High-entropy alloy boride ceramic, and preparation method and application thereof

A technology of high-entropy alloys and borides, which is applied in the field of boride ceramic materials, can solve the problems of polluted raw materials, and achieve the effects of less segregation, fine grains, and increased hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] a kind of Al y (FeNiCoCr) 1-x-y B x (x=1 / 3, y=1 / 3) high-entropy alloy boride powder, high-entropy alloy boride powder is composed of Al, Fe, Ni, Co, Cr and B elements, and the molar ratio of each element is Al:Fe :Ni:Co:Cr:B=1:1:1:1:1:1. Put it into the ball mill jar and carry out ball milling for 200 hours according to the ball milling design process parameters, and the powder after ball milling.

[0042] The ball-milled high-entropy alloy boride powder was put into a spark plasma sintering mold for sintering. The sintering process parameters were: heating rate 100°C / min, sintering temperature 1100°C, holding time 10min, constant pressure 30Mpa, and obtained Al 1 / 3 (FeNiCoCr) 1 / 3 B 1 / 3 ceramics.

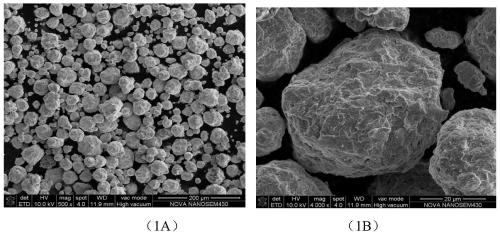

[0043] figure 1 Al prepared for Example 1 1 / 3 (FeNiCoCr) 1 / 3 B 1 / 3 SEM images of high-entropy alloy boride powders at different magnifications. Among them, 1A is magnified 500 times, and 1B is magnified 4000 times. Depend on figure 1 It can be seen that the parti...

Embodiment 2

[0046] a kind of Al y (FeNiCoCr) 1-x-y B x (x=1 / 5, y=2 / 5) high-entropy alloy boride powder, high-entropy alloy powder is composed of Al, Fe, Ni, Co, Cr and B, and the molar ratio of each element content is Al:Fe:Ni: Co:Cr:B=1:1:1:1:1:0.5. After putting into the ball milling tank, carry out ball milling for 60 hours according to the ball milling design process parameters, the particle shape is spherical or nearly spherical with uniform particle size, and the particle size ranges from 5 to 45 μm.

[0047] The ball-milled high-entropy alloy boride powder was put into a spark plasma sintering mold for sintering. The sintering process parameters were: heating rate 100°C / min, sintering temperature 1100°C, holding time 10min, constant pressure 30Mpa, and obtained Al 0.2 (FeNiCoCr) 0.6 B 0.2 ceramics.

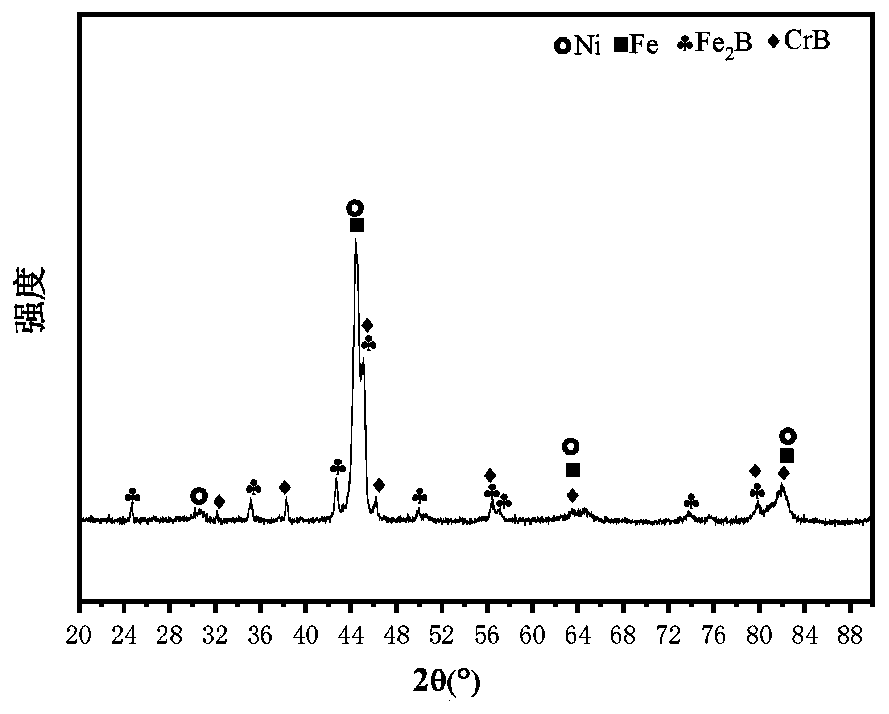

[0048] Figure 7 Al prepared for Example 2 0.2 (FeNiCoCr) 0.6 B 0.2 XRD pattern of high entropy alloy boride bulk. Such as Figure 7 It can be seen that the amount of borid...

Embodiment 3

[0050] a kind of Al y (FeNiCoCr) 1-x-y B x (x=1 / 2, y=1 / 4) high-entropy alloy boride powder, high-entropy alloy boride powder is made up of Al, Fe, Ni, Co, Cr and B, and each element content molar ratio is Al:Fe: Ni:Co:Cr:B=1:1:1:1:1:2. After putting into the ball milling tank, carry out ball milling for 60 hours according to the ball milling design process parameters, the particle shape is spherical or nearly spherical with uniform particle size, and the particle size ranges from 5 to 45 μm.

[0051] The ball-milled high-entropy alloy boride powder was put into a spark plasma sintering mold for sintering. The sintering process parameters were: heating rate 100°C / min, sintering temperature 1100°C, holding time 10min, constant pressure 30Mpa, and obtained Al 0.25 (FeNiCoCr) 0.25 B 0.25 ceramics. Figure 9 Al prepared for Example 3 0.25 (FeNiCoCr) 0.25 B 0.25 XRD pattern of high entropy alloy boride bulk. Such as Figure 9 It can be seen that the amount of borides gene...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com