Shield synchronous grouting construction method and construction material

A technology of synchronous grouting and construction method, which is applied in earthwork drilling, shaft lining, tunnel lining, etc. It can solve the problems of large ground subsidence, easy segregation, and large loss of single liquid slurry, so as to prevent floating and deformation, and easy Guaranteed grouting volume and short initial setting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

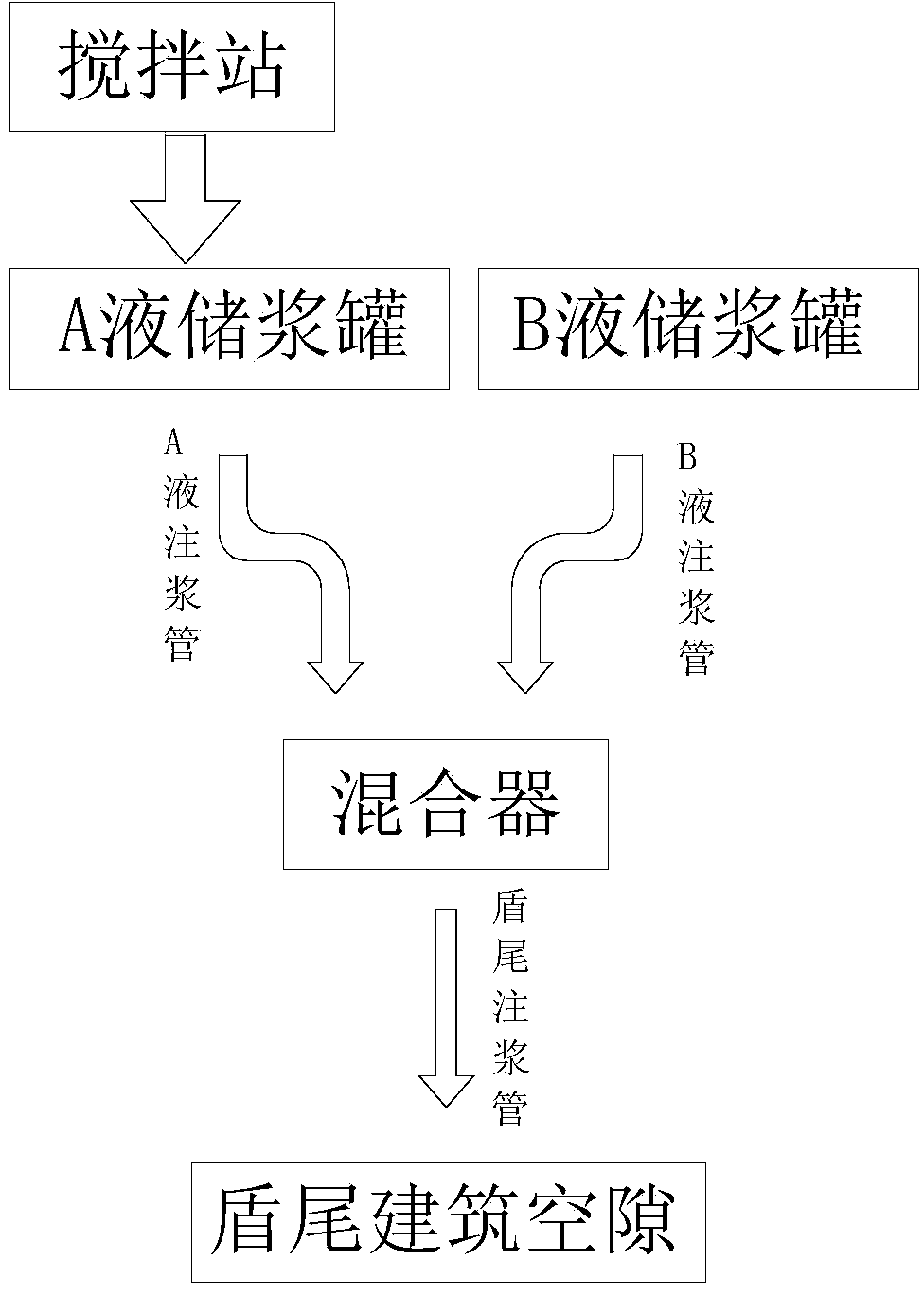

Method used

Image

Examples

Embodiment Construction

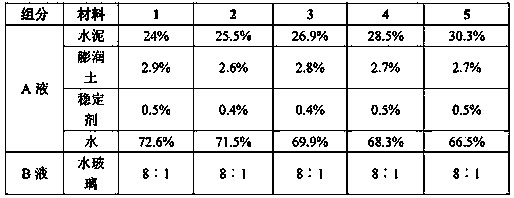

[0021] The invention provides a shield synchronous grouting construction material, including A liquid and B liquid, wherein, the A liquid includes 25.5wt% cement, 2.6wt% bentonite, 0.4wt% stabilizer and 71.5wt% the water; the B liquid is water glass, and the volume ratio of the A liquid and the B liquid is 8:1~15:1. The stabilizer is one or more of naphthalene-based superplasticizers, polycarboxylic acid-based superplasticizers, melamine-based superplasticizers or sulfamic acid-based superplasticizers.

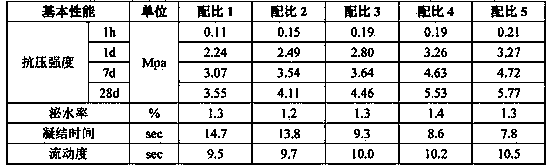

[0022] The initial setting time of the double-liquid slurry composed of the A liquid and the B liquid is 10s to 14s; the 28d uniaxial compressive strength is not less than 2.5Mpa; it has good water dispersion resistance and injectability, and the gelation time is generally 4 ~10 hours, not less than 0.2MPa per day (equivalent to the unconfined compressive strength of soft rock formations), not less than 2.5MPa (slightly greater than the natural compressive strength of strongly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com