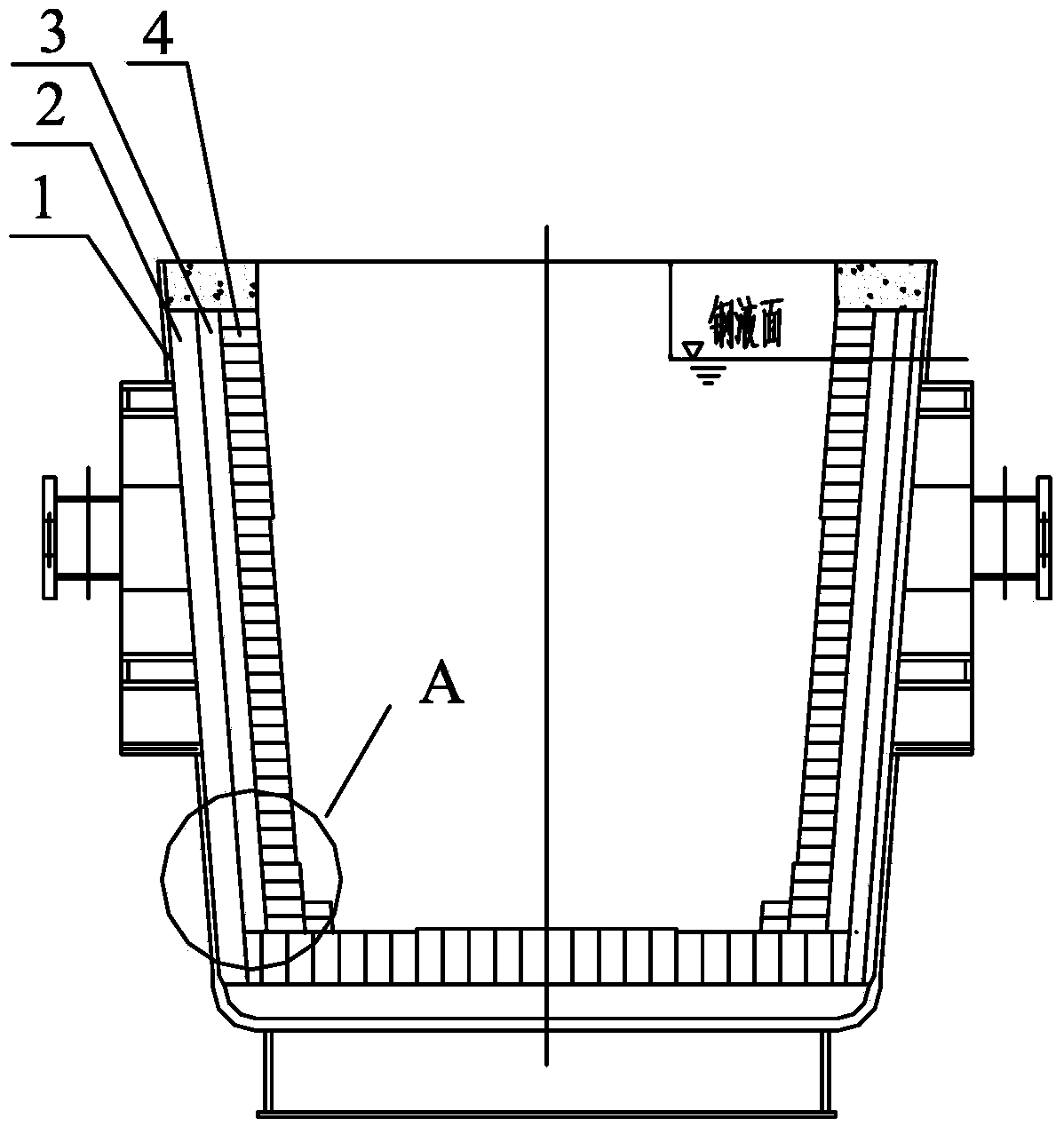

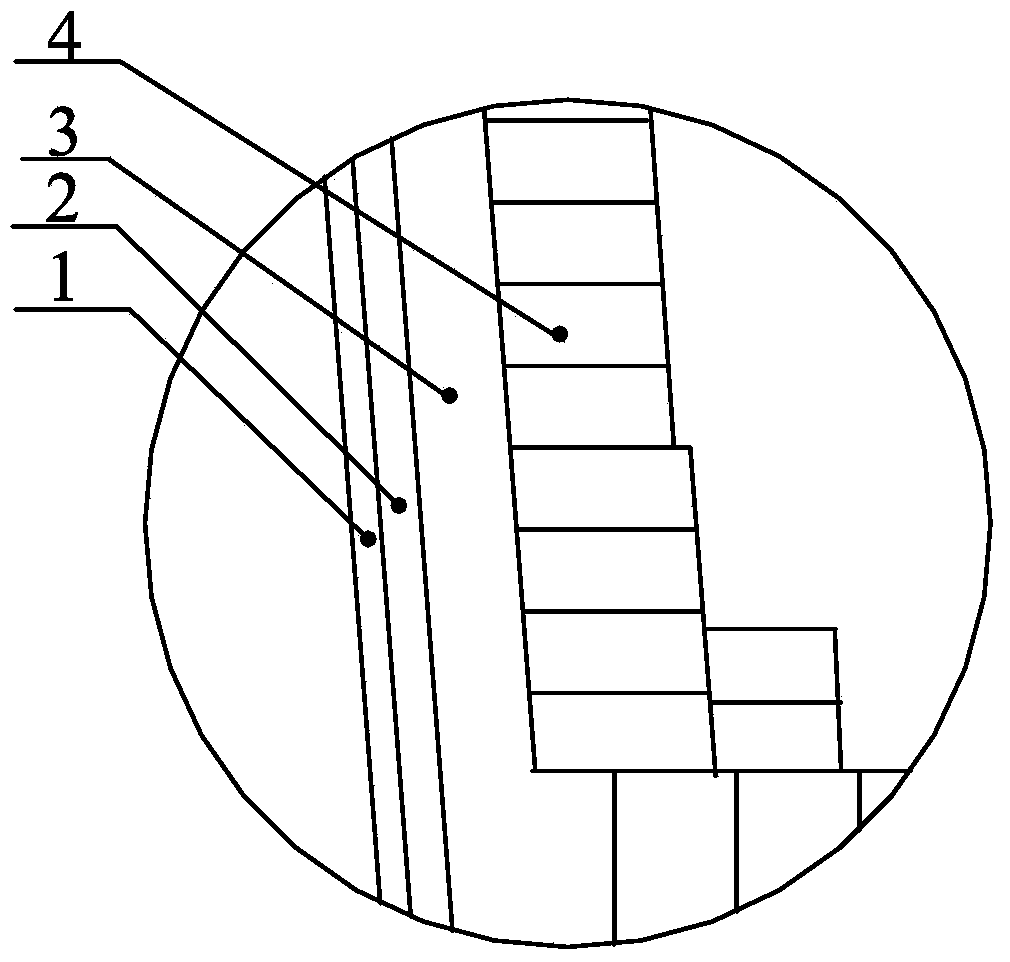

Optimized long-life low-material-consumption refining ladle

A technology for ladles and consumables, which is applied in the field of optimized high-life and low-consumables smelting ladles, can solve the problems of low thermal conductivity, thermal shock stability, no castables for circulating working layers, and no development of circulating working layers, etc., to improve Insulation performance, excellent resistance to molten steel erosion, and the effect of improving thermal shock stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

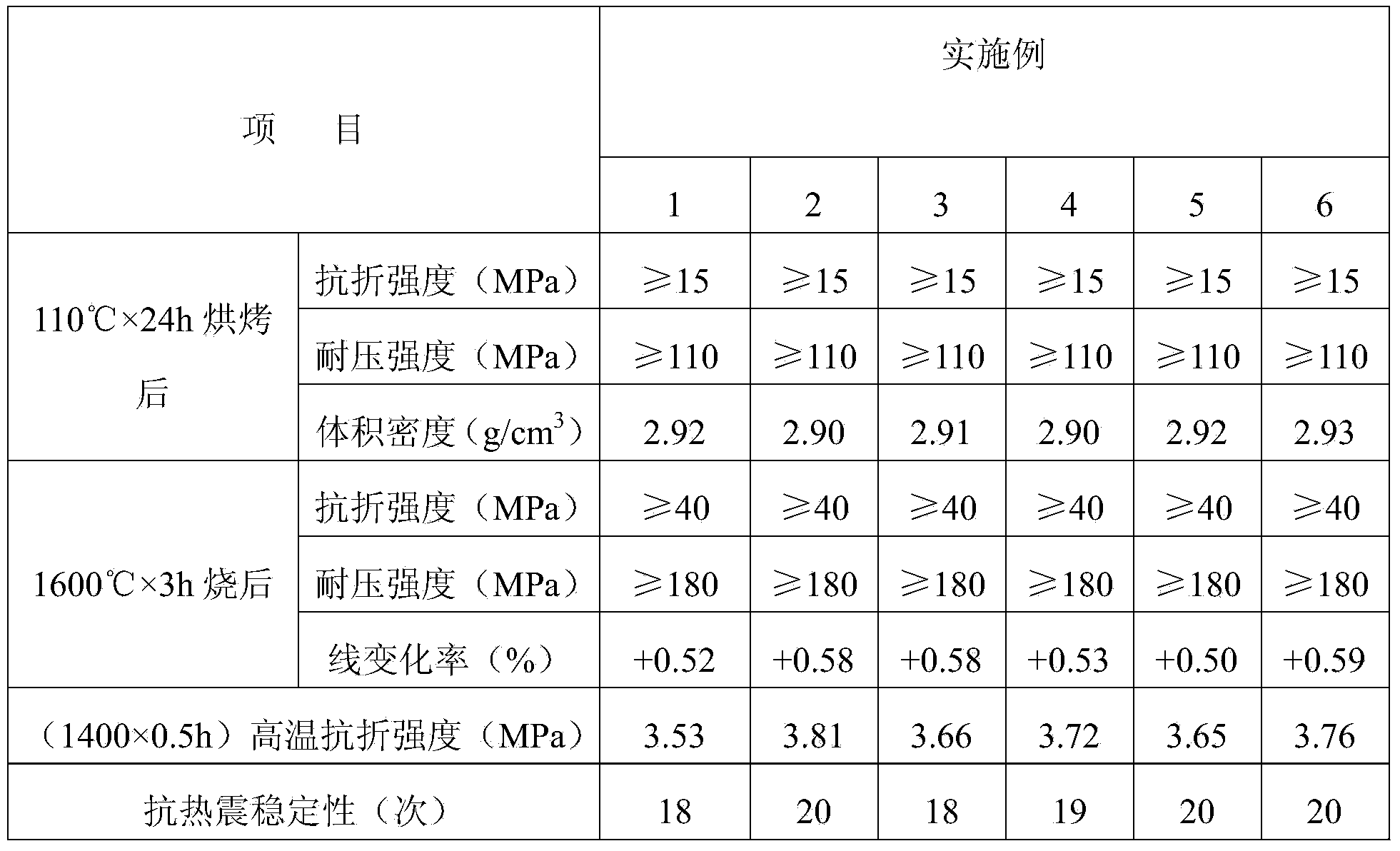

Embodiment 1

[0049] The castable of the circulating working layer 3 is based on 55 parts of sintered microporous corundum aggregate, 10 parts of aluminum-magnesium spinel aggregate, 20 parts of fine powder, 5 parts of fine powder, 5 parts by weight ratio of raw materials. It is composed of 3 parts of binding agent, 0.3 parts of anti-explosive agent, 1 part of water reducing agent and 0.05 part of foaming agent;

[0050] Sintered microporous corundum aggregate is divided into five levels according to particle size: 12mm<particle size≤2mm, 7mm<particle size≤12mm, 3mm<particle size≤7mm, 1mm<particle size≤3mm and 0mm<particle size≤1mm With; the weight percentages are: 13%, 32%, 18%, 22% and 15%;

[0051] Wherein, the fine powder is a mixture of fused white corundum and aluminum-magnesium spinel, and the weight ratio of fused white corundum to aluminum-magnesium spinel is 6:1;

[0052] Micropowder is SiO 2 Micropowder and active α-Al 2 O 3 Micro powder mixture, SiO 2 Micropowder and active α-Al 2 O 3...

Embodiment 2

[0056] The castable of the circulating working layer 3 is composed of 60 parts of sintered microporous corundum aggregate, 5 parts of aluminum-magnesium spinel aggregate, 20 parts of fine powder, 8 parts of fine powder, 7 parts by weight ratio of raw materials. It is composed of 2 parts of binding agent, 0.1 part of anti-explosive agent, 0.1 part of water reducing agent and 0.1 part of foaming agent;

[0057] Sintered microporous corundum aggregate is divided into five levels according to particle size: 12mm

[0058] The fine powder is a mixture of sintered tabular corundum and fused magnesia, and the weight ratio of sintered tabular corundum to fused magnesia is 3:1;

[0059] Micropowder is SiO 2 Mixture of micropowder and sintered corundum micropowder (brand number CL370), SiO 2 The weight ratio of micro po...

Embodiment 3

[0064] The castable of the circulating working layer 3 is calculated according to the weight ratio of the raw materials by 65 parts of sintered microporous corundum aggregate, 8 parts of aluminum-magnesium spinel aggregate, 25 parts of fine powder, 6 parts of micropowder, 4 It is composed of 2 parts of binding agent, 0.2 parts of anti-explosive agent, 2 parts of water reducing agent and 0.1 part of foaming agent;

[0065] Sintered microporous corundum aggregate is divided into five levels according to particle size: 12mm

[0066] The fine powder is a mixture of sintered tabular corundum and sintered magnesia, and the weight ratio of sintered tabular corundum to fused magnesia is 1:1;

[0067] Micropowder is SiO 2 Mixture of micropowder and sintered corundum micropowder; where SiO 2 The weight ratio of micropo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com