Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

140results about How to "Short initial setting time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cement-based composite material used for 3D printing technology as well as preparation method and application thereof

ActiveCN104310918AEasy to get materialsLow costSolid waste managementHouse buildingConstruction 3D printing

The invention provides a cement-based composite material used for a 3D printing technology as well as a preparation method and application thereof. The cement-based composite material is prepared from the following raw materials based on the total weight of the composite material: 33%-40% of cement, 0%-8% of inorganic powder, 32%-38% of tailing machine-made sand, 2.5%-3% of a high-molecular polymer, 0.1%-0.5% of a water reducing agent and 16.7%-20% of mixing water; a composite thickening time control agent, a thixotropic agent, a volume stabilizer and the like are added into a mixture to prepare an inorganic composite material; and then the inorganic composite material can be directly pumped into a 3D printer for building to be applied to construction. The cement-based composite material is an inorganic material and the materials are easily available; a lot of industrial waste materials can be used; therefore, the cement-based composite material is low in cost, energy-saving and environment-friendly; the condensation time can be flexibly controlled, and the material has super early strength, good caking property and strong stability; the requirements of 3D printing construction continuity of the building and the building strength are met so that the house building has good global stability and use safety; and the application and popularization of 3D printing technology can be greatly promoted.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION

Shield synchronous grouting construction method and construction material

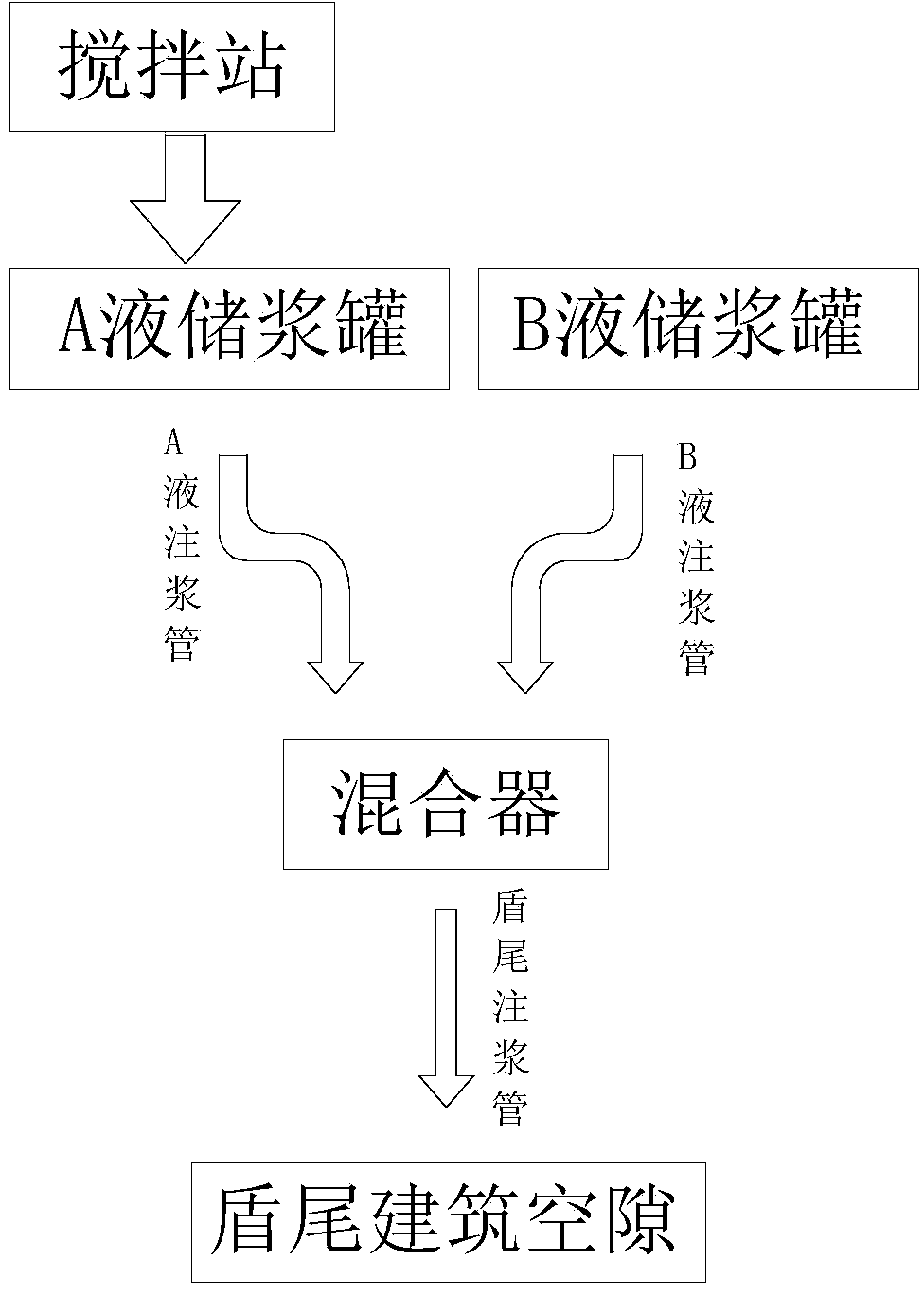

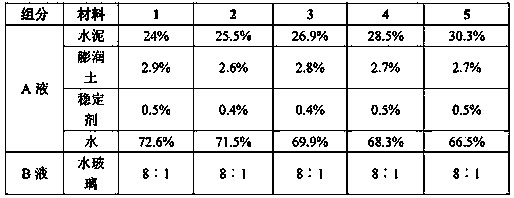

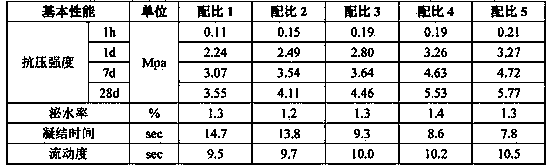

ActiveCN104074530AImprove stabilityShort entry into initial setting timeUnderground chambersTunnel liningSlurryMaterials science

The invention discloses a shield synchronous grouting construction method and a construction material. The construction material comprises liquid A and liquid B, wherein the liquid A comprises 25.5 weight percent of cement, 2.6 weight percent of bentonite, 0.4 weight percent of stabilizing agents and 71.5 weight percent of water; the liquid B is water glass; and the volume ratio of the liquid A to the liquid B is 8:1-15:1. During synchronous grouting construction, the liquid A is prepared in a mixing station, and the liquid A and the liquid B are respectively conveyed into a liquid A slurry storage tank and a liquid B slurry storage tank which are arranged on a shield machine; the liquid A and the liquid B are respectively conveyed into a mixer positioned at the shield tail part of the shield machine through a liquid A slurry injection pipe and a liquid B slurry injection pipe; and the liquid A and / or the liquid B in the mixer are / is synchronously injected into a shield tail building gap through a shield tail slurry injection pipe. The shield synchronous grouting construction method solves various problems in subsequent grouting, synchronous single slurry injection, in-time grouting and secondary grouting in the prior art through utilizing good performance of the liquid A and the liquid B before and after the mixing of the liquid A and the liquid B and combining a primary synchronous grouting process.

Owner:CHINA RAILWAY 15TH CONSTR BUREAU GRP

Preparation technology for slag foamed concrete block

InactiveCN102219546AGood early strengthShort initial setting timeCeramicwareFoam concreteFoaming agent

The invention discloses a preparation technology for a slag foamed concrete block. The preparation technology comprises: (1) preparing a slag early strength agent; (2) preparing a slag cementing material; (3) preparing a compound admixture; (4) preparing foam of a foaming agent; (5) preparing a mixed slurry; (6) mixing the mixed slurry and the foam of the foaming agent according to a volume ratio of 1:6, followed by carrying out stirring to prepare a foamed slurry having a volume weight of 20-130 mm; (7) conveying the foamed slurry in a standing room, and supplying saturated vapor to the standing room, wherein a heating rate on the standing room is 5-8 DEG C per hour, followed by standing for 3-6 hours at a temperature of 55-60 DEG C, then conveying the stood foamed slurry in a autoclave, wherein steam pressure in the autoclave is increased to 0.8-1.2 Mpa in 2-3 hours, then remaining a constant temperature for 4-6 hours, followed by decreasing the steam pressure to zero in 2-2.5 hours to prepare the finished product. Each technical index of the solid slag autoclaved foamed concrete block provided by the present invention is superior to or accords with standard requirements of JC / T1062-2007 foamed concrete block.

Owner:杜世永

Light-weight concrete for 3D printing, and preparation method and application thereof

ActiveCN105948668AShort initial setting timeSolve the problem of special-shaped formworkAdditive manufacturing apparatusPortland cementUltimate tensile strength

The invention provides a light-weight concrete for 3D printing, and a preparation method and application thereof. The light-weight concrete is prepared from the following raw materials in parts by weight: 100 parts of 52.5R ordinary Portland cement, 6-12 parts of quick-setting sulfoaluminate cement with the strength level of not less than 42.5, 7-10 parts of fly ash, 100-250 parts of composite inert light-weight filler, 1.2-6.5 parts of polypropylene fiber, 0.06-0.2 part of viscosity modifier, 0.5-1.5 parts of flexibility modifier and 25-40 parts of water. Compared with the traditional concrete material, the dead weight of the material is obviously lowered by 25-40%, the pressure deformation from the upper layer material to the lower layer material in the printing process is greatly reduced, and the number of layers of one-step continuous printing can be further increased, thereby shortening the construction period. Besides, the material has certain heat-shielding and heat-insulating properties, so that the light-weight concrete is more energy-saving and environment-friendly when being applied to the field of buildings.

Owner:CHONGQING CONSTR ENG NEW BUILDING MATERIALS +1

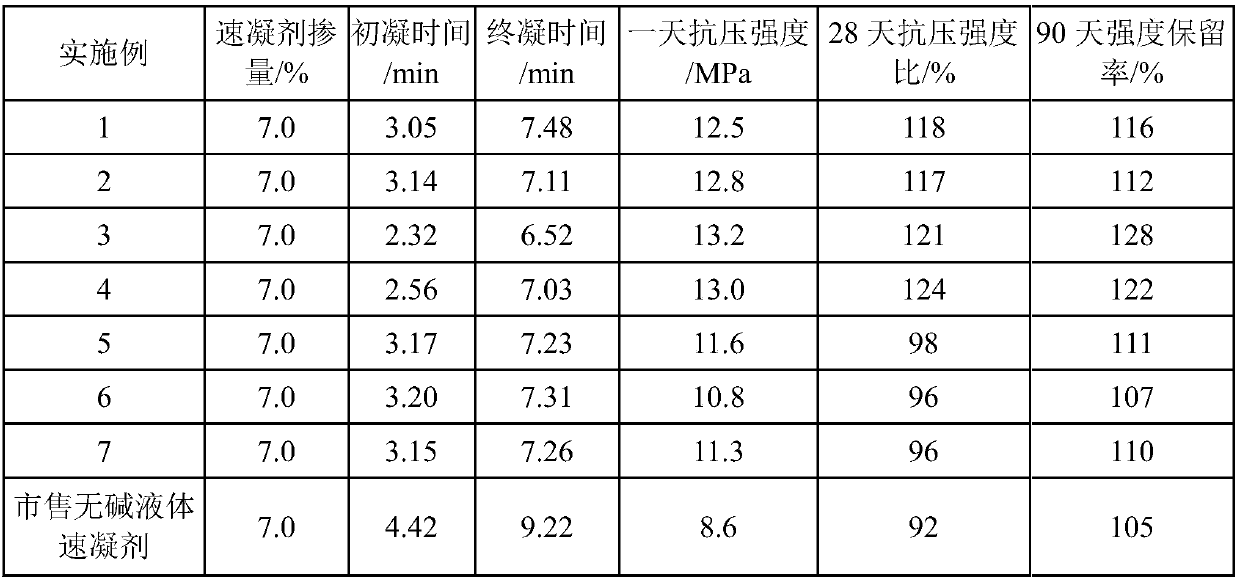

Alkali-free liquid accelerator and preparation method thereof

The invention provides an alkali-free liquid accelerator and a preparation method thereof and belongs to the technical field of concrete admixtures. The alkali-free liquid accelerator is prepared fromthe following raw materials: aluminum sulfate, ferrous sulfate, sodium fluoride, magnesium fluosilicate, precipitated hydrated magnesium silicate, diethanol amine and water. The alkali-free liquid accelerator has a good rapid hardening effect, can effectively shorten the coagulating and final setting time of concrete, and effectively improves the early strength and the later strength of concrete.The preparation method of the alkali-free liquid accelerator comprises the following steps: stirring water and precipitated hydrated magnesium silicate for 15-20 min at 40 DEG C; then adding ferroussulfate and sodium fluoride, and performing mixing and stirring for 8-15 min; after that, adding aluminum sulfate; performing heating up to 75-85 DEG C; after a reaction for 1 h, adding magnesium fluosilicate, and performing stirring for 20-40 min; and at last, adding diethanol amine, performing stirring for 18-25 min to prepare the alkali-free liquid accelerator. The preparation method is simple,the reaction is safe, and the prepared accelerator has good dispersibility.

Owner:PANZHIHUA CITY JIYUAN TECH

Alkali-activating-agent-doped early strength super-high performance concrete and preparation method thereof

ActiveCN106517934AShort initial setting timeImprove early strengthHigh performance concreteSetting time

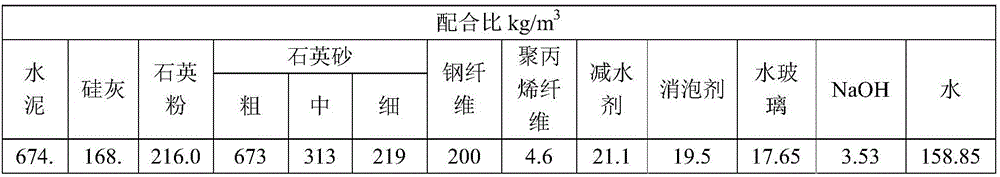

The invention discloses alkali-activating-agent-doped early strength super-high performance concrete and a preparation method thereof. The concrete comprises, by mass, 1019-1059 parts of a cementing material, 1120-1271 parts of quartz sand, 165-205 parts of fibers, 20.38-21.18 parts of a water reducing agent, 12.2-25.6 parts of a de-foaming agent, 20.38-21.18 parts of an alkali activating agent and 152.85-180.03 parts of water. Under the effect of the alkali activating agent, the cementing material contains lots of Si-O and Al-O bond rupture, SiO4 and AlO4 tetrahedrons are made to be fast dissolved out, lots of inorganic high-molecular polymers are fast formed through a polycondensation reaction, the early strength of the concrete is improved fast, and the super early strength effect is achieved. The alkali activating agent is doped in, the initial setting time of the super-high performance concrete is greatly shortened, the super-high performance concrete is made to have very high early strength, the stripping time is shortened, and the circulation efficiency of preparation of the concrete is accelerated.

Owner:西安华清科教产业(集团)有限公司

Epoxy mortar used for repairing sea oil gas pipeline and preparation method thereof

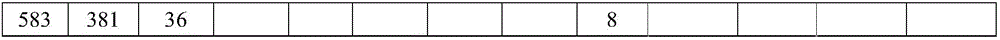

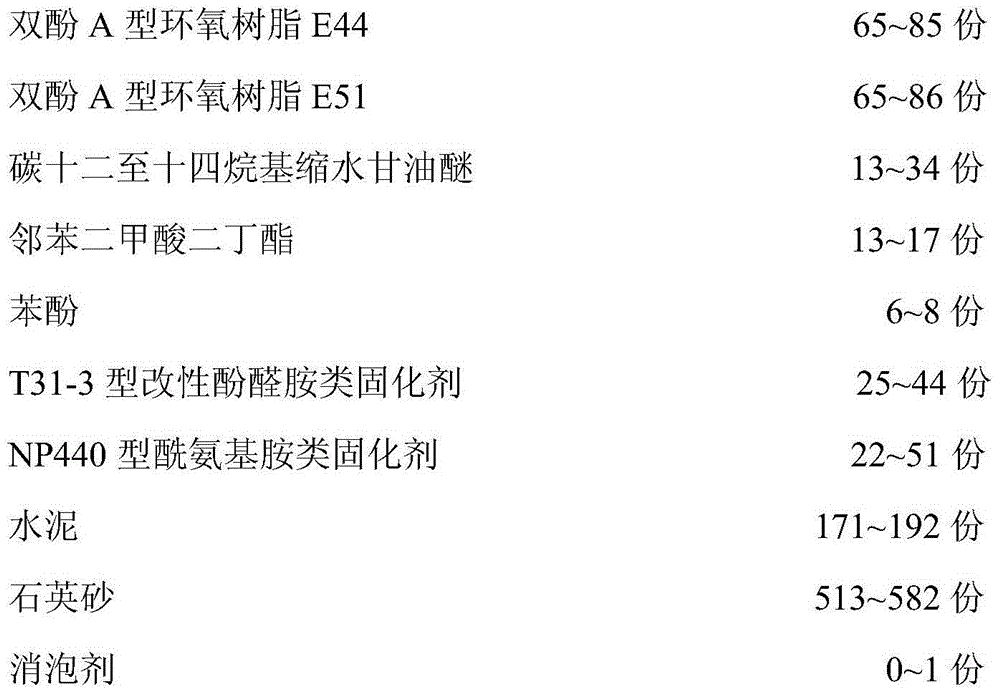

The invention discloses an epoxy mortar used for repairing sea oil gas pipeline and a preparation method thereof, which belongs to the technical field of polymer mortar application. The epoxy mortar is composed of a component A, a component B and a component C, the component A is prepared by bisphenol A epoxy resin E44, E51 and a certain amount of auxiliary agent, the component B is prepared by mixing a T31-3 type modified phenolic amine curing agent and a NP440 amidoamines curing agent according to a certain proportion, and the component C is an aggregate by mixing cement and quartz sand according to a certain proportion. The preparation method comprises the following steps: heating the component A to the temperature of 30-50 DEG C, stirring to homogeneous phase, then mixing the component A and the component B according to a certain proportion, uniformly mixing, adding the component C according to a certain proportion, and uniformly blending to obtain the epoxy mortar. The preparation method has simple technology, the epoxy mortar has strong cohesiveness, the epoxy mortar through solidification has excellent anti-compression, anti-punching and anti-seawater corrosion performances, and the epoxy mortar can be used for repairing and reinforcing a concrete coating on the sea oil gas pipeline and a thin layer of an underwater concrete structure.

Owner:TIANJIN UNIV OF SCI & TECH +1

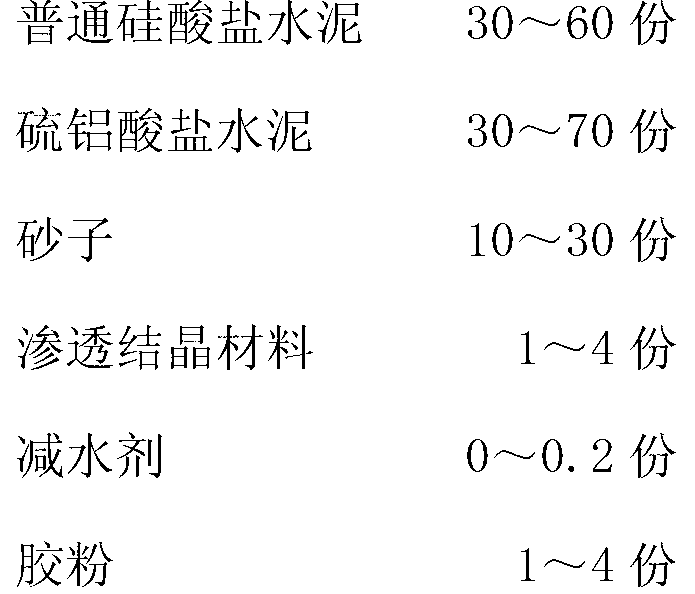

Capillary crystalline patch plaster

The invention discloses a capillary crystalline patch plaster which comprises the following components in parts by weight: 30-60 parts of ordinary portland cement, 30-70 parts of sulphate aluminum cement, 10-30 parts of sand, 1-4 parts of capillary crystalline materials, 0-0.2 part of water-reducing agents, 1-4 parts of rubber powder, 0-0.3 part of water retention agents and 0.1-0.3 part of anti-crack fibers. The capillary crystalline patch plaster disclosed by the invention has the advantages of high early strength, excellent bonding property, excellent anti-crack property, very good restoration function on microcracks, convenience for construction and environment friendliness without toxicity.

Owner:CHONGQING JIUSHENGCHENG WATERPROOF MATERIALS

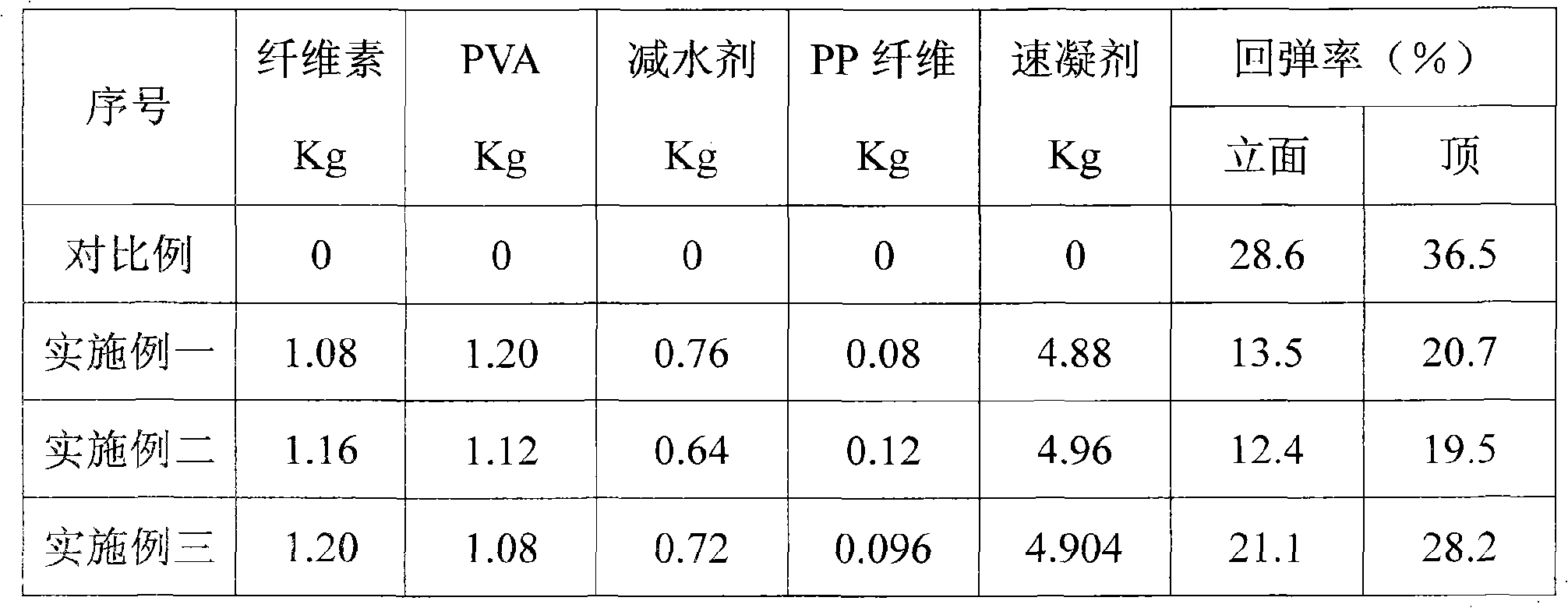

Superfine quick-setting self-compacting repair mortar and preparation method thereof

The invention relates to superfine quick-setting self-compacting repair mortar material and a preparation method thereof; the superfine quick-setting self-compacting repair mortar material is characterized by being prepared from, by total weight of the materials, 35.0-55.0% of quick-hardening early strength cement, 35.0-55.0% of fine aggregate, 3.0-10.0% of a mineral admixture, 2.5-5.0% of an excitant, 0.80-2.00% of redispersible latex powder, 0.25-0.50% of a water-reducing agent, 0.25-0.50% of a thickening time control agent, and 0.01-0.05% of a defoaming agent. The preparation method comprises: weighing the materials to a proportion, and mixing well in a mixing machine. The superfine quick-setting self-compacting repair mortar material has good constructability, is up to 330 mm in initial mobility, has initial setting time of < / =20 min and final setting time of < / =30 min, is up to 33.0 MPa and 50.0 MPa in 6 h compressive strength and 24 h compressive strength, has stably increasing late strength, is up to 4.0 MPa and 6.0 MPa in 1 d and 3 d interfacial flexural-tensile strength of concrete interface, has the advantages of micro-expansion effect and good construction operational simplicity, and is suitable for the quick repair of housing and roads, particularly for the repair of concrete fracture surfaces and damaged rail plates of high-speed railway ballastless tracks.

Owner:JIANGSU CHINA RAILWAY ARIT NEW MATEIRALS CO LTD

Low-water-absorption foamed concrete and preparation method thereof

InactiveCN104150951AShort initial setting timeReduced open porosityCeramicwareFoam concreteAluminate

The invention relates to a low-water-absorption foamed concrete and a preparation method thereof. The low-water-absorption foamed concrete is prepared from ordinary Portland cement, sulphoaluminate cement, raw material soil, water, a thickening agent, a water-reducing agent, a foam-stabilizing agent, an accelerator and a foaming agent. Through addition of the sulphoaluminate cement and the accelerator which can accelerate coagulation of the ordinary Portland cement, break of bubbles during an initial setting time is reduced and an opening porosity and water absorption of the foamed concrete are reduced. Through addition of the thickening agent, thickness of the foamed concrete can be adjusted and upward-floating of the bubbles is reduced so that the bubble is distributed uniformly. The foamed concrete is low in water absorption, is uniform in volume weight, is stable in compressive strength and has a better thermal-insulation and temperature-preserving performance, a better mechanical performance and a better freeze-thaw-destroy resistant performance.

Owner:WUHAN UNIV OF TECH

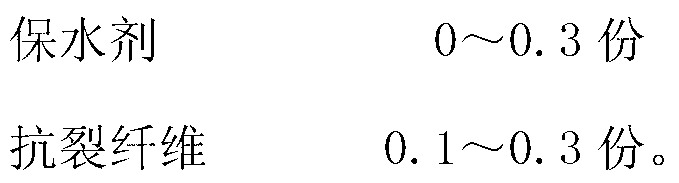

Concrete spraying additive

The invention discloses a shotcrete admixture, comprising: 13 to 15 parts by weight of cold water quick dissolving powdery methylcellulose ether or cold water quick dissolving powdery hydroxyethyl cellulose ether, 13 to 15 parts by weight of cold water quick dissolving powdery polyvinyl alcohol, 8 to 11 parts by weight of naphthalene-series powdery water-reducing agent, 1 to 2 parts by weight of mesh polypropylene fiber and 58 to 62 parts by weight of cement accelerator. The shotcrete admixture is prepared by adding the constituents into the concrete together for increasing the cohesion of concrete and viscosity of early-stage slurry, the slurry initial setting time is short, and the resilience amount of concrete can be reduced by 30 to 50 percent.

Owner:山东科技大学教育服务有限公司

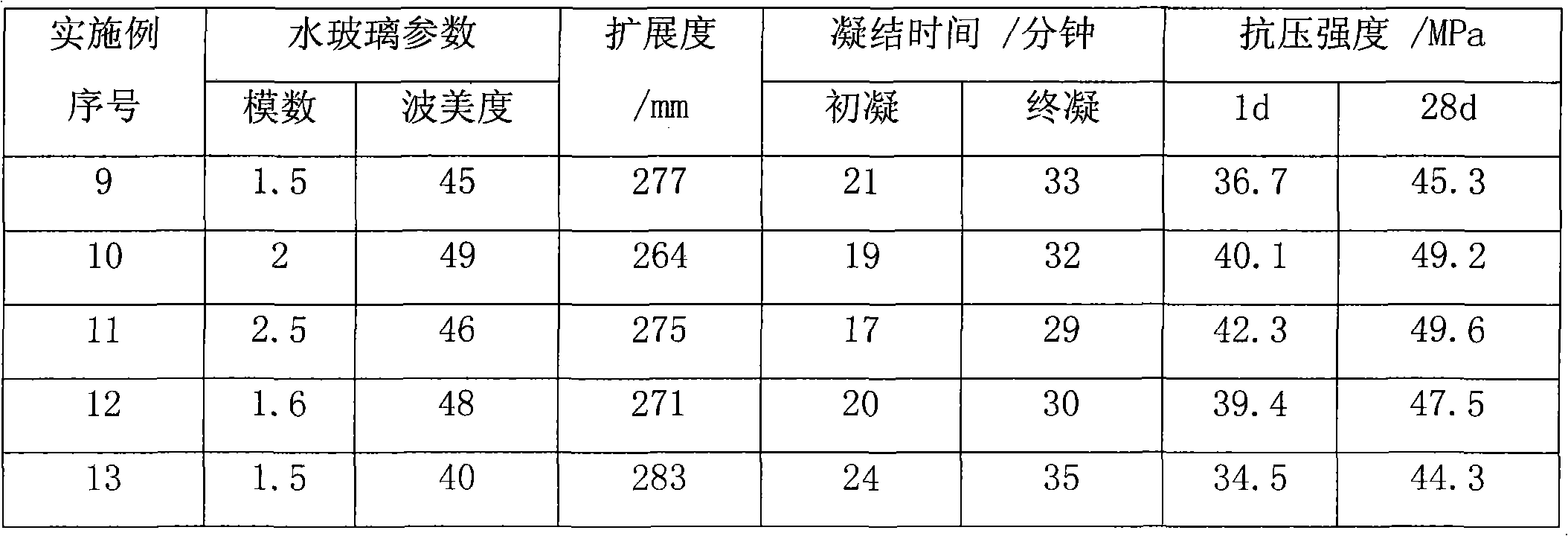

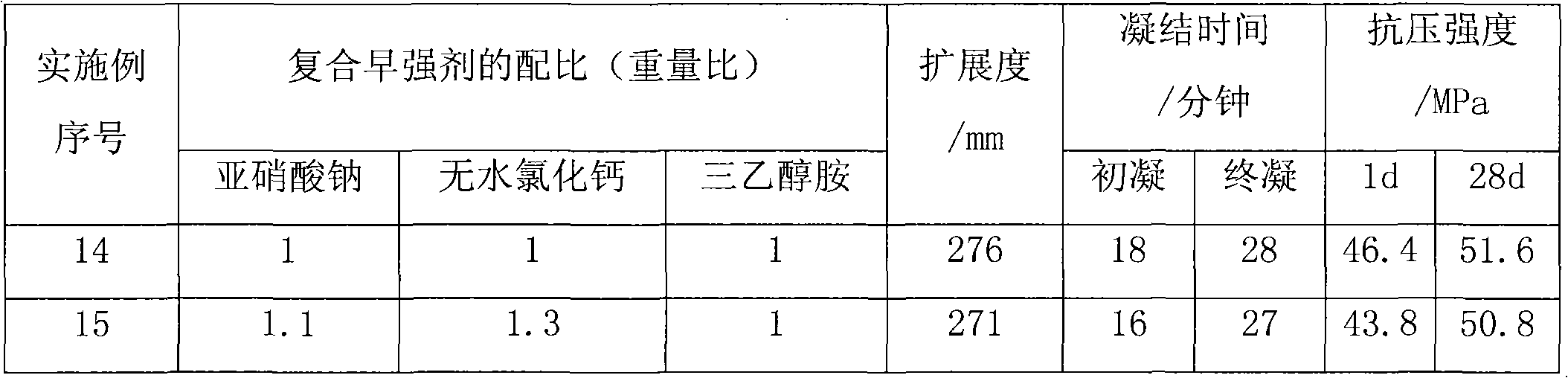

Cement-base quick repairing material and preparation method thereof

ActiveCN101891448ALarge specific surface areaLoose structureSolid waste managementCement slurryMetakaolin

The invention relates to a cement-base quick repairing material and a preparation method thereof. The cement-base quick repairing material is characterized by being prepared from the following raw materials: sulphate aluminum cement, dehydrated phase of cement slurry, metakaolin, water glass solution, a water reducing agent, water and a compound early strength agent, wherein the weight ratio of the sulphate aluminum cement to the dehydrated phase to the cement slurry to the metakaolin to the water glass solution to the water reducing agent to the water to the compound early strength agent is 1:0.05-0.5:0.05-0.5:0.02-0.3:0.01-0.1:0.2-0.6:0.0006-0.06. The dehydrated phase of cement slurry is prepared by grinding waste cement slurry in waste concrete into powder, and sintering the powder for2 to 4 hours at the temperature of between 500 and 1,000 DEG C. The material has the advantages of high working performance, high early strength, and energy saving and environmental protection, and is widely applied to repairing engineering of roads, airports, water conservancy, defense facilities, oil wells, mineral trail supports and the like.

Owner:WUHAN UNIV OF TECH +1

Controllable clay and cement seepage-proof reinforcement paste

The invention discloses controllable clay and cement seepage-proof reinforcement paste. The controllable clay and cement seepage-proof reinforcement paste is mainly prepared from clay raw stock, cement and water, wherein the clay raw stock is mainly obtained by stirring clay and water. A modifier is added in the controllable clay and cement seepage-proof reinforcement paste; the doping amount of the modifier is 1 to 3 percent; the modifier mainly comprises mineral additives, sulfate and bentonite in a mass ratio of a:b:c; and a:b:c is 5:(5-0):(0-5). The product has the advantages of high stability and water flow dilution resistance, controllable setting time, adjustable strength, high antiseepage performance, low cost, environment friendliness and the like.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

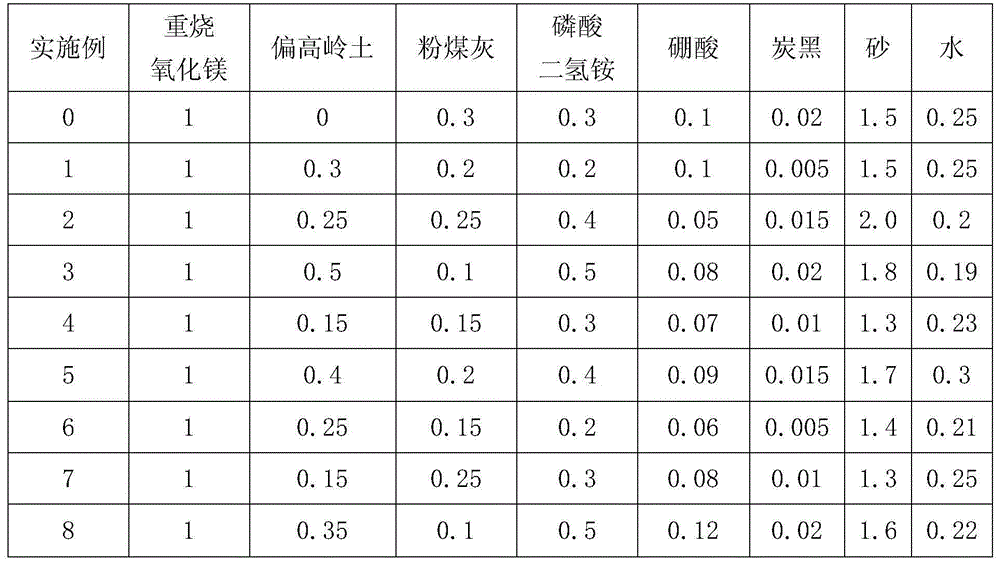

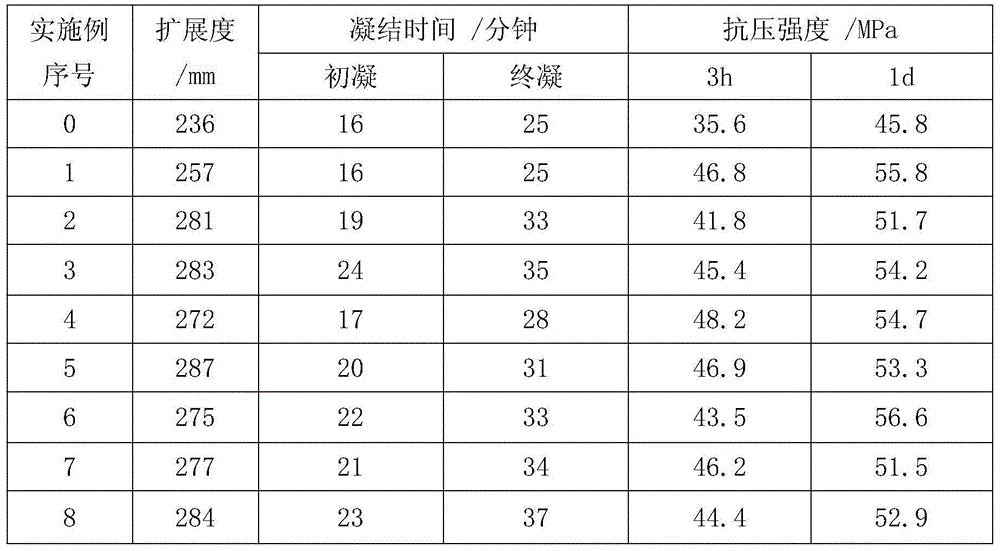

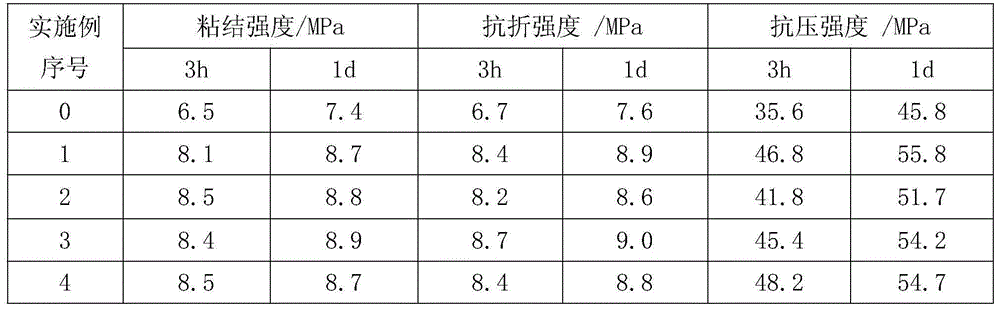

Preparation method of metakaolin-based magnesium oxide type rapid repair material

The invention discloses a preparation method of a metakaolin-based magnesium oxide type rapid repair material. The preparation method comprises the following steps: calcining magnesian marble at the temperature of 1200-1500 DEG C for 2-4 hours, naturally cooling to room temperature, and carrying out ball milling to obtain dead burnt magnesium oxide; calcining a kaolin powder at the temperature of 550-800 DEG C for 2-4 hours, cooling to room temperature, and carrying out ball milling to obtain metakaolin; uniformly mixing dead burnt magnesium oxide, metakaolin, fly ash, carbon black and sand in a mixer so as to obtain a solid raw material; uniformly mixing ammonium biphosphate, boric acid and water to obtain a liquid raw material; and uniformly stirring the solid raw material and the liquid raw material in the mixer to obtain the metakaolin-based magnesium oxide type rapid repair material. According to the invention, initial setting time is basically controlled within 15-25 min and is extremely obviously shortened in comparison with 3-4 hours' initial setting time of a common cement-based repair material. A certain amount of waste fly ash can be consumed. The preparation method has advantages of environmental protection, energy conservation and emission reduction.

Owner:WUHAN UNIV OF TECH

Method for producing building gesso by using semi-hydrated phosphogypsum and dihydrate phosphogypsum

ActiveCN102731000AStandard consistency requires less waterHigh strengthPhosphogypsumWater requirement

The present invention discloses a method for producing building gesso by using semi-hydrated phosphogypsum and dihydrate phosphogypsum, and belongs to the field of building gypsum production, wherein the building gesso has characteristics of small water requirement of normal consistency and high strength. The method comprises processes of raw material calcination, grinding and aging, wherein the raw materials comprise, by weight, 5-60% of semi-hydrated phosphogypsum, and 40-95% of dihydrate phosphogypsum. According to the present invention, the match use of the semi-hydrated phosphogypsum andthe dihydrate phosphogypsum is adopted, and the ratio of the semi-hydrated phosphogypsum to the dihydrate phosphogypsum is strictly controlled, such that the disadvantage of single use of the semi-hydrated phosphogypsum or the dihydrate phosphogypsum is overcome, performances of the semi-hydrated phosphogypsum and the dihydrate phosphogypsum can be supported each other, and the prepared building gesso has characteristics of small water requirement of normal consistency and high strength; and the phosphogypsum is adopted to replace the natural gypsum to produce the building gesso so as to reduce production cost, change the phosphogypsum waste into treasure, effectively treat pollution and hazard on the environment due to phosphogypsum waste, and provide good environmental benefits, social benefits and economic benefits.

Owner:GUIZHOU CHANHEN CHEM CO LTD

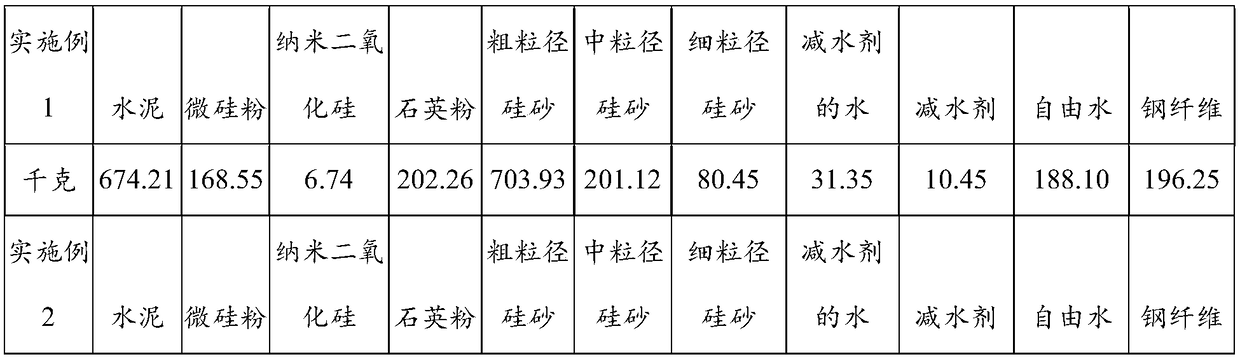

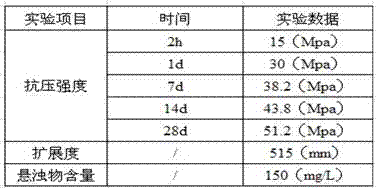

Ultra-high performance concrete slurry, ultra-high performance concrete and preparation method thereof

Belonging to the technical field of building materials, the invention in particular relates to an ultra-high performance concrete slurry, an ultra-high performance concrete and a preparation method thereof. The ultra-high performance concrete slurry comprises: cement, microsilica, nano silica, quartz powder, silica sand, steel fiber, a water reducing agent and water. According to the theory of theclosest packing, the adding proportion of each material is calculated, and trial mix experiments are carried out repeatedly, thus researching and developing the ultra-high performance concrete with the characteristics of minimum raw material variety, simple mixing process and maintenance technology, and the best mechanical properties.

Owner:GUANGDONG UNIV OF TECH

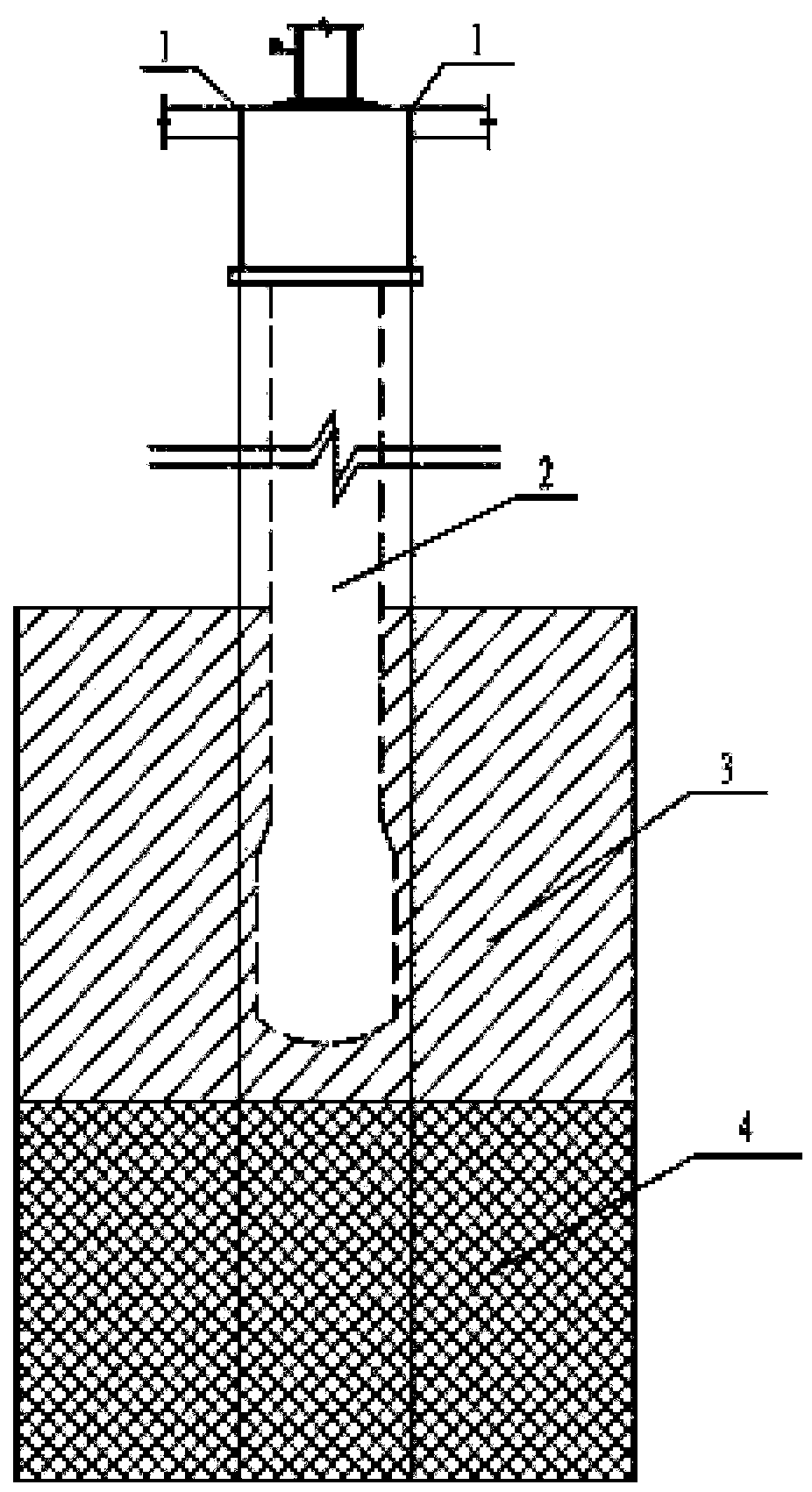

Settling, reinforcing, jacking and leveling technology suitable for independent pile foundation of industrial plant

ActiveCN108547336AImprove bearing capacityShort initial setting timeSoil preservationSlurryHigh pressure

The invention discloses a settling, reinforcing, jacking and leveling technology suitable for an independent pile foundation of an industrial plant. The technology comprises the steps that a soft soillayer around a pile is subjected to compaction grouting for reinforcement at first, specifically, the reinforcing depth is gradually increased in layered and downward modes, the grouting pressure isgradually increased, each grouting section is 0.5-1.0 m long, drilling continues for 0.5-1.0 m after the first grouting section is grouted, then the second grouting section is grouted, and operation is carried out downwards section by section until compaction grouting is completed; and drilling continues downwards 12-24 h after the soft soil layer around the pile is reinforced, upward counterforceis formed in a high-pressure grouting mode, and a pile foundation is slowly jacked to the design allowable deviation range. The independent pile foundation is reinforced in a wrapped state by adoption of a reinforcing and jacking method, good integrality and high stability are achieved, the integral foundation bearing capacity is improved, and meanwhile the jacking and leveling purposes can be achieved; and by adoption of the drilling and injection integrated advancing grouting process, the situation that the soil layer settles for the second time due to water-weakening impact of the soil layer in the drilling process can be avoided, the slurry initial setting time is short, the diffusion radius is controllable, the cementing capacity is high, the strength is high, and environment friendliness and no pollution are achieved.

Owner:BEIJING HENGXIANG HONGYE FOUND REINFORCEMENT TECH CO LTD

Slag Portland cement and preparing method thereof

InactiveCN104761162AGuaranteed hydraulic hardnessHydraulic activationCement productionGranularityPortland cement

The invention relates to slag Portland cement and a preparing method thereof and relates to the field of building materials. The slag Portland cement comprises following components by mass: (1) 30.0-65.0% of silicate Portland cement clinker, (2) 5.0-15.0% of copper slag, (3) 15.0-30.0% of blast furnace slag, (4) 5.0-15.0% of molybdenum slag, (5) 5.0-12.0% of flue dust and (6) 2.5-5.0% of gypsum. The slag Portland cement is high in hydraulicity performance, short in interval between initial setting time and final setting time, high in later strength, high in compression resistance and suitable for use in various occasions. The preparing method adopts a process including primary smashing, mixing and grinding. The prepared cement is low in particle size, uniform in quality, high in specific surface area, and improved in hydraulicity performance.

Owner:苏州市德莱尔建材科技有限公司

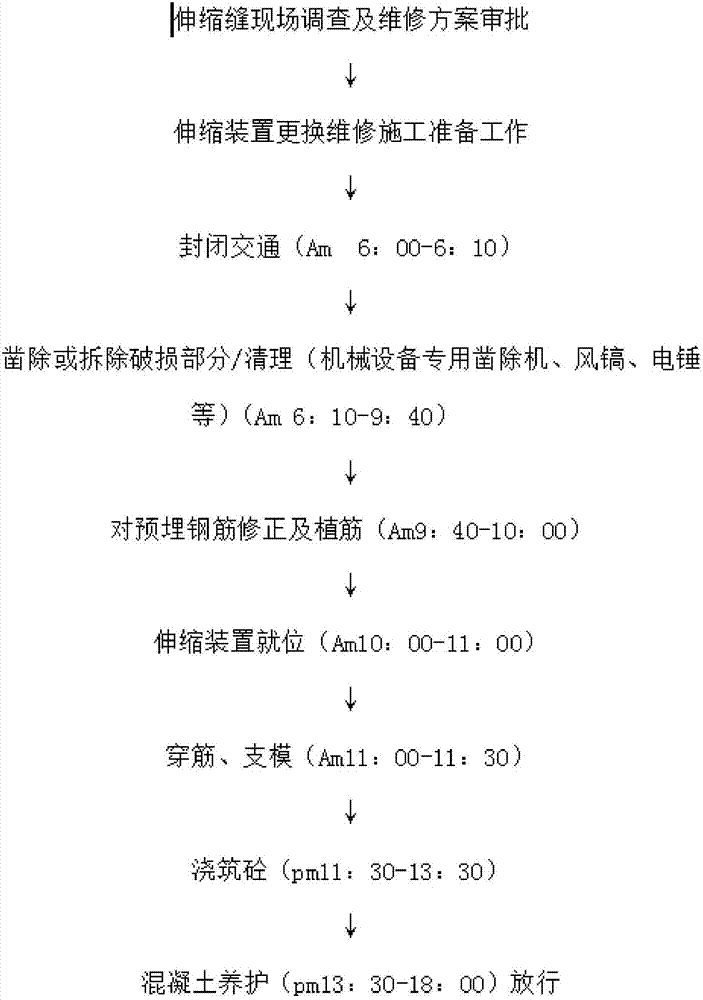

Modular-type telescopic seam fast repairing and replacing construction method

InactiveCN107476205AQuickly increase the strengthShort initial setting timeBridge structural detailsBridge erection/assemblyButt jointArchitectural engineering

The invention discloses a modular-type telescopic seam fast repairing and replacing construction method. The modular-type telescopic seam fast repairing and replacing construction method comprises the step of construction preparing, specifically, needed mechanical equipment is well prepared, and traffic closing is conducted on the construction site of replacing telescopic seams. According to the modular-type telescopic seam fast repairing and replacing construction method, a scientific maintenance program is worked out through professional technical service, appropriate measures are achieved, and the repairing quality is ensured; through professional seamless butt joint construction, the operation time of each process is compressed to the utmost extent, and especially the time of cleaning waste seams by using special equipment; damaged telescopic seams are replaced with a new type telescopic seam product; and 3h fast hard concrete is used, and the maintenance time is shortened.

Owner:JIANGSU PINGSHAN TRANSPORTATION FACILITIES CO LTD

Modified phosphorous slag powder, concrete prepared from modified phosphorous slag powder and preparation method of concrete

ActiveCN103755186AReduce dosageReduce the effect of hydration reaction rateSolid waste managementMetallurgyStarch

The invention provides a modified phosphorous slag powder, a concrete prepared from the modified phosphorous slag powder and a preparation method of the concrete, and belongs to the technical field of concrete preparation. The modified phosphorous slag powder comprises a phosphorous slag powder, an organic salt and cationic starch. The organic salt and the cationic starch are used for modifying the phosphorous slag powder in stead of common chemical excitation carried out on the phosphorous slag by using an inorganic alkali activator in the prior art; when the modified phosphorous slag powder is used for preparing the concrete, the dosage of the modified phosphorous slag powder accounts for 38-70wt% of the total amount of the cementing material; the 3d compressive strength of the concrete ranges from 14.5 to 33.5MPa, and the 28d compressive strength of the concrete ranges from 30.6 to 77.3MPa, and the stability of the concrete is good; the utilization rate of the phosphorous slag powder is greatly reduced while the cost of the concrete is reduced, and therefore, the environmental pollution problem caused by the phosphorous slag can be reduced.

Owner:北京东方建宇混凝土科学技术研究院有限公司

Novel flexible composite shotcrete layer support material

The present invention relates to a novel flexible composite shotcrete layer support material which comprises the following components in parts by weight: 80-100 parts of cement, 80-120 parts of sands, 100-120 parts of stones, 60-100 parts of rubber particles, 40-60 parts of coal ash, 20-30 parts of hooked end steel fibers, 50-80 parts of water, 6-7 parts of a crosslinking agent, 5-8 parts of an additive, 2-10 parts of polyamic acid resin with a solid content of 10%-25% and 3-5 parts of a 1% silane coupler solution. The prepared shotcrete layer material is greatly improved in compression strength, rupture strength and flexural toughness. The novel flexible composite shotcrete layer support material can be applied to the field of support to surrounding rocks of complex rock layers with characteristics of high stress, soft rock, expansion, flowing deformation, fault structure fracture zones, mining influence and the like or other dynamic pressure tunnel as well as the field of underground engineering of tunnels, subways and the like.

Owner:SHANDONG UNIV

Waterproof plastering gypsum and preparation method thereof

The invention relates to waterproof plastering gypsum and a preparation method thereof. The waterproof plastering gypsum is prepared from components in parts by weight as follows: 50-60 parts of desulfurized gypsum, 5-20 parts of quartz sand, 1-3 parts of natural stone powder, 0.3-0.4 parts of a retarding admixture, 0.2-0.5 parts of cellulose ether, 0.1-0.2 parts of dispersible latex powder and 0.05-0.3 parts of a waterproof binding agent. The waterproof plastering gypsum has the beneficial effects as follows: the prepared waterproof plastering gypsum is low in cost and good in waterproof effect, the waterproof rate reaches 90% or higher, shear adhesive strength of the waterproof plastering gypsum is 0.3 Mpa or higher, breaking strength is 15 Mpa or higher, and initial setting time and final setting time are short.

Owner:湖北萨利赫新材料有限公司

Composite fast-hardening silicate leakage stopping slurry and leakage stopping method thereof

InactiveCN106147732AHigh salinityIncrease moisture contentDrilling compositionSealing/packingOrganic EsterSlurry

The invention provides composite fast-hardening silicate leakage stopping slurry and a leakage stopping method thereof. The silicate leakage stopping slurry comprises a main agent and a curing agent, a volume ratio of the main agent to the curing agent is 5:1, and the main agent and the curing agent are mixed to form solid gel. Industrial sodium silicate serving as the main agent and organic ester serving as the gel delay curing agent to form the solid gel under an alkaline condition to realize leakage stopping, water repellency of a leakage stopping system is improved, strength of a leakage stopping layer is improved, mixed alternation of formation water and the leakage stopping slurry can be effectively inhibited, gradual enhancement along with time after injection of the slurry into a leak layer is kept, pressure bearing capacity of the leak layer is improved, the problem of leakage of loss return type absorption wells is solved, one-time leakage stopping success rate is increased and exceeds 50%.

Owner:中国石油集团川庆钻探工程有限公司长庆钻井总公司

Underwater non-dispersive quick-setting and rapid-hardening cement-based composite material and preparation method and application thereof

The invention belongs to the field of composite materials and particularly relates to an underwater non-dispersive quick-setting and rapid-hardening cement-based composite material and a preparation method and application thereof. The underwater non-dispersive quick-setting and rapid-hardening cement-based composite material is prepared from the following raw materials in percentages by weight: 32-34% of portland cement, 8.8-9% of calcium aluminate, 5-7% of magnesium oxide, 0.5-2% of sulfur trioxide, 0.2-0.3% of a polycarboxylate concrete admixture, 0.3-0.7% of a flocculating agent, 0.05-0.2% of an accelerator, 0.05-0.2% of an air entraining agent, 0.05-0.3% of a corrosion inhibitor, 26-31% of a fine aggregate, 13-18% of a coarse aggregate and 8.4-8.5% of water. The material can be used for quickly repairing a concrete building in a water conservancy project, and the repair material is capable of quickly setting and ensuring the early strength.

Owner:俞家欢

Light fireproof thermal-insulation building material

The invention discloses a light fireproof thermal-insulation building material, and belongs to the technical field of research and development of building materials. The light fireproof thermal-insulation building material is composed of the following ingredients in parts by weight: 50-90 parts of cement, 30-70 parts of foam, 3-5 parts of a modifier and 5-8 parts of an additive. In the thermal-insulation building material disclosed by the invention, foam particles and cement are combined closely, so that no peeling is realized. The light fireproof thermal-insulation building material has the functions of dehumidification, damp prevention, efficient thermal insulation and fire prevention, can be widely applied to roof thermal insulation, ground filling of industrial plants, external wall thermal insulation, internal wall thermal insulation, floor heating pipeline cushion layers, wooden floor cushion layers and elimination of hot and cold bridges.

Owner:北京顺港筑邦环保科技有限公司

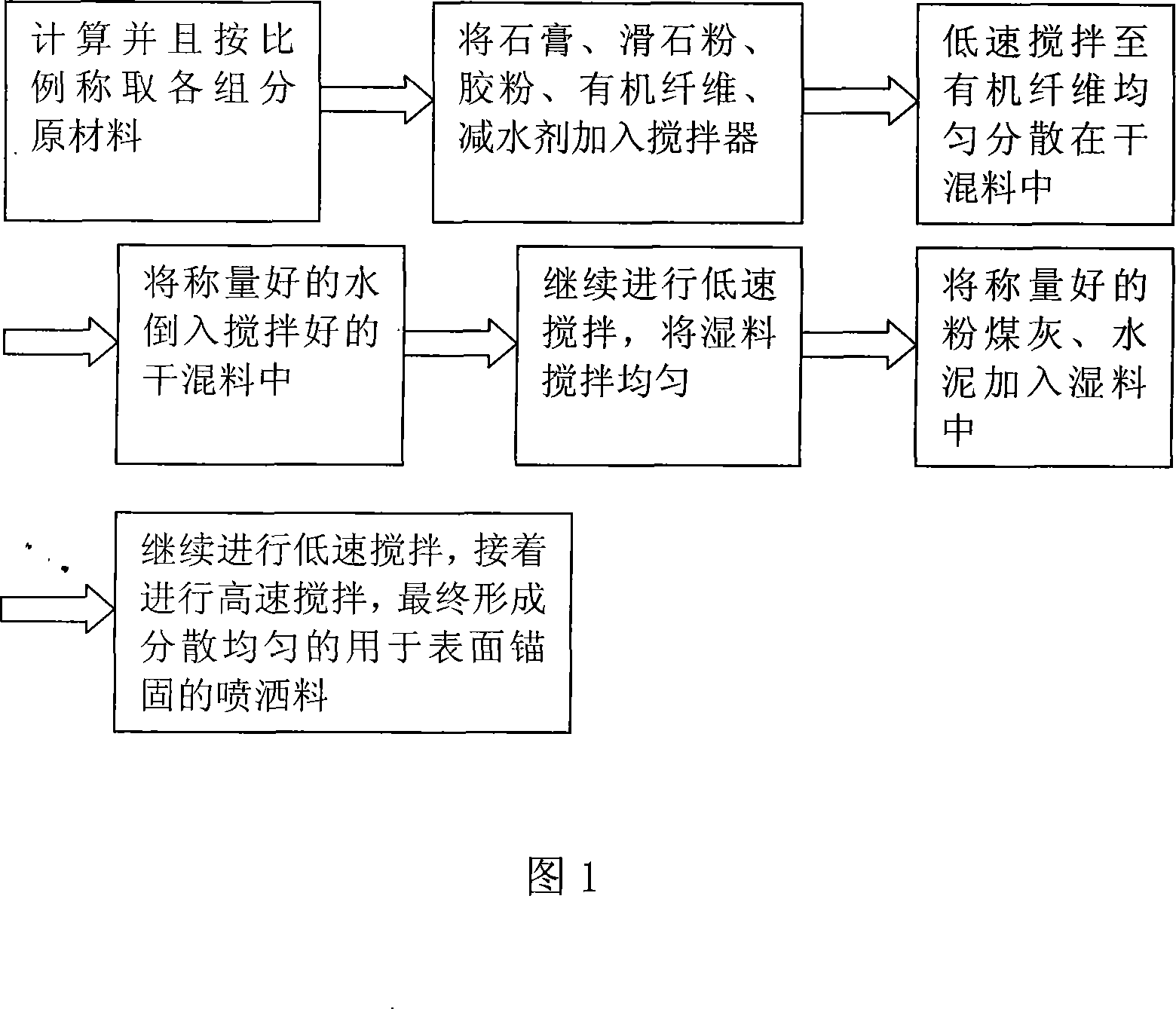

Sprinkling material used for surface anchoring and preparation method thereof

The invention relates to a spray material used for surface anchorage and a preparation method thereof, which solves the technical problems of being difficult in construction, bad safety, high cost and land wasting of the existing covering measure. The spray material of the invention comprises the following components of parts by weight: 30 to 60pbw of water, 10 to 30pbw of powder coal ash, 15 to 40pbw of cement, 0.5 to 1.2pbw of adhesive powder, 2.5 to 6pbw of talcum powder, 1 to 3pbw of gypsum, 0.1 to 0.5pbw of water reducing agent and 0.1 to 0.4pbw of organic fibers. The preparation method of the invention comprises procedures that: raw material of each component is weighted and taken; the gypsum, the talcum powder, the adhesive powder, the organic fiber and the water reducing agent are put into a blender and stirred at a low speed; the water is poured into the dry mixture; low speed stirring is carried out again; the powder coal ash and the cement are added into the wet mixture; the mixture is firstly stirred at low speed and then at high speed in succession, the spray material used for surface anchorage is finally formed. The covering layer formed in the invention has good tightness, good anti-pressure and anti-breaking intensity, strong anti-moisture and bonding capacities, superior environmental protection capacity and strong anti-combustion capacity after solidification, which can prevent toxic and defilement gase from escaping. The preparation method is simple and easy for operation.

Owner:张小群

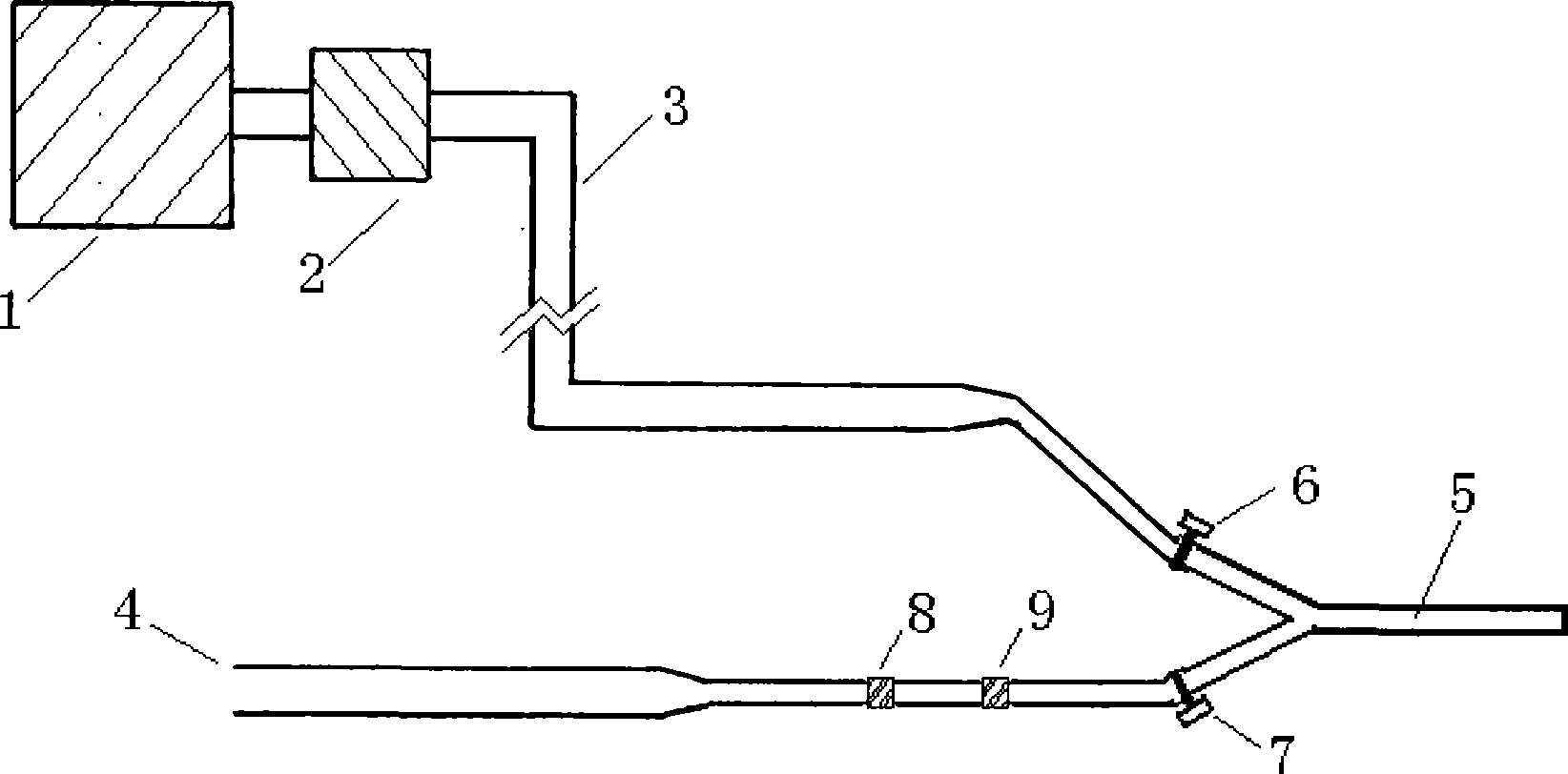

Spray coating material for preventing air leakage in roadway, use method thereof and special spray gun

The invention discloses a coating material used for preventing the air leakage of a laneway, an application method and a special spray gun thereof. The components of the coating material are clay, cement, sodium silicate, glass fiber and water which are mixed, stirred and made into clay cement slurry according to certain proportion and processes. The clay cement slurry is transported to an underground spraying area by a slurry pump through a grouting pipe, and sprayed to a coal roadway wall by the special spray gun to prevent the air leakage of the laneway. The clay cement slurry has strong suspension property, short initial concreting time, certain strength after solidification, rinse-resistance, not easy craze, excellent air partition performance, strong flame-retardant property, ideal effect of preventing the air leakage of the laneway, quick shotcreting process operations, safety and simplicity, is applicable to the spraying to the coal roadway walls of mines with serious hazards, and prevents the air leakage of the laneway so as to reduce the possibility of the occurrence of spontaneous combustion.

Owner:冀中能源股份有限公司葛泉矿

Foam sludge mixed light soil and preparation method thereof

The invention relates to traffic construction engineering materials, in particular to foam sludge mixed light soil and a preparation method thereof. The foam sludge mixed light soil is characterized by being prepared from, by mass, 45-50% of raw material soil, 15-17% of water, 1-3% of a drying agent, 10-13% of a cement consolidation agent, 12-17.5% of a foaming agent, 1.5-3% of an early strength agent and 5-7% of a thickening water-retaining agent; the raw material soil is sludge with the particle diameter smaller than 4.5 mm and water content of 40-65%. The foam sludge mixed light soil and the preparation method thereof have the advantages that the pressure to the lower structure is lower, the strength is higher, sludge waste soil is recycled, and the foam sludge mixed light soil has highindustry value.

Owner:JIANGSU ZHAOTONG ENG TECH CO LTD

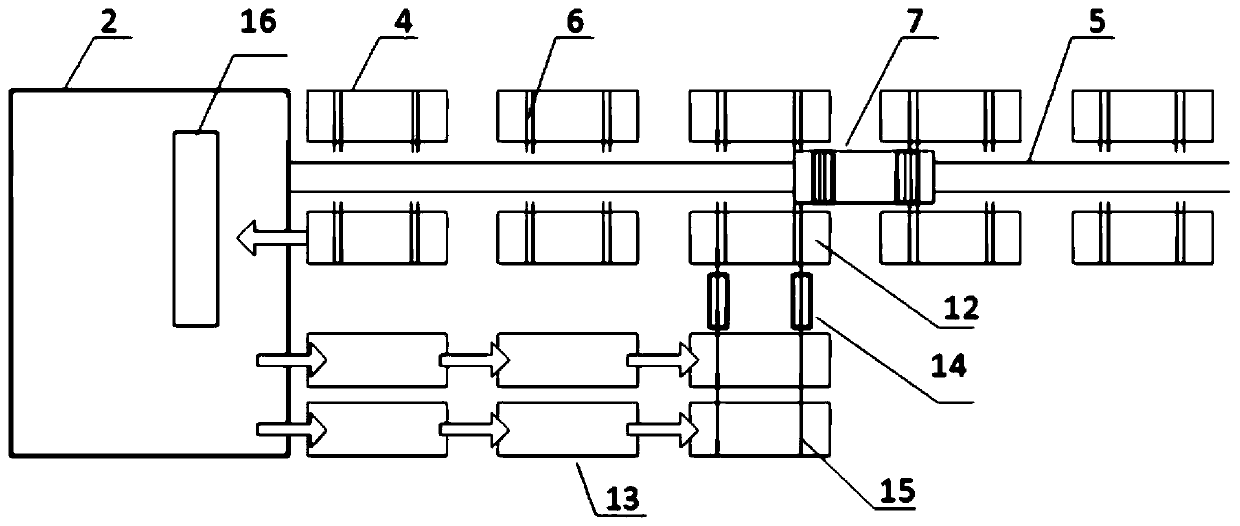

Prefabricated component production line

The invention provides a prefabricated component production line. The prefabricated component production line comprises a first area, a second area and curing kilns, and the curing kilns are arrangedat one ends of the first area and the second area in an adjoining neighbor mode side by side; the first area comprises a plurality of fixed stations arrayed in rows, bench formworks placed on the upper parts of the fixed stations, a horizontal track parallel to the fixed stations, a vertical track arranged on each fixed station and perpendicular to the horizontal track, and a child-mother vehicle,and the child-mother vehicle conveys the bench formworks into the curing kilns through the horizontal track and the vertical tracks; and the second area comprises a plurality of flowing stations anda transverse conveying line connecting the multiple flowing stations, and the bench formworks subjected to curing procedures in the curing kilns are circulated on all the flowing stations along the transverse conveying line. The prefabricated component production line can be suitable for production of prefabricated components with different structural types, has flexible production and organization modes, and can also achieve assembly line operation, the bench formworks enter the curing kilns for three-dimensional storage and curing, and the advantages of both a fixed bench formwork productionline process and an assembly line production process are achieved.

Owner:筑友智造智能科技有限公司

Micro-expansion high-belite sulphoaluminate cement and production method thereof

InactiveCN112456830AImprove qualityExpand the scope of applicationCement productionAluminatePhysical chemistry

The invention relates to micro-expansion high-belite sulphoaluminate cement and a production method thereof. The cement comprises 28-40% of C4A3S, 20-35% of C2S, 10-20% of f-SO3, 5-10% of f-CaO and 4-7% of C4AF, and comprises the following chemical components: 10-13% of SiO2, 12-25% of Al2O3, 1.1-6% of Fe2O3, 50-60% of CaO and 16-20% of SO3. The clinker rate value range Cm is 1.4-2.0, the clinkerrate value range P is 1-2, the clinker is prepared by calcining 40-60% by mass of limestone, 20-40% by mass of low-grade bauxite and 10-30% by mass of anhydrite in a rotary kiln at the temperature of1300 + / -50 DEG C, and 50-80% by mass of the clinker, 10-25% by mass of anhydrite and 10-30% by mass of limestone are mixed and ground into the micro-expansion high belite sulphoaluminate cement.

Owner:ZHENGZHOU JIANWEN SPECIAL MATERIAL TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com