High-workability high-toughness concrete and preparation method thereof

A technology with high workability and high toughness, applied in the field of building materials, can solve the problems of high compressive strength, poor workability and toughness, etc., and achieve the effect of improving toughness, strength and good adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The unilateral dosage ratio of each component of high toughness concrete with high workability (kg / m 3 )As shown in Table 1. The ratio of unilateral dosage refers to 1m 3 The weight ratio of each component in high toughness concrete with high workability.

[0026] Table 1 Proportion of high toughness concrete with high workability (kg / m 3 )

[0027] cement microwire steel fiber Silica fume Middle sand Admixture water 1000 250 50 1000 30 185

[0028] Preparation method:

[0029] Prepare high toughness concrete with high workability according to the formula in Table 1, including the following steps:

[0030] Step 1. Add cement, sand and silica fume into the mixer, and stir for 30s;

[0031] Step 2: Add additives and water, and stir for 240s;

[0032] Step 3: Add microwire steel fibers and stir for 30 seconds to complete the preparation of high toughness concrete with high workability.

[0033] After testing, the workability and mech...

Embodiment 2

[0036] The unilateral dosage ratio of each component of high toughness concrete with high workability (kg / m 3 )As shown in table 2.

[0037] Table 2 has the ratio of high toughness concrete with high workability (kg / m 3 )

[0038] cement microwire steel fiber Silica fume Middle sand Admixture water 1500 200 60 800 35 200

[0039] The method for preparing high-toughness concrete with high workability according to the formula in Table 2 is the same as that of Example 1, and will not be repeated here.

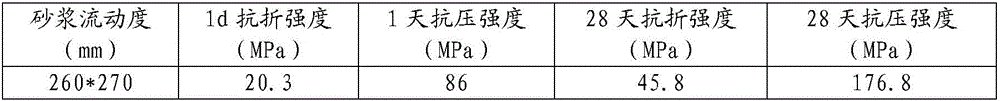

[0040] After testing, the workability and mechanical properties of the high workability high toughness concrete prepared according to the above method are as follows:

[0041]

Embodiment 3

[0043] The unilateral dosage ratio of each component of high toughness concrete with high workability (kg / m 3 )as shown in Table 3.

[0044] Table 3 Proportion of high toughness concrete with high workability (kg / m 3 )

[0045] cement microwire steel fiber Silica fume Middle sand Admixture water 600 300 40 1200 25 175

[0046] The method for preparing high-toughness concrete with high workability according to the formula in Table 3 is the same as that of Example 1, and will not be repeated here.

[0047] After testing, the workability and mechanical properties of the high workability high toughness concrete prepared according to the above method are as follows:

[0048]

[0049] control group

[0050] cement RPC special end hook steel fiber Silica fume Middle sand Ordinary superplasticizer water 1000 250 250 1100 30 250

[0051] After testing, the working performance and mechanical properties of the ultra-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com