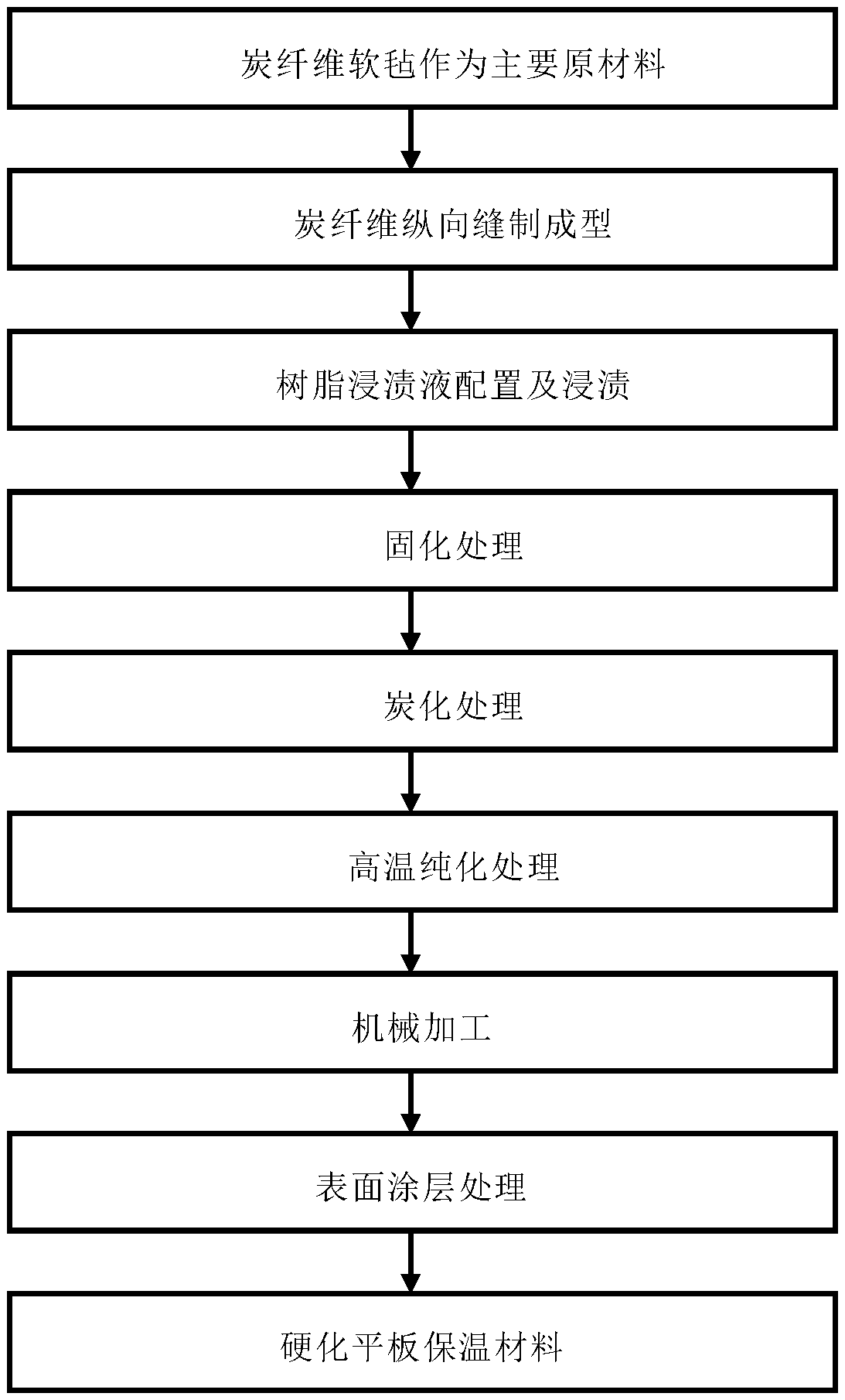

Method for preparing carbon fiber-sewed hard plate thermal insulation material

A technology of thermal insulation material and carbon fiber, which is applied in the field of hot field material accessories for high-temperature furnaces. It can solve the problems of easy delamination, easy delamination of felt body, and poor processability of products, so that it is not easy to fall off and has good bonding performance. , Excellent anti-airflow erosion ability and anti-oxidation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Step 1: Use PAN-based carbon felt as the main raw material, and control the density of the soft felt at 0.06g / cm 3 , the thickness is 4mm.

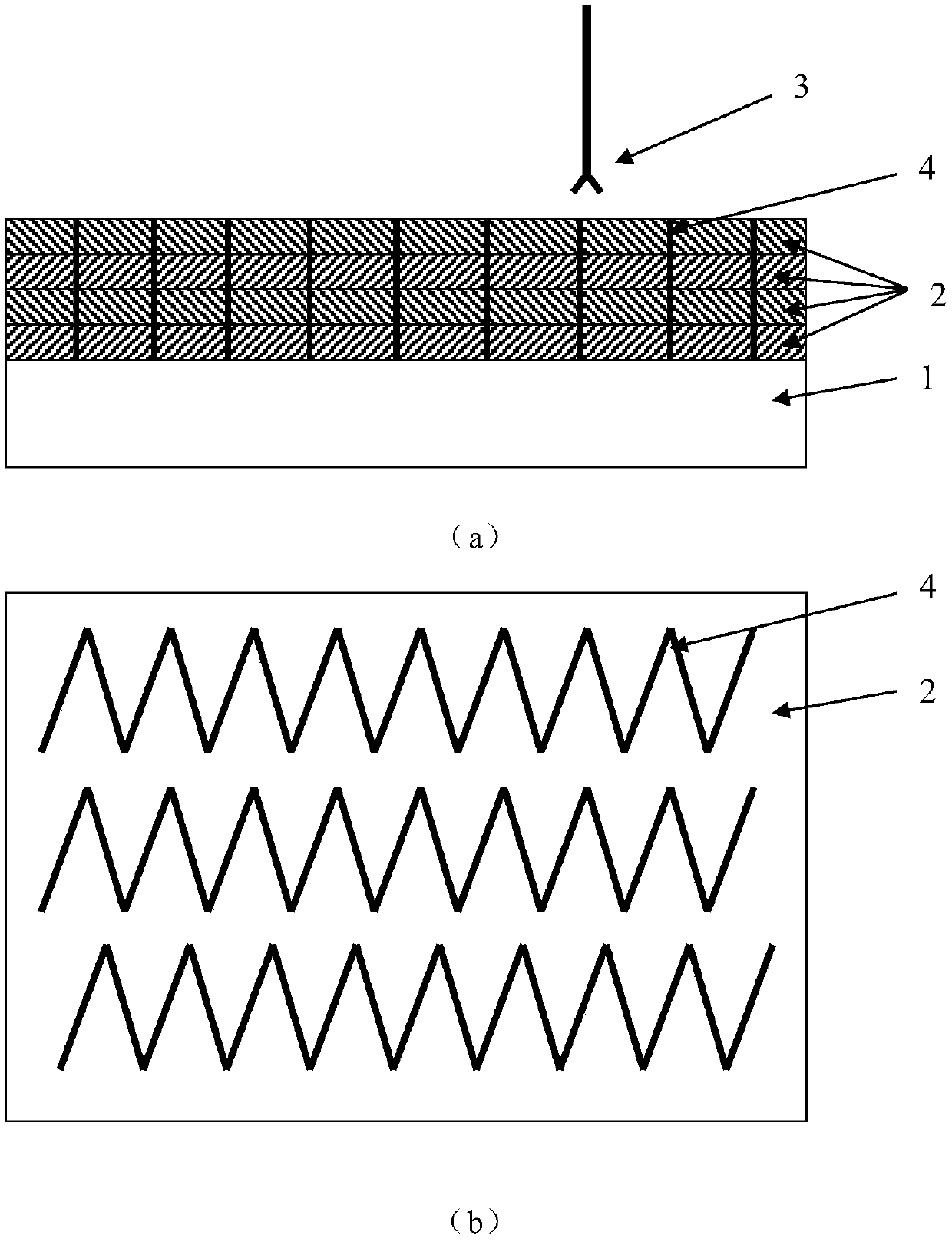

[0035] Step 2: The carbon fiber is longitudinally sewn into shape, the carbon fiber is PAN-based carbon fiber, the number of tows is 1K, the size of the foam board tooling 1 is placed on the bottom layer, and then 12 layers of PAN carbon felt 2 are laid, and the barb needle 3 is used to wrap The carbon fiber 4 is vertically inserted in the soft felt, and each layer of the carbon fiber soft felt is connected with carbon fibers to form a whole.

[0036] Step 3: Prepare the resin impregnating solution, the resin is furan resin, the solvent is alcohol, mix the resin and solvent in a weight ratio of 1:2, and stir evenly.

[0037]Step 4: Soak the sewn carbon fiber felt in the resin impregnating liquid prepared in step 3, until the resin impregnating liquid completely submerges the carbon fiber felt, and the impregnating time is 2 hours....

Embodiment 2

[0045] Step 1: Use PAN-based graphite felt as the main raw material, and control the density of the soft felt at 0.08g / cm 3 , the thickness is 10mm.

[0046] Step 2: Carbon fiber is longitudinally sewn into shape. The carbon fiber is PAN-based carbon fiber, and the number of tows is 3K. Place the foam board tooling 1 and other sizes on the bottom layer, and then lay 6 layers of PAN-based graphite felt 2, using barb needles 3 The carbon fiber (4) is vertically inserted into the soft felt, and each layer of the carbon fiber soft felt is connected with the carbon fiber to form a whole.

[0047] Step 3: Prepare resin impregnating solution, the resin is phenolic resin, the solvent is acetone, mix the resin and solvent in a weight ratio of 1:6, and stir evenly.

[0048] Step 4: Soak the sewn carbon fiber felt in the resin impregnating liquid prepared in step 3, until the resin impregnating liquid completely submerges the carbon fiber felt, and the impregnating time is 6 hours.

[...

Embodiment 3

[0056] Step 1: Use viscose-based carbon felt as the main raw material, and control the density of the soft felt at 0.14g / cm 3 , the thickness is 15mm.

[0057] Step 2: Carbon fiber is longitudinally sewn into shape, the carbon fiber is PAN-based carbon fiber, the number of tows is 6K, the size of the foam board tooling 1 is placed on the bottom layer, and then 4 layers of viscose-based carbon felt 2 are laid, using barbed needles 3. Insert the carbon fiber 4 longitudinally and vertically into the soft felt, and connect each layer of the carbon fiber soft felt with carbon fibers to form a whole.

[0058] Step 3: Prepare the resin impregnating solution, the resin is phenolic resin, the solvent is alcohol, mix the resin and solvent in a weight ratio of 1:15, and stir evenly.

[0059] Step 4: Soak the sewn carbon fiber felt in the resin impregnating liquid prepared in step 3, until the resin impregnating liquid completely submerges the carbon fiber felt, and the impregnating time...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com