Overall composite towing beam arching structure for railway steel truss girder cable-stayed bridge

A cable-beam anchoring and composite technology, which is applied in the direction of cable-stayed bridges, bridge forms, bridges, etc., can solve the problems of stress concentration and plastic zone of the anchor plate, achieve compact layout, improve fatigue resistance, and avoid defects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

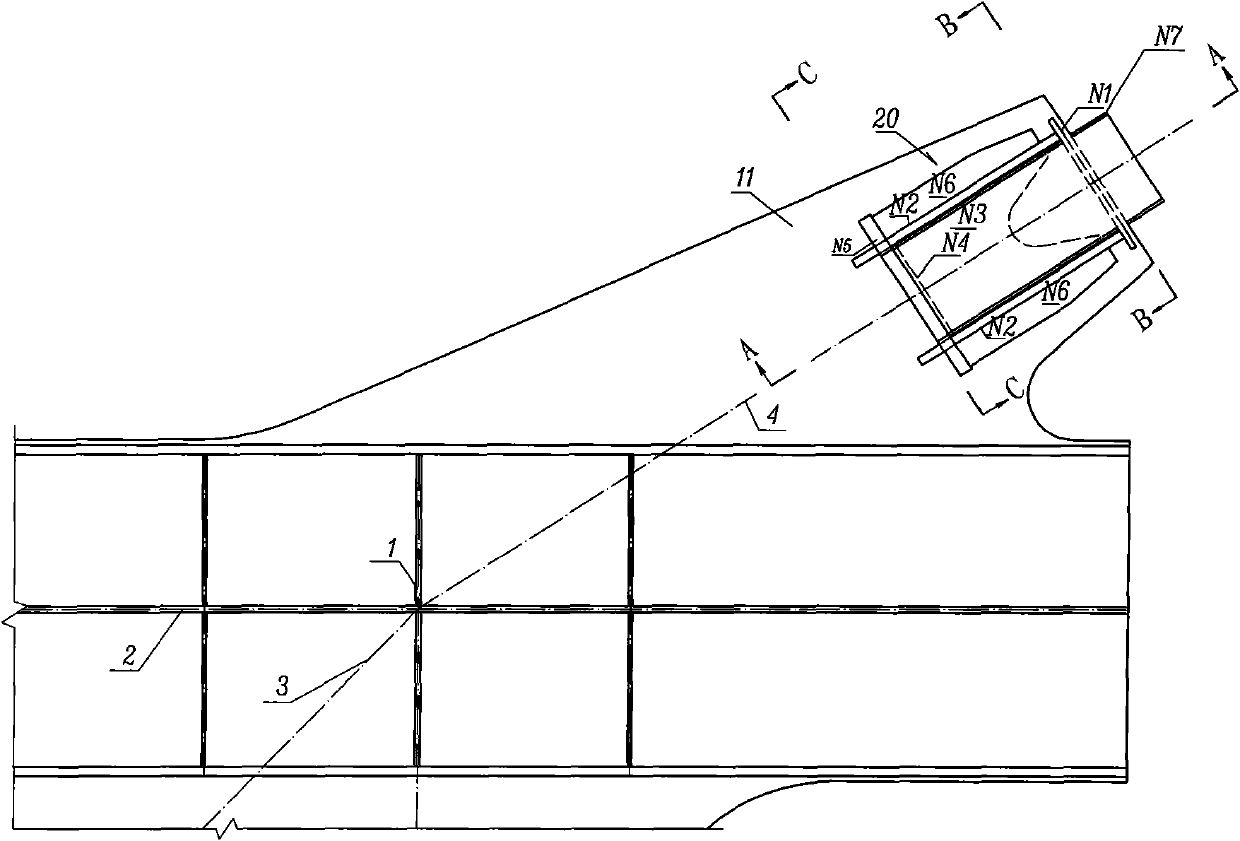

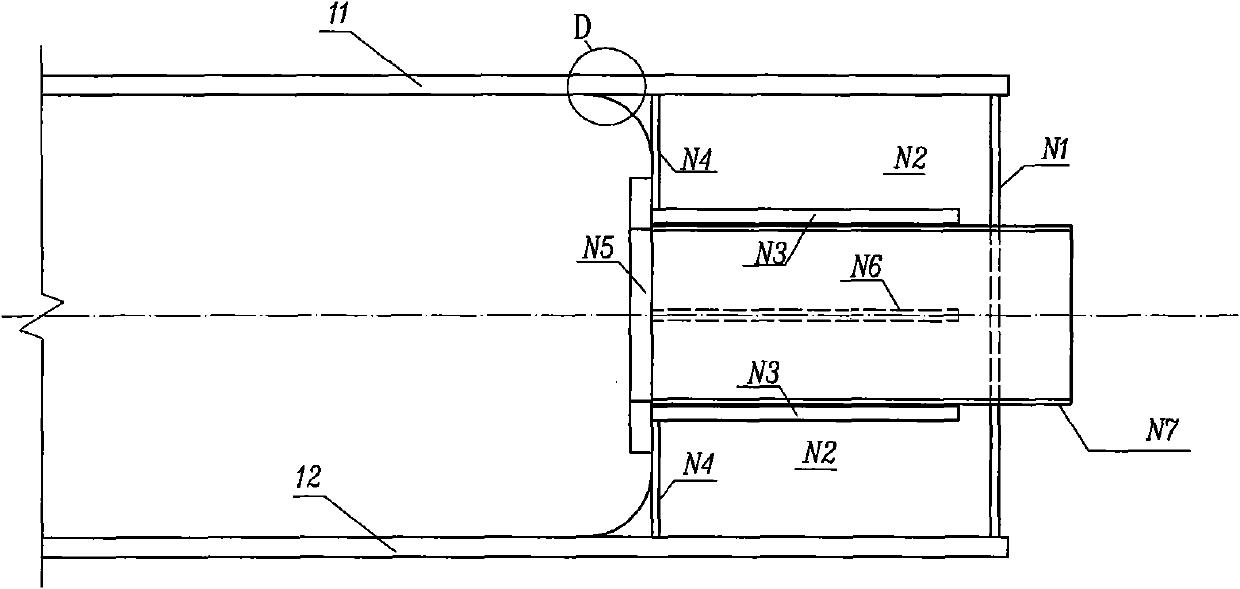

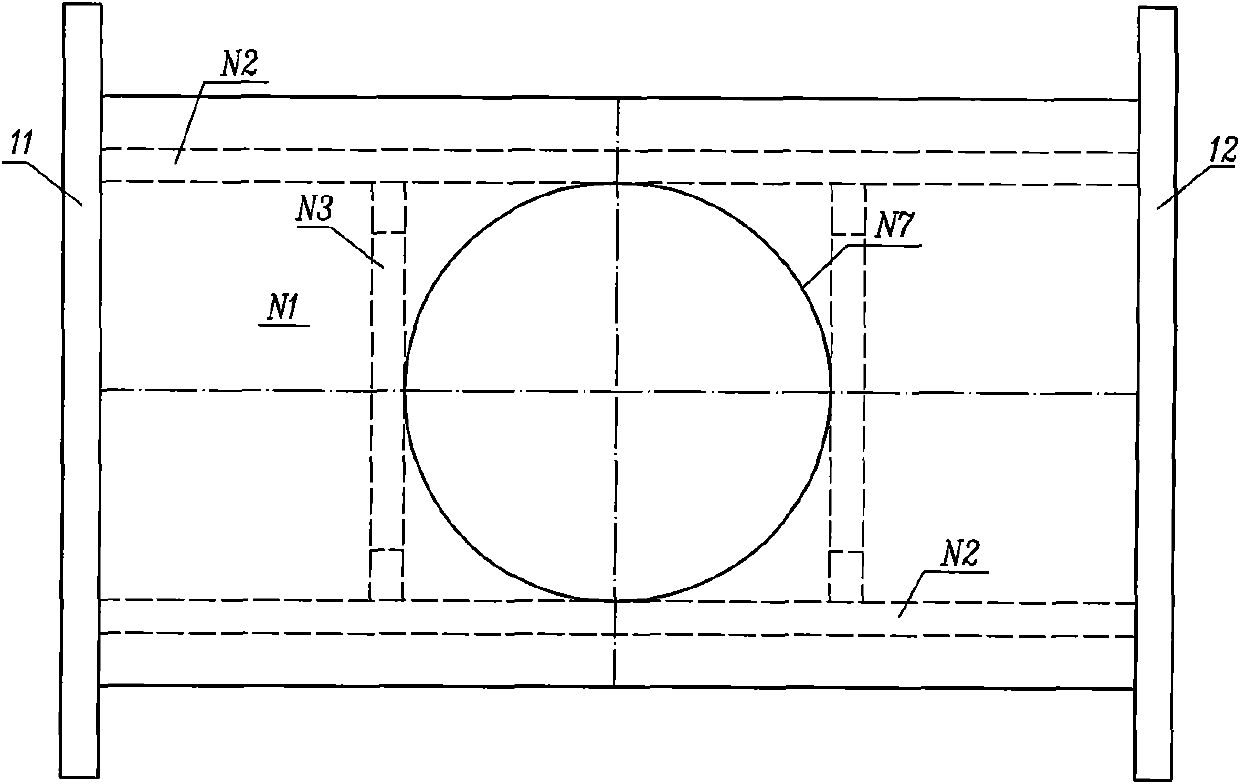

[0020] refer to figure 1 with image 3 , the overall composite cable-girder anchorage structure of the railway steel truss girder cable-stayed bridge of the present invention includes a pair of integral anchor stay plates 11, 12 formed by extending directly upward from the gusset plates on both sides of the upper chord of the main truss, and being arranged on the pair of integral anchor The steel anchor box 20 fixedly connected between the upper parts of the pull plates 11 and 12. That is, the cable-beam anchorage structure is composed of integral anchor stay plates 11, 12 and steel anchor box 20, and the integral anchor stay plates 11, 12 are integrated with the upper chord gusset plate of the main truss, which has good integrity and improves the structural resistance. Fatigue performance effectively overcomes the shortcomings of various existing cab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com