Bamboo-wood furniture production paint brushing device with drying function

A technology for furniture and utensils, which is applied in the field of paint brushing devices with drying function for the production of bamboo and wood furniture, which can solve the problems affecting the paint effect of bamboo and wood furniture, dead angles, uneven application, etc., and achieve convenient and fast paint process, The effect of improving efficiency and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

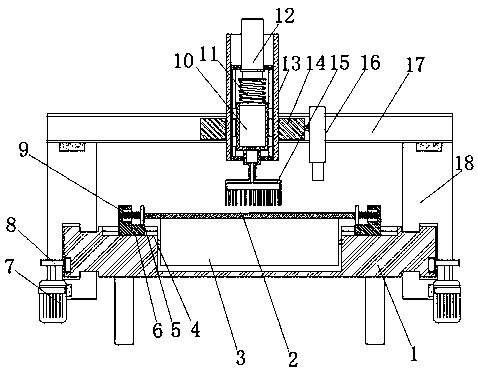

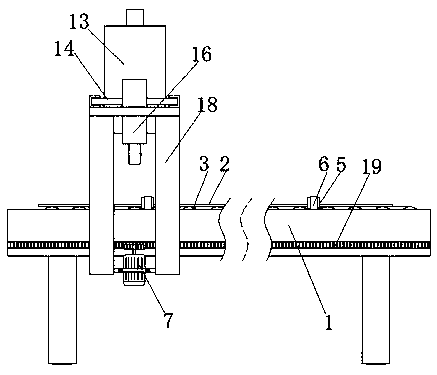

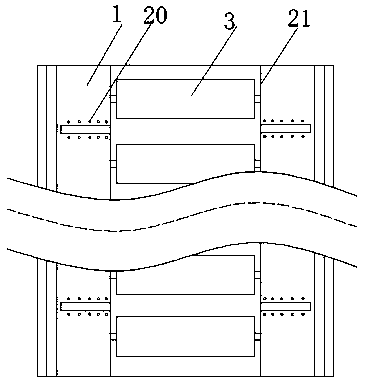

[0022] refer to Figure 1-3 , a paint brushing device with a drying function for the production of bamboo and wood furniture, comprising an operating table 1 and a bamboo floor body 2, a rectangular groove 21 is opened in the middle of the upper surface of the operating table 1, and the middle of the rectangular groove 21 is connected with etc. Conveyor rollers 3 with a distance distribution, the upper surface of the operating platform 1 close to the opposite sides of the rectangular groove 21 are provided with an inverted T-shaped chute 4, and a T-shaped slider 6 is slidably connected to the T-shaped chute 4, and the operating platform Both sides of 1 are slidably c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com