Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

178results about "Brick-hot blast stoves" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Top burning hot blast stove using annular airflow spray upward with premixing combustion and reflux heating

ActiveCN101381786AFixing Poor MixingResolve Insufficient CombustionBrick-hot blast stovesCombustion processSocial benefitsCombustor

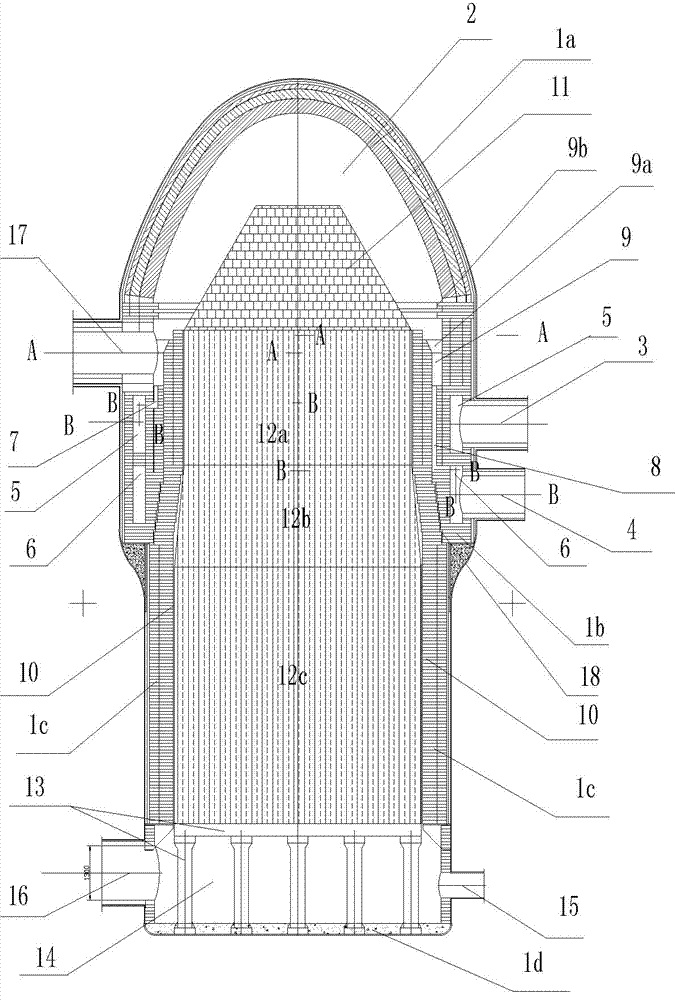

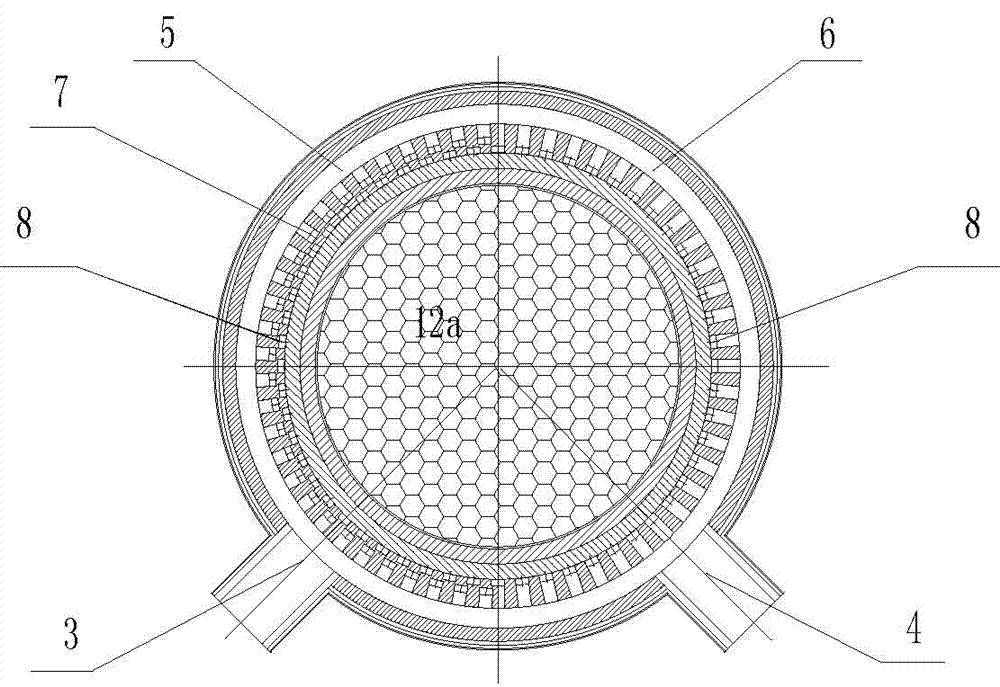

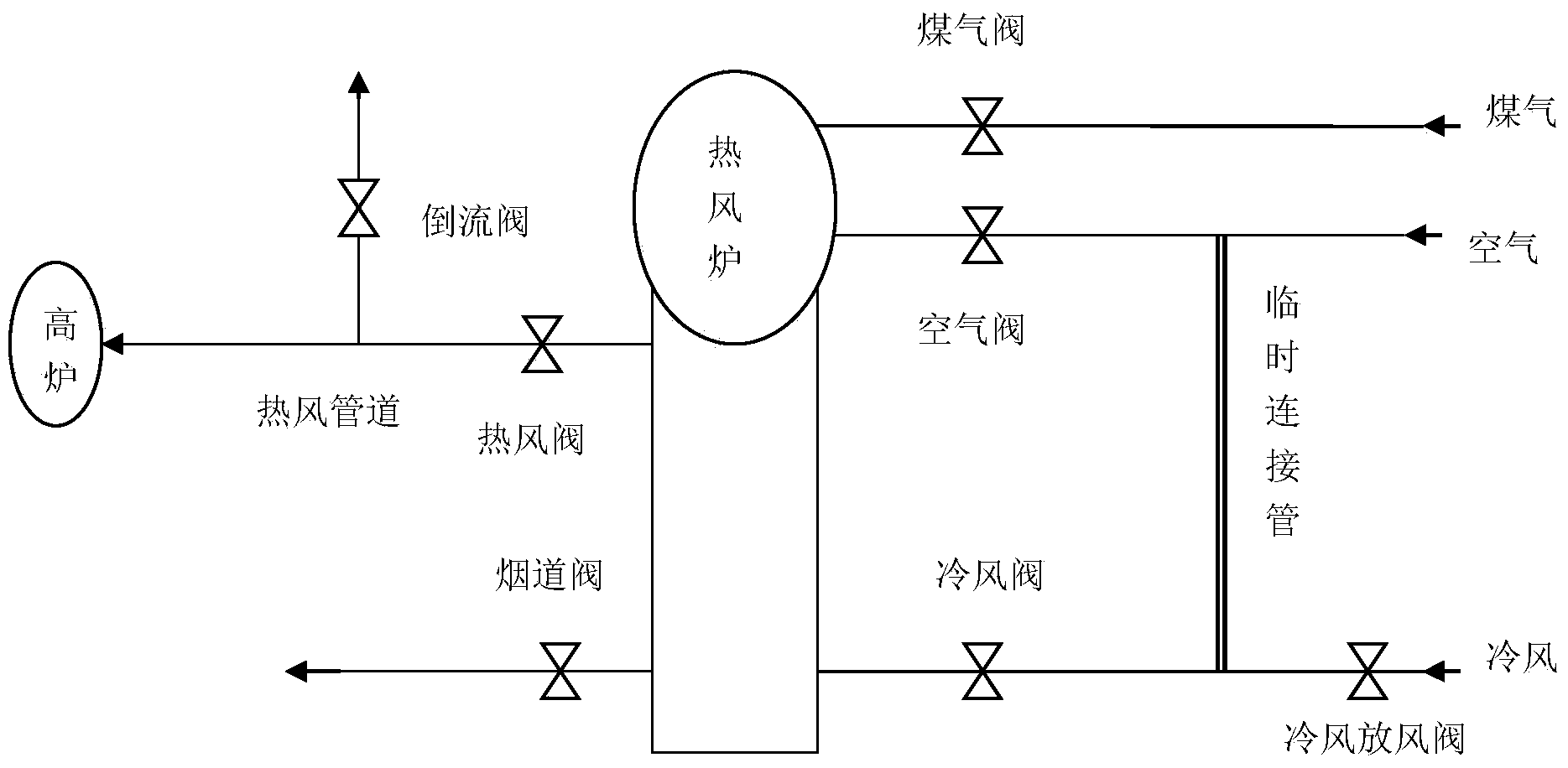

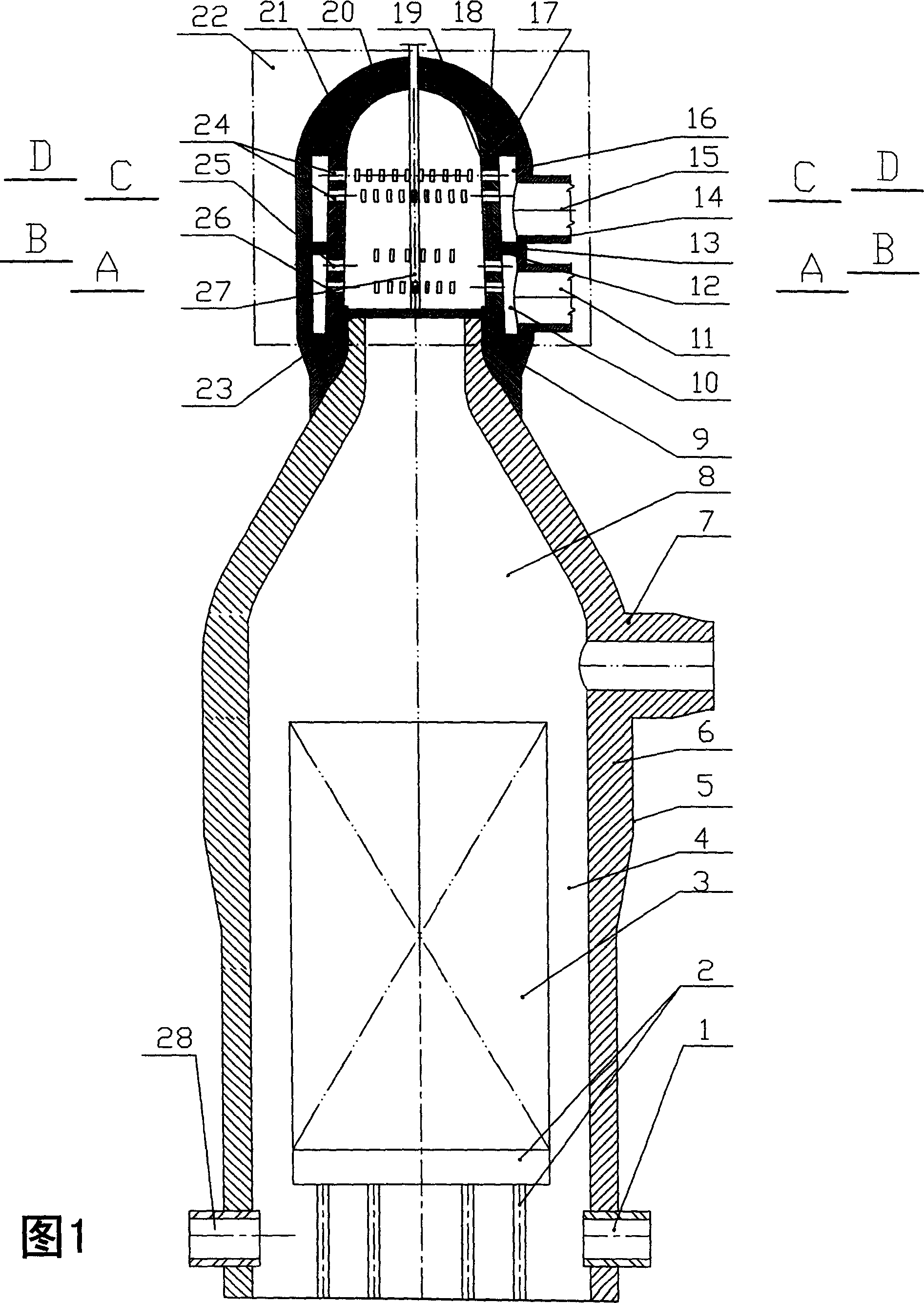

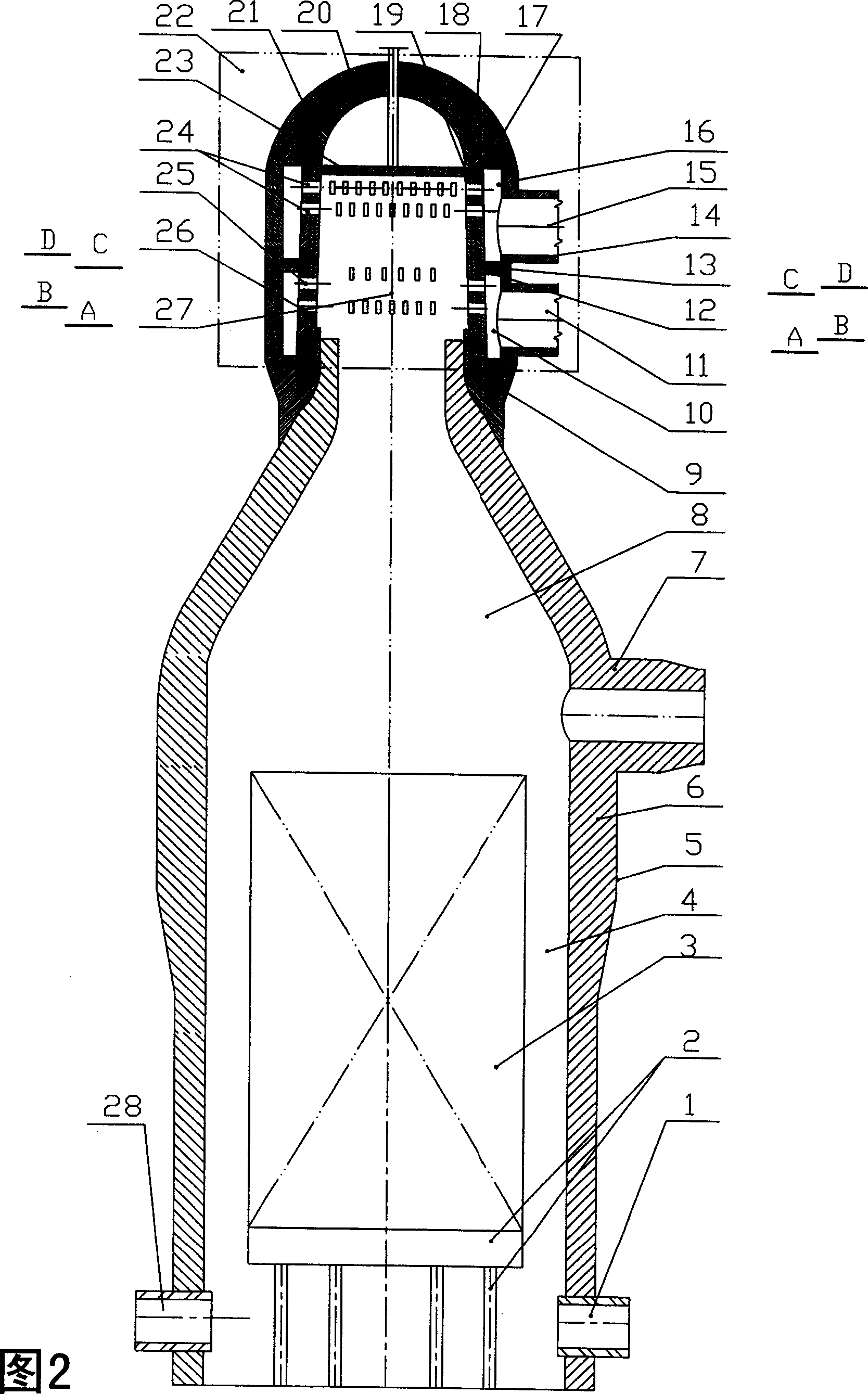

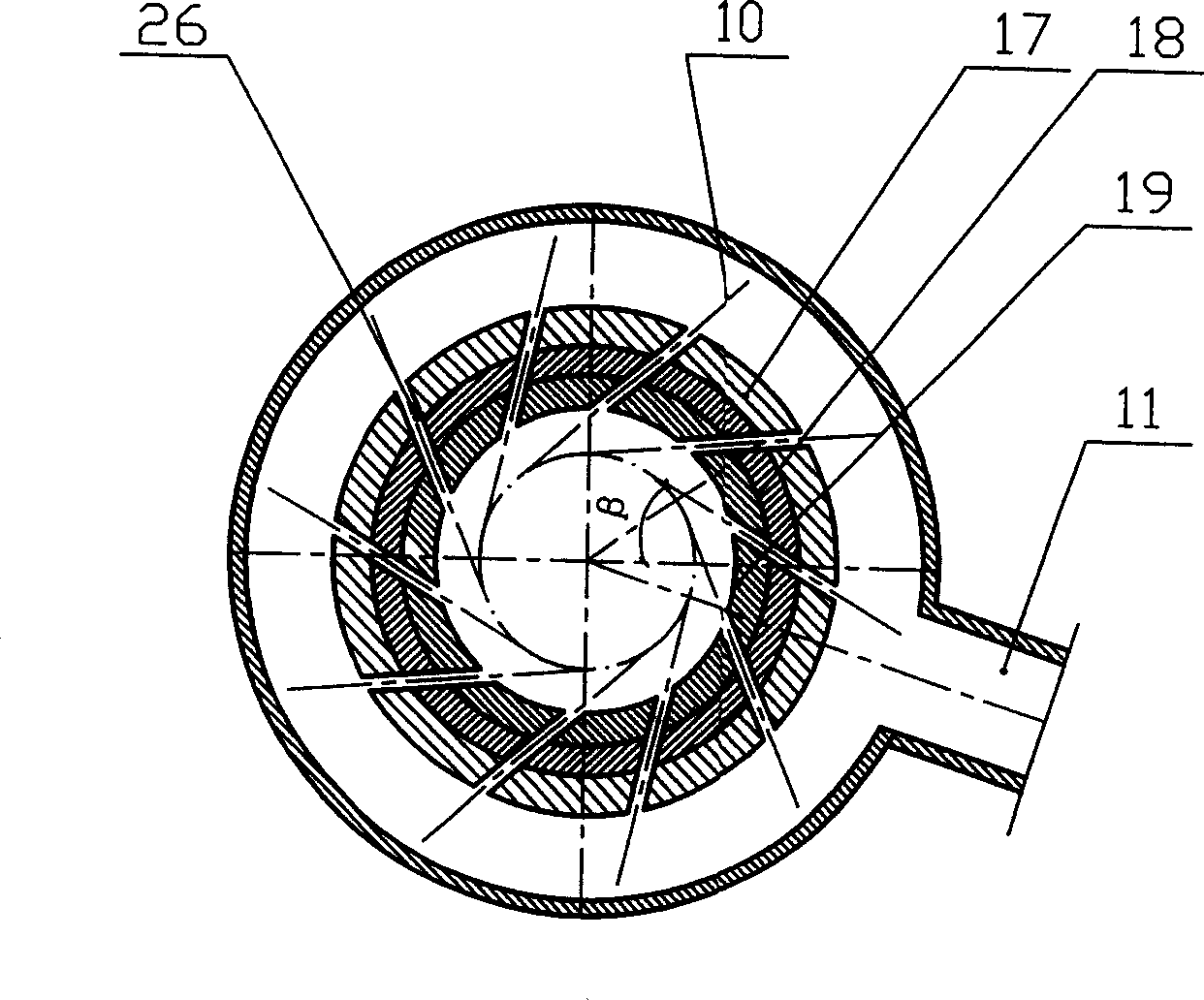

The invention relates to a top-firing hot blast furnace which adopts upper spraying, premixing, firing, reflux and heating by annular airflow and effectively solves the problems of the rationality and stability of the fluid flow in the hot blast furnace and the sufficiency and uniformity of the mixing of different fluids. The top-firing hot blast furnace has the following structure: a vault is positioned on a burner of the upper part of a furnace body; the lower part of a furnace grate under the furnace body is provided with a cold wind chamber; a flue gas outlet pipe and a cold wind inlet pipe are arranged on the sidewall of the cold wind chamber; a combustion chamber is formed between a straight cylinder part on the upper part of the burner and the vault; a hot blast outlet pipe is arranged on the straight cylinder part; the lower part of the burner is provided with a heat storage chamber; the outer wall of the burner is positioned on an outer supporting annular plate of the upper part of the furnace body; the inside of the burner is separated into a coal gas distribution circuit and an air distribution circuit by a partition wall of an oblique circuit; the outer ends of the coal gas distribution circuit and the air distribution circuit are provided with a coal gas inlet pipe and an air inlet pipe respectively; a conduit is formed between the upper parts of the outer wall and the inner wall of the burner; the coal gas distribution circuit and the air distribution circuit are connected with an annular airflow premixing conduit through the respective nozzle tube distributed on the peripheral wall of the burner; and a flow equalizing and obstructing baffle plate is formed between the upper part of the conduit and the combustion chamber. The top-firing hot blast furnace has good economical and social benefits.

Owner:河南省豫兴热风炉工程技术有限公司

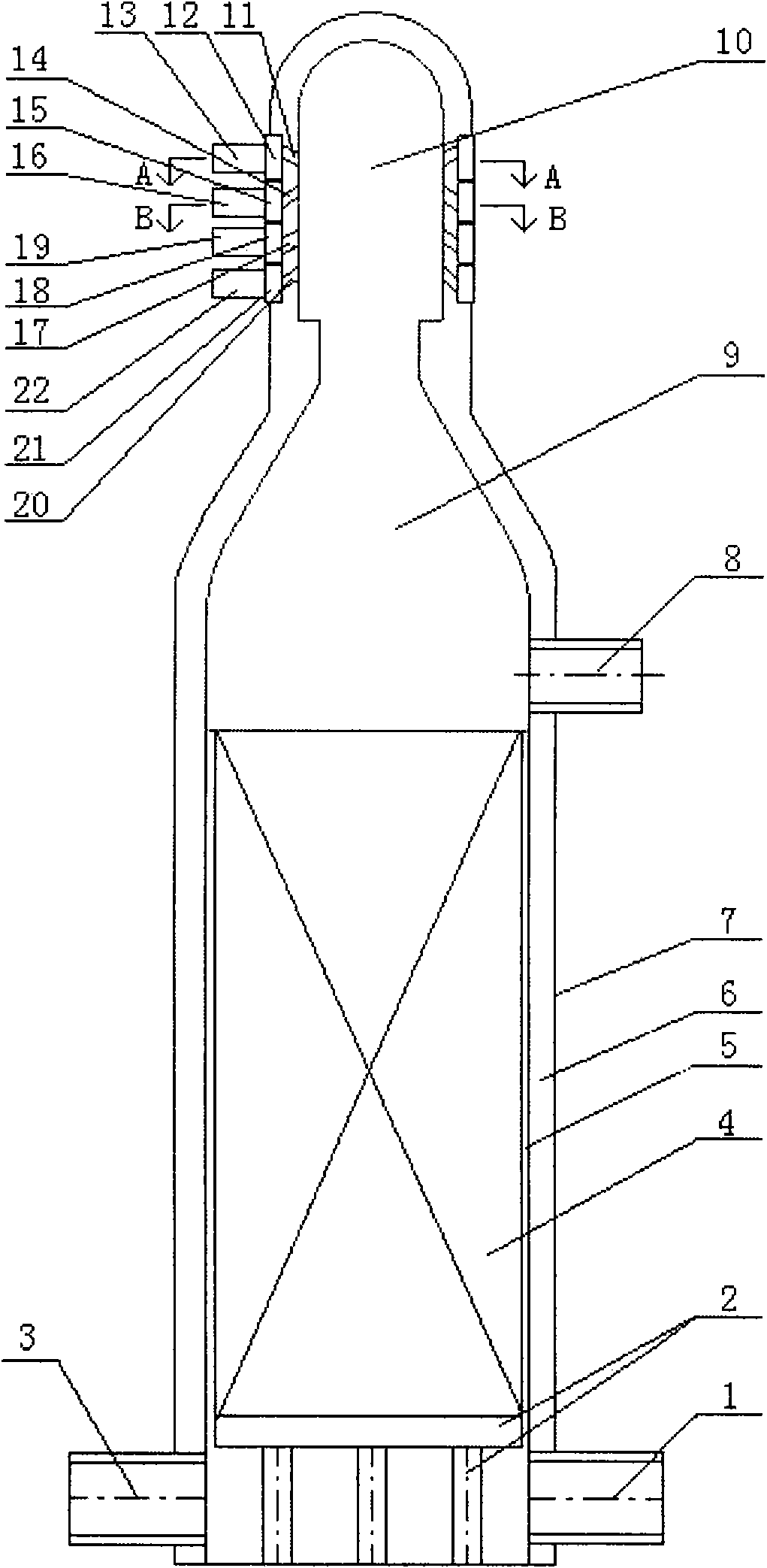

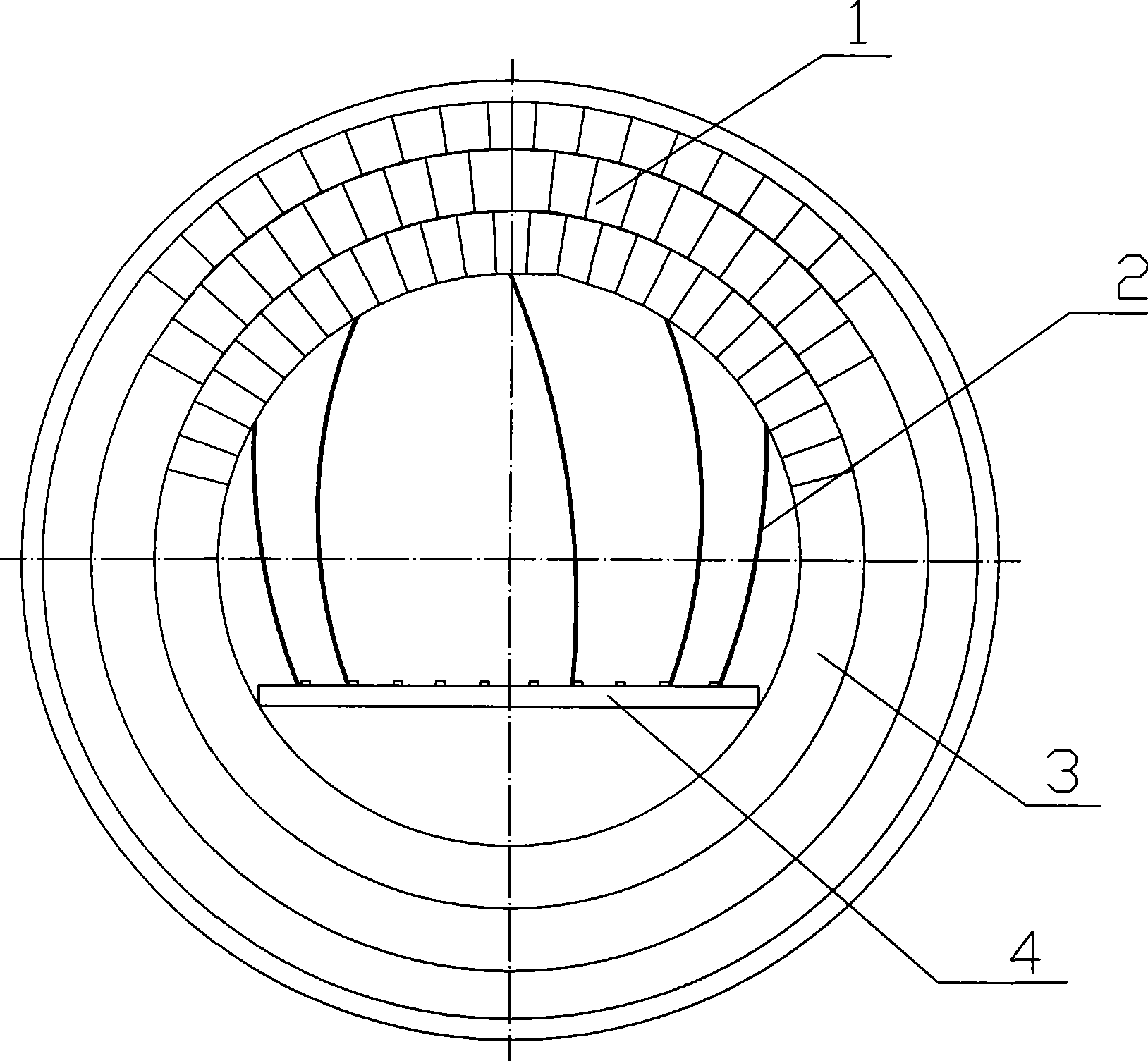

High-temperature low-oxygen top-combustion-type air heating furnace

ActiveCN101792837ABalanced utilizationEfficient use ofBrick-hot blast stovesCombustion chamberEngineering

The invention relates to a high-temperature low-oxygen top-combustion-type air heating furnace belonging to the technical field of air heating furnaces and comprising a cold air inlet, a furnace grate, columns, grid blocks, a regenerative chamber, a furnace liner, a furnace shell, a high-temperature low-oxygen combustor, a combustion chamber, an arc top, a hot air outlet and a flue gas outlet. The high-temperature low-oxygen top-combustion-type air heating furnace is characterized in that the high-temperature low-oxygen combustor is arranged at the upper part of the air heating furnace and comprises two gas inlets, circular tracks, nozzles, two air inlets and hollow gas pre-combustion chambers, each inlet, circular track and nozzle comprise 1-20 layers, combustion-supporting air over 800 DEG C sucks combustion products by fractional combustion and high-temperature airflows in the high-temperature low-oxygen combustor, and the oxygen volume density of a reaction area is diluted to realize high-temperature low-oxygen combustion fully different from a traditional combustion process. The invention is suitable for air heating furnaces used for ironmaking with blast furnaces or by smelting reduction in the ironmaking industry and can also be used in the industrial technical field of heating gaseous media over 1000 DEG C.

Owner:BEIJING SHOUGANG INT ENG TECH

Method and device for dismantling refractory materials at arch crown of hot blast stove

ActiveCN102888481AGood removal effectWill not pose a safety hazardBrick-hot blast stovesLinings repairFire brickRefractory

The invention discloses a dismantling method of refractory materials, and particularly relates to a method for dismantling refractory materials at the arch crown of a hot blast stove, which is high in construction speed, and simple and convenient to implement. According to the characteristics of self-weight falling and mutual extruding and locking function of the refractory materials at the arch crown, stopper bricks are dismantled first, and then an impact bar acts on refractory bricks on the arch crown from bottom to top, so that the refractory bricks at the arch crown move upwards to break away from self-weight falling and mutual extruding and locking states and fall off naturally; and after the refractory bricks fall off,a heat-insulation refractory material layer can be easily removed, and simultaneously, all operators only need to stand on a steel platform at the top of the hot blast stove, therefore, potential safety hazards cannot be caused when the refractory bricks fall into the hot blast stove. Compared with the conventional manner of cracking the refractory bricks, the method directly damages the extrusion locking between the refractory bricks at the arch crown, and does not need to crack the refractory bricks, thereby greatly reducing the workload and reducing a great quantity of work.

Owner:CHINA 19TH METALLURGICAL CORP

High-blast-temperature hot-blast stove burnt in convection swirling heat storage medium

InactiveCN101906496AFix stability issuesSolve the strength problemBrick-hot blast stovesCombustion chamberBrick

The invention relates to a high-blast-temperature hot-blast stove burnt in a convection swirling heat storage medium, effectively solving the problems of complicated structure, non-uniform gas mixing, insufficient burning, environmental pollution and energy waste. The stove adopts the structure that a pre-burning chamber of a bell jar on the top of a ball and a taper-section barrel-shaped burning chamber below the pre-burning chamber are connected by using a labyrinth without stress action; the taper-section burning chamber is sufficiently filled with porous heat storage bodies; a coal gas inlet pipe and an air inlet pipe are distributed on the vertical wall of the pre-burning chamber; a barrel-shaped heat storage chamber is arranged below the burning chamber, and checker brick heat storage bodies are stacked on grates in the heat storage chamber; a cold air chamber is arranged below the heat storage chamber, and a smoke exhaust pipe and a cold air inlet pipe are connected to the wall; the grates for holding the heat storage bodies are mutually spaced with expansion gaps, put on a beam and supported by grate supporting posts; the supporting posts are fixed on a rigid base of the hot-blast furnace; and a central vault line of the pre-burning chamber is provided with a hot-blast outlet pipe coaxial with the hot-blast furnace. The invention has the advantages of simple structure, high mixed burning intensity, good air flow heat exchange effect and raised hot-blast temperature.

Owner:ZHENGZHOU YUXING REFRACTORY MATERIAL

Multiple fire hole flame-free ceramic burner

InactiveCN1858492ANovel structureExtended service lifeBrick-hot blast stovesIndirect carbon-dioxide mitigationCombustorBrick

The multiple fire hole flame-free ceramic burners is used in flameless combustion industrial furnace and kiln, especially hot blast stove for iron making blast furnace. The multiple fire hole flame-free ceramic burner has two outer ring gas channels. After air through the air inlet and gas through the gas inlet enter the air preheating ring channel and the gas ring channel, gas and air are preheated in between two ring channels before jetting to the mixer for mixing and jetting through the combustion nozzle to combust. The gas ring channel has guide bricks for homogeneous distribution of gas. The present invention has unique structure, small size and great power, and is suitable for various kinds of hot blast stove with heat accumulator.

Owner:武汉冶金建筑研究院 +1

Method for repairing crown brick of large wall of combustion chamber of internal-combustion stove

InactiveCN101701273AExtended service lifeLow costBrick-hot blast stovesLinings repairCombustion chamberBrick

The invention belongs to the technical field of stove repair, in particular to a method for repairing a crown brick of a large wall of a combustion chamber of an internal-combustion stove, which comprises the following steps of: removing the combustion chamber and a checker brick, preserving the large wall, removing the damaged crown brick on the large wall, digging a groove at the damaged part of the crown brick; fixing a crown brick insulation layer in the groove of the large wall by using a high-temperature adhesive to enable the crown brick to be combined with the large wall together; and building a new combustion chamber and a new checker brick and enabling an expansion gap to be formed between the crown brick and the combustion chamber. The invention can improve the effect of locally repairing the stove while the damaged combustion chamber and the damaged checker brick are replaced in the stove, can prolong the service life of the locally repaired stove, and can save the cost and shorten the off-production repair time.

Owner:NANJING IRON & STEEL CO LTD

Heat exchanger with covering layer

ActiveCN1696596AIncrease heat absorptionIncrease heat releaseBrick-hot blast stovesFurnace componentsPlate heat exchangerEmissivity

The present invention relates to a heat exchanger with covering layer, belonging to the field of heat exchanger technology. Said heat exchanger is characterized by that one side or several sides of surface of its heat storage body are coated with a layer of high radiation material, whose radiation factor is higher than that of heat storage body base material. The heat storage body form can be honeycomb, fin form, ball form or plate form, and base body of heat storage body is made up by using refractory material, ceramic material or metal material.

Owner:山东慧敏科技开发有限公司

Heat insulation method for top combustion type silicon brick hot-blast stove

InactiveCN101705323AThere is no phenomenon such as shedding of refractory materialsPrevent lattice transformationBrick-hot blast stovesCombustionBrick

The invention discloses a heat insulation method for a top combustion type silicon brick hot-blast stove. Each heat insulation operation procedure of the heat insulation method comprises the following operation steps: burning, banking, blasting and burning again; all the heat insulation operation procedures are circularly performed in sequence; when the temperature of the arch of the hot-blast stove drops to 900 DEG C, burning is started, and a combustion-supporting air combustion valve, a gas shut-off valve and an air and gas regulating valve are opened to adjust the volume of gas to 40000 to 55000 m3 / h, the gas pressure to 6 to 10 kpa, the combustion-supporting air pressure to 4 to 5 kpa, and the ratio of the combustion-supporting air flow rate to the volume of gas to 0.6 to 0.7; after the temperature of the arch at the upper part of the hot-blast stove is burnt to 1350 DEG C, the burning is stopped, and banking operation is performed; when the temperature of the arch of the hot-blast stove drops to 900 DEG C, blasting is started, a manhole at the lower part of the hot-blast stove is opened, and air is sent to the hot-blast stove with the reference that the increasing rate of the arch temperature is 1 DEG C / min; and when the temperature of silicon bricks drops to 900 DEG C, air supply is stopped, and the manhole, a hot blast valve and a backflow blowing-down valve are closed; and burning is repeated, and the cycle is conducted sequentially.

Owner:BAOSTEEL GROUP XINJIANG BAYI IRON & STEEL

Building and supporting method for semiring brick on hoogoven's warm-air duct inside lining

InactiveCN101509051AEasy to control masonry qualityGuarantee the quality of masonryBrick-hot blast stovesBrickEngineering

The invention relates to a method for supporting lining upper semiring masonry of hoogoven type warm-air duct, comprising the steps that bricking is carried out from external ring to internal ring, hidden construction is changed into open-type construction, and thin bamboo strips and assorted boards are utilized to temporarily support the masonry during bricking up light bricks and heavy bricks; wherein, two ends of the boards are put on the lining lower semiring of the duct, the upper ends of the thin bamboo strips are utilized to prop the upper semiring masonry being bricked up, the lower ends of the thin bamboo strips are exerted on the boards and prevented from sliding by the transverse parting strips on the boards, and the thin bamboo strips are taken down after the slurry is dried or the upper semiring is closed; and the thin bamboo strips and the boards are dismounted after the bricking is finished. The invention replaces the traditional support method by wooden arch stuffing to support the lining upper semiring masonry by the thin bamboo strips and the boards, thereby not only being convenient for construction but also good for improving masonry quality of lining upper semiring bricks of the duct.

Owner:CHINA FIRST METALLURGICAL GROUP

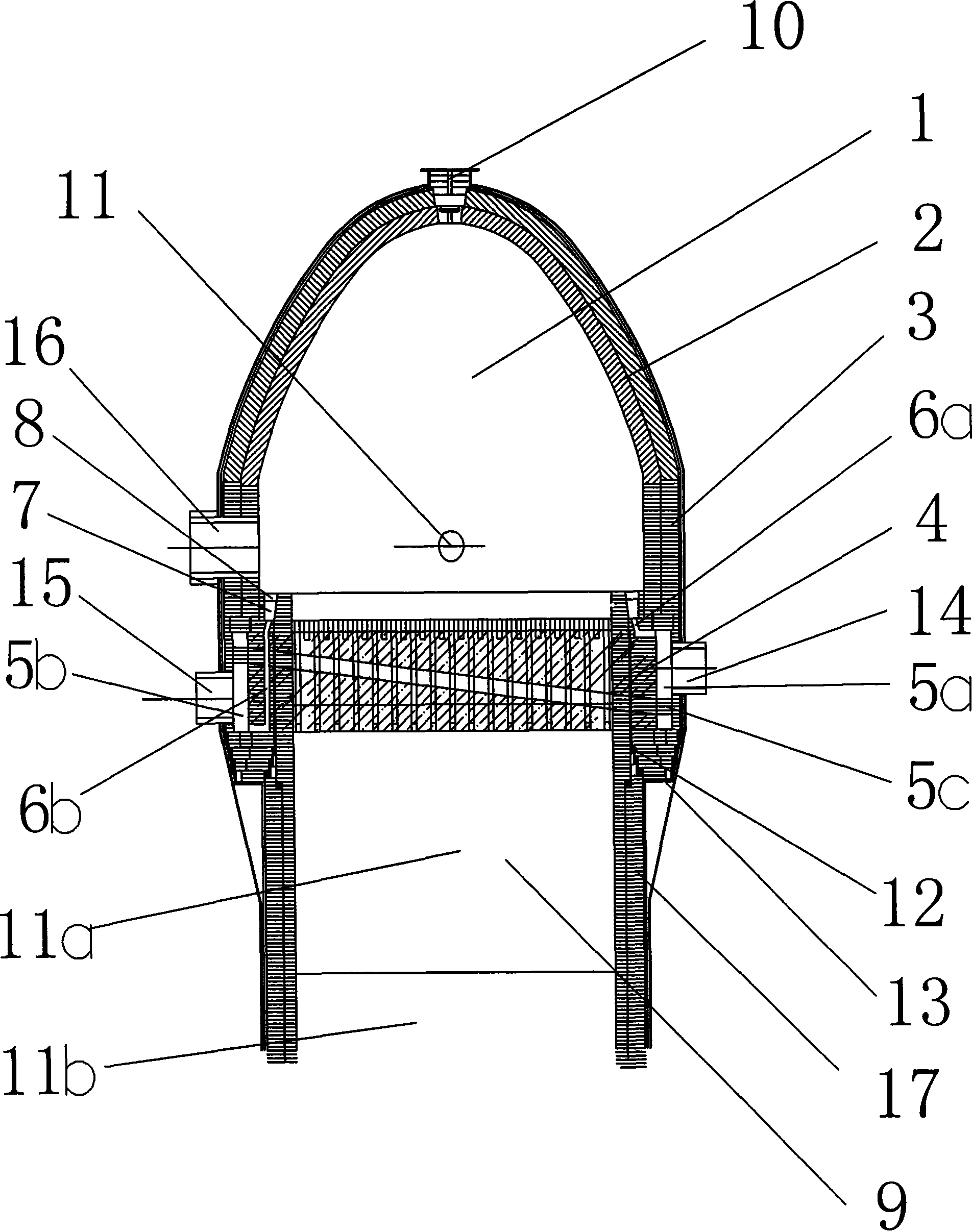

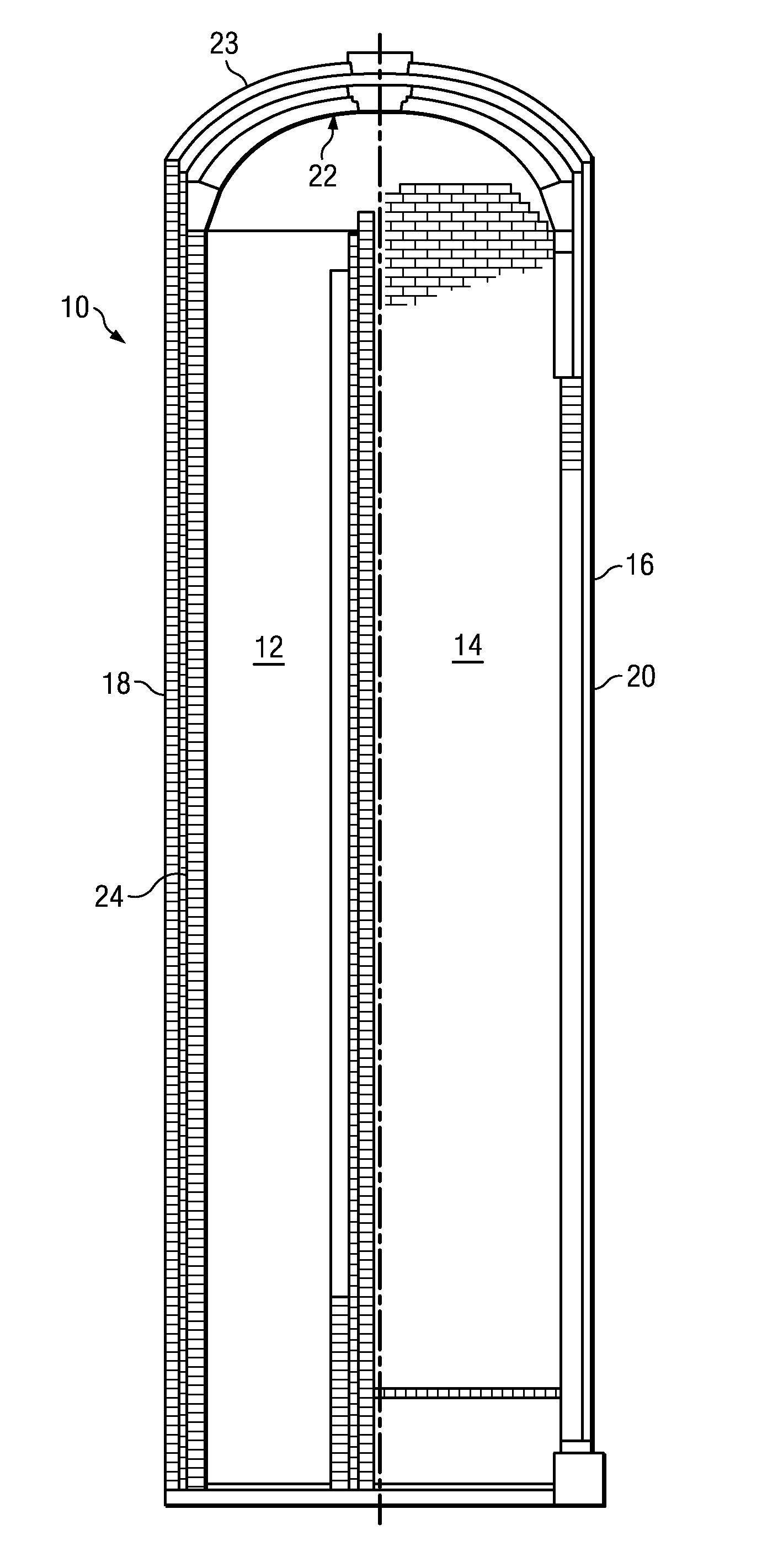

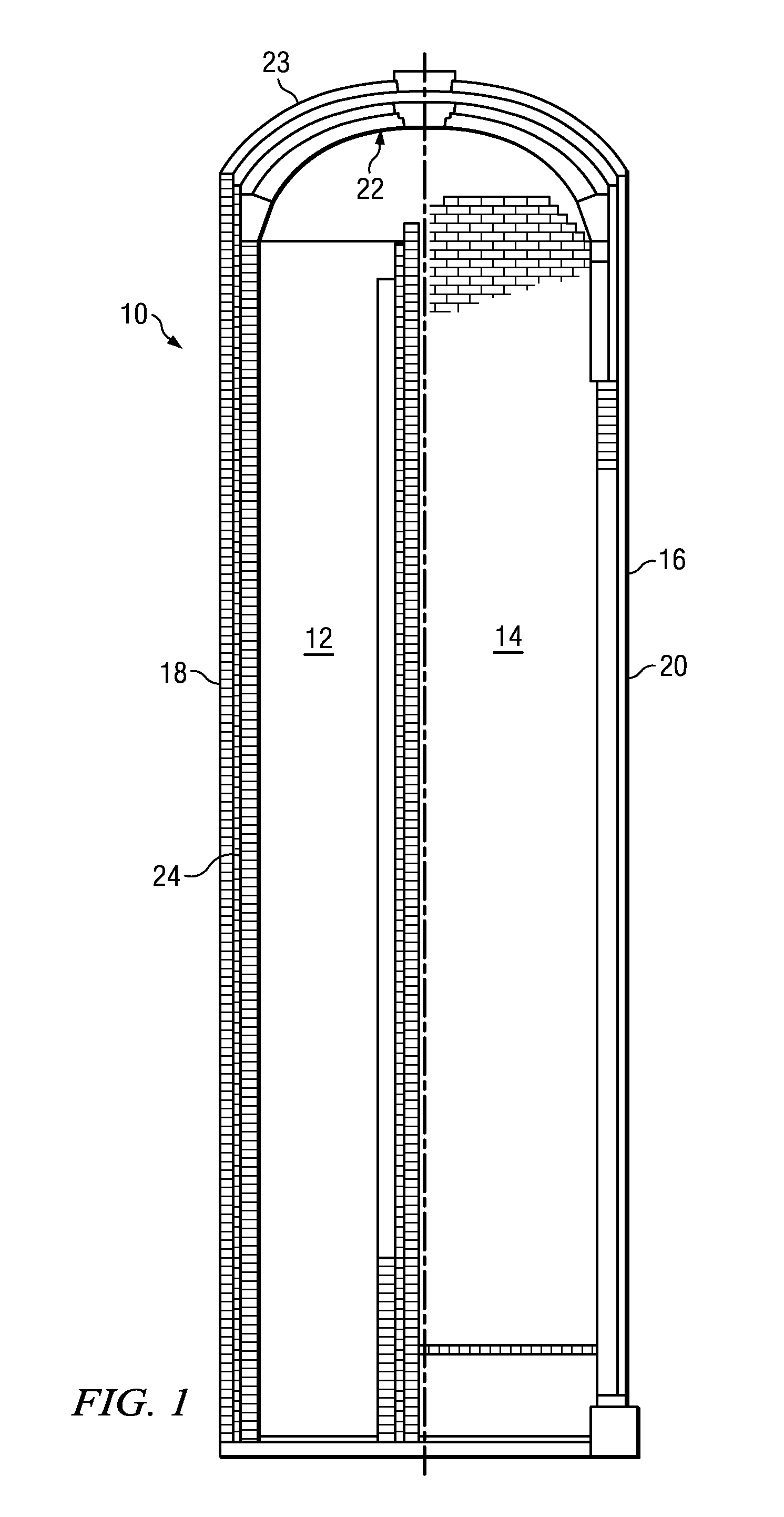

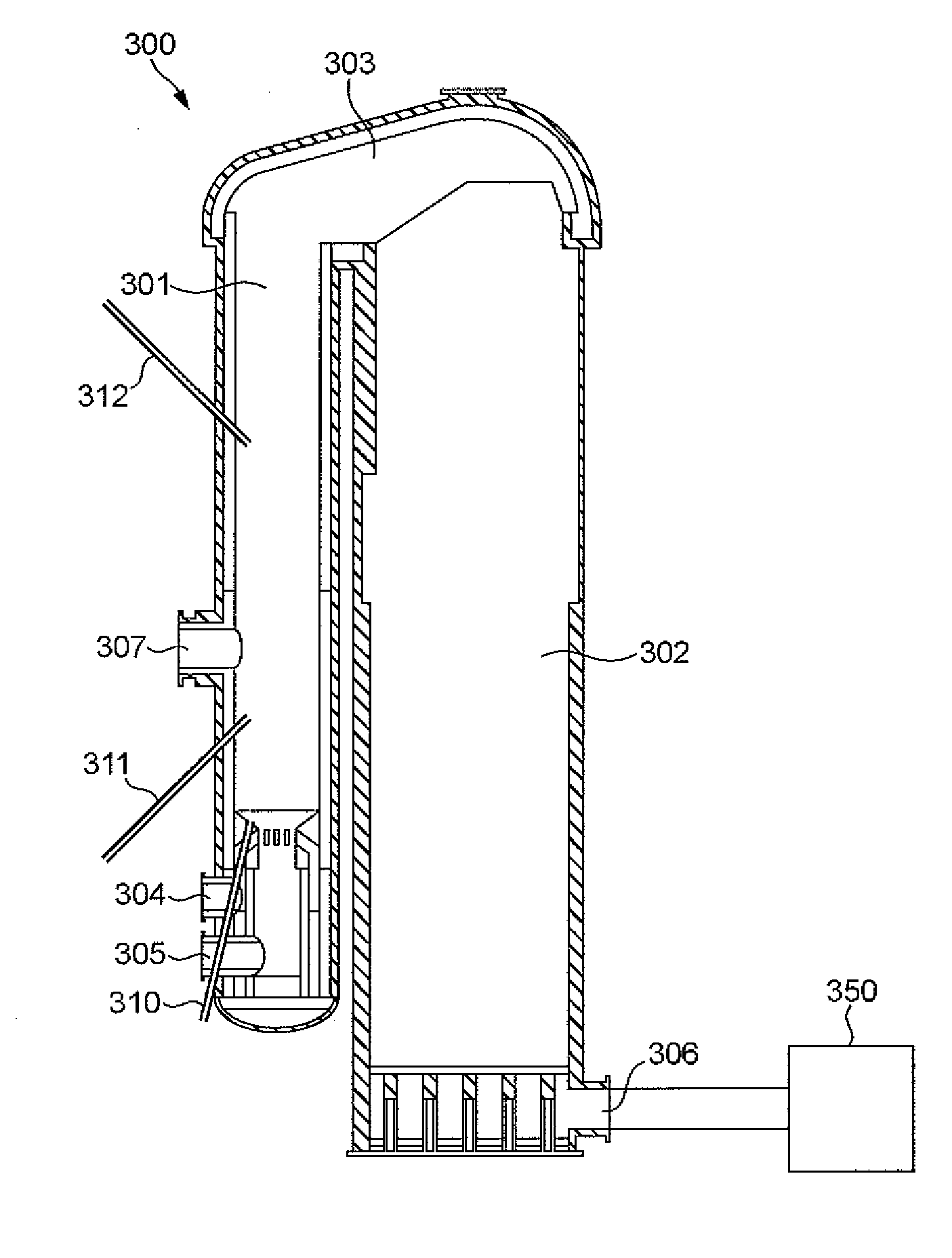

Hot Blast Stove Dome and Hot Blast Stove

ActiveUS20110200958A1Significant engineeringSignificant materialBrick-hot blast stovesLining supportsCombustion chamberEngineering

A hot blast stove dome comprises a first dome portion adapted for support on a combustion chamber wall of a hot blast stove, and a second dome portion adapted for support on a checker chamber wall of a hot blast stove, wherein a vertical expansion joint is provided between the first dome portion and the second dome portion and is adapted to allow the first dome portion and the second dome portion to independently accommodate vertical expansion of their respective supporting walls. The dome is suitably provided in a hot blast stove which comprises a combustion chamber, a checker chamber, a cylindrical housing comprising a combustion chamber wall and a checker chamber wall.

Owner:ALLIED MINERAL PROD LLC

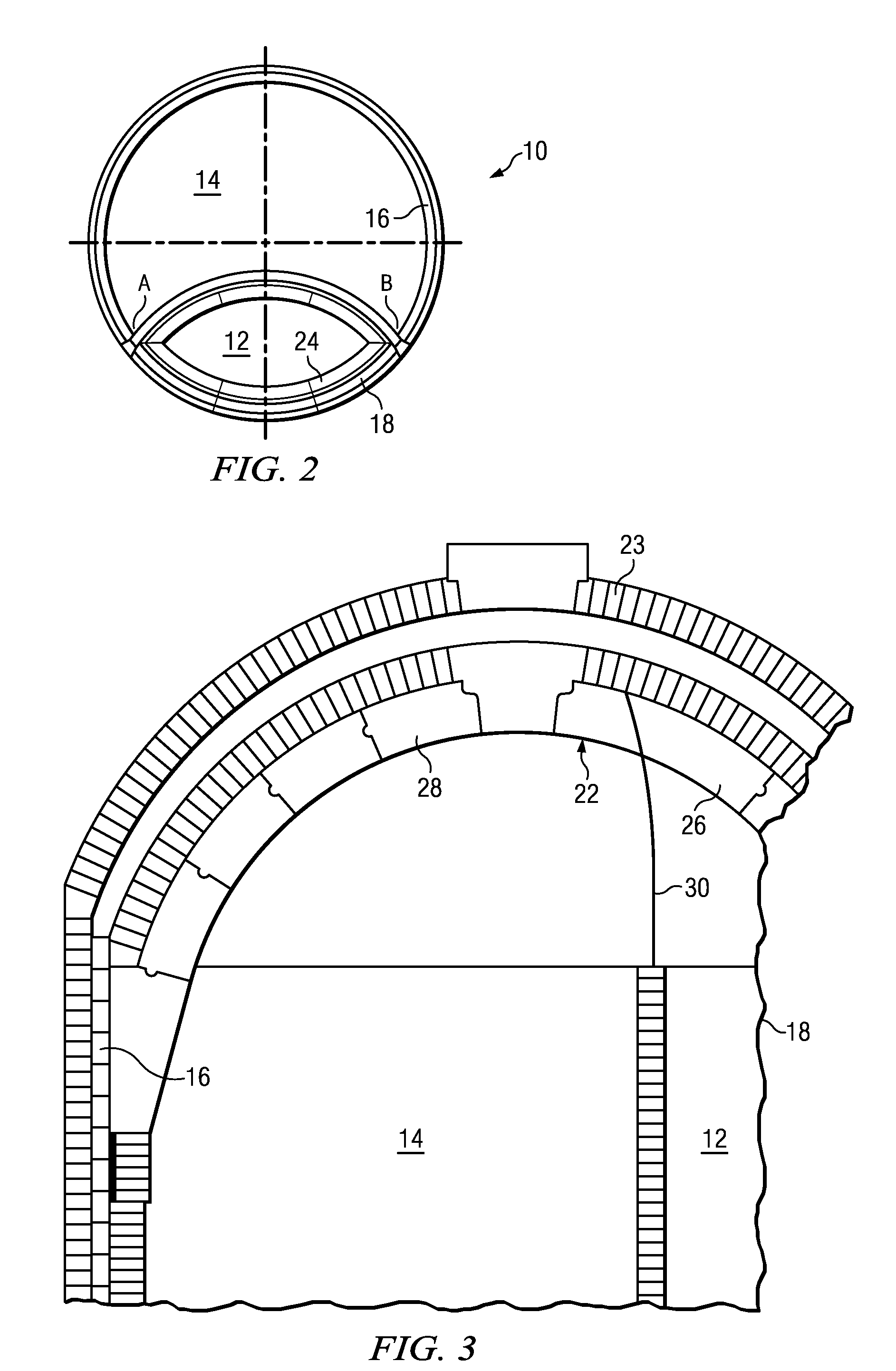

Apparatus and method for heating a blast furnace stove

A method for heating a blast furnace stove includes combusting fuel in a combustion chamber in the stove, providing combustion gases from the combustion chamber to heat refractory material in the stove, recirculating exhausted combustion gases into the combustion chamber, enriching the combustion chamber with oxygen sufficient for maintaining combustion in the combustion chamber without damaging the refractory material in the stove.

Owner:LINDE AG

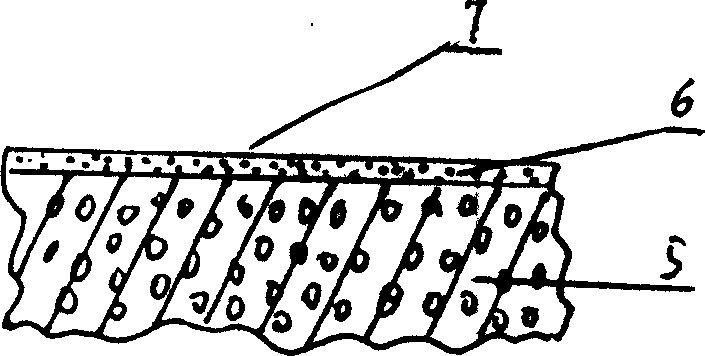

Device for protecting metallic surfaces from high-temperature condensates of corrosive media in technical installations

InactiveUS20090042156A1Improve insulation effectReduce energy consumptionBrick-hot blast stovesFurnace liningsThermal insulationRefractory

The supporting structure of a technical installation made from a material that is not resistant to corrosion and whose inner wall at least temporarily contains a corrosive and abrasive gas-vapor mixture and is protected from acid corrosion by a gas-vapor mixture barrier. This barrier is either placed between a refractory coating (6) and a thermal insulating layer (7) or is integrated into the refractory layer (6) or in the thermal insulating layer (7). The mechanical protection from the permeation of the gas-vapor mixture though the thermal insulation (7) up to the inner wall of the supporting structure allows a thermal insulating material to be selected that has a distinctly reduced thermal conductivity and thus allows the temperature on the exterior of the supporting structure to be lowered reducing energy consumption and improving occupational safety.

Owner:TH JANSEN ARMATUREN

Top combustion type hot air furnace arranging annular flameless combustion device below arch roof of combustion chamber

ActiveCN103484588AGuaranteed uptimeRunning at average speedBrick-hot blast stovesCold airCombustion chamber

The invention relates to a top combustion type hot air furnace arranging an annular flameless combustion device below an arch roof of a combustion chamber, which is used for solving the problems of low mixing rate of coal gas and air and low combustion intensity. The structure is as follows: a wall body of the combustion chamber is shaped like the spherical arch roof, a combustion-supporting ceramic porous body is arranged in the wall body of the combustion chamber, the wall body of the combustion chamber and the wall body of a combustor at the lower part are connected into a whole, a coal gas inlet pipe and an air inlet pipe on the wall body of the combustor are built on a coal gas distribution ring path and an air distribution ring path, a pre-mixed gas spout is arranged at the upper part of a coal gas and air pre-mixing ring path, and a gas flow blocking ring is arranged above the pre-mixed gas spout; and a hot air outlet pipe is arranged on the wall body of the combustor, the inner side of a lower cylindrical body and the outer side of an inner-layer cylindrical wall body at the upper part of the wall body of a heat accumulation chamber are mutually sheathed and connected in a slippage manner via a ladder joint type labyrinth hermetic connection structure, a porous heat accumulation body is arranged in the heat accumulation chamber, a cold air chamber is constituted between the wall body of the heat accumulation chamber at the lower part of a furnace grate and the bottom of the furnace, and a flue gas outlet pipe and a cold air inlet pipe are arranged on the wall body of a cold air chamber. The top combustion type hot air furnace provided by the invention can save fuel and reduce the temperature of waste gas and the emission of harmful gas.

Owner:陈维汉

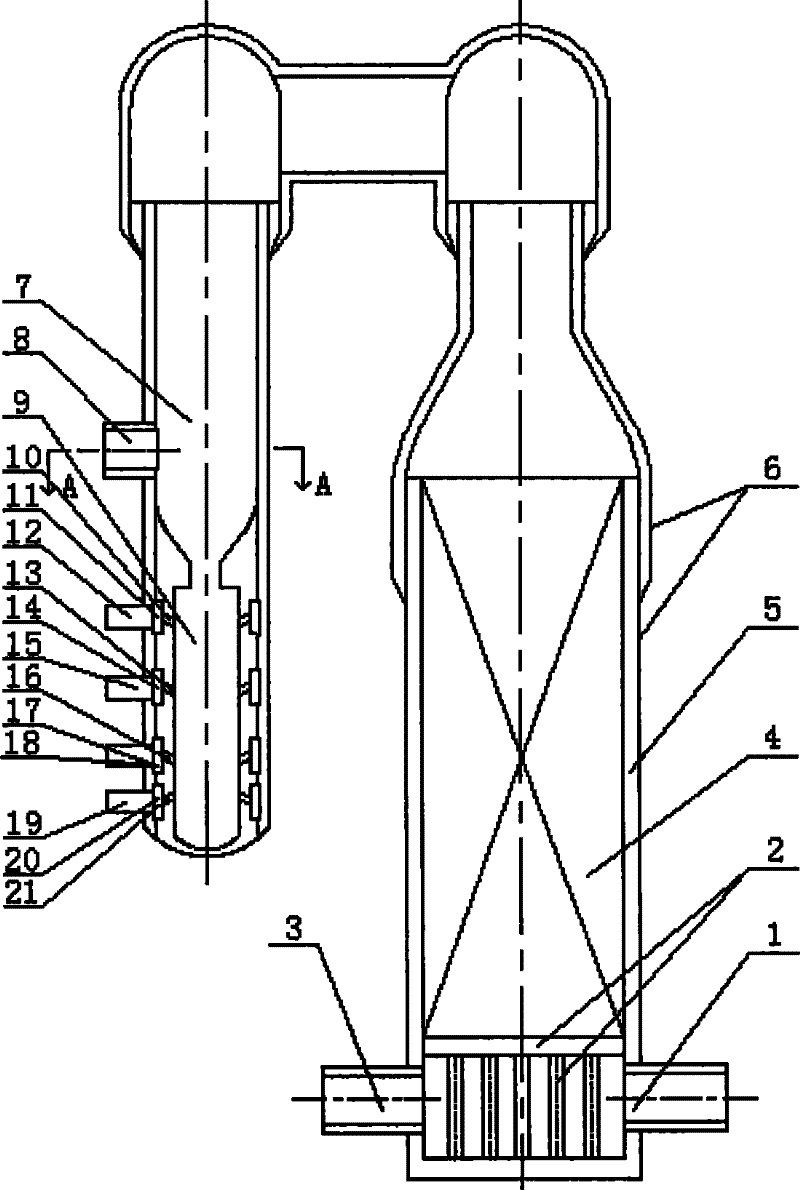

High-temperature low-oxygen external combustion stove

The invention relates to a high-temperature low-oxygen external combustion stove, belonging to the technical field of hot-blast stoves. The high-temperature low-oxygen external combustion stove comprises a cold air inlet, a grate, a supporting column, checker bricks, a heat accumulation chamber, a stove lining, a stove shell, a high-temperature low-oxygen combustor, a combustion chamber, an arch crown, a hot air outlet and a smoke outlet, wherein the combustion chamber and the heat accumulation chamber of the external combustion stove are respectively positioned in two independent cylindrical shells; the combustion chamber is connected with the heat accumulation chamber through a cylindrical channel in the space of the arch crown; the high-temperature low-oxygen combustor for fractional combustion is arranged at the bottom of the combustion chamber; the high-temperature low-oxygen combustor comprises two groups of gas inlets, loops and spouts, two groups of air inlets, loops and spouts, and an air and gas precombustion chamber; and combustion-supporting air of which the temperature is higher than 800 DEG C entrains combustion products through fractional combustion and high-temperature air flow in the high-temperature low-oxygen combustor to dilute the oxygen-containing volume concentration of a reaction zone. The invention is suitable for hot-blast stoves used for blast furnace ironmaking and smelting reduction ironmaking in ironmaking industries or other industrial technical fields in which the gaseous medium needs to be heated to the temperature higher than 1000 DEG C.

Owner:BEIJING SHOUGANG INT ENG TECH

Combustion chamber wall and a method of manufacturing a combustion chamber wall

A combustion chamber wall is hollow, has a first surface and a second surface and includes a plurality of polyhedron shaped chambers defined by a matrix of integral interconnected walls. The walls of the chambers in a first layer define the first surface of the combustion chamber wall and the walls of the chambers in a third layer define the second surface of the combustion chamber wall. The chambers are fluidly interconnected by apertures extending through the integral interconnected walls of the chambers for the flow of coolant there-between. The walls of the chambers in the first layer have apertures extending there-through to supply coolant into the first layer and the walls of the chambers in the third layer have apertures extending there-through to supply coolant from the third layer into the combustion chamber. The combustion chamber wall is manufactured by additive layer manufacture.

Owner:ROLLS ROYCE PLC

Heat exchanger device with heat-radiative coating

InactiveUS20120208142A1Facilitate heat exchangeHighly-efficient and energy-savingBrick-hot blast stovesStorage heatersDecompositionAbsorbed energy

A heat retainer for a hot blast stove of a blast furnace, the heat retainer adapted to function without decomposition at temperatures of about 1200° C., wherein: at least one surface of said heat retainer is coated with a high radiative and highly-emissive material forming said coating layer; the thickness of said coating layer is critically between 0.02 mm and 3 mm; the heat retainer absorbs energy or emits energy mainly by radiation; and energy of radiation is mainly at a wavelength of 1-5 μm.

Owner:ZHOU HUIMIN

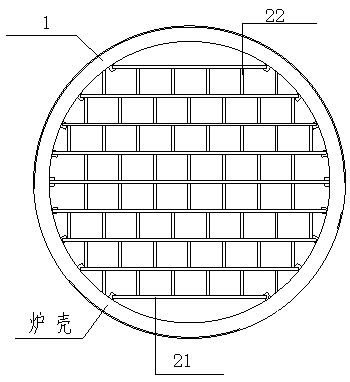

Blast furnace hot-blast stove orifice combination brick structure

ActiveCN103088179AEliminate lossesEliminate the bad condition of collapseBrick-hot blast stovesFurnace componentsThermal engineeringEllipse

The invention provides a blast furnace hot-blast stove orifice combination brick structure relating to the technical field of thermal engineering. Based on a key technology of building an elliptical ring by ingeniously using T-shaped and L-shaped refractory bricks, according to the practical situation of the diameter size of a blast furnace hot-blast stove orifice, the combination brick structure is composed of an outer ring, a neighboring outer ring, an inner ring and a neighboring inner ring, wherein the outer ring and the neighboring outer ring of which the inner diameters are shaped like an ellipse are built by using one T-shaped refractory brick for the ring top and the ring bottom respectively and using L-shaped refractory bricks both sides of the ring; the inner ring and the neighboring inner ring of which the outer diameters are shaped like an ellipse are built by using sealed refractory bricks; the outer ring and the neighboring outer ring as well as the inner ring and the neighboring inner ring are fixedly connected by refractory cement in a mutual sticking state; the elliptical ring of the outer ring and neighboring outer ring is fixedly connected by refractory cement in a state of being sleeved with the inner ring and the neighboring inner ring; and the bending angle of the L-shaped refractory bricks is 1-180 degrees. The invention is used for the manufacturing of a blast furnace hot-blast stove orifice. The combination brick structure is scientific and ingenious in design, high in production efficiency and excellent in quality, and can resist a harsh environment.

Owner:ZHENGZHOU ANNEC IND

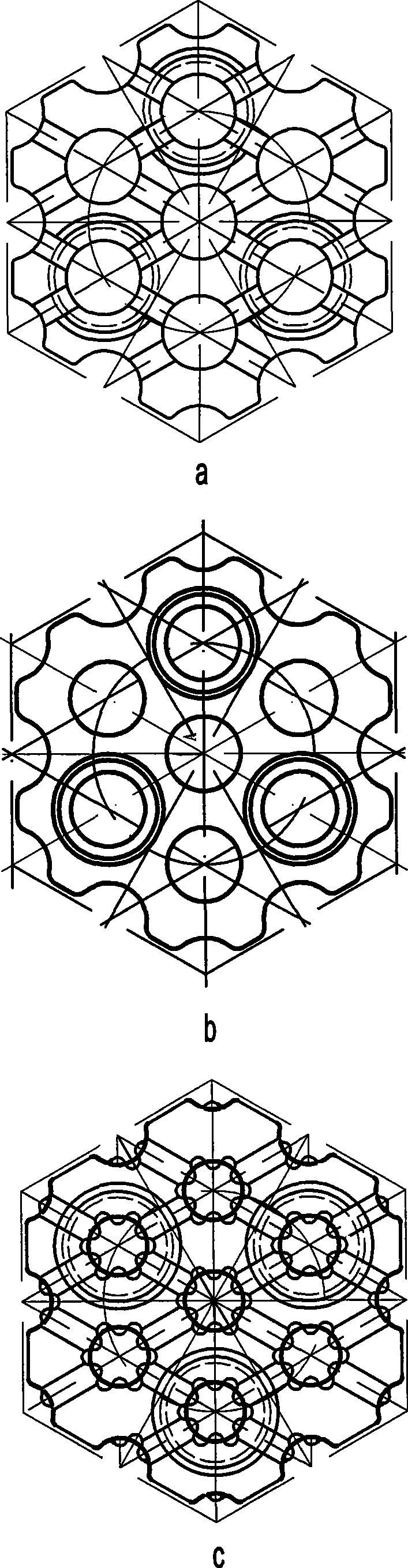

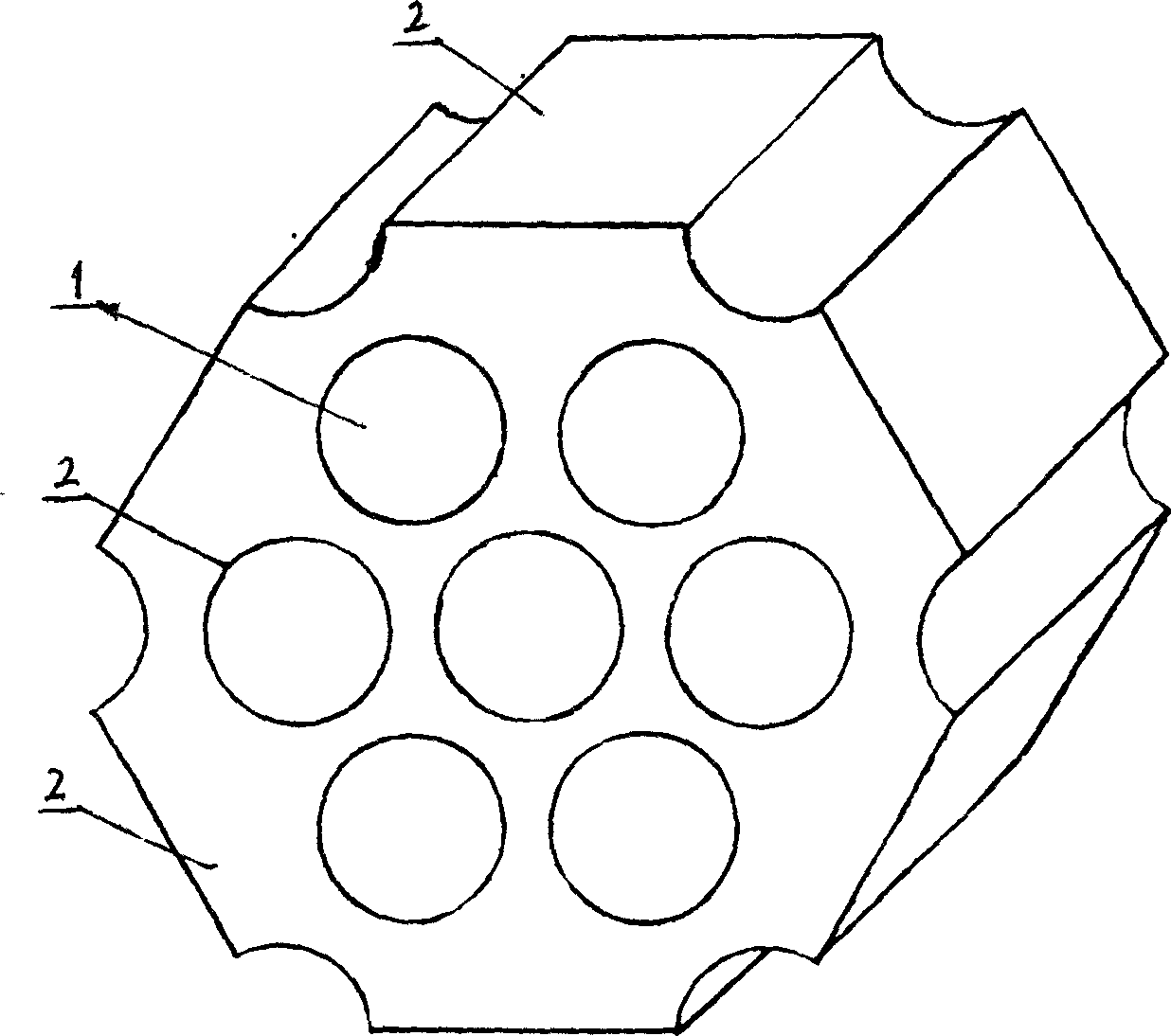

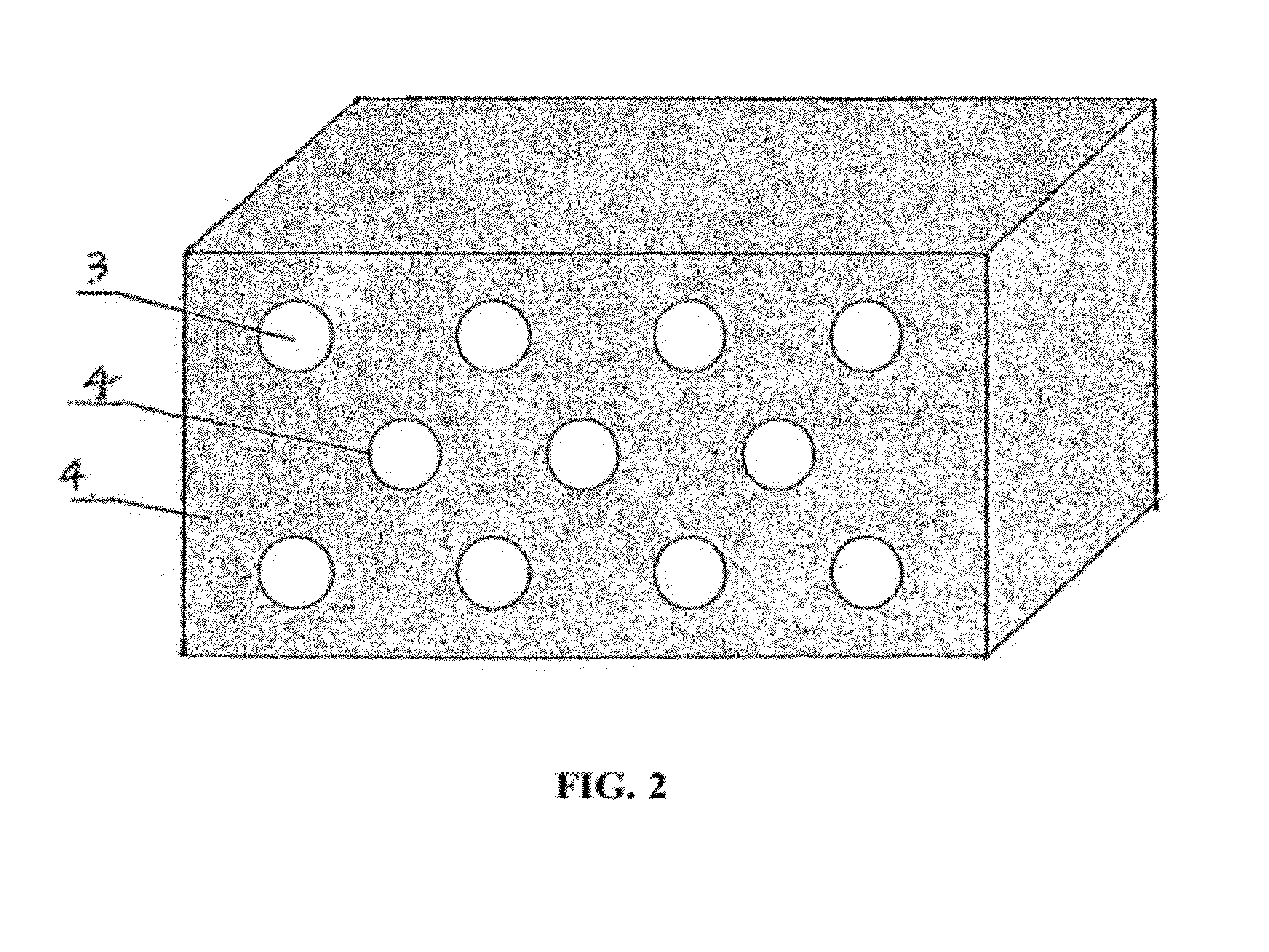

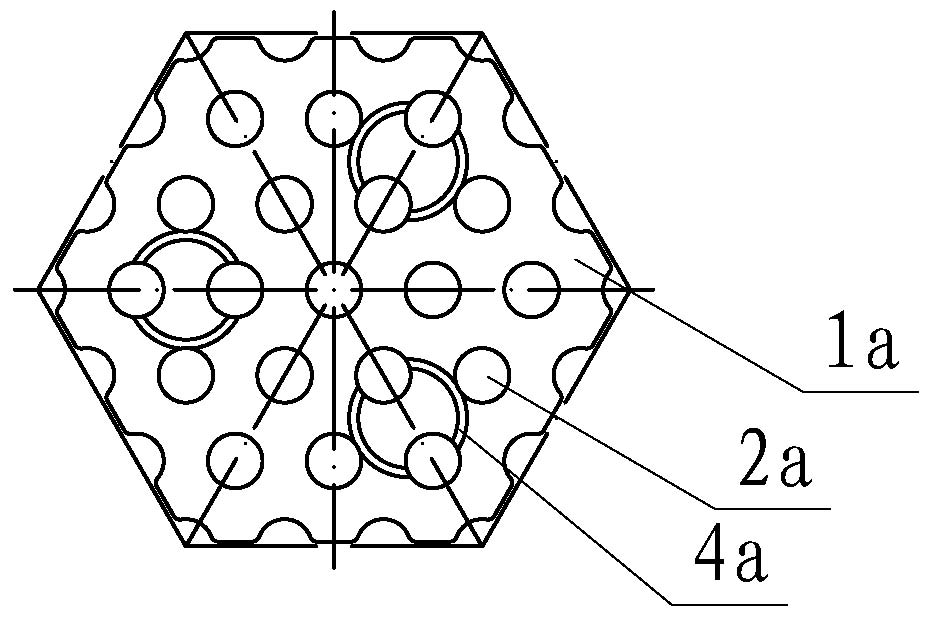

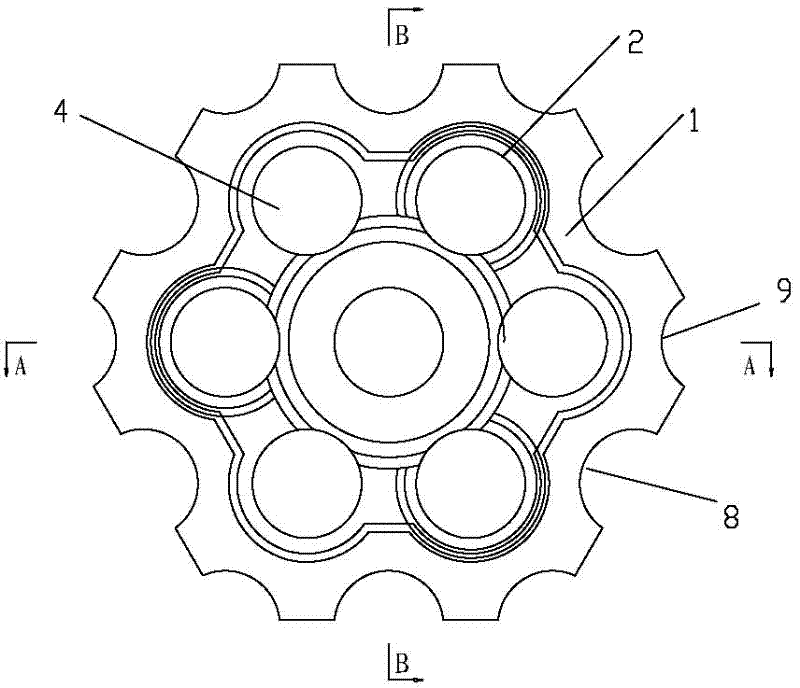

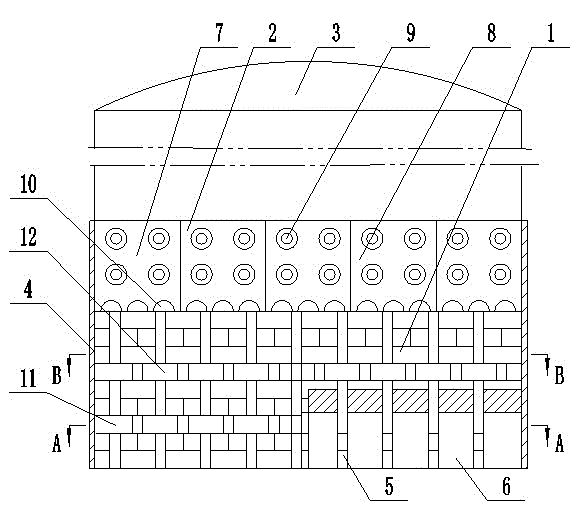

Combination checker brick with two types of different brick structures

ActiveCN102352420ARealize the function of voltage regulation and current equalizationImprove heat transfer performanceBrick-hot blast stovesBrickEngineering

The invention relates to a combination checker brick with two types of different brick structures, which can effectively solve the problem of improving the heat exchange capability under the condition of the heat exchange area of the given unit volume of the heat storage checker brick, is a regular hexagon which consists of a 19-hole checker brick part and a 37-hole checker brick part, a conical lattice hole is respectively arranged between the two end surfaces of the 19-hole checker brick part and the 37-hole checker brick part, a total of seven grooves of round grooves and central grooves are arranged at the lower side of each checker brick, positioning bosses are arranged at the upper side of each checker brick and correspond to the round grooves alternatively, the hole pitch of the 37-hole checker brick part is 0.75 time of that of the 19-hole checker brick part, and the 19-hole checker brick part and the 37-hole checker brick part are mutually combined to form the combination checker brick. The combination checker brick fully realizes the airflow pressure regulating and flow equalizing functions and improves the heat transfer effect between the airflow and a lattice porous wall side, so convenience is brought to regulate the heat exchange capability of different upper and lower parts of a heat accumulator.

Owner:河南省豫兴热风炉工程技术有限公司

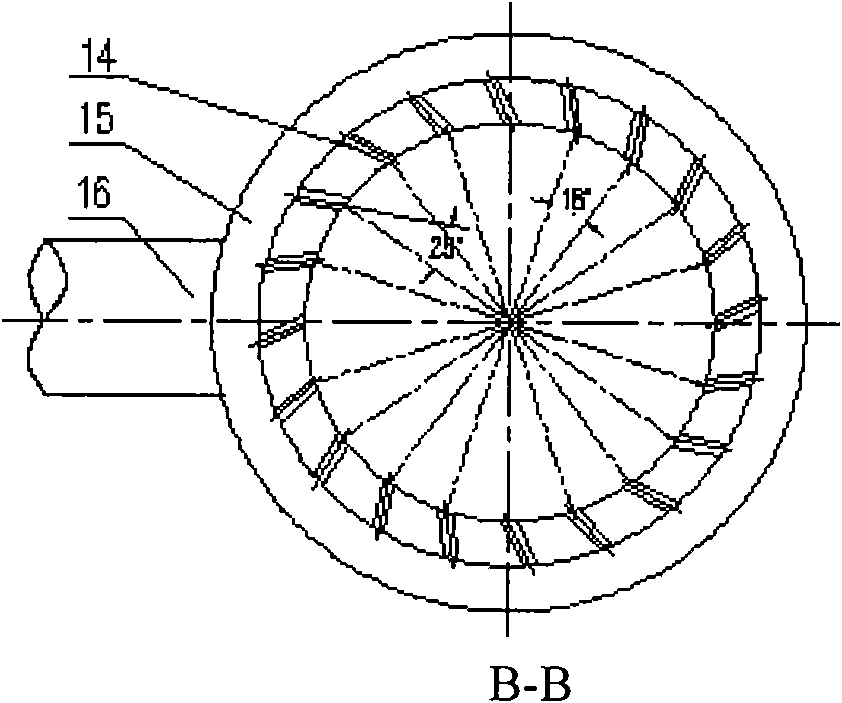

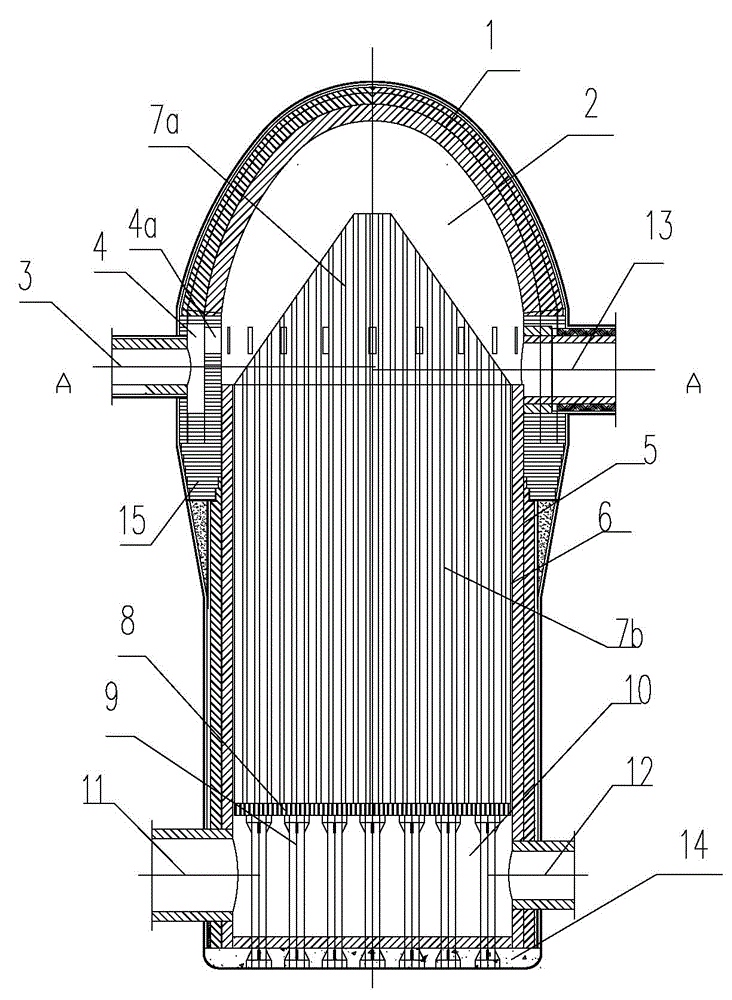

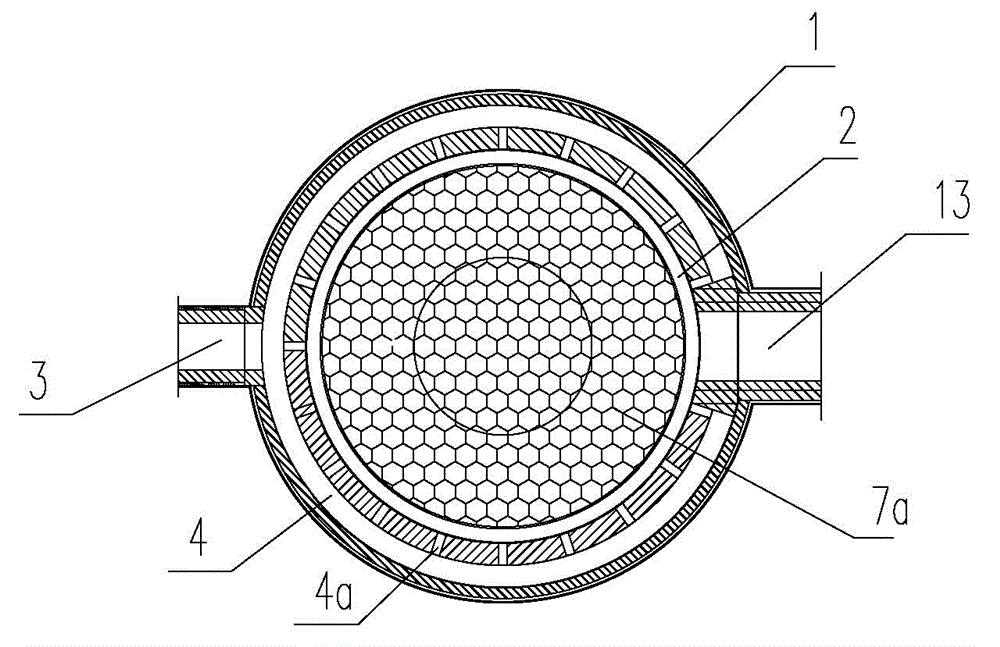

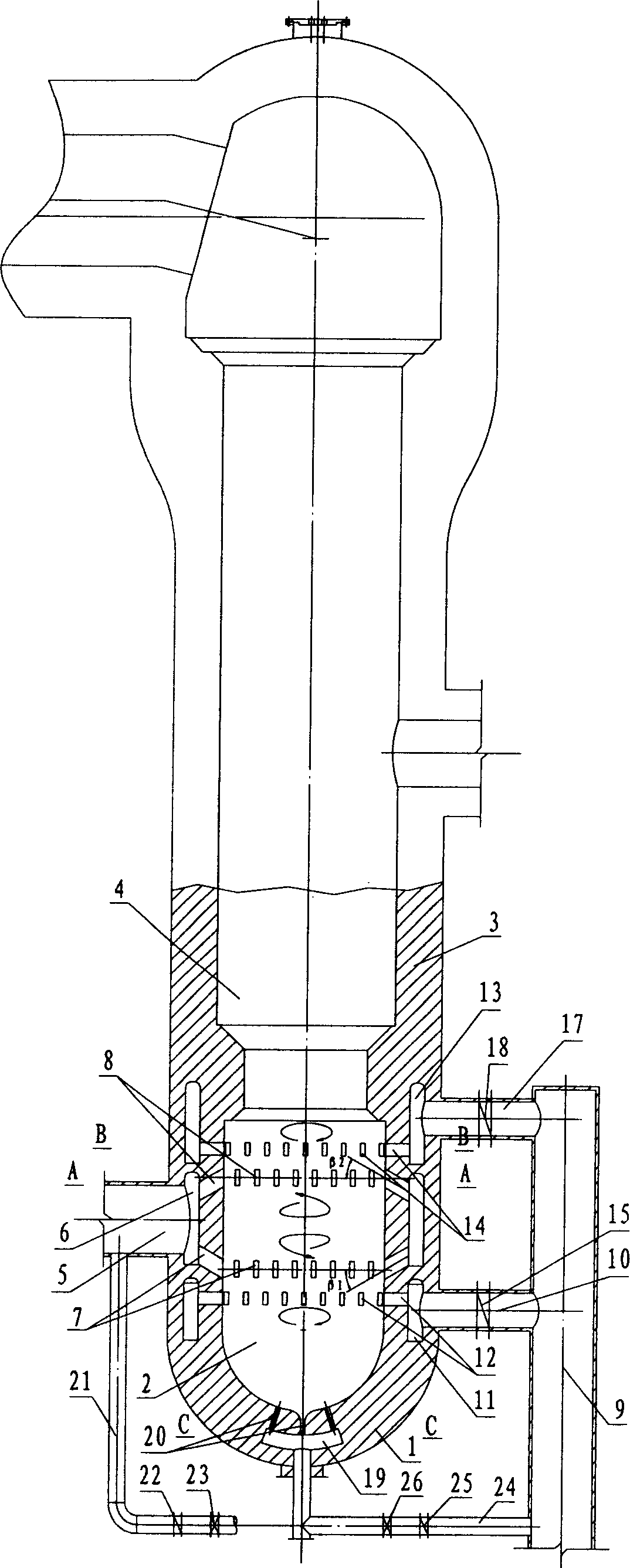

Hot blast heater realizing preheated combustion of horizontal spraying heat accumulator of premixed air flow of gas and air

InactiveCN102719584AReduce manufacturing costImprove completenessBrick-hot blast stovesCold airCombustion chamber

The invention relates to a hot blast heater realizing preheated combustion of a horizontal spraying heat accumulator of premixed air flow of gas and air, effectively solving the problems that the mixing is slow and nonuniform, the combustion strength is insufficient and incomplete, larger combustion chamber is required, and a combustor is complex. The hot blast heater has the structure as follows: a hot air outlet pipe and a mixed air flow inlet pipe are arranged on the wall of a combustion chamber; a distribution annular channel communicated with the mixed air flow inlet pipe is arranged in the inner wall of the wall of the combustion chamber; a spray nozzle communicated with the combustion chamber in the wall of the combustion chamber is arranged at the inner side of the distribution annular channel; a grate positioned in a cold air chamber is arranged on the lower part of a heat accumulation chamber on the lower part of the combustion chamber; a heat accumulator is arranged in the heat accumulation chamber; a support pillar fixed at a blast bottom is arranged on the lower part of the grate; the grate, the wall of the hot blast heater and the grate bottom form the cold air chamber; an exhaust gas outlet pipe and a cold air inlet pipe are arranged on the cold air chamber; and a labyrinth connection structure is formed between the upper part of the wall of the hot blast heater and the lower part of the wall of the combustion chamber. According to the invention, a simple sleeve combustor is adopted, and high-strength combustion is realized by virtue of the heat accumulator, the structure of the hot blast heater is simplified and is compact so that the investment cost is reduced, and the hot blast heater is stable in structure.

Owner:郑州豫兴热风炉科技有限公司

Thermal insulation method of silica brick hot blast stove

InactiveCN104232825ATo achieve the purpose of heat preservationReduce consumptionBrick-hot blast stovesCold airCombustion

The invention discloses a thermal insulation method of a silica brick hot blast stove. The thermal insulation method comprises the following steps: 1) stove firing circulation: when the temperature at the arch crown is lower than a first temperature or the temperature of silica bricks in the middle of the stove is close to a second temperature, starting stove firing; when the temperature at the arch crown achieves a third temperature or flue temperature achieves a fourth temperature, stopping stove firing and starting thermal insulation; when the temperature at the arc crown is stable and the flue temperature is heated to the fourth temperature, stopping circulation of stove firing, and adopting back-blowing stove firing; and 2) back-blowing stove firing: introducing combustion-supporting air into a cold air pipeline, and providing back-blowing cold air for a hot-blast stove, when back-blowing achieves arch crown and the temperature is not increased and begins to decline, stopping back-blowing, performing thermal insulation by adopting firing stove circulation, and sequentially circulating. The stove firing and air supply integration can be realized by utilizing the self pipeline of the hot-blast stove, and the thermal insulation purpose of the silica brick hot-blast stove can be achieved; the energy consumption can be reduced while the thermal insulation purpose can be met; and the operation is simple and easy and can be realized by utilizing the original pipeline of the hot-blast furnace without the need of new equipment, thus being small in investment.

Owner:LAIWU IRON & STEEL GRP

Top burning type hot blast stove with thermal insulation layer in precombustion chamber

ActiveCN1727498AReduce expansion stressReduce thermal stressBrick-hot blast stovesBlast furnace detailsCombustion chamberThermal insulation

A top combustion type hot air furnace with thermally isolating layer for preburning chamber features that said thermally isolating layer can prevent the transfer of heat from preburning chamber to the internal walls of annular gas cavity and annular air cavity to lower their temp and decrease their temp stress and thermal expansion, so elongating the service life of hot air furnace. A heat isolating layer is also arranged in the second liner between annular gas and air cavities. A movable heat isolating cover is arranged between preburning and burning chambers.

Owner:SHANDONG PROVINCE METALLURGICAL ENG CO LTD

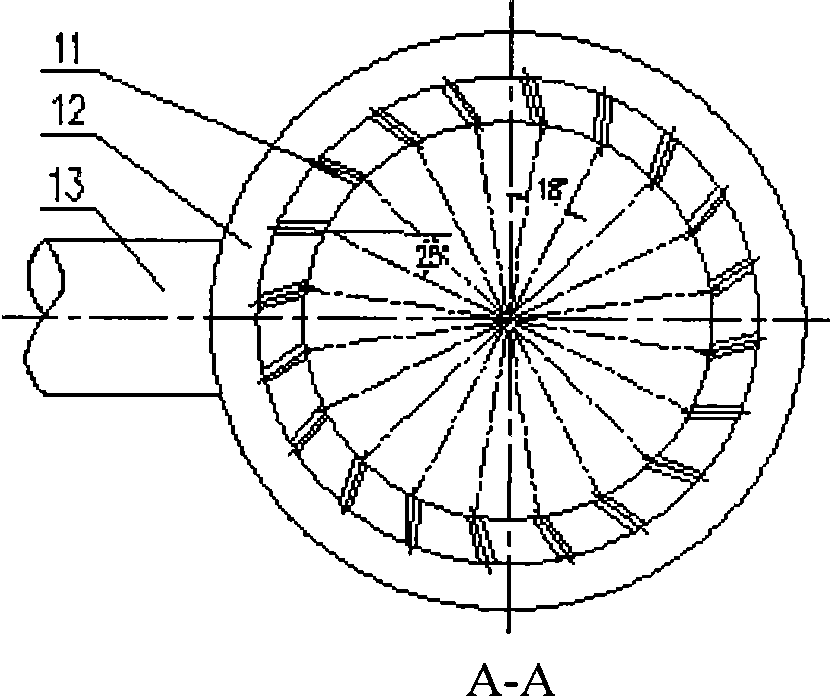

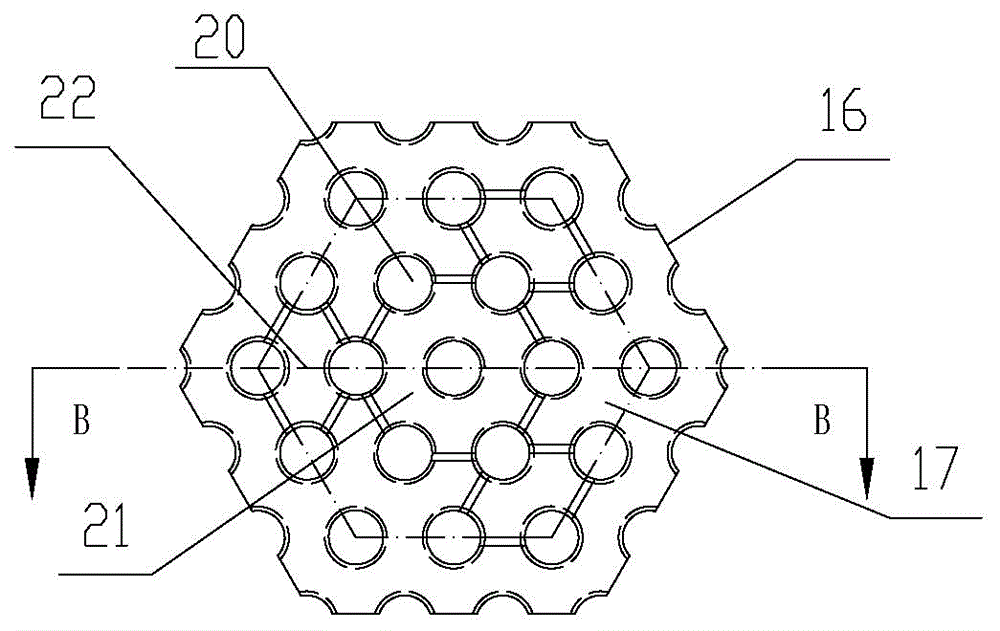

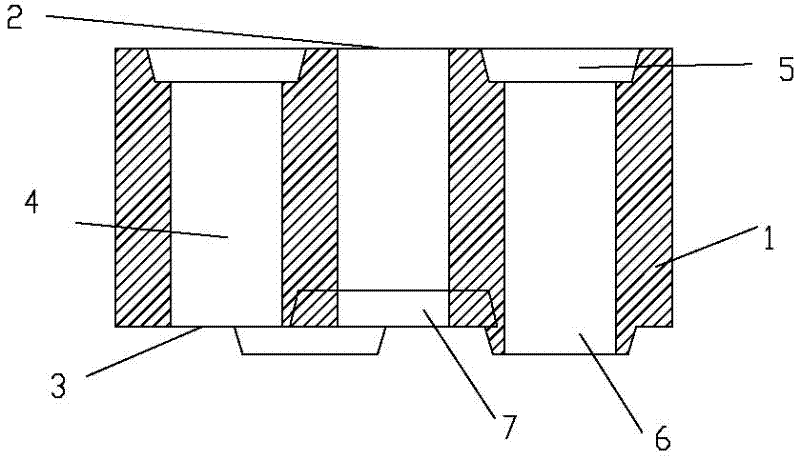

Pressure-balancing flow-balancing honeycomb checker brick

ActiveCN102392090ADoes not affect passingDisplacement is not easy to produceBrick-hot blast stovesProcess efficiency improvementHoneycombAir volume

The invention relates to a pressure-balancing flow-balancing honeycomb checker brick, which can effectively solve the problems of low through hole rate, strong intense pulse generation, nonuniform air volume, and short service life; the checker brick comprises a brick body and through holes; the brick body is a regular hexagonal cylinder; the through holes are uniformly distributed on the brick body; the axis of the through holes is vertical to the cross section of the brick body; the upper ends are smaller than the lower ends of the through holes; and thus conic through holes of the checker brick are formed; an upper end surface annular groove is disposed outside the periphery of a central hole on the upper end surface of the brick body, adopts the central hole as a center, and is bendedas an arc; the upper end surface annular groove is communicated with an intersectant conic through hole; three bosses are uniformly distributed on the lower end surface of the brick body; round grooves with the central hole as a center are disposed among the three bosses; the conic through holes are communicated with the round grooves; conic grooves which occupy half of the through hole cross sections are uniformly distributed on each side surface of the brick body; the invention has a lot of gas channels, and good using effect; balanced exchange of gas flow is realized vertically and horizontally; deformation or displacement is not easy to occur, and the service life of the regenerative chamber checker brick is prolonged.

Owner:刘世聚

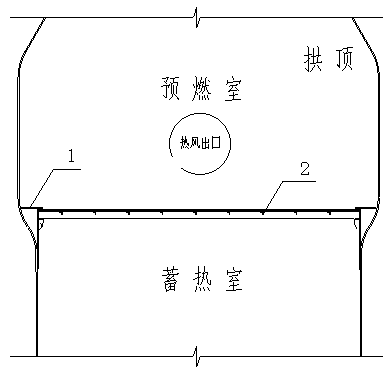

Top-combustion type hot-blast stove refractory material sectioned masonry construction method

InactiveCN107739766AGuarantee the quality of masonryImprove construction efficiencyBrick-hot blast stovesBrickHot blast

The invention relates to the field of metallurgical engineering construction, in particular to a top-combustion type hot-blast stove refractory material sectioned masonry construction method. The top-combustion type hot-blast stove refractory material sectioned masonry construction method is characterized by comprising the steps that 1, a platform is reasonably designed and erected according to the size of the construction platform needing to be erected on a brick holder and the mass of people, objects and machines on the platform, and it is guaranteed that the platform meets the safety requirements; 2, the construction platform in the step 1 is erected on the brick holder; and 3, refractory material masonry is simultaneously conducted on a regenerative chamber on the lower portion of a furnace body and a pre-combustion chamber above the construction platform. According to the top-combustion type hot-blast stove refractory material sectioned masonry construction method, the construction platform is erected on the brick holder at a hot air outlet, thus refractory material sectioned simultaneous construction on the lower regenerative chamber and the upper pre-combustion chamber is achieved, the construction efficiency is improved while the masonry quality is guaranteed, the construction period is shortened, the construction cost is reduced, and good application prospects are achieved.

Owner:SHANGHAI ERSHIYE CONSTR CO LTD +1

Hot blast stove for preheating combustion in gas and air jet mixed porous body

InactiveCN102277460AFix stability issuesSolve the strength problemBrick-hot blast stovesBlast furnace detailsCombustion chamberBrick

The invention relates to a hot blast furnace for preheating and combusting a gas-air jet mixture in a porous body, which effectively solves the problems of non-uniform gas mixing, insufficient combustion and resource wastage of a hot blast furnace. A porous combination block body is arranged in a flameless combustion chamber in a housing, a premixed gas intake pipe on the flameless combustion chamber is connected with a gas intake pipe and an air intake pipe through a jet premixer, and a flow guide block is partitioned in the premixed gas intake pipe. A hot blast outlet pipe is arranged on the flameless combustion chamber, the lower part is butted with a conical regenerative chamber, a cylindrical heat accumulation chamber is arranged below the conical heat accumulation chamber, and lattice brick heat accumulators are arranged in the conical regenerative chamber and the cylindrical heat accumulation chamber. A smoke exhaust pipe and a cold blast inlet pipe are arranged on a cold blastchamber below the cylindrical heat accumulation chamber, lattice brick heat accumulators are arranged on a furnace grill, and pillars below the furnace grill are fixed on a pedestal. Through the hot blast furnace, gas and air are quickly, stably and intensively combusted through jet mixing, the manufacturing cost is effectively lowered, and the heat transfer and heat accumulation effects of lattice bricks are improved.

Owner:ZHENGZHOU YUXING REFRACTORY MATERIAL

Highly regenerative fireproof ball

The heat accumulating refractory ball consists of high-aluminum alumina as aggregate 58-62 wt%, refined bauxite as stuffing 29-31 wt%, high-grade white clay as high temperature adhesive 9-11 wt% and paper pulp as adhesive 3 wt%. The high-aluminum alumina contains Al2O3 not less than 70 % and has granular size of 2-4 mm, the refined bauxite contains Al2O3 not less than 85 % and has granular size of 300 mesh, and the while clay contains Al2O3 not less than 36 %. The refractory ball of the present invention has good heat accumulating performance, bulk density of 2.6 g / cu cm and strength of 25 KN each ball, has less scaling and breaking, no jamming of ventilation channel and high heat utilization rate.

Owner:郑州豫兴氮氧结合耐火材料有限公司

Silicon-based dry-type ramming material used for thermal insulation of hot blast stove

InactiveCN107188588AImprove insulation effectReduce heat lossBrick-hot blast stovesBrickCombustion chamber

The invention relates to a silicon-based dry-type ramming material used for the thermal insulation of a hot blast stove. 10-20 weight parts of waste silica bricks with the particle size of 3-5 mm, 20-30 weight parts of waste silica bricks with the particle size of 1-3 mm and 25-35 weight parts of silica with the particle size of 0-1 mm are weighed, matched well and placed in a stirring device for stirring for 1-2 min, 25-35 weight parts of silica with the particle size less than 0.088 mm and 0.5-3 weight parts of boric acid are weighed, matched well and mixed in a premixer for 1-2 min to obtain a fine powder matrix, the fine powder matrix is added into the stirring device for stirring for 3-5 min to obtain the silicon-based dry-type ramming material, the prepared silicon-based dry-type ramming material is poured into gaps among a heat storage chamber of the hot blast stove, a working lining of a combustion chamber and a stove shell, and a thermal insulation layer is formed after uniform ramming. The silicon-based dry-type ramming material has the advantages of being low in thermal conductivity, good in heat-insulating property, and convenient to construct and transport, and the thermal insulation and energy saving effects of the hot blast stove can be effectively improved.

Owner:ZHENGZHOU ANNEC IND

Flame length controllable high-efficient burner

InactiveCN1862091AStrengthen the total heat storage capacityReduce the total heat storage capacityBrick-hot blast stovesGaseous fuel burnerCombustorRefractory

A length-controllable high-efficiency burner comprises a mixed precombustion chamber, a throat section, a middle switch-in port, a middle circuit and a middle nozzle. On the refractory annular block or the pouring body on top of the mixed precombustion chamber is disposed a top circuit with at least one top nozzle. One end of the top nozzle is in communication with the mixed precombustion chamber, and the other end of the top nozzle is in communication with the top circuit connected with a medium branch pipeline.

Owner:WISDRI ENG & RES INC LTD

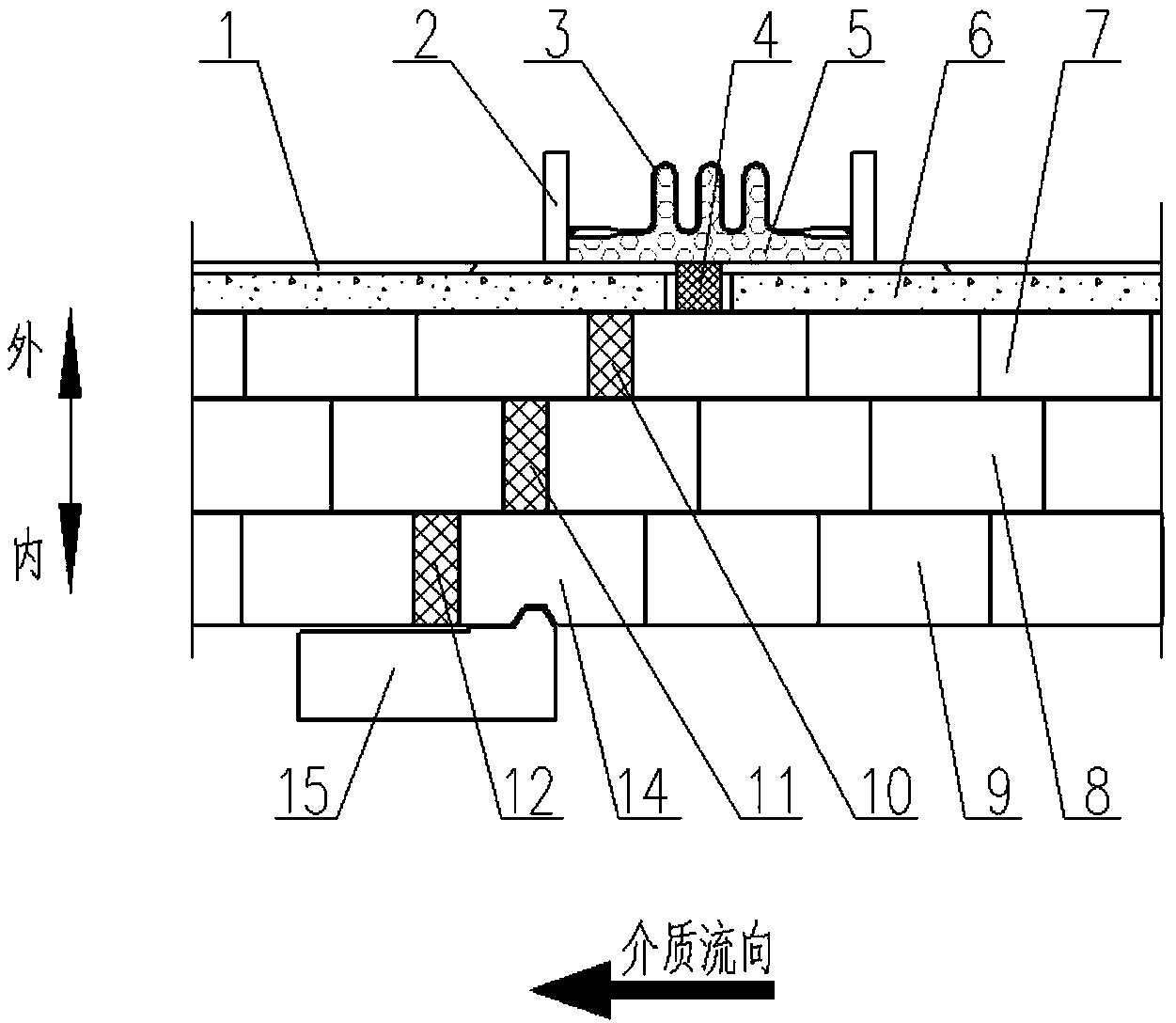

Masonry structure of refractory material in hot-blast stove warm-air pipe ripple compensator

ActiveCN103409573AImprove stabilityStability does not affectBrick-hot blast stovesBlast furnace detailsFiberThermal insulation

The invention discloses a masonry structure of a refractory material in a hot-blast stove warm-air pipe ripple compensator and belongs to the technical field of a hot-blast stove in a metallurgy industry. The masonry structure comprises a pipe steel casing, an annular plate, bellows, an expansion joint, a thermal insulation layer, a refractory spraying material, a first heat-insulating brick layer, a second heat-insulating brick layer, a first refractory brick layer, a first heat-insulating brick expansion joint, a second heat-insulating brick expansion joint, a first refractory brick expansion joint, special-shaped refractory bricks and diversion bricks. The masonry structure has the advantages that the diversion bricks can effectively protect a refractory fiber blanket filled in the expansion joints so that it is avoided that the refractory fiber blanket in a warm-air pipe is carried by high-temperature high-pressure air flows in work; under the dual action of the diversion bricks and the hot pressing, the refractory fiber blanket can stably work for a long time, absorb the heat expansion and protect the bellows; the reverse maze expansion joint is arranged in an air flow reverse direction so that the expansion joint enters into the bellows difficultly and multi-protection of the bellows is realized; and interlocking of the refractory bricks, the special-shaped refractory bricks and the diversion bricks improves integral masonry stability so that the bellows can stably work for a long time.

Owner:BEIJING SHOUGANG INT ENG TECH

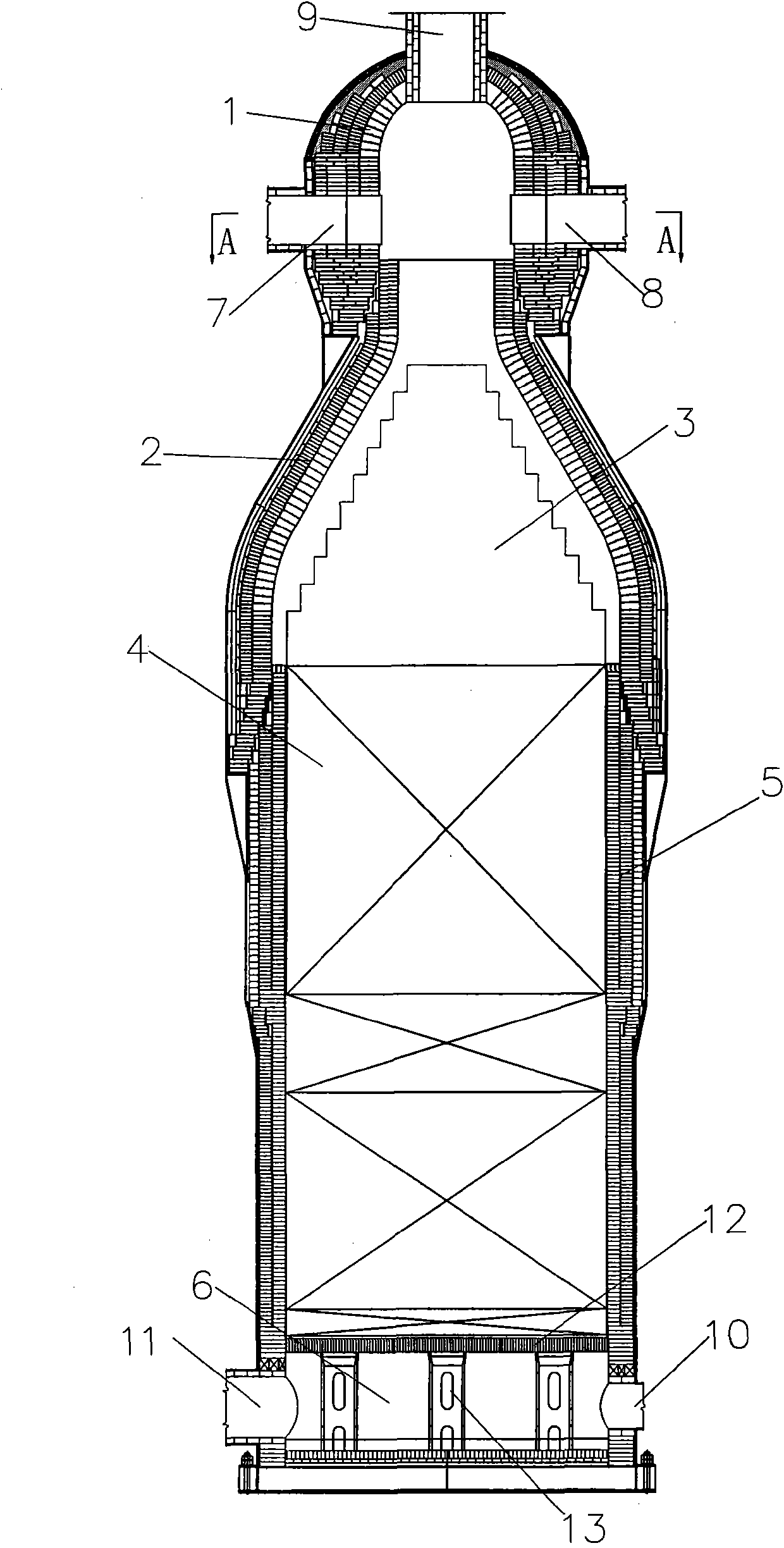

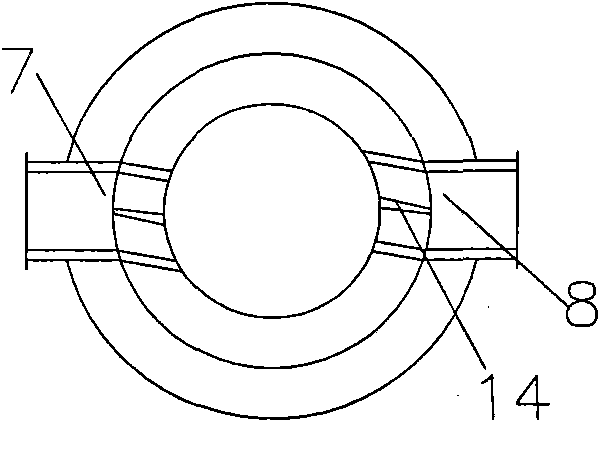

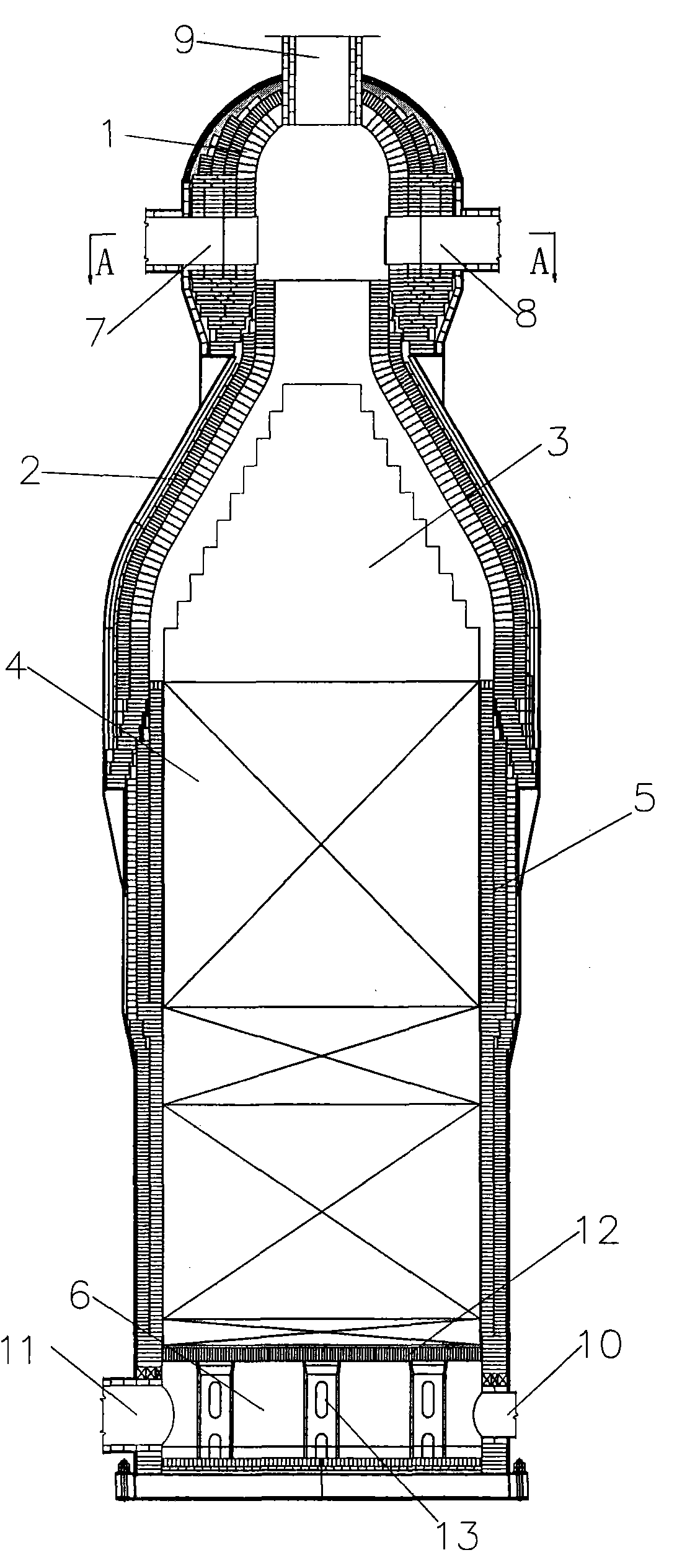

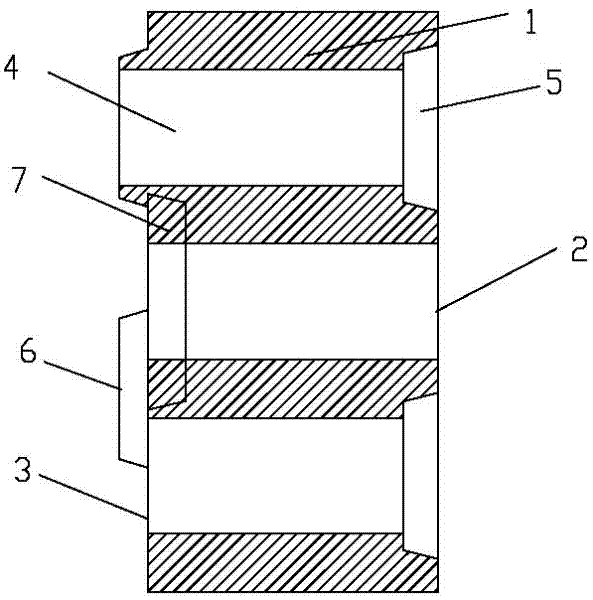

Hot blast stove for refining iron and improved construction process

The invention discloses a hot blast stove for refining iron and an improved construction process. The stove body comprises a straight body segment (1), a hot blast outlet (2), a stage body segment (3), a distribution mixing segment and an arch crown (5), wherein the combustion area (6) of the hot blast stove is arranged inside the stage body segment (3). By adopting the technical scheme, an external combustor is not needed so that the hot blast stove is transformed into a stable and efficient Kalugin type hot blast stove which has long service life , thereby reducing the temperature of the arch crown of the hot blast stove, improving the combustion efficiency, prolonging the service life, solving complex and dangerous maintenance work for welding nozzles in the structure, eliminating the safety potential, reducing the weight of the arch crown structure, improving the structural stability and wind temperature stability, greatly reducing the maintenance working capacity of the hot blast stove crown and providing favorable condition for offering stable high-temperature wind during blast stove production.

Owner:WUHU XINXING DUCTILE IRON PIPES

Blast furnace hot blast stove and construction method thereof

ActiveCN102747177AHigh heat resistanceIncrease the utilization areaBrick-hot blast stovesMaterials scienceBlast furnace

The invention discloses a blast furnace hot blast stove and a construction method thereof, belonging to the technical field of hot blast stoves. With the adoption of the blast furnace hot blast stove and the construction method thereof, the deficiencies of the prior art are overcome, and the blast furnace hot blast stove which is low in manufacture cost and high in heat utilization efficiency andthe method of constructing the blast furnace hot blast stove are provided. A stove wall is in a shape of a cylinder, a plurality of parallel bottom walls are arranged in the stove wall at equal intervals, two ends of each bottom wall are both connected to the stove wall, a main air duct is arranged at one side of the stove wall vertical to the direction of the bottom walls and penetrates through all the bottom walls, a circular stove grate arranged in the stove wall is arranged above the bottom walls, and the stove top is arranged at the upper part of the stove grate. The construction method comprises the following steps firstly, constructing a foundation and the stove wall, and reserving the arched main air duct on the stove wall; secondly, constructing the plurality of parallel bottom walls in the stove wall at equal intervals; thirdly, installing the stove grate at the upper part of the bottom walls; and fourthly, installing the stove top at the upper part of the stove grate. The blast furnace hot blast stove and the construction method thereof are mainly used for metallurgy industry.

Owner:岚县三鑫实业继亨铸造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com