Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

119results about How to "Not easy to segregate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Shield method tunnel synchronous grouting slurry applied to compound stratum with upper soft part and lower hard part

ActiveCN101654356AImprove consistencyNot easy to segregateSolid waste managementUnderground chambersSlurryEarth surface

The invention discloses shield method tunnel synchronous grouting slurry which belongs to the technical field of shield tunnel engineering. The shield method tunnel synchronous grouting slurry consists of mortar and water glass, wherein the weight ratio of the mortar to the water glass is 1:4, and the weigh ratio of various raw materials in the mortar of cement to sand to fly ash to swell soil towater is 1:4.8-5.71:2.93-3.31:0.25-0.27:3.13-3.30. The shield method tunnel synchronous grouting slurry has good consistency and insusceptible separation, can effectively prevent the phenomena of slurry separation and grouting pipe blockage, can timely and effectively fill a building gap between a digging surface and the periphery of a pipe piece and control the ground surface settlement within 5to 7mm.

Owner:CHINA RAILWAY NO 2 ENG GRP CO LTD

Shield synchronous grouting construction method and construction material

ActiveCN104074530AImprove stabilityShort entry into initial setting timeUnderground chambersTunnel liningSlurryMaterials science

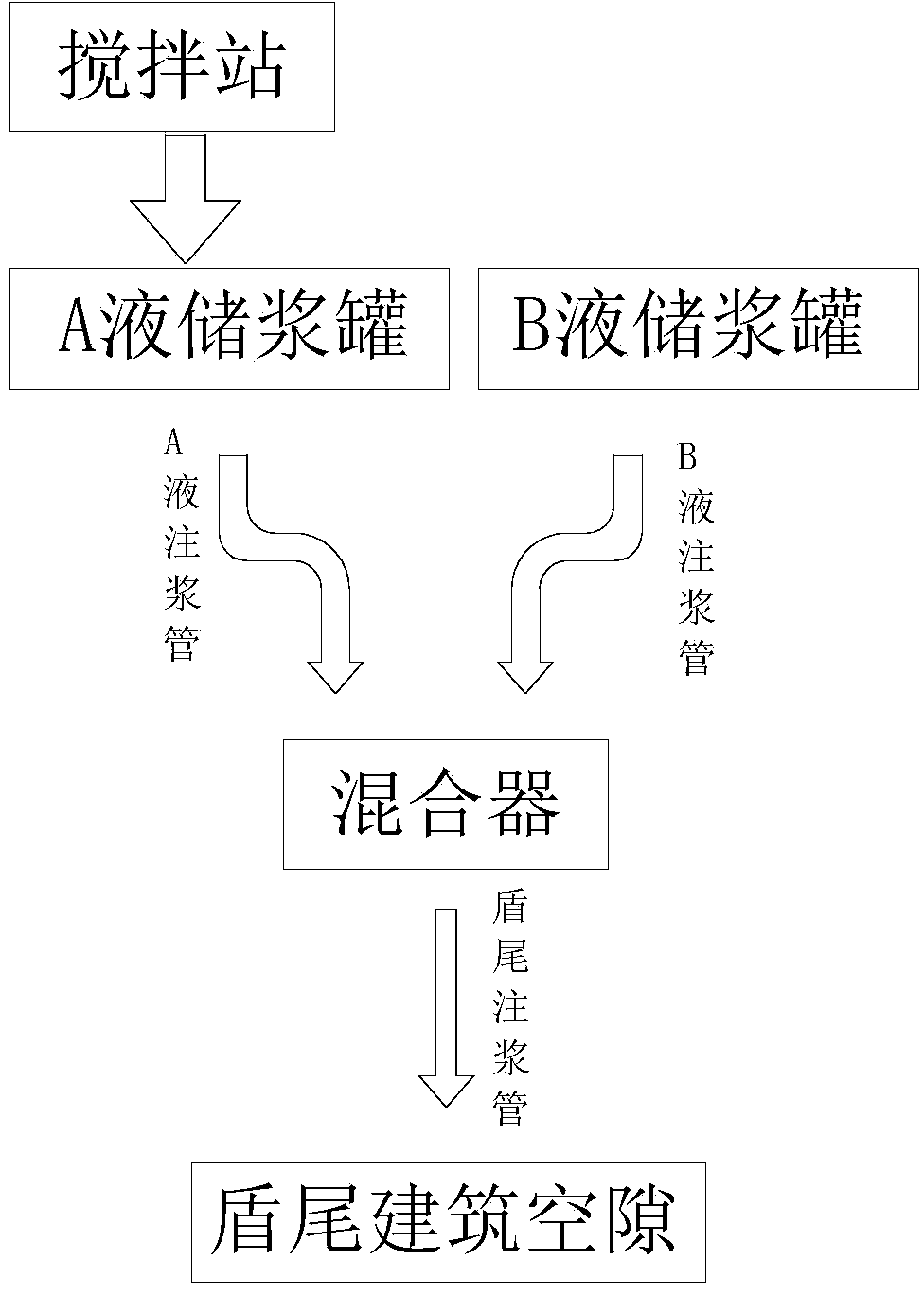

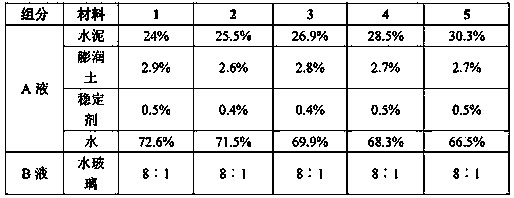

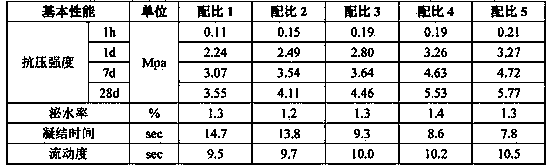

The invention discloses a shield synchronous grouting construction method and a construction material. The construction material comprises liquid A and liquid B, wherein the liquid A comprises 25.5 weight percent of cement, 2.6 weight percent of bentonite, 0.4 weight percent of stabilizing agents and 71.5 weight percent of water; the liquid B is water glass; and the volume ratio of the liquid A to the liquid B is 8:1-15:1. During synchronous grouting construction, the liquid A is prepared in a mixing station, and the liquid A and the liquid B are respectively conveyed into a liquid A slurry storage tank and a liquid B slurry storage tank which are arranged on a shield machine; the liquid A and the liquid B are respectively conveyed into a mixer positioned at the shield tail part of the shield machine through a liquid A slurry injection pipe and a liquid B slurry injection pipe; and the liquid A and / or the liquid B in the mixer are / is synchronously injected into a shield tail building gap through a shield tail slurry injection pipe. The shield synchronous grouting construction method solves various problems in subsequent grouting, synchronous single slurry injection, in-time grouting and secondary grouting in the prior art through utilizing good performance of the liquid A and the liquid B before and after the mixing of the liquid A and the liquid B and combining a primary synchronous grouting process.

Owner:CHINA RAILWAY 15TH CONSTR BUREAU GRP

Fire-resistant gravity flow pouring material and method for making same

The present invention relates to a preparation method for a fireproof self-flow pouring material. The technical scheme in the present invention is that: the fireproof self-flow pouring material is mixed and milled by the following components with the weight ratio that are: 35-55wt percent of bauxite grain, 5-20wt percent of bauxite powder, 5-25wt percent of corundum powder, 5-30wt percent of electrical-melting sand grain, 2-10wt percent of pure calcium aluminate cement, 2-6wt percent of silicon powder, 2-10wt percent of alpha -Al2O3 powder, 0.1-0.2wt percent of water reducer and so on. The fireproof and self-pouring material prepared by the present invention is characterized in non-segregation, good fluidity, easy to be constructed, higher density, better intension and much lower cost and so on. The present invention is widely adaptable to be used in the heat stove bushing including a heat stove bushing, steel enveloping persistent level and middle enveloping level and so on.

Owner:WUHAN UNIV OF SCI & TECH

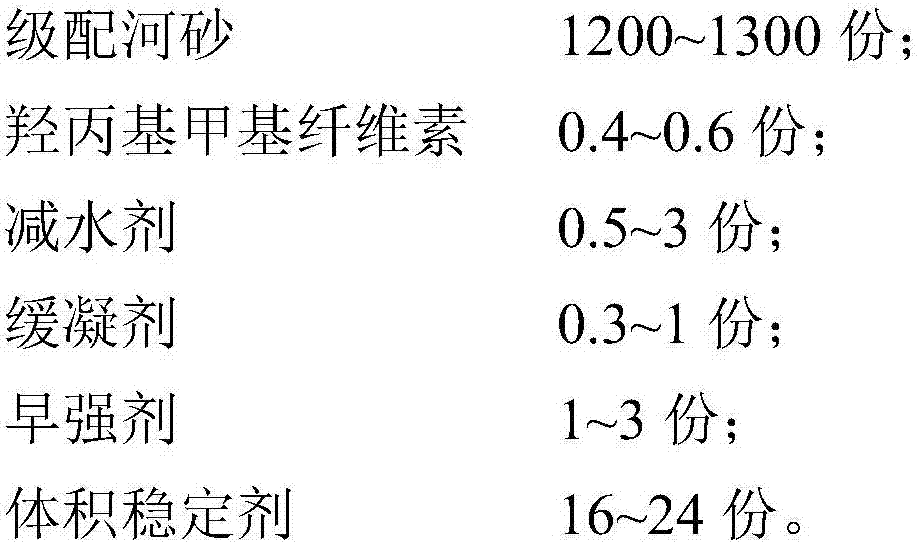

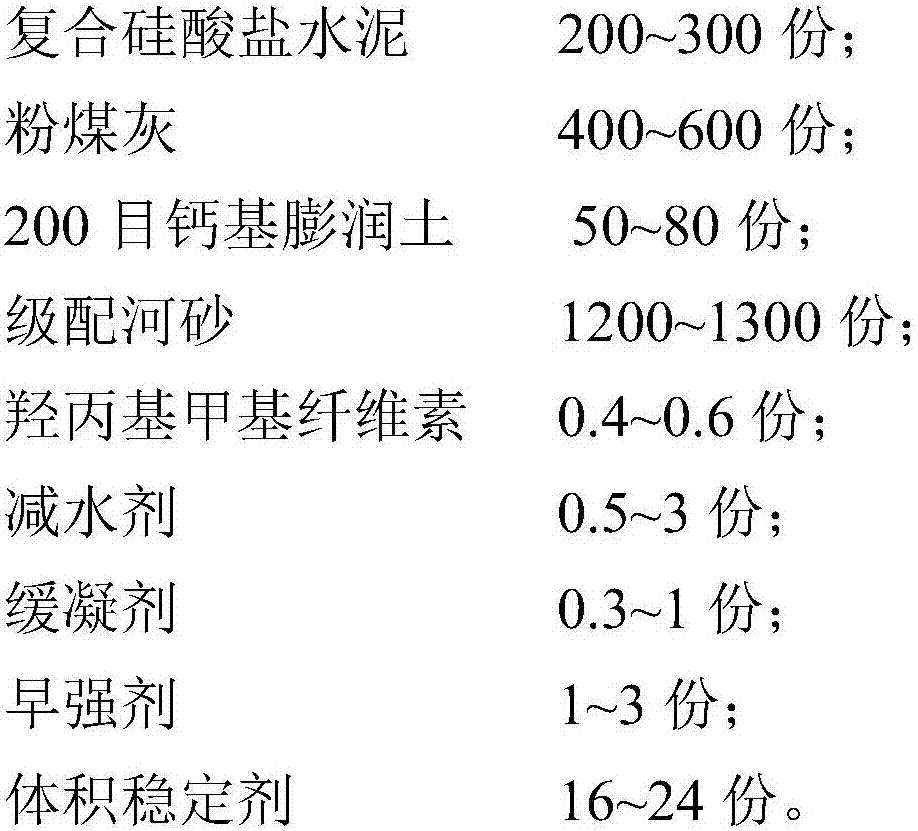

Shield synchronous grouting construction material

ActiveCN106946522AControl the compressive strengthControl bleeding rateSodium BentonitePortland cement

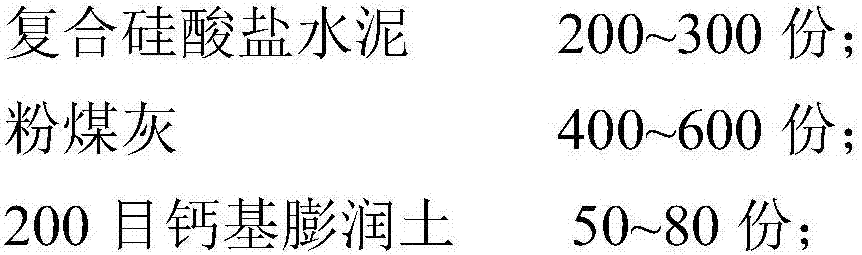

The invention discloses a shield synchronous grouting construction material including, by weight, 200-300 parts of composite Portland cement, 400-600 parts of fly ash, 50-80 parts of 200-mesh calcium based bentonite, 1200-1300 parts of grading river sand, 0.4-0.6 parts of hydroxypropylmethyl cellulose, 0.5-3 parts of a water reducer, 0.3-1 part of a retarder, 1-3 parts of an early strength agent and 16-24 parts of a volume stabilizing agent. Through reasonable adjustment of composition and content of the components, the compressive strength, bleeding ratio, setting time and flowability of the construction material are controlled, so that the construction material has long initial setting time, is quick in early strength development, is not liable to dissociation, has good volume stability, can effectively fill in gaps in buildings and prevent floatation and deformation of tunnel segments, has good flowability and anti-dispersing property, and is easy to transport and to store for a long period.

Owner:北京艺高世纪科技股份有限公司

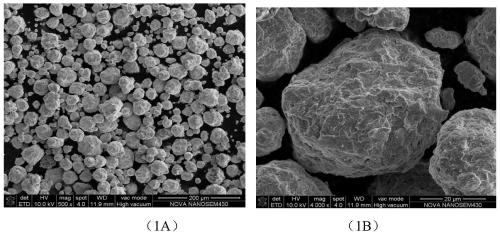

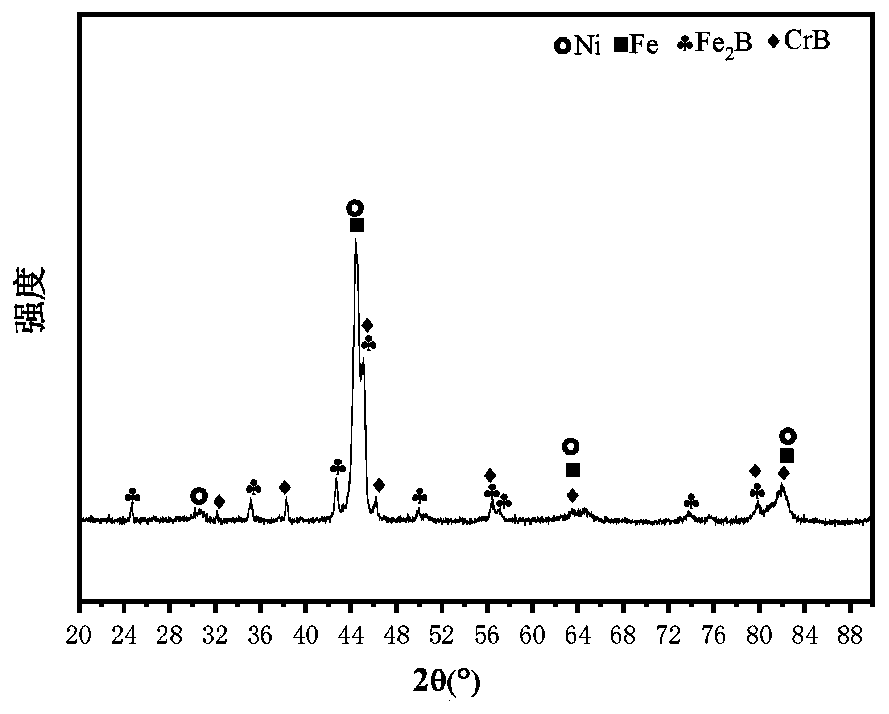

High-entropy alloy boride ceramic, and preparation method and application thereof

The invention belongs to the technical field of boride ceramic materials, and discloses high-entropy alloy boride ceramic, and a preparation method and application thereof. The molecular formula of the high-entropy alloy boride ceramic is Al<y>(FeNiCoCr)<1-x-y>B<x>, wherein x is greater than or equal to 0 and less than or equal to 1, and y is greater than or equal to 0 and less than or equal to 1.The high-entropy alloy boride is prepared by the following steps: carrying out ball milling on Al, Fe, Ni, Co, Cr and B to prepare Al<y>(FeNiCoCr)<1-x-y>B<x> powder; then carrying out sintering by spark plasma sintering at a heating rate of 50-200 DEG C / min, a temperature of 800-1500 DEG C, and a constant pressure of 10-50 MPa; and carrying out furnace cooling. The Al<y>(FeNiCoCr)<1-x-y>B<x> high-entropy alloy boride powder prepared by the method consists of spheroids and is small in particle size, the ceramic main phase is a face center cubic (FCC) solid solution dispersed and distributed with Fe and Cr metal borides, and high density and relatively high hardness and wear resistance are achieved.

Owner:GUANGDONG UNIV OF TECH

Roll surface material of high-pressure roller mill for crushing ore and preparation method of roll surface

The invention belongs to the field of mining machinery and in particular relates to a roll surface material of a high-pressure roller mill for crushing ore and a preparation method of the roll surface. The roll surface material comprises the following chemical components in percentage by weight: 1.0%-3.0% of C, 2.0%-10.0% of V, 2.0%-10.0% of Mo, 2.0%-7.0% of Cr, 0.3%-6.0% of Nb, 0.1%-3.0% of Ti, 0.7%-1.0% of Si, 0.5%-1.0% of Mn, 0.1%-0.7% of Ni, 0-0.02% of P, 0-0.01% of S and the balance of Fe and inevitable impurities. The preparation method comprises the following steps: firstly smelting molten steel, and molding a high-alloy steel roll surface by centrifugal casting in one step; cooling a casting to room temperature; then carrying out a heating treatment process on the casting; adjusting the rigidity of the roll surface to about 50 HRC; processing blind holes in the roll surface in the manner of staggered distribution; carrying out heat treatment under protection atmosphere; then embedding sintered carboloy studs into the blind holes to obtain a highly wear-resistant composite roll surface. The roll surface material of the high-pressure roller mill is uniform in texture, and a final roll surface has stable strength and wear resistance and longer service life.

Owner:NORTHEASTERN UNIV +1

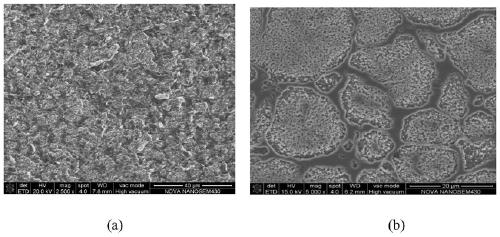

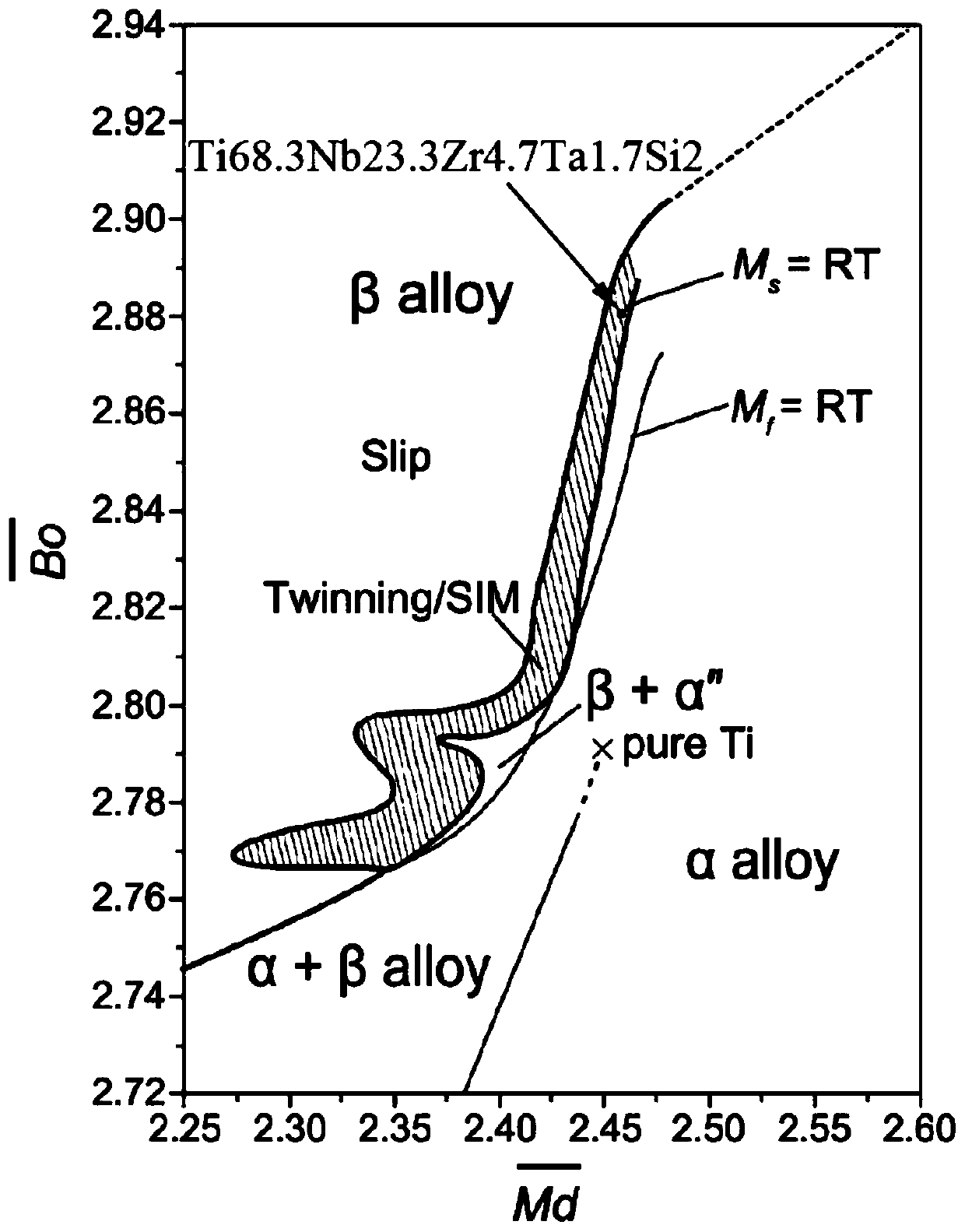

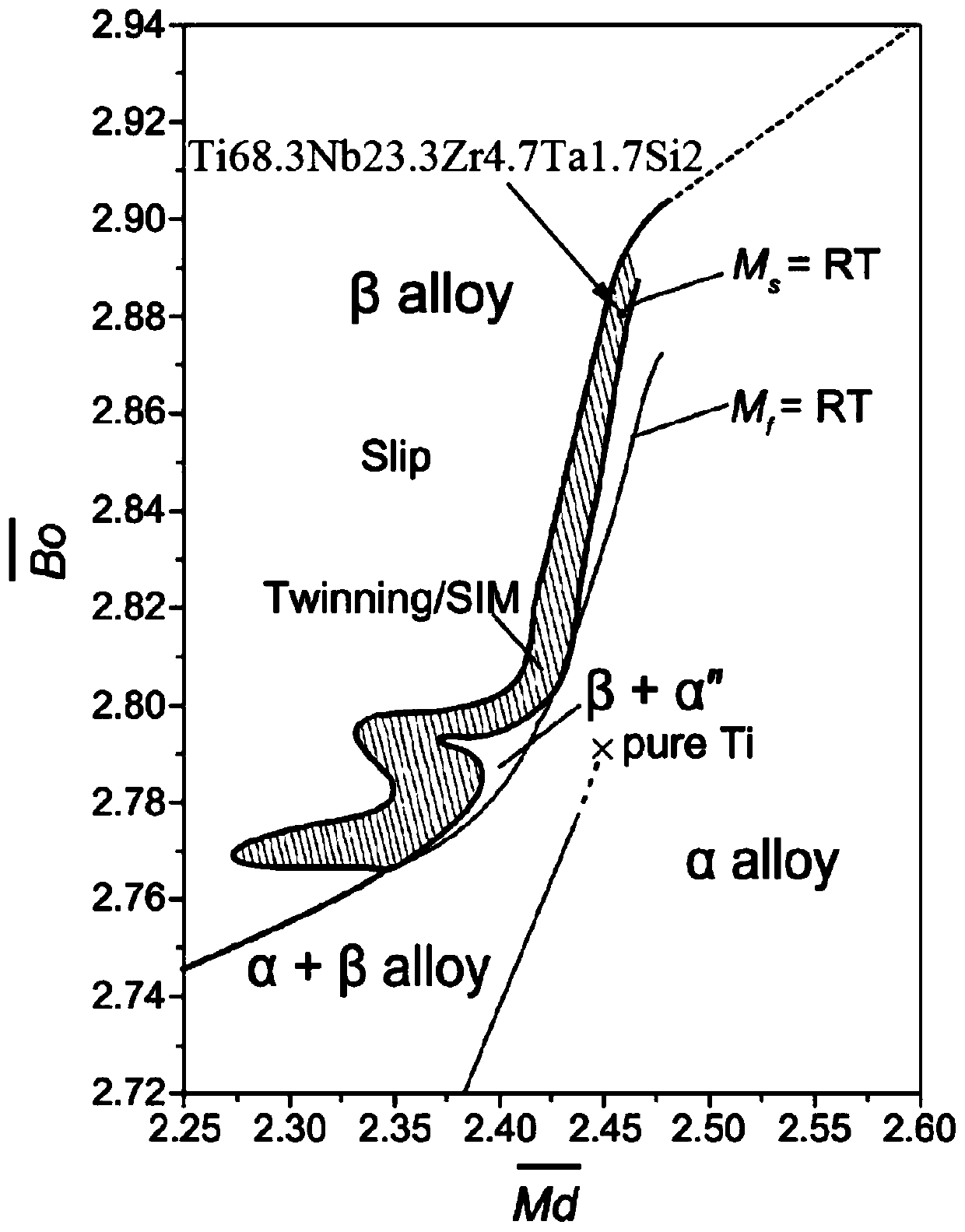

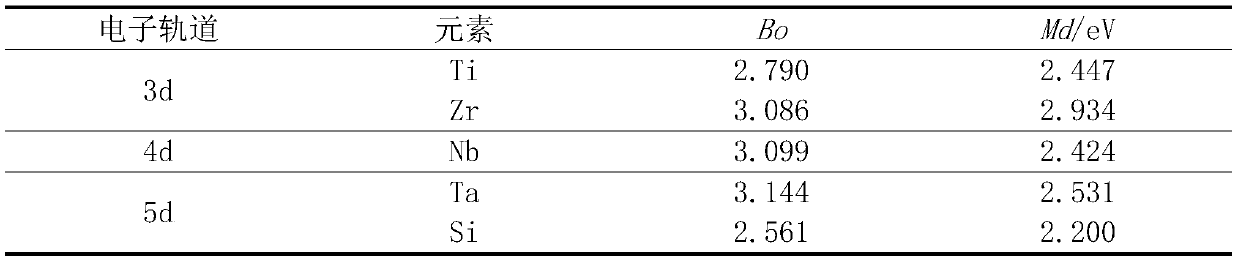

Si-containing high-strength low-modulus medical titanium alloy and additive manufacturing method and application thereof

ActiveCN111118339ALow elastic modulusGood biocompatibilityAdditive manufacturing apparatusIncreasing energy efficiencyBiocompatibilityTitanium alloy

The invention discloses a Si-containing high-strength low-modulus medical titanium alloy and an additive manufacturing method and application thereof. The preparation method comprises the following steps of designing an alloy component, preparing powder, constructing a model, preheating a substrate and manufacturing an additive, wherein the designed Si-containing high-strength low-modulus medicaltitanium alloy comprises, 60-70 at.% of Ti, 16-24 at.% of Nb, 4-14 at.% of Zr, 1-8 at.% of Ta and 0.1-5 at% of Si. According to the manufacturing method, the high-strength low-modulus and good-biocompatible medical beta-type titanium alloy is designed according to a D electronic theory, the thermal expansion difference value between silicide and a beta-Ti crystal phase is reduced through preheating, and meanwhile, the sufficient cooling degree in the additive manufacturing process is ensured to promote the transition of the alloy from a discrete eutectic crystal to the desorption reaction, andthe common problems such as easy cracking caused by continuous distribution of a Si-containing phase along a grain boundary are solved.

Owner:SOUTH CHINA UNIV OF TECH

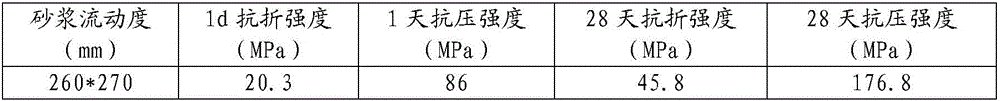

Ecological dustproof type seawater sea-sand anti-corrosion marine concrete and preparation method thereof

The invention discloses an ecological dustproof type seawater sea-sand anti-corrosion marine concrete and a preparation method thereof. The concrete comprises the following raw materials: cement, silica fume, coal ash beads, blast furnace slag powder, corroding ion inhibitors, sea sand, steel fibers, a water reducing agent and seawater. The preparation method comprises the following steps: mixingcement, silica fume, coal ash beads, blast furnace slag powder, corroding ion inhibitors and steel fibers and then uniformly stirring with a stirrer; adding sea sand and continuing to uniformly stir;adding seawater and the water reducing agent; mechanically stirring till uniformly stirring, thereby acquiring a concrete slurry; pouring and then removing a mold and maintaining for 48h at 80 DEG C under the condition of humidity of 95%, thereby acquiring the marine concrete. The concrete disclosed by the invention has the advantages of high curing rate of chloride ions, excellent working performances, high durability, lower cost, locally acquired raw materials, short construction period and suitability for popularization and application.

Owner:HOHAI UNIV

Color-adjusting spraying rapid-hardening liquid rubber waterproof material and using method thereof

ActiveCN103396707AImprove waterproof reliabilitySimple production equipmentConjugated diene hydrocarbon coatingsChloropene polymer coatingsRosinEmulsion

The invention discloses a color-adjusting spraying rapid-hardening liquid rubber waterproof material. The color-adjusting spraying rapid-hardening liquid rubber waterproof material comprises liquid modified rubber and a curing agent, wherein the liquid modified rubber comprises latex, a viscosity increasing filler, cassava starch modified with a coupling agent, an auto-vulcanization bag, emulsifying rosin, an inorganic filler and color paste in parts by weight; and the curing agent is an anhydrous calcium chloride solution. The color-adjusting spraying rapid-hardening liquid rubber waterproof material has the advantages that a coating-type waterproof structure is formed on a waterproof base layer in a liquid spraying manner, the waterproof reliability is improved, connecting overlaid seams do not exist by one-step spraying, the color-adjusting spraying rapid-hardening liquid rubber waterproof material is similar to a conventional spraying rapid-hardening asphalt waterproof material, and as a waterproof membrane is semi-transparent, the color is easy to adjust; production equipment is simple, and investment is small; a waterproof material emulsion is stable and difficult to layer and separate; the elongation rebound rate which is less than or equal to 5% is beneficial to the creep resistance of the waterproof layer; and the tensile strength of a waterproof adhesive film reaches 1.8Mpa, which is twice as much as the previous strength; and the color-adjusting spraying rapid-hardening liquid rubber waterproof material has good adhesive force being higher than or equal to 0.3Mpa.

Owner:GUIZHOU LANTU NEW MATERIALS

Subway tunnel grouting admixture and preparation method thereof

The invention belongs to the field of new materials for construction, and particularly relates to a subway tunnel grouting admixture and a preparation method thereof. The preparation method is characterized by comprising the following steps: taking 1000 parts by weight of modified lignosulfonate concrete high-efficiency water reducing agent, dissolving 1000-2000 parts by weight of water, heating to 60-100 DEG C while stirring, adding 20-200 parts by weight of crosslinking agent, and performing polycondensation reaction for 0.5-10 hours; adding 1-50 parts by weight of air entraining agent, 100-500 parts by weight of inorganic salt reinforcer and 10-50 parts by weight of water-soluble high-molecular polymer, and stirring for 10-60 minutes; and cooling to obtain a liquid product, and drying to obtain a solid powder product, wherein the modified lignosulfonate concrete high-efficiency water reducing agent can be prepared according to the ZL98116516.8 patent, the crosslinking agent is one of or a mixture of more than one of formaldehyde, melamine, polyalcohol and polyamine, and the air entraining agent is one of or a mixture of more than one of turpentine soap, rosin thermopolymer, anionic surfactant or multi-element compounds thereof.

Owner:张淑华

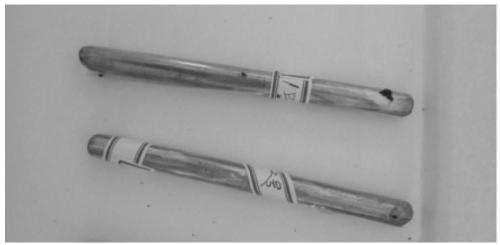

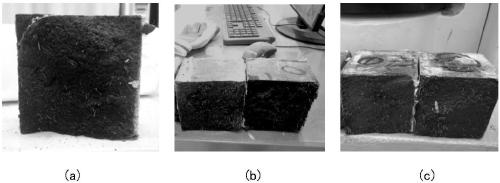

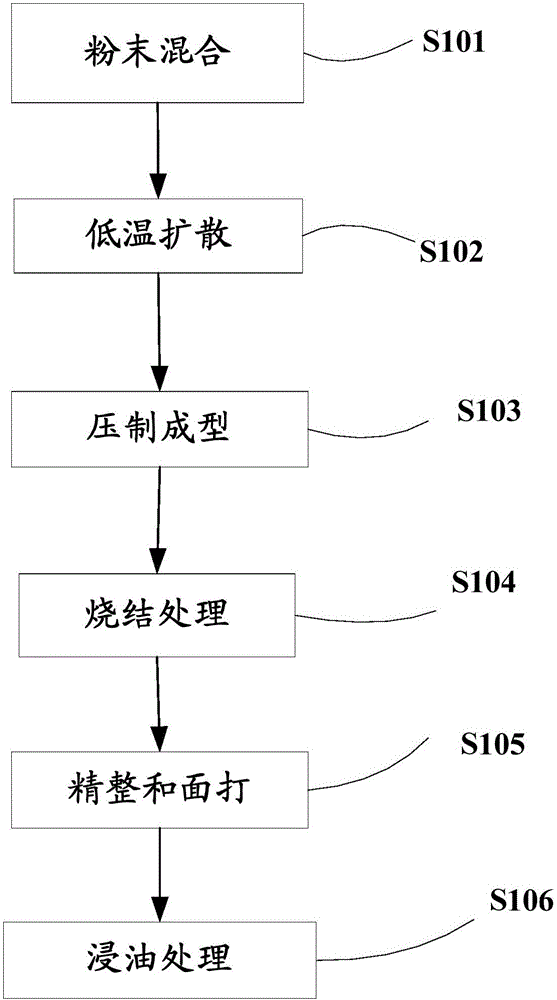

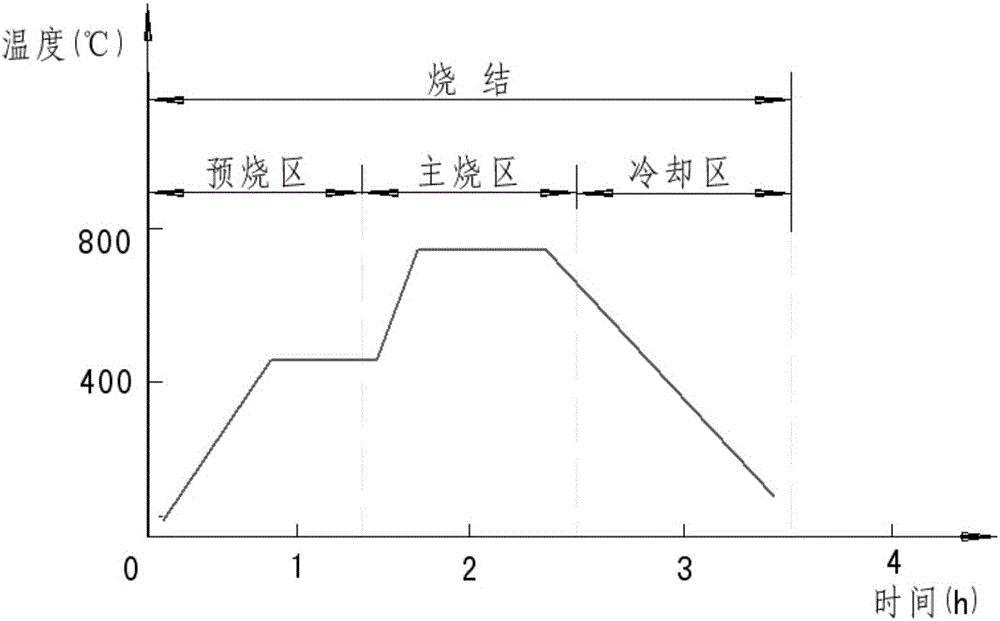

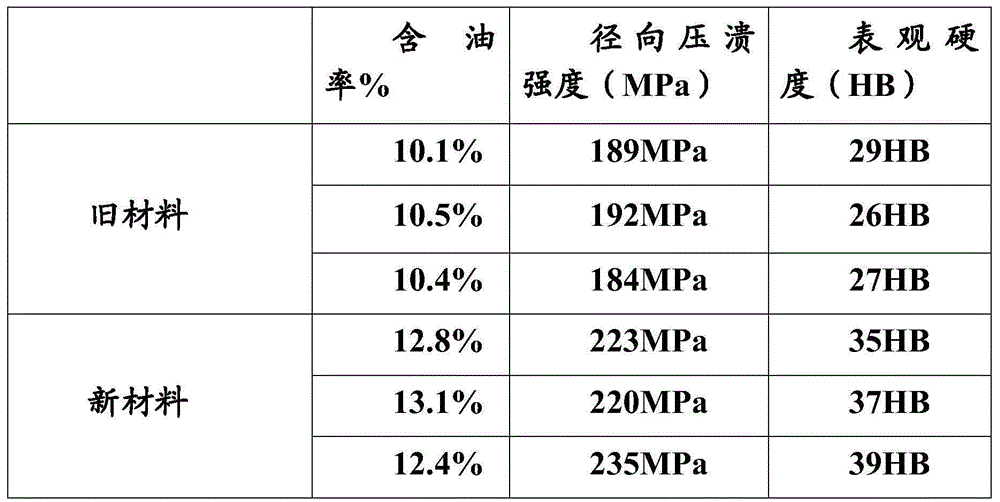

Petrol pump motor oil bearing manufacturing method based on powder metallurgy

InactiveCN105149593AImprove wear resistanceWell mixedTurbinesOther manufacturing equipments/toolsNitrogenAlloy

The invention discloses a petrol pump motor oil bearing manufacturing method based on powder metallurgy. The method comprises the steps of powder mixing, low-temperature diffusion, press molding, sintering, finishing and surface beating, and oil-impregnated treatment. In the powder mixing process, 70%-85% of Sn powder, 5%-10% of composite graphite powder and the balance copper powder are mixed by weight. In the low-temperature diffusion process, evenly mixed powder is subjected to low-temperature diffusion in a diffusion furnace under the protection of nitrogen. In the press molding process, powder subjected to low-temperature diffusion is placed in a die for press molding and pressed into a pressed blank. In the sintering process, the pressed blank is sintered into an alloy sintered body in the N and H reducing atmosphere. In the finishing and surface beating process, the alloy sintered body is pressed and shaped with a molding die. In the oil-impregnated treatment process, the pressed part is placed in a vacuum oil impregnation machine for oil-impregnated treatment. According to the method, the copper-coated graphite powder is added to serve as the solid lubricant to enable Cu-Sn alloy to be combined more easily at a low temperature; furthermore, graphite is evenly mixed and not prone to segregation.

Owner:JIANGSU YINGQIU GRP CO LTD +1

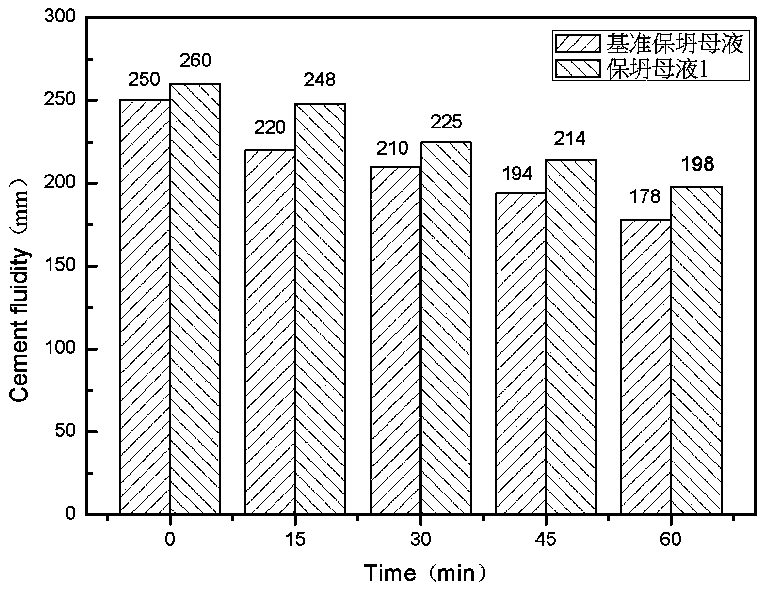

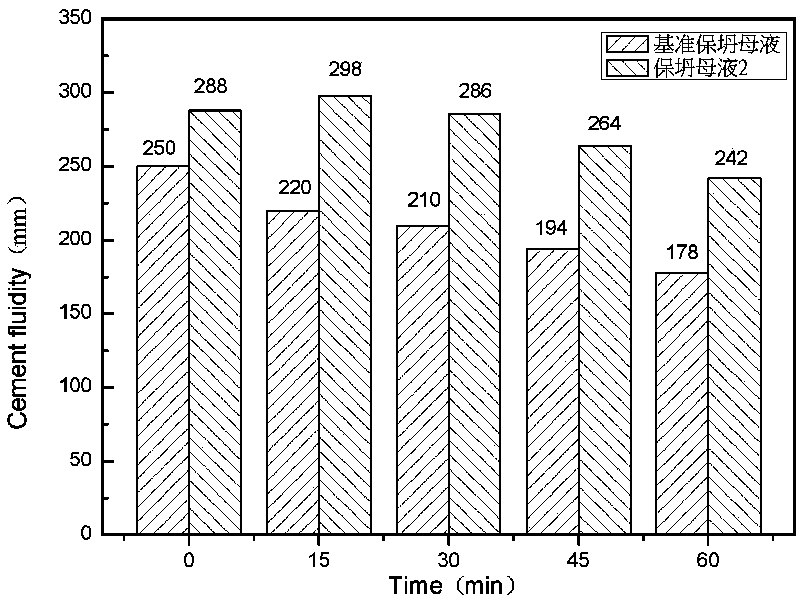

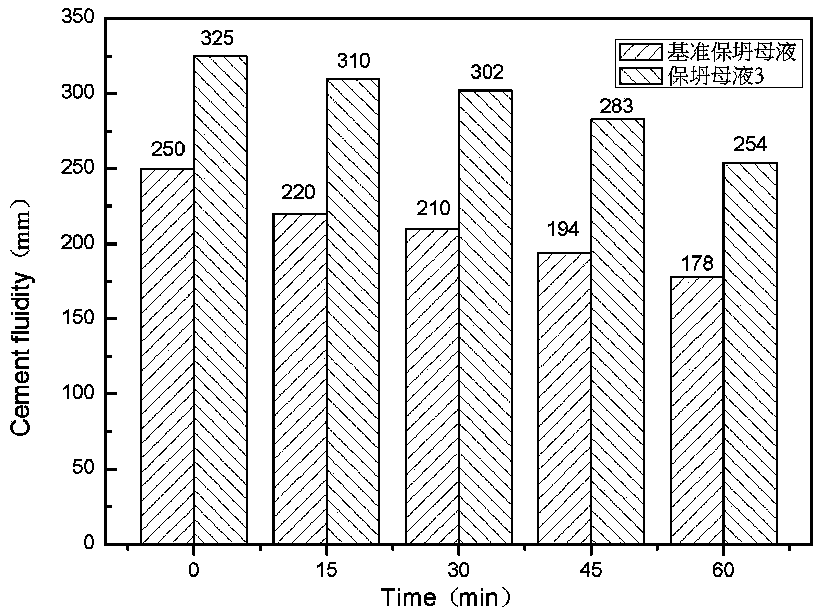

Anti-mud slump-loss-resistant multifunctional unsaturated monomer for production of polycarboxylate slump-loss-resistant mother liquor

The invention relates to an anti-mud slump-loss-resistant multifunctional unsaturated monomer for production of a polycarboxylate slump-loss-resistant mother liquor, in particular to an unsaturated functional monomer with the functions of mud prevention, slump loss resistance, sustained release and the like. The monomer is characterized in that common chemical raw materials or chemical reagents are selected, and the unsaturated monomer is prepared through a reaction at a certain temperature. The unsaturated functional monomer can effectively improve the mud prevention, slump loss resistance and sustained release performance of a polycarboxylate superplasticizer and the workability of concrete, for example, the water retention and slurry retention performance of the concrete can be significantly improved; the segregation of the concrete does not easily occur, and wrapping performance to gravels is good; the doping amount of the superplasticizer or the water consumption amount is appropriately increased, and the segregation and bleeding phenomenon cannot occur; the ground gripping phenomenon of the concrete can be effectively reduced.

Owner:YANTAI UNIV

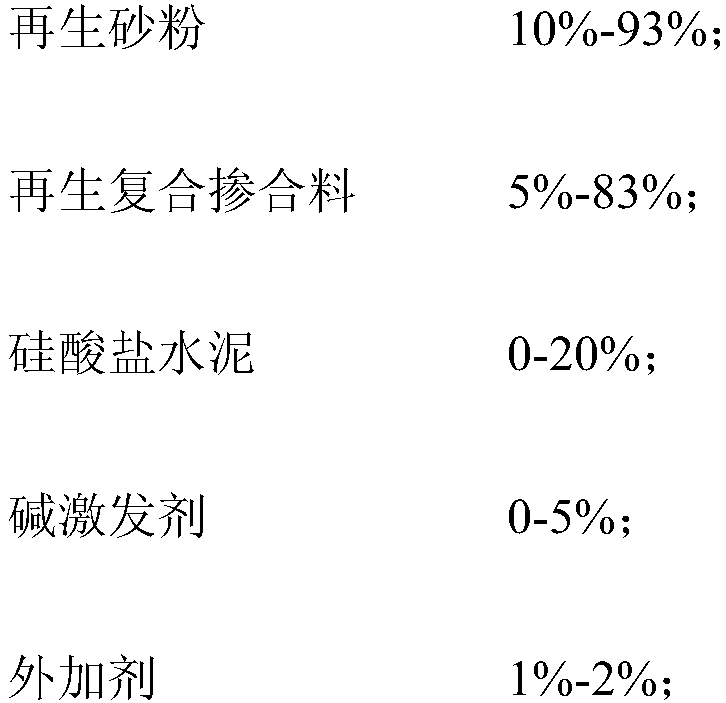

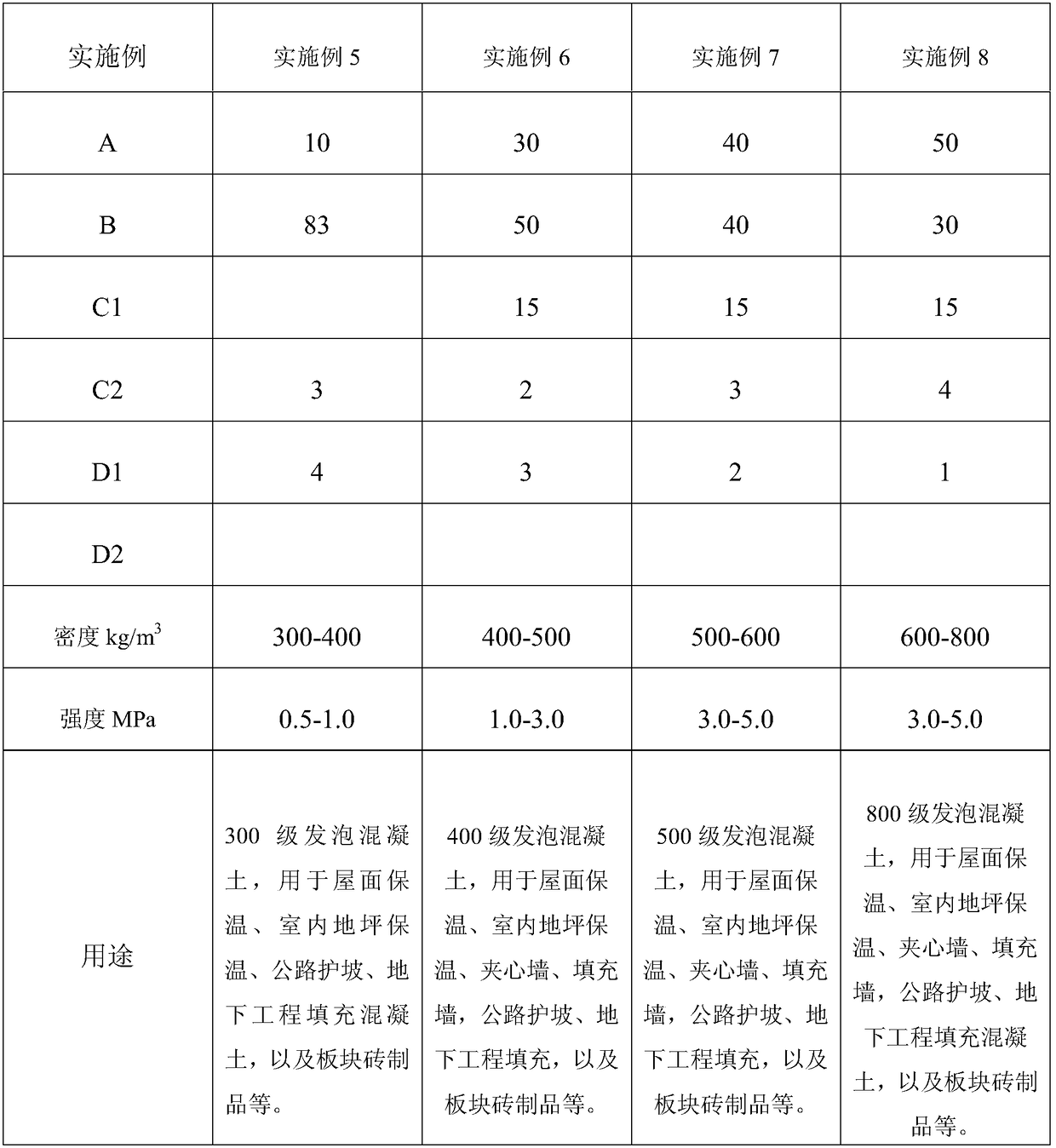

Regenerated sand powder green concrete, and preparation method thereof

The invention provides a regenerated sand powder green concrete. The regenerated sand powder green concrete comprises, by mass, 10 to 93% of regenerated sand powder, 5 to 83% of a regenerated composite admixture, 0 to 20% of Portland cement, 0 to 5% of an alkali-activator, and 1 to 2% of an additive; a coarse aggregate free lightweight concrete with a density smaller than 1900kg / m<3> is prepared from regenerated sand powder and regenerated composite admixture at a double component doping amount of 70% or larger. The invention also discloses a preparation method of the regenerated sand powder green concrete. According to the preparation method, waste concrete cement stone flour and brick-concrete regenerated sand powder are subjected to mixing grinding so as to obtain the regenerated composite admixture which is a multi-component composite gelling material and possesses composite gelling and superimposed effect. The regenerated sand powder green concrete possesses the filling effect andmicro-aggregate effect of regenerated sand powder, and the gelling performance of the regenerated composite admixture, the double component doping amount is higher than 70%, so that regenerated material large amount doping is realized, and it is beneficial for promotion of building waste resource utilization and green development of concrete industry.

Owner:SHANGHAI GUOTONG ENVIRONMENTAL PROTECTION EQUIP

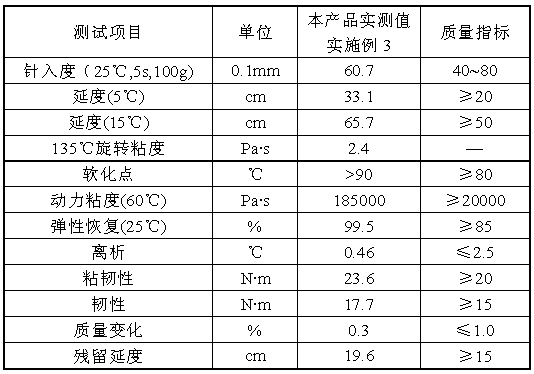

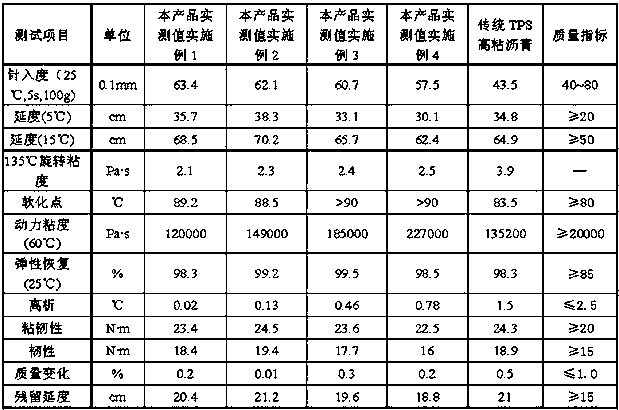

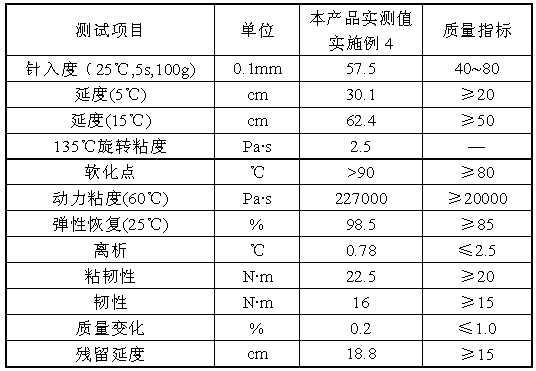

High-viscosity asphalt and preparation method thereof

InactiveCN108410185AImprove performanceMeet the performance requirements of high-viscosity asphaltBuilding insulationsDodecylsulfonic acidAsphalt

The present invention relates to high-viscosity asphalt. The high-viscosity asphalt is composed of the following raw materials in percentages by weight: 3-8% of a styrene-butadiene-styrene block copolymer (SBS), 1-3% of styrene-butadiene rubber (SBR), 2-10% of a compatibilizer, 0.08-0.3% of a stabilizer, 0.5-2% of sodium dodecyl sulfate, 0.8%-1.5% of polyphosphoric acid (PPA) and the balance of matrix asphalt. At the same time, the present invention also discloses a preparation method of the high-viscosity asphalt. The high-viscosity asphalt provided by the present invention has excellent performance, can satisfy high-viscosity and high-elastic properties, can satisfy simplification of production and construction, and has low costs.

Owner:甘肃路桥善建科技有限公司

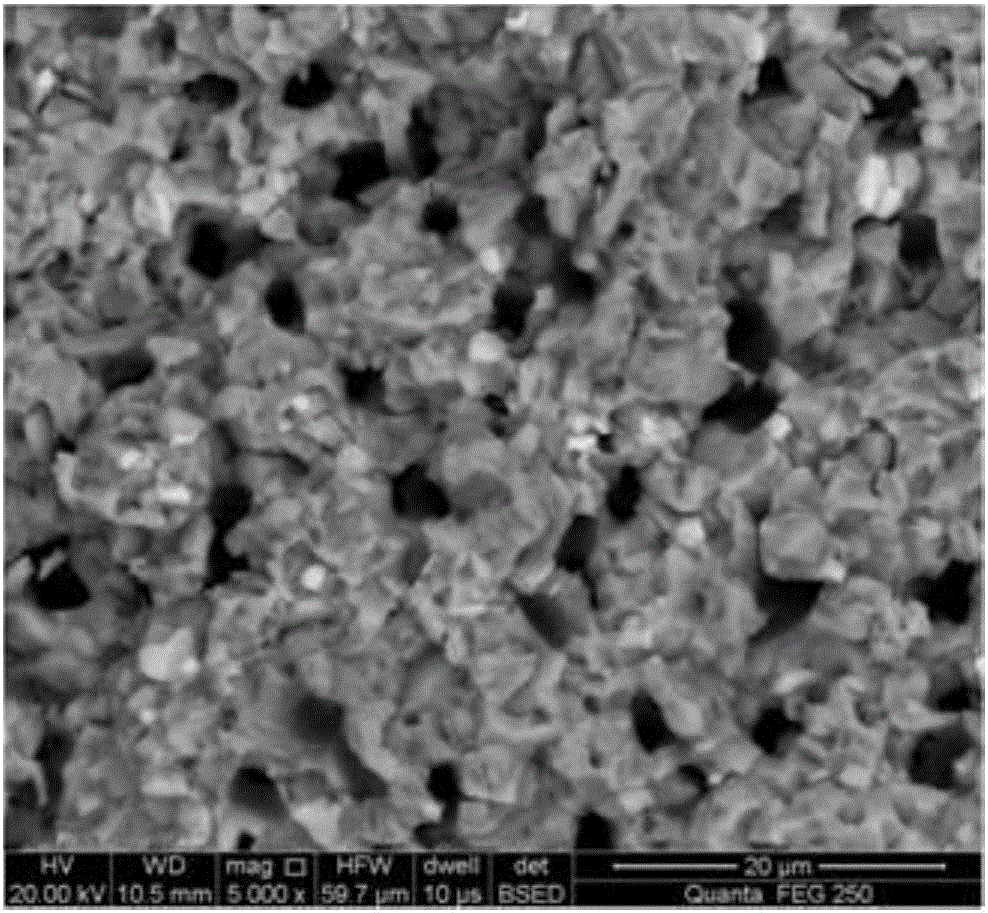

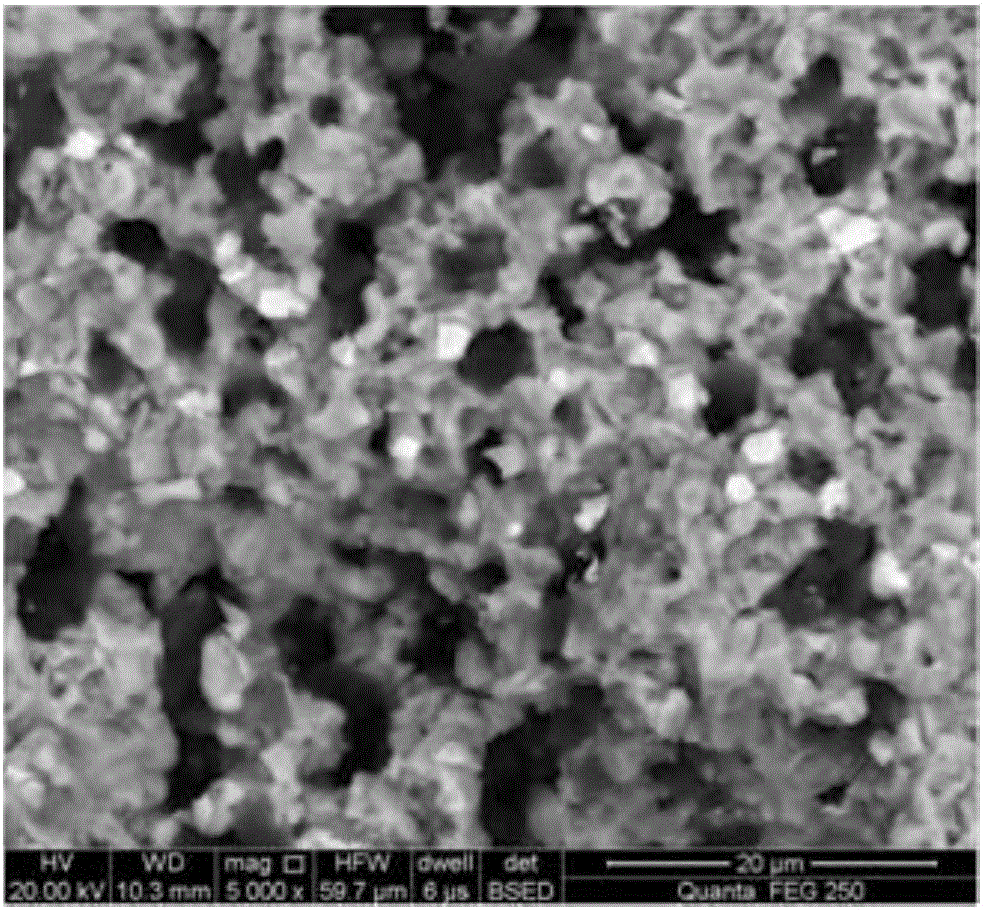

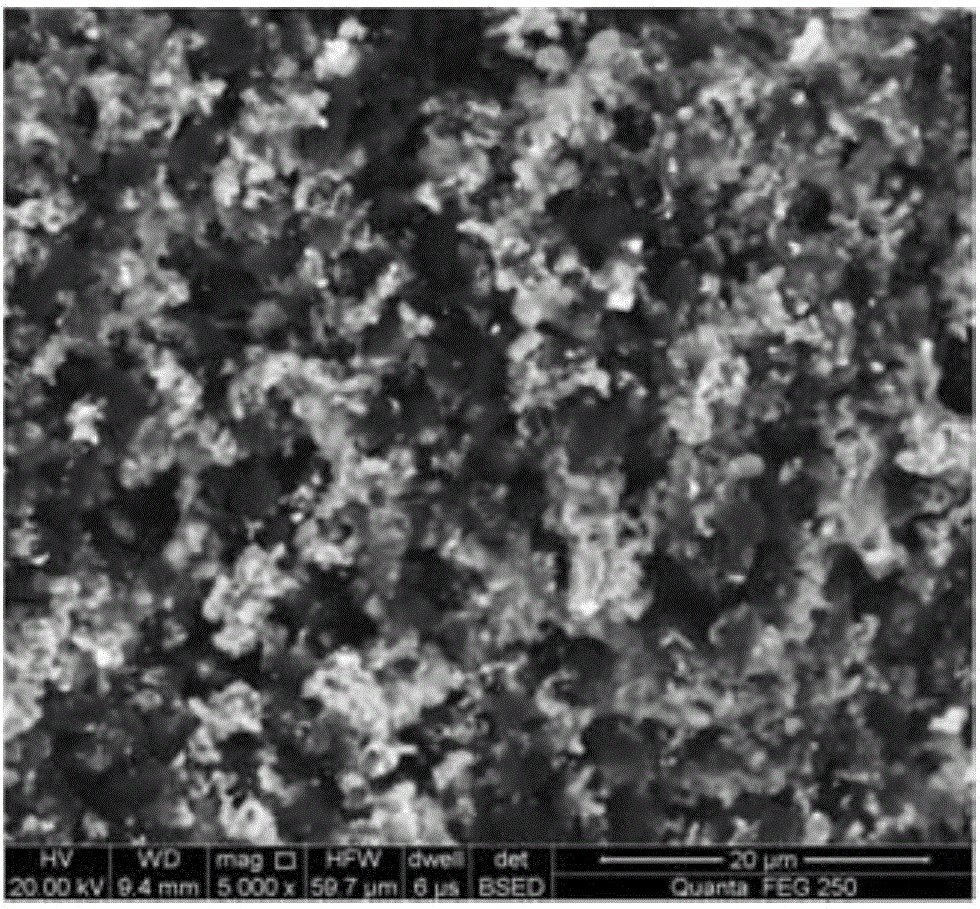

cBN-high speed steel composite material and preparation method thereof

The invention discloses a high speed steel precursor powder mixture used for preparing a cBN-high speed steel composite material. The high speed steel precursor powder mixture comprises, by mass, 3%-15% of Co powder, 32%-75% of Fe powder, 20%-50% of carbide powder selected from Group 4 metal, Group 5 metal and Group 6 metal of the periodic table of the elements, and 0-2% of C powder. The cBN-high speed steel composite material comprises, by mass, 1%-30% of cBN, 2.7%-13.5% of Co, 1.7%-5.4% of C, 14%-45% of Group 4 metal, Group 5 metal and Group 6 metal selected from the periodic table of the elements, and 40.6%-67.5% of Fe. Non-atomized powder is adopted to replace atomized powder, a local eutectic liquid phase can be avoided, erosion to cBN by the local eutectic liquid phase is prevented, the cBN can be kept stable, and therefore usability of the final cBN-high speed steel composite material is improved.

Owner:长沙市萨普新材料有限公司

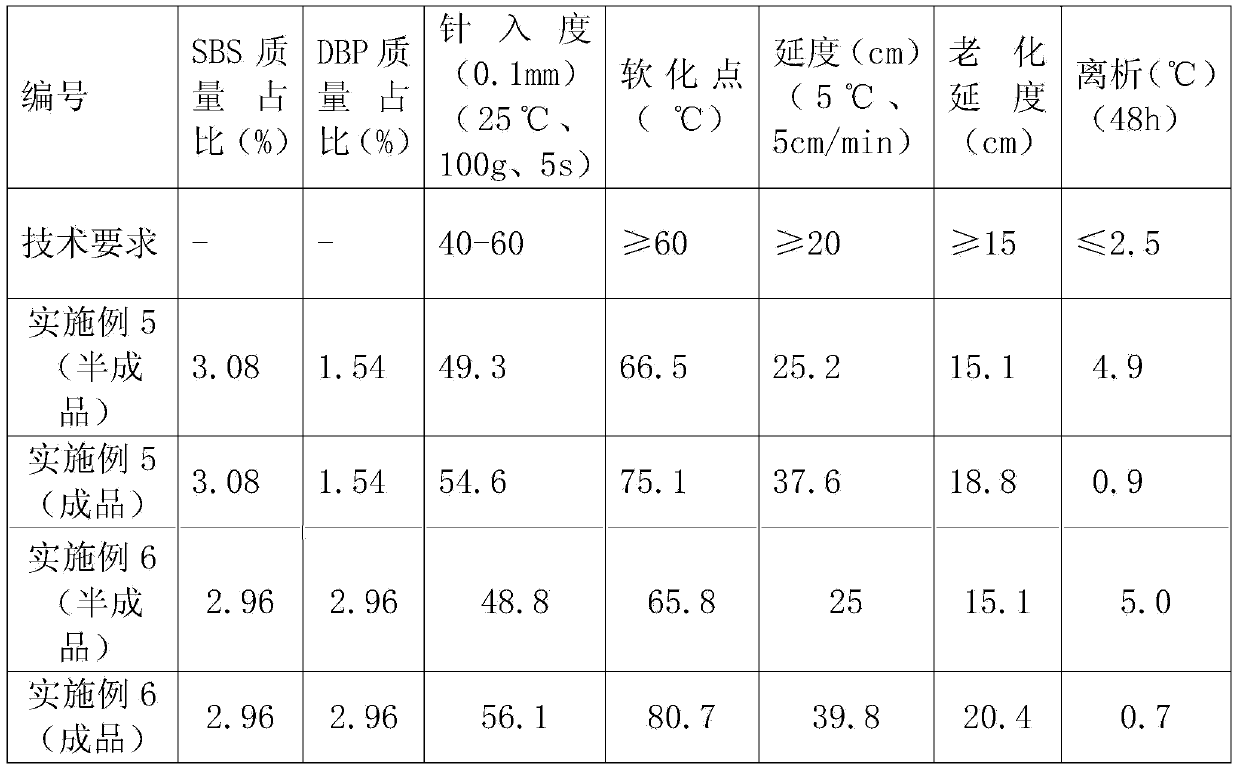

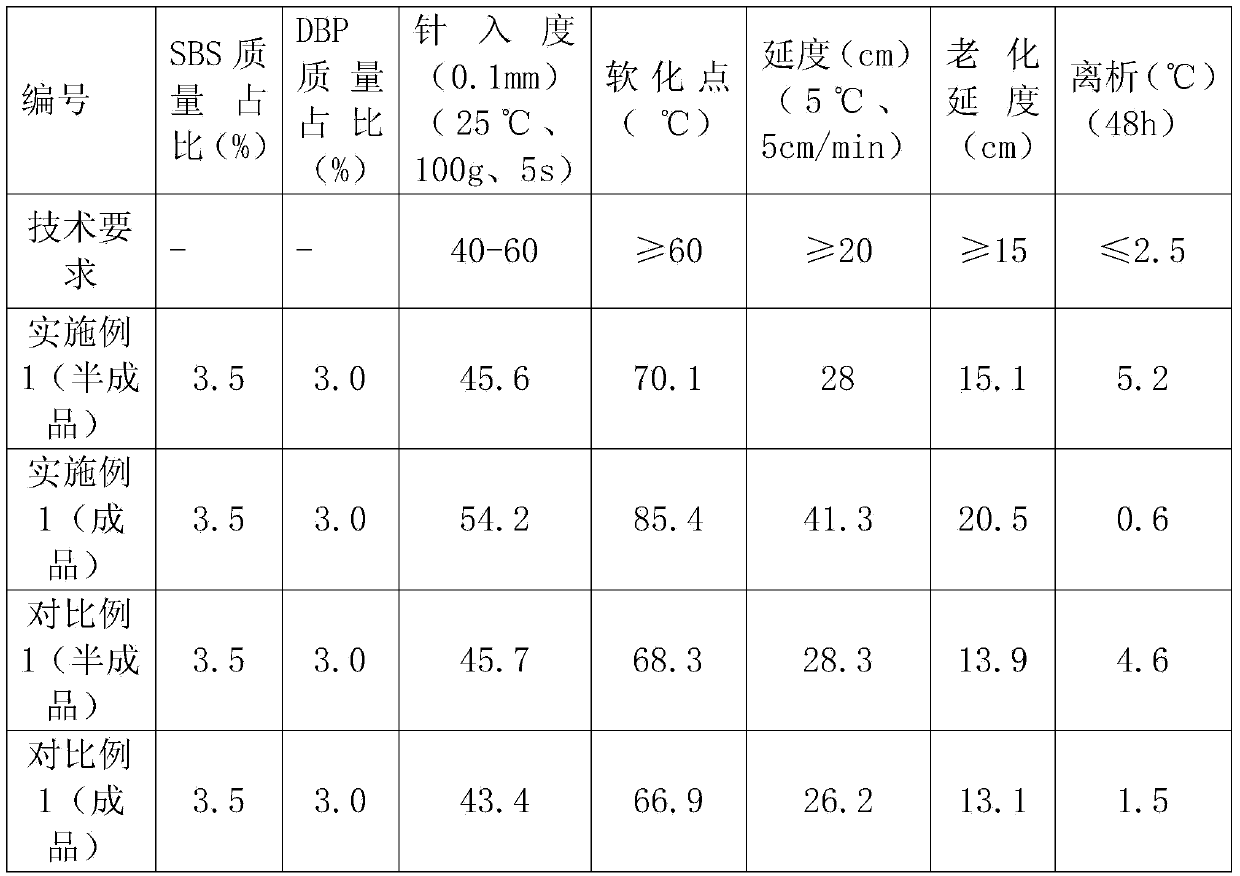

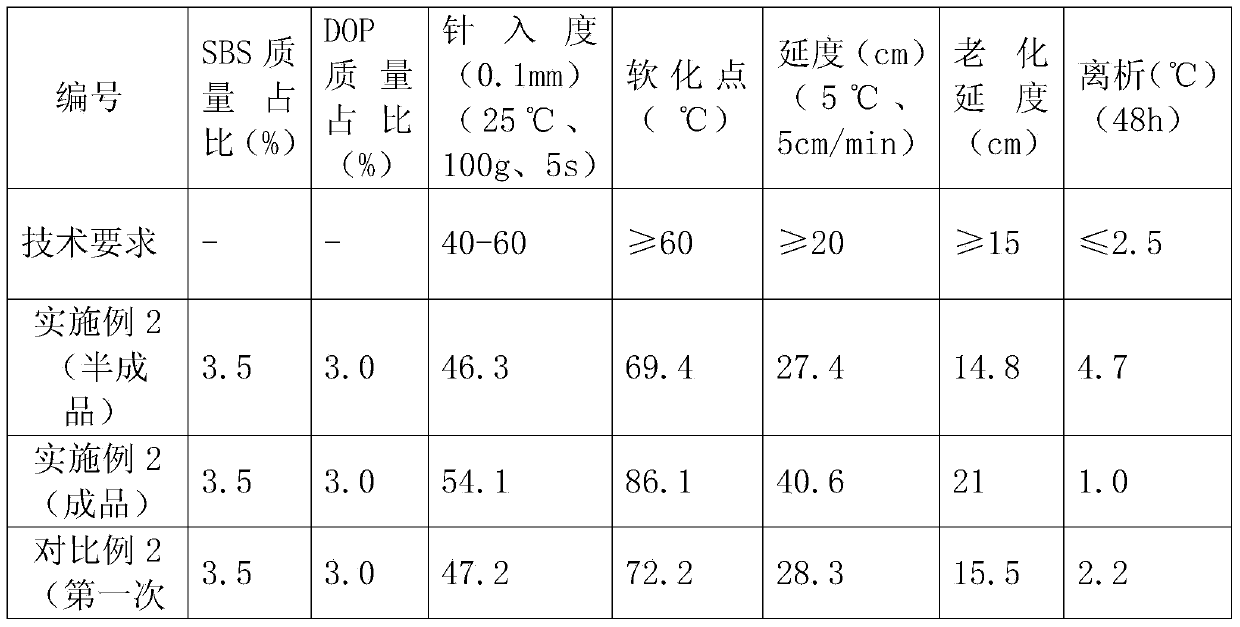

Compound SBS (styrene butadiene styrene) modified asphalt and production process thereof

ActiveCN104194365AAvoid performance degradationHigh softening pointBuilding insulationsPlasticizerColloid

The invention provides compound SBS (styrene butadiene styrene) modified asphalt. The compound SBS modified asphalt consists of 70# matrix asphalt, 50# matrix asphalt, an SBS modifier, a plasticizer, an anti-ageing agent and a stabilizer. A production process for the compound SBS modified asphalt comprises the following steps: swelling the 70# matrix asphalt and then adding the SBS modifier, the anti-ageing agent and the plasticizer, uniformly stirring, passing the mixture through a colloid mill to shear at a high speed to obtain a material mixture; growing the material mixture for 0.5-1.5 hours at 180-185 DEG C, adding the stabilizer and the swelled 50# matrix asphalt, cooling to 170-180 DEG C to grow for 0.5-1.5 hours, and continuously growing for 12-16 hours in a process of loading and transporting to a construction site to obtain the compound SBS modified asphalt. In a long-distance transportation process, the performance of the modified asphalt is not weakened, but improved, so that not only are a softening point and ductility are high, but also separation is not easy.

Owner:广西国创道路材料有限公司

Preparation method of in-situ synthesized aluminum-based composite bar

The invention discloses a preparation method of an in-situ synthesized aluminum-based composite bar. The preparation method comprises the steps of preparing TiB2 reinforced aluminum-based composite billet by adopting a mixed salts method; installing and welding the aluminum-based composite billet to form a consumable electrode with the cross section of Phi 150-500mm; then, smelting to obtain a vacuum consumable ingot of Phi 200-600mm; feeding the vacuum consumable ingot into a resistance furnace, heating, preserving the heat, and forging the vacuum consumable ingot to obtain the aluminum-based composite bar with the cross section of Phi 150-500mm. Through microscopic and macroscopic metallographic inspection, the aluminum-based composite bar prepared by using the preparation method is very uniform in TiB2 reinforced phase distribution and very compact in tissue; and through ultrasonic inspection, the bar has no inclusion defect and has the tensile strength of 415MPa and the rupture elongation of 2.5%.

Owner:西安超晶科技股份有限公司

Container with inner heating casing

InactiveCN104326185ALarge specific heat capacityNot easy to segregateLarge containersTank wagonsHeat conductingEngineering

The invention discloses a container with an inner heating casing. A heating pipe consists of an inner casing and an outer casing which are coaxially sheathed, wherein heat conducting medium fills between the inner casing and the outer casing. Therefore, when the inner casing is heated, heat of the inner casing is transferred to the outer casing through the heat conducting medium layer, and then the outer casing transfers the heat to modified asphalt which is in direct contact with the outer casing; since the specific heat capacity of the heat conducting medium layer is higher and the temperature rise speed is lower than that of the outer casing, the temperature of the outer casing can be more easily controlled by controlling the temperature of the heat conducting medium layer; since the heat conducting medium layer is arranged and the temperature of the outer casing is stable, the temperature of the modified asphalt in a tank body can be stably controlled within a temperature interval in which the modified asphalt is not easily segregated, the fluidity is good and the asphalt is not solidified, the technical problems that the modified asphalt is segregated and decomposed at high temperature and is easily solidified at low temperature and the modified asphalt close to the heating pipe is easily aged are avoided, and the quality of the modified asphalt is guaranteed.

Owner:TIANJIN ZHAOHUA LOGISTICS CO LTD

Making method for aluminum oxide-silicon carbide crystal whisker reinforced cold work die steel material

ActiveCN105925918AImprove organizational stabilityImprove mechanical propertiesNano al2o3Nitrogen gas

The invention belongs to the field of die steel materials, and particularly relates to a making method for an aluminum oxide-silicon carbide crystal whisker reinforced cold work die steel material. Aluminum oxide-silicon carbide crystal whisker reaction precursor powder is blown into WCrMoV melt in a vacuum melting furnace through nitrogen and carbon dioxide; during a blowing process, self-propagating combustion synthesis reaction is caused, so that nanometer aluminum oxide-silicon carbide crystal whiskers and a small amount of carbon and silicon are obtained; and then the aluminum oxide-silicon carbide crystal whisker reinforced cold work die steel material is obtained through mechanization mixing and blending, modification treating, refining and pouring. The reinforcing nanometer crystal whiskers are small in diameter size, uniform in distribution and high in texture stability, is contamination-free on the surface, and is well combined with the WCrMoV substrate. The room-temperature mechanical property and wear-resisting property of the material are obviously improved; and the material is especially suitable to application of cold work die alloy steel, drill bits, cutters and the like.

Owner:SHANDONG JIANZHU UNIV

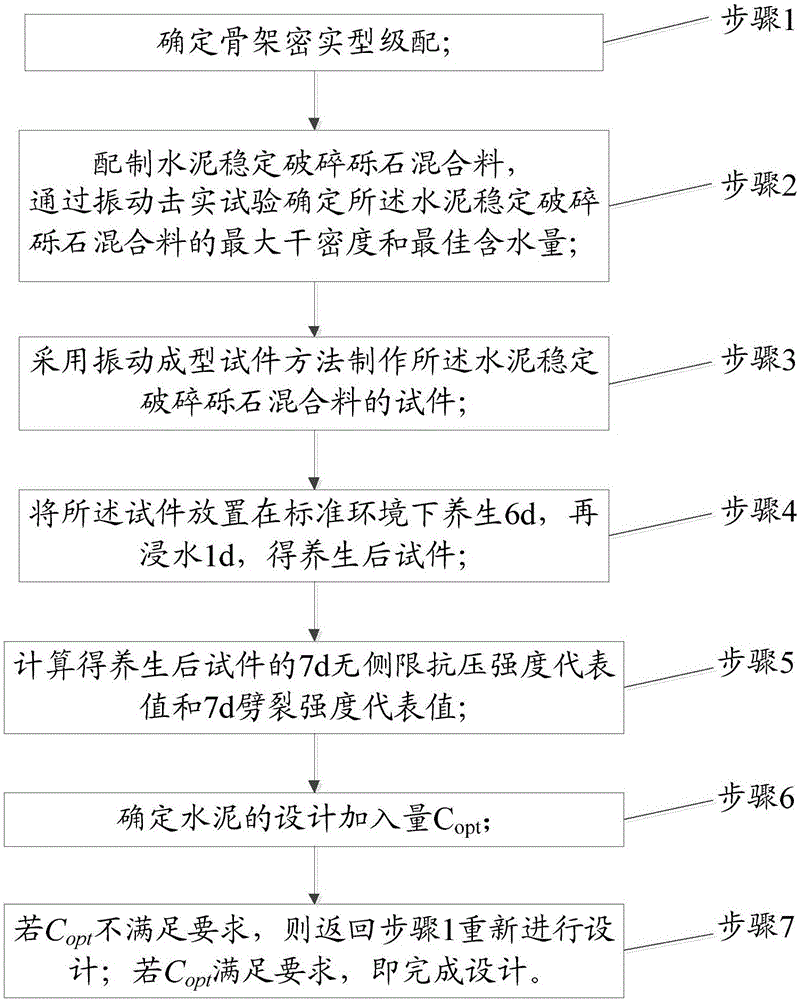

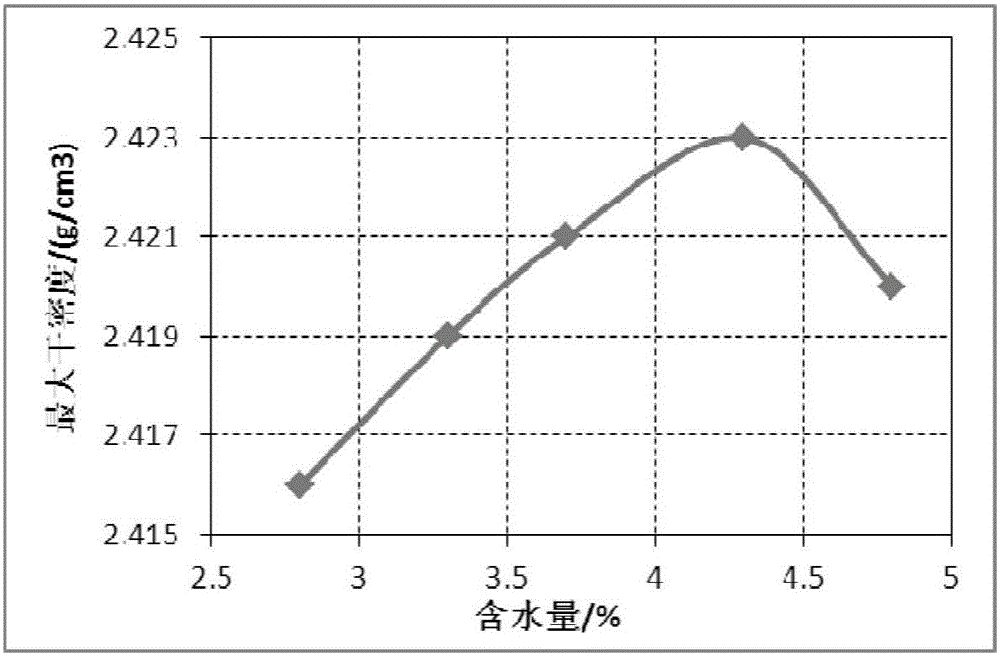

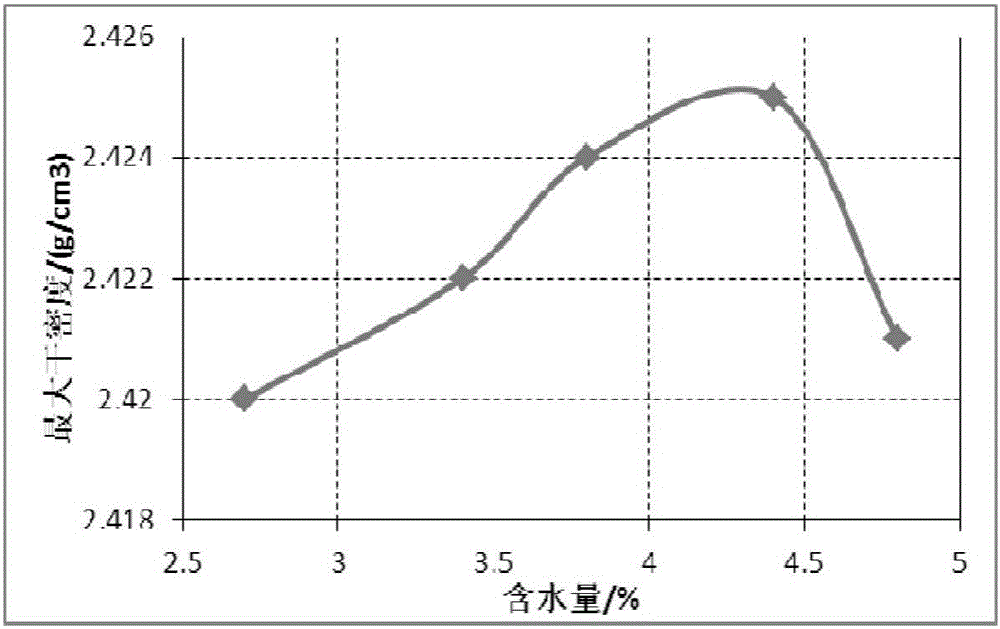

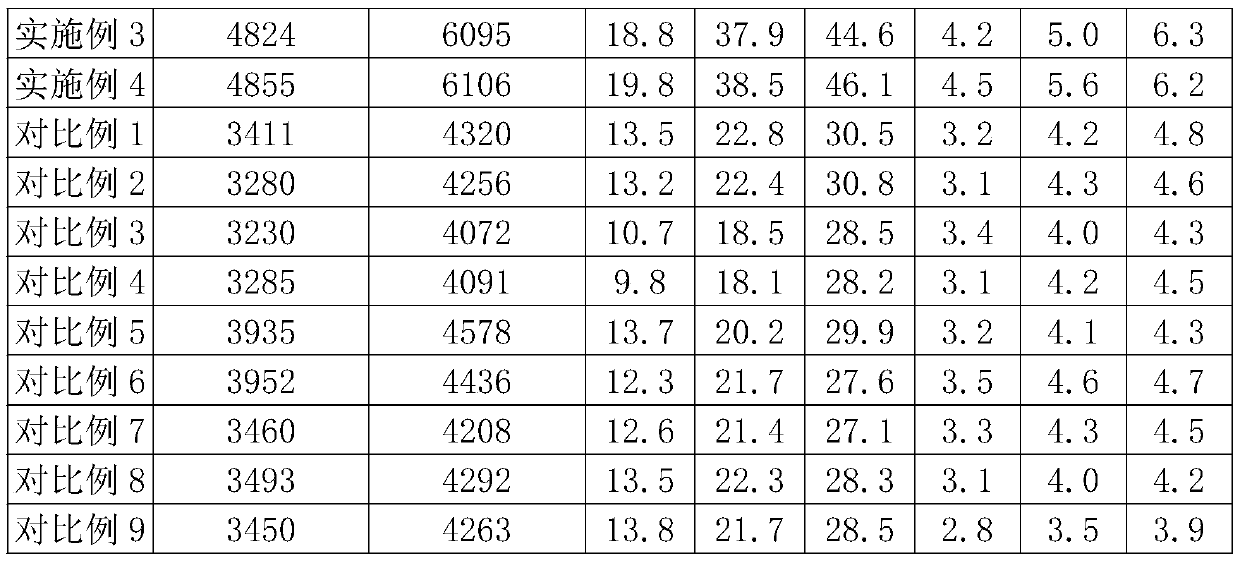

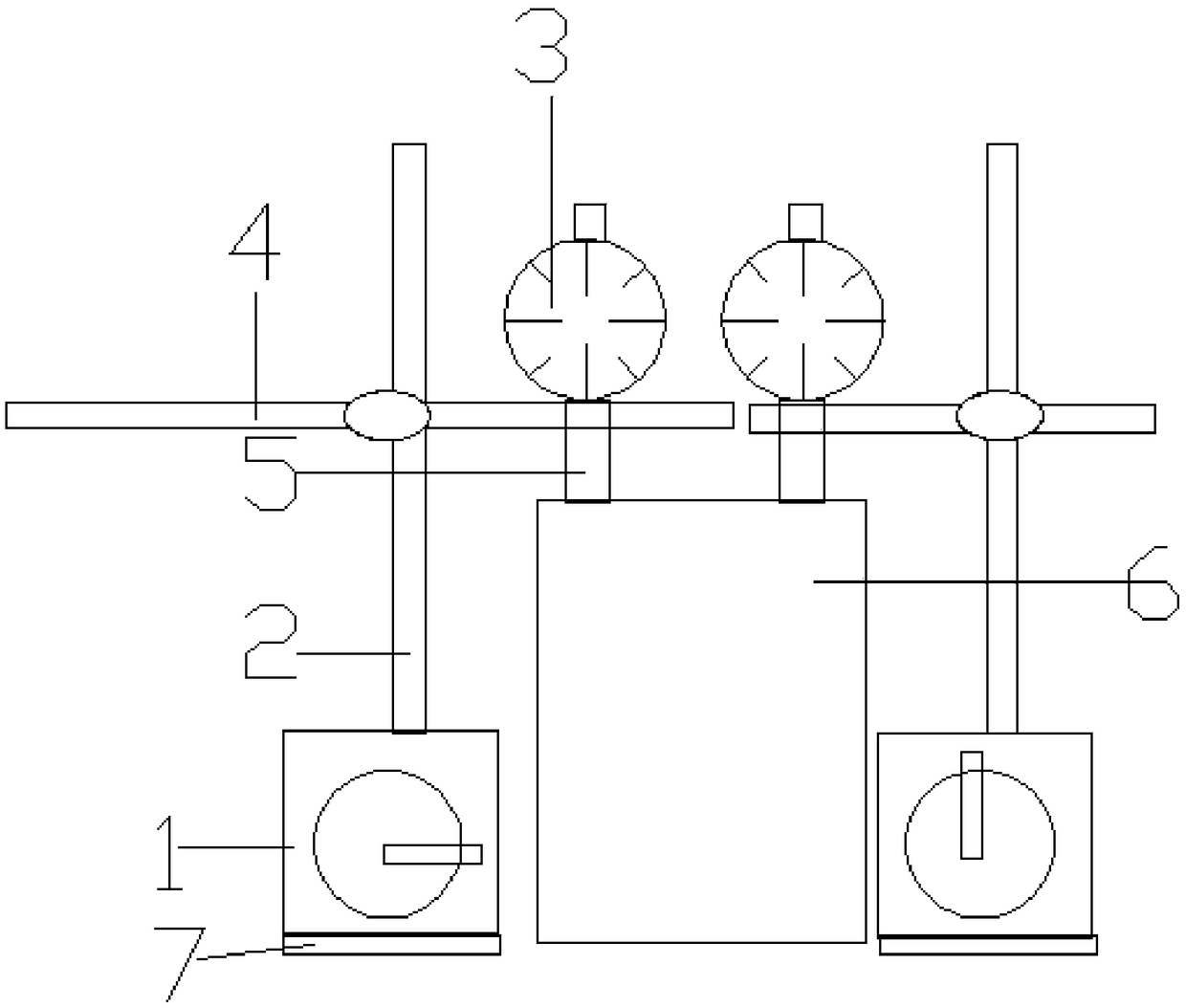

Cement stabilization broken gravel matching ratio design method based on vibration tests

InactiveCN106738205ANot easy to segregateSave cementMixing operation control apparatusPreparing sample for investigationMaximum dry densityMaterial Design

The invention discloses a cement stabilization broken gravel matching ratio design method based on vibration tests. The cement stabilization broken gravel matching ratio design method includes the following steps that firstly, dense skeleton type grading is determined; secondly, cement is added into broken gravel, and a cement stabilization broken gravel mixed material is prepared, and the maximum dry density and the best water content of the mixed material are determined; thirdly, a test piece of the cement stabilization broken gravel mixed material is manufactured; fourthly, the test piece is cured by 6 d in a standard environment and is immersed in water by 1 d; fifthly, the 7 d unconfined compressive strength and the 7 d splitting strength of the test after curing are tested, and the 7 d unconfined compressive strength representative value and the 7 d splitting strength representative value are calculated; sixthly, the designed adding amount Copt of the cement is determined; and if the Copt meets the requirement, design can be completed. By means of the cement stabilization broken gravel mixed material designed through the method, a dense framework structure can be well formed and is not likely to be separated, the cement is saved by 20% to 40%, the strength is improved by about 30%, and social and economic benefits are obvious.

Owner:CHANGAN UNIV

Super retarding concrete

The invention relates to the technical field of building materials, in particular to super-retarding concrete. The formula comprises the following raw materials in parts by weight: 210-250 parts of cement, 30-50 parts of an admixture, 3-5 parts of basalt fiber, 8-10 parts of an additive, 805-810 parts of river sand, 985-1010 parts of stone and 165-170 parts of water. The additive comprises a waterreducing agent, a retarder, a water retaining agent and a defoaming agent, the weight ratio of the water reducing agent to the retarder to the water retaining agent to the defoaming agent is (6-8): (7-9): (3-5): (1-2), the admixture comprises phosphorus slag, coal ash and microbeads, and the weight ratio of the phosphorus slag to the coal ash to the hollow glass microbeads is (10-20) :(40-50) :(10-15). The super-retarding concrete with higher strength and longer setting time is obtained by reasonably proportioning the cement, the admixture, the basalt fibers, the additive, the river sand, thestone and the water and matching the raw materials, pumping construction can be carried out, segregation and layering are not likely to happen, and the super-retarding concrete has important significance on development of the concrete industry.

Owner:深圳市鸿力健混凝土有限公司

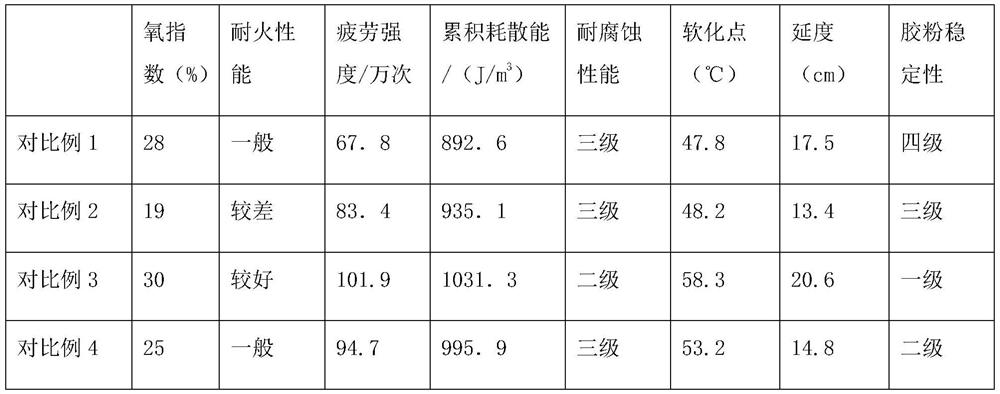

Rubber powder modified asphalt with high fatigue resistance and cracking resistance and preparation method of rubber powder modified asphalt

PendingCN111978749AHigh compressive strengthImprove compression and crack resistanceBuilding insulationsPolystyreneWaste rubber

The invention discloses a rubber powder modified asphalt with high fatigue resistance and cracking resistance and a preparation method of the rubber powder modified asphalt. Firstly, nano-crystallinecellulose is grafted with an epoxy group, and then nano-crystalline cellulose is subjected to a reaction with white carbon black, and modified white carbon black is obtained; the surface of waste rubber powder is grafted with polystyrene, the waste rubber powder is modified with polyphenyl ether and hydrogenated styrene-ethylene-styrene terpolymer particles, and modified rubber powder is obtained;glass fibers are modified with a silane coupling agent, the modified glass fibers, the modified rubber powder and limestone are mixed into matrix asphalt, the modified rubber powder, the modified glass fibers and groups in asphalt raw materials are reacted mutually, a dense and stable network structure is formed, pores of an asphalt mixture are filled with the limestone, and the rubber powder modified asphalt is prepared. The principle is simple, reaction conditions are mild, waste rubber tire resources are utilized reasonably, environmental pressure is relieved, and the prepared asphalt mixture has good overall performance, is cheap and is quite practical.

Owner:郭仁圆

Preparation method for ceramic fiber composite crumb rubber modified asphalt

The invention discloses a preparation method for ceramic fiber composite crumb rubber modified asphalt, and belongs to the technical field of modified asphalt. According to the method, barium acetate and tetrabutyl titanate are mixed to prepare a ceramic fiber, the ceramic fiber and a waste tyre are milled to prepare mixed crumb rubber, the crumb rubber is coupled to be mixed in a high-speed shear apparatus to prepare the modified asphalt, and by the coupling effect, the asphalt is connected with the crumb rubber more closely, the strength of the asphalt is strengthened and the performance of the asphalt is improved. The preparation method has the benefits that the preparation method is simple, and in a preparation process, the ceramic fiber, the crumb rubber and the asphalt are high in compatibility and dispersibility, unlikely to be separated and easy to load, unload and transport; the modified asphalt is easy to heat, high in stability and unlikely to be influenced by low temperature and high temperature.

Owner:CHANGZHOU DAAO NEW MATERIAL TECH CO LTD

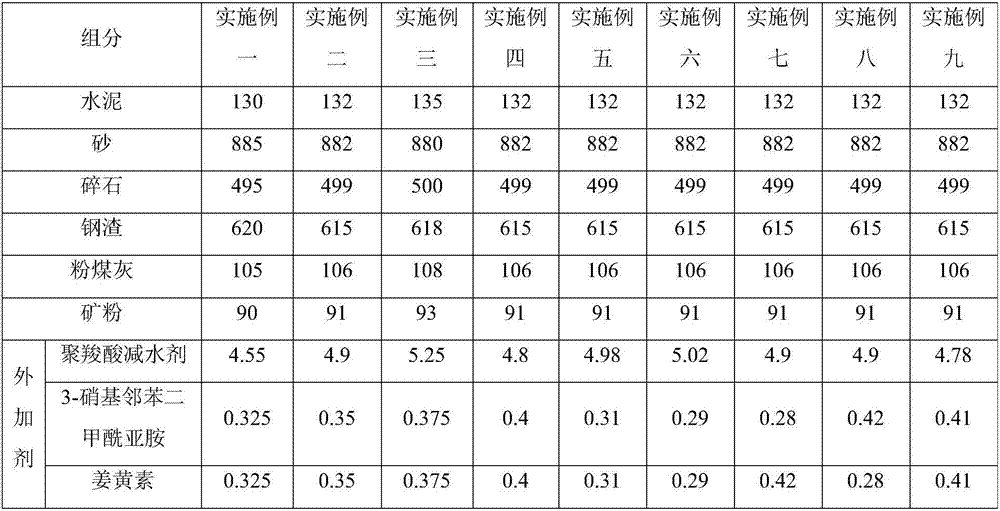

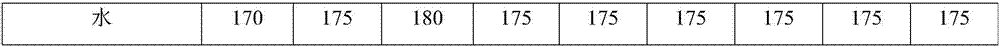

Heavyweight concrete

The invention relates to heavyweight concrete, technically characterized be being made from 130-135 parts of cement, 880-885 parts of sand, 495-500 parts of crushed stone, 615-620 parts of steel slag, 105-108 parts of fly ash, 90-93 parts of mineral powder, 5.2-6.0 parts of an admixture, and 170-180 parts of water, wherein the admixture is composed of a polycarboxylate superplasticizer, 3-nitrophthalimide and curcumin. The heavyweight concrete has the advantages that slump may reach 200 mm, the heavyweight concrete may be pumped for construction, segregation and layering rarely occur, and the heavyweight concrete has good solid density uniformity after formation.

Owner:北京城建亚泰金砼混凝土有限公司

Flyash-haydite concrete

InactiveCN1375475AThermal insulationFire resistantSolid waste managementCeramicwareExpanded clay aggregateSuperplasticizer

The present invention relates to a fly-ash ceramsite concrete, which is characterized by that its composition comprises (by weight portion) 25-33 portions of fly-ash ceramsite, 17-26 portions of cementing material, 42-51 portions of light fine aggregate, and air-guiding agent whose content is 1X10 to the minus fourth % and high-effective water-reducing agent whose content is 0.6% of cementing material and water. It can improve workability of new-stirred concrete, its strength can be up to 45 Mpa, and its durability and after-strength are also can be raised.

Owner:DAQING OILFIELD CO LTD

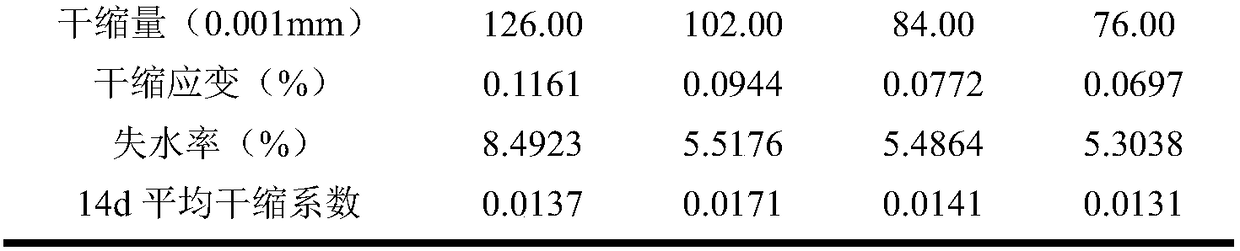

Method for determining dry shrinkage coefficient of cement stabilized macadam

The invention relates to a method for determining the dry shrinkage coefficient of cement stabilized macadam. The method comprises the following successive steps: step 1, determining the grading, optimum moisture content and maximum dry density of the cement stabilized macadam and determining the dosage of cement; step 2, calculating the dosage and water content of cement in a cement mortar test piece; step 3, making the test piece, and subjecting the shaped cement mortar test piece to maintenance; step 4, after completion of maintenance, placing the test piece in a dry shrinkage chamber to measure dry shrinkage amount and water loss rate; and step 5, calculating the dry shrinkage strain and dry shrinkage coefficient of the cement mortar test piece according to the measured water loss rateand dry shrinkage amount, and evaluating the dry shrinkage performance of the cement-stabilized graded macadam.

Owner:HENAN ZHONGYUAN EXPRESSWAY +1

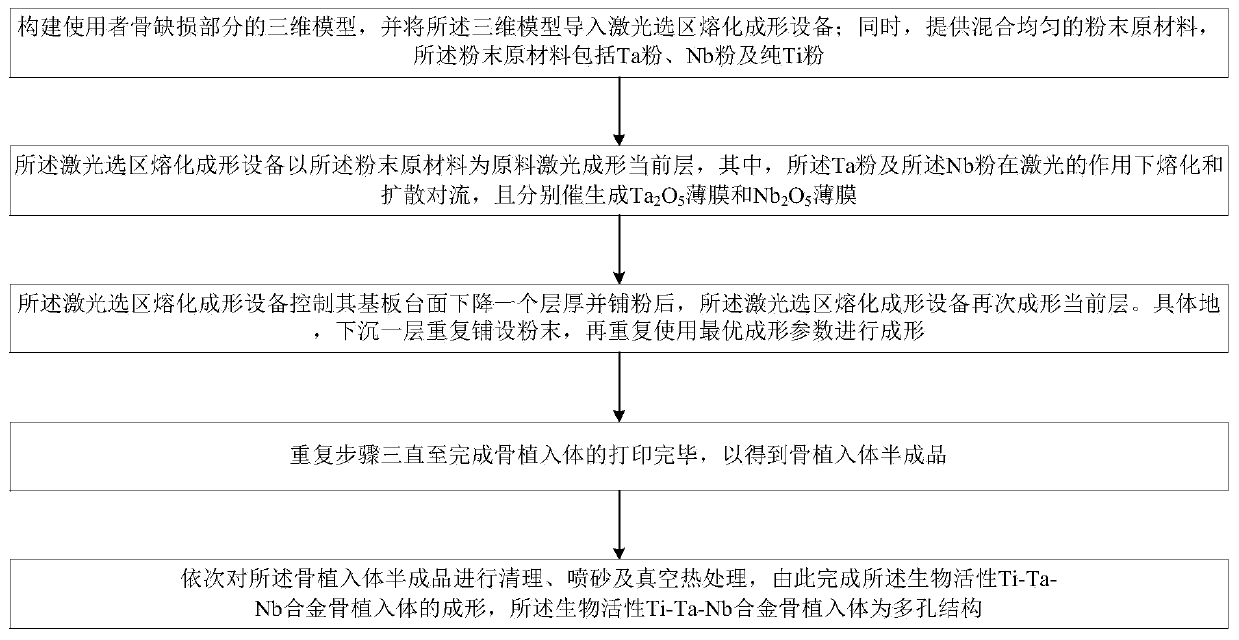

Bioactive Ti-Ta-Nb alloy bone implant and forming method thereof

InactiveCN110791681AHigh strengthImprove fatigue resistanceAdditive manufacturing apparatusTissue regenerationMetallurgyBone implant

The invention belongs to the technical field related to additive manufacturing, and discloses a bioactive Ti-Ta-Nb alloy bone implant and a forming method thereof. The method comprises the following steps that (1) powder raw materials which are uniformly mixed are provided, the powder raw materials are prepared in situ, the raw materials comprise Ta powder, Nb powder and pure Ti powder, in the powder raw materials, the mass percentage of the Ta powder is 20wt%-30wt%, and the mass percentage of the Nb powder is 15wt%-40wt%; and (2) the powder raw materials are taken as raw materials and are subjected to laser selective melting to form the bone implant based on a three-dimensional model of a defect part of a user, the bone implant is of a porous structure, wherein the Ta powder and the Nb powder are melted and achieve diffusion convection current under the action of laser beams, and the Ta powder and the Nb powder are induced to form a Ta2O5 thin film and a Nb2O5 thin film respectively.According to the bioactive Ti-Ta-Nb alloy bone implant and the forming method thereof, the cost is reduced, the flexibility is good, and the applicability is high.

Owner:HUAZHONG UNIV OF SCI & TECH

High-workability high-toughness concrete and preparation method thereof

ActiveCN106348685AImprove work performanceHigh workability and high toughnessFiberUltimate tensile strength

The invention discloses a high-workability high-toughness concrete and a preparation method thereof, belonging to the technical field of construction materials. The invention aims to solve the problems of low toughness and poor workability in the existing ultrahigh-performance concrete. The high-workability high-toughness concrete is prepared from cement, high-strength fibers, a nano material, medium sand, an additive and water according a certain proportion at normal temperature. A calcium silicate hydrate gel solution water reducing agent introduced as the additive effectively increases the early strength of the high-workability high-toughness concrete, enhances the binding degree between the fibers and mortar matrix and enhances the binding effects, thereby effectively enhancing the concrete ductility. Besides, the high-toughness concrete has the characteristics of lower nano material doping amount and low water consumption, thereby being beneficial to enhancing the concrete strength. The additive has the advantages of controllable doping amount and favorable adaptability to the nano material, so the concrete has the advantages of low viscosity, low isolation tendency, favorable flowability, favorable stability and favorable plasticity.

Owner:SHANGHAI CONSTRUCTION GROUP

Method for preparing copper-tungsten alloy from ultrafine tungsten powder

ActiveCN112708794AHigh hardnessHigh strengthTransportation and packagingMetal-working apparatusCopper coatingHigh wear resistance

The invention discloses a method for preparing copper-tungsten alloy from superfine tungsten powder. The method comprises the following steps of S1, tungsten powder pretreatment: ball milling, powder preparation through atomization, and alkali / acid pickling; S2, superfine tungsten powder surface copper coating: primary electroplating and secondary electroplating; S3, copper-coated tungsten powder reduction; S4, preforming and S5, vacuum hot pressed sintering. Compared with the copper-tungsten alloy prepared by other methods, the copper-tungsten alloy prepared by the preparation method has higher hardness, higher strength, higher wear resistance and higher arc ablation resistance, and the ultrafine-grained tungsten powder is used for coating, so that the coated particles are more stable and not easy to segregate, and the coating rate is higher, so that the uniformity of the product is ensured, and the service life of the copper-tungsten alloy is prolonged.

Owner:SHAANXI SIRUI ADVANCED MATERIALS CO LTD

Quick-freezing edible oil

The invention relates to quick-freezing edible oil. The quick-freezing edible oil comprises the following raw material components in parts by weight: 45-75 parts of lard oil, 15-30 parts of palm oil, 15-25 parts of water, 0.1-0.3 part of monoglyceride and 0.1-0.3 part of lecithin. The quick-freezing edible oil has the advantages of moderate grease hardness and good taste.

Owner:SUZHOU FULL FORTUNE FOOD CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com