Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

132results about How to "Not prone to delamination" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

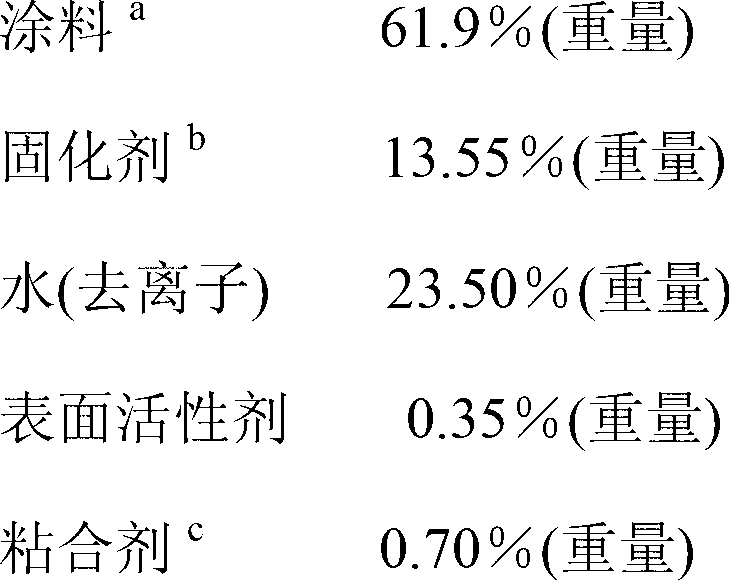

Surface skid-resistant coating composition

ActiveCN103013274APromote wettingImprove corrosion resistanceEpoxy resin coatingsEpoxySURFACTANT BLEND

The invention relates to a surface skid-resistant coating composition which comprises the following components in parts by weight: 12-75 parts of epoxy resin and organic silicon resin, 30-60 parts of a synthetic particle material and 2-13 parts of an amine function curing agent. The surface skid-resistant coating composition also comprises a surfactant and a conventional additive. The synthetic particle material is used for replacing traditional glass beads, quarts sand and the like, thus the surface skid-resistant coating composition is better in hand feel of a coating film, has skid resistance of the existing product, and has high scratch resistance, abrasion resistance, and resistivity to outside chemical materials.

Owner:ANHUI KAILIN ADVANCED MATERIAL CO LTD

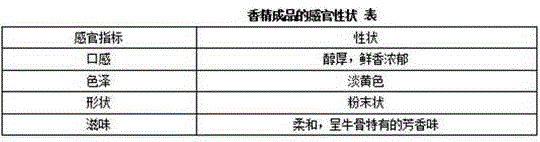

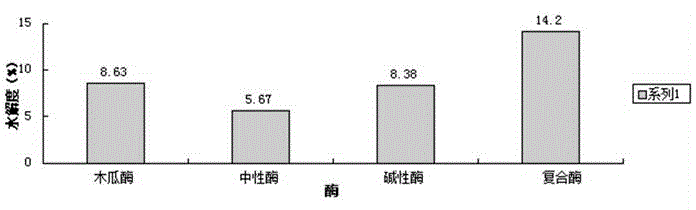

Beef-flavored essence preparation method

InactiveCN104855918AImprove conversion ratePromote digestionFood preparationMaillard reactionFlavoring essences

A beef-flavored essence preparation method, comprising the following steps of: degreasing cleaned ox bones at a high temperature crushing the ox bones by using a crusher after drying treatment for 30 minutes, and sieving by using a 100-mesh sieve to obtain ox bone powder; adding the ox bone powder into a reaction kettle, adding water into the reaction kettle in a material and liquid ratio of 1:14 to prepare an ox bone powder primer solution, adjusting the pH, adding a pepsase for enzymolysis for 3 hours and then adding a compound enzyme in proportion for further enzymolysis, and on the basis, inoculating compound bacteria in a certain proportion to ferment to obtain a bone collagen peptide solution; carrying out Maillard reaction on the bone collagen peptide solution and a reducing sugar to obtain an essence base material; and then mixing the base material with marinade in a certain proportion, blending, concentrating and drying to obtain the beef flavor essence. The beef-flavored essence prepared by the preparation method in the invention has the advantages of being natural in raw material, pure in meat flavor, lasting in fragrance and the like, and is widely applied to foods such as instant noodles, soup bases, fast foods and the like so as to increase or endow the food with a unique meat flavor.

Owner:HENAN UNIV OF SCI & TECH

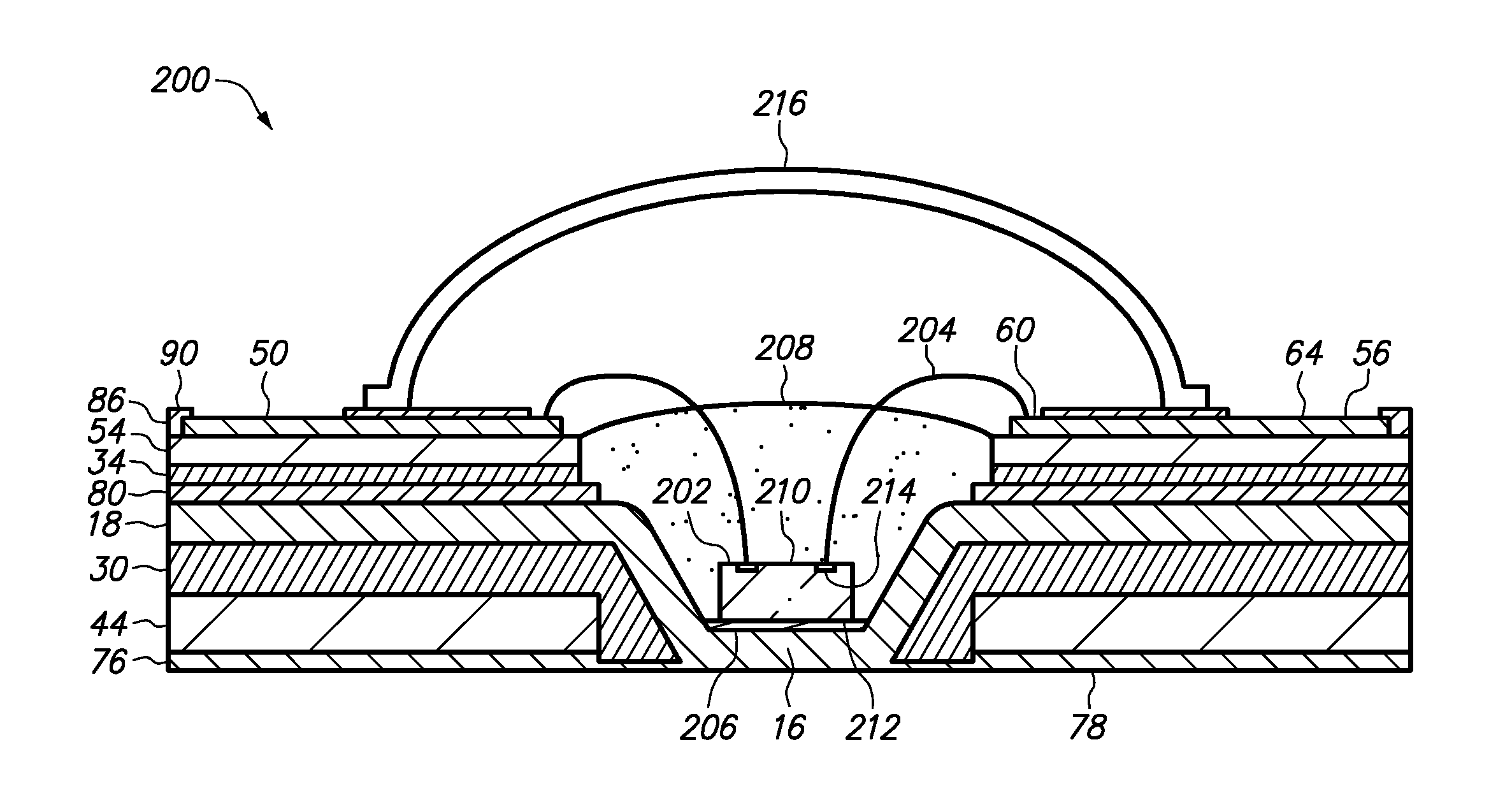

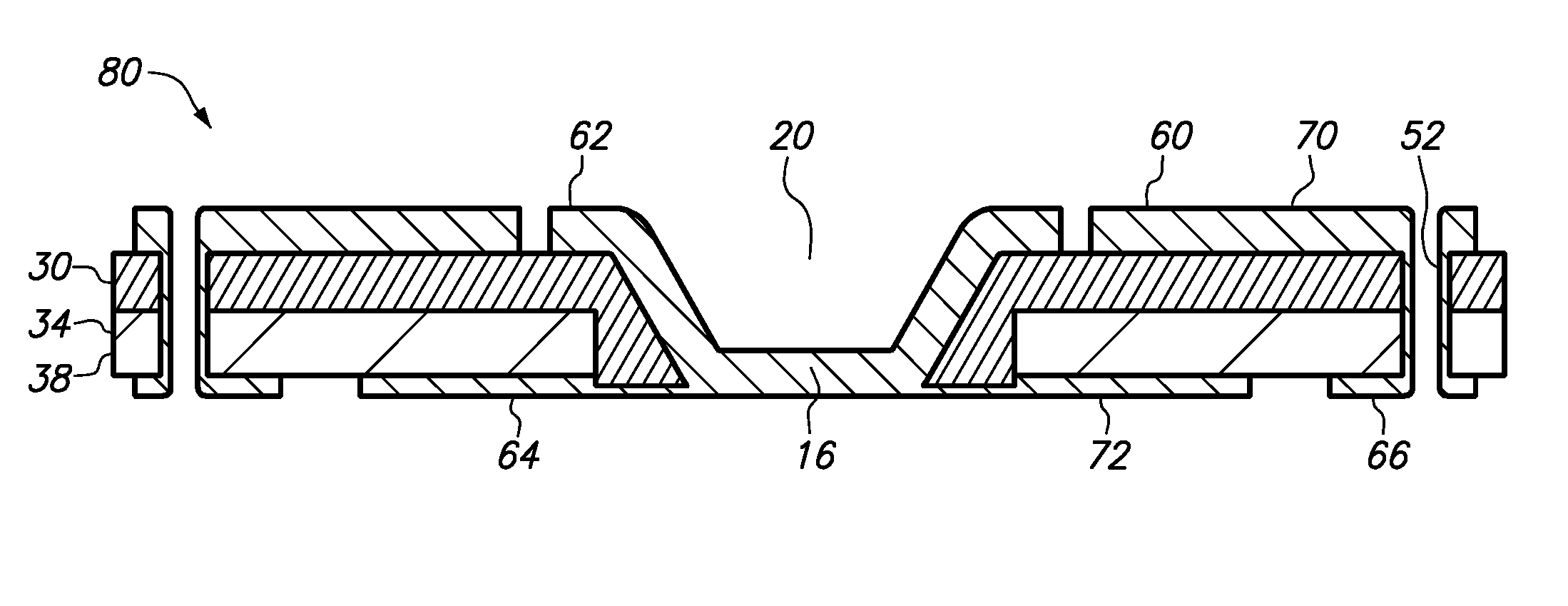

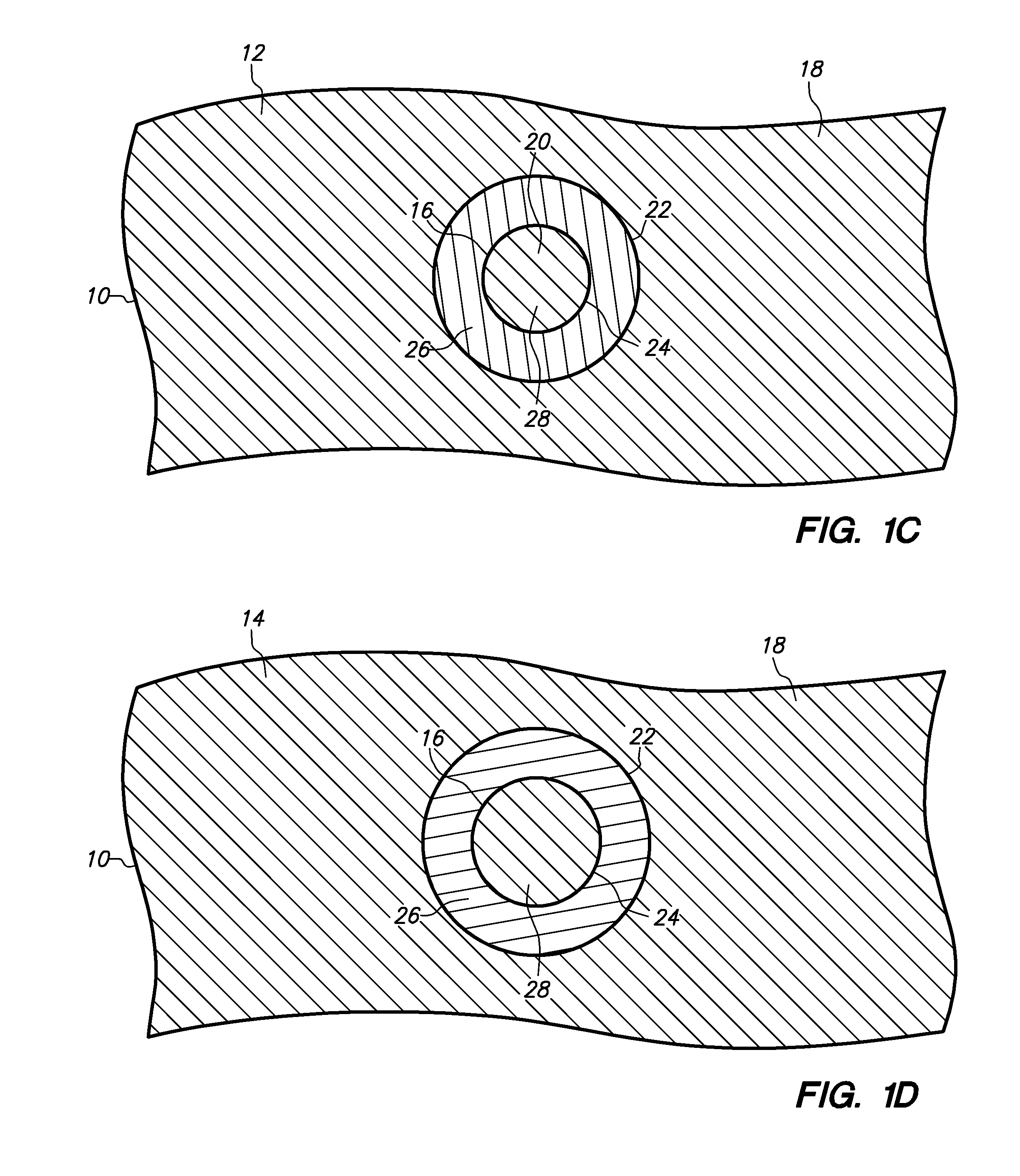

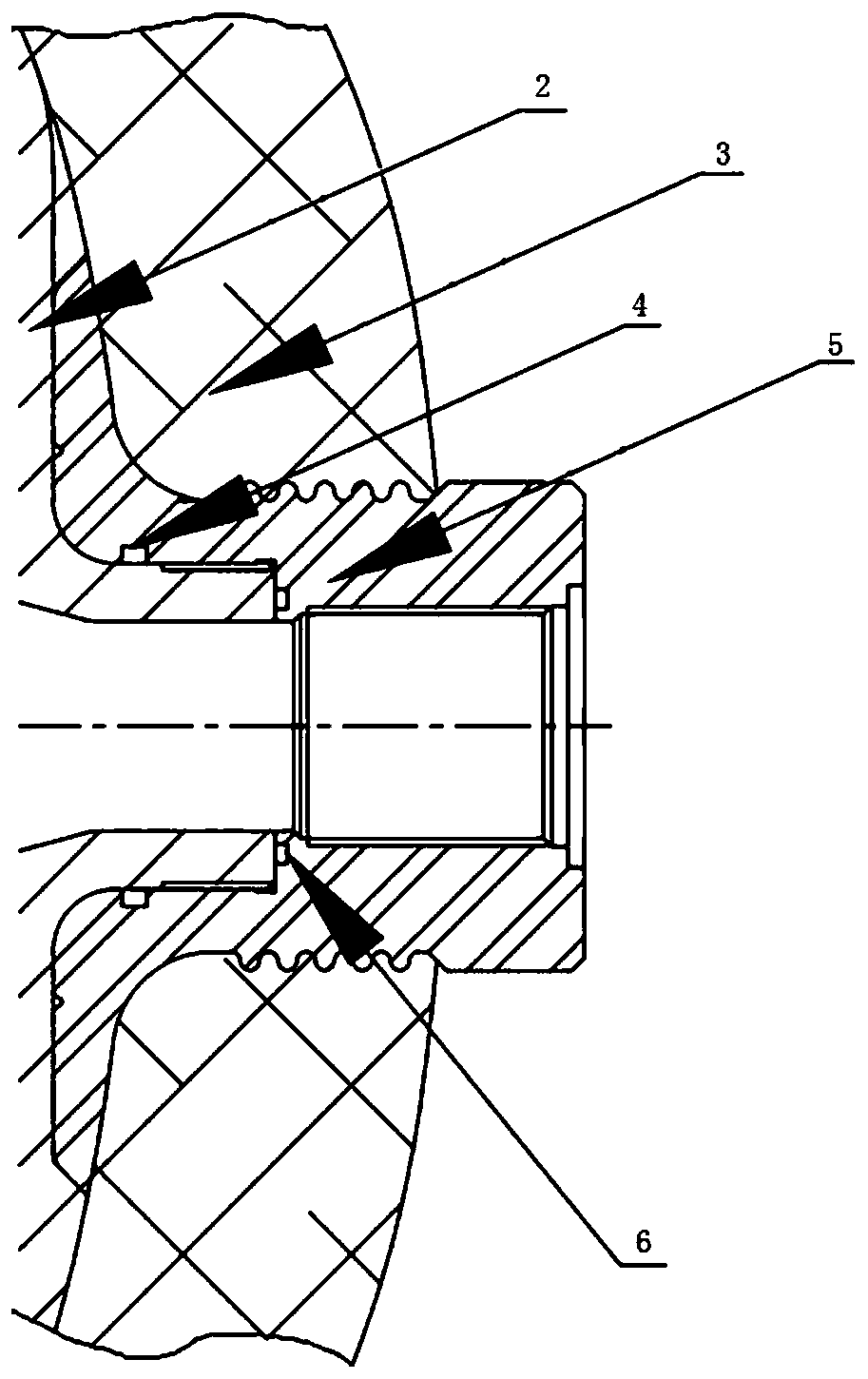

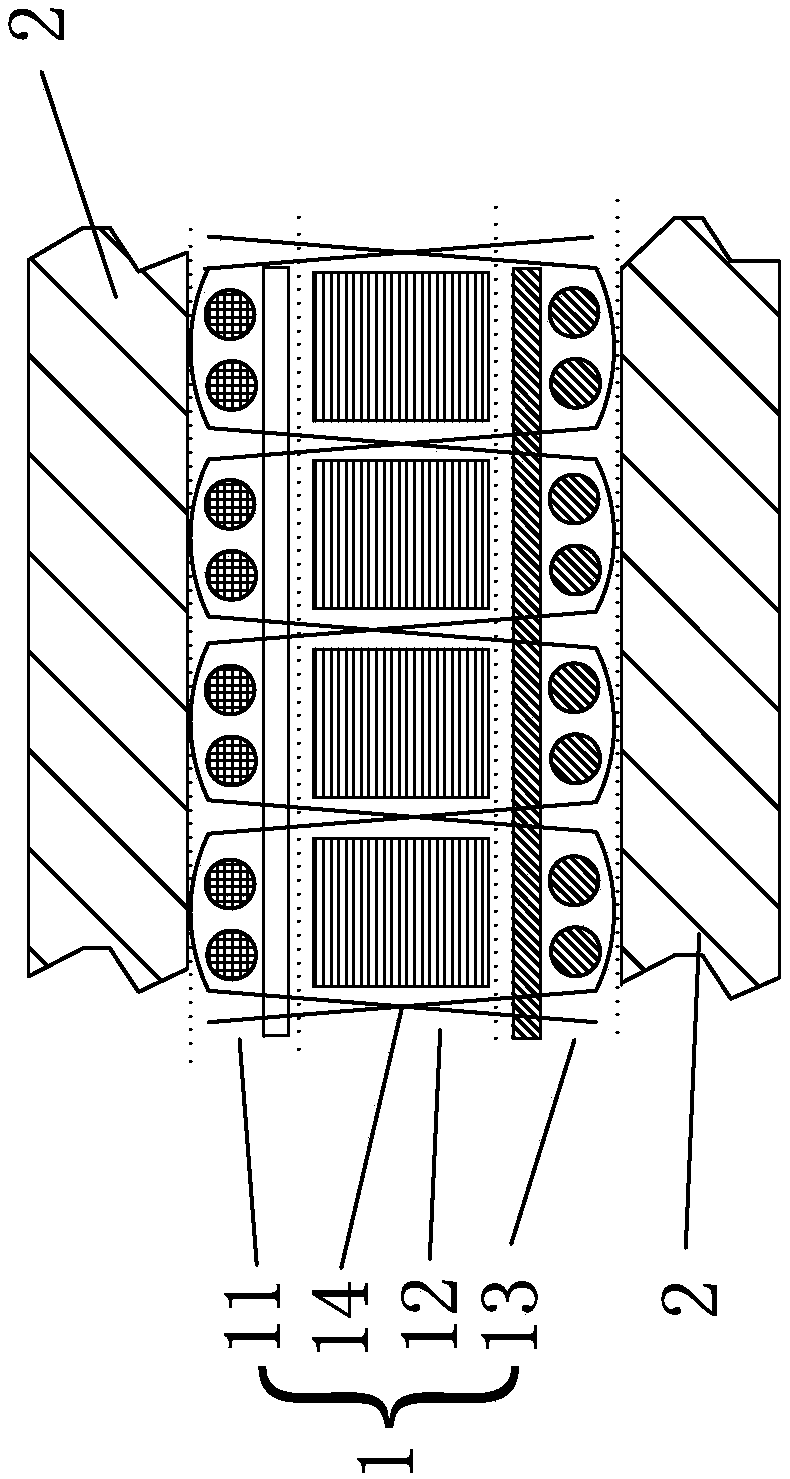

Semiconductor chip assembly with bump/base/ledge heat spreader, dual adhesives and cavity in bump

InactiveUS20120091493A1Excellent heat spreading and heat dissipationNot prone to delaminationSemiconductor/solid-state device detailsPrinted circuit aspectsEngineeringAdhesive

A semiconductor chip assembly includes a semiconductor device, a heat spreader, a conductive trace and dual adhesives. The heat spreader includes a bump, a base and a ledge. The conductive trace includes a pad and a terminal. The semiconductor device is mounted on the bump in a cavity in the bump, is electrically connected to the conductive trace and is thermally connected to the heat spreader. The bump extends into an opening in the first adhesive and is aligned with and spaced from an opening in the second adhesive. The base and the ledge extend laterally from the bump. The first adhesive is sandwiched between the base and the ledge, the second adhesive is sandwiched between the conductive trace and the ledge and the ledge is sandwiched between the adhesives. The conductive trace is located outside the cavity and provides signal routing between the pad and the terminal.

Owner:BRIDGE SEMICON

Preparation method of organic silicon-modified polyurethane copolymer fabric softener

InactiveCN106432670AKeep hydrophilicImprove wearing comfortLight resistant fibresLiquid repellent fibresPolyolPrepolymer

The invention discloses a preparation method of an organic silicon-modified polyurethane copolymer fabric softener. The method comprises the following steps: (a) carrying out a stirring reaction on polyether polyol, a hydroxyl-terminated polysiloxane linear body and diisocyanate for 2-3h at the temperature of 75-85 DEG C under the action of a tin catalyst, so as to obtain an isocyanate-terminated organic silicone-modified polyurethane prepolymer; (b) adding a small molecular amine chain extender into the organic silicone-modified polyurethane prepolymer, and carrying out a stirring reaction for 1-2h at the temperature of 50-60 DEG C, so as to obtain an organic silicon-modified polyurethane copolymer; (c) evenly mixing the organic silicon-modified polyurethane copolymer obtained in the step (b) with an emulsifying agent at the temperature of 50-70 DEG C, and slowly adding deionized water into the mixture for emulsifying, so as to obtain the organic silicon-modified polyurethane copolymer fabric softener. The softener prepared by the method is good in stability, endows fabric with excellent softnesss, smoothness and hydrophilic property, has excellent yellowing resistance, and can maintain the brightness of the light-colored fabrics and the whiteness of the white fabrics.

Owner:ZIBO LURUI FINE CHEM CO LTD

Repair weld composite leveller roll and its production process

InactiveCN1736627AHigh strengthImprove impact resistanceArc welding apparatusOther manufacturing equipments/toolsChemical compositionWorking life

It relates to a pile-up welding composite straightener roll and the preparation technique, belonging to the art of mechanical device, and it especially relates to a straighter roll for a plate hot straightening machine. The straightener roll uses alloy constructional steel 42CrMo wrought-steel as the base metal to prepare mandrel of roll body, and is built-up an operational layer of 5-15mm by thicken on the surface of the roll body, the chemical composition of the deposited material of the operational layer being: C:0.36-0.45%, Cr: 12.00-14.00%, Ni:2.00-2.50%, Mo: 2.00- 3.00%, W: 2.00- 3.00%, Ti: 0.85-1.25%, Si: <=1.50%, Mn: <= 2.00%, P<= 0.035%, and S: <=0.03%. In the technique it uses 1250 type automatic buried arc building-up device, applies bobbing building-up to build up the operation layer of roll body, and uses the 260 weld flux as the welding material. The straightener roll has a long work life and a high strength of roll body, and it can be repaired and reproduced a plural of times.

Owner:UNIV OF SCI & TECH BEIJING

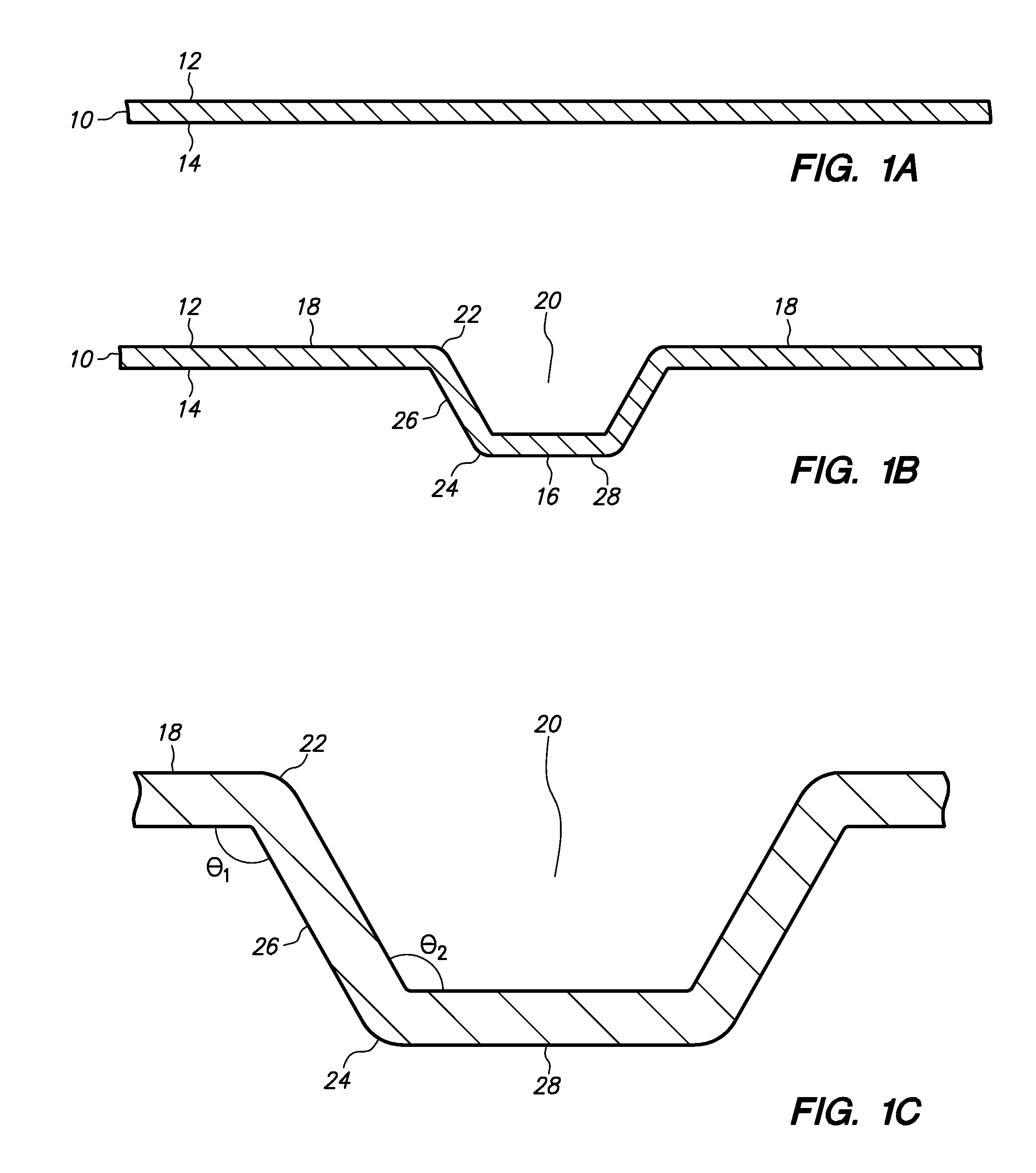

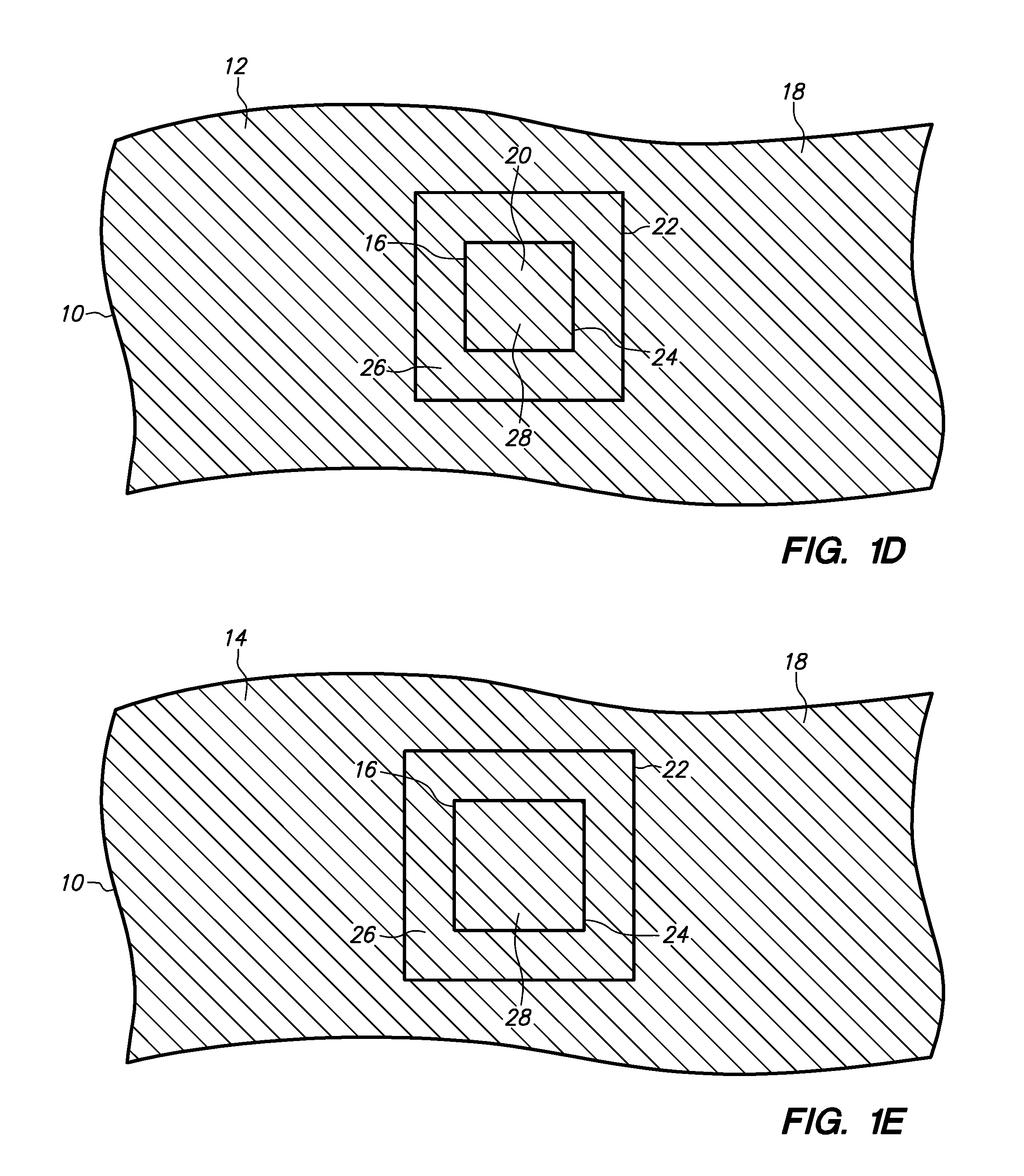

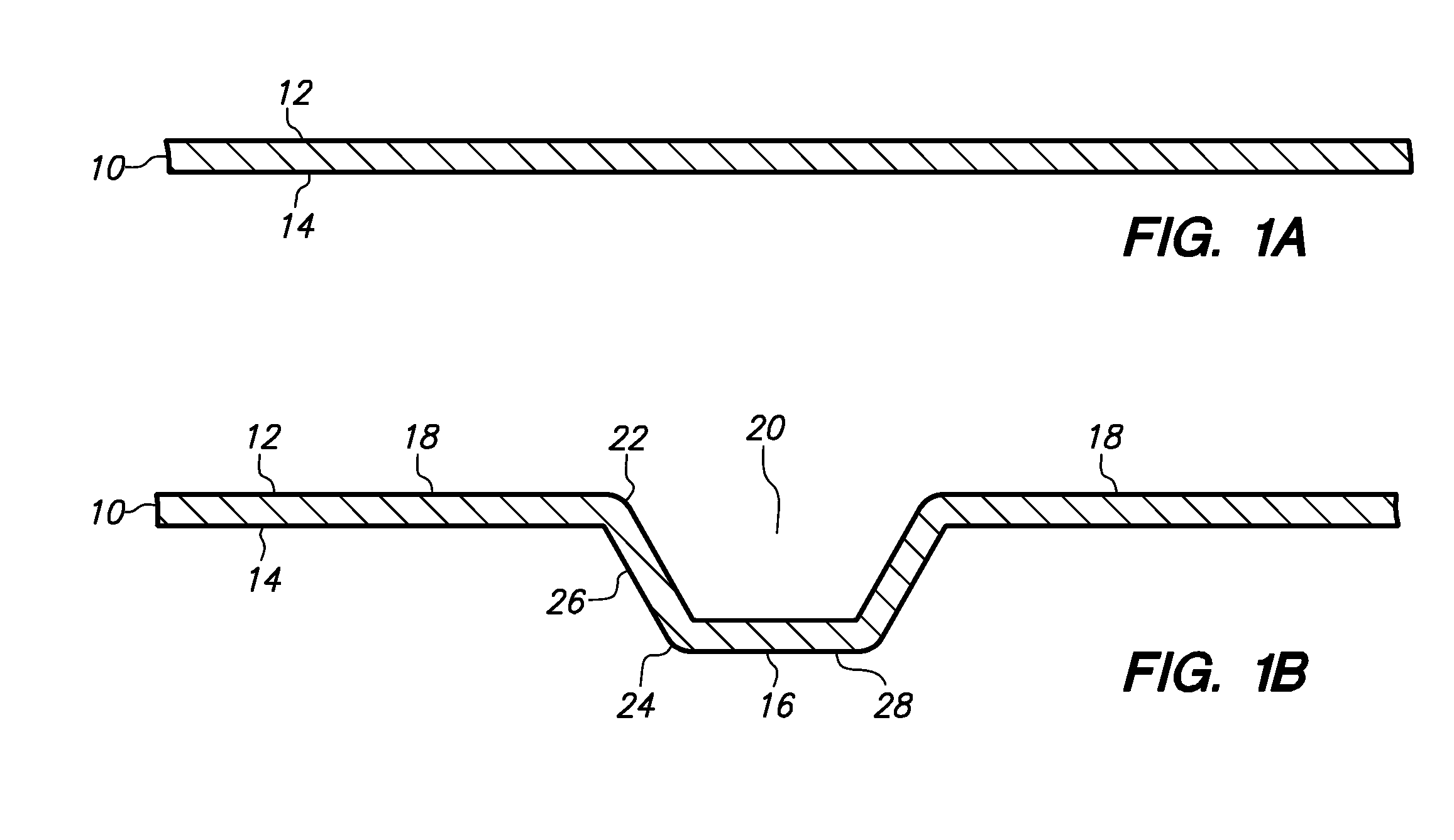

Method of making a semiconductor chip assembly with a bump/base heat spreader and a cavity in the bump

InactiveUS20110039374A1Excellent heat spreading and heat dissipationNot prone to delaminationSemiconductor/solid-state device detailsPrinted circuit aspectsAdhesiveEngineering

A semiconductor chip assembly includes a semiconductor device, a heat spreader, a conductive trace and an adhesive. The heat spreader includes a bump, a base and a flange. The conductive trace includes a pad and a terminal. The semiconductor device extends into a cavity in the bump, is electrically connected to the conductive trace and is thermally connected to the bump. The bump extends from the base into an opening in the adhesive, the base extends vertically from the bump opposite the cavity and the flange extends laterally from the bump at the cavity entrance. The conductive trace is located outside the cavity and provides signal routing between the pad and the terminal.

Owner:BRIDGE SEMICON

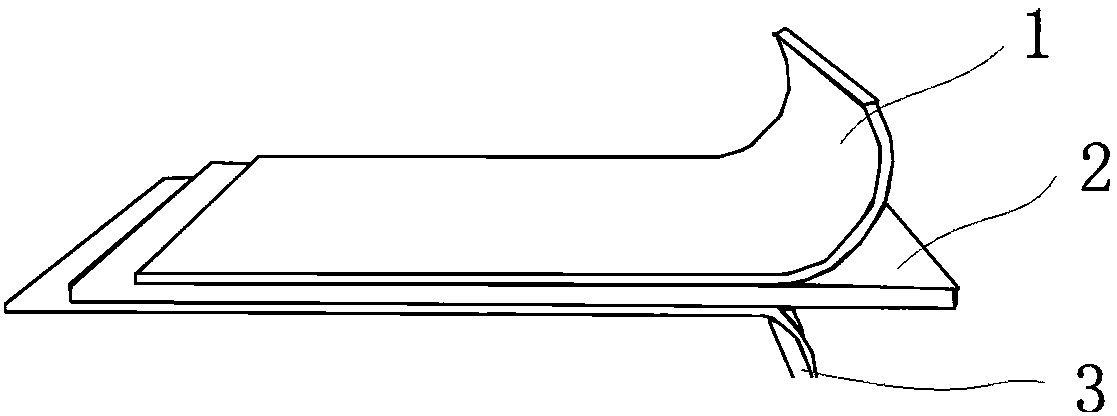

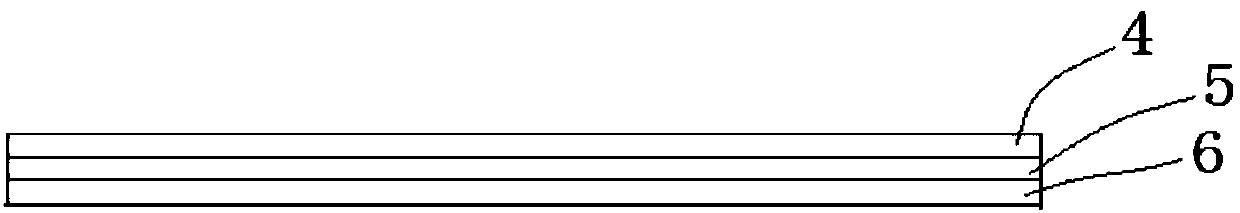

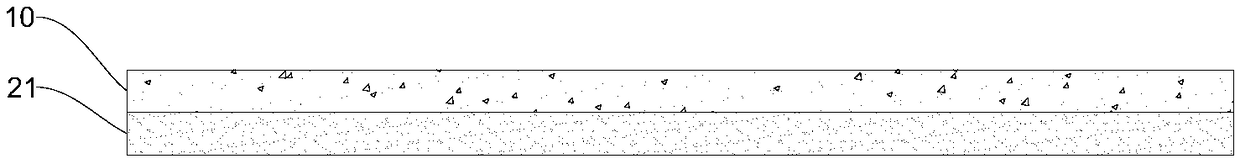

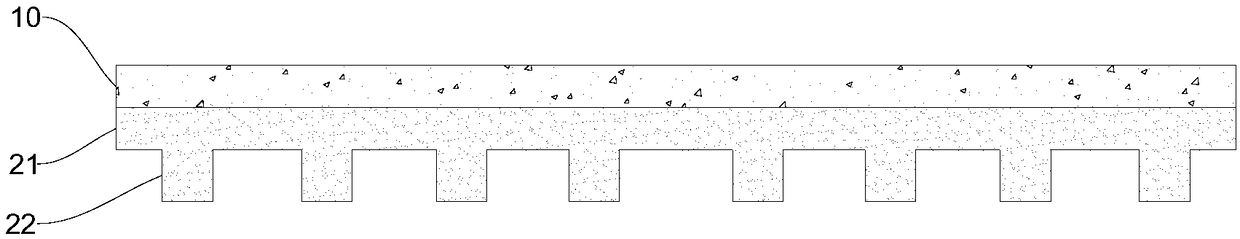

Functional floor heating floor made of alloy materials and preparation method thereof

ActiveCN103541539ASimple preparation processImprove thermal conductivityAntifouling/underwater paintsSynthetic resin layered productsPolymer alloyPolyvinyl chloride

The invention discloses a functional floor heating floor made of alloy materials and a preparation method thereof. The floor heating floor is structurally characterized by being of a four-layer composite structure, wherein the bottom layer is a vacuum coating reflective layer; a backing material layer is arranged on the reflective layer and made of polyvinyl chloride (PVC)-based polymer alloy composite materials; a coextru-lamination decorative layer is arranged on the backing material layer; the backing material layer and the decorative layer are integrally formed to an integral structure through a co-extrusion extrusion process; the top layer is an ultraviolet (UV) processing transparent antibacterial wear-resisting layer. The invention further discloses a method for preparing the functional floor heating floor. The method comprises the following steps of (1) blending and preparing of the backing material layer; (2) online coextru-lamination of the decorative layer and the backing material layer; (3) online embossing processing of the surface of the decorative layer; (4) vacuum coating of the surface of a board; (5) UV antibacterial wear-resisting processing of the surface layer. The method is simple in process progress. The floor heating floor prepared by the method is good in floor heating conductivity, dimension stability, antifouling and environment-friendly performance and using durability.

Owner:安徽圣源橡塑科技有限公司

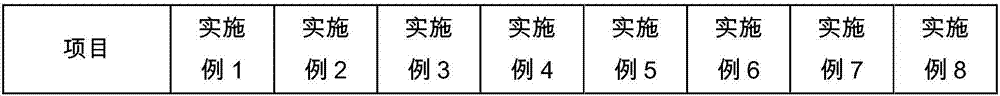

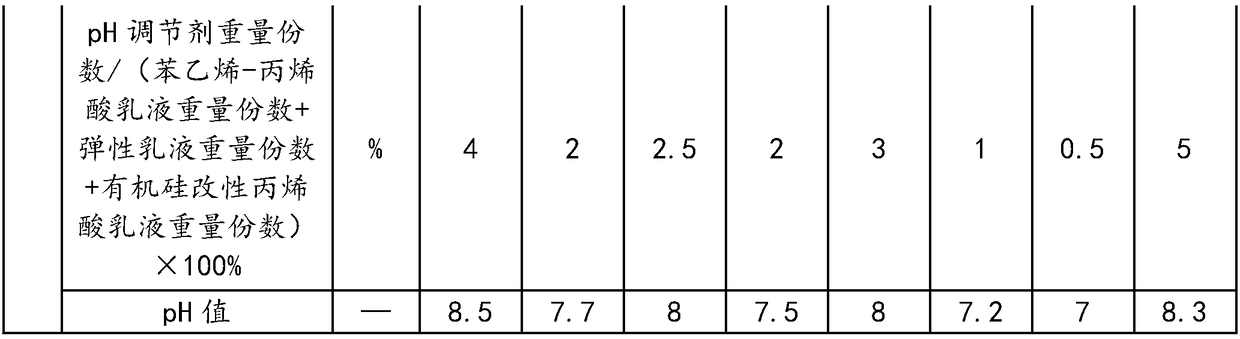

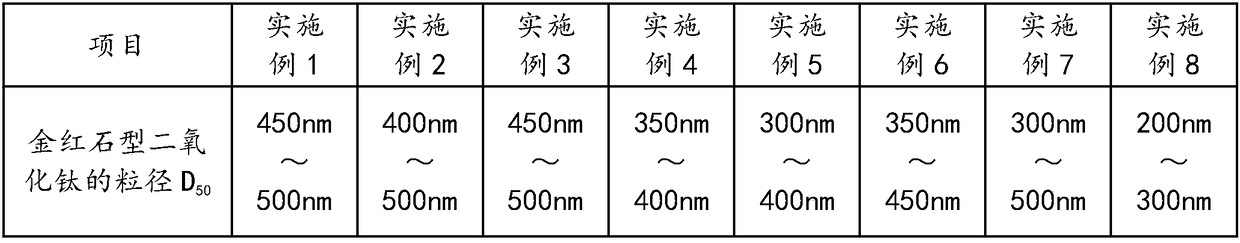

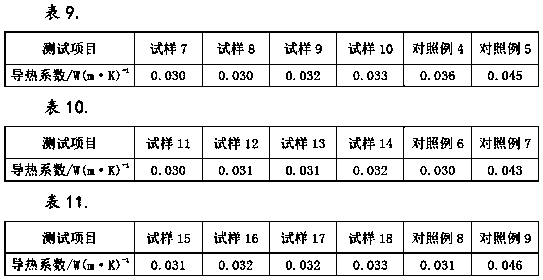

Silica aerogel reflective insulation exterior wall coating and preparation method thereof

ActiveCN107163855AShorten the replacement periodReduce deliveryAntifouling/underwater paintsPaints with biocidesPolymer scienceEmulsion

The invention belongs to the technical field of functional coatings and in particular relates to a silica aerogel reflective insulation exterior wall coating which comprises water A, rutile titanium dioxide, a silica aerogel precursor, pigments and filler, a flatting agent, a dispersant, a preservative, a defoamer, a styrene-acrylic emulsion, an elastic emulsion, an organosilicone modified acrylic emulsion, a coalescing agent, a thickener and a pH adjustor. The preparation method comprises the following steps: mixing the materials in order; and grinding the mixture. Compared with a conventional reflective insulation coating, the reflective insulation coating prepared by adopting formula materials and method provided by the invention is quite excellent in reflective insulation property and has the advantages of low production cost and environmental protection.

Owner:天津朗华睿博科技有限公司

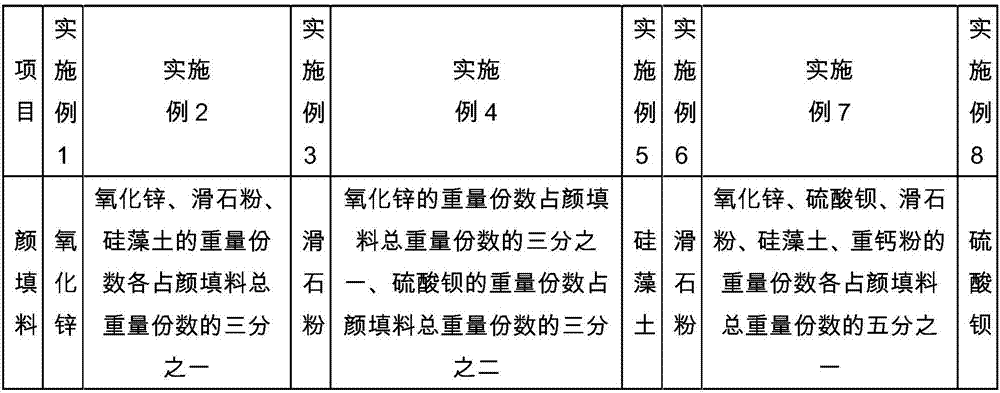

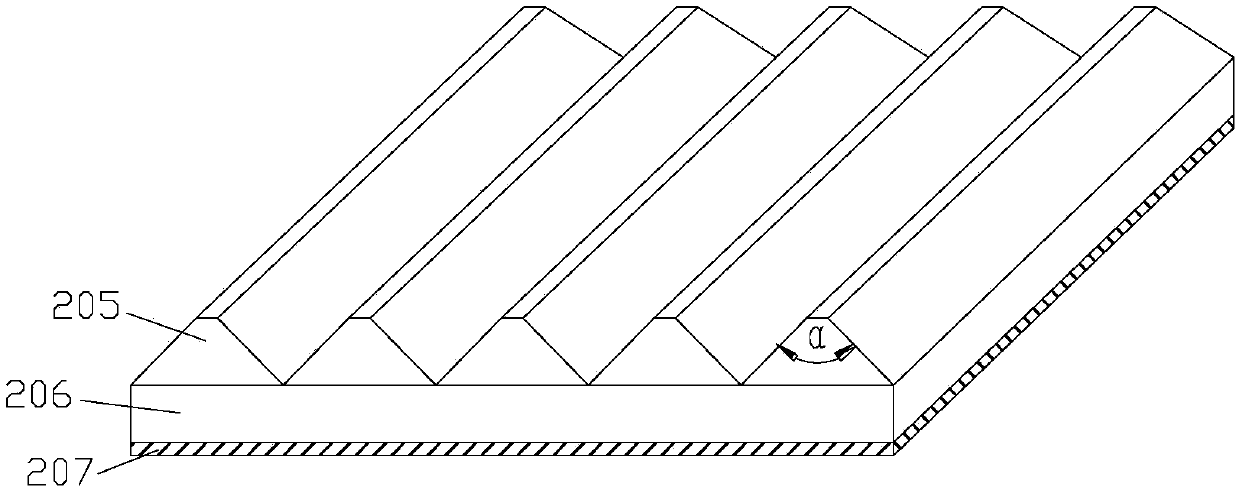

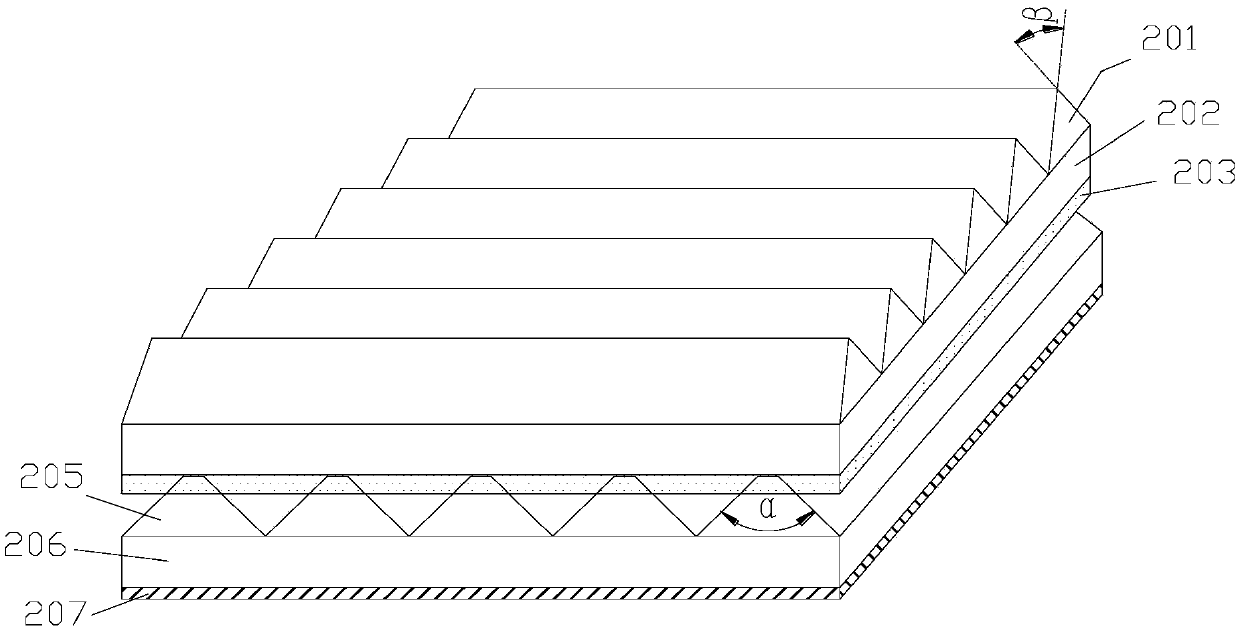

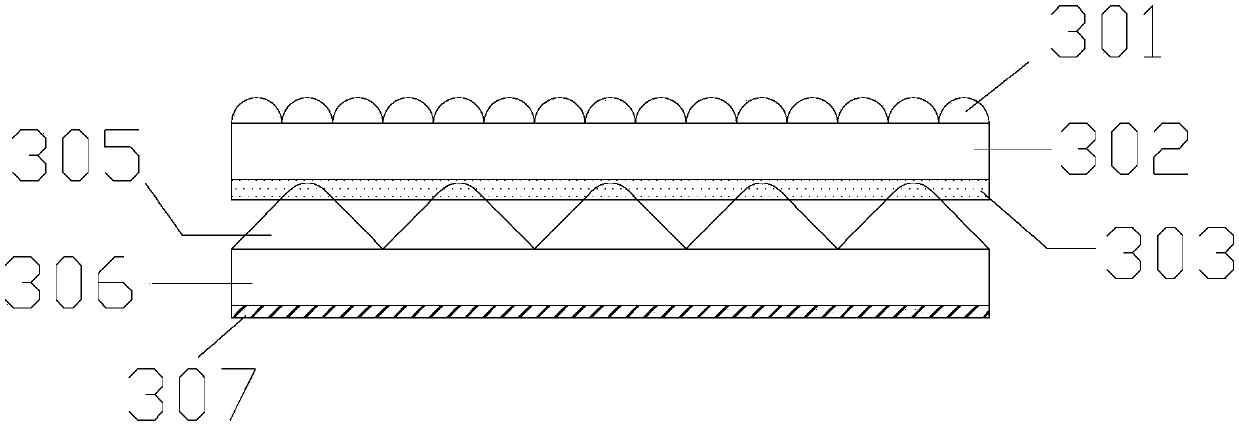

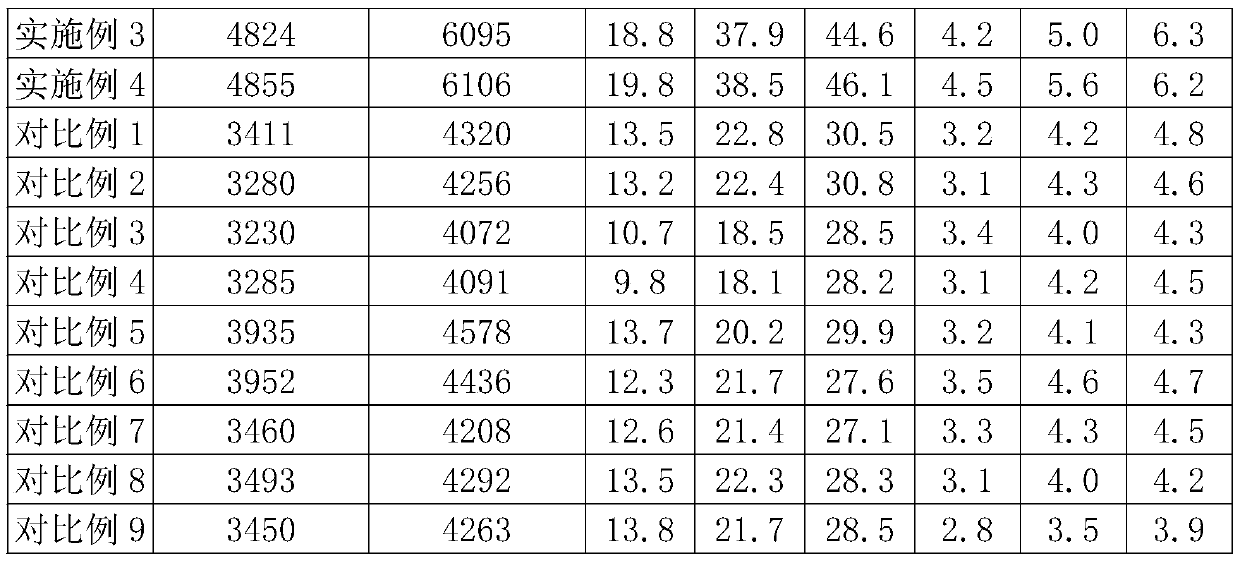

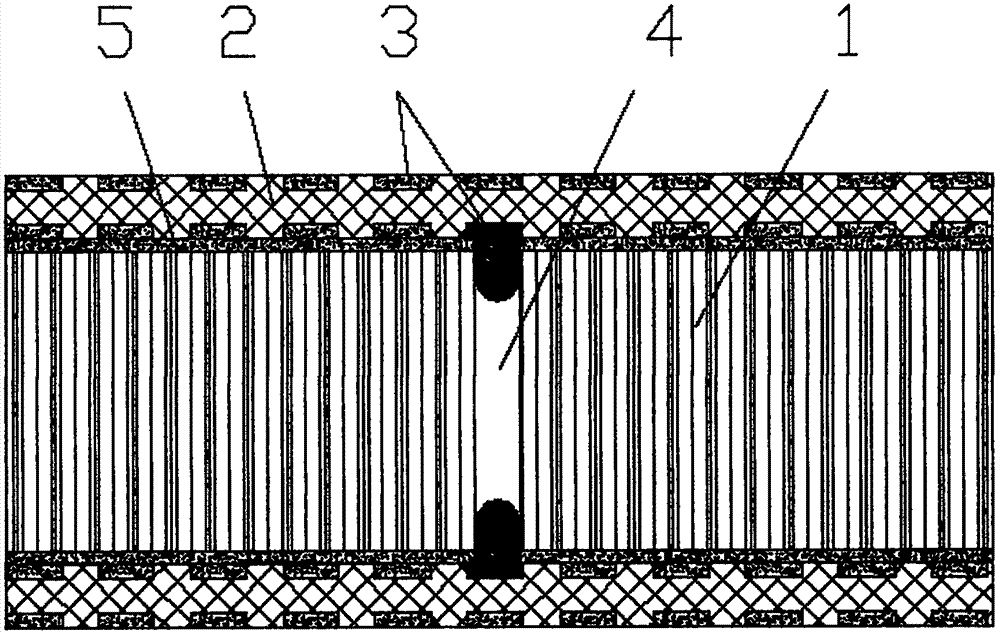

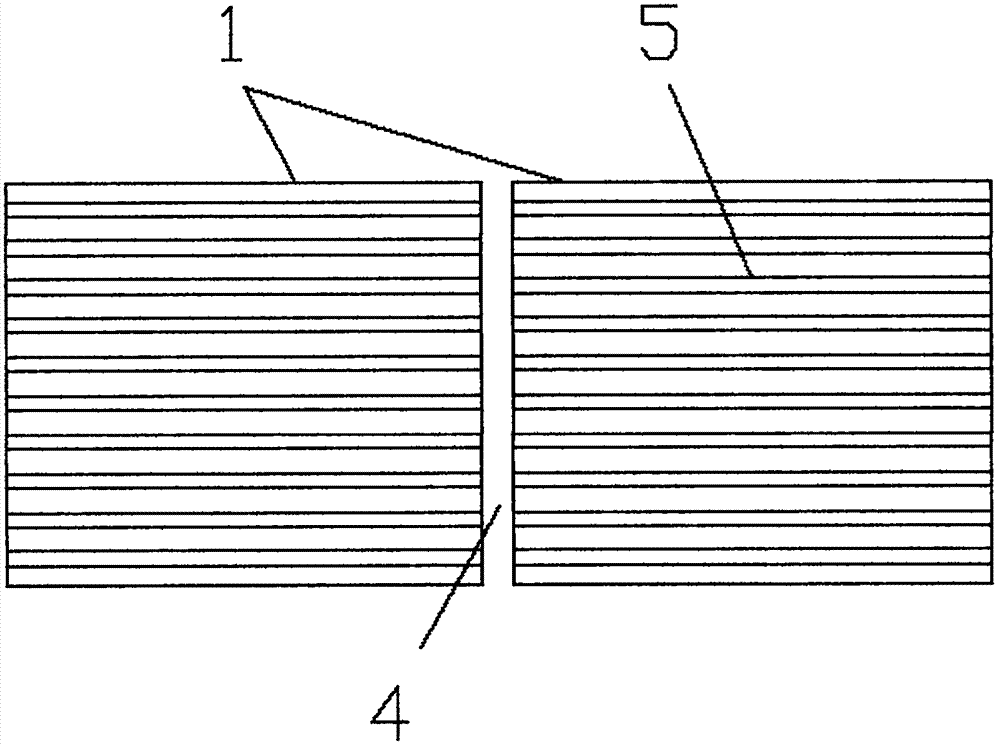

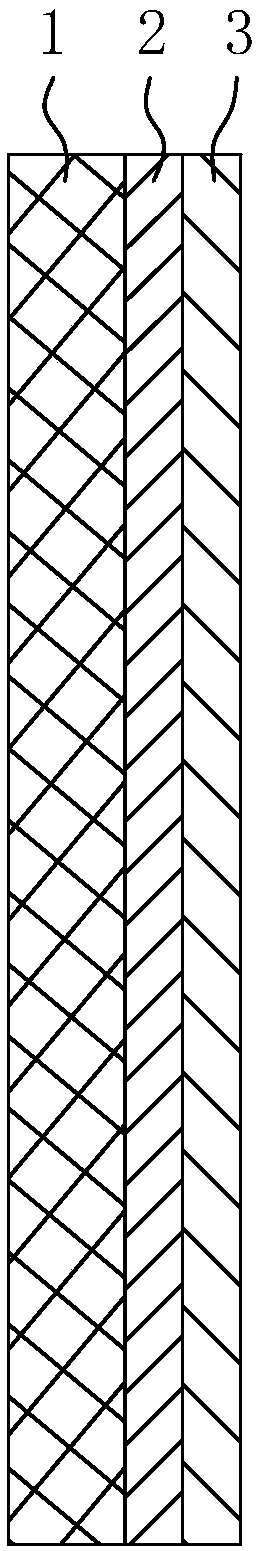

Multi-layer optical film

PendingCN107831561ANot prone to delaminationLess prone to problems such as peelingPrismsDiffusing elementsPrismAdhesion strength

The invention discloses a multi-layer optical film. The film comprises a first layer optical membrane and a second layer optical membrane. The first layer optical membrane is a prism membrane. The second layer optical membrane is one kind of a prism membrane, a diffusion membrane and a micro-lens membrane. The second layer optical membrane is coated with an adhesive layer. The first layer opticalmembrane and the second layer optical membrane are adhered together through the adhesive layer. According to the invention, due to the design of the prism structure, the adhesion strength between themultiple optical membranes can be improved by 50% or more than that of the current optical composite membrane; through the improving of the adhesion strength, the multiple optical membranes are free from problems of difficult layering and difficult stripping in following cutting, assembling and use; the cutting yield is improved; and the module assembly yield is improved.

Owner:CHANGZHOU HUAWEI ADVANCED MATERIAL

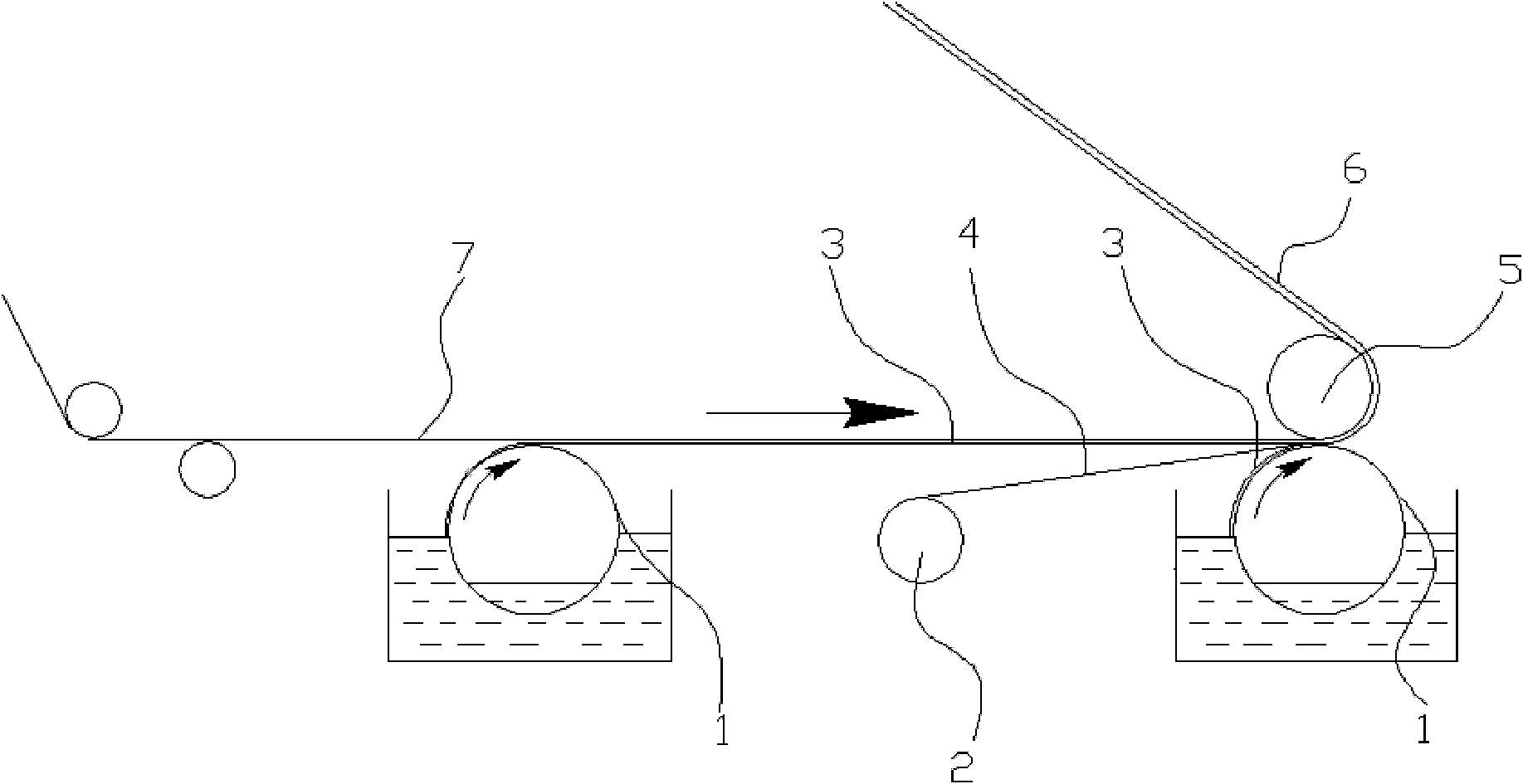

Anti-counterfeiting cloth paper and preparation method thereof

InactiveCN102277797ADehydratingImprove breathabilityNon-fibrous pulp additionSpecial paperPapermakingMachining process

The invention relates to an anti-counterfeit cloth paper and a preparation method thereof. The anti-counterfeit cloth paper has a sandwich structure composed of two layers of paper sheets and one layer of cloth. The present invention also provides a method for preparing the above-mentioned anti-counterfeit cloth paper, which includes the following steps: using a cylinder paper machine to form at least two layers of wet paper sheets with double cylinders; compounding at least one layer of cloth between the wet paper sheets on at least two sides , form a sandwich structure, and complete subsequent papermaking to obtain the anti-counterfeit cloth paper. The anti-counterfeit cloth paper of the present invention is compounded with cloth with specific properties in the middle of the paper, realizing the combination of two different technical fields of papermaking and textile, making the performance of cloth and paper complementary, enhancing the physical strength of paper, and greatly improving the physical properties of paper At the same time, it does not affect the performance of paper printing. It can also give a variety of anti-counterfeiting information during the weaving and processing of cloth, greatly improving the anti-counterfeiting performance of cloth and paper, and bringing novel expressions and effects to paper anti-counterfeiting technology.

Owner:BAODING BANKNOTE PAPER CO LTD +1

Active lactobacillus beverage preparation method and active lactobacillus beverage prepared therethrough

The invention discloses an active lactobacillus beverage preparation method and an active lactobacillus beverage prepared therethrough. The preparation method comprises the following steps: homogenizing, sterilizing and cooling fresh milk or reconstituted milk as a raw material, inoculating a starter, adding 0.01-1mass% of aseptic light calcium carbonate, and fermenting at 28-42DEG C for 48-72h to prepare a fermented milk base material; and diluting the obtained fermented milk base material with sterile water according to a volume ratio of the fermented milk base material to water of 1:1-1:9, homogenizing at 30-40DEG C under a pressure of 17-25MPa while (without) adding a sweetener and / or an essence, and filling at 10-20DEG C to obtain the active lactobacillus beverage. The active lactobacillus beverage obtained through the preparation method contains a high quantity of live bacteria, and the preparation method enhances the degradation degree of fermenting strains to milk proteins, allows the content of milk protein peptides in the active lactobacillus beverage to be high, and realizes the stability and difficult layering of the active lactobacillus beverage.

Owner:BRIGHT DAIRY & FOOD CO LTD

Phase change heat storage type electric heating floor

InactiveCN103776080ACompact and reasonable structureImprove securityLighting and heating apparatusElectric heating systemElectricityElectrical connection

The invention discloses a phase change heat storage type electric heating floor. The phase change heat storage type electric heating floor comprises a floor main body and an electric heating assembly. Socket positions which are connected with the adjacent electric heating floor portions during usage are formed on the periphery of the floor. The phase change heat storage type electric heating floor is characterized by also comprising a flat phase change unit; the floor main body comprises a panel component and a base plate; the corresponding positions of the panel component and the base plate in the vertical direction are bonded and fixed together to form the floor main body, wherein the inside of the floor main body comprises the first installation space; the electric heating assembly comprises an electric heating piece, a transmission unit and connection sockets which are located at the front end and the rear end of the electric heating piece respectively and used for performing electrical connection externally; the electric heating piece and the phase change unit are fixedly arranged in the first installation space of the floor main body; the panel component, the electric heating piece, the phase change unit and the base plate are arranged in turn from top to bottom and are in close contact with each other in turn in the vertical direction.

Owner:江苏德威木业有限公司

Five-layer co-extrusion laminated board for sanitary ware and preparation method thereof

InactiveCN101670694ASolve ABSSolving Consistency IssuesSynthetic resin layered productsLaminationCrack resistanceUltraviolet

The invention discloses a five-layer co-extrusion laminated board for sanitary ware and a preparation method thereof, wherein the first layer and the fifth layer are made from PMMA and UV; the secondlayer and the fourth layer are made from the PMMA, ABS, the UV and a titanium dioxide color master batch; and the third layer is made from the ABS and the titanium dioxide color master batch. The preparation method of the board comprises the following steps: uniformly mixing and stirring the raw materials of each layer in respective mixing hoppers; drying the raw materials and then plasticizing, melting and extruding the raw materials into corresponding flow channels of a distributor at a certain temperature by three extruders; and extruding the raw materials by a T-shaped die head and flattening the raw materials through a flattening system to prepare the board. The invention has the advantages that after long-term uneven cold and hot changes, the board is not easy to generate delamination to crack, has good hot water circulation resistance and the function of ultraviolet ray resistance, can be guaranteed to be not easy to fade during use and have cracking resistance, chemical corrosion resistance, hot water circulation resistance, stable color, difficult fading after being exposed to the sun and the rain for a long term, and the like. The invention is also widely suitable for other fields such as indoor and outdoor decoration, and the like.

Owner:CHANGZHOU BOSHUANG PLASTICS

Solder paste applied to signal distributor and preparation method of solder paste

InactiveCN107309577AHigh activation temperatureEnhanced ability to deoxidizePrinted circuit assemblingWelding/cutting media/materialsAlloyCleansing Agents

The invention relates to solder paste applied to a signal distributor. The solder paste is composed of flux paste and tin-based alloy welding powder. The flux paste is obtained after 25%-40% of solvent, 42%-50% of modified rosin, 2%-5% of organic acid, 2%-5% of borofluoride, 7%-10% of a thixotropic agent and 5%-10% of an antioxidant are added in a reaction kettle to be stirred, heated to 150 DEG C and dissolved. The flux paste is evenly mixed with any one of several types of solder powder, including Sn96.5Ag3.0Cu0.5, Sn97.5Ag2.0Cu0.5, Sn98.5Ag1.0Cu0.5, Sn99Ag0.3Cu0.7, Sn99Cu0.7, Sn42Bi58, Sn64Bi35Ag1.0, Sn64.7Bi35Ag0.3 and Sn64.9Bi35Ag0.1, in a mixing machine according to the weight ratio being (10-15):(85-90) to obtain the solder paste suitable for the signal distributor. The solder paste is particularly suitable for the signal distributor, the production cost can be reduced, and the production efficiency can be improved; viscosity is appropriate, thixotropy is high, the solder paste is not likely to be layered when a glue dispenser conducts dispensing, and the solder paste can be uniformly sprayed on an assigned welding area; an oxidation film of an electroplated coating on the surface of the solder powder can be completely removed within 5-8 seconds, and false solder and missing solder can be prevented; and the storage life of the solder paste is long, and the solder paste can bear a high welding temperature. Post-soldering residues are few, and cleaning can be easily conducted through an environment-friendly cleaning agent.

Owner:赛伦(厦门)新材料科技有限公司

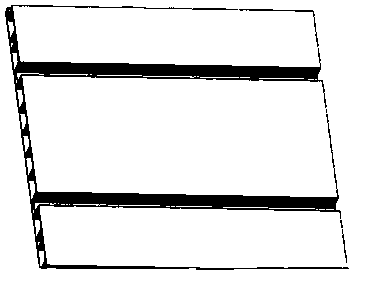

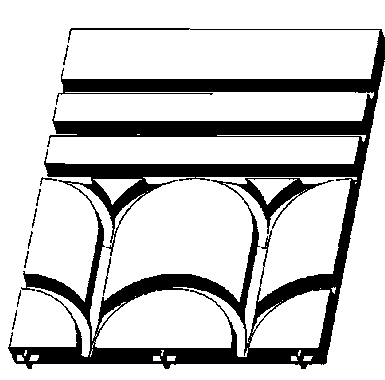

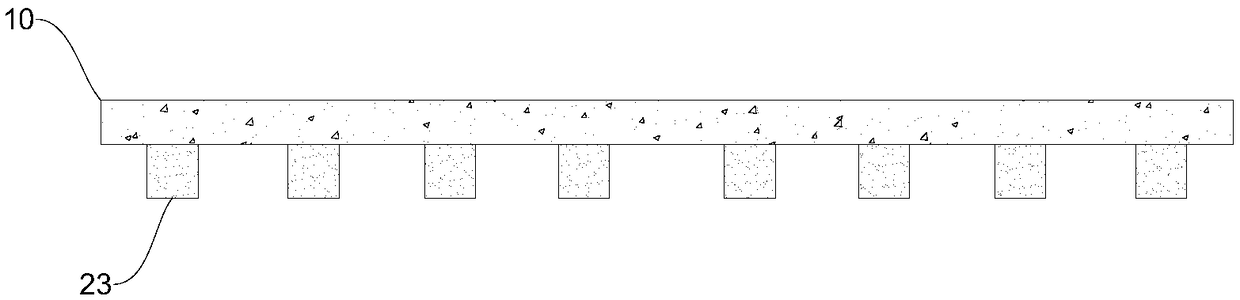

Combined type composite material floor heating trough plate and manufacturing method thereof

The invention relates to the field of building decoration materials, in particular to a combined type composite material floor heating trough plate and a manufacturing method of the trough plate. The combined type composite material floor heating trough plate is composed of a straight pipe type composite material trough plate module and a bend type composite material trough plate module, and plate edges and plate heads are spliced through lock catch structures of tenons and mortises. The two modules can be freely combined according to the required number and the hot source requirements of a room structure, single-S structure or double-S structure arranging and mounting of a heating cable and a hot water pipe for floor heating are achieved, and even radiation of the heat source is ensured. The composite trough plate is of a double-layer structure, a body layer is made of functional polymer alloy sheet materials, and the body layer resists to heat, has the inflaming retarding effect and is high in strength. A functional aluminum foil heat conduction layer is arranged on the upper layer and is rapid in heat conduction and high in heat efficiency utilization rate.

Owner:安徽圣源橡塑科技有限公司

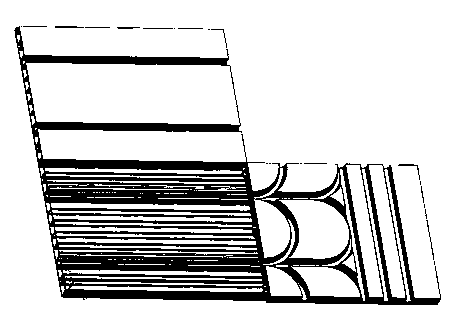

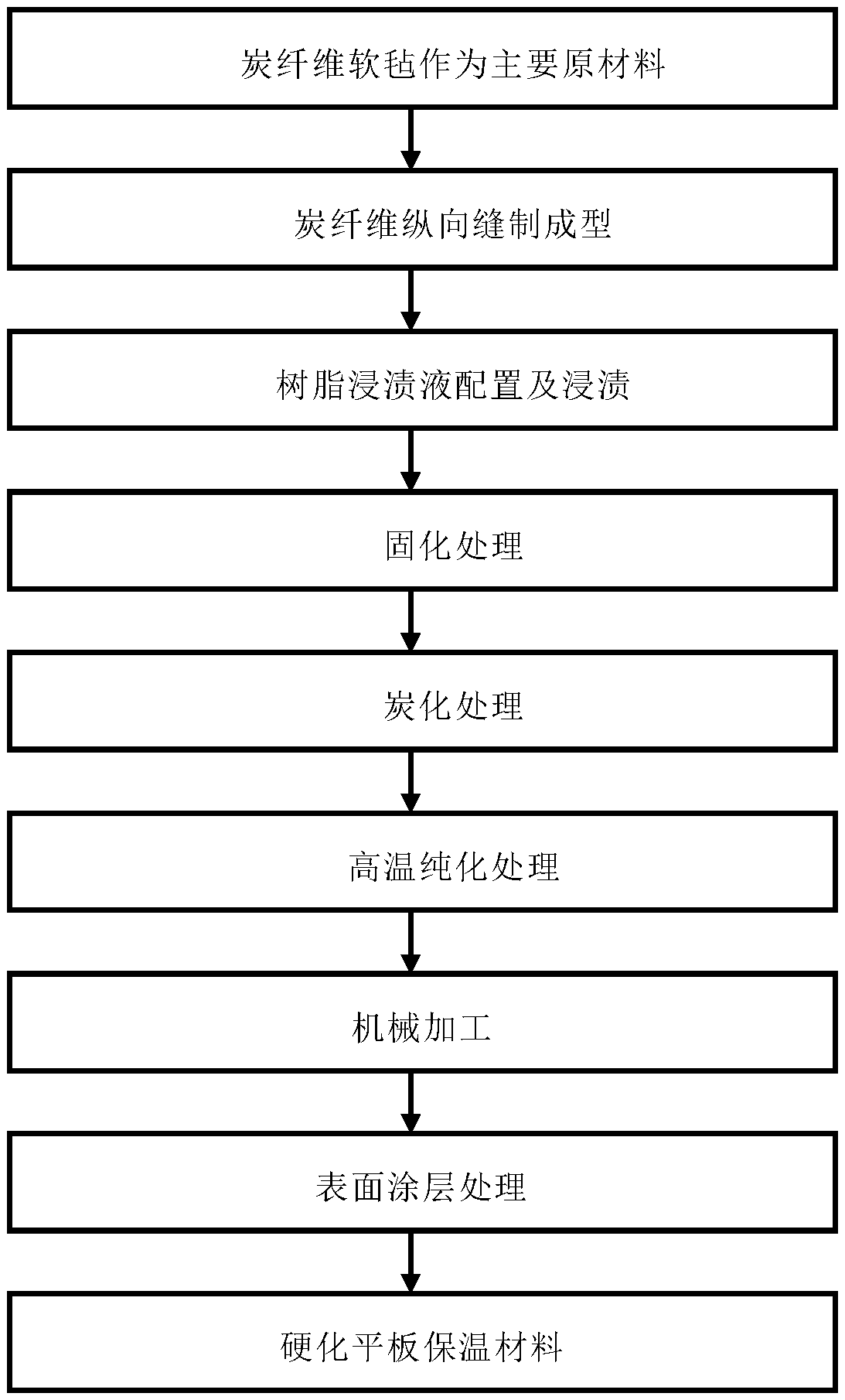

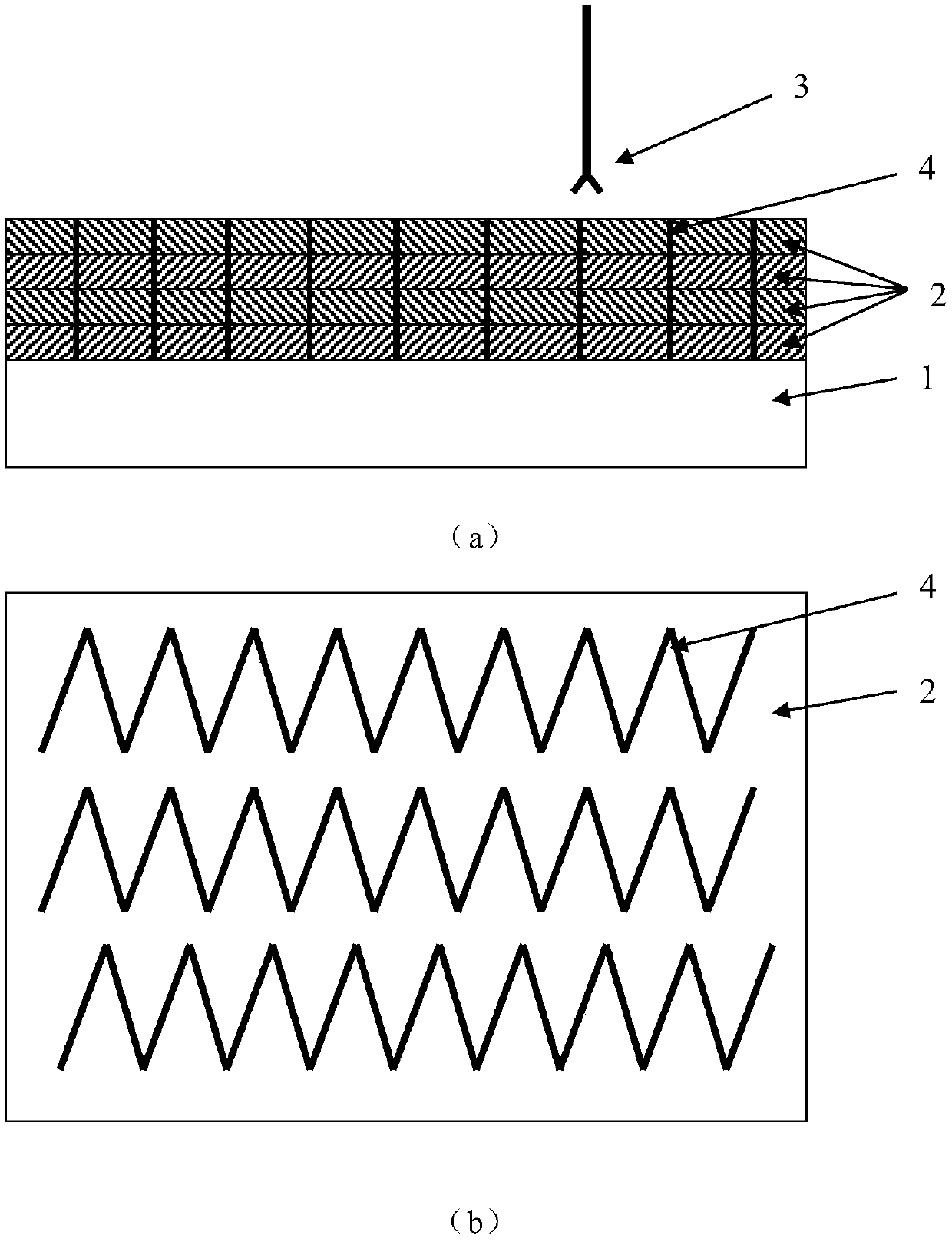

Method for preparing carbon fiber-sewed hard plate thermal insulation material

The invention discloses a method for preparing a carbon fiber-sewed hard plate thermal insulation material. The method comprises the following concrete steps: 1, using of a carbon fiber soft felt as amain raw material; 2, longitudinal sewing molding of carbon fibers; 3, preparation of a resin impregnation solution; 4, resin impregnation; 5, curing treatment; 6, carbonizing treatment; 7, high temperature purifying treatment; 8, machining; and 9, surface coating treatment for producing the hard plate thermal insulation material. The carbon fiber longitudinal sewing molding process using the carbon fiber soft felt as the main raw material and a resin carbon matrix as a reinforcement is adopted to make the hard plate thermal insulation material with a low density and a certain mechanical strength, the hard plate thermal insulation material undergoes surface coating hole-sealing treatment to achieve the characteristics of low density, difficult layering, low thermal conduction coefficient,good high temperature stability and strong processability, and the process cost is low.

Owner:JIANGSU UNIV

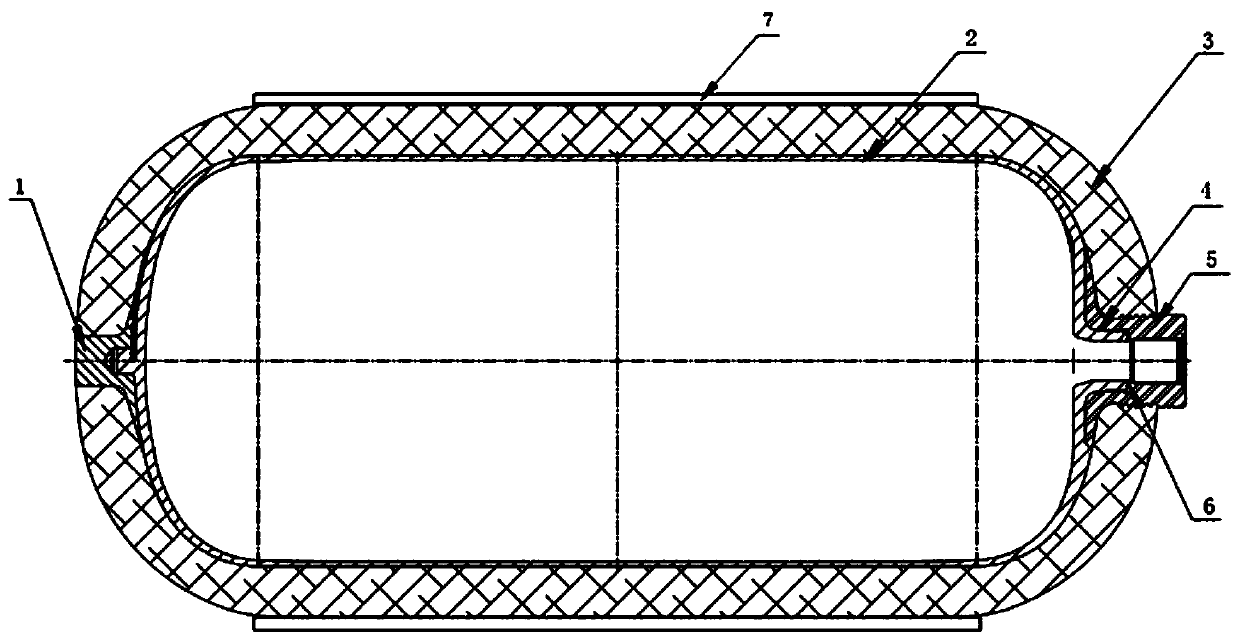

Plastic inner container carbon fiber fully wound gas cylinder and manufacturing method thereof

InactiveCN111188991AImprove adhesionTight bondVessel mounting detailsVessel manufacturingCarbon fibersAlcohol

The invention discloses a plastic inner container carbon fiber fully wound gas cylinder and a manufacturing method thereof. The manufacturing method comprises the step of cylinder opening assembling,wherein the outer surface of an inner container and a cylinder opening and a tail top needing to be mounted on the inner container are cleaned by absolute ethyl alcohol with the concentration being 99% or above, a sealing ring, a sealing gasket and the cylinder opening are assembled to form a to-be-assembled body, the to-be-assembled body is mounted on the cylinder opening of the inner container,the tail top is mounted at the tail of the inner container and is opposite to the cylinder opening, the to-be-assembled body, the tail top and the inner container are subjected to cold assembling, andit is guaranteed that the gas cylinder cannot shrink again under the work temperature of the inner container, the to-be-assembled body and the tail top. The problems that the inner container and a fiber winding layer are prone to being separated, and the sealing performance fails are solved, the sealing effect is better, the inner container and the fiber winding layer are bonded closely, layeringis not prone to happening, and the use stability of the gas cylinder is improved.

Owner:山东奥扬新能源科技股份有限公司

Production method for low-smoke halogen-free mica mineral reinforced fire-resistant cable material

InactiveCN104341657AStrong fire resistanceHigh insulation levelInsulatorsLow-density polyethyleneStrong acids

A production method for a low-smoke halogen-free mica mineral reinforced fire-resistant cable material is disclosed. The cable material is composed of mica mineral, silica gel, an antioxygen adhesion rheological agent, polyethylene master batch, low-density polyethylene and high-density polyethylene, and is prepared by performing mixing, hot melting, extrusion, wind cooling and pelletizing. The cable material is easy for production, stable in performances and reliable in quality. After being added with the cable material, a cable has strong fire resistance, high insulation grade, strong shielding property, and strong resistance to strong acids and alkalis, and also is improved in ultraviolet resistance. After being added with a little amount of the cable material, a cable has the mechanical strength improved by two times or more, and does not easily generate layering phenomenon.

Owner:YANGZHOU DEBAO CABLE

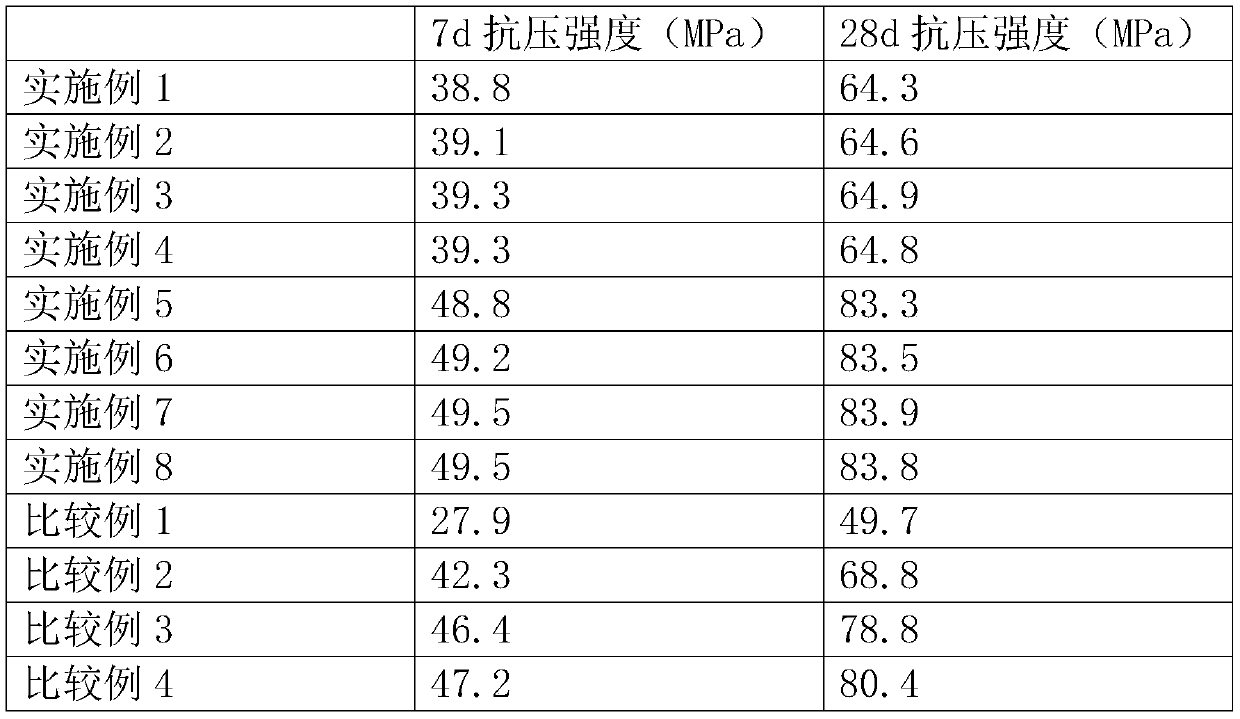

Super retarding concrete

The invention relates to the technical field of building materials, in particular to super-retarding concrete. The formula comprises the following raw materials in parts by weight: 210-250 parts of cement, 30-50 parts of an admixture, 3-5 parts of basalt fiber, 8-10 parts of an additive, 805-810 parts of river sand, 985-1010 parts of stone and 165-170 parts of water. The additive comprises a waterreducing agent, a retarder, a water retaining agent and a defoaming agent, the weight ratio of the water reducing agent to the retarder to the water retaining agent to the defoaming agent is (6-8): (7-9): (3-5): (1-2), the admixture comprises phosphorus slag, coal ash and microbeads, and the weight ratio of the phosphorus slag to the coal ash to the hollow glass microbeads is (10-20) :(40-50) :(10-15). The super-retarding concrete with higher strength and longer setting time is obtained by reasonably proportioning the cement, the admixture, the basalt fibers, the additive, the river sand, thestone and the water and matching the raw materials, pumping construction can be carried out, segregation and layering are not likely to happen, and the super-retarding concrete has important significance on development of the concrete industry.

Owner:深圳市鸿力健混凝土有限公司

Macromolecular composite membrane modified bituminous waterproof roll

InactiveCN107627691AImprove mechanical propertiesGood chemical propertiesSynthetic resin layered productsBituminous layered productsBituminous waterproofingMembranous layer

The invention provides a macromolecular composite membrane modified bituminous waterproof roll. The roll comprises at least one macromolecular composite membrane and at least one modified bituminous size layer bonded to the at least one macromolecular composite membrane, wherein the macromolecular composite membrane adopts a multilayer structure and can prevent layer separation, resist high temperatures and resist ultraviolet rays. Through optimization design of different membrane layer structures and materials of the multilayer macromolecular composite membranes in the macromolecular composite membrane modified bituminous waterproof roll, the waterproof roll has good bituminous swelling resistance and permeability, has good ultraviolet resistance at the high temperature and under ultraviolet irradiation and has the significant waterproof effect, and separation of composite membrane layers cannot occur easily.

Owner:XI NIU PI WATERPROOFING TECH CO LTD

Weatherproof high-barrier solar cell backboard and preparation method thereof

ActiveCN109605880ARaw materials are easy to getMild reaction conditionsSynthetic resin layered productsElectrical equipmentEpoxyWeather resistance

The invention discloses a weatherproof high-barrier solar cell backboard, which comprises a first weatherproof layer, a core layer and a second weatherproof layer sequentially from top to bottom. Thefirst weatherproof layer and the core layer, the core layer and the second weatherproof layer are all bonded by laminating through bonding layers, the first weatherproof layer and the second weatherproof layer are each independently formed by tetramethyl piperidine terminated poly2,3,5,6-tetrafluoroterephthalic acid 1,8-naphthalene dimethanol ester; the core layer is formed of a blend of nylon MXD6 and PET; the bonding layer is formed of a triazole tetramethylpiperidine co-modified epoxy resin. The invention also discloses a preparation method of the weatherproof high-barrier solar cell backboard. The weatherproof high-barrier solar cell backboard disclosed by the invention has more excellent weathering-resistance and high-barrier property, and other comprehensive properties are better.

Owner:徐州日托新材料科技有限公司

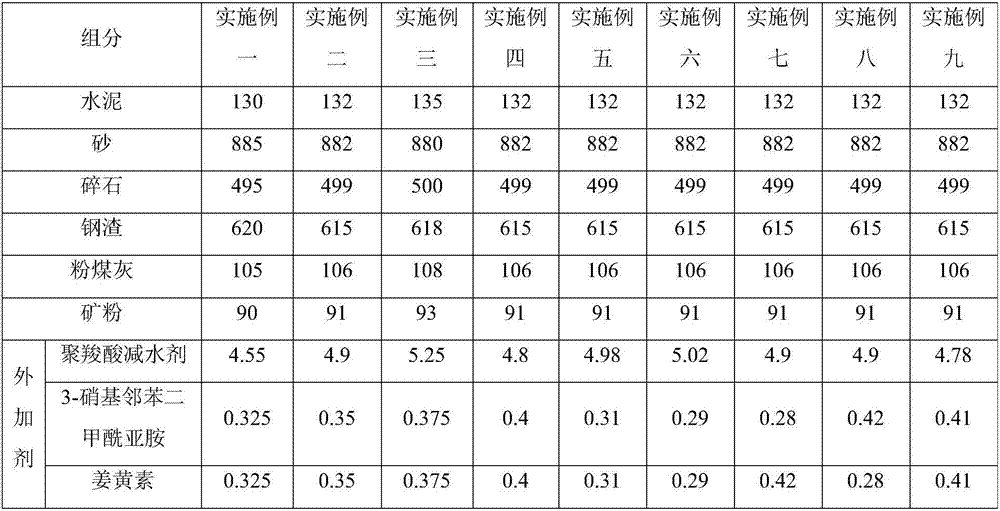

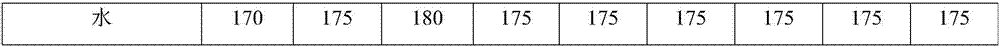

Heavyweight concrete

The invention relates to heavyweight concrete, technically characterized be being made from 130-135 parts of cement, 880-885 parts of sand, 495-500 parts of crushed stone, 615-620 parts of steel slag, 105-108 parts of fly ash, 90-93 parts of mineral powder, 5.2-6.0 parts of an admixture, and 170-180 parts of water, wherein the admixture is composed of a polycarboxylate superplasticizer, 3-nitrophthalimide and curcumin. The heavyweight concrete has the advantages that slump may reach 200 mm, the heavyweight concrete may be pumped for construction, segregation and layering rarely occur, and the heavyweight concrete has good solid density uniformity after formation.

Owner:北京城建亚泰金砼混凝土有限公司

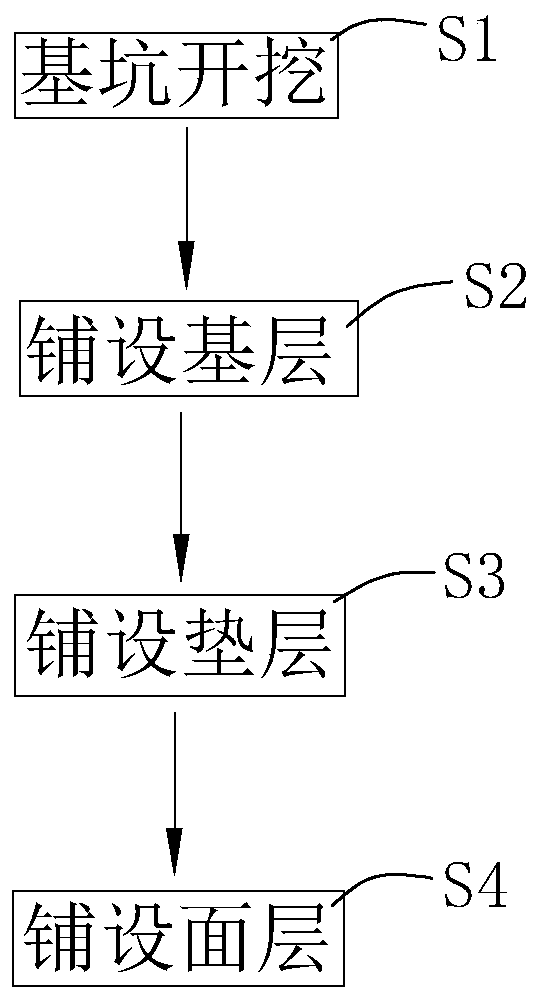

Municipal asphalt concrete pavement construction method

ActiveCN110668752ARutting is not easy to produceExtended service lifeIn situ pavingsGlass fiberHexaphenylbenzene

The invention relates to the field of pavement construction, and provides a municipal asphalt concrete pavement construction method aiming at the problem of easy formation of ruts. The municipal asphalt concrete pavement construction method comprises following steps: S1, excavating a foundation pit; S2, laying a base layer; S3, laying a cushion layer; S4, paving a surface layer, wherein the step S4 comprises following steps: S41, paving a first asphalt layer; S42, paving a second asphalt layer; and S43, pouring a concrete layer. The concrete layer is formed by pouring a concrete slurry; the concrete slurry comprises: 100 parts of Portland cement; 300 to 400 parts of fine aggregate; 200 to 250 parts of a nanometer filling material; 90 to 110 parts of water; 3 to 5 parts of hexaphenylbenzene; 30 to 45 parts of glass fiber; 10 to 12 parts of a silane coupling agent; and the length of the glass fiber is 0.5-1 mm. The concrete layer is poured after the first asphalt layer and the second asphalt layer are laid, so that an asphalt concrete structure is formed on the surface layer, the rigidity of concrete is used for reinforcing asphalt, the surface layer is soft and rigid, the anti-ruteffect is good, ruts are not prone to being generated on the municipal asphalt concrete pavement, and the service life of the municipal asphalt concrete pavement is prolonged.

Owner:广东一业建设股份有限公司

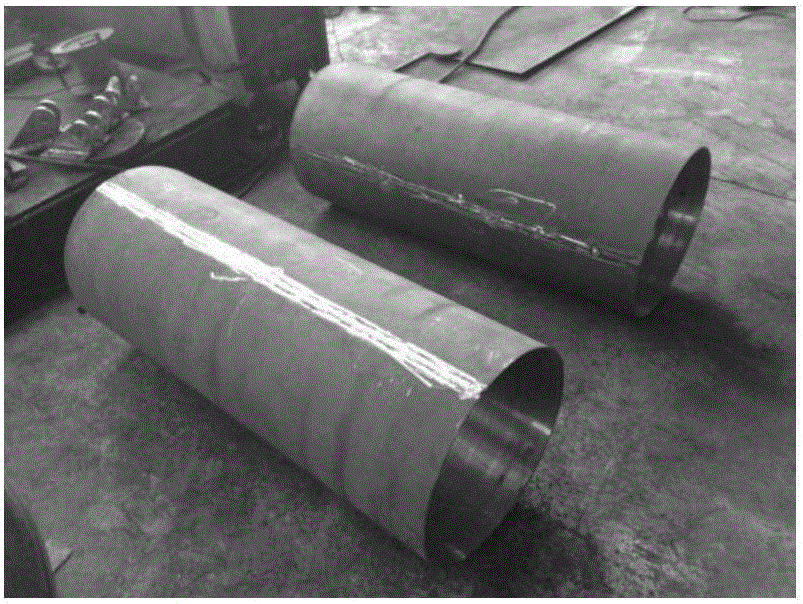

Welding forming method of highly corrosion-resistant stainless steel composite tube

InactiveCN105945525ANot prone to delaminationImprove mechanical propertiesArc welding apparatusWelding/soldering/cutting articlesStainless steel electrodeComposite plate

The invention provides a welding forming method of a highly corrosion-resistant stainless steel composite tube. The method comprises the following steps: (1) cutting a stainless steel composite plate into panels in required sizes; (2) symmetrically processing long sides of the panels of the stainless steel composite tubes into X-shaped grooves; (3) bending the stainless steel composite tubes into stainless steel composite tubes, wherein the outer diameter is a required diameter; (4) performing preweld cleaning; (5) performing electric-arc welding on a cladding metal by using a welding rod, wherein the welding rod is a stainless steel welding rod; (6) performing electric-arc welding on a base metal by using a welding rod, wherein the welding rod is a stainless steel welding rod or a carbon steel welding rod; and (7) grinding and straightening the welded stainless steel composite tubes. According to the method provided by the invention, various welding steps such as sealing, transition welding and overlay welding are reduced, the welding efficiency is extremely improved and the production cost is extremely lowered. Furthermore, the method is relatively simple, and a relatively strong metallurgical bonding interface prevents occurrence of delamination cracks.

Owner:HEBEI UNIV OF TECH

Spontaneous heating floor

ActiveCN102607096AEasy to installImprove thermal efficiencyLighting and heating apparatusElectric heating systemElectricityPower flow

The invention discloses a spontaneous heating floor, which is characterized by comprising a panel, a soleplate and a spontaneous heating component. The heating body of the spontaneous heating component is an electric heating plate. The panel is adhered on the soleplate from above to form a main floor body with an inner cavity. The electric heating plate of the spontaneous heating component is arranged in the inner cavity of the main floor body. Power supply plug connectors belonging to the spontaneous heating components are arranged on the front and back sides of the main floor body. The power supply plug connectors are reliably limited and fixed in the main floor body and are capable of realizing electric connection and current transmission with an adjacent spontaneous heating floor at an insertion hole position exposed outwards from the power supply plug connectors and provided with copper inserting pins by means of a corresponding electric connecting component; and in the invention, the spontaneous heating floor is installed simply and conveniently, and a technical guarantee for safe and reliable application, high heat efficiency and durable structure is provided.

Owner:枣庄高新区利民供热服务有限公司

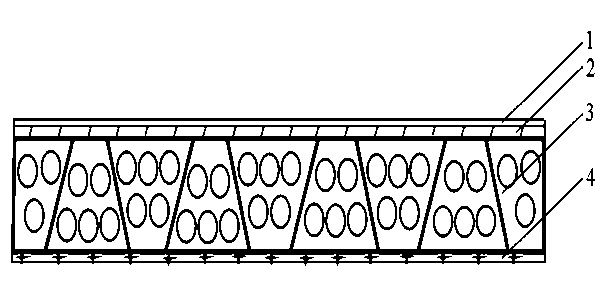

Electrothermal composite material with three-dimensional filling structure

InactiveCN108882408ASimple mechanical structureImprove impact resistanceOhmic-resistance heatingWoven fabricsGlass fiberThermal insulation

The invention discloses an electrothermal composite material with a three-dimensional filling structure. The electrothermal composite material comprises a fabric layer with a three-dimensional fabricstructure and two resin layers composited on the fabric layer; the fabric layer comprises an electrothermal layer, a thermal insulation layer, a support layer and binder yarn, wherein the electrothermal layer, the thermal insulation layer and the support layer are connected through the binder yarn, and the binder yarn is arranged on a protection layer, the electrothermal layer, the thermal insulation layer and the support layer in a penetrating mode; a conducting material is welded to the electrothermal layer, and the electrothermal layer is a fabric layer formed by weaving basalt fiber-coatedcopper wires which serve as warp yarn and weft yarn; the thermal insulation layer is a phenolic resin foaming material layer; the support layer is a fabric layer formed by weaving glass fiber; the binder yarn is glass fiber; and the two resin layers are composited on the two side faces of the fabric layer respectively and are unsaturated polyester resin layers. The electerothermal composite material has the advantages of being good in structure integrity, high in heating speed and heating efficiency and resistant to impact.

Owner:QUANZHOU NORMAL UNIV

Conductive leather substance and preparation method thereof

ActiveCN109300578AReduce processing stepsNot prone to delaminationConductive layers on insulating-supportsApparatus for manufacturing conducting/semi-conducting layersInsulation layerEngineering

The present invention discloses a conductive leather substance and a preparation method thereof, and relates to the technical field of conductive substances. The conductive leather substance comprisesa non-conductive layer and a conductive structure located at one side of the non-conductive layer; the non-conductive layer is a film-shaped structure formed after drying of non-conductive slurry, and the conductive structure is formed by drying conductive slurry. The conductive leather substance is conductive at one surface and is insulated at the other surface to avoid the later processing processes of an insulation layer, the non-conductive layer and the conductive structure are fused and combined to allow stratification not to be easily generated. The preparation method of the conductiveleather substance are subjected to twice coating to form the non-conductive layer and the conductive structure on a film formation die, and therefore, the method is simple and practicable and is suitable for industrialized application.

Owner:博脉有限公司

Enhanced-type thermal-insulation rock-wool composite board and manufacturing method thereof

InactiveCN107476453AHigh tensile strengthNot prone to delaminationHeat proofingGlass/slag layered productsThermal insulationSlurry coating

The invention discloses an enhanced-type thermal-insulation rock-wool composite board, and relates to the field of building materials. The enhanced-type thermal-insulation rock-wool composite board comprises a plurality of rock wool boards and fiberglass gridding cloth. Each rock wool board is formed by splicing a plurality of rock wool strips, the fiberglass gridding cloth covers the upper sides and the lower sides of the rock wool boards and is bonded on the rock wool boards through slurry coatings, the rock wool strips are perpendicular to the plane where the fiberglass gridding cloth is located, a plurality of parallelly arranged grooves are further formed in the upper surface and the lower surface of each rock wool board, and a gap which is 5-9 mm is reserved between every two adjacent rock wool boards; and the slurry coatings comprise cement, quartz sand, polymer emulsion powder, water-retaining agents, accelerants and water. The invention further discloses a manufacturing method of the composite board, the composite board is high in strength and tensile strength, the bonding force of the fiberglass gridding cloth and the rock wool boards is high, heat preservation, thermal insulation and sound absorption are good, and environmental protection and energy conservation are achieved.

Owner:芜湖领航新材料科技有限公司

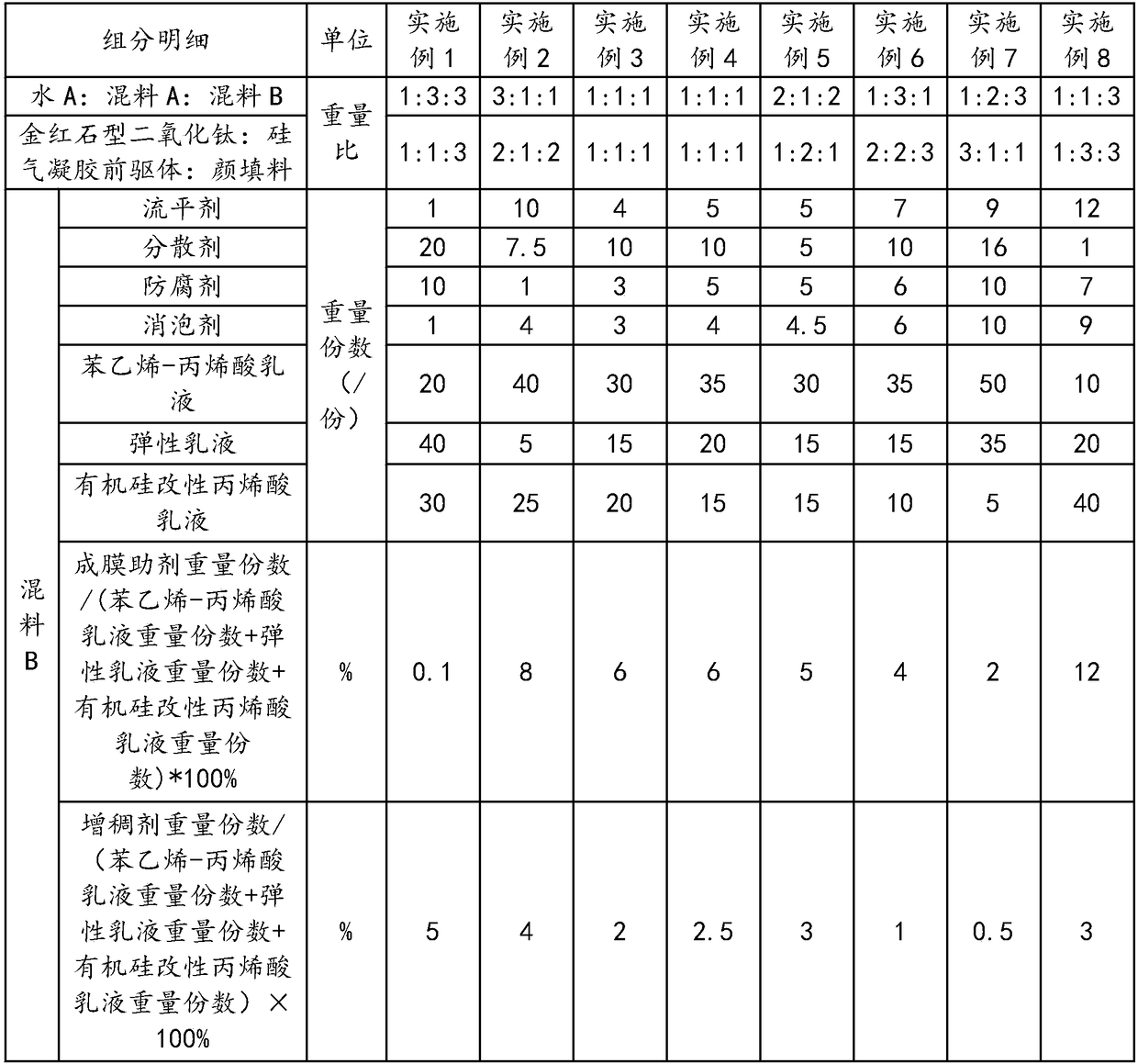

Preparation method of silica aerogel reflecting heat-insulation exterior wall coating

ActiveCN108531083ALow priceStable manufacturing processAntifouling/underwater paintsPaints with biocidesEmulsionPreservative

The invention belongs to the technical field of functional coatings, and particularly relates to a preparation method of a silica aerogel reflecting heat-insulation exterior wall coating. The silica aerogel reflecting heat-insulation exterior wall coating comprises water A, rutile type titanium dioxide, a silica aerogel precursor, pigments and fillers, a leveling agent, a dispersing agent, a preservative, a defoaming agent, styrene-acrylic emulsion, elastic emulsion, silicone modified acrylic emulsion, a coalescing agent, a thickening agent and a pH regulator. The preparation method comprisesthe steps of mixing materials orderly and then grinding the mixture to obtain the silica aerogel reflecting heat-insulation exterior wall coating. Compared with a traditional reflecting heat-insulation coating, the reflecting heat-insulation coating prepared from formula materials by the method in the invention is quite excellent in reflecting heat-insulation property and has the advantages of lowproduction cost and environmental protection.

Owner:天津朗华睿博科技有限公司

High-strength-gypsum-based sound insulation and thermal insulation machine spraying mortar and composite thermal insulation layer

The invention discloses high-strength-gypsum-based sound insulation and thermal insulation machine spraying mortar, belongs to the technical field of building and ornament materials and preparation, and solves the problem that in the prior art, gypsum-based mortar is not applicable to machine spraying construction. The high-strength-gypsum-based sound insulation and thermal insulation machine spraying mortar is characterized by being prepared from the following components in parts by weight: 800-850 parts of white high-strength gypsum, 30-60 parts of hollow glass beads, 30-60 parts of light glass beads, 60-120 parts of hydrophobic type dispersible latex powder, 3-5 parts of cellulose ether, 2-10 parts of bentonite, 4.0-5.5 parts of gypsum retarder and 900-1,000 parts of water. The gypsum-based mortar has the advantages of high liquidity and high stability, is applied to machine spraying construction, has a good thermal insulation effect after construction, and is high in sound insulation performance and water resistance. The invention correspondingly discloses a preparation method of the high-strength-gypsum-based sound insulation and thermal insulation machine spraying mortar, anda composite thermal insulation layer applying the machine spraying mortar and a construction method of the composite thermal insulation layer.

Owner:苏州高新大乘低碳环保新材发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com