Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

353 results about "Bamboo floor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A bamboo floor is a type of flooring manufactured from the bamboo plant. The majority of today's bamboo flooring products originate in China and other portions of Asia. Moso bamboo is the species most commonly used for flooring.

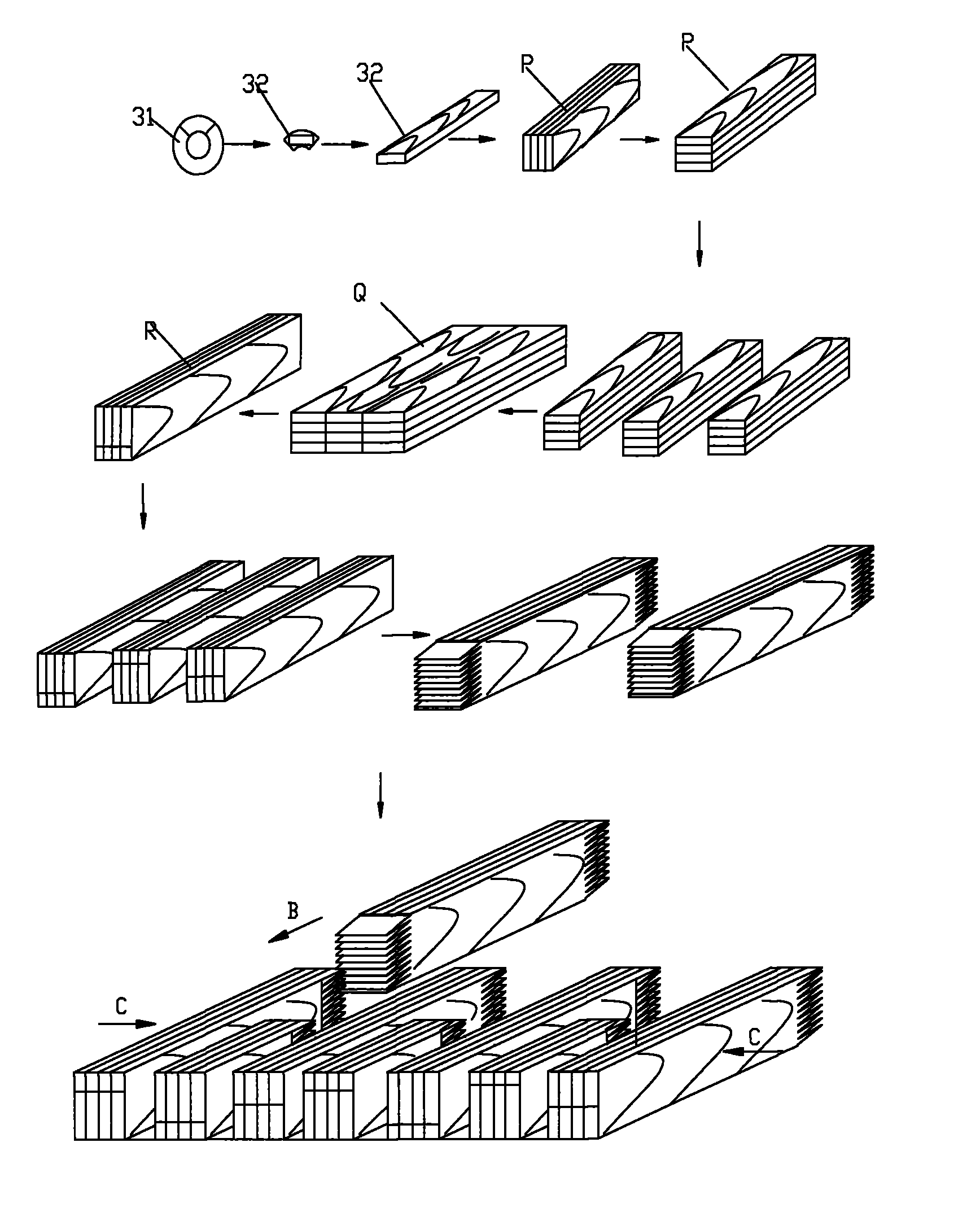

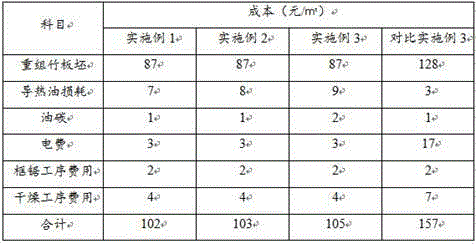

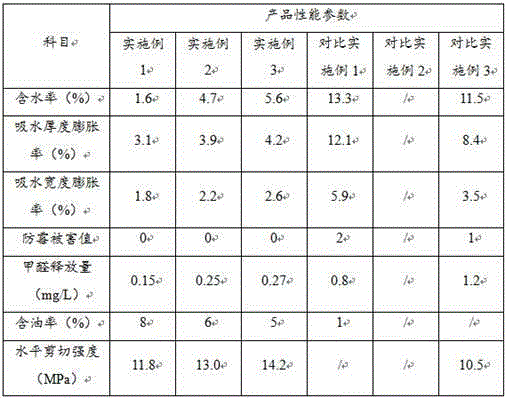

Recomposed bamboo board producing process

ActiveCN103496024AHigh hardnessHigh strengthFlat articlesDomestic articlesHardnessVolumetric Mass Density

The invention relates to the field of bamboo production, in particular to recomposed bamboo board producing process. The recomposed bamboo board producing process uses renewable bamboo as raw materials, the utilization rate of bamboo is high and can reach more than 90%, and resource waste is reduced. The density of recomposed bamboo boards manufactured in the recomposed bamboo board process is high as 1200kg / m<3> and is more than 1.6 times of the density of ordinary bamboo floors. The recomposed bamboo boards have the advantages of being high in hardness, high in strength, high impact toughness and wearproof. The recomposed bamboo boards manufactured in the recomposed bamboo board producing process further have the advantages of being capable of resisting to water absorption, free of deformation and the like. Tests show that the thickness expansion rate is only 0.4% after the recomposed bamboo boards absorb water for 24 hours and is far better than and smaller than the European standard of 2.0%. The free formaldehyde emission of the recomposed bamboo boards manufactured in the recomposed bamboo board producing process is below 0.4mg / L, so that harm of formaldehyde to people is reduced.

Owner:ZHEJIANG CHANGXING SENDA BAMBOO & WOOD PRODCO

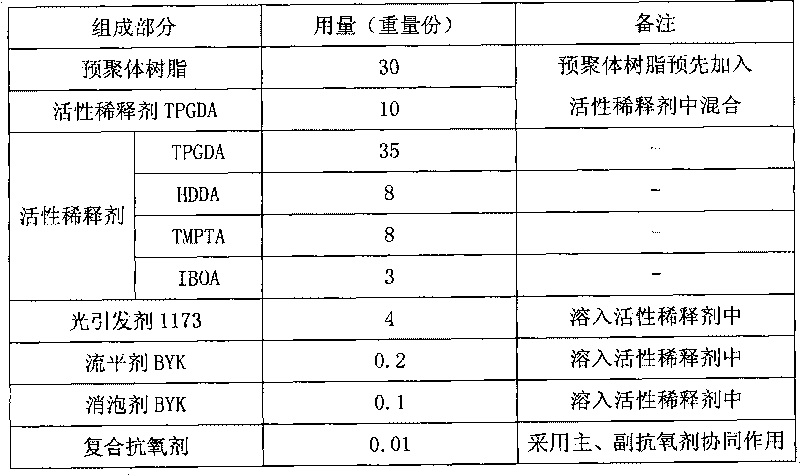

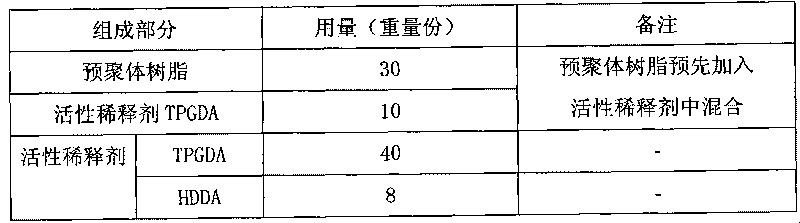

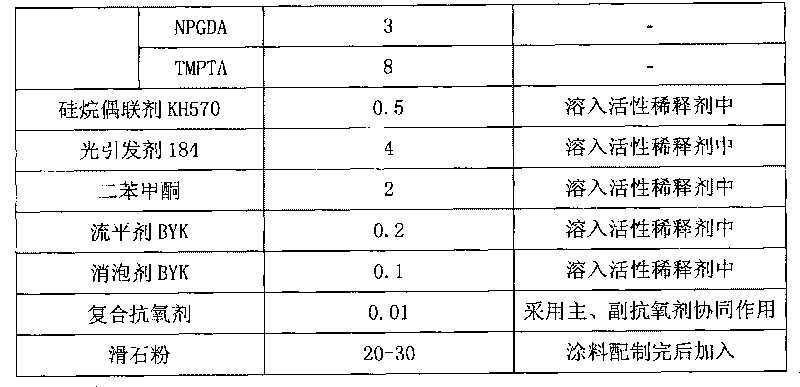

Epoxy acrylate prepolymer resin and preparation method thereof and application in photocurable coating

The invention relates to an epoxy acrylate prepolymer resin and a preparation method thereof and an application in a photocurable coating. The prepolymer has the characteristics of low viscosity, good flexibility, good adhesion and basic colorlessness and can be used for preparing various photocurable coatings and coating various base materials, such as bamboo floor. The epoxy acrylate prepolymer resin is prepared by epoxy resin and methacrylate under the action of the catalyst through ring-opening esterification and is characterized in that the prepolymer resin comprises the following components according to parts by weight: 100 parts of epoxy resin, 35-50 parts of methacrylate, 2-8 parts of long chain saturated dicarboxylic acid, 12-25 parts of polyethylene glycol, 8-12 parts of diglycidyl ether, 0.01-0.05 parts of antioxidant, 0.2-0.5 parts of catalyst and 0.005-0.01 parts of polymerization inhibitor. The viscosity reduction, toughening and modification are carried out for the epoxy acrylate prepolymer resin, the flexibility and strength are improved, the viscosity of the prepolymer resin is effectively reduced, and the prepolymer resin is applicable for preparing the photocurable coatings.

Owner:浙江天和树脂有限公司 +1

Production method of aldehyde-free bamboo floor

ActiveCN103144178ANo pollutionPromote environmental protectionProtein adhesivesWood veneer joiningProteinase activityHydrogen

The invention relates to a production method of an aldehyde-free bamboo floor, which comprises the following steps that firstly, modified soyabean albumen glue is prepared by components in parts by mass as follows: 100 parts of water, 5-60 parts of soybean albumen powder, 0.01-15 parts of a modifying agent, 0-5 parts of compound protease, 0-15 parts of a pH (potential of hydrogen) modifier, 0-15 parts of a viscosity modifier, 0.1-15 parts of an antiseptic mildew preventive, 0-10 parts of an auxiliary and 0-10 parts of a filler; secondly, the modified soyabean albumen glue is sheared to reduce viscosity by a mixer or a blending machine at the revolving speed of 50-300 revolutions per minute for 5 to 30 minutes; and thirdly, bamboo chips are used as a raw material and manufactured into the bamboo floor through processes of gluing, ageing, assembling and hot pressing. By means of the production method, free formaldehyde is absent, the environmental pollution is avoided, the environmental protection property is good, the water resisting property is good, and the gluing property is excellent.

Owner:ZHEJIANG FORESTRY ACAD

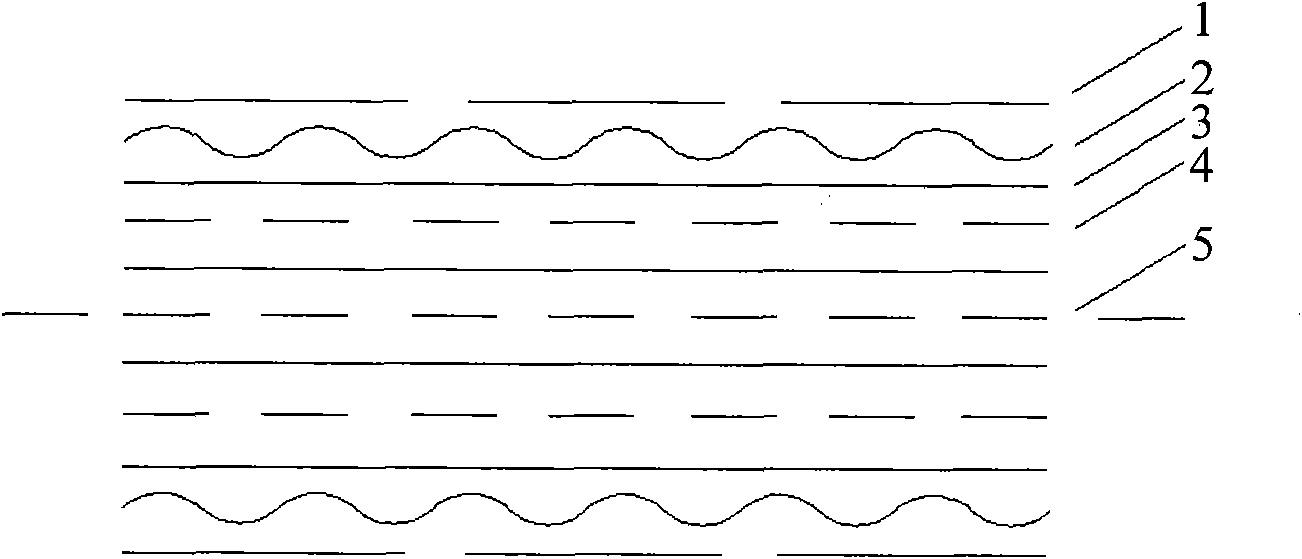

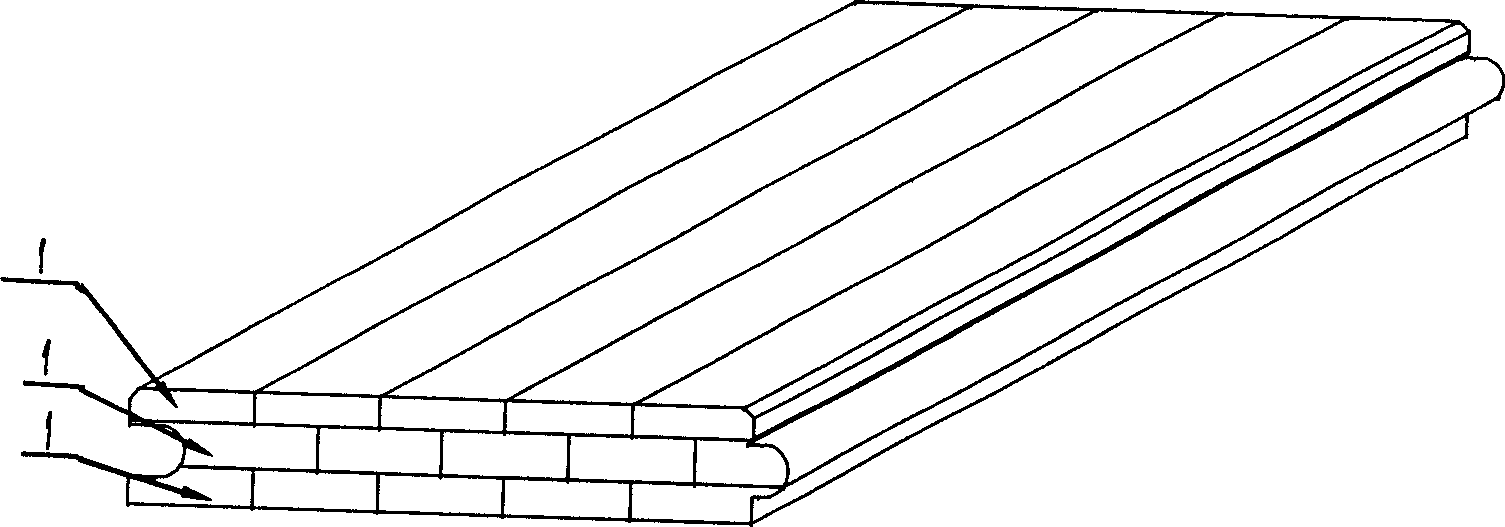

Strength natural figured bamboo floor

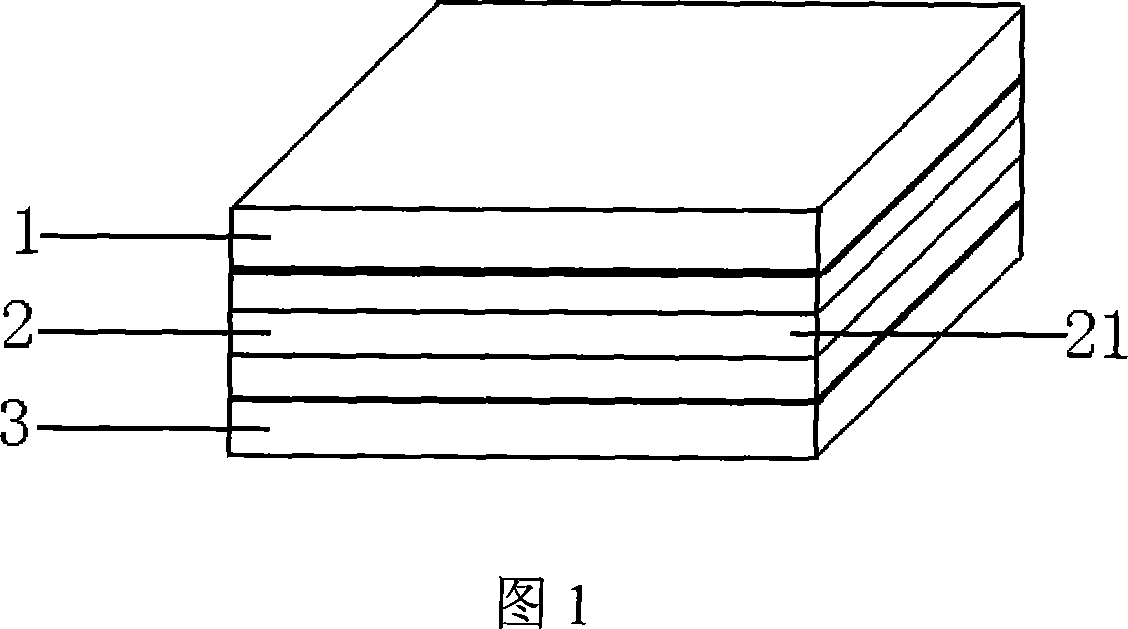

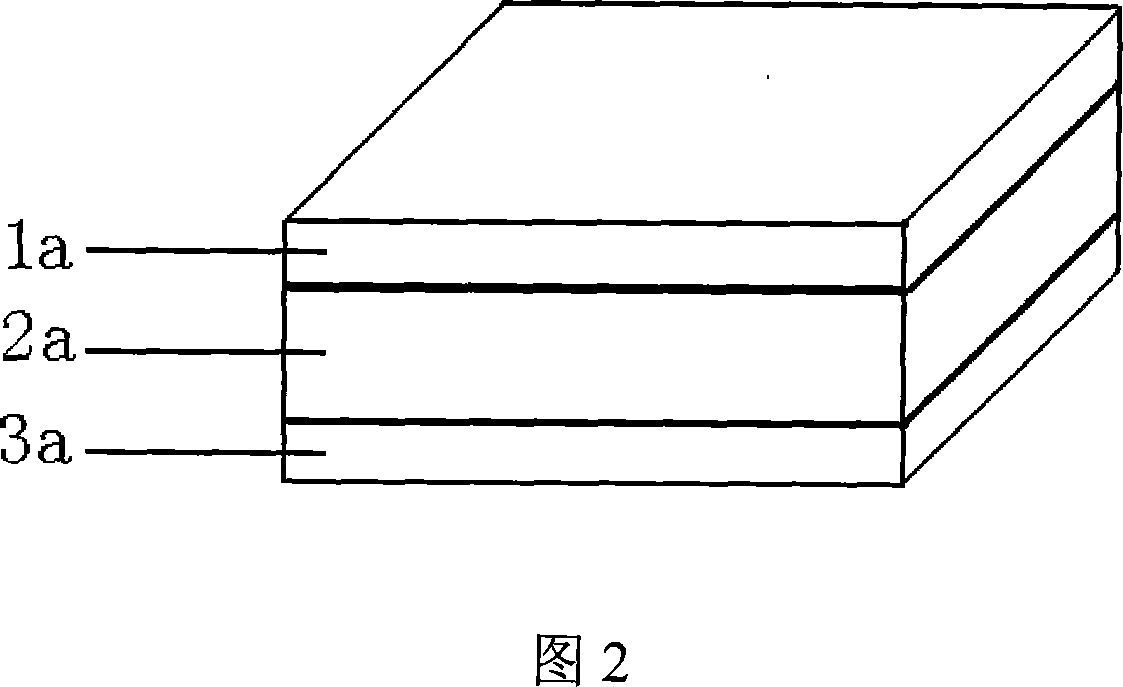

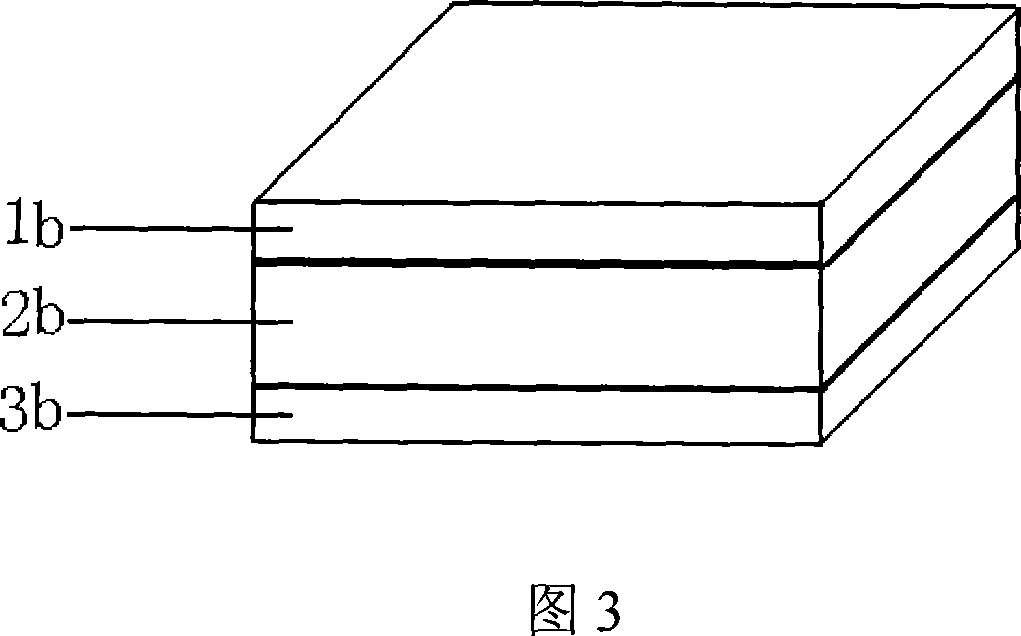

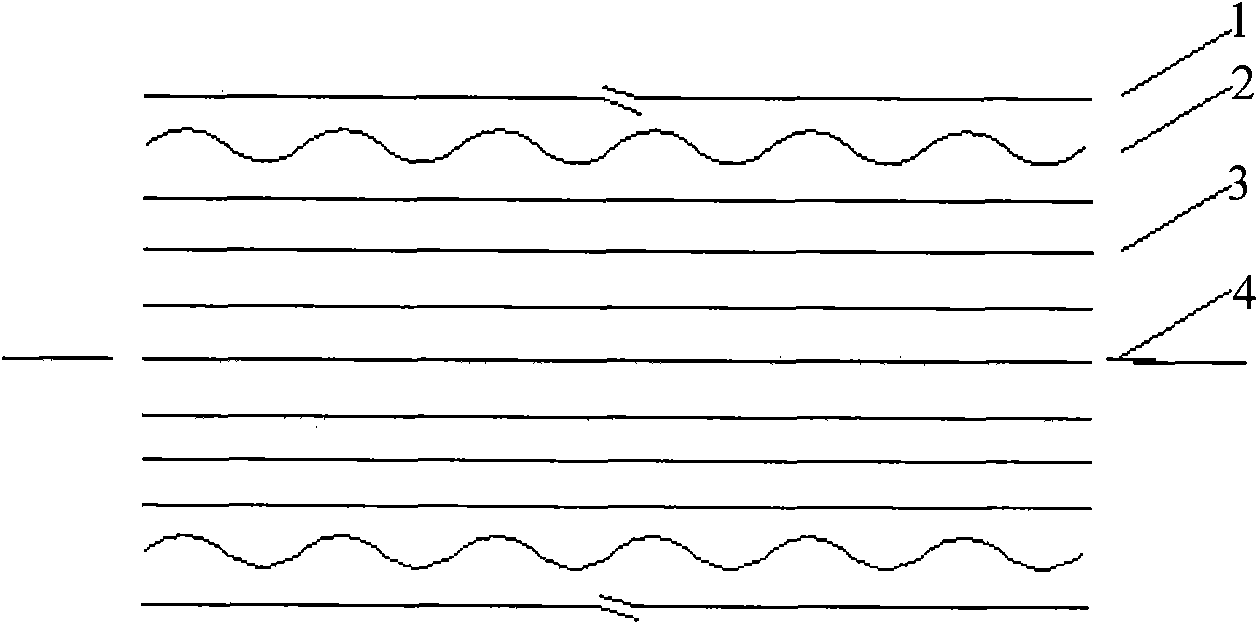

The present invention relates to one kind of high strength bamboo floor board with natural patterns. Technologically, the high strength bamboo floor board with natural patterns includes one facing layer, one bottom layer and one core layer adhered together with polymer resin, pressed at high temperature and high pressure and cut in required sizes. The facing layer and the bottom layer consist of arranged bamboo strips in the same or different thickness, length and width; and the core layer is bamboo mat, bamboo curtain, bamboo board, etc. The bamboo floor board has high strength, natural patterns, optimized performance and best utilization of bamboo resource.

Owner:浙江缘竹源新材料科技有限公司

Bamboo floor preparation process

ActiveCN104085031AGuarantee processing qualityHigh strengthWood veneer joiningWood charring/burningMaterials preparationCarbonization

The invention discloses a bamboo floor preparation process. The bamboo floor preparation process includes the following steps of firstly, material preparation, secondly, rough milling, thirdly, cooking and carbonization, fourthly, drying, fifthly, manual selection, sixthly, finish milling, seventhly, splicing and pressing, eighthly, planing, tenthly, end-face tenoning, eleventhly, polishing and twelfthly, paint spraying. In the material preparation step, purchased raw bamboo is truncated and sliced into bamboo slices of the same specification and the same size; in the rough milling step, bamboo joints are planished, and part of bamboo outer skin and tabasheer of the bamboo slices are milled and removed; in the cooking and carbonization step, sugar and fat in the bamboo slices are removed; in the drying step, the bamboo slices are dried with the moisture content smaller than 7%; in the manual selection step, the bamboo slices meeting the splicing condition are selected; in the finish milling step, the bamboo outer skin and the tabasheer of the dried bamboo slices are completely milled and removed; in the splicing and pressing step, the bamboo slices are glued in a hot-press mode through a hot press, and then a bamboo blank is formed; in the planing step, the bamboo blank is planed, so that the surface of the bamboo blank is smooth; in the polishing step, a crude bamboo floor is polished through a polishing machine; in the paint spraying step, paint is sprayed to rabbets of the crude bamboo floor, then three times of priming paint coating, photocuring and priming paint polishing are sequentially and respectively conducted on the surface of the crude bamboo floor, and a finished bamboo floor is acquired. The bamboo floor prepared through the process has enough strength and rigidity, and is not prone to getting mildew and further capable of effectively resisting moths.

Owner:贵州新锦竹木制品有限公司

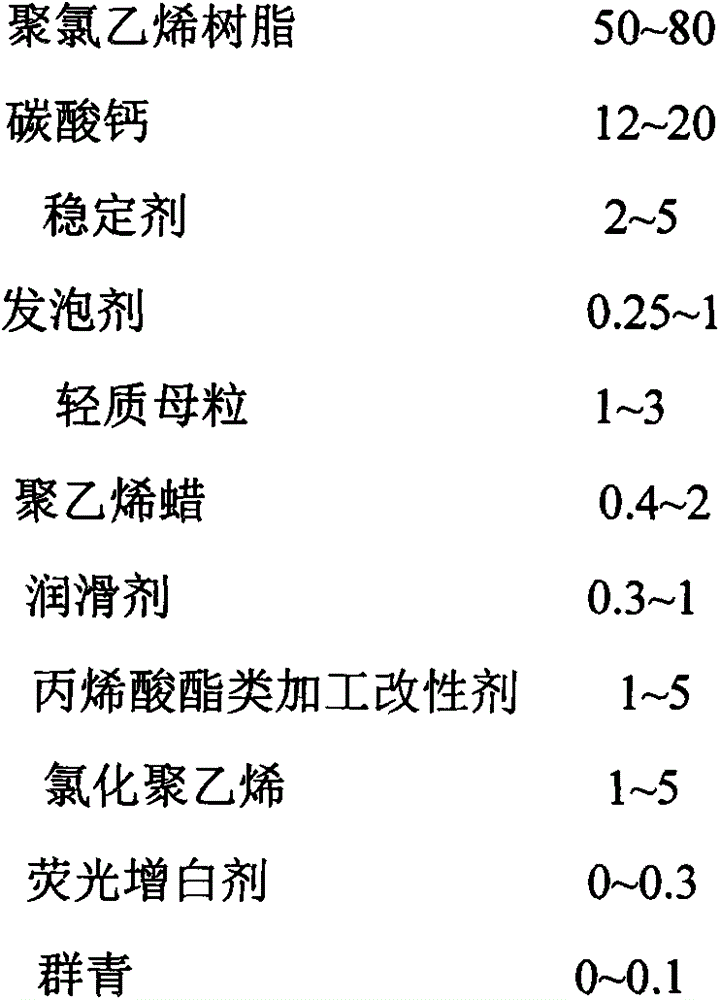

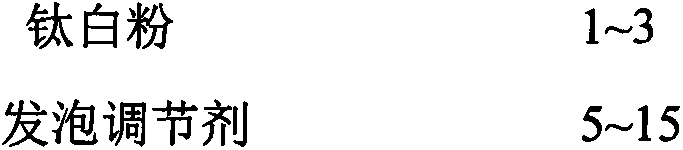

Polyvinyl chloride low-foaming car plate and preparation method thereof

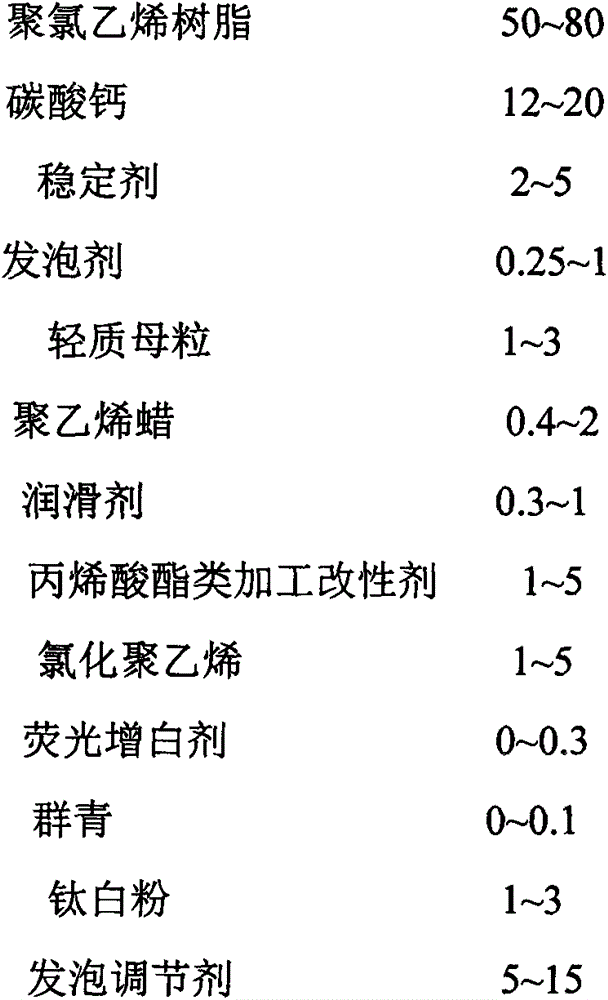

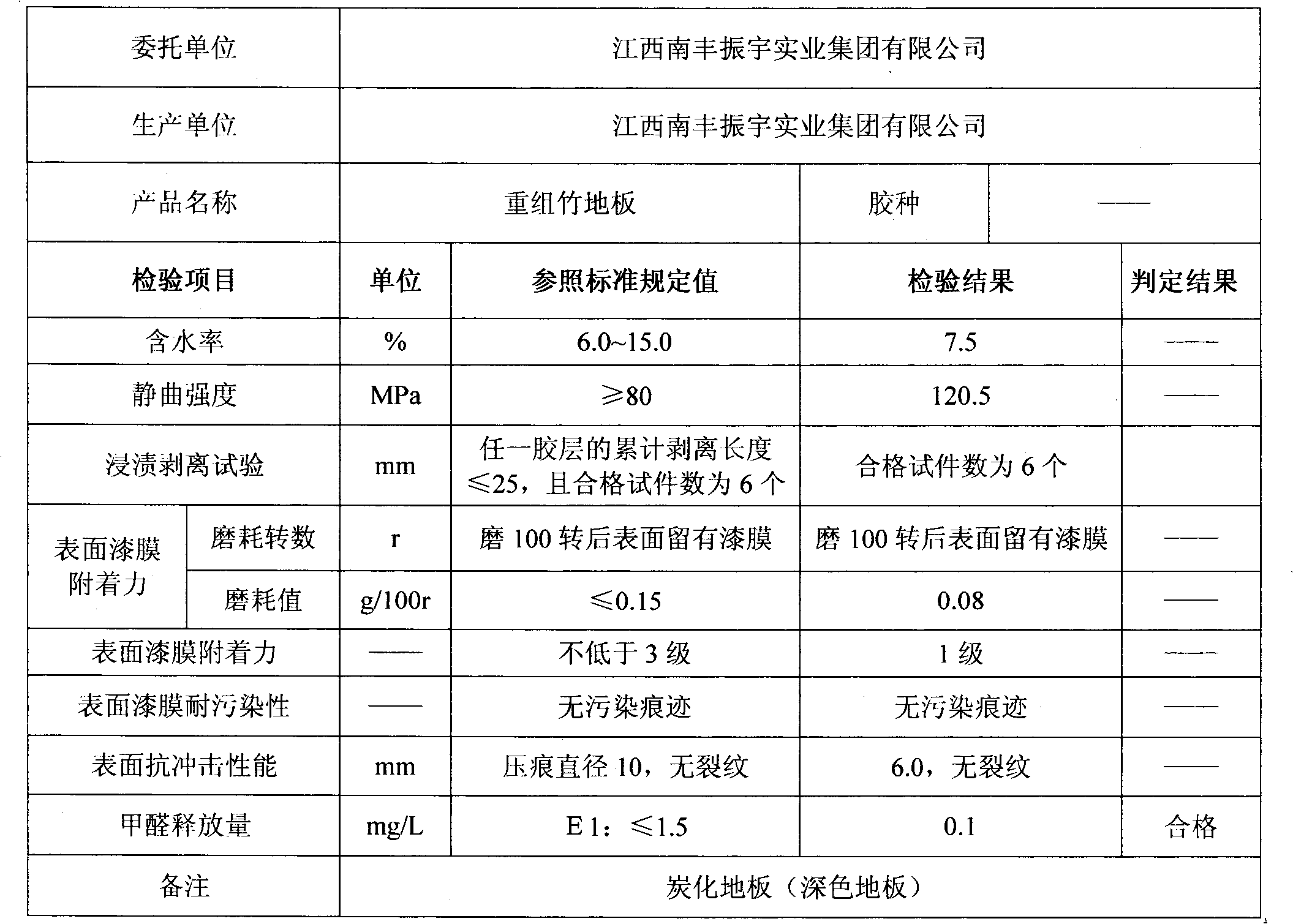

The invention relates to a polyvinyl chloride low-foaming car plate and a preparation method thereof. The polyvinyl chloride low-foaming car plate is characterized by comprising the following raw materials in parts by weight: 50-80 parts of polyvinyl chloride resin, 12-20 parts of calcium carbonate, 2-5 parts of a stabilizer, 0.25-1 part of a foaming agent, 1-3 parts of light-weight master batch, 0.4-2 parts of polyethylene wax, 0.3-1 part of a lubricating agent, 1-5 parts of an acrylate processing modifier, 1-5 parts of chlorinated polyethylene, 0-0.3 part of a fluorescent whitening agent, 0-0.1 part of ultramarine, 1-3 parts of titanium dioxide and 5-15 parts of a foaming regulator, wherein the total weight parts of the raw materials are 100 parts. The polyvinyl chloride low-foaming car plate disclosed by the invention has light weight (the density being less than or equal to 605kg / m<3>), and meanwhile, is high in hardness, excellent in mechanical property, good in size stability, water-resistant, corrosion-resistant and mildew-resistant, can not be damaged by worms, is soundproof, heat-insulating, pollution-free and long in service life, has good flame-retardant properties, is a novel environment-friendly material for replacing wood materials and bamboo floors, can be used for reducing the weight of a car body when being applied to the floor of a car, is good in energy-saving effect, and meanwhile, can be used for prolonging the service life of the car floor and reducing the maintenance cost.

Owner:无锡市宏宇汽车配件制造有限公司

Bamboo floor machining process

ActiveCN102335943AIncrease profitHigh ignition pointWood working apparatusFlat articlesEngineeringAdditional values

The invention relates to a bamboo product machining method, in particular to a bamboo floor machining process which sequentially comprises the steps of: sawing bamboo, chipping, hacking, pressing, bleaching or carbonizing, gum-dipping, drying, stamping and forming. Bamboo fiber powder and bamboo charcoal powder which are subjected to gum dipping are doped during the stamping. After the machining process in the invention is adopted, because bamboo scraps and the bamboo fibers are fully utilized, the utilization rate of raw materials is greatly increased and the production cost is reduced. Meanwhile, a bamboo floor machined by adopting the two materials can be used for effectively purifying air in the family environment, thus the additional value of the bamboo floor is increased. Ammonium polyphosphate is added during the gum dipping, the fire point of the floor can be increased, and the safety property of the bamboo floor is improved.

Owner:JIANGXI NANFENG ZHENYU IND GRP

Method for manufacturing composite bamboo floor

ActiveCN101439531AWide variety of sourcesIncrease profitWood veneer joiningWood layered productsWood veneerSurface layer

A manufacturing method of a composite bamboo flooring comprises the following steps: (1) cutting branch extruding parts on a bamboo branch tip; (2) splitting a small-diameter bamboo or the bamboo branch tip into 2-4 pieces of bamboo chips according to the size of the diameter by a bamboo splitting machine; (3) rolling the bamboo strips by a bamboo roller to obtain rolled bamboo strips; and (4) processing the rolled bamboo strips with a specific width and a specific thickness; then, taking the rolled bamboo strips as a core layer, bamboo splints of a large-diameter bamboo as a surface layer and a wood veneer or a bamboo veneer as a back layer, and obtaining a board blank after glue spreading, assembling and hot pressing; and the board blank is made into the bamboo flooring by procedures of trimming, opening chase mortise, sanding, finishing, drying and the like. The method can help improve the utilization rate of the bamboo, lower the production cost and realize the high-efficiency utilization of the small-diameter bamboo and the processing remainder of the bamboo, that is, the bamboo branch tip.

Owner:ZHEJIANG FORESTRY ACAD

Processing technique for bamboo flooring with wood grains

InactiveCN102500535AEnhanced mechanical adhesionReduce roughnessPretreated surfacesWood working apparatusWear resistantBamboo floor

A processing technique for bamboo flooring with wood grains includes the steps: sanding the upper surface of the bamboo flooring; roll-coating transparent putty, drying the transparent putty to be totally solidified and sanding the transparent putty; roll-coating white priming paint and drying the white priming paint to be totally solidified; roll-coating primary colors of wood and drying the primary colors to be totally solidified; automatically correcting the wood grains, roll-coating wood grain colors and drying the wood grain colors to be totally solidified; roll-coating wear-resistant priming paint and drying the wear-resistant priming paint to be semi-solidified; roll-coating elastic priming paint, drying the elastic priming paint to be totally solidified and sanding the elastic priming paint; roll-coating hardened priming paint, drying the hardened priming paint to be totally solidified and sanding the hardened priming paint; roll-coating scratch-resistant finish paint and drying the scratch-resistant finish paint to be semi-solidified; and roll-coating scratch-resistant finish paint, drying the scratch-resistant finish paint to be totally solidified and packaging the bamboo flooring. The manufacturing processes of roll-coated white priming paint, the roll-coated primary colors of the wood and the roll-coated wood grain colors after automatically correcting the wood grains require drying to be totally solidified, interpenetration of the primary colors of the wood, the wood grain colors and other adjacent coatings is eliminated, the coated wood grains are ensured to be clear and neat, and product quality is improved.

Owner:余胜辉

Bamboo floor producing technology

The present invention relates to a processing method for bamboo floor, which belongs to the technical field of floor material. The bamboo is processed to bamboo chips with tantamount size specification, the internal and external nodes are flattened, and the outer part and inner part of bamboo are removed. The bamboo chips is boiled and then is dried to a water content of less than 7%. A plurality of bamboo chips are subjected to hot press gluing to form bamboo floor by mean s of vapour heated bi-directional piezometry, and then the bamboo floor is subjected to sanding, painting, and solidity. The bamboo floor after carbonizing and drying is easy to be painted and glued, can effectively prevent the floor from dry shrinkage, cracking and deformation while in use, and can prevent wormeaten and milden and rot.

Owner:朱成功

Wood grain bamboo floor and preparing method thereof

InactiveCN101538927AMeet the needs of diversityWood working apparatusFlooringBamboo floorWear resistance

The invention discloses a wood grain bamboo floor which comprises a bamboo floor body. The upper surface of the bamboo floor body is wood grain. A method for preparing the wood grain bamboo floor is also disclosed which is carried out according to the following steps: the upper surface of the bamboo floor body is sanded; transparent putty is coated in a rolling way, and heating and sanding are carried out; the wood grain ground color is coated in a rolling way and heating is carried out; the wood grain is corrected automatically, the wood grain color is coated in a rolling way, and heating is carried out; wear resistance primer is coated in a rolling way, and heating is carried out; elastic primer is coated in a rolling way, and heating is carried out; hard primer is coated in a rolling way, and heating and sanding are carried out; elastic topcoat is coated in a rolling way, and heating and packaging are carried out. The wood grain bamboo floor and the preparing method thereof has the beneficial effects that the wood grain color is coated on the upper surface of the bamboo floor body in a rolling way, the upper surface of the bamboo floor has the wood grain effect, and diverse demands of people for bamboo floor products can be satisfied.

Owner:朱江福

Glued laminated bamboo floor and manufacturing method thereof

ActiveCN101891047AReduce consumptionMeet the use requirementsBio-packagingLarge containersEngineeringBamboo floor

The invention discloses a method for manufacturing glued laminated bamboo floors. The bamboo is applied to containers, so the consumption of wood resources in inland container floors is reduced, the use requirement of the container floors is better met, and the manufacturing cost of the container floors is reduced; meanwhile, an intermittent continuous production method is adopted, so the method for manufacturing the glued laminated bamboo floors can produce various specifications of inland container floors, and better meets the requirements on the strength and fatigue resistance of the inland container floors.

Owner:SHENGSHI CONTAINER MANAGEMENT SHANGHAI

Method for processing assembling type bamboo floor

The invention discloses a processing method of an assembled bamboo floor, which utilizes bamboo with a short growth period and abundant resources as a raw material, and after selecting bamboo, breaking bamboo, cooking, drying, matching colors, cutting materials, assembling, and gluing, Put it in a hot press and glue it together, then polish it with a heavy sand machine, cut it with mechanical equipment, paint it and dry it, and then it will be the finished product. The whole assembly process is simple, practical, and the finished product has no peculiar smell, and the assembled bamboo floor has a compact structure, is not easy to deform, has good pressure resistance, and feels comfortable on the feet. It avoids mold, insects, deterioration and other phenomena during the use of bamboo flooring, and uses the top layer of bamboo chips, carbonized bamboo chips or other colored bamboo chips to be placed regularly in the top layer, which greatly enriches the surface of the bamboo floor. It has the advantages of anti-mildew, anti-corrosion, waterproof, not easy to deform, energy saving and environmental protection.

Owner:孙长桥

Method for machining bamboo floor

InactiveCN102729309AHigh strengthImprove the carbonization effectLiquid surface applicatorsDomestic articlesProcess engineeringBamboo floor

The invention relates to the technical field of floor materials and particularly relates to a method for machining a bamboo floor. By improving a carbonization process, a gluing process, a painting process and the like and adding a new process, the total quality of the bamboo floor is improved; the carbonization is good; the bamboo floors with different colors can be produced according to production demands; and the color is uniform. The total quality of the bamboo floor can be further improved by finely polishing; the gluing process is better, so that the integral strength of the floor can be effectively improved with a hot pressing process, the glue using amount is effectively controlled, and the production cost is effectively reduced; and the painting technique is improved, and a coating quantity is reduced, so that the painting amount is greatly reduced, the coating is more stable, and the quality is higher.

Owner:安吉华信竹木制品有限公司

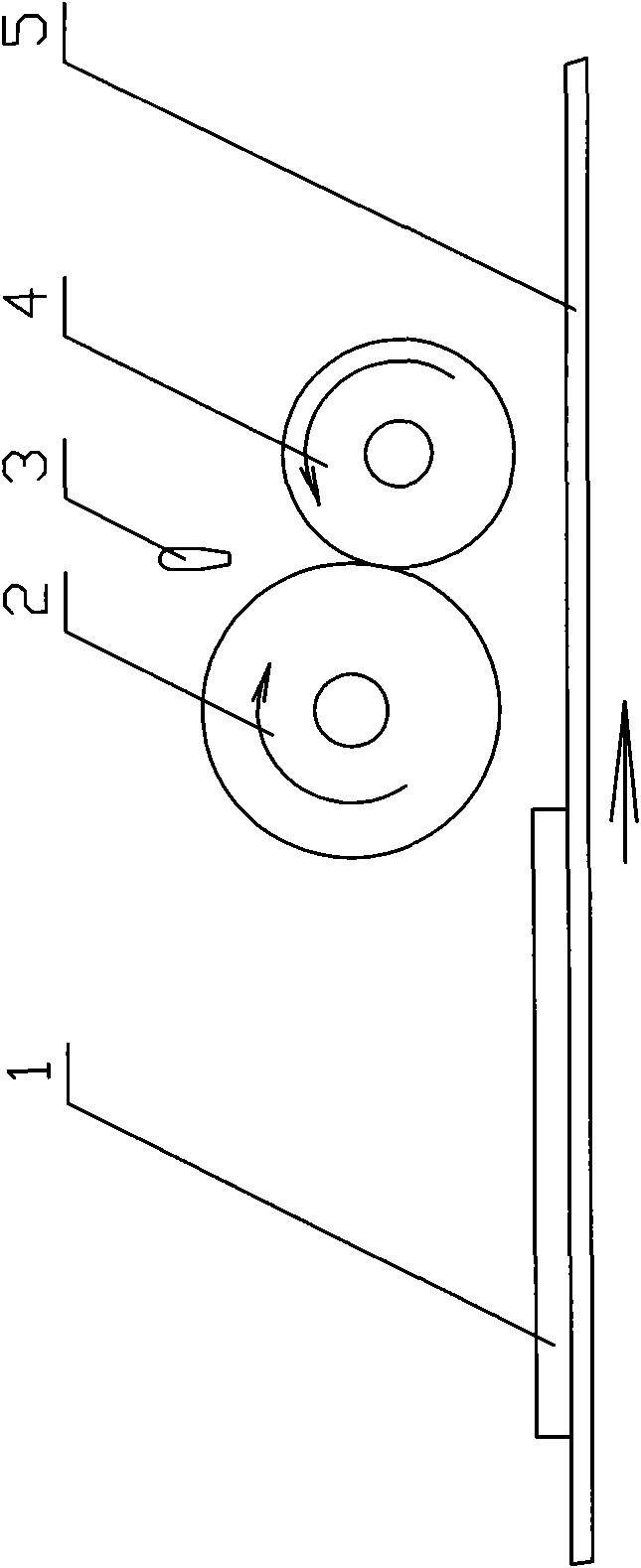

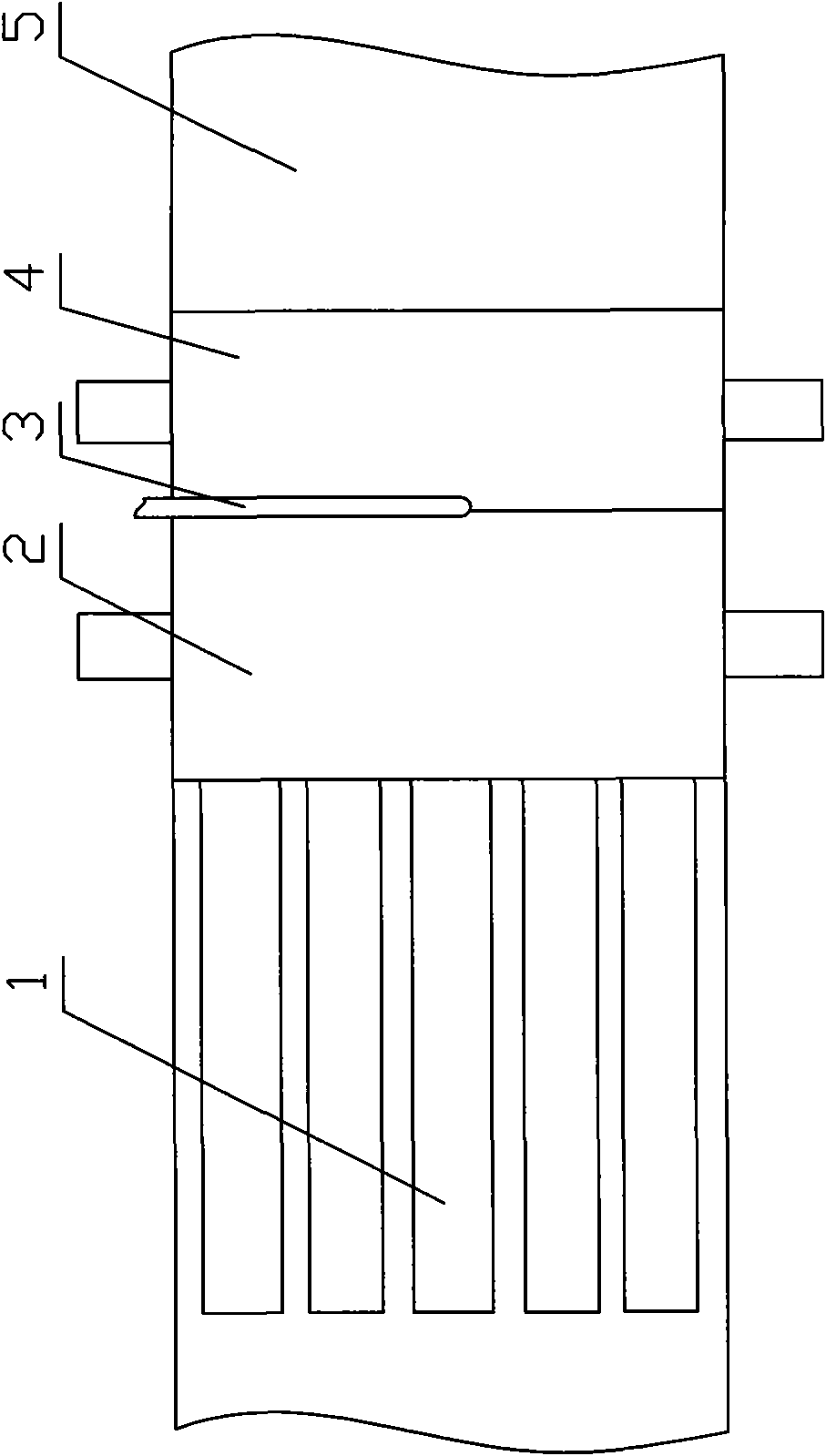

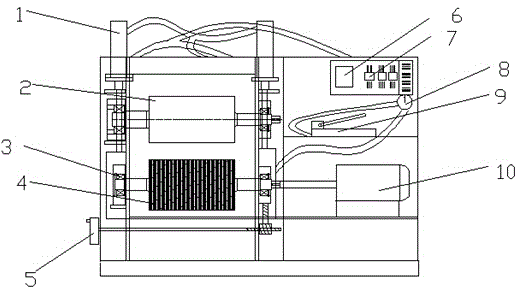

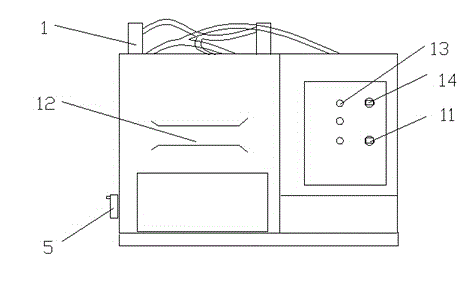

Bamboo floor mold pressing production process and equipment

InactiveCN104085030ASimple production processThe embossing process in the production process is simpleWood working apparatusEmbossing decorationsSolid woodLower grade

The invention relates to a bamboo floor mold pressing production process. The bamboo floor mold pressing production process includes the working procedures of moso bamboo selection, material fracture, slicing, rough planing, cooking bleaching or carbonization, drying, bamboo batten finish planing, separation, assembly gluing, hot-press gluing, sanding, truncation at fixed length, four-side planing, double-end milling, longitudinal and transverse tenoning, surface coating, inspection and packaging. An embossing working procedure exists behind the sanding working procedure and further involves embossing machine equipment composed of a steel press roller and an embossing roller and used for achieving the embossing working procedure, wherein a roller is sleeved with the embossing roller. One-time mold pressing is conducted through the embossing machine equipment, the embossing working procedure in the production process is finished, and bamboo floors are machined into solid wood floors. The bamboo floor mold pressing production process is simple in production working procedure, short in time period and low in cost, patterns pressed on the bamboo floors through mold pressing are durable, embossment does not bounce, and the bamboo floor mold pressing production process and equipment are suitable for imitating high-grade wood floors through low-grade wood.

Owner:ANHUI LIAOYUAN TRADE

Manufacturing method for impregnated paper veneer bamboo plywood

InactiveCN101653956AAccurate thicknessBoard surface glossWood veneer joiningDomestic articlesWood veneerSurface layer

The invention relates to a manufacturing method for impregnated paper veneer bamboo plywood, which belongs to the field of manufacturing the bamboo plywood of artificial boards. The manufacturing method comprises the following steps: taking a bamboo shade, a bamboo mat and a wood veneer which are applied with a phenolic-resin adhesive and are dried as base materials; using the bamboo shade as a core layer, the bamboo mat as an inner layer and the wood veneer as a surface layer to assemble two base material plate blanks including a bamboo plywood formwork and a composite bamboo floor respectively; arranging metal liner plates on the upper and lower surfaces of the two base material plate blanks; gluing the two base material plate blanks into two base materials in a multilayer thermal pressby adopting a 'hot-hot' process; performing close piling pressure treatment on the two base materials, placing 1 to 2 pieces of impregnated paper on two sides of the base material of the bamboo plywood formwork and one side of the base material of the composite bamboo floor respectively after thick processing of longitudinal and transverse edge cuttings, double-sided sanding and the like, then configuring the two base materials with other apparatuses, putting the materials into the multilayer thermal press respectively, and gluing the materials into two types of impregnated paper veneer bambooplywood through the 'hot-hot' process; and finally, processing the two types of the impregnated paper veneer bamboo plywood into a panel with a steel frame plywood formwork and a composite bamboo floor for outdoor use respectively through different post productions.

Owner:赵仁杰

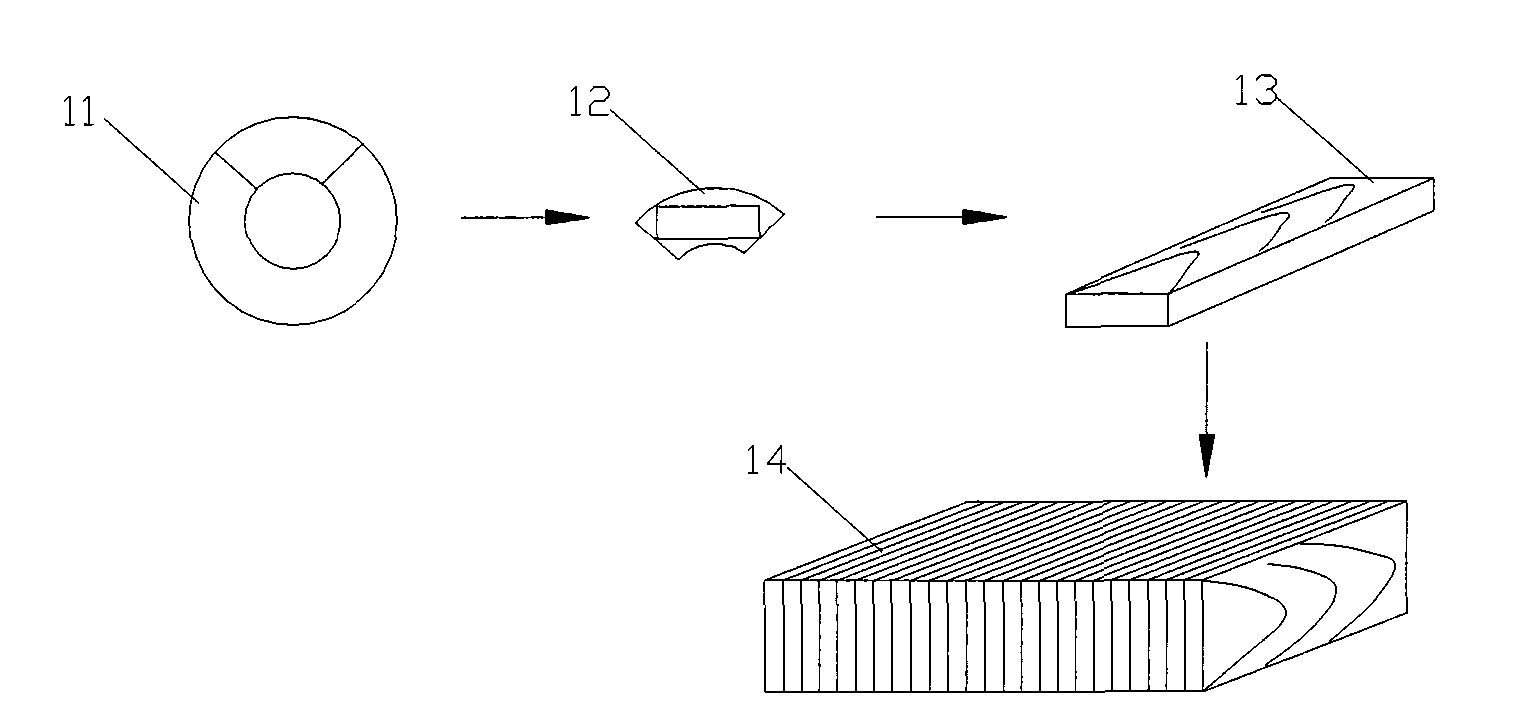

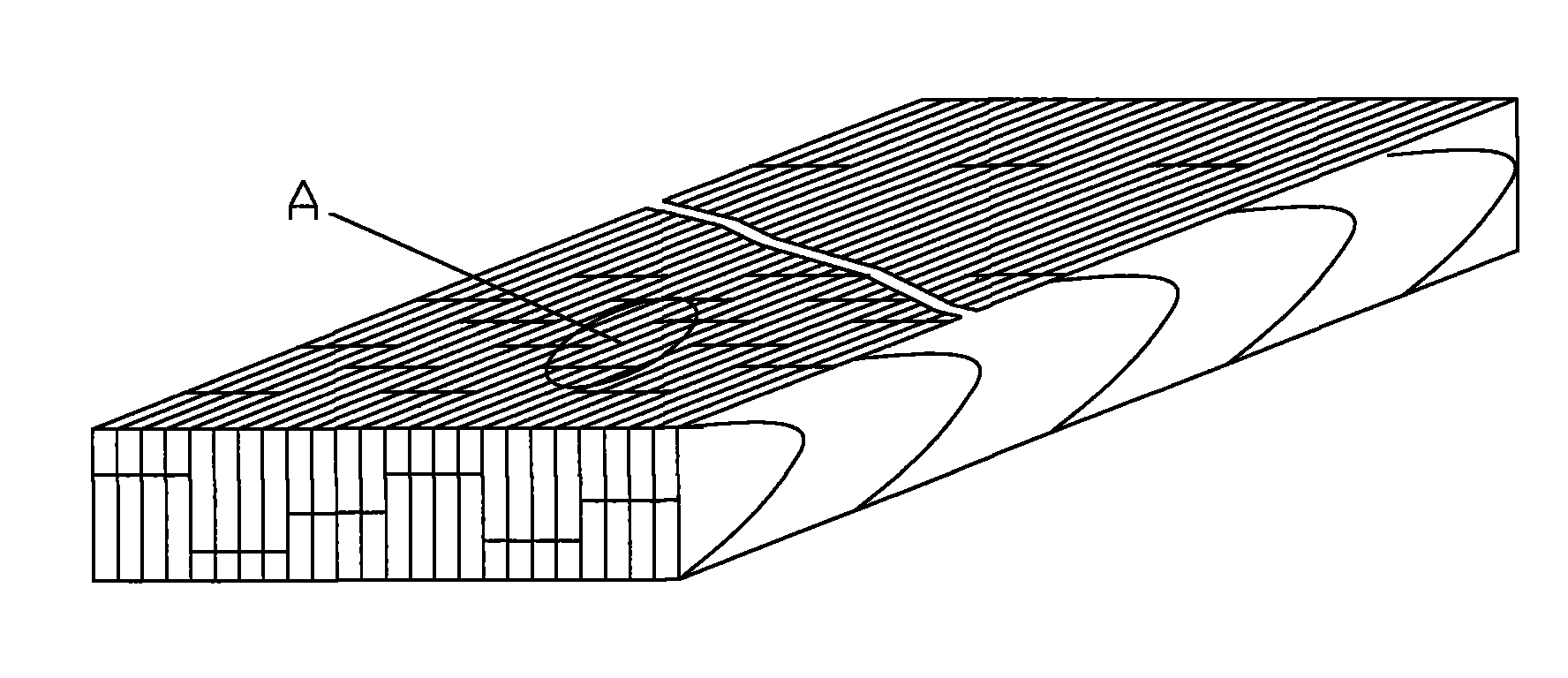

Processing technique for bamboo batten of bamboo floor

InactiveCN102310441AFull and even absorptionEvenly distributedWood treatment detailsAdhesive glueEngineering

The invention relates to a processing technique for bamboo products, in particular to a processing technique for a bamboo batten of a bamboo floor. The processing technique for the bamboo batten of the bamboo floor comprises the following steps of: (1) cutting off bamboo according to the requirement and then breaking the cut bamboo into pieces, and removing bamboo joints to obtain bamboo chips; (2) further finely cutting the bamboo chips and separating bamboo chips with bamboo green from bamboo chips with tabasheer; (3) pressing the bamboo chips with the tabasheer into bundled bamboo silks with fiber bamboo filaments by using a bamboo batten press wheel crusher; (4) carrying out carbonizing or bleaching treatment on the bamboo silks; and (5) placing the bamboo silks obtained in the step (4) into a drying room and drying until the water content is not higher than 7 percent. According to the processing technique disclosed by the invention, after strip bamboo battens are pressed by using the pressure of a wheel press, the interiors of fine strip bamboo battens are gradually pressed and scattered to form complete fiber bamboo filament bundles by using a filament pressing wheel with a sharp edge blade. When the bamboo battens are immersed with glue, the glue can completely penetrate into the interiors of the fiber bamboo filament bundles, the phenomena of filament jumping, cracking, burrs and the like can be avoided, and the quality of the floor is greatly improved.

Owner:JIANGXI NANFENG ZHENYU IND GRP

Method of treating bamboo floor using plasma

InactiveCN1718391AImprove wettabilityEasy to glueWood treatment detailsWood veneer joiningEngineeringBamboo floor

A method for treating bamboo floor boards by plasma includes such steps as drying bamboo strips, plasma treating to make its surface wet angle less than 25 deg, coating resin, laminating and hot pressing.

Owner:NANJING FORESTRY UNIV

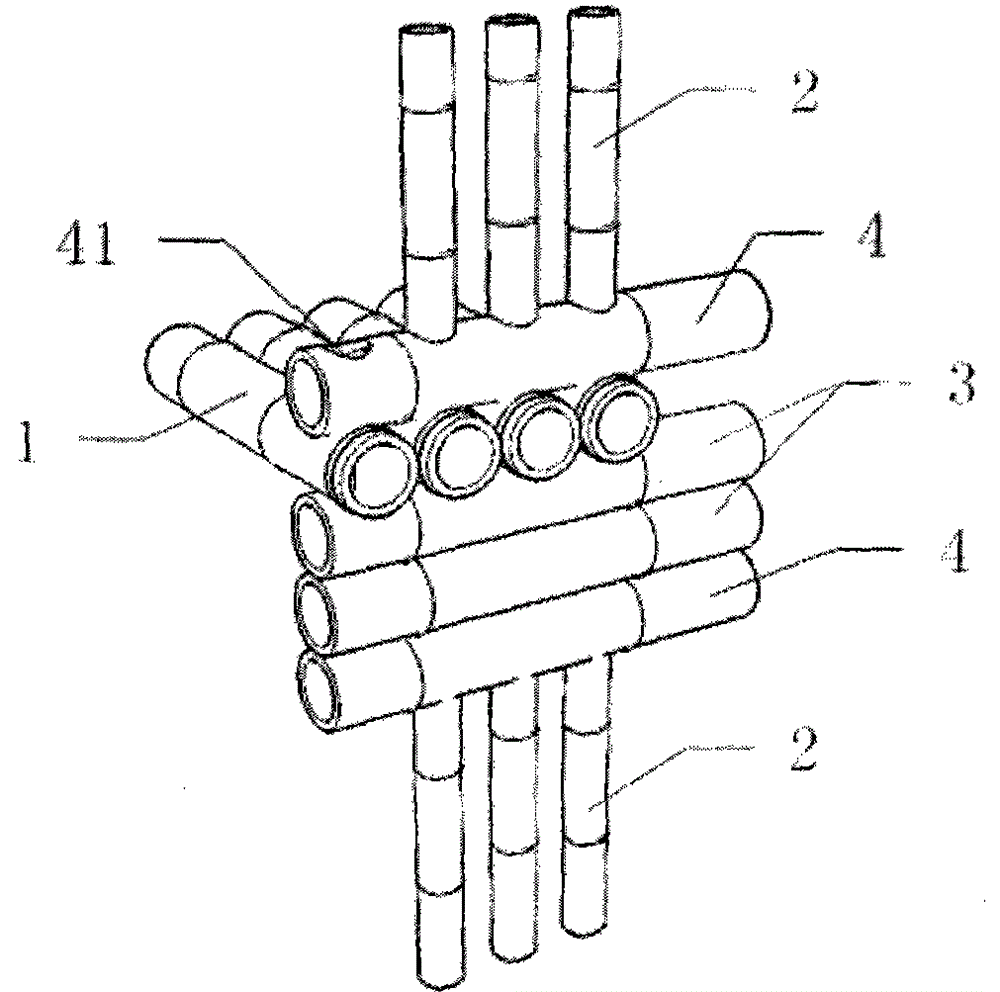

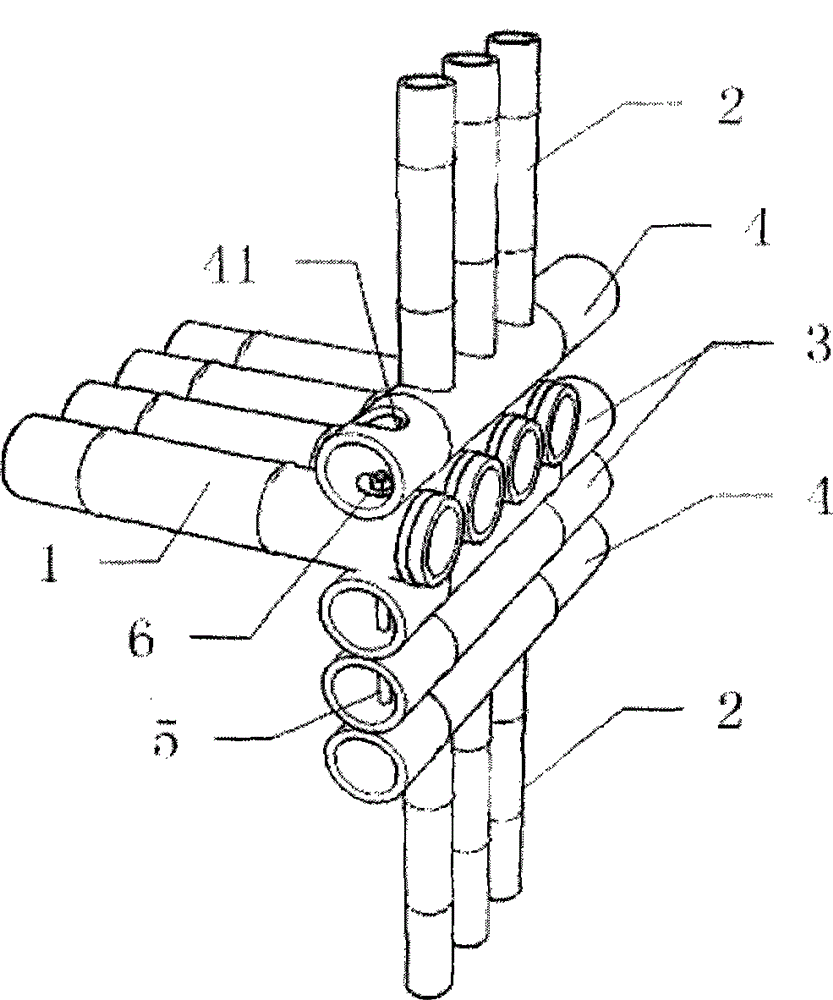

Connecting structure of raw-bamboo floor, wall and beam

InactiveCN103938726AImprove connection strengthImprove connection stabilityBuilding constructionsEngineeringBamboo floor

The invention discloses a connecting structure of a raw-bamboo floor, a wall and a beam. The connecting structure comprises the floor, wall bodies and the beam, wherein the floor is formed by mutually arranging raw bamboo. The end of the floor is erected on the beam, wall-body cross struts are fixed to the upper surface of the floor and the bottom surface of the beam respectively, the wall bodies are arranged on the wall-body cross struts, and the wall-body cross struts, the floor and the beam are fixedly connected into a whole through connecting parts. The connecting structure is simple in structure, ingenuous in design, and convenient to use. Besides, the components are connected stably and reliably, the connecting strength and stability among the floor, the wall and the beam can be effectively enhanced, overall tensile resistance performance is improved, the overall seismic performance of a raw-bamboo structure system building is further enhanced, and further popularization of the connecting structure is facilitated.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Bamboo floor surface coating method

InactiveCN102500536AIncrease suitStrong aging resistancePretreated surfacesCoatingsAdhesiveHigh probability

The invention discloses a bamboo floor surface coating method, and belongs to the technical field of surface treatment. The bamboo floor surface coating method comprises the following steps of: sanding; coating wood oil; a roll-coating an aqueous adhesive; drying; roll-coating transparent putty; drying and then sanding; roll-coating a covering primer; drying; coating UV (Ultraviolet) printing ink; drying; roll-coating a wear-resistant primer; drying; spraying a varnish; spraying a UV surface paint; drying; and packaging. By using the method, the phenomena of high probability of dulling, surface cracking, paint film stripping and the like of bamboo floor caused by the conventional bamboo floor surface coating method are solved; the bamboo floor surface coating method is easy to operate and has practicability; and aging resistance of bamboo floor can be improved.

Owner:朱江福

Manufacturing process of outdoor strand woven bamboo floors

ActiveCN105196395AAnti-corrosion and insect-proof performance is outstandingDeformation and cracking rate reductionWood working apparatusFlat articlesBamboo floorIndustrial engineering

The invention provides a manufacturing process of outdoor strand woven bamboo floors. The process comprises two main stages, namly cold pressing and manufacturing plates, and carrying out oil heat treatment, and comprises the following steps: putting processed and manufactured plate blanks into a hydrophobic organic medium of 100-300 DEG C after the stage of cold pressing and manufacturing bamboo filaments or bamboo sheets into plates, then dipping the plate blanks for 1-10 hours, taking the plate blanks out, standing and cooling to the room temperature, and coating the surfaces of the plate blanks with a layer of plant oil. Compared with a manufacturing process of strand woven bamboo floors in the prior art, the outdoor strand woven bamboo floors manufactured by the process have the advantages of mold resistance, insect damage resistance, deformation resistance and cracking resistance; the process is high in efficiency, low in cost, high in compressive property and free of surface color difference.

Owner:ZHEJIANG YONGYU FURNITURE CO LTD

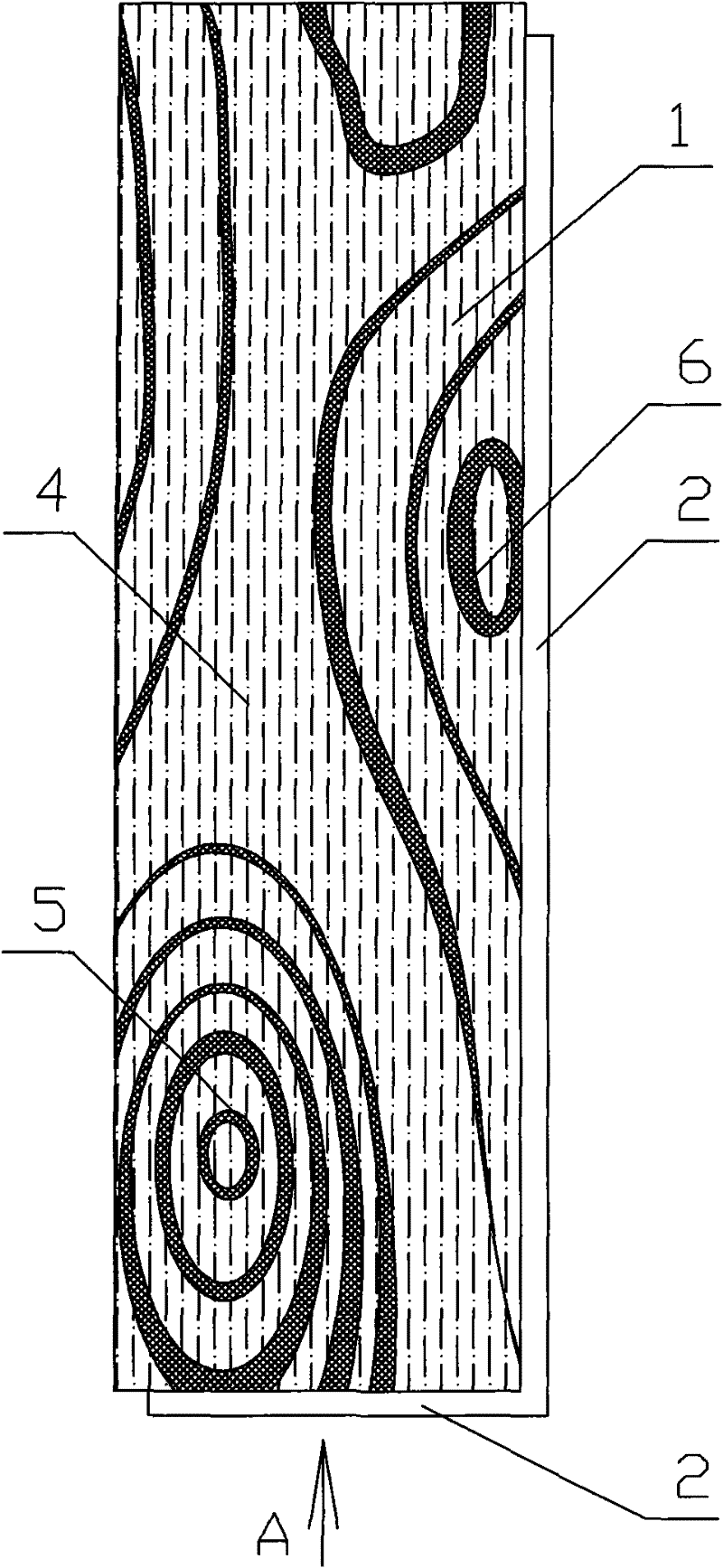

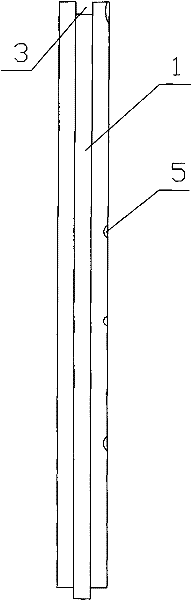

Production method of bamboo floor with wood line strips, annual ring lines, branch scar lines and colours on upper surface

InactiveCN102528883AFully reflect the texture patteFull expression of colorWood veneer joiningAll solid stateWear resistant

The invention discloses a production method of a bamboo floor with wood line strips, annual ring lines, branch scar lines and colours on the upper surface. The production method comprises the following steps of: (1) preparing a blank plate; (2) pressing the annular ring lines and the branch scar lines; (3) processing a rabbet and a riveting slot; (4) spraying paint; (5) brushing inlet line strips; (6) spraying wear-resistant priming paint; (7) spraying paint elastic priming paint; (8) spraying hard priming paint and sanding; (9) spraying elastic finish paint, carrying out drying treatment into an all-solid state to obtain the bamboo floor with the wood line strips, the annual ring lines, the branch scar lines and colours on the upper surface, and packaging. The production method disclosed by the invention has the beneficial effects that the wood line strips, the annular ring lines and the branch scar lines are rolled on the upper surface of a floor body composed of bamboo, and paint with the colour of wood is sprayed, thus texture patterns and colours of natural wood can be fully reflected, third dimension can be displayed, and slipping can be difficultly caused.

Owner:肖德兴 +1

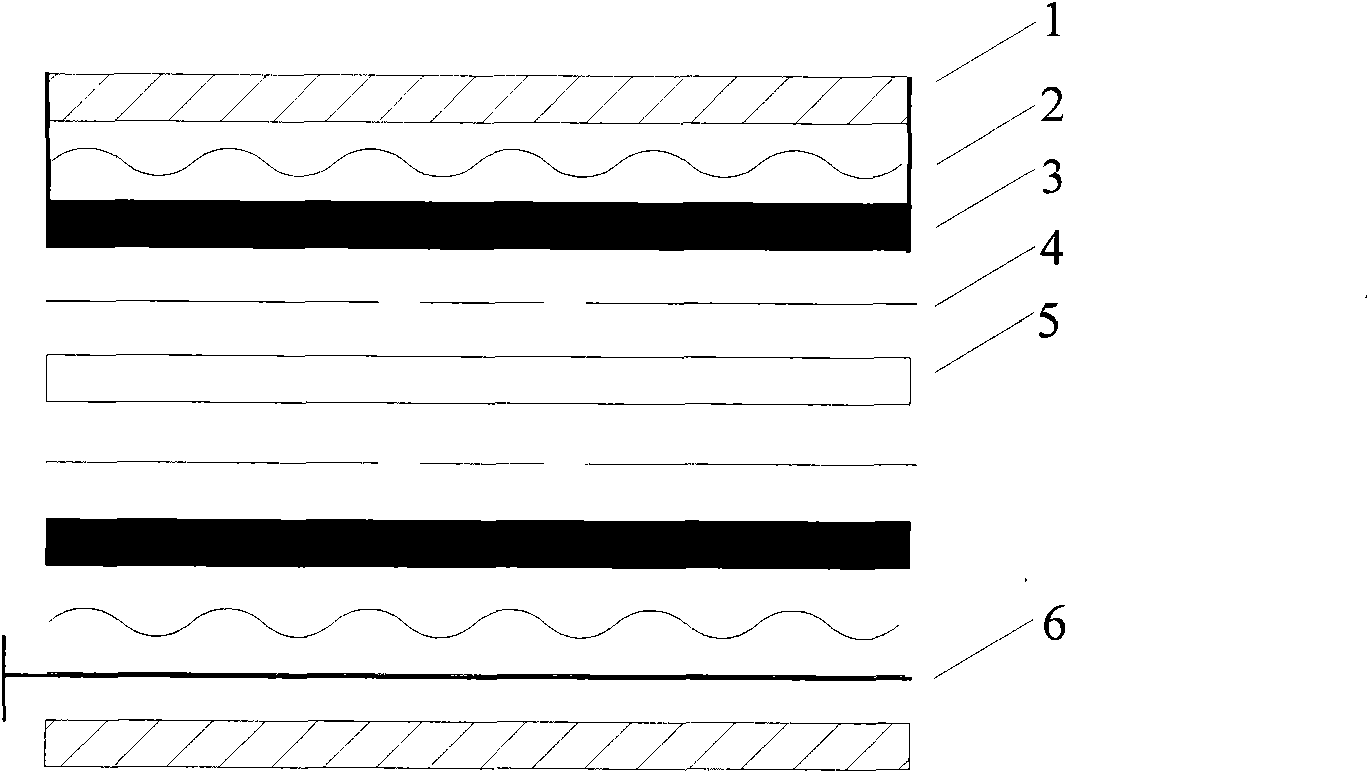

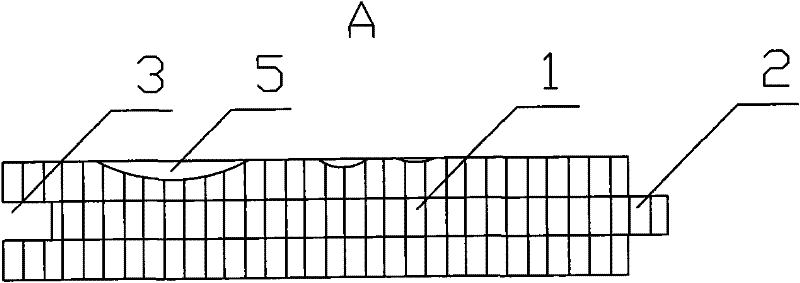

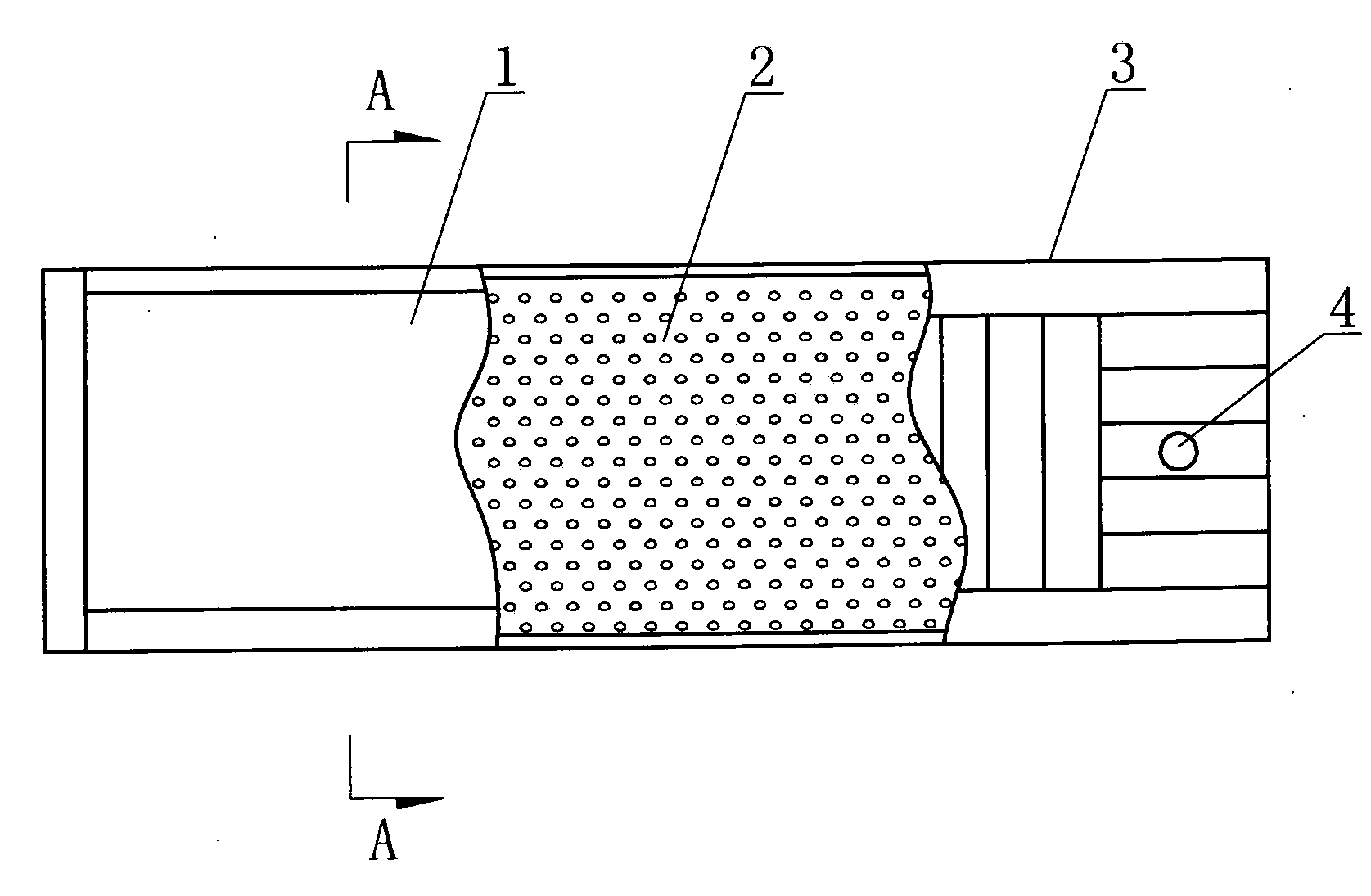

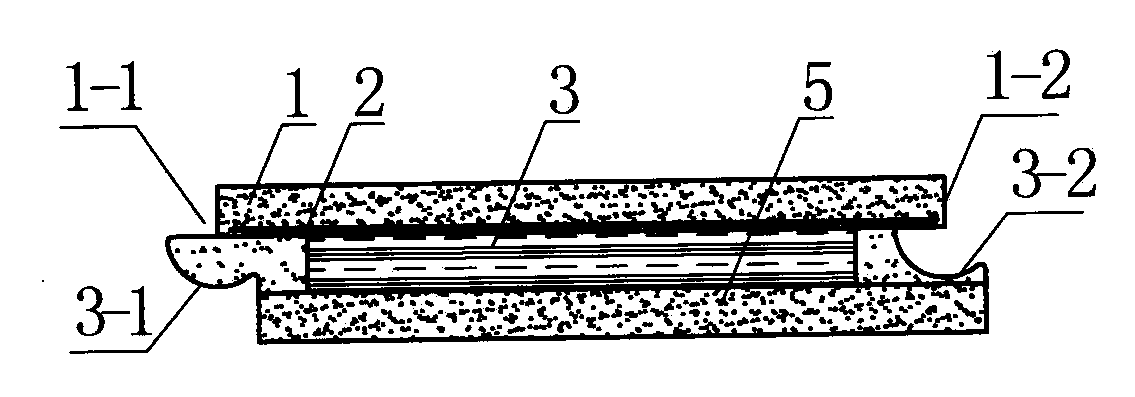

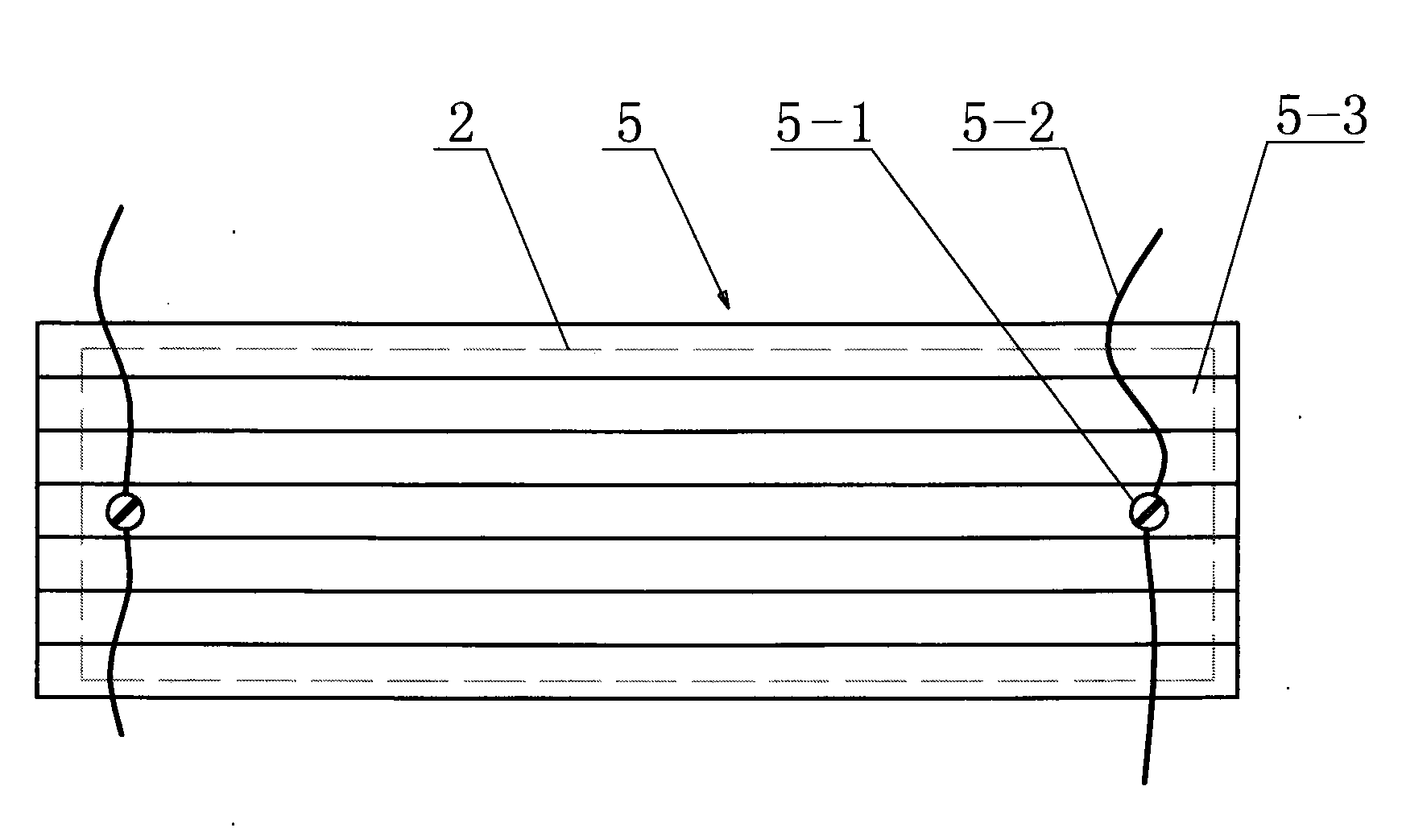

Electric heating bamboo floor

InactiveCN103423802ADoes not occupy thickness spaceEasy to installLighting and heating apparatusElectric heating systemSolid woodElectricity

The invention discloses an electric heating bamboo floor which comprises a heat conducting face plate, an electric heating body layer, a middle plate and a bottom plate. The electric heating body layer is disposed between the adhesive faces of the middle plate and heat conducting face plate and is electrically connected with electrode connecting screws through conductive holes. Every two forming blocks are matched through a corresponding lock type inserting mechanism. The heat conducting face plate is made by using reorganized bamboo structures as base material. The electric heating body layer comprises a thin paper body, conductive copper foil sticks, a connecting electrode A port, electric heating pieces and a connecting electrode B port. The middle plate comprises elongated straight-side bamboo chip blocks, transverse short bamboo chip sections and longitudinal short bamboo chip sections which are crisscross staggered and spliced, and the conductive holes are formed at two ends of the middle plate. The bottom plate is flatly spliced by elongated bamboo chips along the fiber direction, and the electrode connecting screws are disposed at two ends of the bottom plate. The middle plate and the bottom plate can also be made of multi-layer solid wood plates. The electric heating bamboo floor is small in space occupation, simple in structure, convenient to use and mount, high in safety, and the like.

Owner:刘国兴

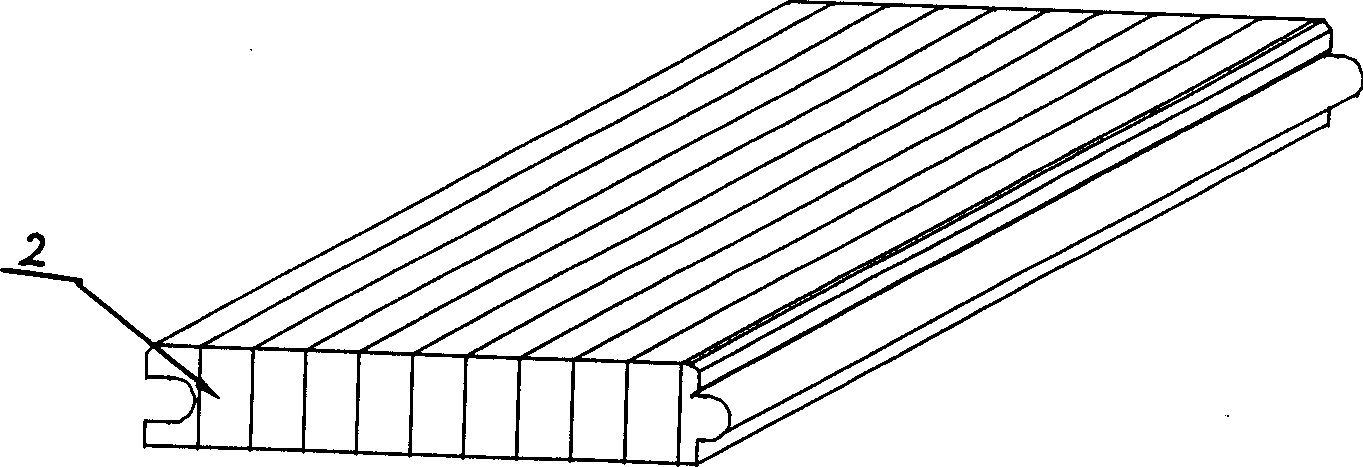

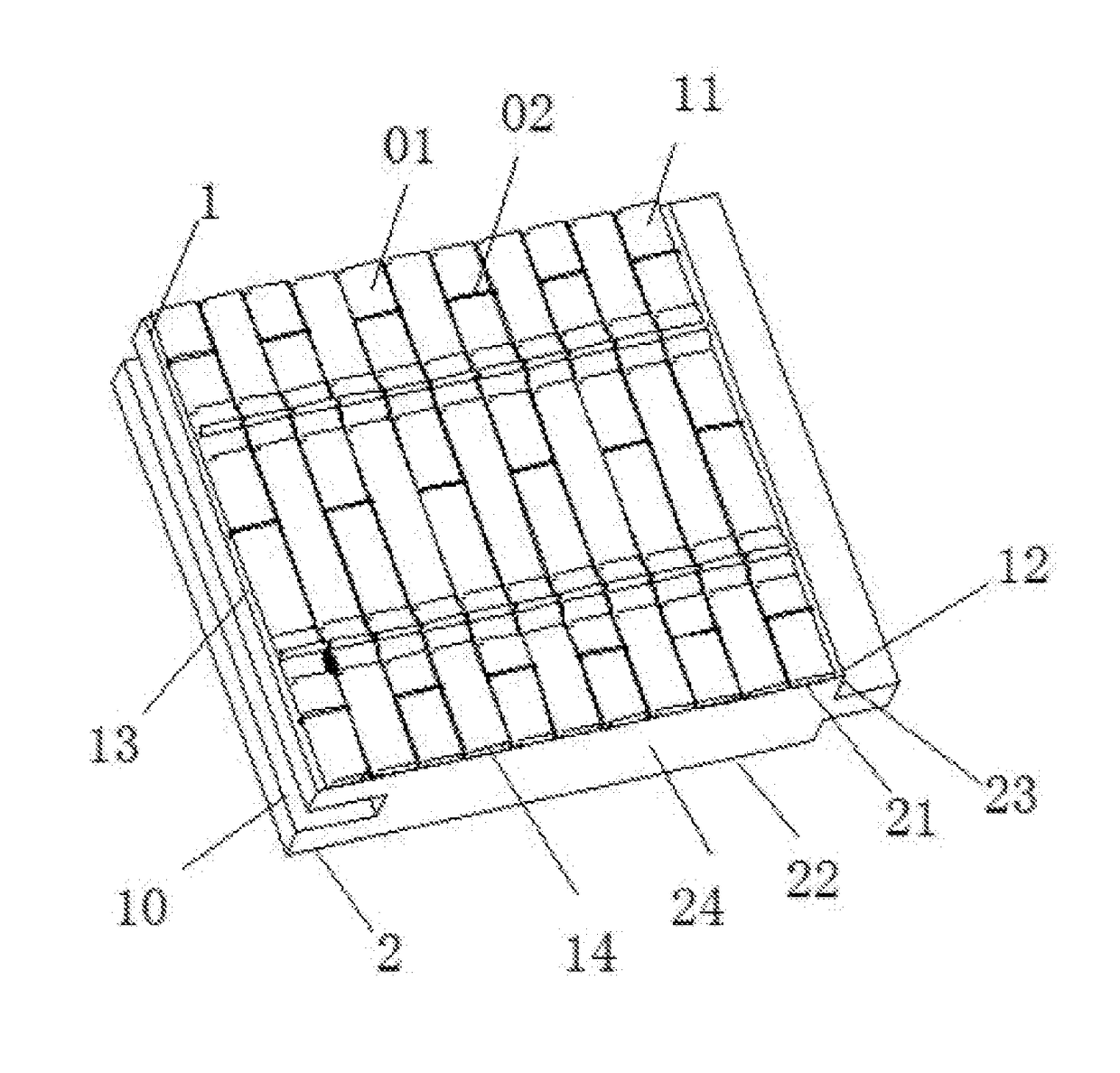

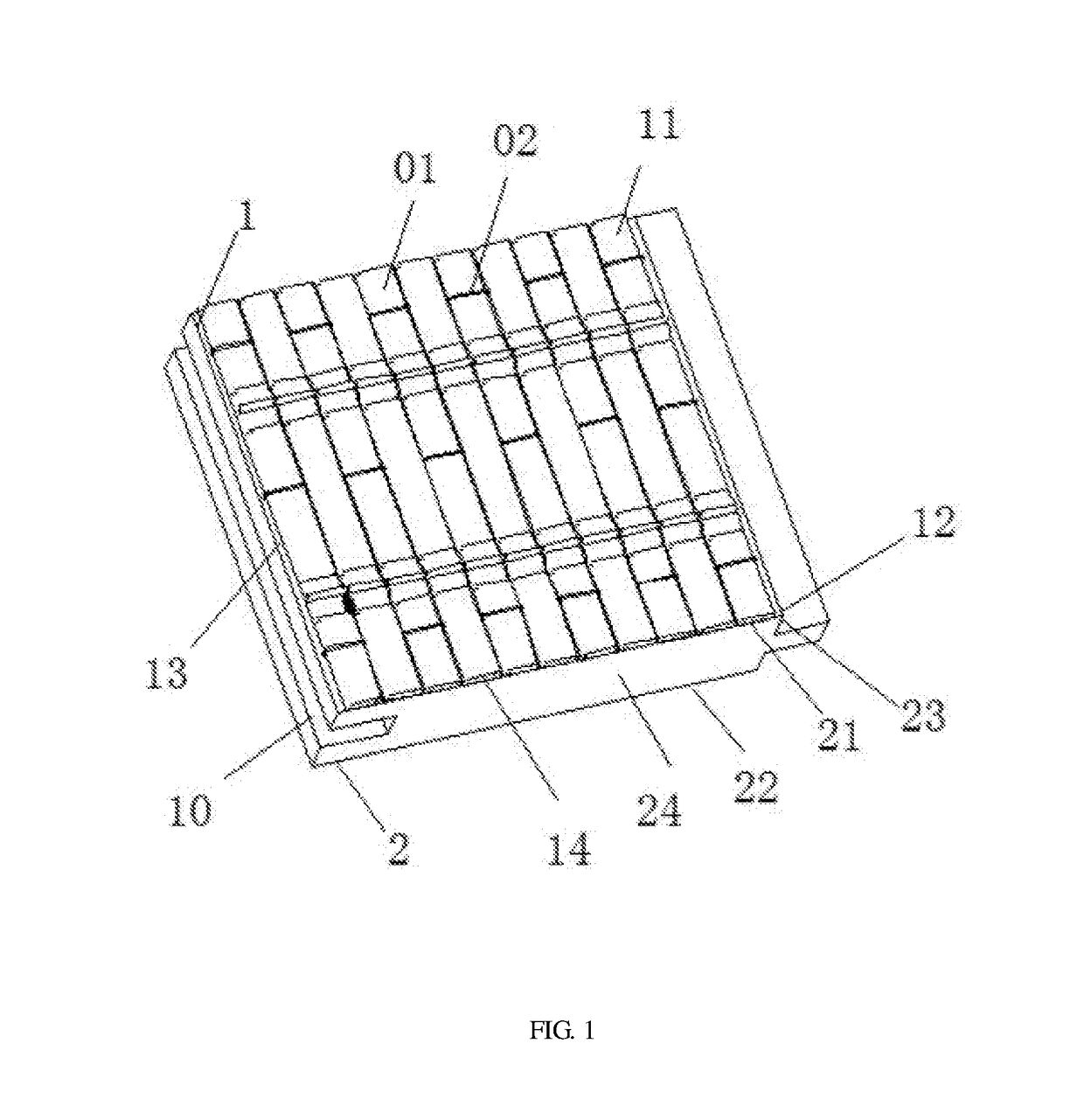

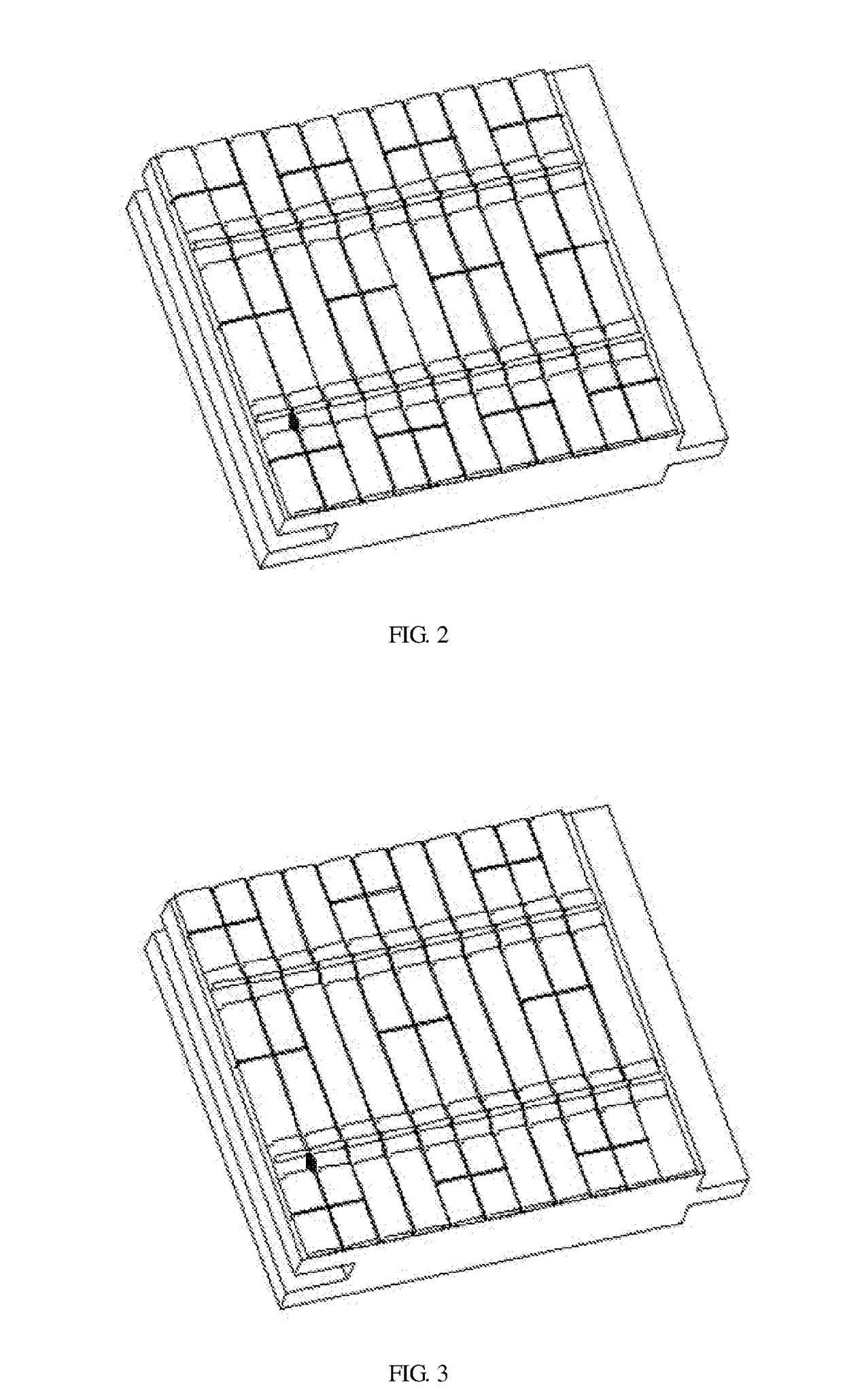

Composite bamboo floor and manufacturing method thereof

ActiveUS20170356193A1Improve stabilityShort processing timeTongue/grooves making apparatusCane mechanical workingEngineeringBamboo floor

The invention relates to a bamboo floor, in particular to a composite bamboo floor. The composite bamboo floor comprises a floor surface board provided with a body, a pressed surface, a connecting surface connected with the core board, at least one cut surface board side face and surface board end faces, and the core board arranged under the floor surface board and provided with a core board surface connected with the floor surface board, a core board bottom surface, core board side faces and core board end faces, and the positions of the core board side faces or the core board side faces and the surface board side faces are provided with notch structures processed in two sides in the length direction of the composite bamboo floor. The composite bamboo floor is high in strength, high in processing efficiency and low in production cost.

Owner:ZHEJIANG YONGYU FURNITURE CO LTD

Processing technology for waterproof strand woven bamboo flooring

InactiveCN102581908AFull and even absorptionEvenly distributedWood compressionAdhesive glueEngineering

The invention relates to a processing method of bamboo products, in particular to processing technology for a waterproof strand woven bamboo flooring. The processing technology includes chipping, bamboo joint removing, fine cutting, pressing to form fiber-shaped bamboo strips, carbonization or cooking bleaching, drying, impregnation, pressing to form bamboo flooring blanks and the like. Filament clamping rollers which are provided with blades with sharp edges are adopted, glue can completely permeate into fiber bamboo filament bundles, various portions of the inside of each bamboo strip can sufficiently absorb the glue, problems of filament jumping, cracking, burrs and the like can be avoided, and the quality of the flooring is greatly improved. In addition, the density and the specific gravity of the glue can meet requirements of waterproof floorings, external moisture cannot enter the flooring easily, an excellent waterproofing effect is achieved, and the service life of the flooring is prolonged.

Owner:JIANGXI NANFENG ZHENYU IND GRP

Bamboo-wood furniture production paint brushing device with drying function

InactiveCN108672198AEasy to moveEasy to paintLiquid surface applicatorsCoatingsEngineeringBrush device

The invention discloses a bamboo-wood furniture production paint brushing device with a drying function. The bamboo-wood furniture production paint brushing device comprises an operating platform anda bamboo floor body. The upper surface of the operating platform is provided with a rectangular slot. Conveying rollers distributed equidistantly are rotatably connected in the middle of the rectangular slot. Inverted-T-shaped sliding grooves are formed in the positions, close to the two opposite sides of the rectangular slot, of the upper surface of the operating platform. T-shaped sliding blocksare slidably connected to the interiors of the T-shaped sliding grooves. Sliding supports are slidably connected to the two sides of the operating platform. Two parallel channel steel slide rails ofwhich openings are opposite are welded between the top ends of the two sliding supports. The same electric sliding block is slidably connected between sliding grooves of the two channel steel slide rails. Two perpendicular vertical plates are welded to the positions, close to the middle of the two channel steel slide rails, of the side face of the electric sliding block. The distance between two antiskid clamping plates is adjusted arbitrarily according to the width of the bamboo floor body, so that the bamboo floor body is tightly fixed to the upper surfaces of the conveying rollers to facilitate paint brushing.

Owner:安吉登冠竹木开发有限公司

Method for preparing environment-friendly high-property bamboo floor

InactiveCN106217524APreserve texture aestheticsFireproofWood treatment detailsCane mechanical workingEnvironmental resistanceBamboo floor

The invention discloses a method for preparing an environment-friendly high-property bamboo floor. The method includes the following steps that (1) materials are obtained, specifically, the bamboo outer skin and bamboo inner skin of purchased raw bamboos are removed, and then the bamboos are cut off and cut to form bamboo strips which are equal in size; (2) surface treatment is performed, specifically, the bamboo strips are subjected to carbonizing treatment and plasma surface treatment; (3) impregnation is performed, specifically, the bamboo strips which are already subjected to surface treatment are soaked in urea resin for two hours, and the impregnated bamboo strips are dried in a constant temperature drying oven for two to five hours; (4) assembling and hot-pressing are performed, specifically, the impregnated bamboo strips are assembled as required and then subjected to hot-press forming; (5) surface polishing is performed, specifically, formed crude products are subjected to surface polishing so as to meet the requirements for brightness and smoothness; and (6) paint spraying is performed, specifically, a layer of transparent and electric paint is sprayed to the polished bamboo floor, and therefore, the finished bamboo floor is obtained. The bamboo floor prepared through the method has the good characteristics of being physically beneficial, environmentally friendly, waterproof, fireproof and attractive in appearance.

Owner:上海轩颂建筑科技股份有限公司

Mobile multifunctional steaming and showering room

ActiveCN105064724AExtended service lifeAdjustable temperatureWallsLighting and heating apparatusFiberCarbon fibers

The invention provides a mobile multifunctional steaming and showering room which comprises a room body and a shower nozzle arranged inside the room body. The room body is a closed space formed by a ceiling, walls on four sides and a floor; a door and a control system are arranged on one wall; each wall is composed of a heat-insulating layer, a heating layer and a heat-conducting layer from outside to inside; a heat-conducting groove used for containing the corresponding heating layer is formed in each heat-insulating layer; an opening of each heat-conducting groove is sealed by using the corresponding head-conducting layer; each heat-insulating layer is formed by compositing an SMC board, a tung wood board and a carbonized reconsolidated bamboo floor; each heating layer is a far infrared carbon fiber heating board; and each heat-conducting layer is a metal heat-conducting piece. Through material improvement, waterproof, mildewproof and electric leakage preventive performances of the room are improved; steaming and showering can be performed in a same space; the service life of the room is prolonged; the temperature and humidity in the room can be adjusted conveniently when the room is in use; and far infrared rays good for human health can be released.

Owner:石家庄邦迪高分子材料有限公司

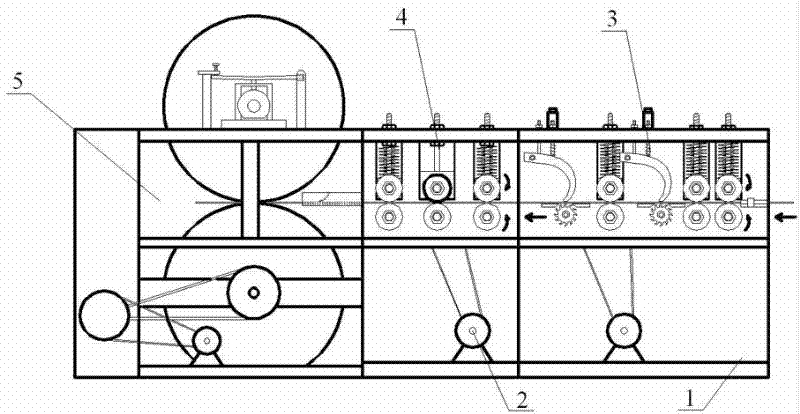

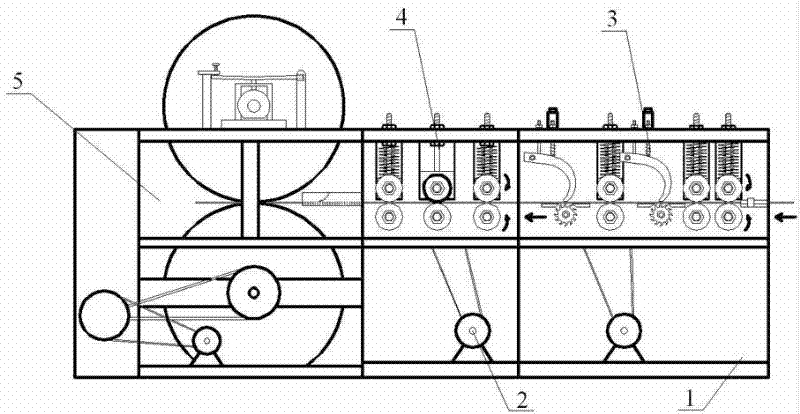

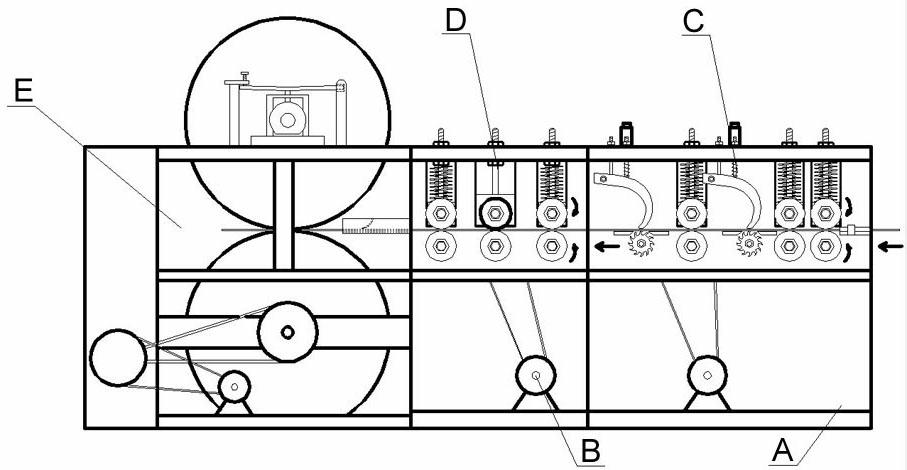

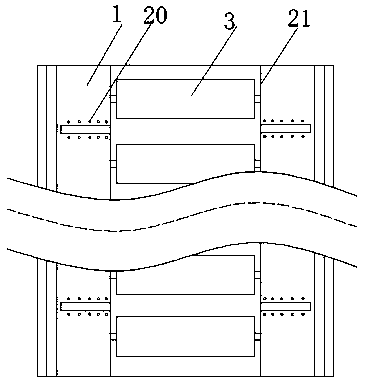

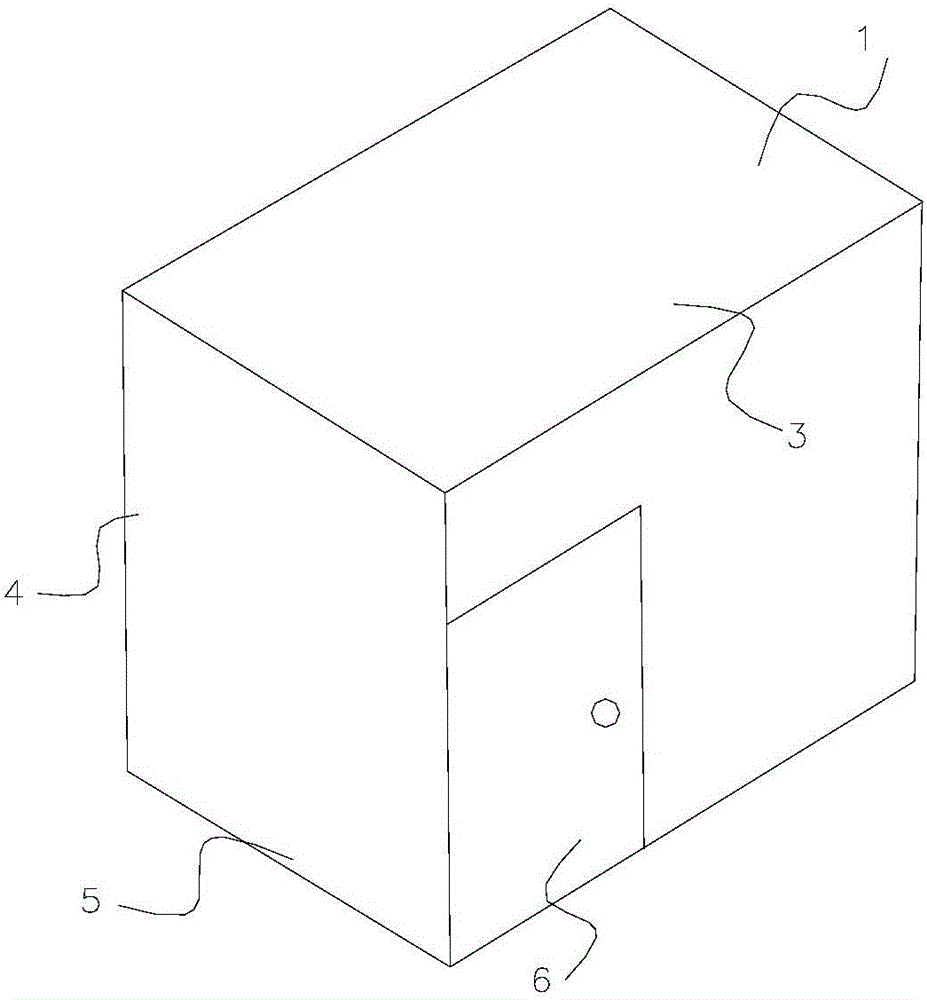

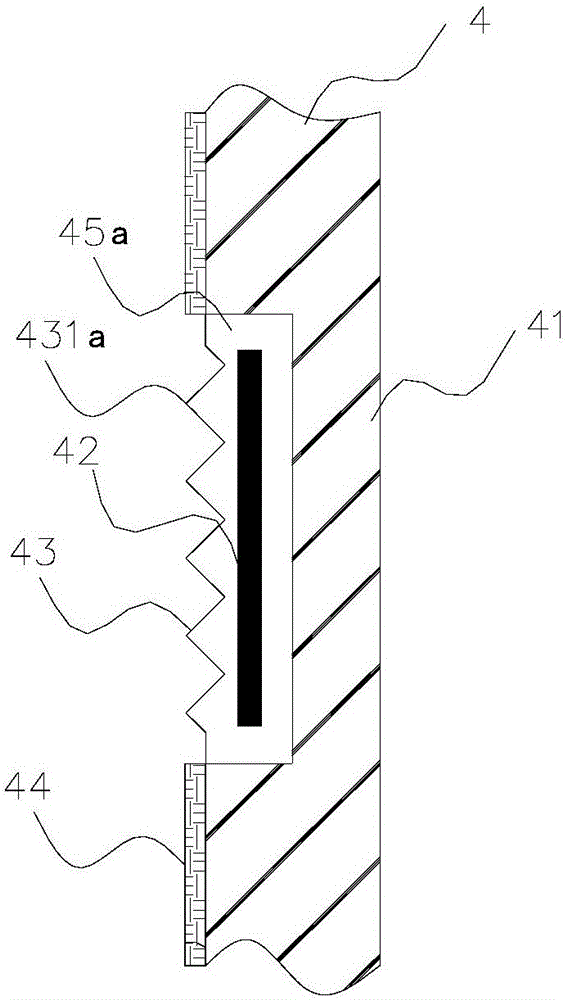

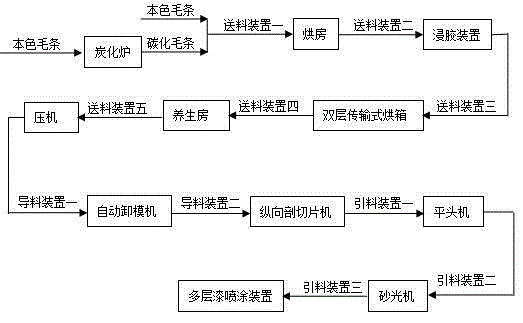

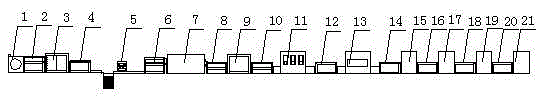

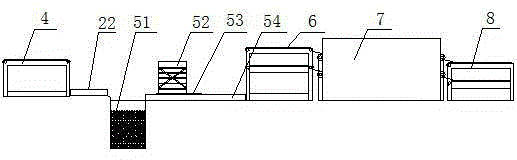

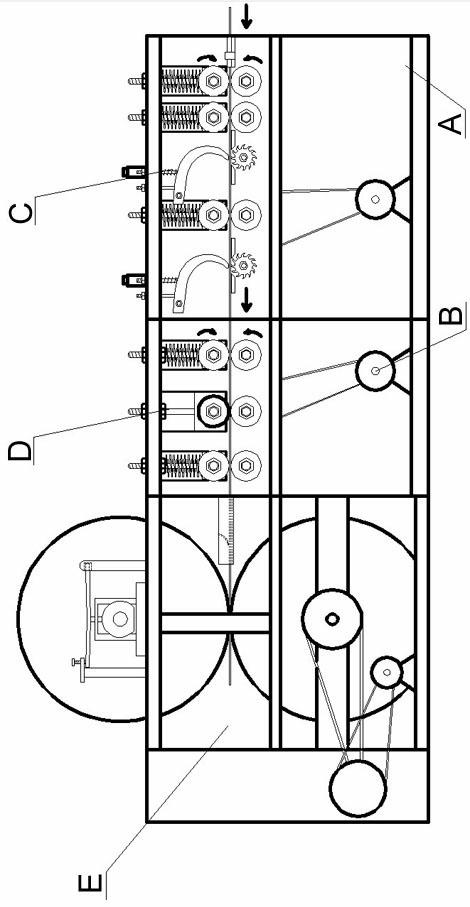

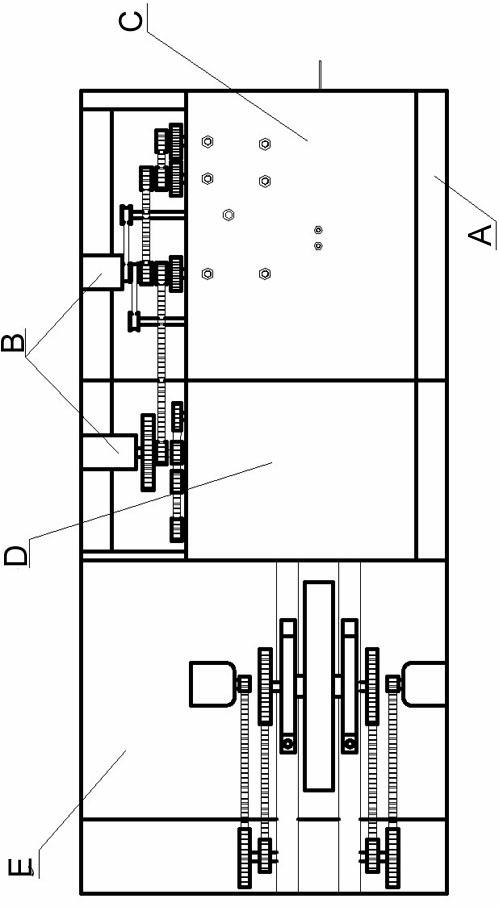

Production line for tiger-stripe bamboo floor

The invention provides a production line for tiger-stripe bamboo floor. The production line comprises a carbonized oven used for wool top carbonization, a double-layer feeding device I, a drying room, a side-by-side material conveying device, an impregnating device, a double-layer feeding device II, a double-layer transmission type drying oven, a double-layer feeding device III, a life-preserving room, a double-layer feeding device IV as well as a press, a material guide device I, an automatic mould unloading device, a material guide device, a longitudinal profile slicing machine, a material guide device, an end-facing machine, a material guide device II, a sanding machine, the double-layer feeding device IV and a multi-layer paint spraying device which are sequentially arranged, wherein the double-layer feeding device II and the double-layer feeding device III are respectively arranged on a loading part and an unloading part of the double-layer transmission type drying oven. The device can realize rapid production for tiger-stripe bamboo floor; natural-color wool tops and carbonized wool tops are mixed before square stock is prepared, so that the square stock is formed into a pattern, and therefore, the finally prepared bamboo floor has a pattern; the carbonized wool tops are embedded into the natural-color wool tops, so that the pattern stability is guaranteed without generating problems such as pattern dropping and the like.

Owner:安徽尧龙竹木制品有限公司

Processing technology for heating strand woven bamboo flooring

InactiveCN102581903AFull and even absorptionEvenly distributedWood working apparatusFlat articlesAdhesive glueBamboo floor

The invention relates to a processing method for bamboo products, in particular to processing technology for a heating strand woven bamboo flooring. The processing technology includes chipping, bamboo joint removal, fine cutting, pressing to form fiber-shaped bamboo strips, carbonization or cooking and bleaching, drying, impregnation, pressing to form bamboo floor blanks and the like. Filament clamping rollers which are provided with blades with sharp edges are adopted, glue can thoroughly permeate into fiber bamboo filament bundles, accordingly, various portions of the inside of each bamboo strip can sufficiently and uniformly absorb the glue, problems of filament jumping, cracking, burrs and the like can be avoided, and the quality of the strand woven bamboo flooring is greatly improved. In addition, the density of the impregnation glue is proper, requirements of the heating flooring can be met, problems of cracking, deformation and the like of the flooring due to change of temperature are avoided, and the service life of the flooring is prolonged.

Owner:JIANGXI NANFENG ZHENYU IND GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com