Functional floor heating floor made of alloy materials and preparation method thereof

A functional, floor heating technology, applied in the field of building decoration materials, can solve the problems of complicated preparation process, the geothermal floor does not have fire-retardant and flame-retardant properties, and is easy to catch fire and burn, and achieves simple preparation process, good floor heating conductivity, and thermal efficiency utilization. high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

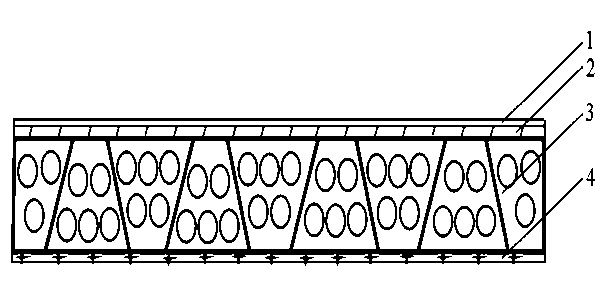

[0042] A floor heating floor made of functional alloy materials, comprising a vacuum-coated reflective layer 4, a PVC-based polymer alloy composite material layer 3, a co-extruded composite decorative layer 2, and a UV-treated transparent antibacterial and wear-resistant layer 1 sequentially laminated from bottom to top;

[0043] Wherein, primer layer 3 comprises the component of following weight fraction:

[0044] PVC resin 100 parts

[0045] ABS resin (747S) 30 parts

[0046] Active fine calcium carbonate (1250 mesh) 80 parts

[0047] Calcium zinc composite stabilizer 5.0 parts

[0048] Flame retardant 7 parts

[0049] Processing aid ACR401 2 parts

[0050] 8 copies of CPE

[0051] Semi-refined paraffin wax 0.6 parts

[0052] 0.5 parts of stearic acid

[0053] Wherein, the main base material of the decoration layer 2 is ASA (acrylonitrile-styrene-acrylate copolymer).

[0054] Wherein, the UV coating used in the UV-treated transparent antibacteria...

Embodiment 2

[0063] A floor heating floor made of functional alloy materials, comprising a vacuum-coated reflective layer 4, a PVC-based polymer alloy composite material layer 3, a co-extruded composite decorative layer 2, and a UV-treated transparent antibacterial and wear-resistant layer 1 sequentially laminated from bottom to top;

[0064] Wherein, primer layer 3 comprises the component of following weight fraction:

[0065] PVC resin 100 parts

[0066] Glutarimide copolymer 20 parts

[0067] Active fine calcium carbonate (1250 mesh) 100 parts

[0068] Calcium zinc composite stabilizer 5.0 parts

[0069] Flame retardant 7 parts

[0070] Processing aid ACR401 2 parts

[0071] 12 copies of MBS

[0072] Semi-refined paraffin wax 0.6 parts

[0073] 0.5 parts of stearic acid

[0074] Wherein, the main base material of the decoration layer 2 is ASA (acrylonitrile-styrene-acrylate copolymer).

[0075] Wherein, the UV coating used in the UV-treated transp...

Embodiment 3

[0084] A floor heating floor made of functional sub-alloy materials, comprising a positive air coating layer 4, a PVC-based polymer alloy composite material layer 3, a co-extruded composite decorative layer 2, and a UV-treated transparent antibacterial and wear-resistant layer 1 sequentially laminated from bottom to top;

[0085] Wherein, primer layer 3 comprises the component of following weight fraction:

[0086] PVC resin 100 parts

[0087] Heat-resistant α-methylstyrene-acrylonitrile copolymer 15 parts

[0088] Active fine calcium carbonate (1250 mesh) 100 parts

[0089] Calcium zinc composite stabilizer 5.0 parts

[0090] Flame retardant 7 parts

[0091] Processing aid ACR401 2 parts

[0092] 9 copies of MBS

[0093] Semi-refined paraffin wax 0.6 parts

[0094] 0.5 parts of stearic acid

[0095] Wherein, the main body of the base material of the decoration layer 2 is PMMA (polymethyl methacrylate).

[0096] Wherein, the UV coating us...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com