Heavyweight concrete

A heavy concrete, apparent density technology, applied in the field of concrete materials, can solve the problems of large resistance, large density deviation, uneven solid density, etc., and achieve the effect of not easy to segregate and uniform solid density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

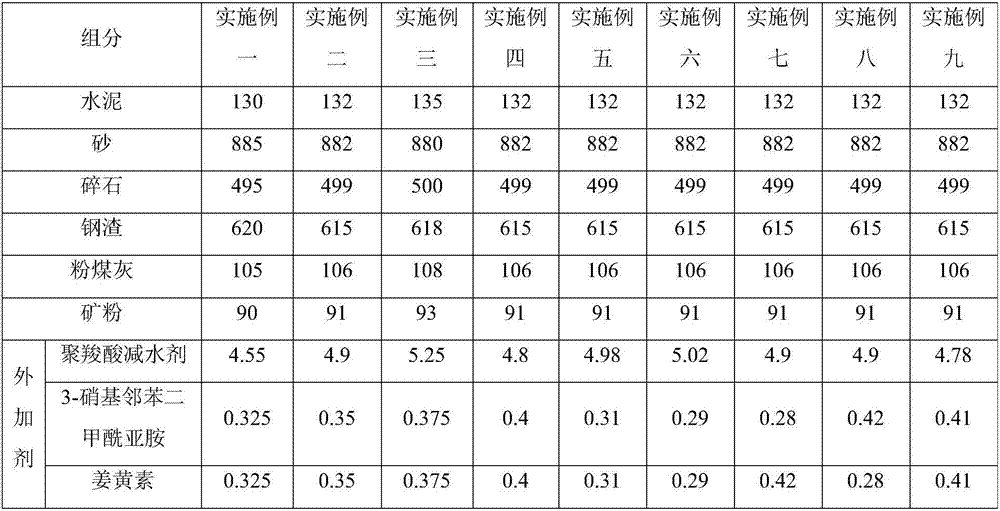

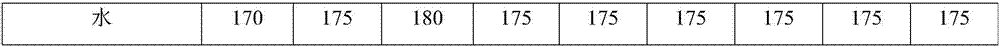

[0020] Hereinafter, the present invention will be further described in detail with reference to the embodiments. It should be understood that the preparation methods described in the examples of the present invention are only used to illustrate the present invention, not to limit the present invention. Simple improvements to the preparation method of the present invention under the concept of the present invention fall within the scope of protection of the present invention. .

[0021] Table 1 Source of raw materials

[0022] raw material

Manufacturer

Hebei Yanxin Cement Factory

sand

Hebei Laishui Sandstone Factory

gravel

Beijing Yulin Lime Factory

Sanhe Xianghe Fly Ash Processing Plant

Mineral powder

Sanhe Xingda Kaiyuan Building Material Co., Ltd.

Polycarboxylic acid water reducer

Beijing Ruili Admixture Factory

3-Nitrophthalimide

Bailingwei Technology Co., Ltd.

Beijing Xinsaiwei Chemical Technology Co., Ltd.

Steel slag

Beij...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com