Manufacturing process of outdoor strand woven bamboo floors

A manufacturing process, heavy bamboo technology, applied in the field of outdoor heavy bamboo flooring manufacturing process, can solve the problems of poor compression resistance, impact on aesthetics, long carbonization time, etc., achieve no loss of mechanical properties, improve dimensional stability, and consolidate The effect of stabilizing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

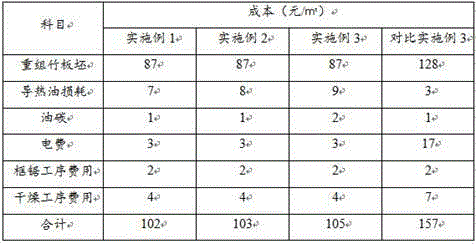

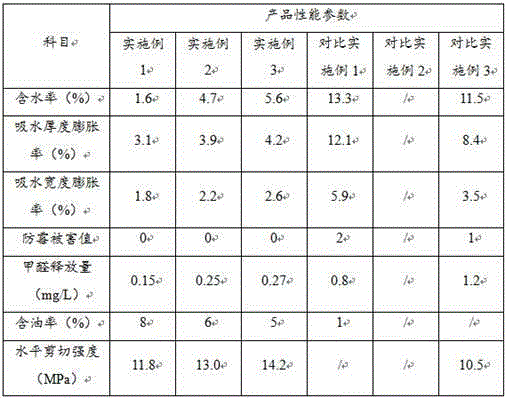

Embodiment 1

[0029] 1. Cold pressing of bamboo

[0030] (1) Lay the soaked and dried bamboo shreds or slices into a press and cold-press them into squares.

[0031] (2) Send the above-mentioned square materials into the tunnel for thermal curing;

[0032] (3) Take out the heat-cured square material from the mold.

[0033](4) Process the square material taken out of the mold into a slab.

[0034] 2. Oil heat treatment

[0035] Slowly put the slab into a 100°C alkylbenzene-type heat-conducting oil bath for 1 hour, and when placed, the direction of the vascular bundles of the bamboo is perpendicular to the surface of the hydrophobic medium. When the temperature of the heat transfer oil is 50°C, take out the heavy bamboo flooring and let it cool down to room temperature naturally.

[0036] 3. Surface treatment

[0037] Coat a layer of vegetable oil on the outer surface of heavy bamboo floor after oil heat treatment.

Embodiment 2

[0039] 1. Cold pressing of bamboo

[0040] (1) Lay the soaked and dried bamboo shreds or slices into a press and cold-press them into squares.

[0041] (2) Send the above-mentioned square materials into the tunnel for thermal curing;

[0042] (3) Take out the heat-cured square material from the mold.

[0043] (4) Process the square material taken out of the mold into a slab.

[0044] 2. Oil heat treatment

[0045] Slowly put the slab into the alkylbenzene type heat transfer oil at 200°C for 2 hours, and the direction of the bamboo vascular bundles is perpendicular to the surface of the hydrophobic medium. When the temperature of the heat transfer oil is 200°C, take out the heavy bamboo flooring and let it cool down to room temperature naturally.

[0046] 3. Surface treatment

[0047] Coat a layer of vegetable oil on the outer surface of heavy bamboo floor after oil heat treatment.

Embodiment 3

[0049] 1. Cold pressing of bamboo

[0050] (1) Lay the soaked and dried bamboo shreds or slices into a press and cold-press them into squares.

[0051] (2) Send the above-mentioned square materials into the tunnel for thermal curing;

[0052] (3) Take out the heat-cured square material from the mold.

[0053] (4) Process the square material taken out of the mold into a slab.

[0054] 2. Oil heat treatment

[0055] Slowly put the slab into the 300°C alkylbenzene heat transfer oil and soak it for 10 hours. When putting it in, the direction of the bamboo vascular bundle is perpendicular to the surface of the hydrophobic medium. When the temperature of the heat transfer oil is 170°C, take out the heavy bamboo flooring and let it cool down to room temperature naturally.

[0056] 3. Surface treatment

[0057] Coat a layer of vegetable oil on the outer surface of heavy bamboo floor after oil heat treatment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com