Construction method of large-volume concrete bearing platform with one-time pouring in winter

A large-volume concrete and construction method technology, which is applied in the direction of construction, building structure, and building material processing, can solve the problems of large concrete temperature gradient, reduce the service life of the structure, and affect the safety of the structure, and achieve good temperature difference control effect. The effect of good quality and low investment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

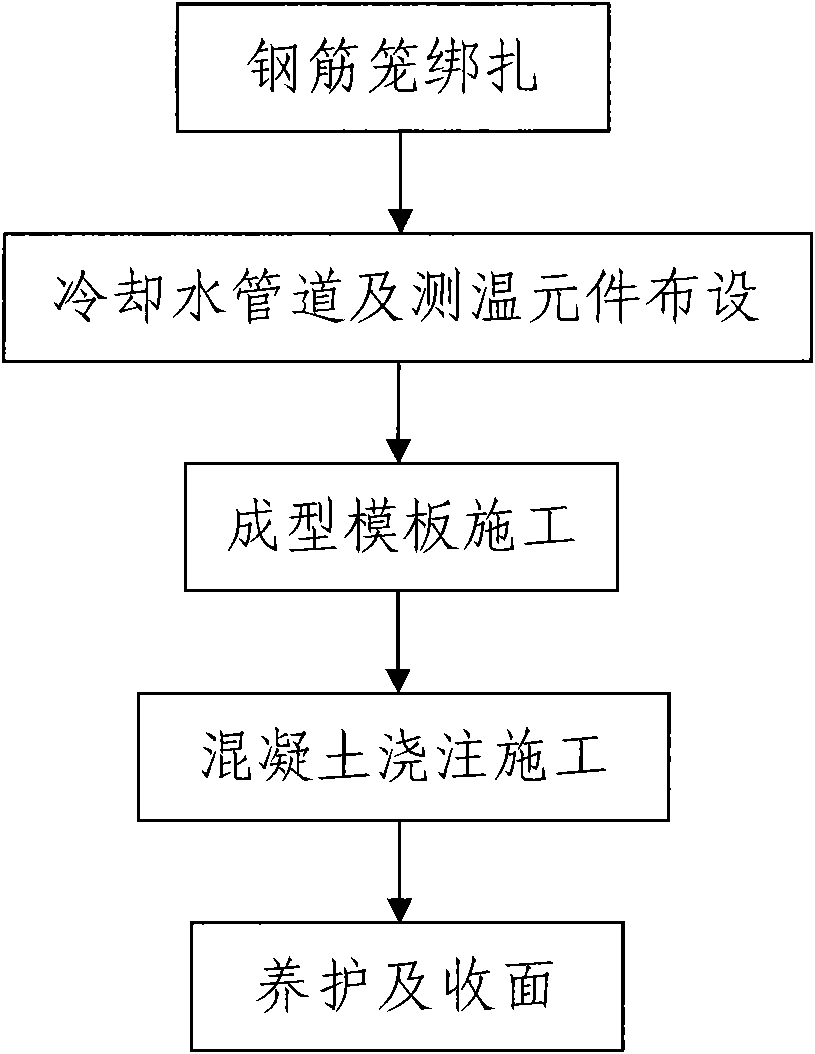

[0044] Such as figure 1 A one-time pouring construction method for large-volume concrete caps in winter includes the following steps:

[0045] Step 1. Binding of reinforcement cages: according to the designed structure and size of the large-volume concrete cap 4 to be formed, the reinforcement cage for forming the large-volume concrete cap 4 is bound on the construction platform.

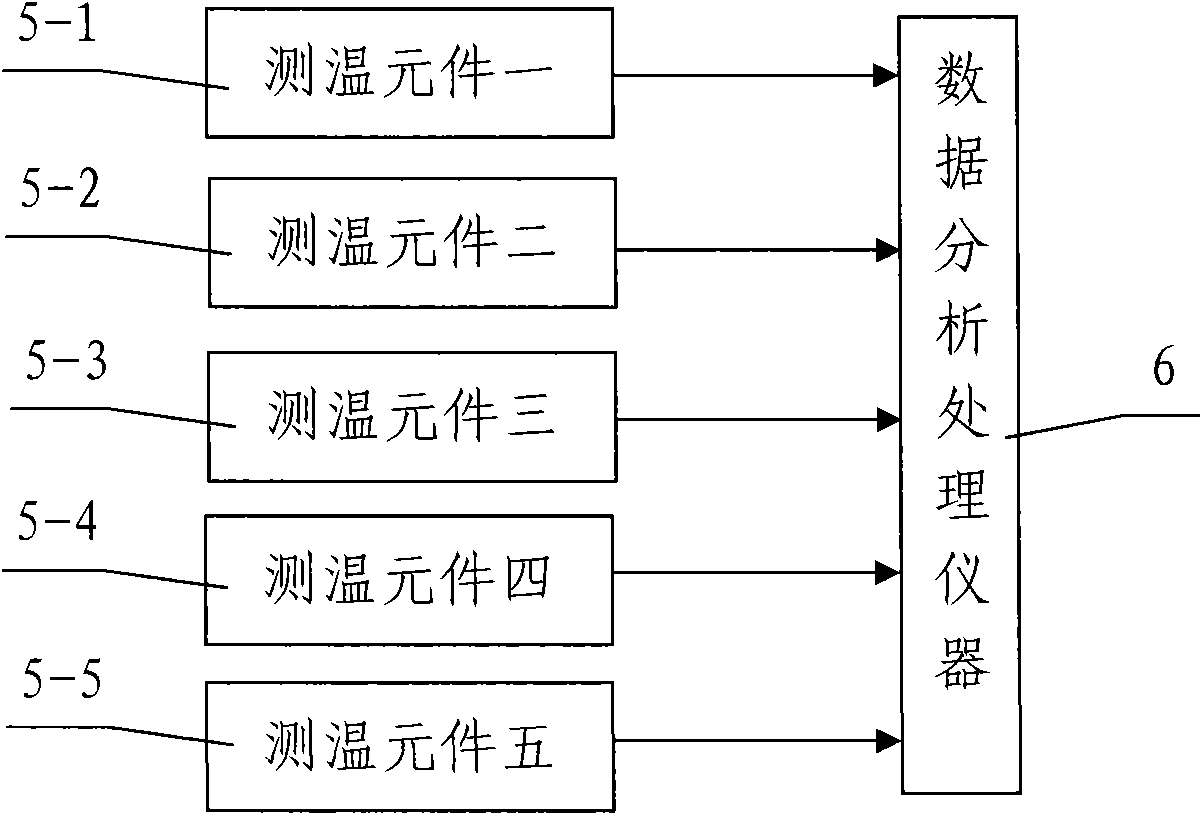

[0046] Step 2. Arrangement of cooling water pipes and temperature measuring elements: After the reinforcement cage is bound or during the binding process, a multi-layer circulating cooling water pipe 1 is horizontally laid out in layers inside the steel cage, and the inlet of the circulating cooling water pipe 1 The water inlet and the water outlet are led out from the top of the steel cage through the water inlet pipe 2 and the water discharge pipe 3 respectively, and then lead into the sump respectively. The deployed temperature measuring elements include a temperature measuring element 5-1 for r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| slump | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com