Combination checker brick with two types of different brick structures

A checker brick and brick type technology, applied in the field of combined checker bricks, can solve the problem of heat storage capacity decline and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

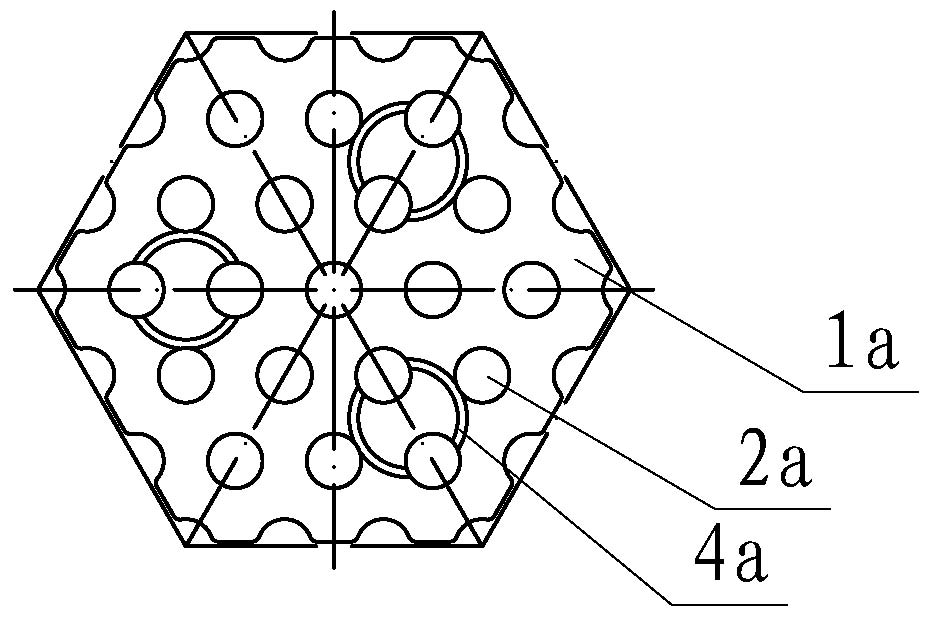

[0012] Depend on Figure 1-Figure 5 Given, the structure of the present invention is a regular hexagon made up of the 19-hole checker brick part 1a and the 37-hole checker brick part 1b, and the 19-hole checker brick part 1a and the 37-hole checker brick part 1b are all regular hexagons of the same size Cylinder, the first tapered lattice hole 2a is evenly and vertically opened between the two end faces of the 19-hole checker brick part 1a, and the second tapered lattice hole 2a is evenly and vertically opened between the two end faces of the 37-hole checker brick part The grid hole 2b is symmetrical to the center on the lower end surface of each grid brick, and six first circular grooves 3a or second circular grooves 3b are arranged at a distance of 60°, plus the first central groove or the second circular groove 3b in the cent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com