Bioactive Ti-Ta-Nb alloy bone implant and forming method thereof

A ti-ta-nb, bioactive technology, applied in the field of additive manufacturing, can solve the problems of uneven segregation of alloy components, low diffusion coefficient, and reduced elastic modulus, so as to prolong the fatigue cycle, simplify the process, and improve the strength. and the effect of toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

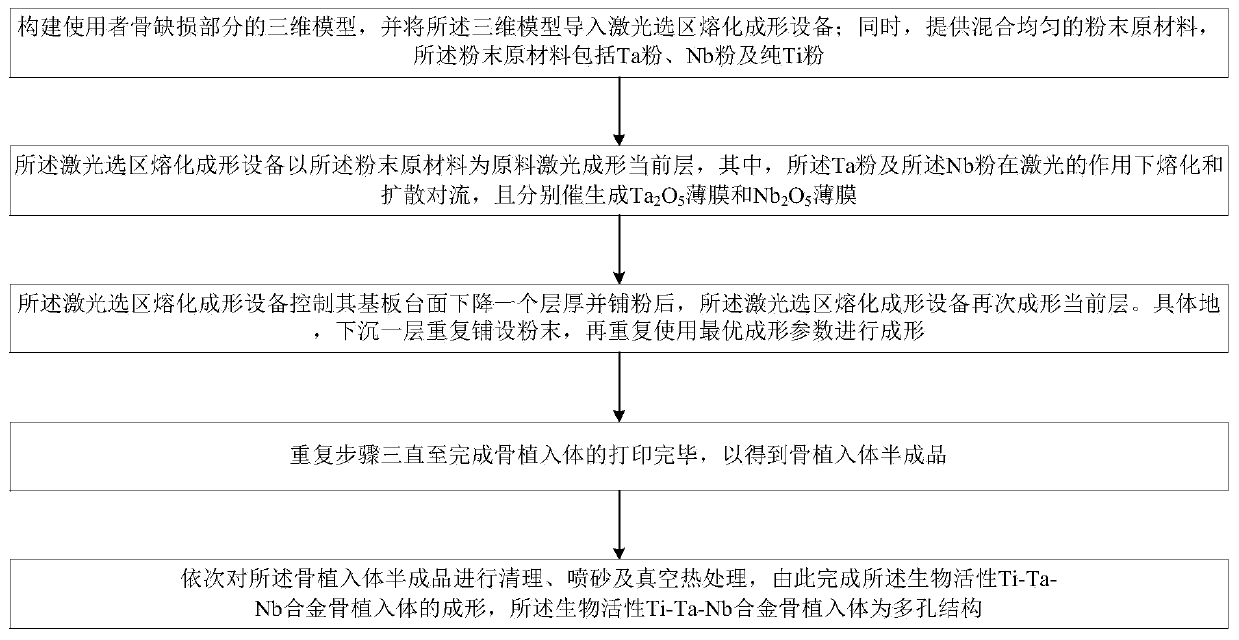

[0044] The bone implant prepared by the forming method of the bioactive Ti-Ta-Nb alloy bone implant provided in Example 1 of the present invention is suitable for young people, and the method mainly includes the following steps:

[0045] (1) Scan the bone defect of the patient through CT / MRI, build a 3D model based on the obtained CT data and export the STL format file of the 3D model, and then import it into the laser selective melting forming equipment.

[0046] (2) Weighing Ta powder, Nb powder, Zr powder and pure titanium (Ti) powder and performing mechanical ball milling to mix uniformly, thereby obtaining uniformly mixed powder raw materials. Among them, due to the high bone strength of young people, the content of Ta and Nb needs to be increased. The ball-to-material ratio used in the mixing process of Ta powder is 3:1, using an all-round planetary ball mill, and using a ball mill tank that can be vacuumed. Argon is introduced into the tank to prevent the powder from be...

Embodiment 2

[0053] The bone implant prepared by the forming method of the bioactive Ti-Ta-Nb alloy bone implant provided in Example 2 of the present invention is suitable for middle-aged people, and the method mainly includes the following steps:

[0054] (1) Scan the bone defect of the patient through CT / MRI, construct a three-dimensional model of the patient's defect part according to the obtained CT data and export the STL format file of the three-dimensional model, and then import it into the laser selective melting forming equipment.

[0055] (2) Weighing Ta powder, Nb powder, Zr powder and pure titanium (Ti) powder for mechanical ball milling and mixing to obtain uniformly mixed powder raw materials. Due to the decline in bone strength of middle-aged people, the Ta content is slightly lower. The ball-to-material ratio used in the mixing process of Ta powder is 2:1, using an all-round planetary ball mill, and using a ball mill tank that can be vacuumed. Feed argon to avoid powder oxi...

Embodiment 3

[0062] The bone implant prepared by the forming method of the bioactive Ti-Ta-Nb alloy bone implant provided in Example 3 of the present invention is suitable for the elderly, and the method mainly includes the following steps:

[0063] (1) Scan the bone defect of the patient through CT / MRI, build a 3D model based on the obtained CT data and export the STL format file of the 3D model, and then import it into the laser selective melting forming equipment.

[0064] (2) Weighing Ta powder, Nb powder, Zr powder and pure titanium (Ti) powder for mechanical ball milling and mixing to obtain uniformly mixed powder raw materials. Due to the low bone strength of the elderly, the elastic modulus decreases, the Ta content is slightly lower, and the Nb and Zr contents need to be increased; the ball-to-material ratio used in the mixing process of Ta powder is 3:1, and the omni-directional planetary ball mill is used. In the ball milling tank with air pumping, argon gas is introduced into t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com