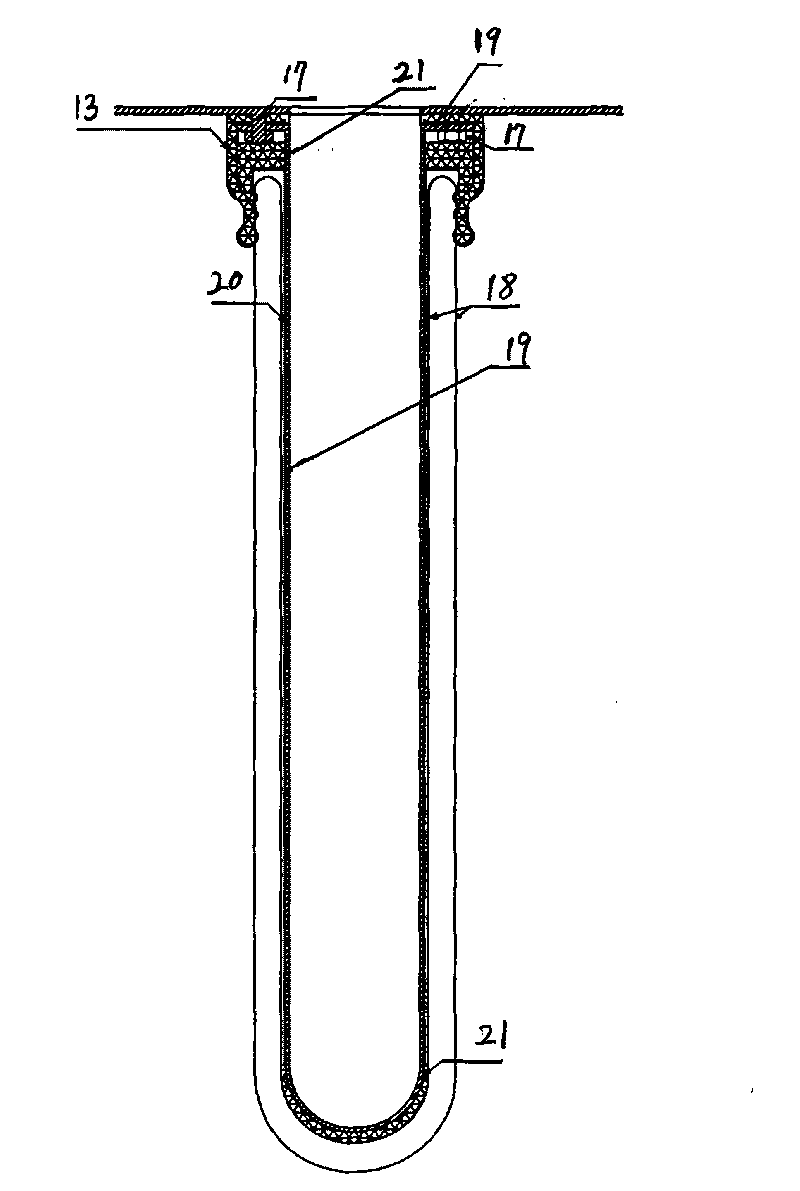

Heat collecting module of metal-glass sheathing heat collecting pipe

ActiveCN101762081AImprove pressure capacityImprove pressure bearing capacitySolar heating energySolar heat devicesCopper platingThermal energy

The invention discloses a heat collecting module of a metal-glass sheathing heat collecting pipe, belonging to the field of the solar thermal energy utilization technology. The current all-glass vacuum heat collecting pipe is not pressure-bearing, is easy to be explosive and is not anti-freezing, thereby being difficult to be applied to a heat collecting project; a selective heat absorption coating layer (a magnetron sputtering vacuum coating film) of the heat collecting pipe inner pipe outer surface of a vacuum heat pipe is easy to fall off under long-term basking. A vacuum glass pipe in the invention is the heat collecting module of the metal-glass suit heat collecting pipe, which does not contact working medium and is pressure-bearing and antiseptic and has high heat absorption efficiency and low heat emissivity. The heat collecting pipe comprises a glass vacuum heat preservation pipe and a metal heat collecting pipe, the heat collecting pipe is arranged in the glass vacuum heat preservation pipe, the outer surface of the heat collecting pipe is plated with copper chemically and a black nickel layer is electroplated after copper plating is carried out. Meanwhile, a flow channel blind plate is additionally arranged in a water filling circulating flow channel to separate cold and hot water working medium, and the water filling circulating flow channel is directly connected with a water filling pipe to guide cold water to directly reach the bottom part of the metal heating collecting pipe; and a new pressure-bearing connection type of connecting a collecting pipe and the heat collecting pipe is provided.

Owner:深圳市中装新能源科技有限公司

Blast furnace hot-blast stove orifice combination brick structure

ActiveCN103088179AEliminate lossesEliminate the bad condition of collapseBrick-hot blast stovesFurnace componentsThermal engineeringEllipse

The invention provides a blast furnace hot-blast stove orifice combination brick structure relating to the technical field of thermal engineering. Based on a key technology of building an elliptical ring by ingeniously using T-shaped and L-shaped refractory bricks, according to the practical situation of the diameter size of a blast furnace hot-blast stove orifice, the combination brick structure is composed of an outer ring, a neighboring outer ring, an inner ring and a neighboring inner ring, wherein the outer ring and the neighboring outer ring of which the inner diameters are shaped like an ellipse are built by using one T-shaped refractory brick for the ring top and the ring bottom respectively and using L-shaped refractory bricks both sides of the ring; the inner ring and the neighboring inner ring of which the outer diameters are shaped like an ellipse are built by using sealed refractory bricks; the outer ring and the neighboring outer ring as well as the inner ring and the neighboring inner ring are fixedly connected by refractory cement in a mutual sticking state; the elliptical ring of the outer ring and neighboring outer ring is fixedly connected by refractory cement in a state of being sleeved with the inner ring and the neighboring inner ring; and the bending angle of the L-shaped refractory bricks is 1-180 degrees. The invention is used for the manufacturing of a blast furnace hot-blast stove orifice. The combination brick structure is scientific and ingenious in design, high in production efficiency and excellent in quality, and can resist a harsh environment.

Owner:ZHENGZHOU ANNEC IND

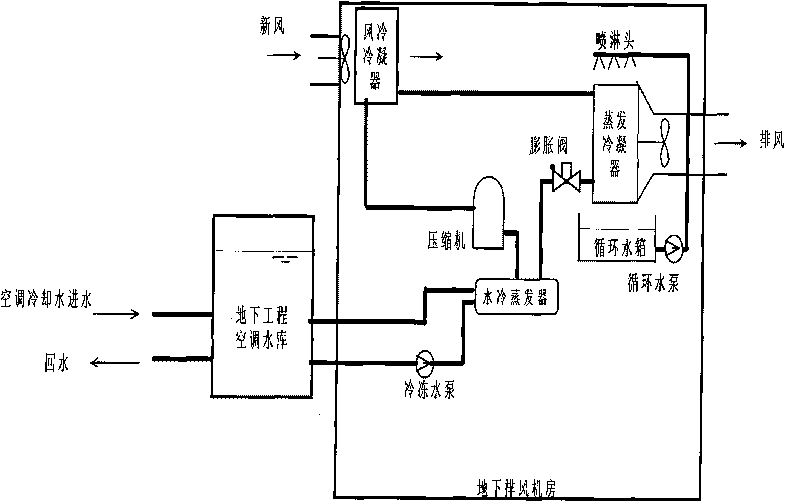

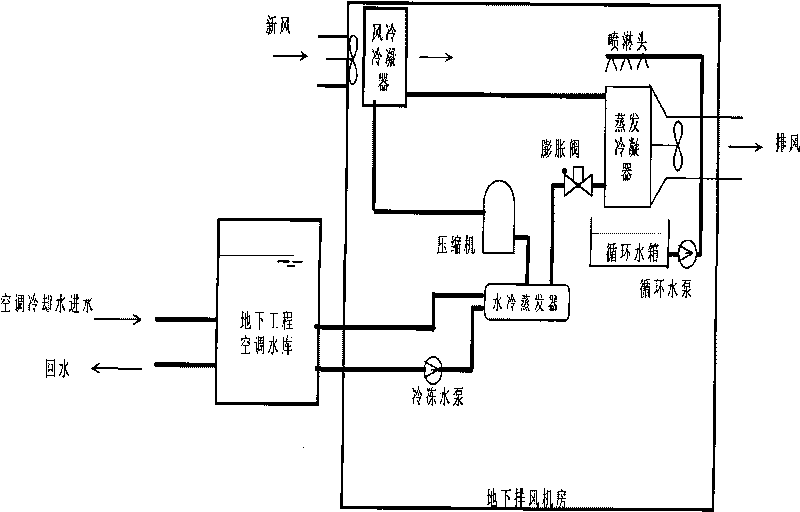

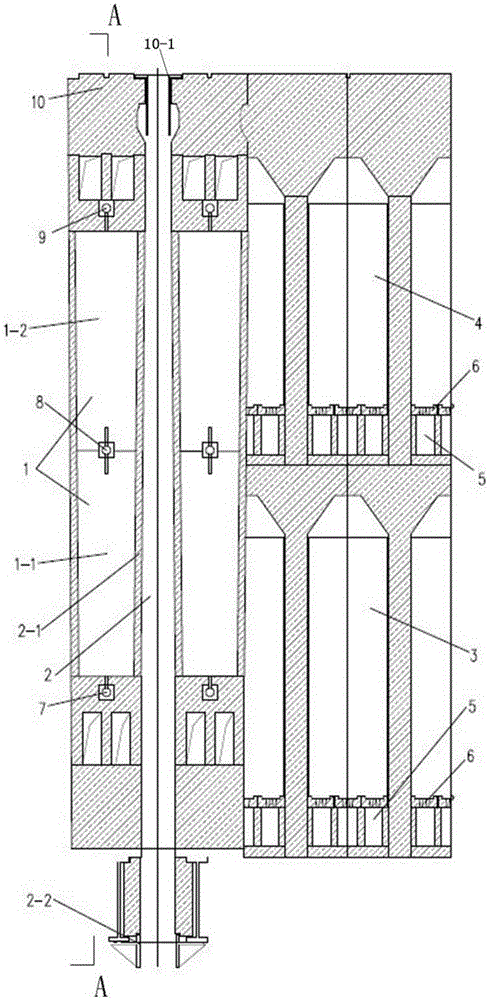

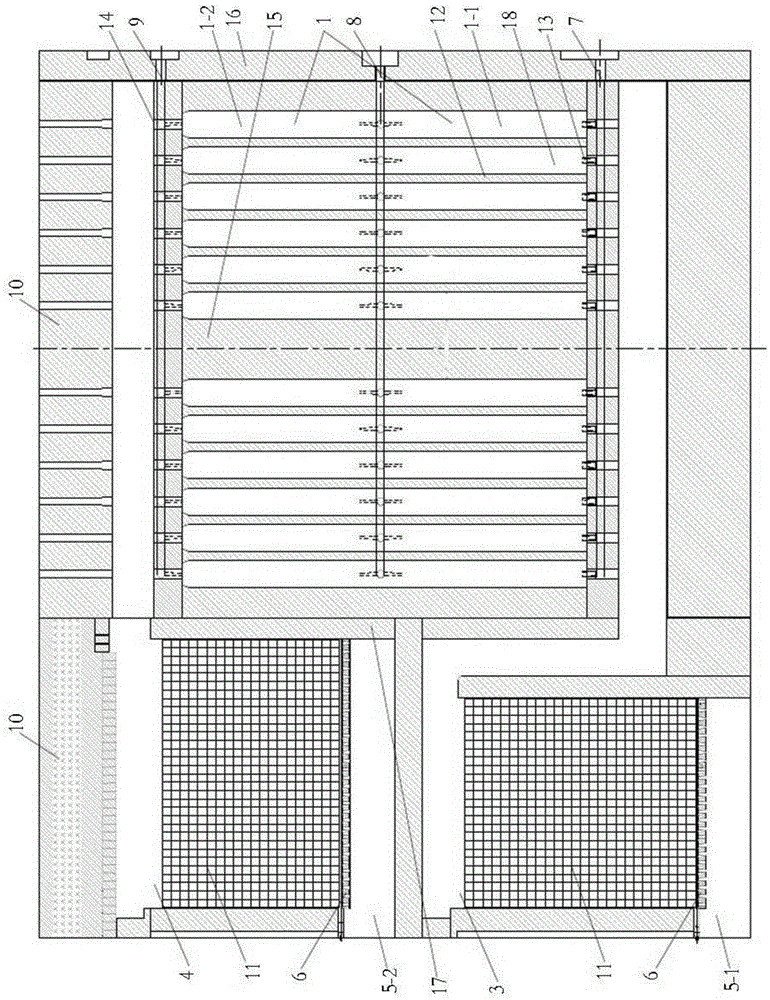

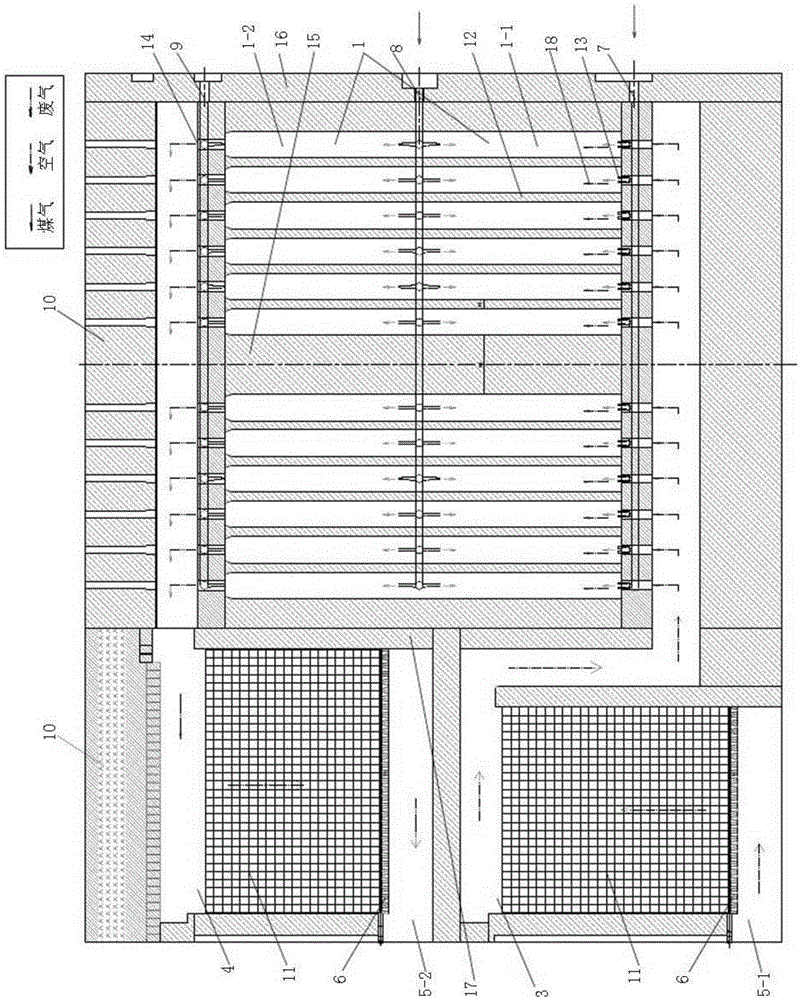

Ventilating and air-conditioning cooling method and device of underground engineering

InactiveCN101718455AIncreased level of controlLighting and heating apparatusSpace heating and ventilation detailsCentral air conditioningAir volume

The invention relates to a ventilating and air-conditioning cooling method of underground engineering for cooling an air-conditioning reservoir of an air-conditioning refrigeration system in underground engineering, wherein heat of condensation is dispersed into the air-conditioning reservoir. A heat pump cooling system is adopted to cool the air-conditioning reservoir, wherein an evaporator of the heat pump cooling system is directly used for cooling the air-conditioning reservoir. Two sets of condensers of the heat pump cooling system are connected in series, wherein the first set of the condensers are air-cooled condensers, and air outlets of the air-cooled condensers are led to the outside of the underground engineering; and the second set of the condensers are arranged at an air inlet of the underground engineering to heat fresh air entering from the outside of the underground engineering so as to ensure that the relative humidity in the underground engineering is not lower than 70 percent. The invention provides a method and a device, which are used for the ventilation of the traditional underground engineering and adopt a cooling medium of an active central air-conditioning to cool. A cooling device is arranged underground, and under the condition of small air inlet and outlet amount of the device, the relative humidity in the underground engineering does not exceed 70 percent.

Owner:中国人民解放军理工大学国防工程学院 +1

Vertical furnace with sectional heating combustion chamber and heating method of vertical furnace

InactiveCN105349156AImprove high-direction heating uniformityRealize large-scale developmentCombustible gas coke oven heatingStationary retortsThermal engineeringCombustion chamber

The invention relates to a vertical furnace with a sectional heating combustion chamber and a heating method of the vertical furnace. The vertical furnace comprises the combustion chamber, a carbonization chamber, a regenerative chamber, a furnace roof and a small flue, wherein the upper part and the lower part of the combustion chamber respectively communicate with the upper part and the lower part of the regenerative chamber; a coal gas first-section supply opening is formed in the bottom of a vertical flue of the combustion chamber; a coal gas second-section supply opening is formed in the middle of the vertical flue of the combustion chamber; a coal gas third-section supply opening is formed in the top of the vertical flue of the combustion chamber; and the combustion chamber is provided with a central partition wall which divides the combustion chamber into a left combustion chamber and a right combustion chamber in the longitudinal direction. High-heating uniformity of the vertical furnace can be improved effectively, the purpose of increasing the height of the carbonization chamber is achieved, and large-scale development of the vertical furnace is realized; meanwhile, combustion temperature and combustion intensity of the bottom and the top of the combustion chamber can be reduced, and the temperature of the high temperature point is reduced, so that generation of NOx is reduced, and environmental protection is facilitated further; and the vertical furnace is convenient to operate and adjustable in air flow, and facilitates improvement of production efficiency and thermal engineering efficiency.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP

Adiabatic suspension

InactiveCN103591411AThermal insulationPipe protection by thermal insulationThermal engineeringCopper foil

The invention relates to an adiabatic suspension, and discloses a super adiabatic technology based on the structural adiabatic principle. A super adiabatic structure with sufficient mechanical strength is realized through collaborative design of adiabatic material, thermal structure, mechanical structure and applicable functions. The adiabatic suspension is characterized by comprising super adiabatic material (silica aerogel or aluminum oxide aerogel or the like), an adiabatic suspending line (aramid or acrylic fibers, silica cantilevers, metal springs and the like), an adiabatic suspension structure (a right square pyramid suspension, a cube suspension and the like), a rigid suspension bucket (an aluminum alloy casing with the surface provided with an aluminum oxide cladding) and a thermal short circuit structure (a graphite particle painting layer with high thermal conductivity or a soaking film formed by copper foils or silver foils ). The adiabatic suspension can serve as a fundamental paradigm for the thermal engineering technology and the packaging technology, and can be used for designing various new concept products, which can operate under super low temperature or super high temperature, such as adiabatic suspension batteries, adiabatic levitation batteries and adiabatic temperature sensing chips, with super adiabatic performances.

Owner:SUZHOU YUANZHENG HOT VOLT

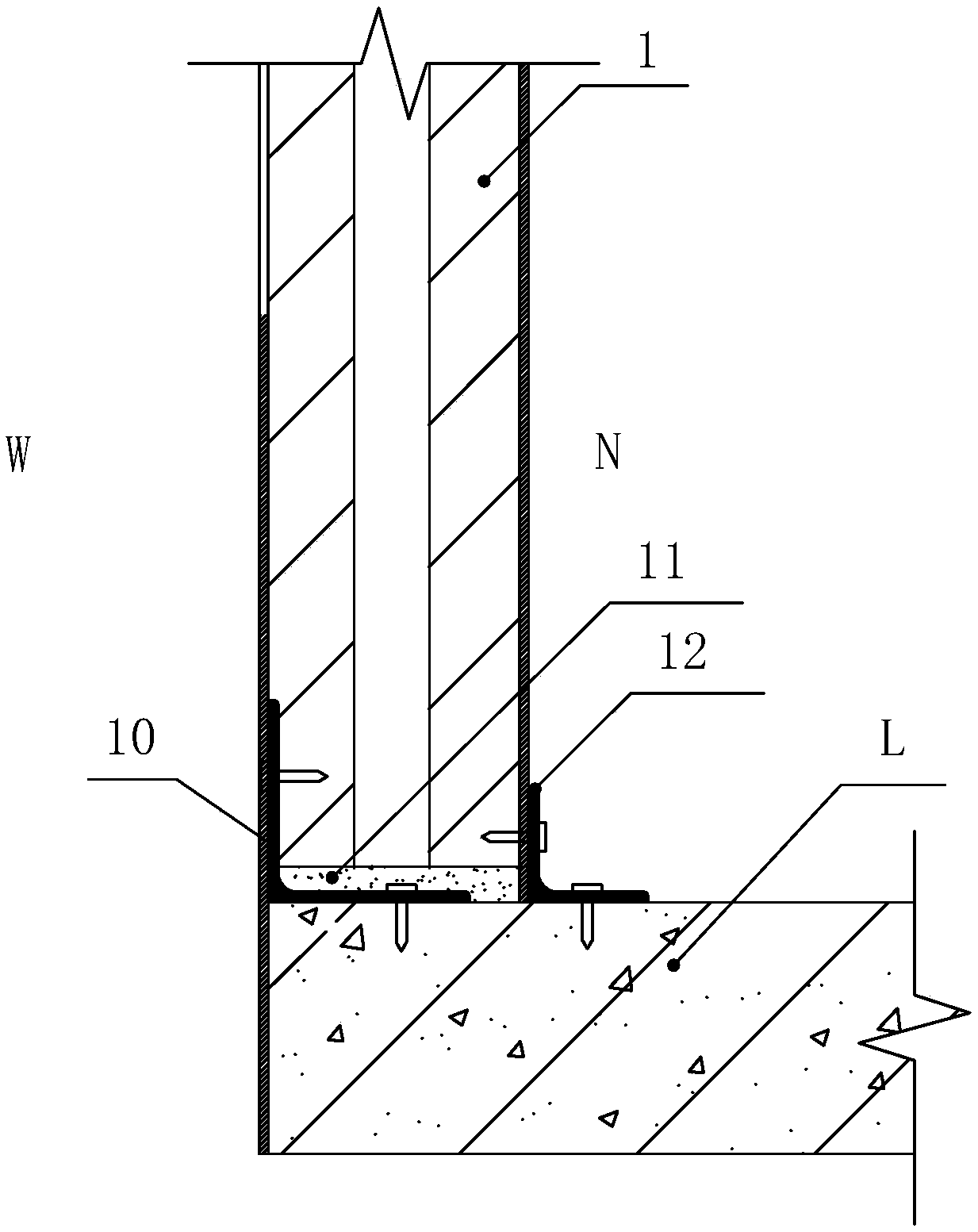

Silicon-magnesium wallboard and steel structure connecting joint structure of steel structure building and construction method for silicon-magnesium wallboard and steel structure connecting joint structure

PendingCN111379329AWell designed and comprehensiveIncrease the air conditionerWallsBuilding material handlingThermal engineeringThermal insulation

The invention discloses a silicon-magnesium wallboard and steel structure connecting joint structure for a steel structure building. The silicon-magnesium wallboard and steel structure connecting joint structure comprises a silicon-magnesium wallboard exterior wall surface layer structure, a silicon-magnesium wallboard interior wall surface layer structure, a silicon-magnesium wallboard board bottom mounting structure, a silicon-magnesium wallboard board top mounting structure, an H-shaped steel beam groove structure connected to a silicon-magnesium wallboard, a silicon-magnesium wallboard splicing seam structure, a silicon-magnesium wallboard and corner steel column joint structure, a silicon-magnesium wallboard and exterior wall steel column joint structure, and the like. The silicon-magnesium wallboard and steel structure connecting joint structure for the steel structure building provided by the invention is simple in structure, is convenient in operation, is firm in mounting, is good in formed appearance, meets requirements of duration of fire resistance of the structure, and meets basic requirements of the structure, thermal engineering, water resistance, fire resistance, thermal insulation, heat insulation, sound resistance, architectural models and the like.

Owner:广西建工第五建筑工程集团有限公司

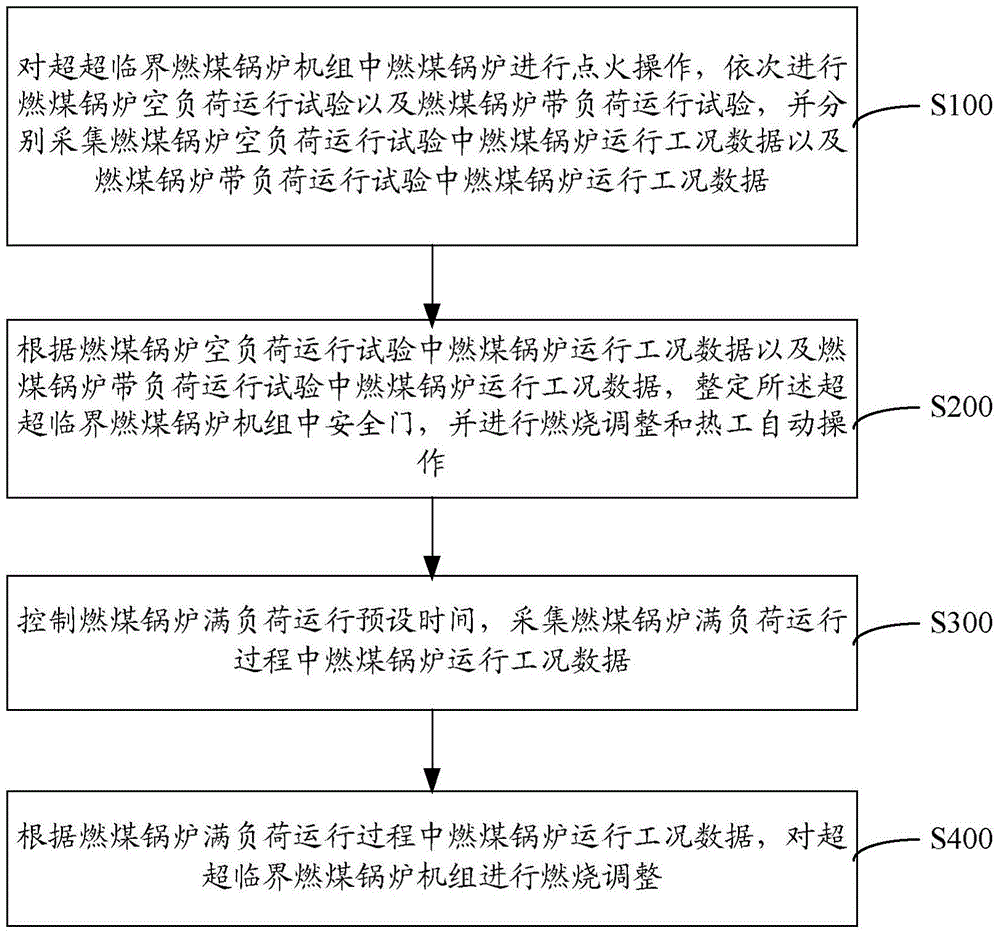

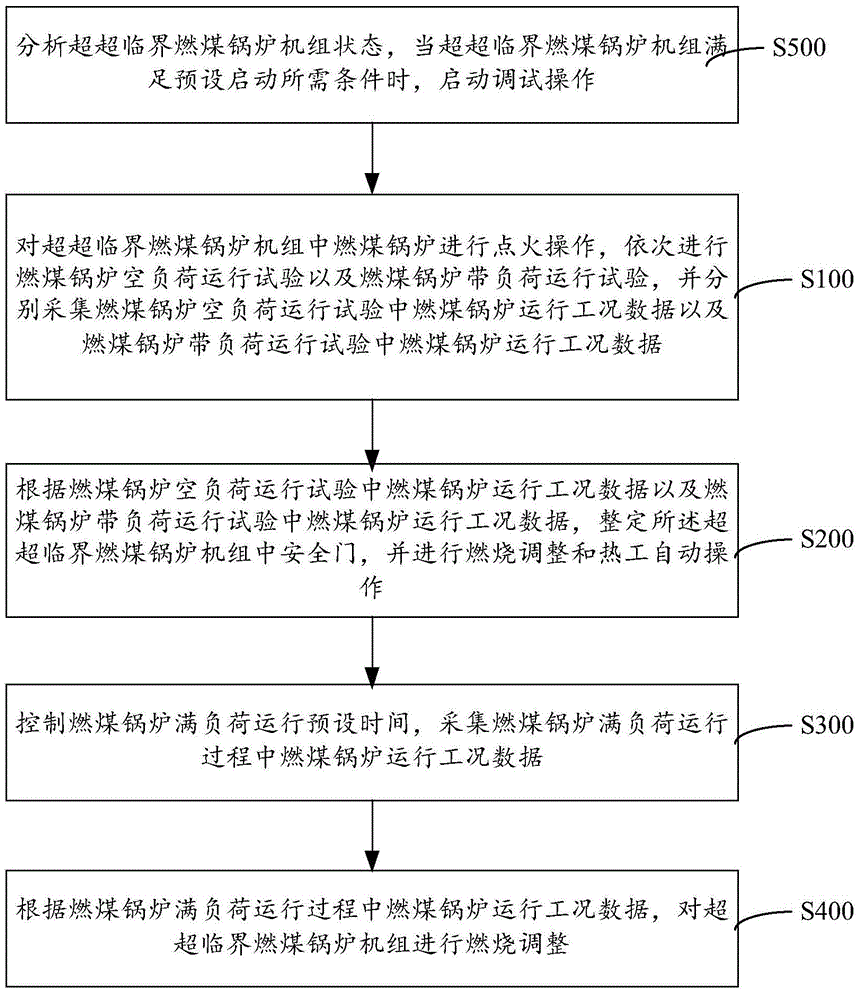

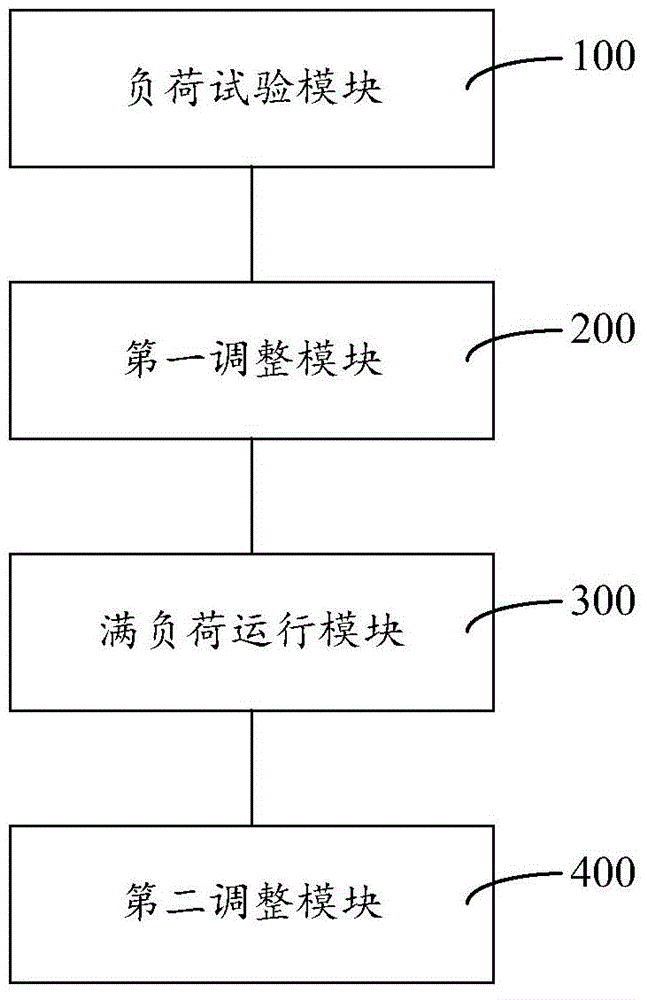

Ultra-supercritical coal-fired boiler unit start adjusting method and system

The invention provides an ultra-supercritical coal-fired boiler unit start adjusting method and system. The method includes the steps of igniting a coal-fired boiler in an ultra-supercritical coal-fired boiler unit, sequentially conducting a coal-fired boiler no-load running test and a coal-fired boiler load running test, collecting the running working condition data of a coal-fired boiler in the no-load running test and the load running test respectively, setting a safety door in the ultra-supercritical coal-fired boiler unit on the basis of the data, conducting combustion adjustment and thermal engineering automatic operation, controlling the full-load running preset time of the coal-fired boiler, collecting full-load running working condition data, and conducting combustion adjustment on the ultra-supercritical coal-fired boiler unit according to the full-load running working condition data. In the whole process, the complete ultra-supercritical coal-fired boiler unit start adjusting mode is adopted, the ultra-supercritical coal-fired boiler unit start adjusting process can be guided and controlled, and the start effect of the ultra-supercritical coal-fired boiler unit and the safe running of a generator set are ensured.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID

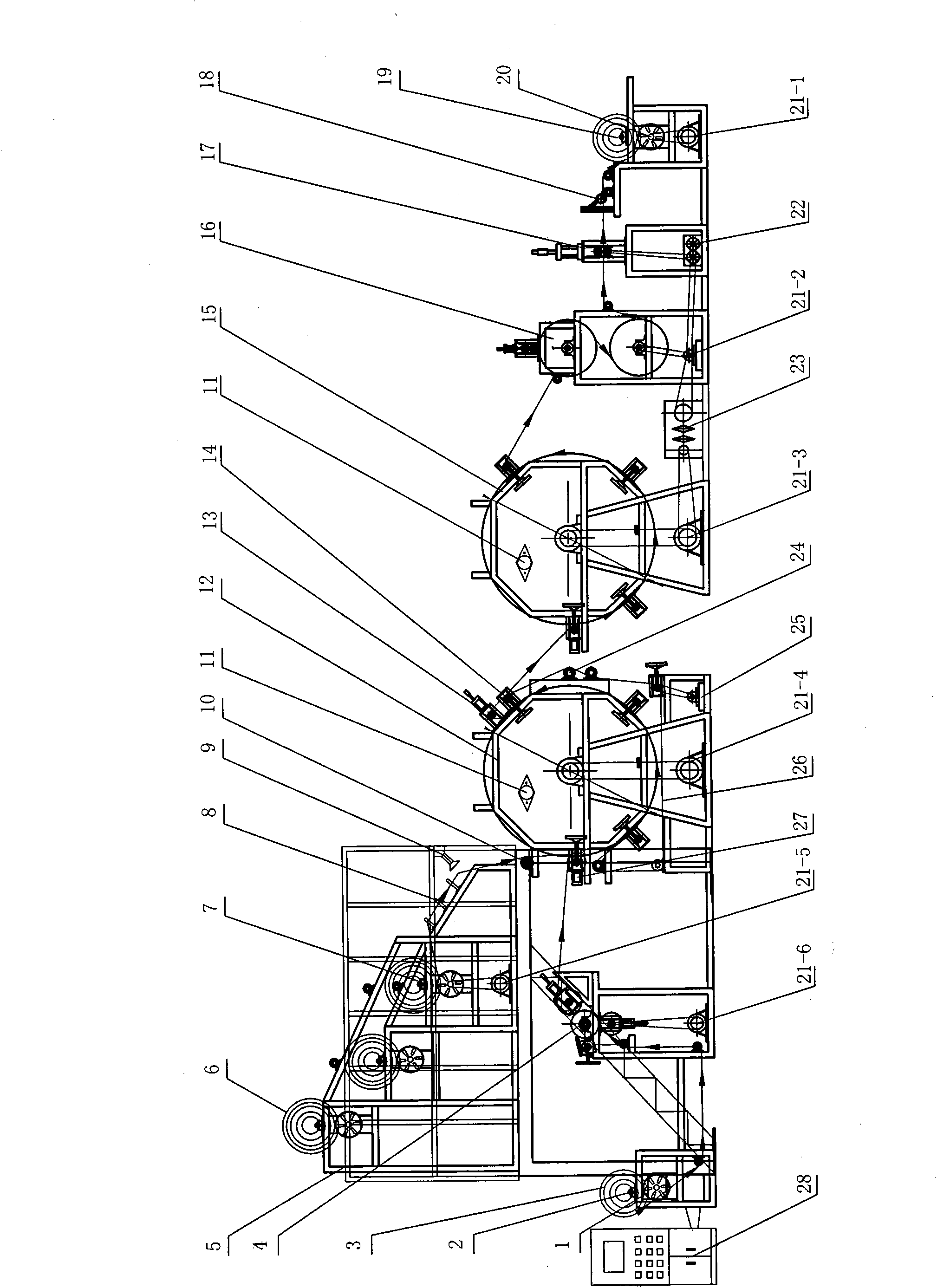

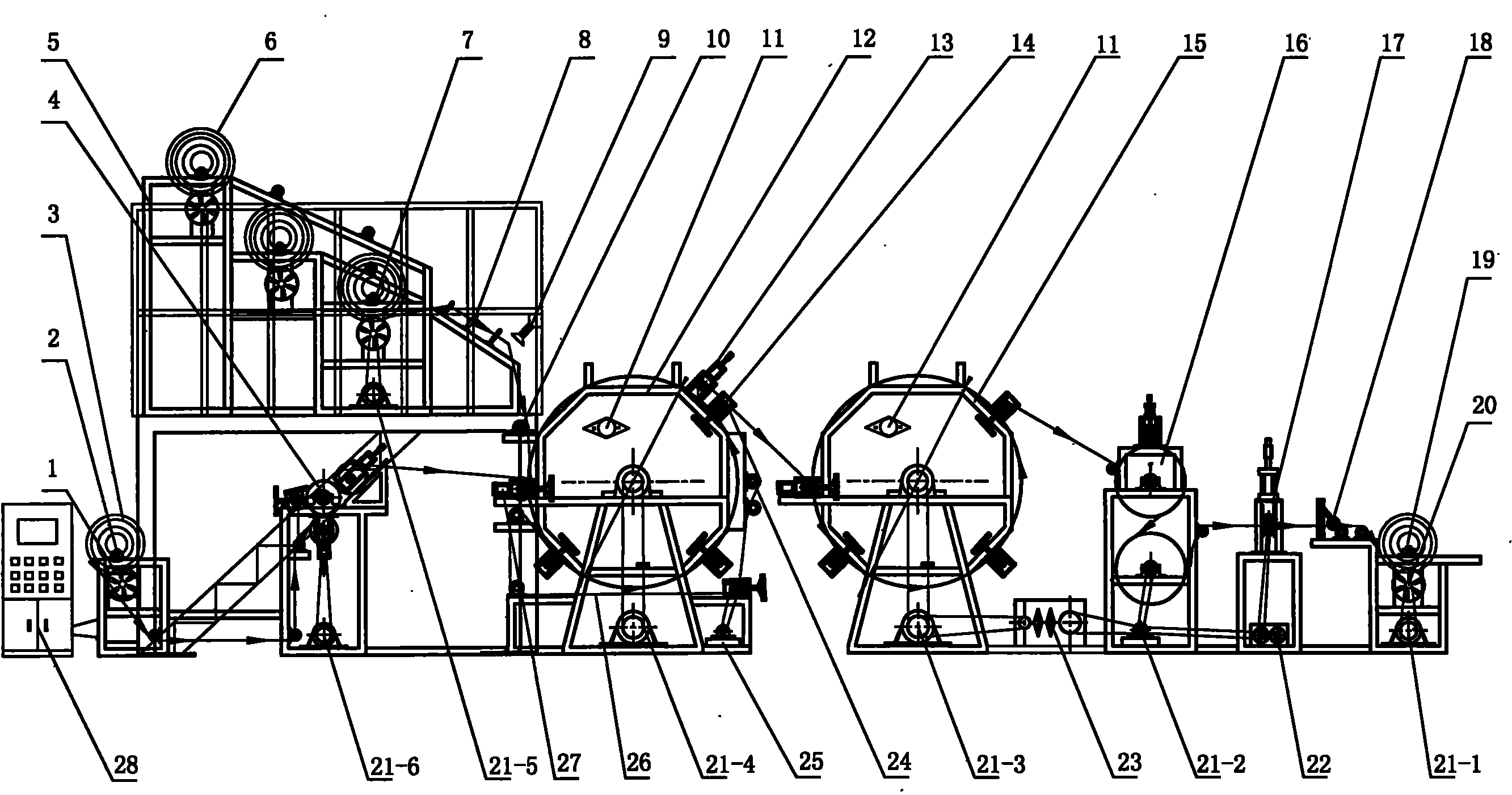

Multifunctional paper yarn wall paper compounding machine

InactiveCN102381001AImprove flexural tensile strengthQuality improvementLamination ancillary operationsLaminationThermal engineeringYarn

The invention relates to a multifunctional paper yarn wall paper compounding machine, which belongs to paper and yarn compounding machinery and comprises a magnetic powder brake, a constant tension uncoiling device, a paper coil, a gluing device, a support frame body, a yarn coil, a constant tension multi-layer yarn uncoiling device, a steel buckle, an optical yarn fracture prevention sensor, an expansion roller, a temperature sensor, a front braking tube device, an air cylinder, a steel roller, a back baking tube device, a cooling device, a traction device, a counter, a constant tension center coiling device, a magnetic powder clutch, a servo motor, a combined gearbox, a stepless speed changer, a deflection correcting roller, a clutch gearbox, a net belt, a main silicon gel roller and a computer control cabinet, wherein the multifunctional paper yarn wall paper compounding machine is designed by adopting and combining a computer closed loop technology and mechanical and thermal engineering principles. The machine has the advantages that the automation degree is high, the production efficiency is high, the production cost is reduced, the operation is safe and convenient, the produced paper and yarn compounding material is a novel environment-protection compounding material, the quality is good, the energy is saved, the environment is protected, the folding resistance and tensioning resistance intensity is high, the colors are rich, the use is convenient, and the pasting is firm.

Owner:JIANGSU KUNTAI MACHINERY

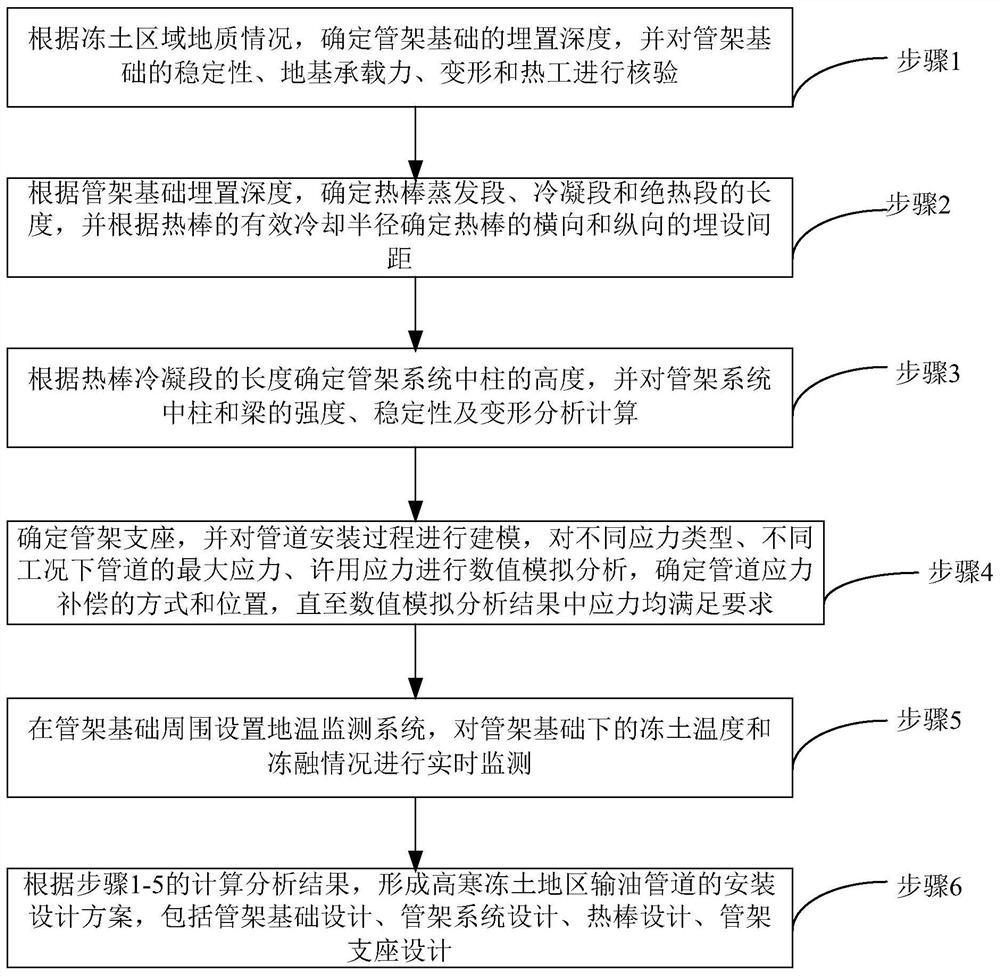

Method for installing and designing oil pipeline in alpine frozen soil area

PendingCN111832190AMeet environmental protection requirementsPipe supportsPipe laying and repairThermal engineeringGround temperature

The invention discloses a method for installing and designing an oil pipeline in an alpine frozen soil area, which comprises the following steps of: determining the burying depth of a pipe frame foundation according to the geological condition of the frozen soil area, and checking the stability, the foundation bearing capacity, the deformation and the thermal engineering of the pipe frame foundation; determining the lengths of an evaporation section, a condensation section and a heat insulation section of the hot rod, and determining the burying distance of the hot rod according to the effective cooling radius of the hot rod; the height of a column of the pipe frame system is determined, and the strength, stability and deformation of the column and a beam in the pipe frame system are analyzed and calculated; determining a pipe frame support, modeling a pipeline installation process, performing numerical simulation analysis on the maximum stress and allowable stress of the pipeline under different stress types and different working conditions, and determining a mode and a position of pipeline stress compensation; a ground temperature monitoring system is arranged around the pipe frame foundation and used for monitoring the frozen soil temperature and the freezing and thawing conditions under the pipe frame foundation in real time; According to calculation and analysis results ofthe steps 1-5, an installation design scheme of the oil pipeline in the alpine frozen soil area is formed.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com