Epoxy mortar used for repairing sea oil gas pipeline and preparation method thereof

A technology of oil and gas pipelines and epoxy mortar, which is applied in the field of polymer mortar application, which can solve the problems of difficult pipeline concrete coating repair and reinforcement, mortar mixture is easily corroded, low compressive and impact strength, etc., and achieves high cost performance, The effect of low viscosity and wide range of compounding ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

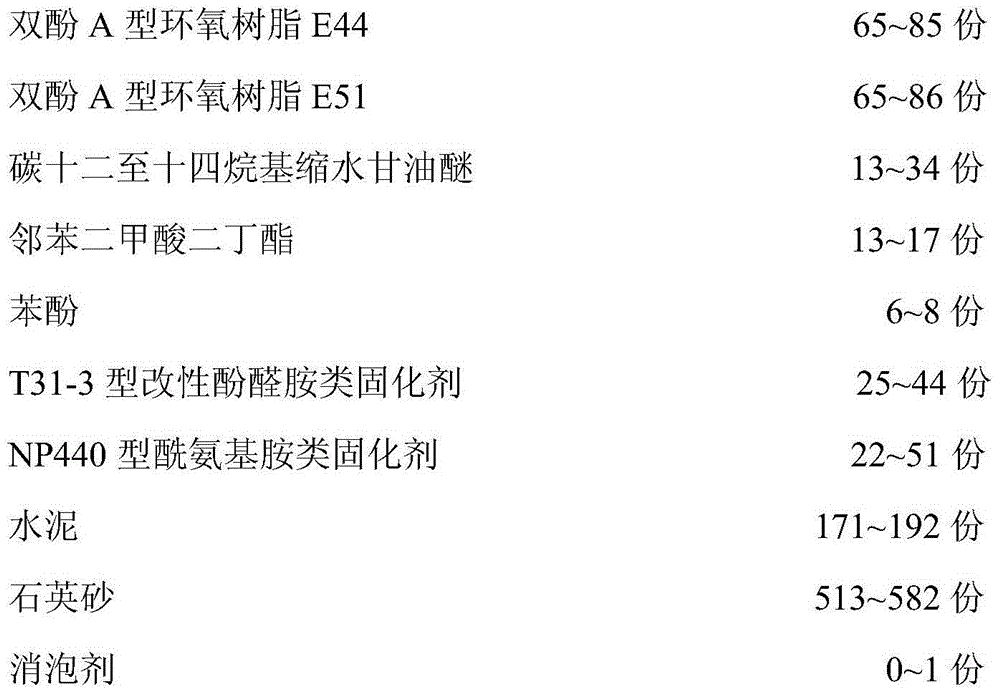

Method used

Image

Examples

Embodiment 1

[0027] Prepare the following materials in parts by weight:

[0028]

[0029] Wherein, the quartz sand is prepared from fine sand with a particle size of 0.3 mm to 0.5 mm, medium sand with a particle size of 1 mm to 2 mm, and coarse sand with a particle size of 2 mm to 4 mm in a weight ratio of 1:1:1. .

[0030]The parts by weight are respectively 65 parts of bisphenol A type epoxy resin E44, 65 parts of bisphenol A type epoxy resin E51, 13 parts of AGE, 13 parts of DBP and 6 parts of phenol are mixed, stirred to homogeneous phase, According to the temperature conditions, heat in a water bath at 40°C to promote uniform stirring, then add 1 part by weight of defoamer and let it stand for 1 to 2 minutes, then add 33 parts by weight of T31-3 type modified phenalkamine curing agent Mix the curing agent with 32 parts of NP440 amidoamine curing agent, stir evenly, pour it into the aggregate for mixing after 3 minutes to 5 minutes, and start the construction operation after mixing...

Embodiment 2

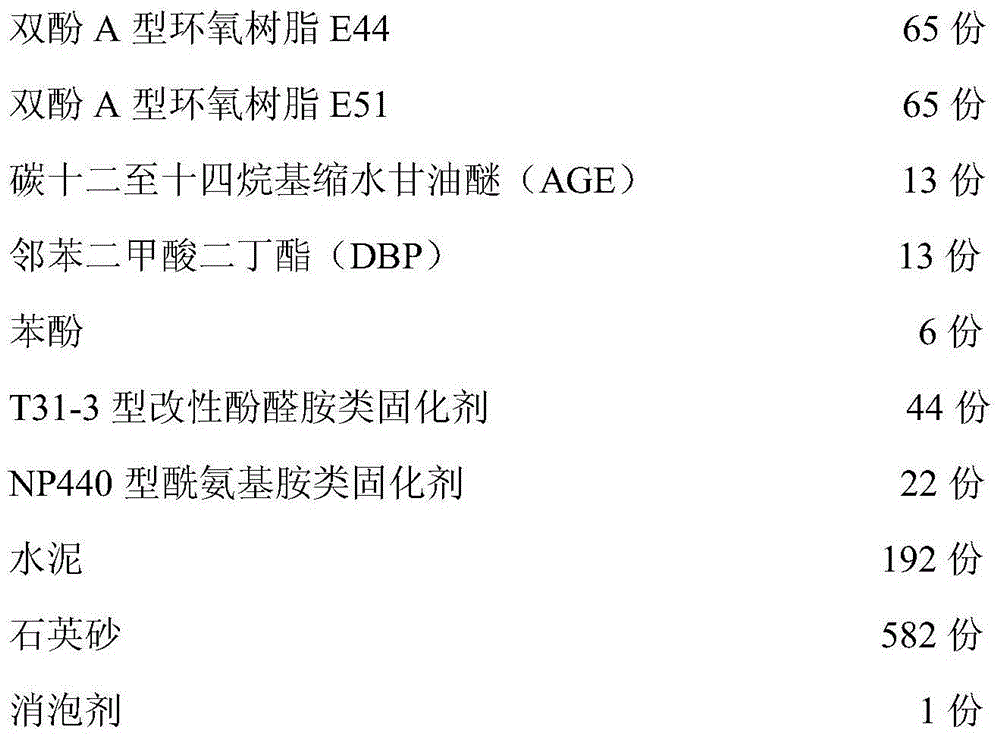

[0033] Prepare the following materials in parts by weight:

[0034]

[0035] Wherein, the quartz sand is prepared from fine sand with a particle size of 0.3 mm to 0.5 mm, medium sand with a particle size of 1 mm to 2 mm, and coarse sand with a particle size of 2 mm to 4 mm in a weight ratio of 1:1:1. .

[0036] The parts by weight are respectively 65 parts of bisphenol A type epoxy resin E44, 65 parts of bisphenol A type epoxy resin E51, 13 parts of AGE, 13 parts of DBP and 6 parts of phenol are mixed, stirred to homogeneous phase, According to the temperature conditions, heat in a water bath at 30°C to promote uniform stirring, then add 1 part by weight of defoamer and let it stand for 1min to 2min, then add 44 parts by weight of T31-3 type modified phenalkamine curing agent Mix the curing agent with 22 parts of NP440 amidoamine curing agent, stir evenly, pour it into the aggregate for mixing after 3 minutes to 5 minutes, and start the construction operation after mixing ...

Embodiment 3

[0039] Prepare the following materials in parts by weight:

[0040]

[0041] Wherein, the quartz sand is prepared from fine sand with a particle size of 0.3 mm to 0.5 mm, medium sand with a particle size of 1 mm to 2 mm, and coarse sand with a particle size of 2 mm to 4 mm in a weight ratio of 1:1:1. .

[0042] The parts by weight are respectively 85 parts of bisphenol A type epoxy resin E44, 86 parts of bisphenol A type epoxy resin E51, 34 parts of AGE, 17 parts of DBP and 8 parts of phenol mix, stir until homogeneous, According to the temperature conditions, heat in a water bath at 40°C to promote uniform stirring, let it stand for 1min to 2min, and then add 34 parts by weight of T31-3 type modified phenalkamine curing agent and 51 parts of NP440 type amidoamine curing agent. Mix the curing agent composed of curing agent, stir evenly, pour it into the aggregate for mixing after 3 minutes to 5 minutes, and start the construction operation after mixing evenly after 3 minut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com