Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1054results about How to "Evenly painted" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

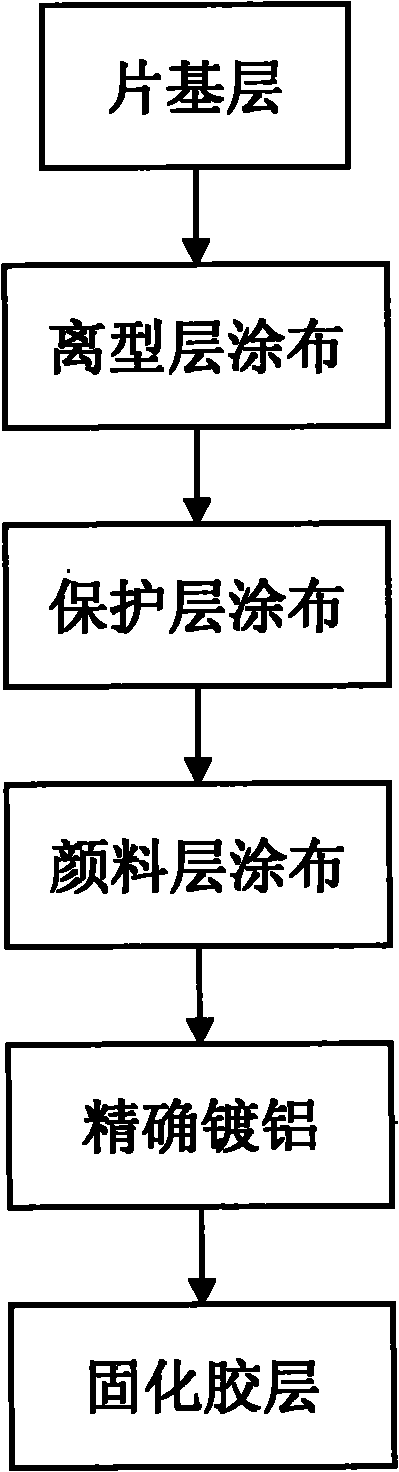

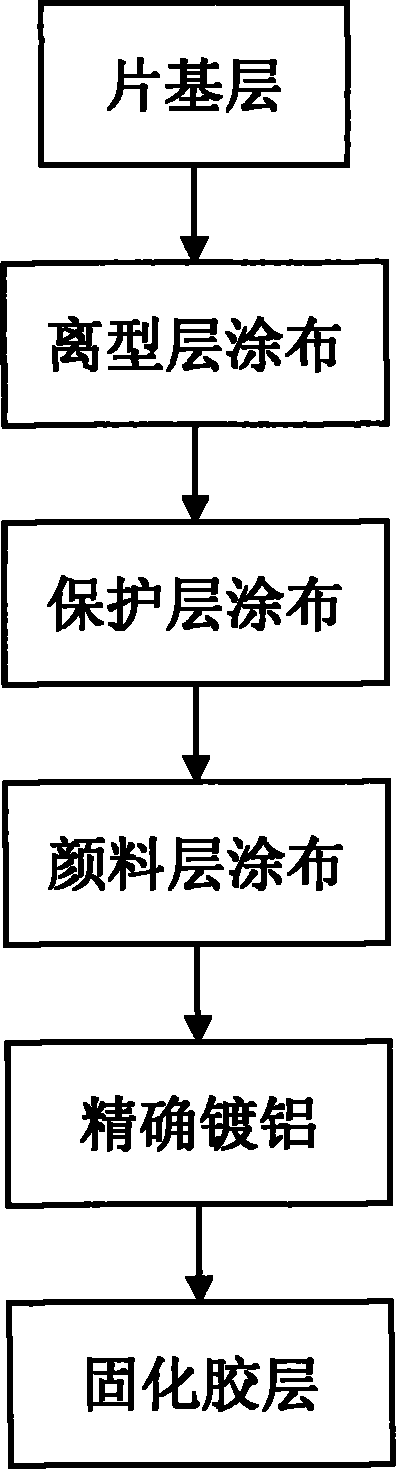

Production method of hot stamping foil

ActiveCN101879819ASolving Hot Stamping RequirementsEvenly paintedCoatingsThermographyPolyvinyl butyralHot stamping

The invention discloses a production method of hot stamping foil, which adopts six production process flows: release coating, protective layer coating, color layer coating, accurate aluminizing and curing glue layer coating. In the whole production process, water soluble glue, water soluble ink and water soluble gloss oil are used to realize the integrated production of the hot stamping foil, methacrylates and monomers which are emulsified and polymerized are mixed in a certain ratio, a dye leveler, thickener and the like are added in the mixture, the resulting product is coated and dried, polyvinyl butyral-based glue is coated, and the whole production of the hot stamping foil is finished. The hot stamping foil produced by the process has the characteristics of energy conservation, environmental protection and sanitation.

Owner:江苏卫星新材料股份有限公司

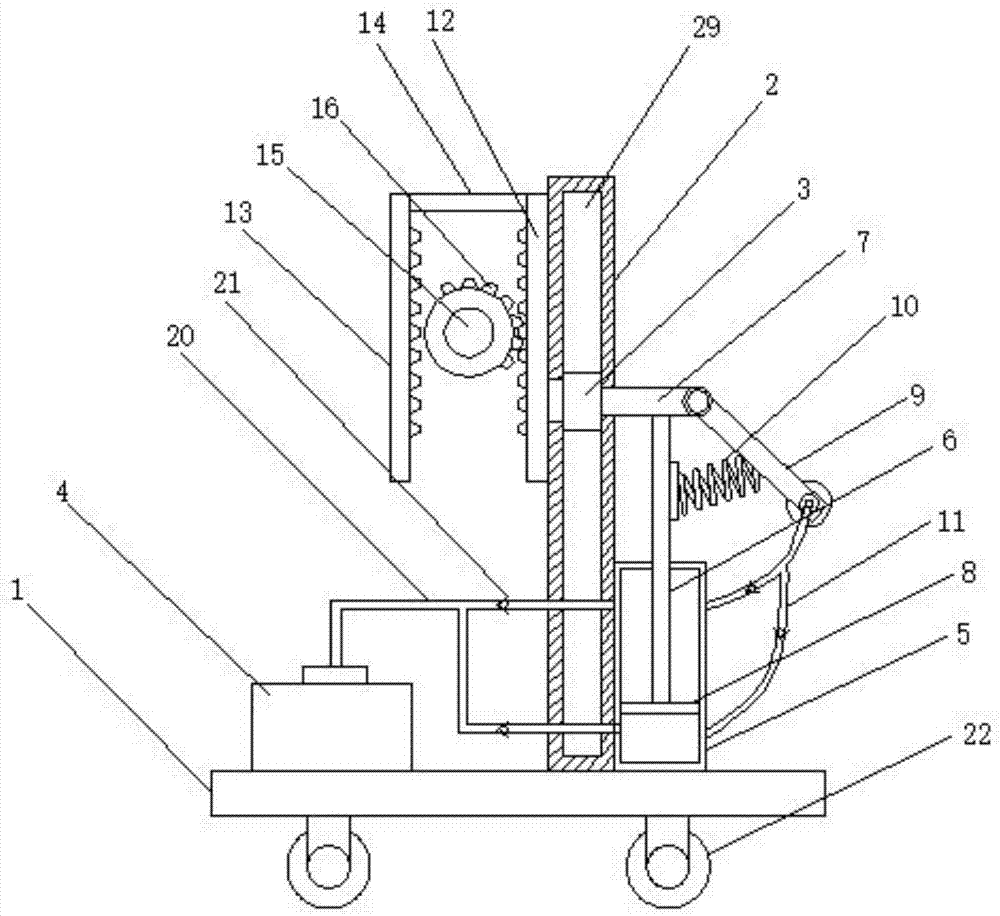

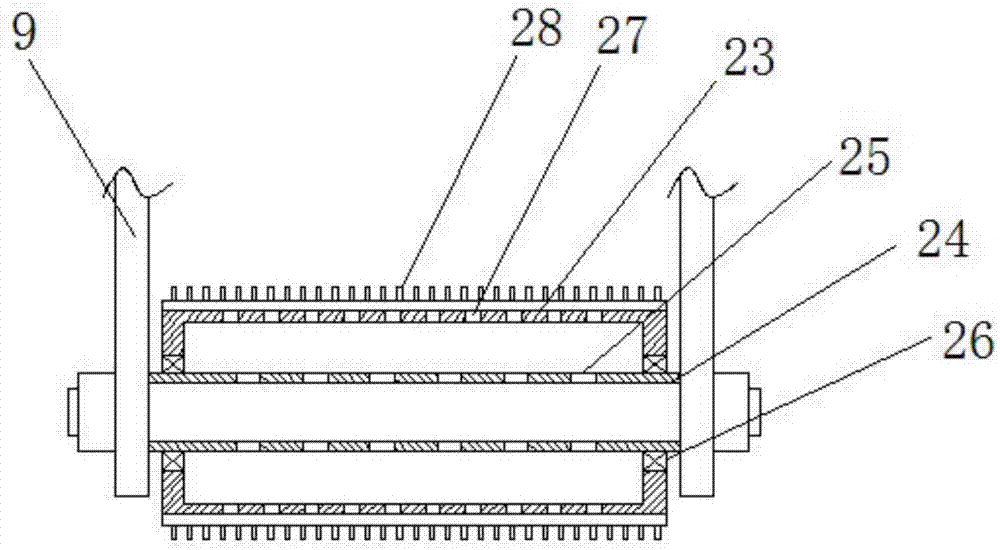

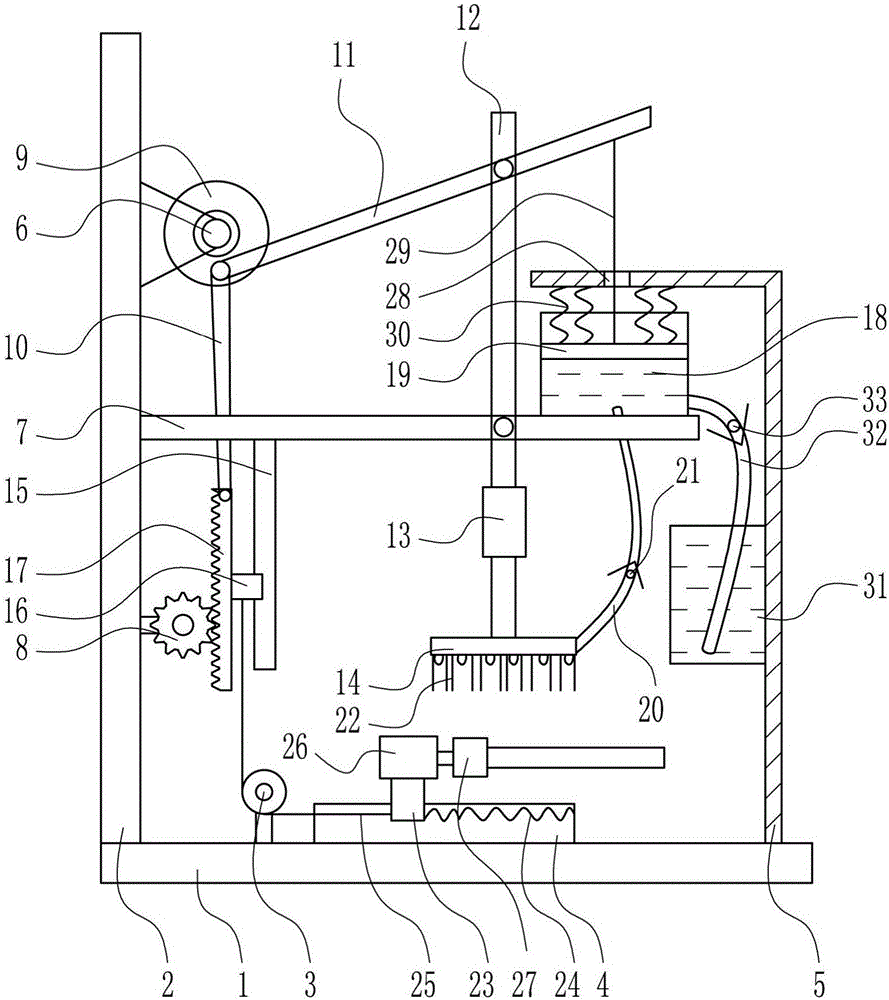

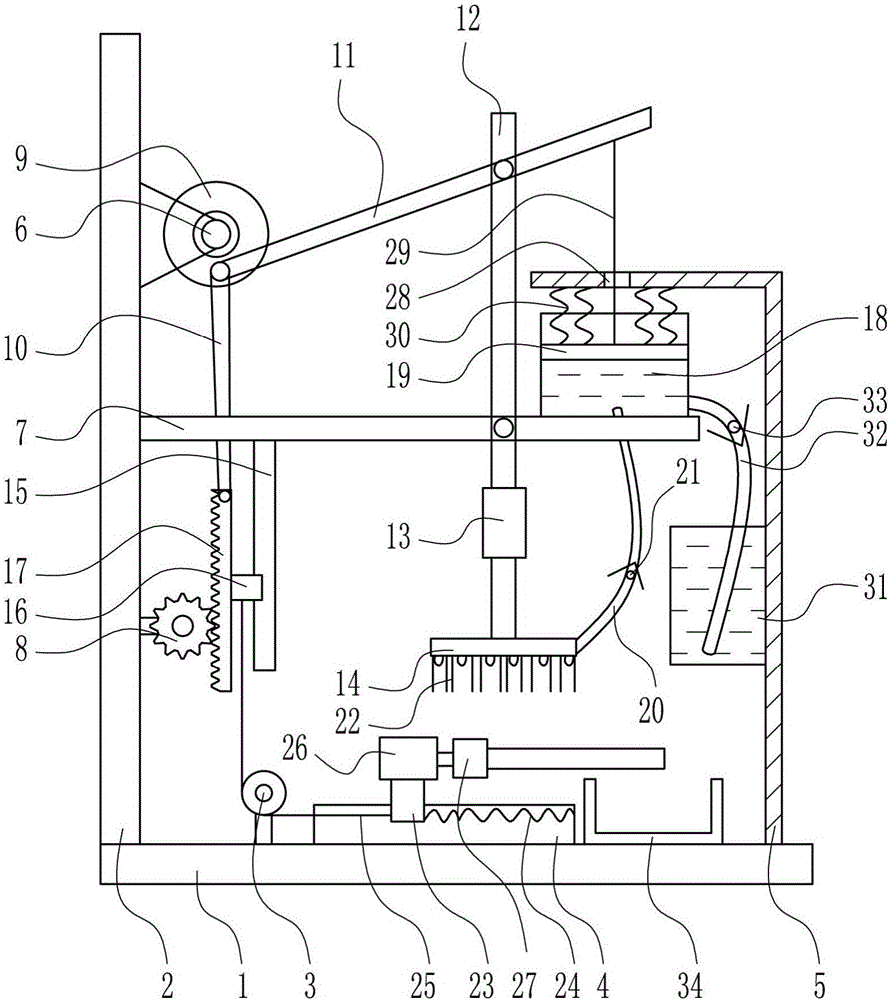

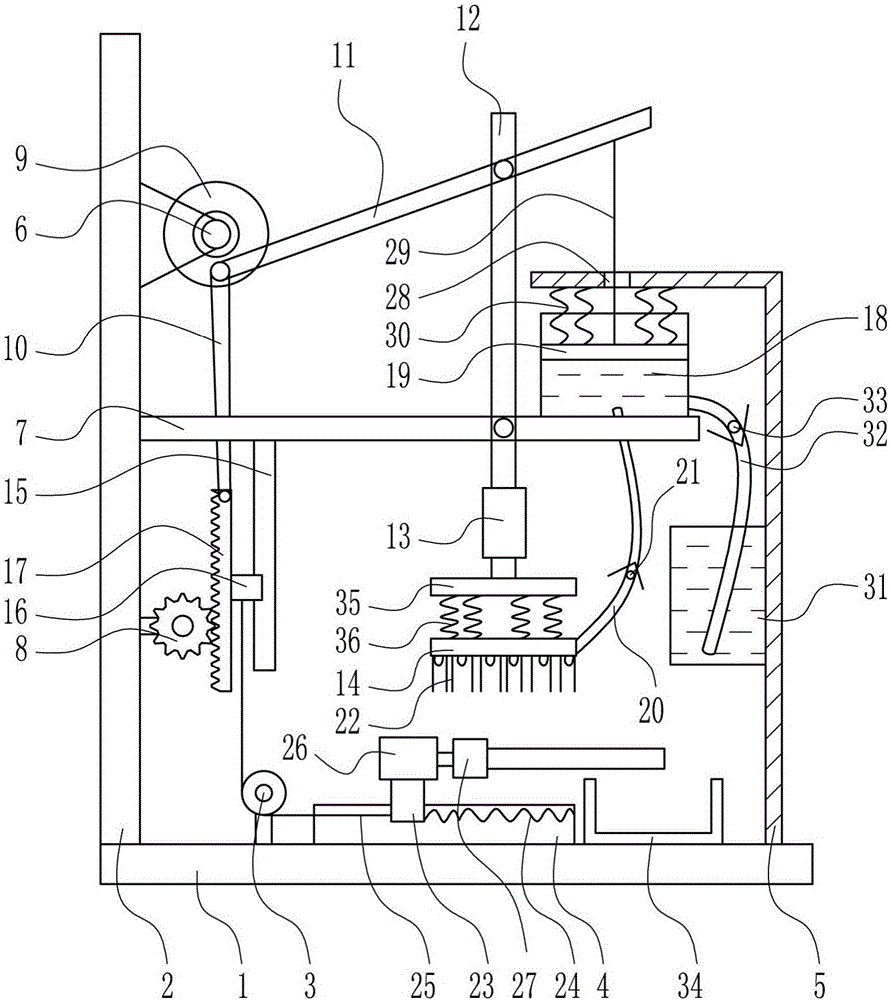

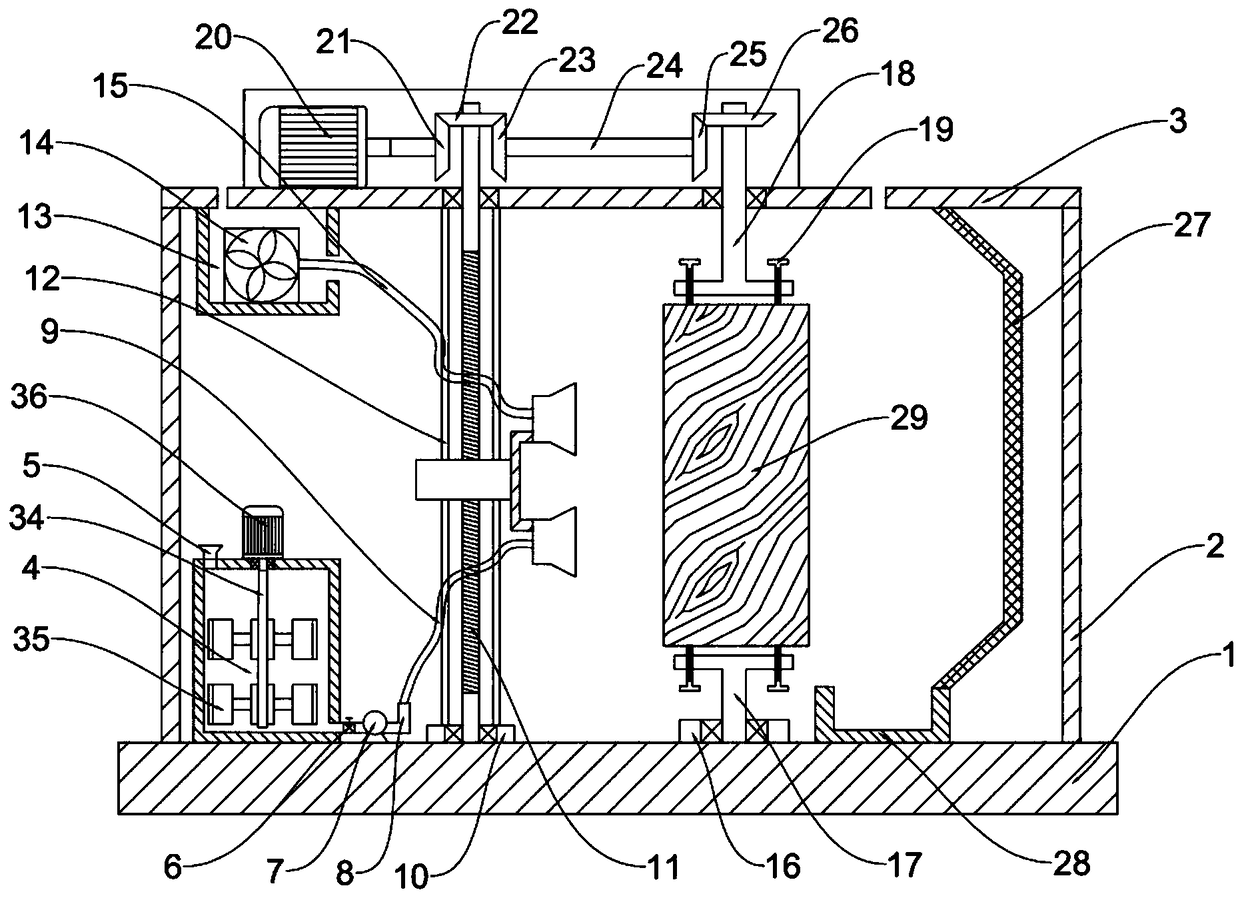

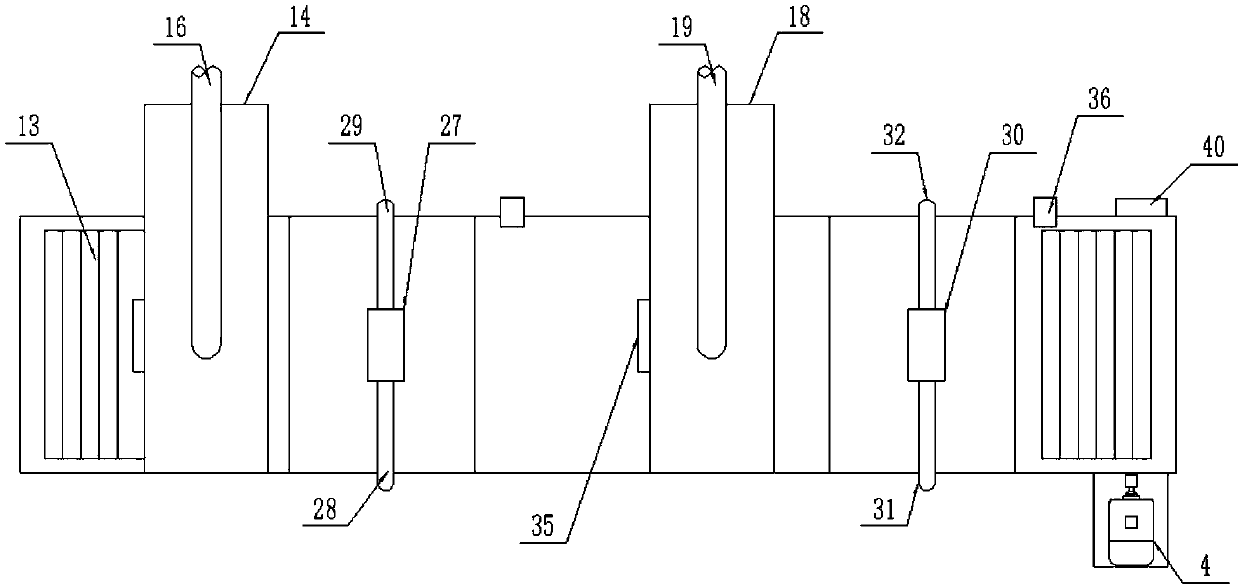

Continuous building wall painting device

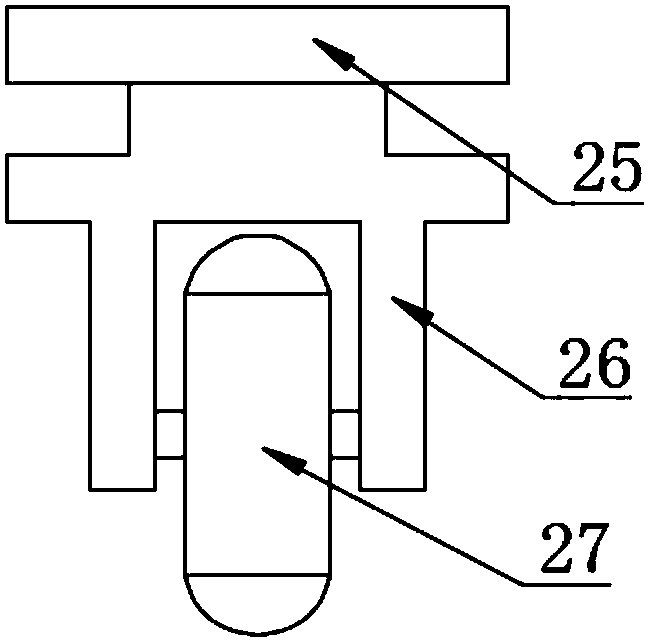

InactiveCN107288320ASimple structureImprove painting efficiencyBuilding constructionsArchitectural engineeringPiston rod

The invention discloses a continuous building wall painting device. The continuous building wall painting device comprises a transverse plate. A vertical supporting plate, a paint box and a cylinder body are arranged on the transverse plate. Both the upper end and the lower end of the cylinder body communicate with the paint box through feed pipes. Two opposite lifting sliding grooves are further formed in the inner wall of the vertical supporting plate. A moving rod is arranged between the two lifting sliding grooves. The two ends of the moving rod are slidably connected with the lifting sliding grooves. A baffle is arranged on the right side of the moving rod. A mounting frame is arranged at the right end of the baffle. A piston is arranged in the cylinder body. A piston rod is arranged at the upper end of the piston, and the top end of the piston rod is fixedly connected with the baffle. A feed cylinder is mounted on the mounting frame. A painting cylinder is arranged on the outer side wall of the feed cylinder. One end of the feed cylinder is connected with the upper end and the lower end of the cylinder body through discharging pipes. The continuous building wall painting device is simple in structure, capable of achieving continuous spraying and painting, high in painting efficiency, uniform in painting, easy and convenient to operate, and high in practicability.

Owner:吴秀女

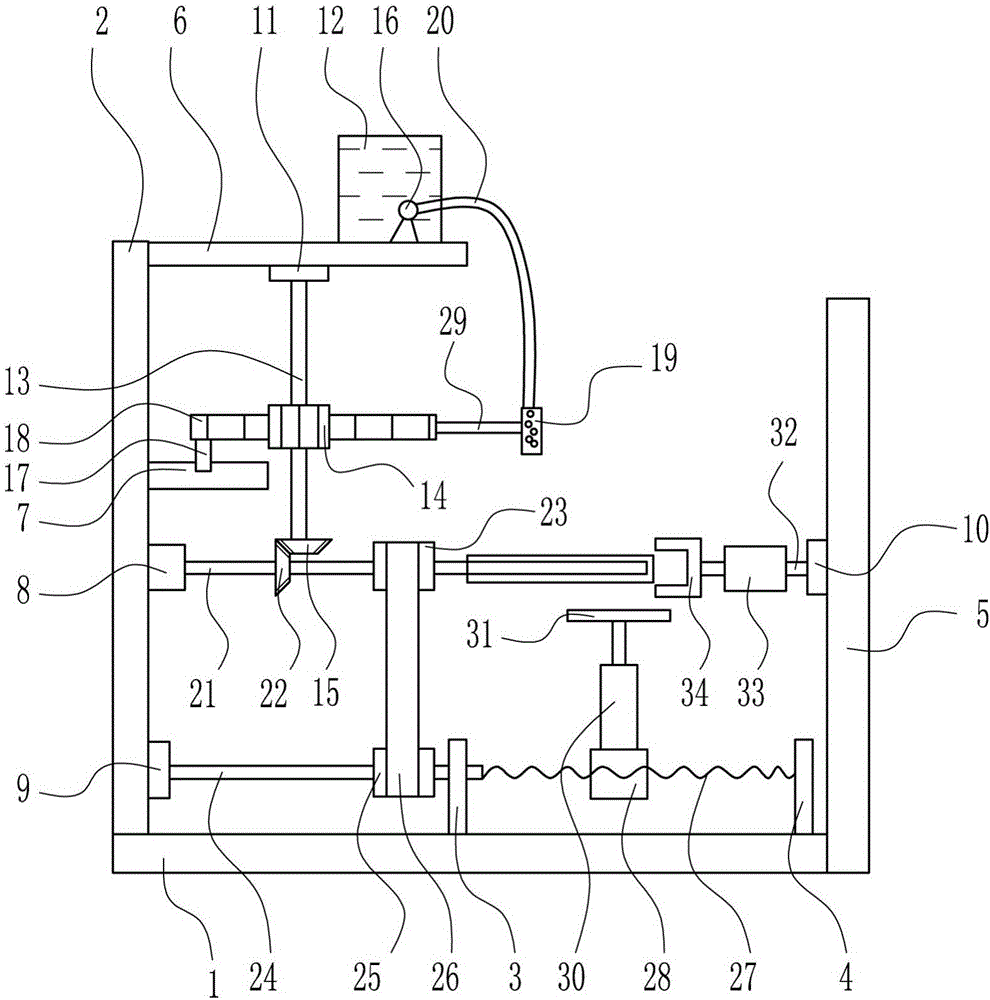

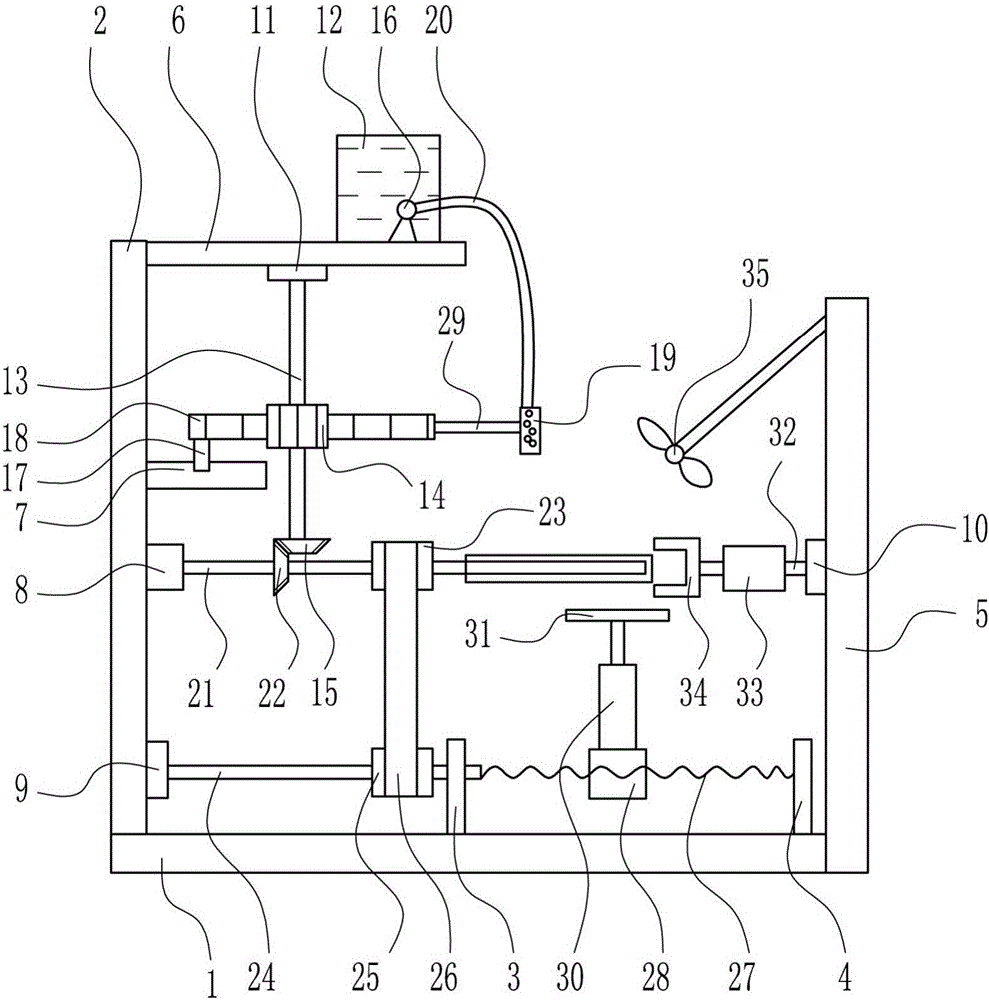

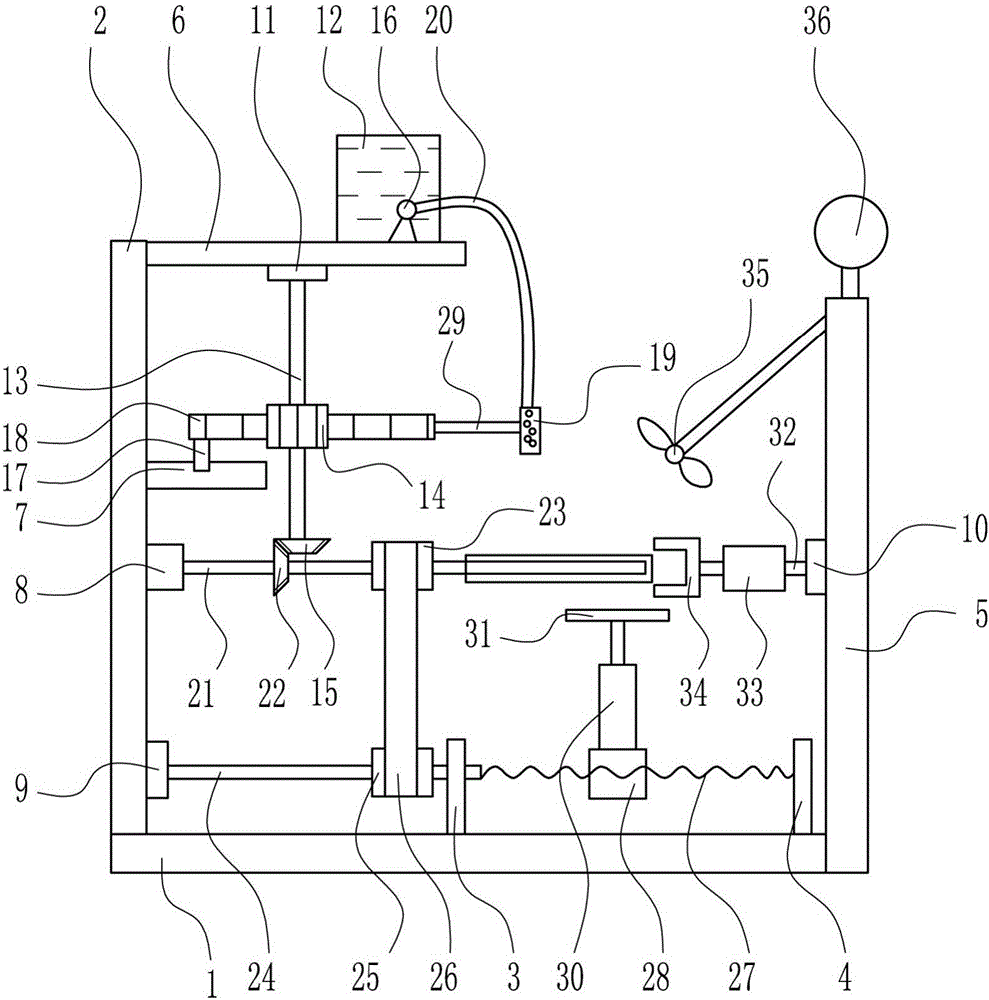

Efficient paint spraying device for spanner for hardware manufacturing

ActiveCN106140538ASave resourcesPrevent fallingLiquid surface applicatorsSpraying apparatusLacquerWrench

The invention relates to a paint spraying device, in particular to an efficient paint spraying device for a spanner for hardware manufacturing. The efficient paint spraying device for the spanner for hardware manufacturing can spray paint more uniformly. The efficient paint spraying device for the spanner for hardware manufacturing comprises a paint inlet hopper, a first sliding rail, a second bearing seat, a framework, a lead screw, a first sliding block, a second sliding rail, a movable rod, a paint box, a paint pump, a hose, a connecting rod and the like, wherein the lead screw is installed on the second bearing seat and provided with a nut; the nut is matched with the lead screw; the lower end of the lead screw is connected with a second bevel gear; the first sliding rail is provided with the first sliding block; and the left end of the nut is connected with the right end of the first sliding block. The efficient paint spraying device for the spanner for hardware manufacturing sprays paint more uniformly. A collecting tank is arranged, so that resources are effectively saved. A covering plate is arranged, so that impurities or dust is prevented from falling into the paint box through the paint inlet hopper.

Owner:无锡市丰伟金属制品有限公司

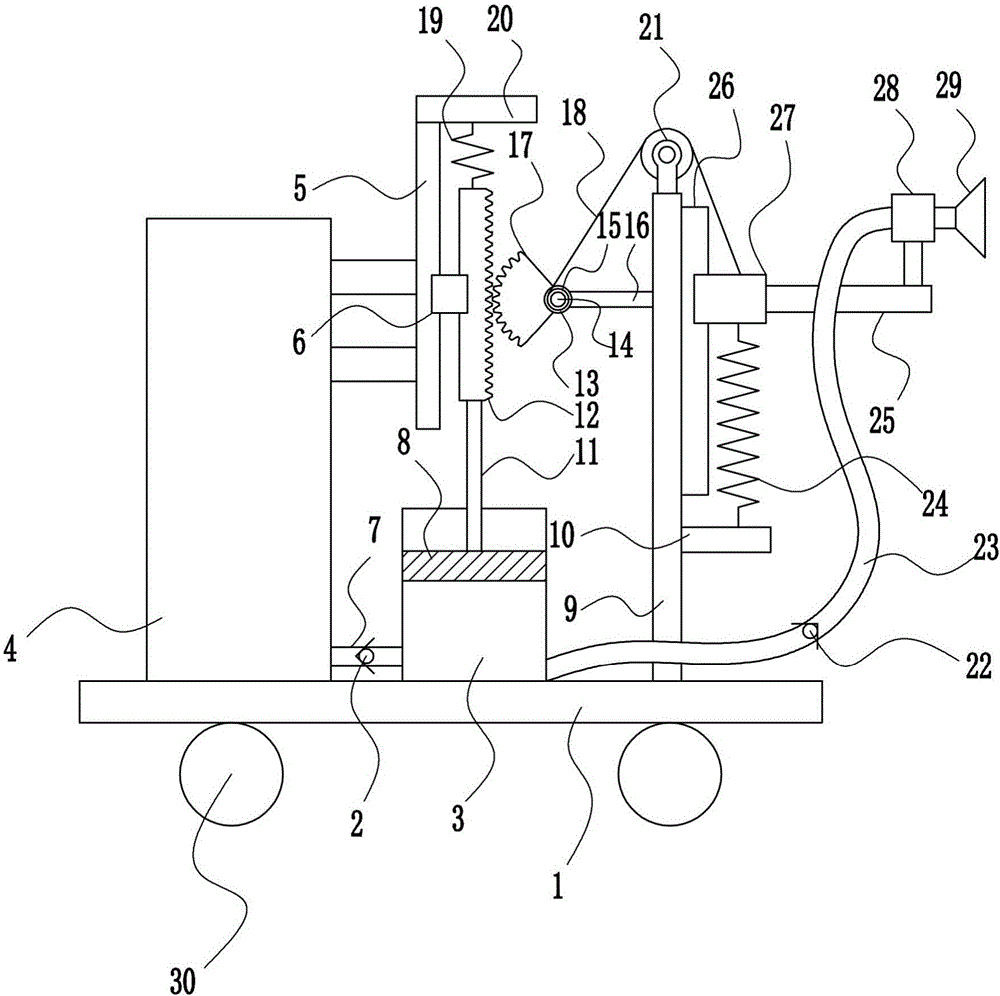

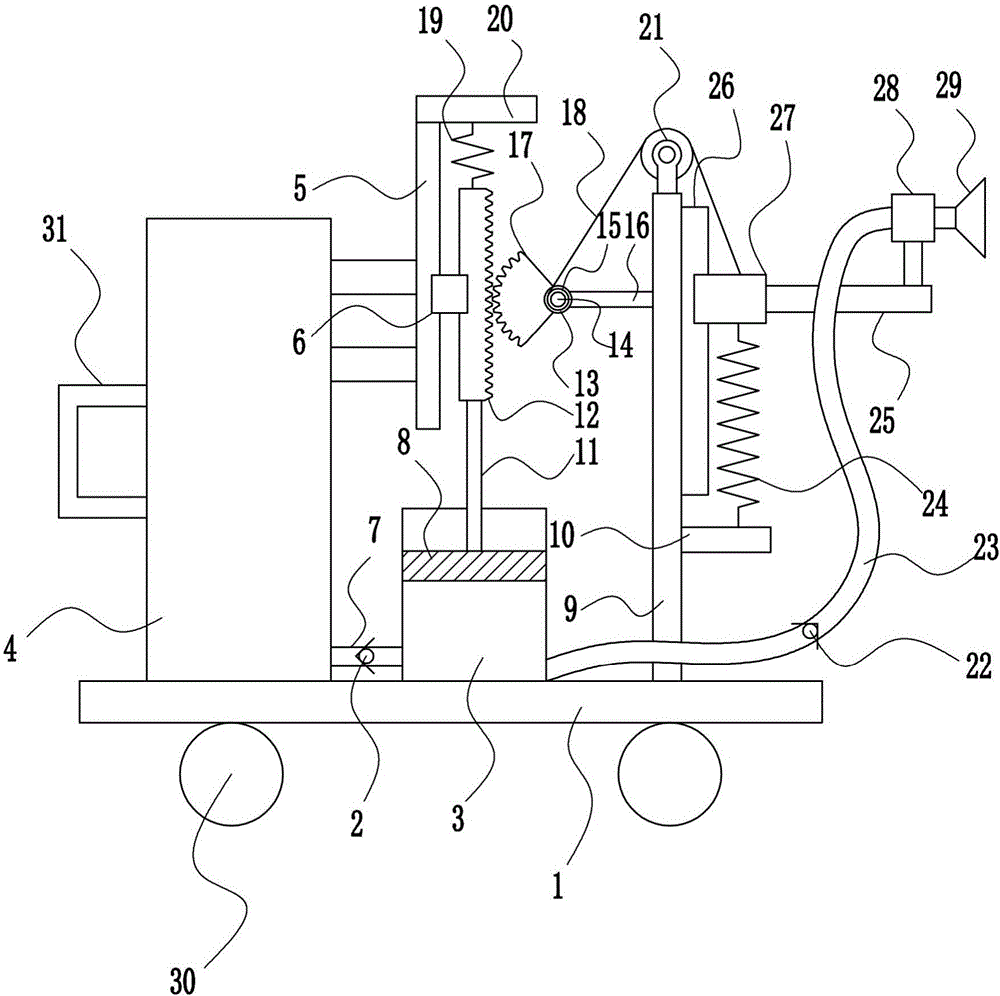

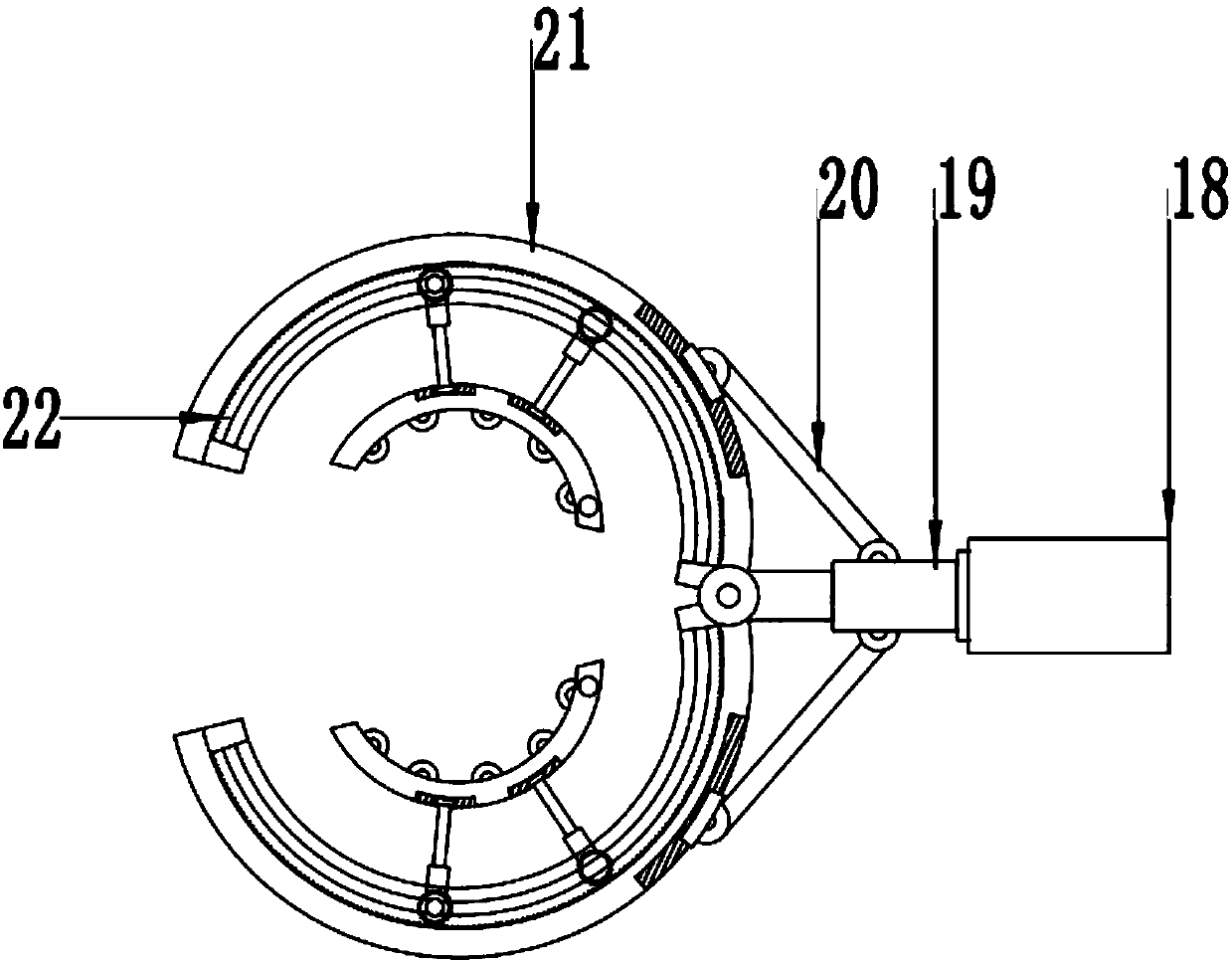

Efficient paint spraying device of circular anti-collision barrel used for traffic bridge

InactiveCN107185750ADoes not affect the painting effectFully paintedPretreated surfacesLiquid spraying apparatusTraffic crashBolt connection

The invention relates to a circular anti-collision barrel paint spraying device for traffic bridges, in particular to a high-efficiency paint spraying device for circular anti-collision barrels for traffic bridges. The technical problem to be solved by the present invention is to provide a high-efficiency painting device for circular anti-collision barrels for traffic bridges, which saves time and labor, sprays paint evenly, does not need to spray paint on the anti-collision barrels manually, and does not cause physical discomfort. In order to solve the above-mentioned technical problems, the present invention provides such a high-efficiency paint spraying device for circular anti-collision buckets for traffic bridges, which includes a cart, a paint box, a lower hopper, a water pump, a discharge pipe, a first fixed sleeve, and a first spray head. etc.; the left side of the top of the trolley is bolted to install a paint box, and the middle of the top of the paint box is bolted to install a lower hopper. The invention achieves the effects of saving time and labor, uniform painting, no need to manually spray paint on the anti-collision barrel, and furthermore, no physical discomfort, and high working efficiency.

Owner:惠安普科优利网络科技有限公司

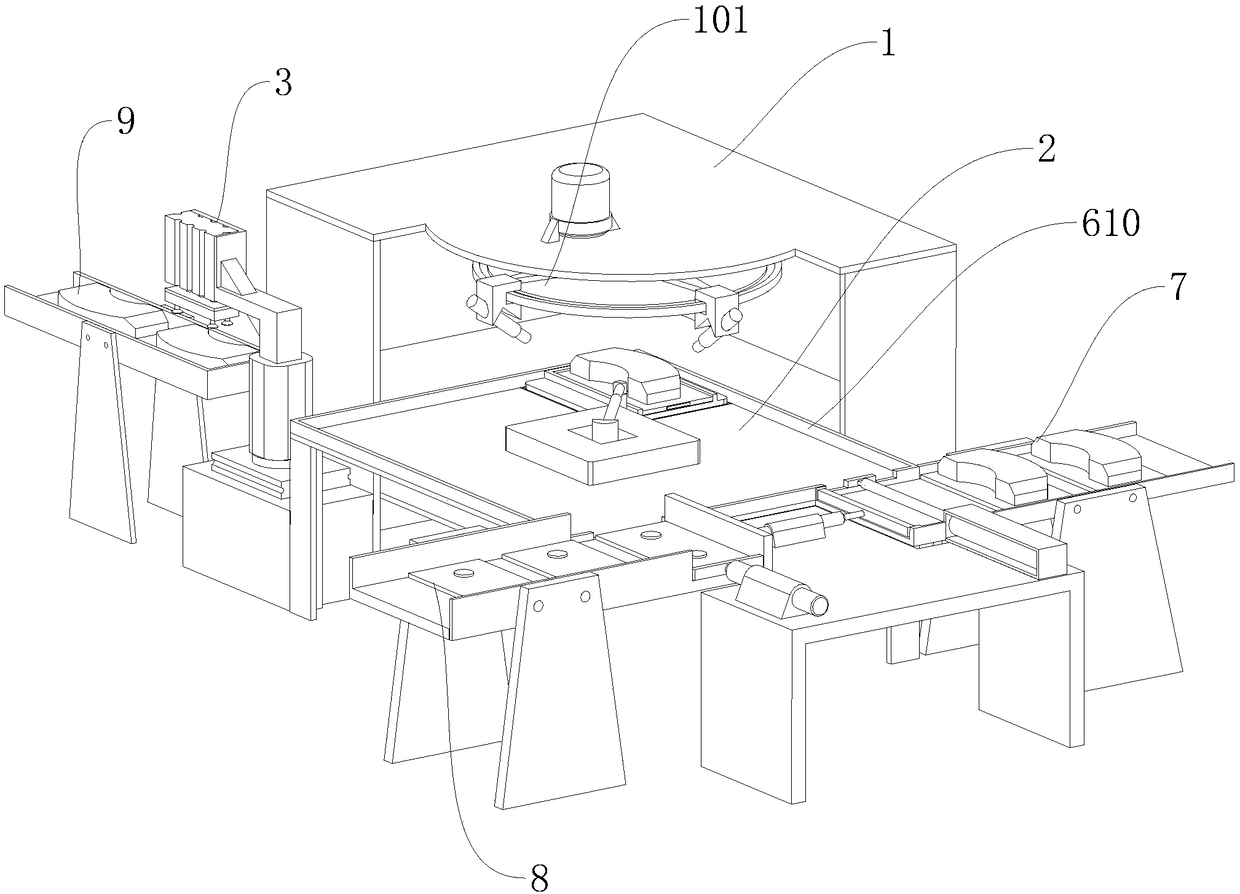

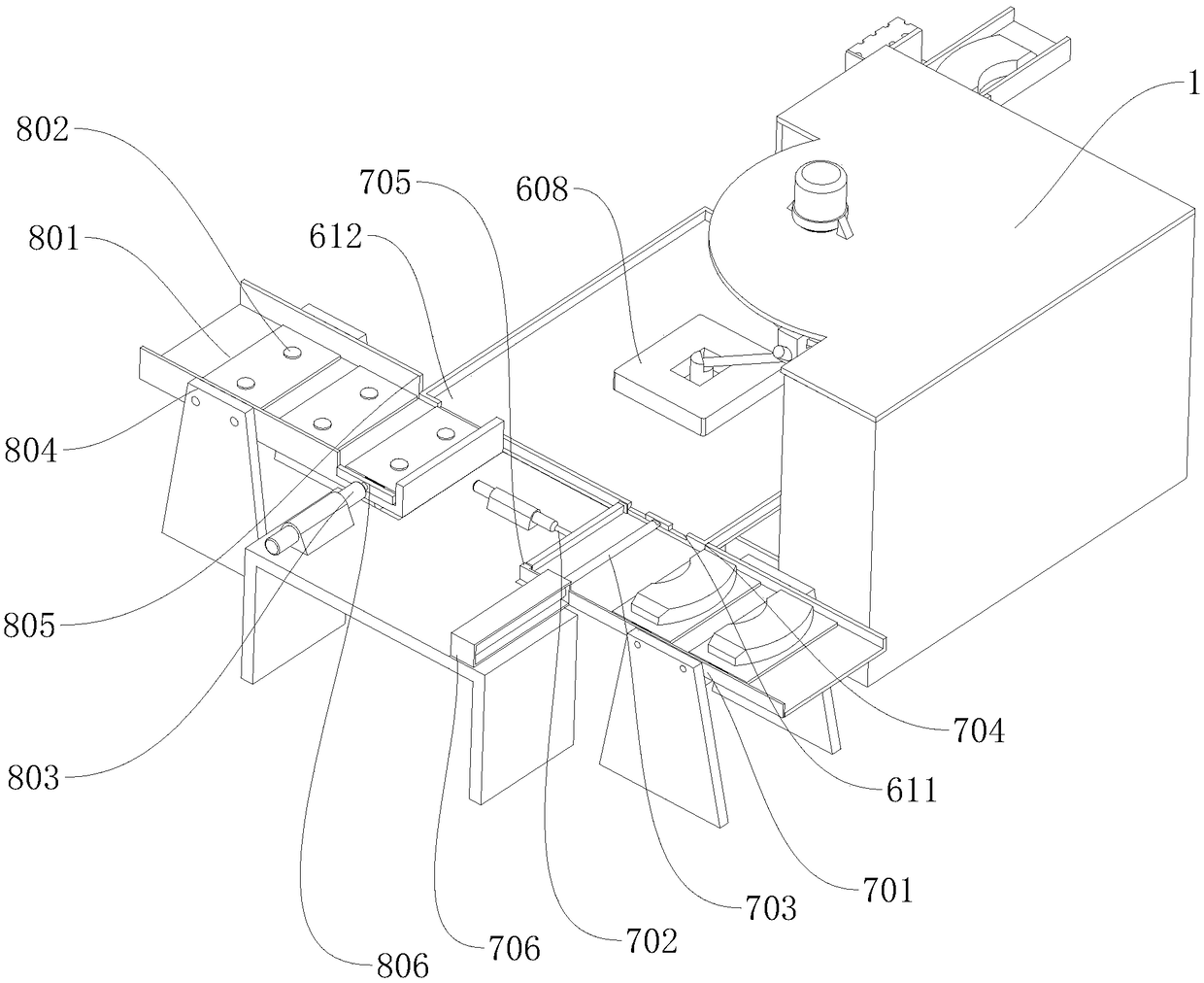

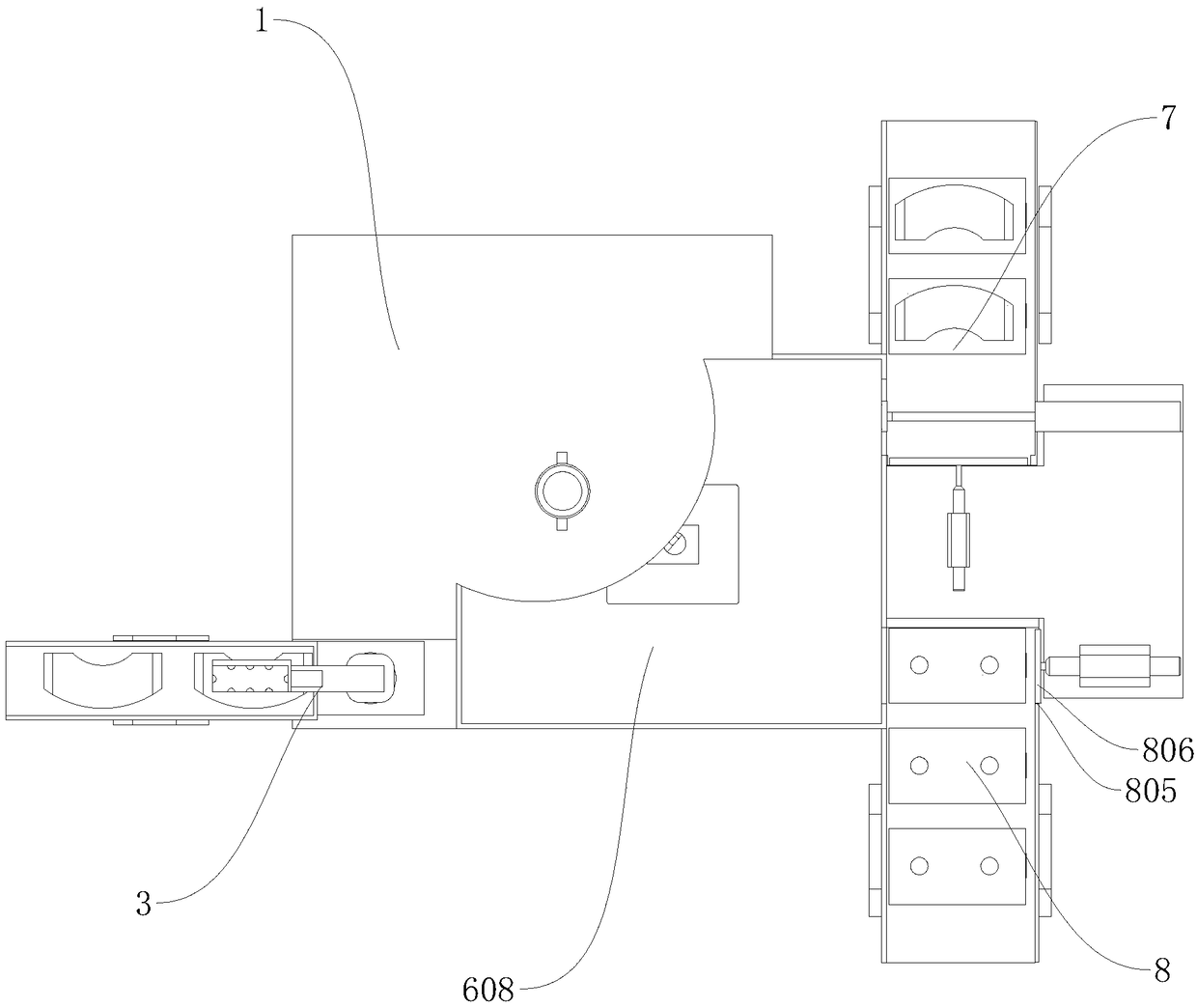

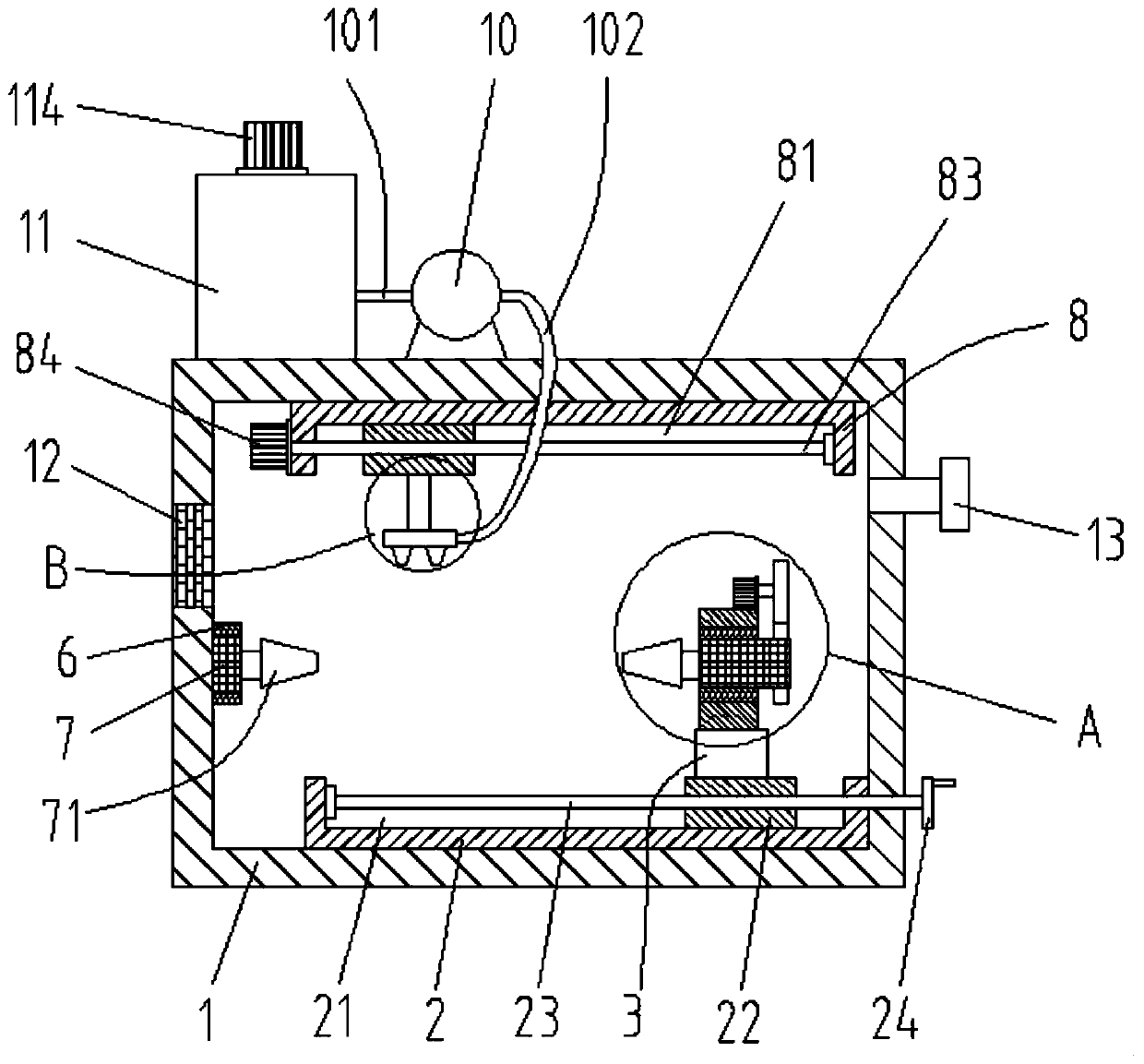

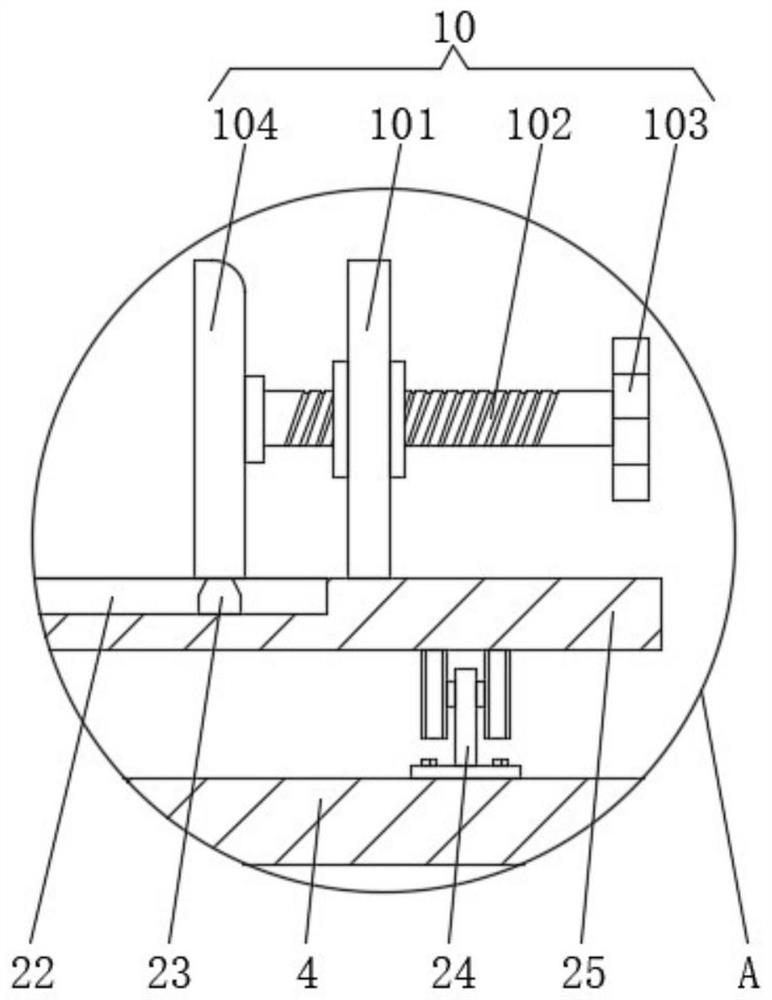

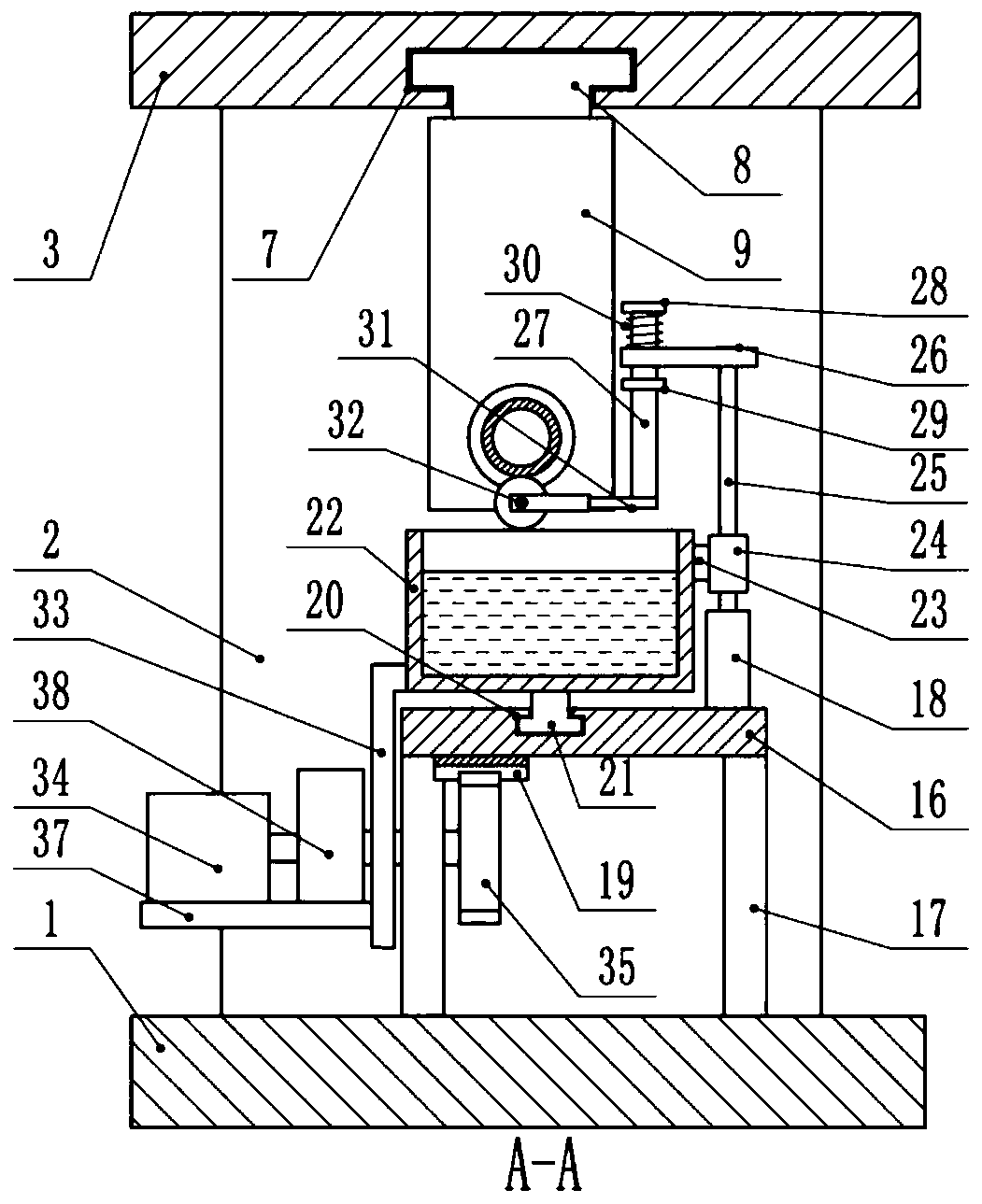

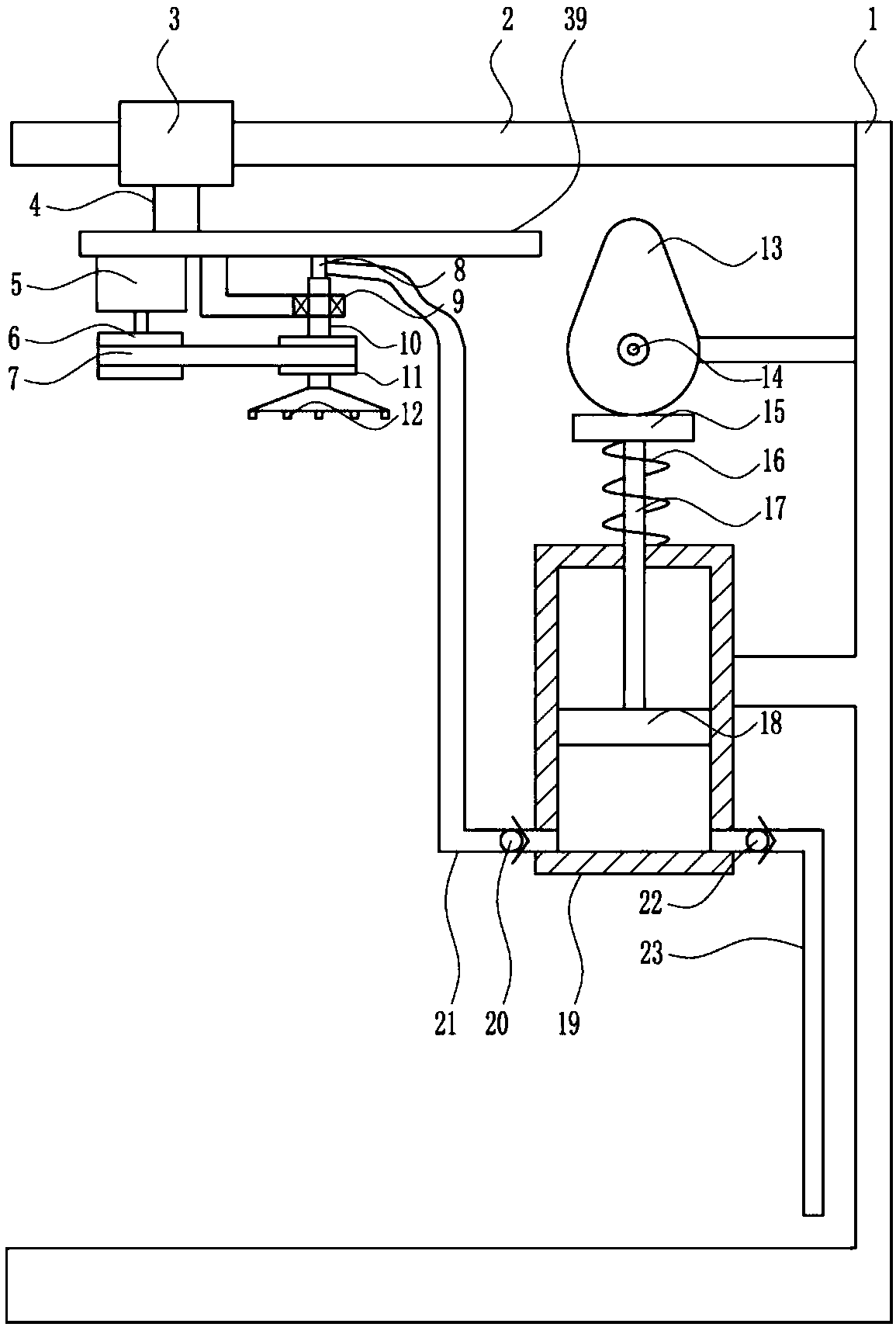

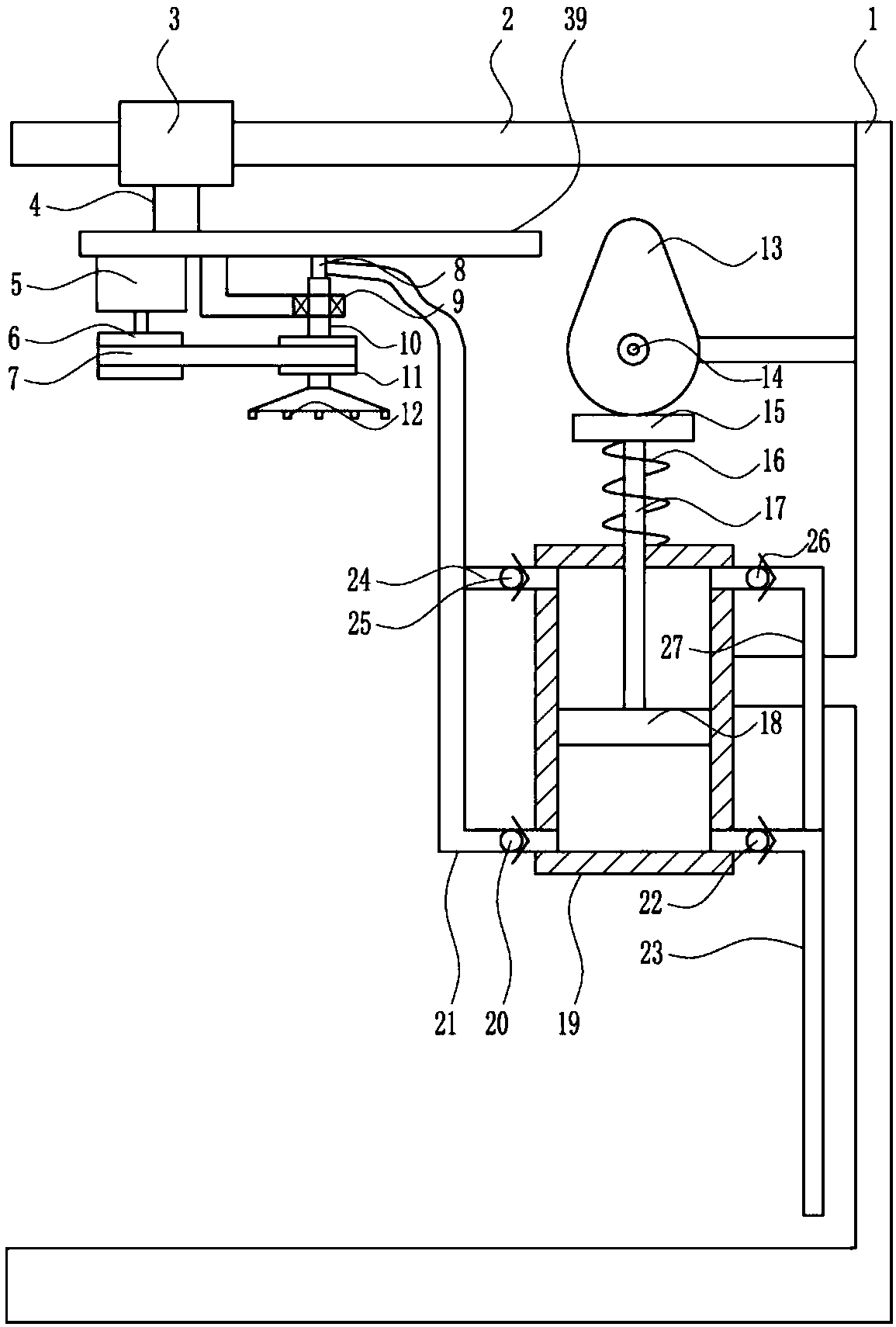

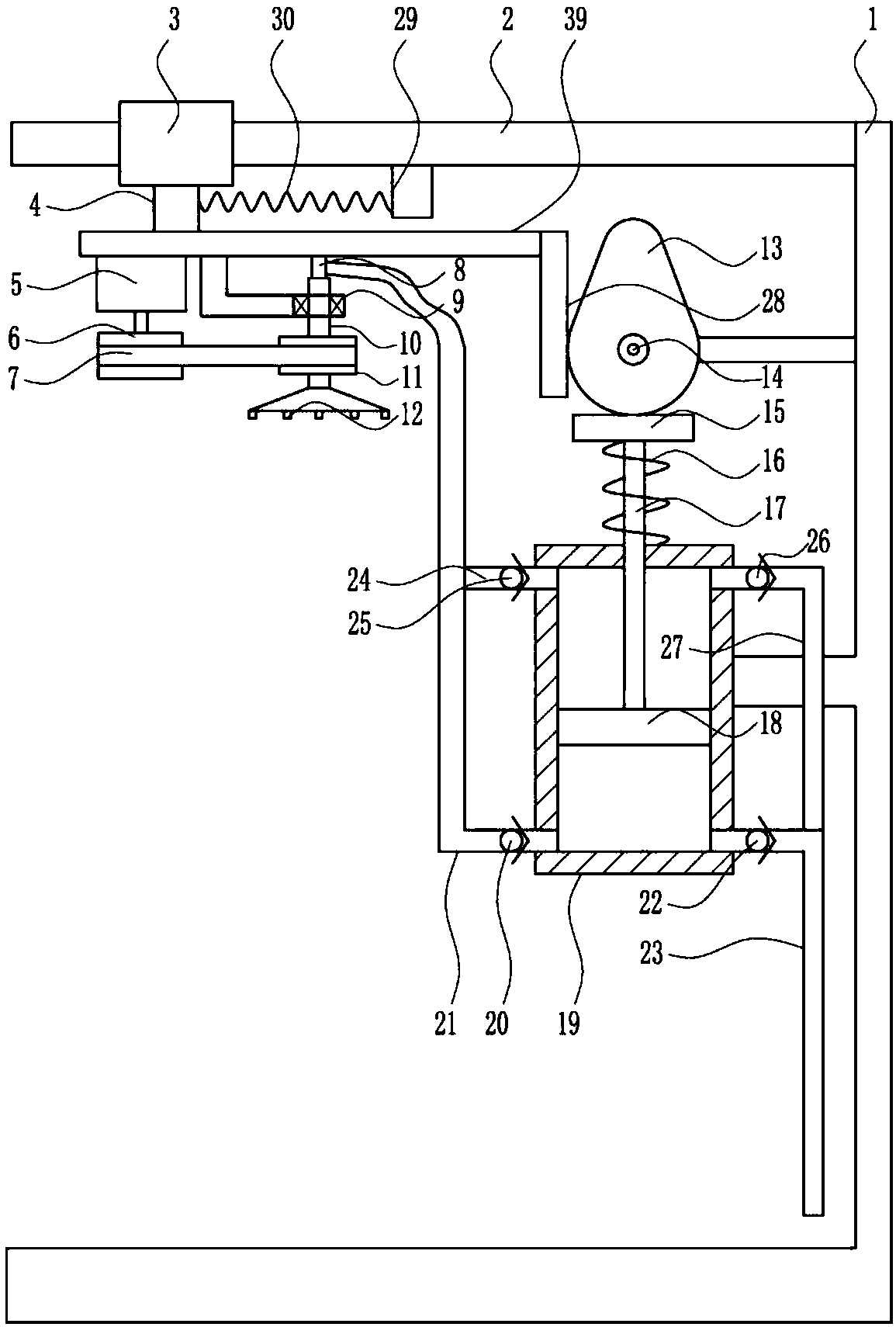

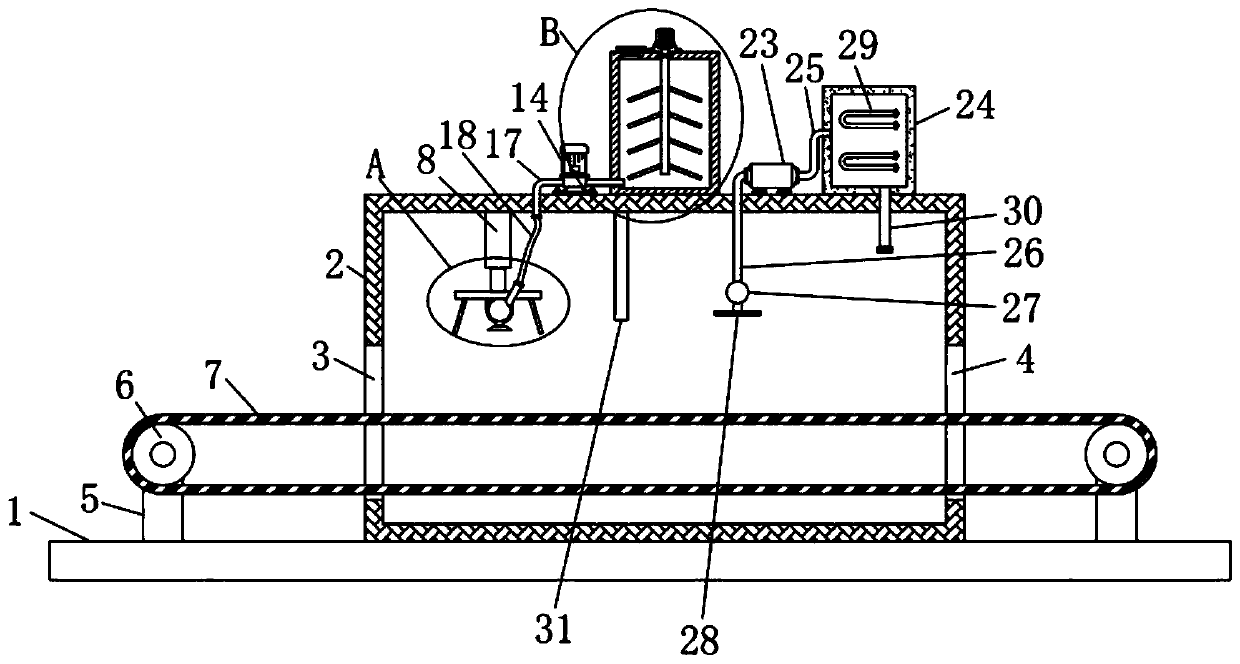

Automatic vehicle brake plate painting equipment

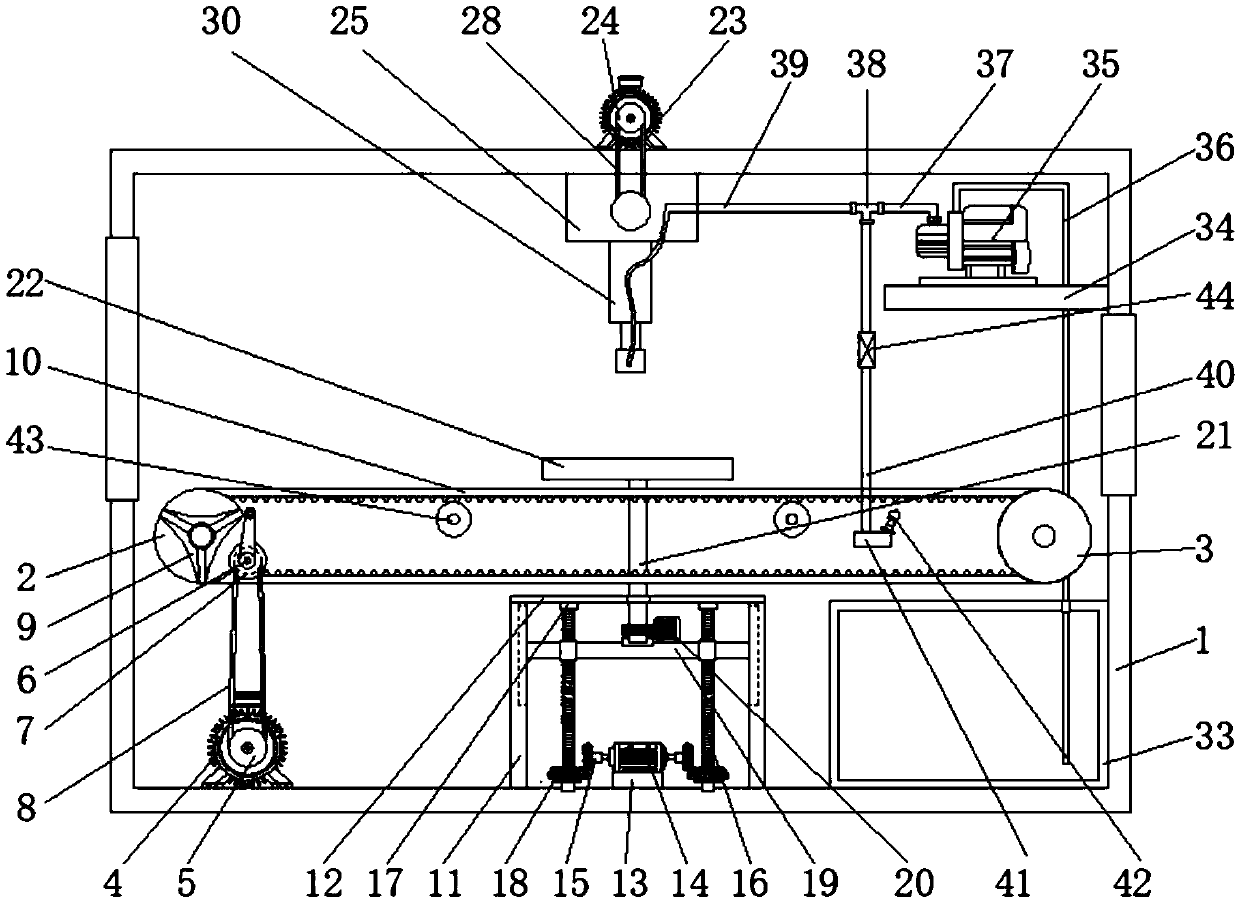

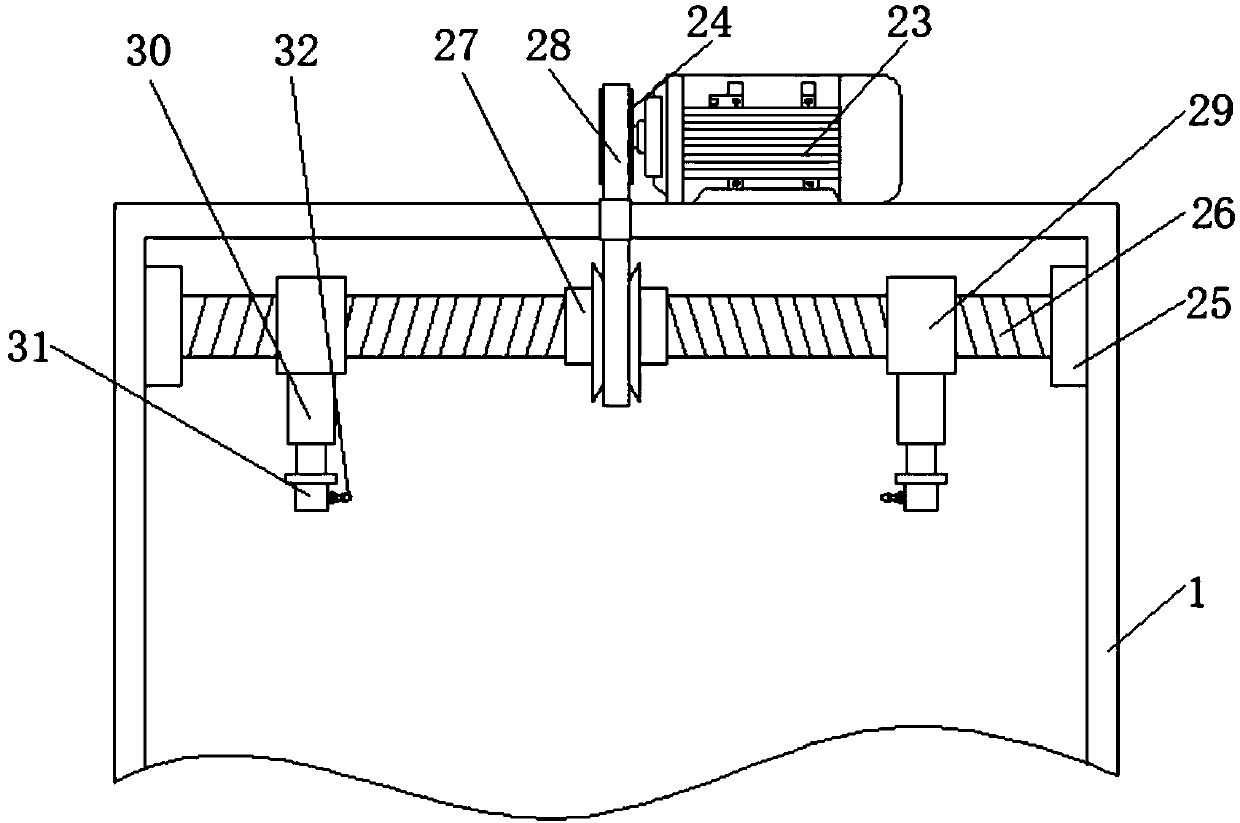

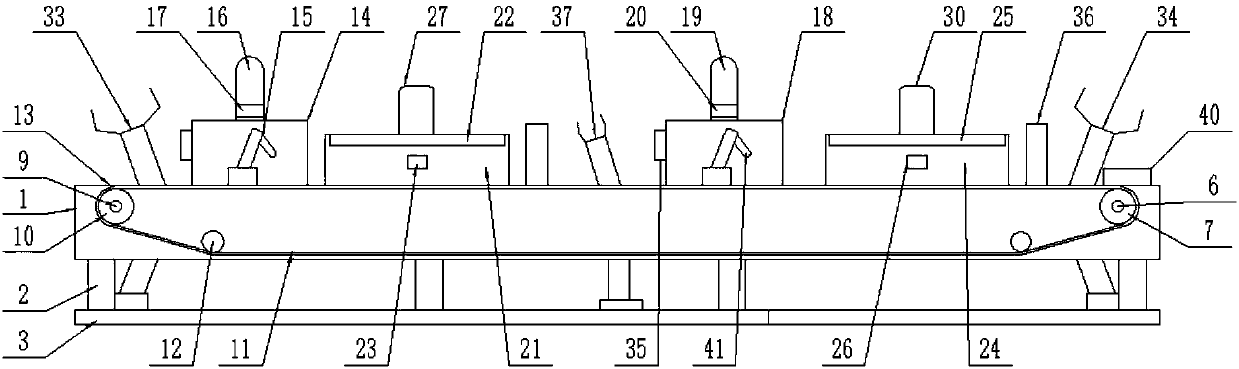

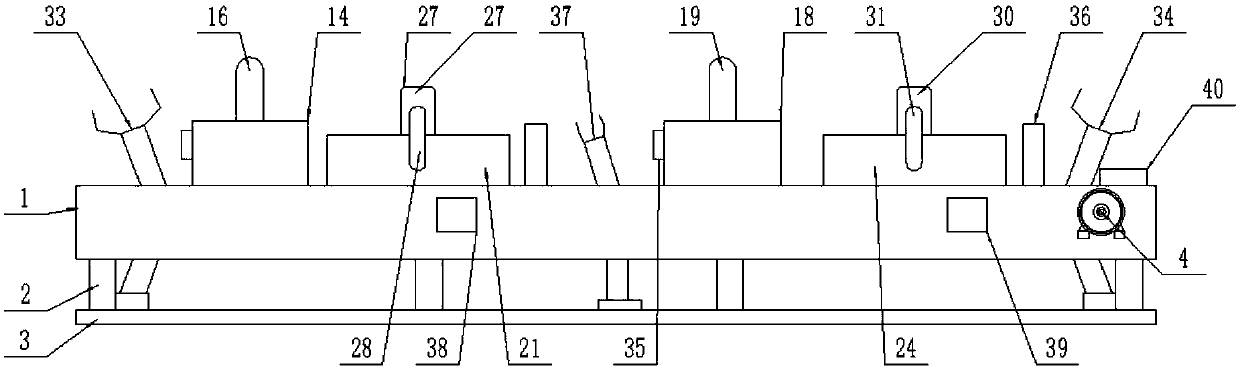

ActiveCN109332067AAchieve the effect of automatic painting processingEvenly paintedSpray boothsAssembly lineEngineering

The invention discloses automatic vehicle brake plate painting equipment. A rotating painting assembly is located above a working platform. A bearing jig is arranged at the top of the working platformby a rail moving mechanism. The rail moving mechanism comprises a telescopic rod rotating on the horizontal surface and a limiting frame used for the bearing jig to move in an attaching mode. A lifting assembly is located below the bearing jig. The rotating painting assembly is located right above a lifting receding opening. A filling assembly is provided with an iron workpiece disc. A feeding assembly is located outside a workpiece feeding opening and is horizontally arranged. The filling mechanism and the feeding mechanism are symmetrically arranged on two sides of the working platform. A loading assembly is provided with a material conveying arm used for moving brake plates. During operation, the brake plates are positioned at an assembly line, the brake plates are automatically conveyed to the jig of the equipment by the material conveying arm arranged beside the assembly line, the rotating painting assembly and the lifting assembly are arranged at the equipment, and therefore theuniform painting effect can be achieved during painting. The feeding assembly is arranged, and therefore the automatic painting effect is achieved, and production efficiency is improved.

Owner:山东高新创达科技创业服务有限公司

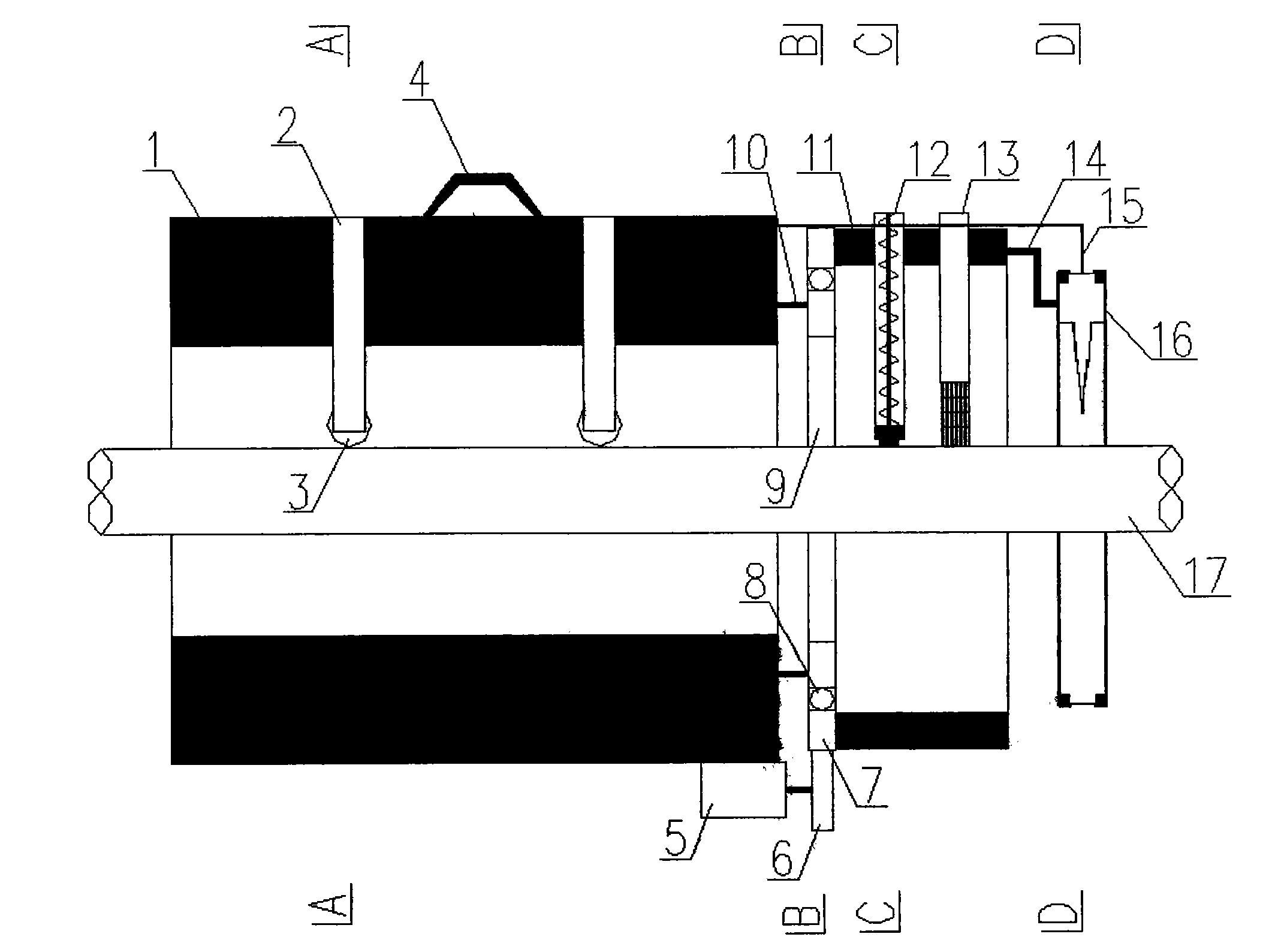

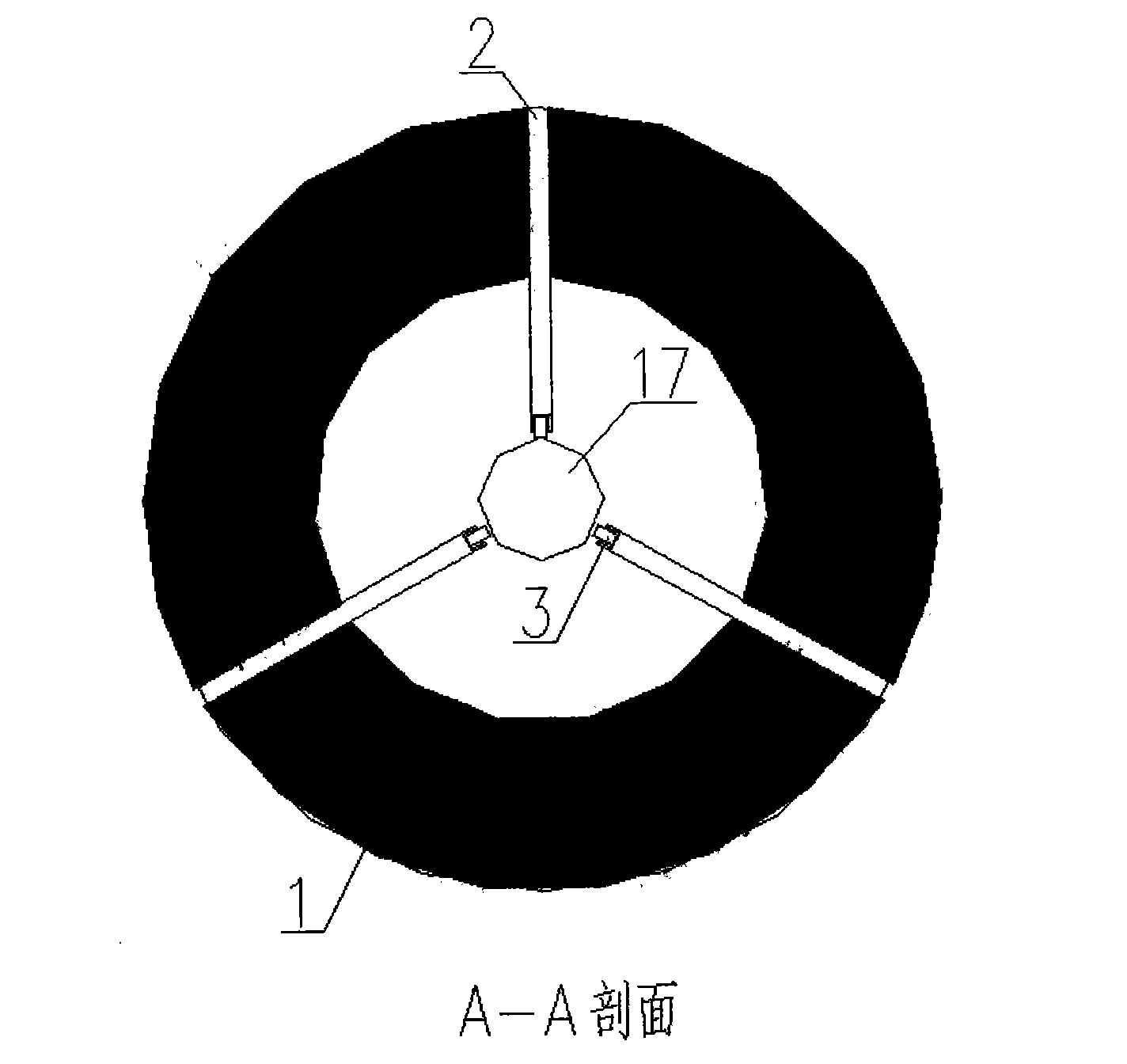

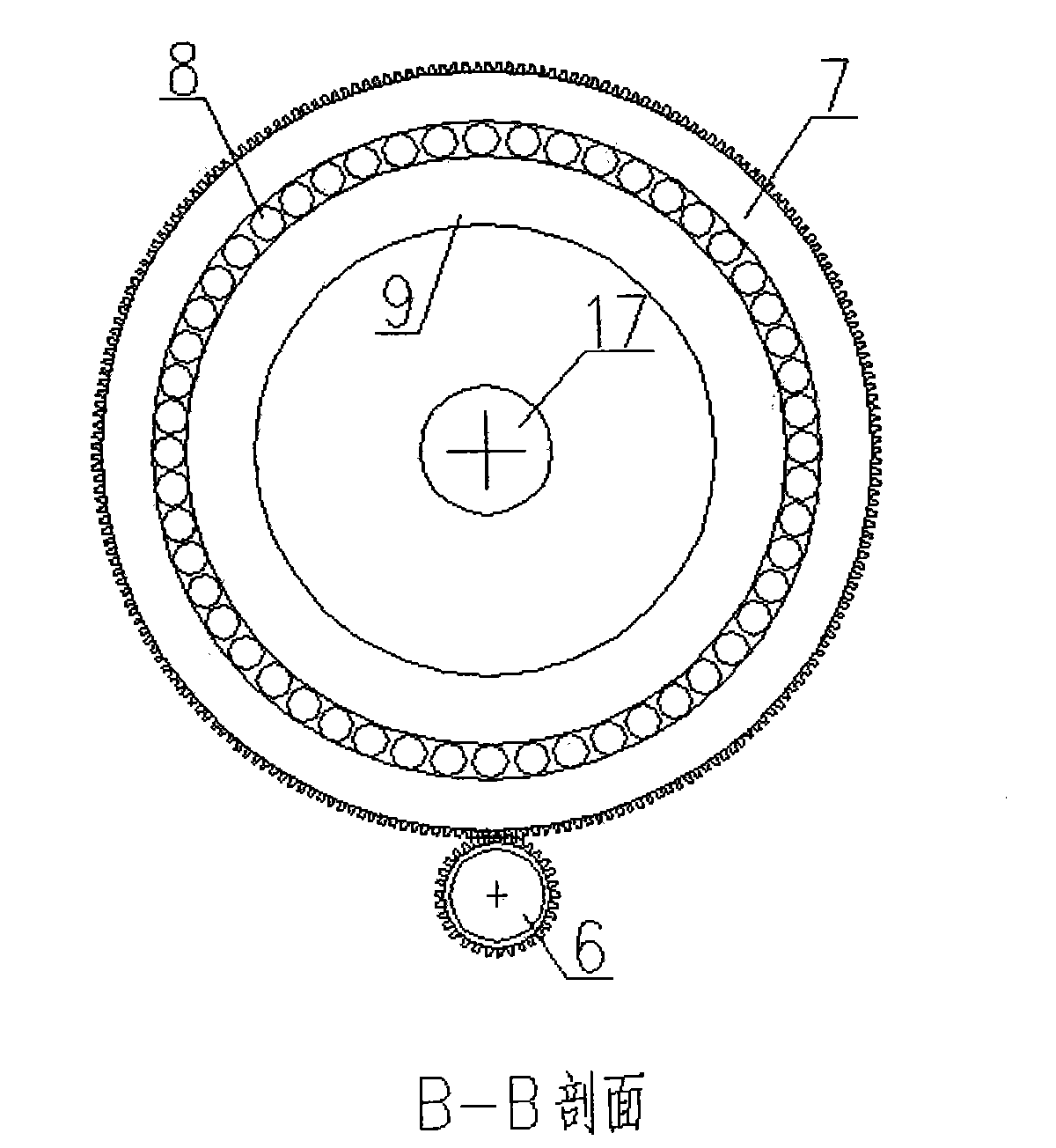

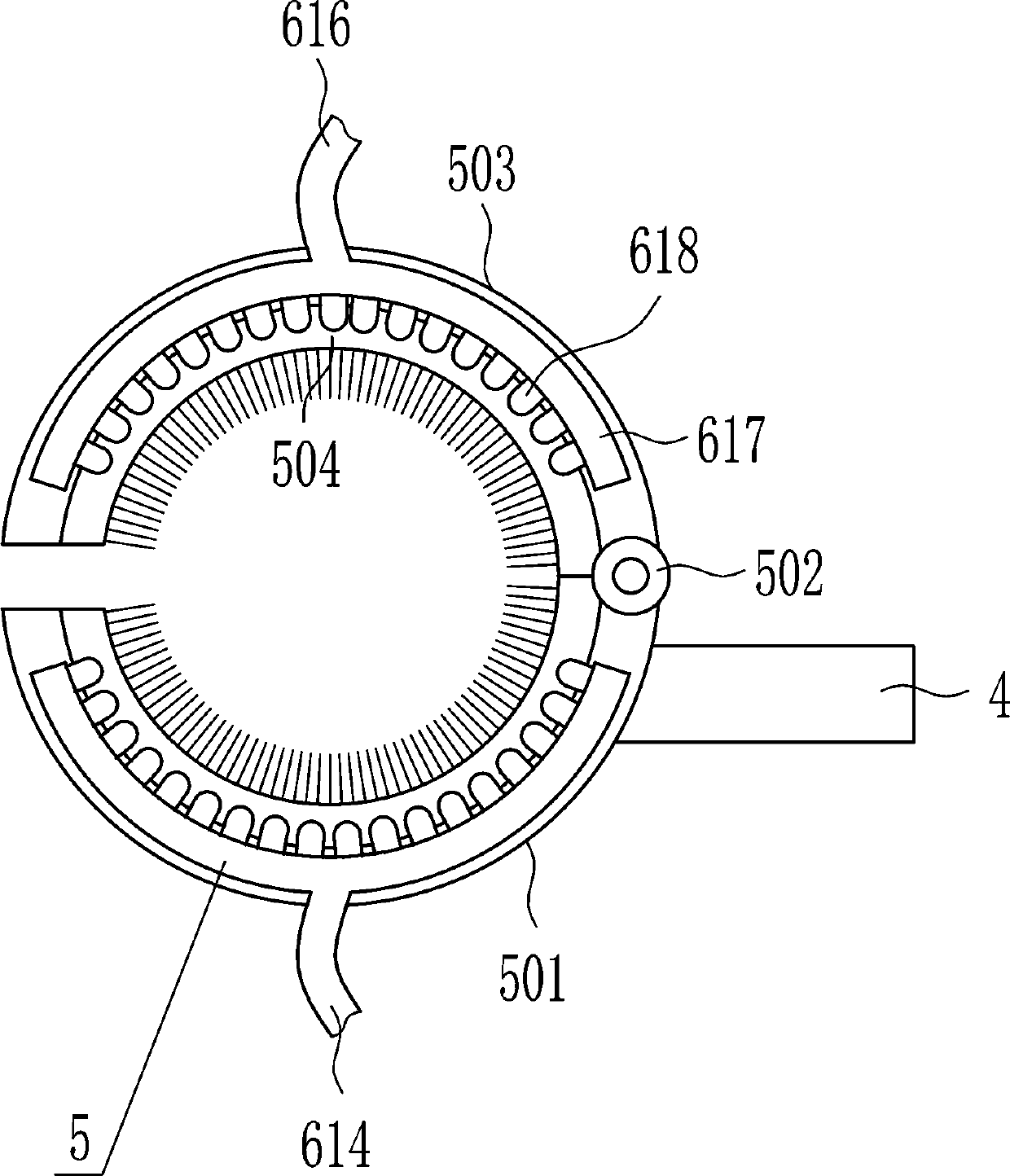

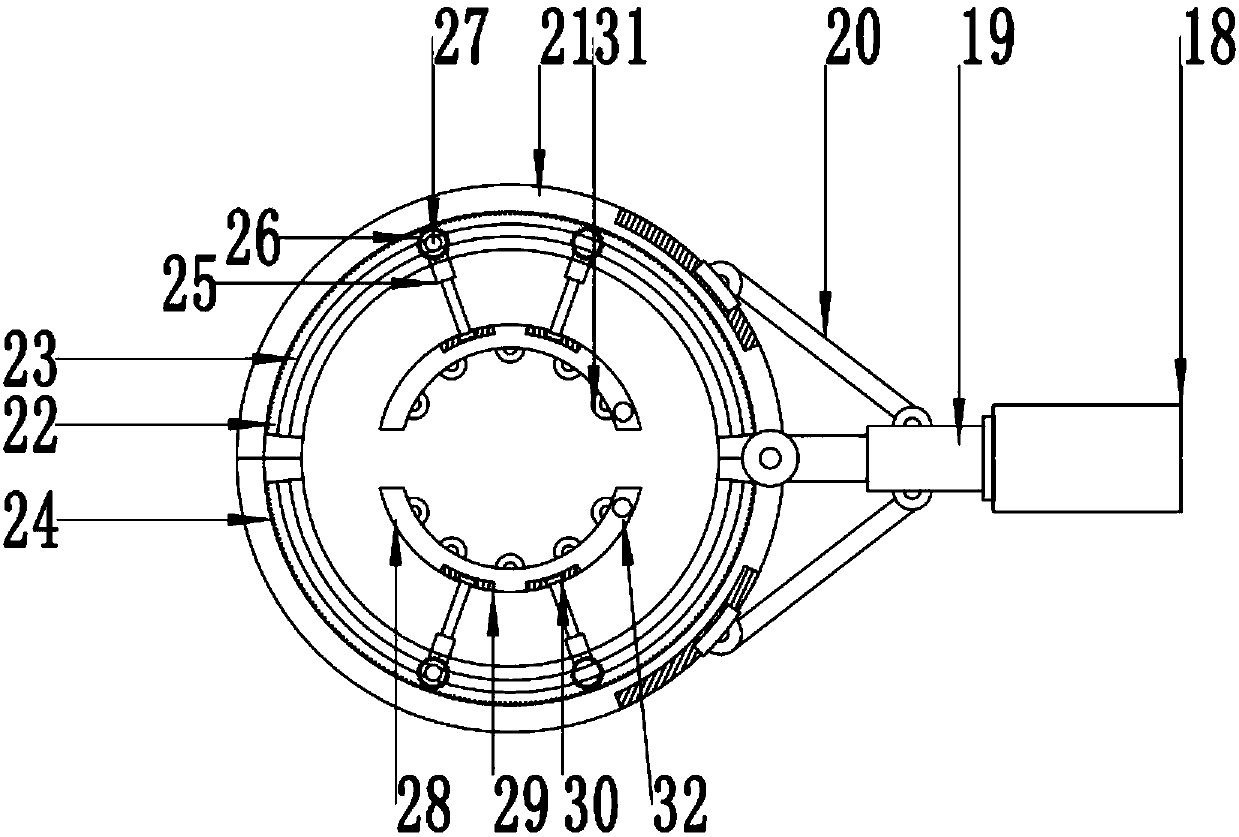

Semi-automatic derusting and paint spraying device for surface of metal tube and derusting and paint spraying method thereof

InactiveCN102151638AImprove work efficiencyGuaranteed cleanlinessCorrosion preventionPipe protection against corrosion/incrustationSemi automaticMetal

The invention relates to a semi-automatic portable derusting and paint spraying device for the surface of a metal tube, which comprises five parts, namely a movable hollow shaft system, a low-rotating speed transmission system, a derusting system, a cleaning system and a paint spraying system, wherein the movable hollow shaft system is used for fixing a metal tube on a central line of the movable hollow shaft system; the whole device moves forwards along a metal tube through the force applied on a handle; the circular motion of a motor self on the device is transferred to the derusting system, the cleaning system and the paint spraying system through the low-rotating speed transmission system, so that the derusting system, the cleaning system and the paint spraying system are driven to respectively carry out the circular motion around the metal tube, thereby performing procedures of derusting, cleaning and paint spraying on the metal tube; the whole device continuously moves forwards along the metal tube through the handle, and then the derusting and paint spraying work of the processed tube is finished.

Owner:贾韶强

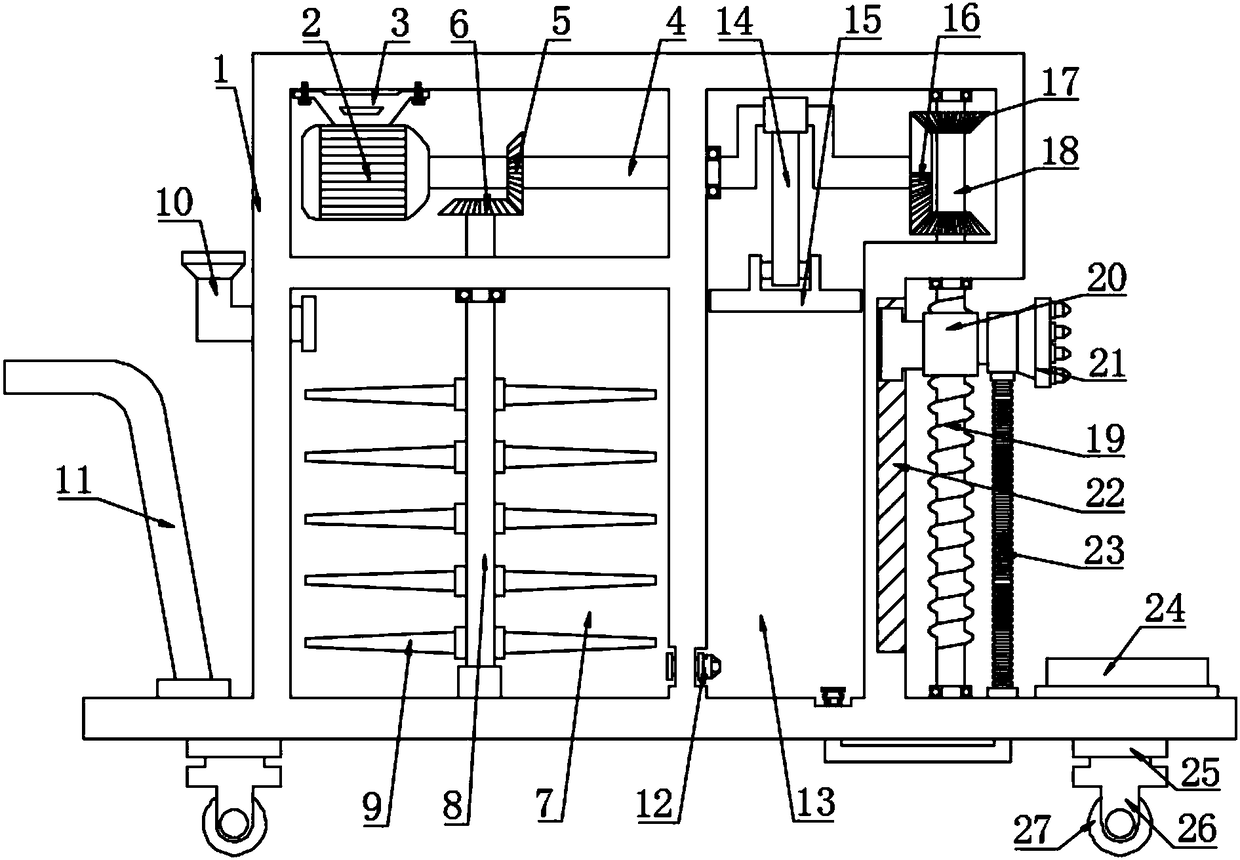

Iron barrel paint spraying device for environmental protection machinery

The invention discloses an iron barrel paint spraying device for environmental protection machinery. The iron barrel paint spraying device comprises a base, a rotating motor, a mounting plate, an adjusting device and paint spraying devices. The rotating motor is arranged on the lower end face of a transverse plate, and the end of an output shaft of the rotating motor is fixedly arranged at the upper end of the mounting plate. The adjusting device comprises a double-shaft motor and two screw rods, sliding blocks are arranged on the screw rods, electronic telescopic rods are arranged at the lower ends of the sliding blocks, and the two paint spraying devices are symmetrically arranged on two sides of the mounting plate. Each paint spraying device comprises a paint barrel, a pump body and a paint spraying head, wherein the paint spraying head is hinged to the lower end of the corresponding electronic telescopic rod, and an inlet and an outlet of the pump body are connected with the paintbarrel and the paint spraying head separately. According to the diameter of an iron barrel, the positions of the paint spraying devices can be adjusted from two sides, the directions of the spraying heads can be adjusted, and thus paint spraying can be conveniently carried out on the outer wall and the inner wall of a barrel body; in combination with the rotating motor and the telescopic rods, therequirement for different-depth paint spraying on the interior and exterior of the barrel body can be met; and rotatable paint spraying is adopted, so that uniformity and practicality are higher.

Owner:彭翠芳

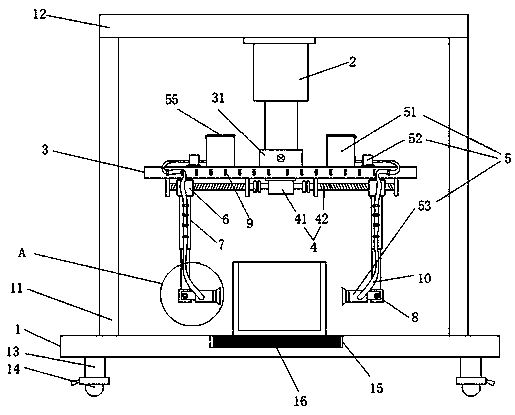

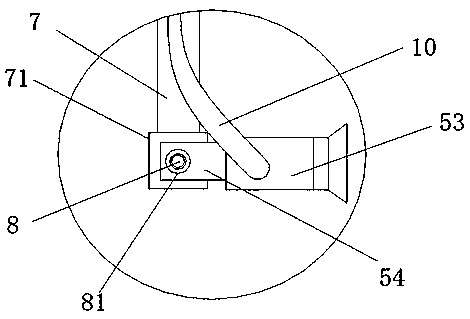

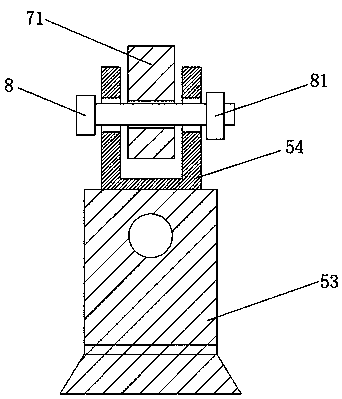

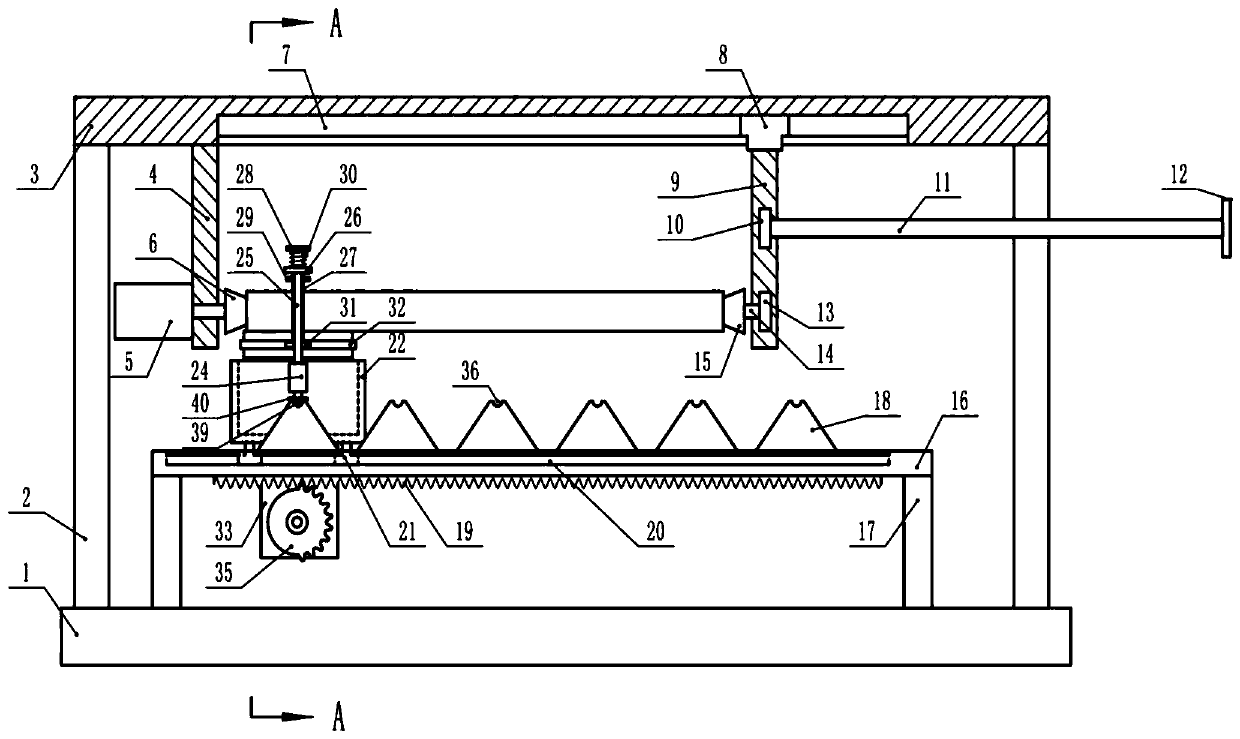

Automatic paint spraying device for steel tube

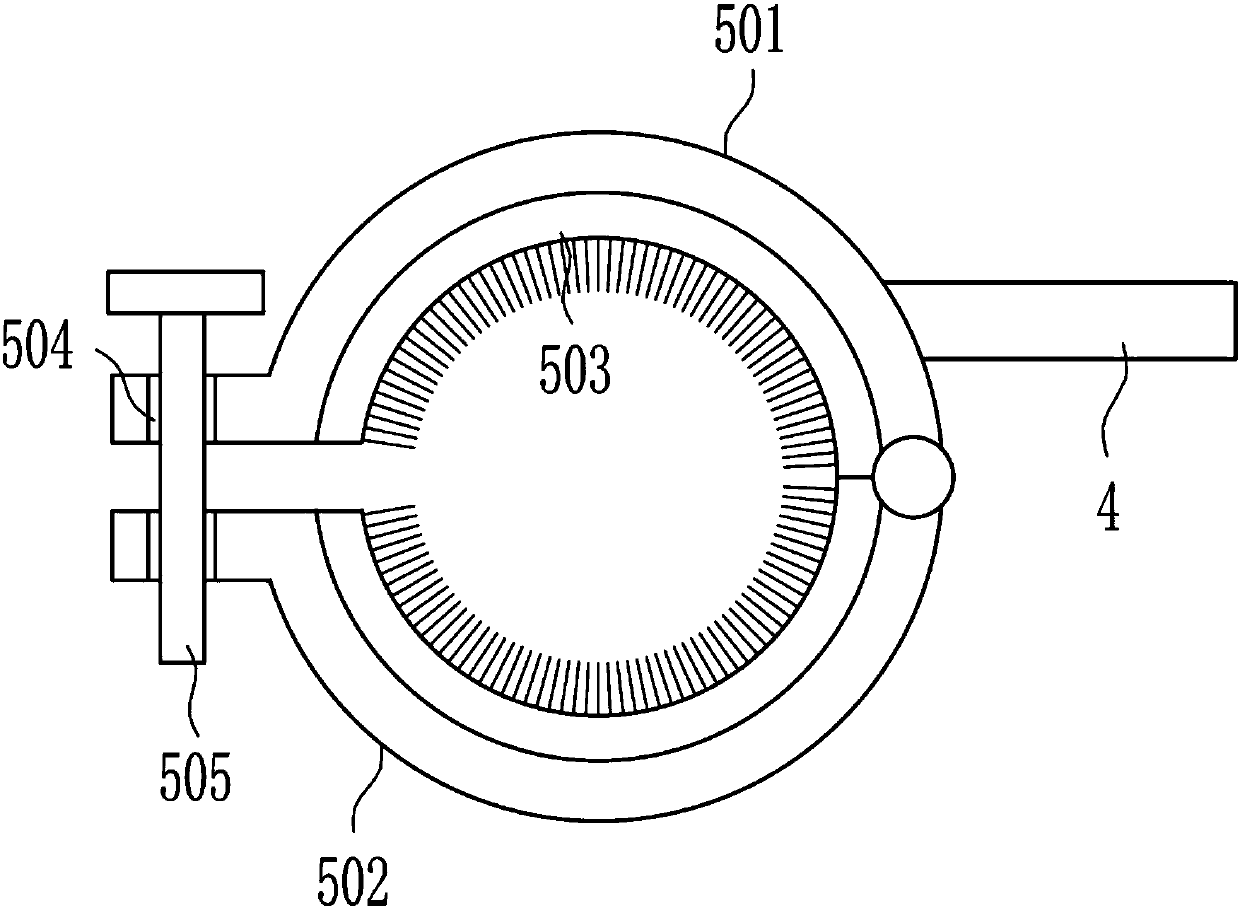

InactiveCN110653109AEvenly paintedPretreated surfacesLiquid spraying apparatusGear wheelElectric machinery

The invention relates to an automatic paint spraying device for a steel tube. The automatic paint spraying device comprises a box body. A horizontally arranged first transverse plate is fixedly connected in the bottom of the box body, a horizontally arranged first chute is formed in the upper side of the first transverse plate, and a first sliding block is in sliding fit connection to the first chute. The automatic paint spraying device has the beneficial effects that according to the automatic paint spraying device for the steel tube, one end, needed to be paint-sprayed, of the steel tube isinserted onto a second cone-shaped block; according to different lengths of the steel tubes, a rotating hand wheel rotates the first sliding block to slide toward the second cone-shaped block, so thata first cone-shaped block is inserted onto the other end of the steel tube to be tightened; a paint spraying pump sprays paint in storage barrel to the steel tube uniformly through a spray head, a third motor drives a first rotating block to rotate as a driving gear rotates to drive a driven gear ring so as to drive the steel tube and the second cone-shaped block to rotate, so that the steel tubecan rotate to be paint-sprayed uniformly; and a second motor rotates a second screw to drive a second sliding block to move horizontally, so that the spray head moves horizontally to spray paint to the surface of the steel tube uniformly.

Owner:江苏华正数控机械有限公司

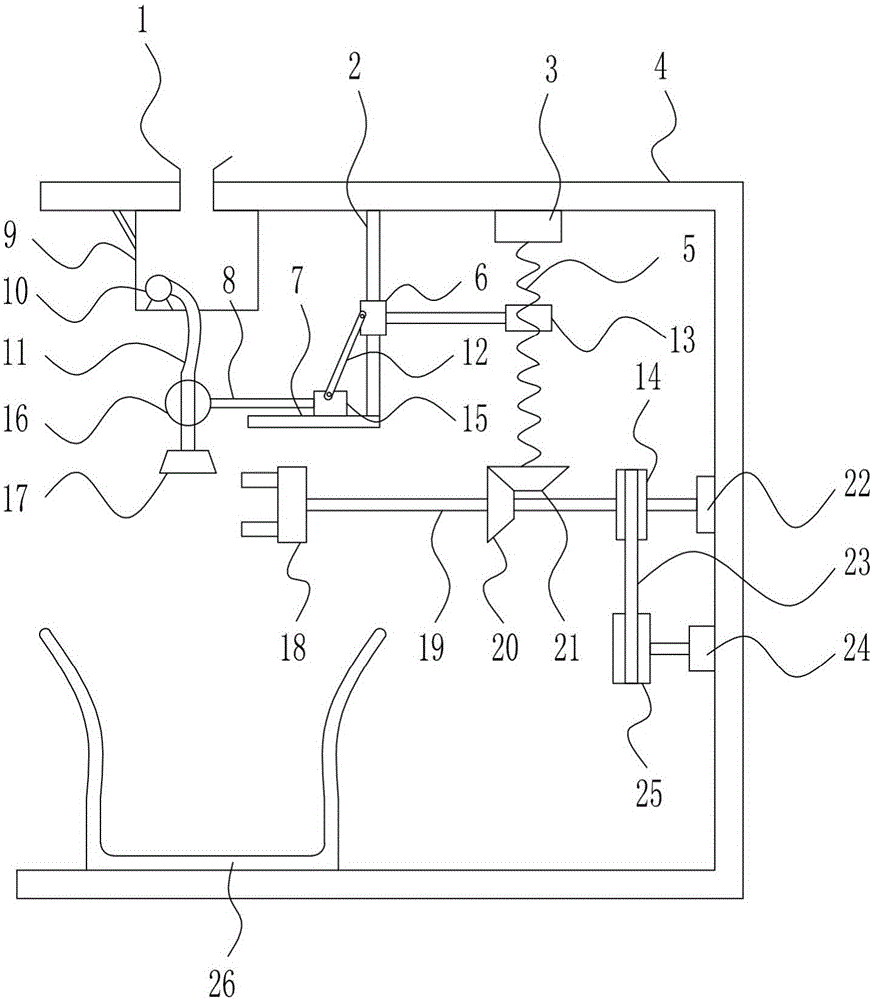

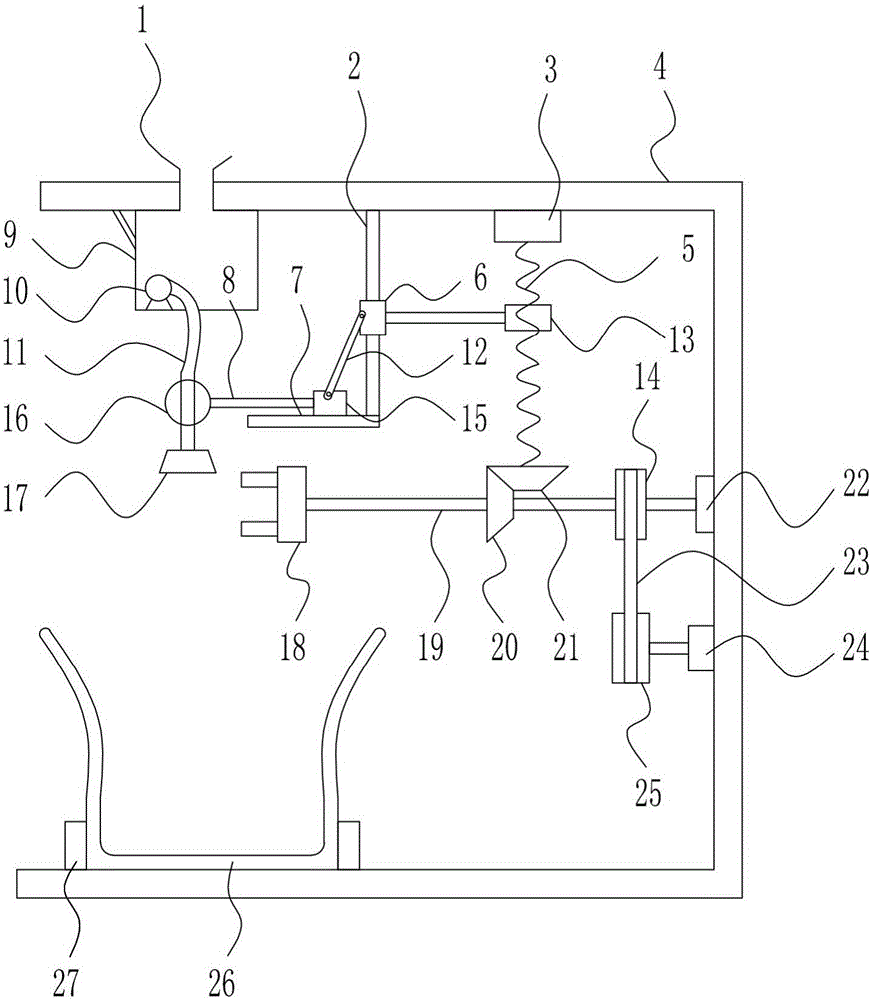

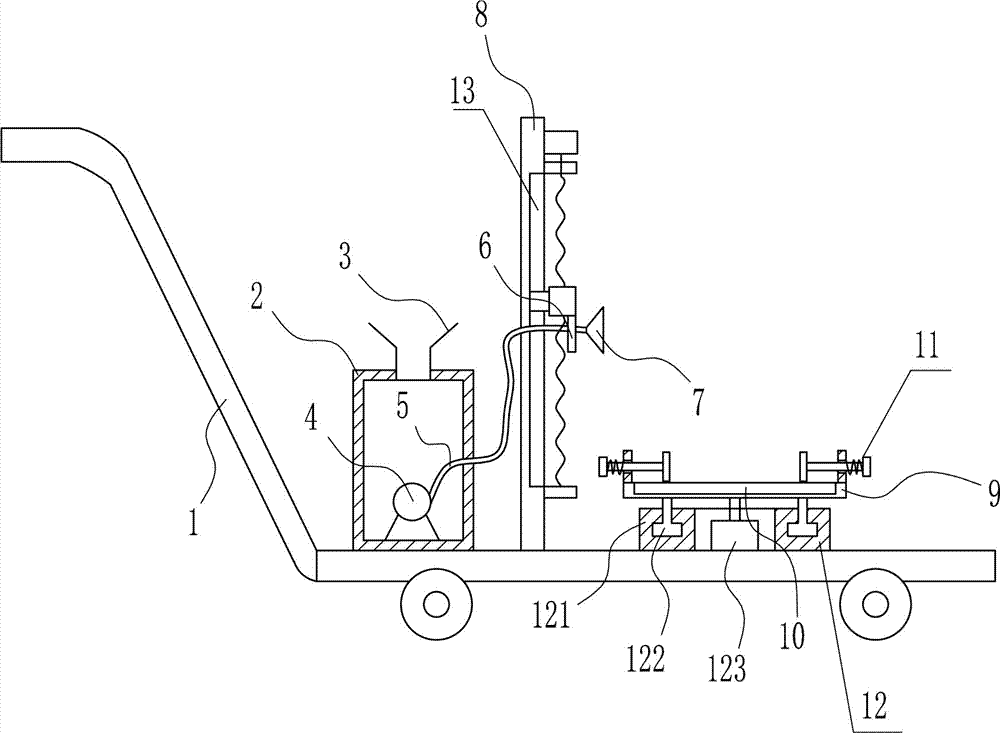

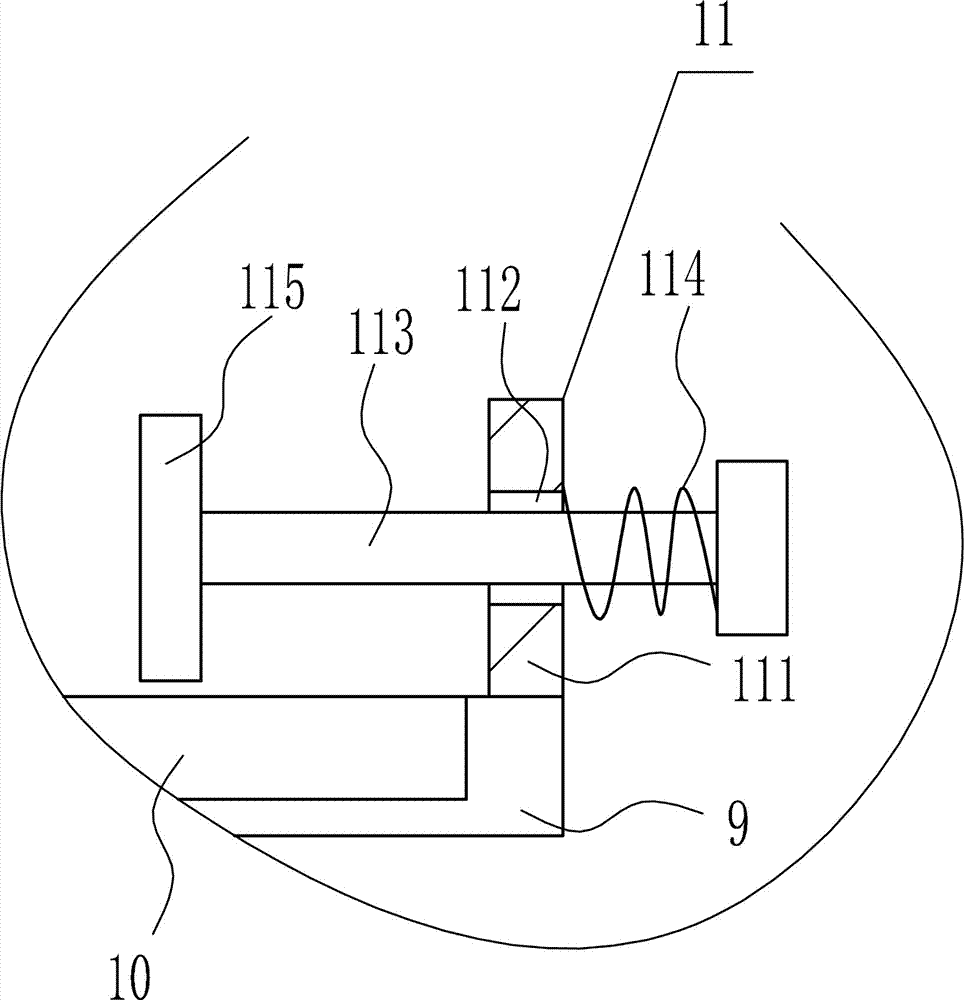

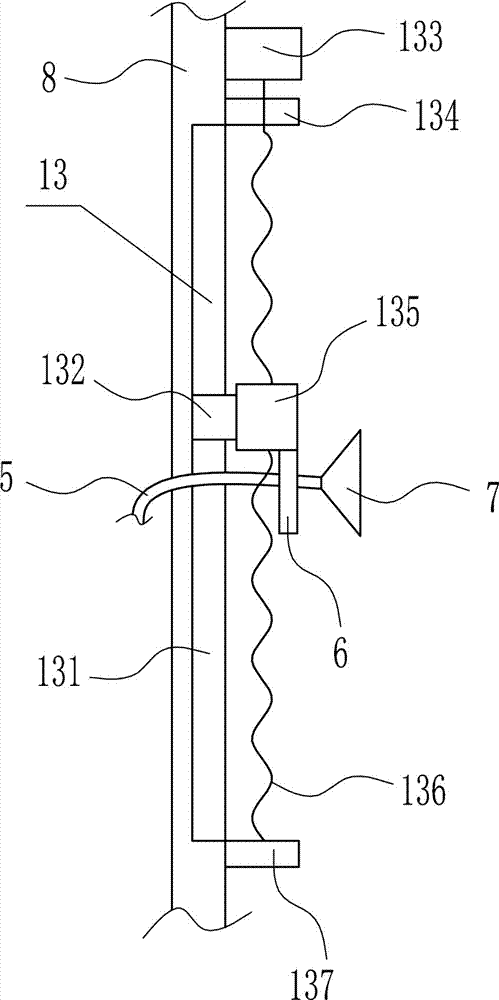

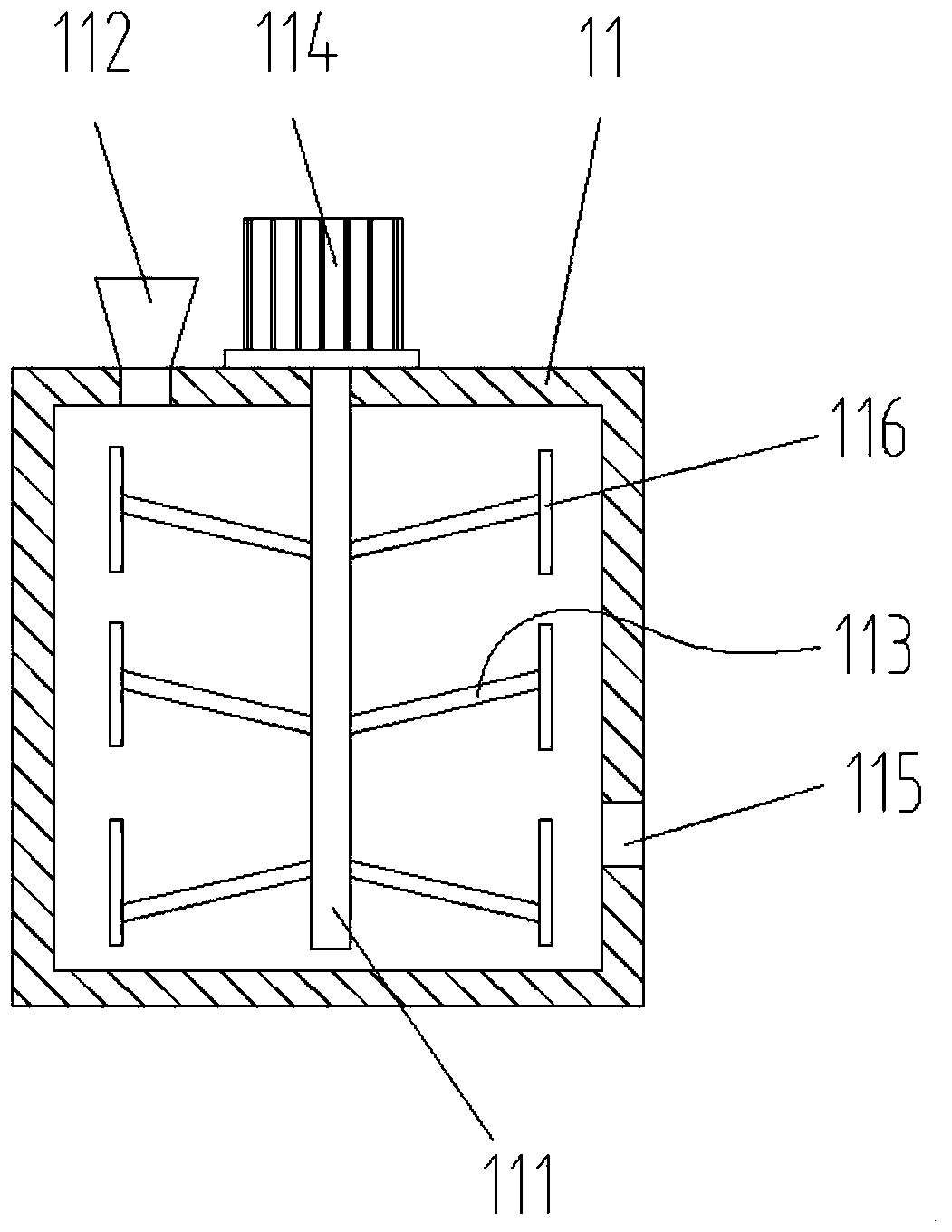

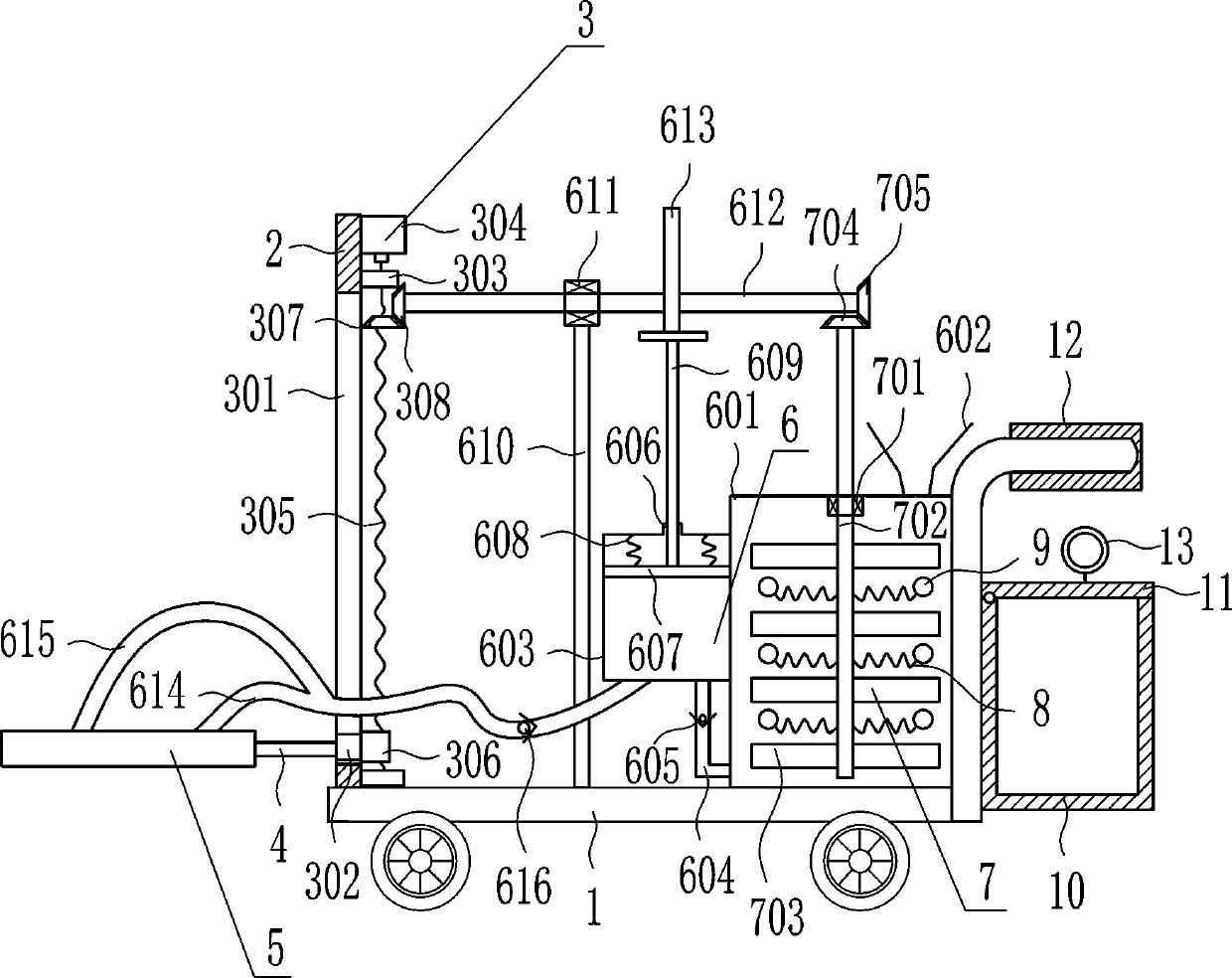

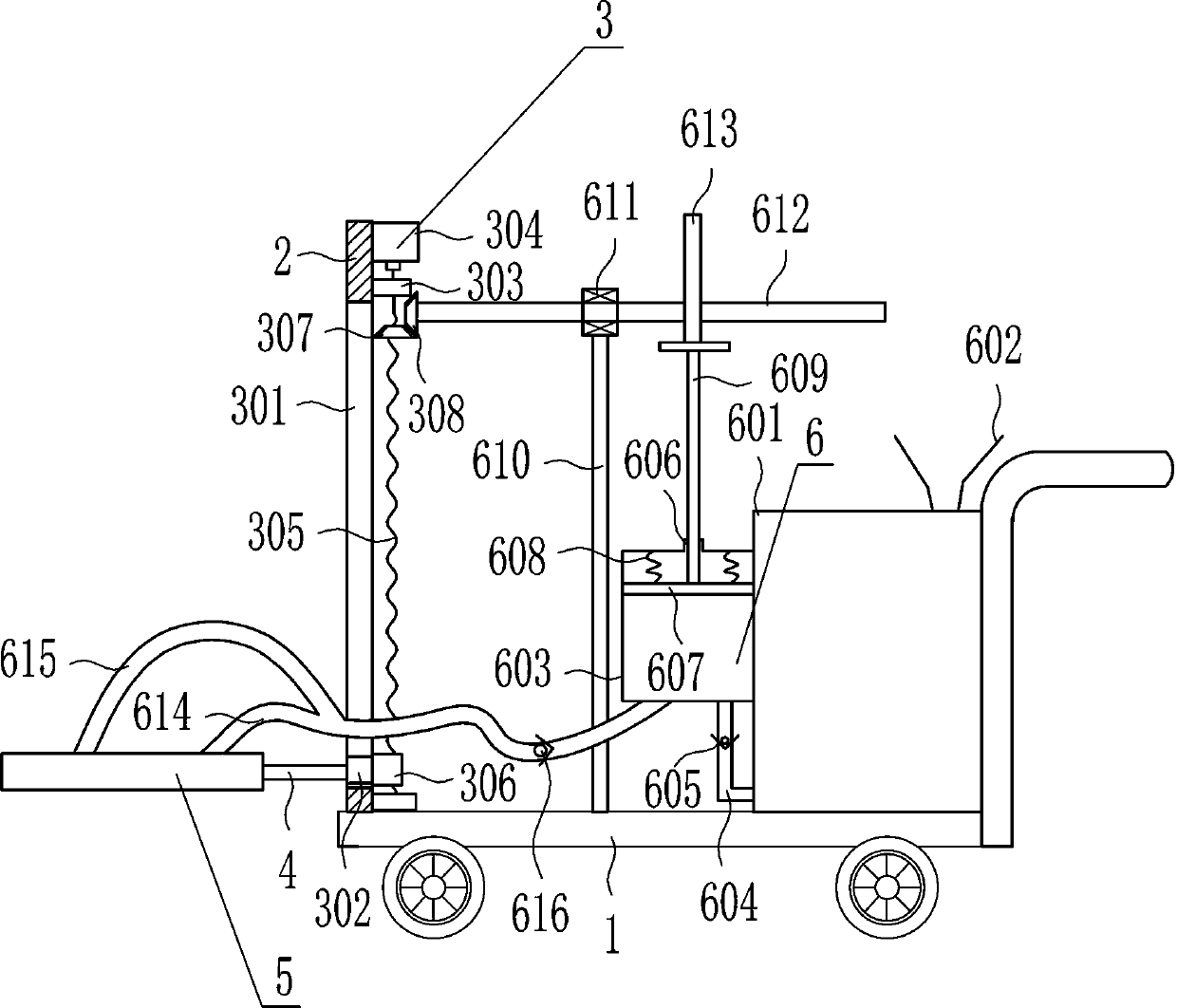

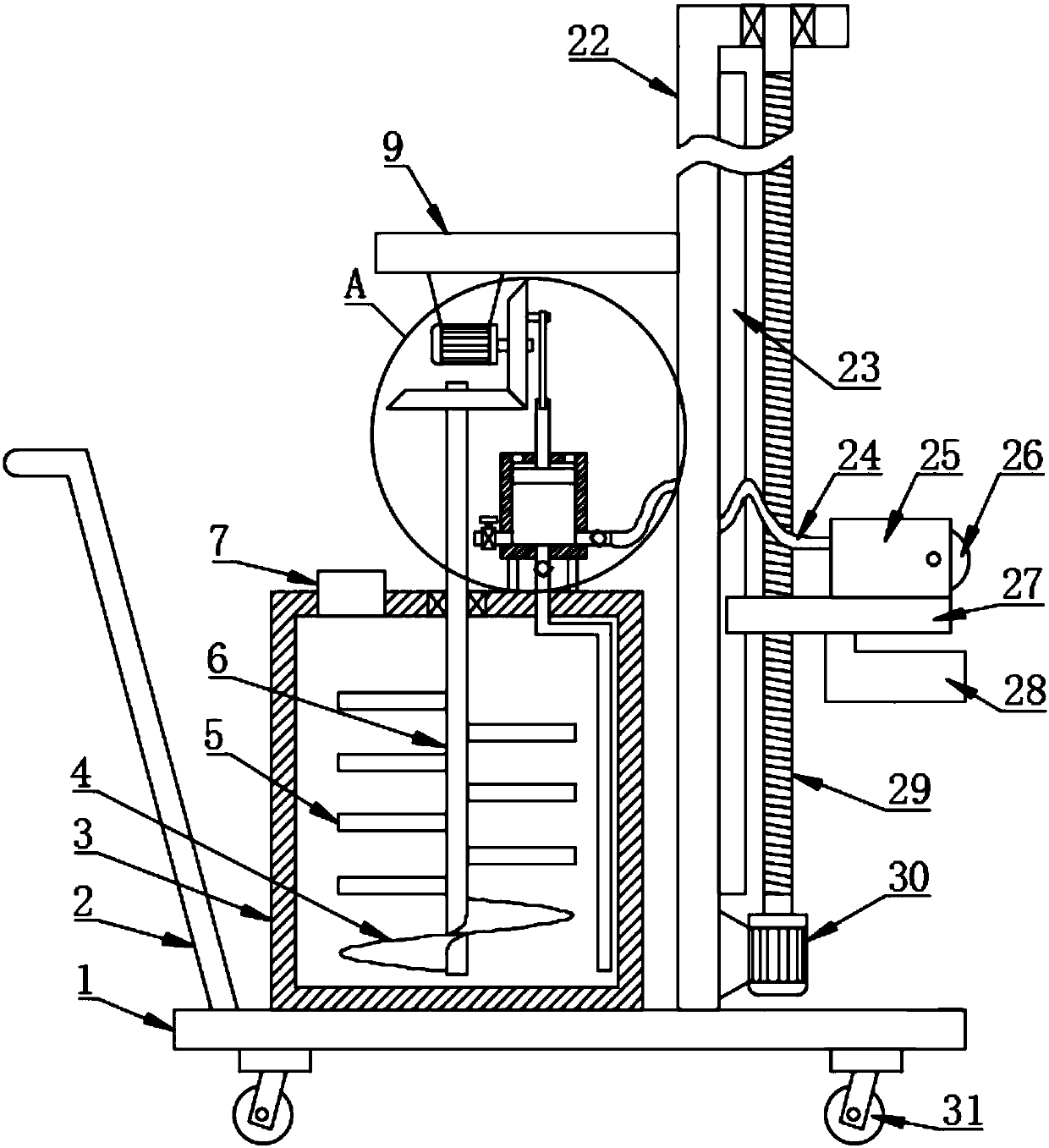

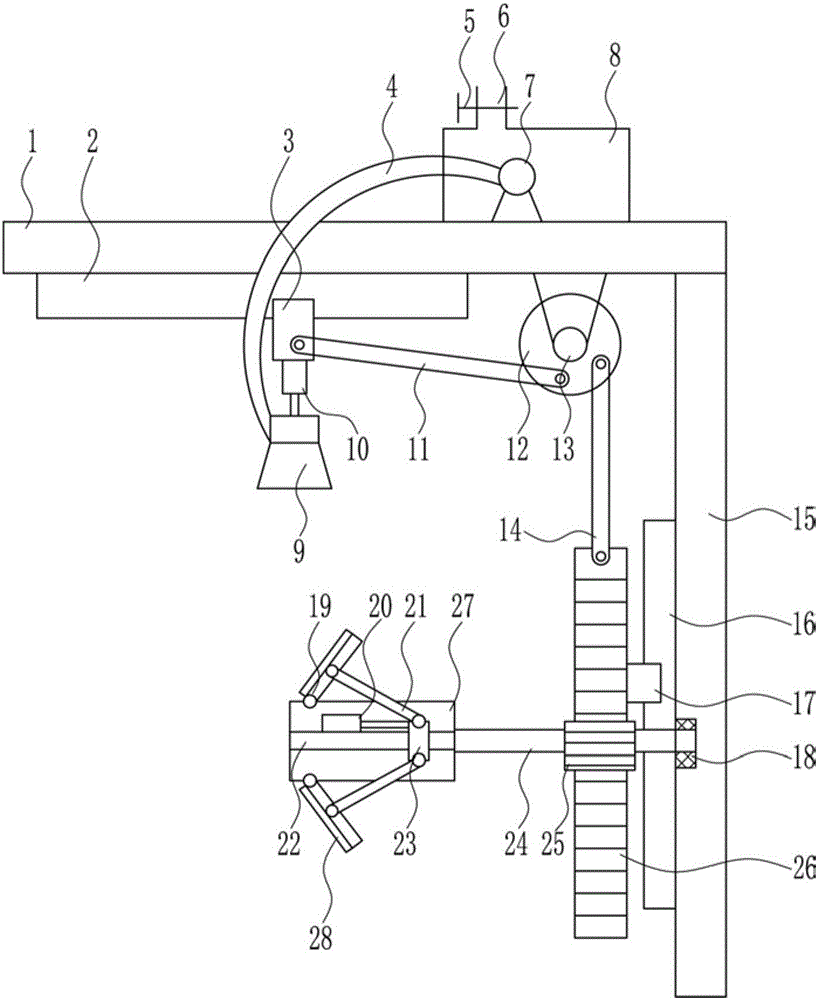

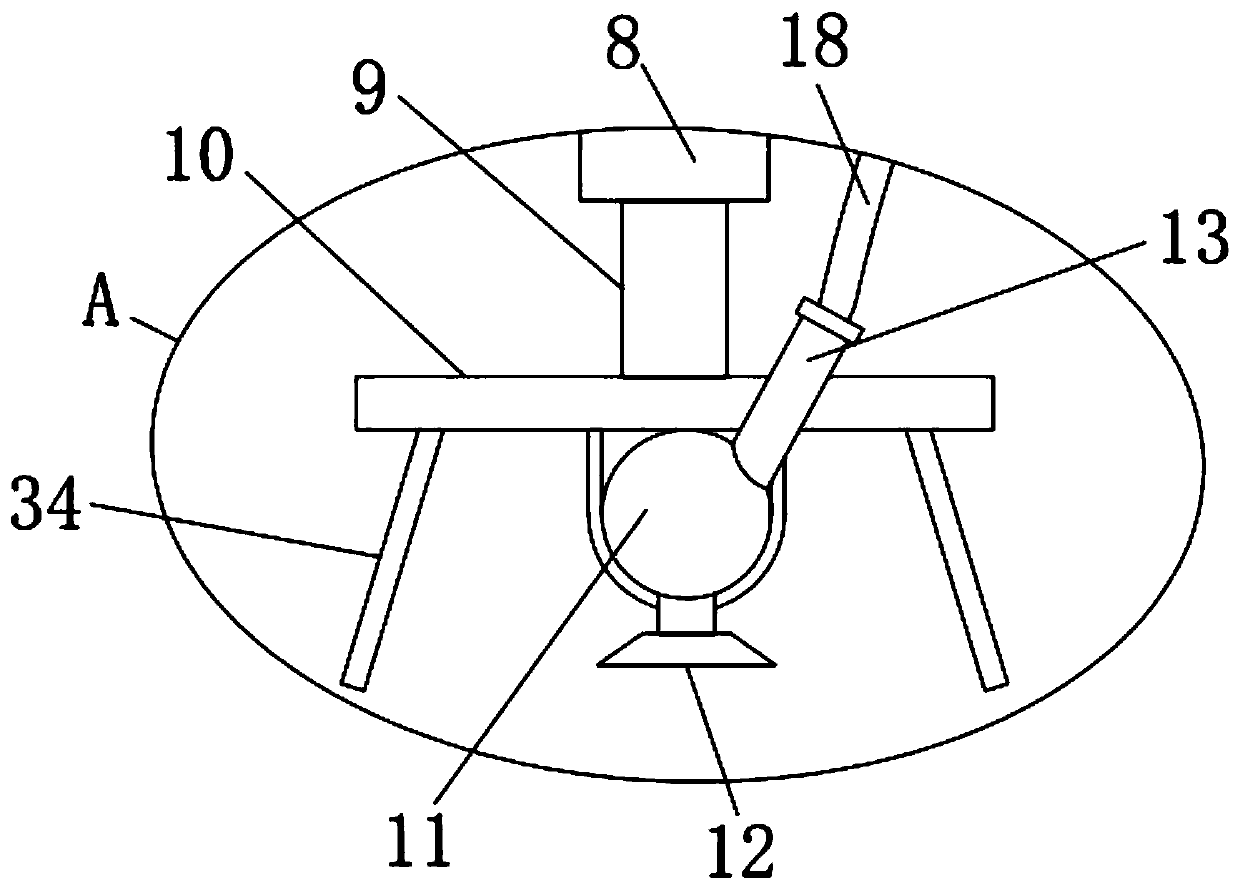

Trunk whitewashing machine for landscaping

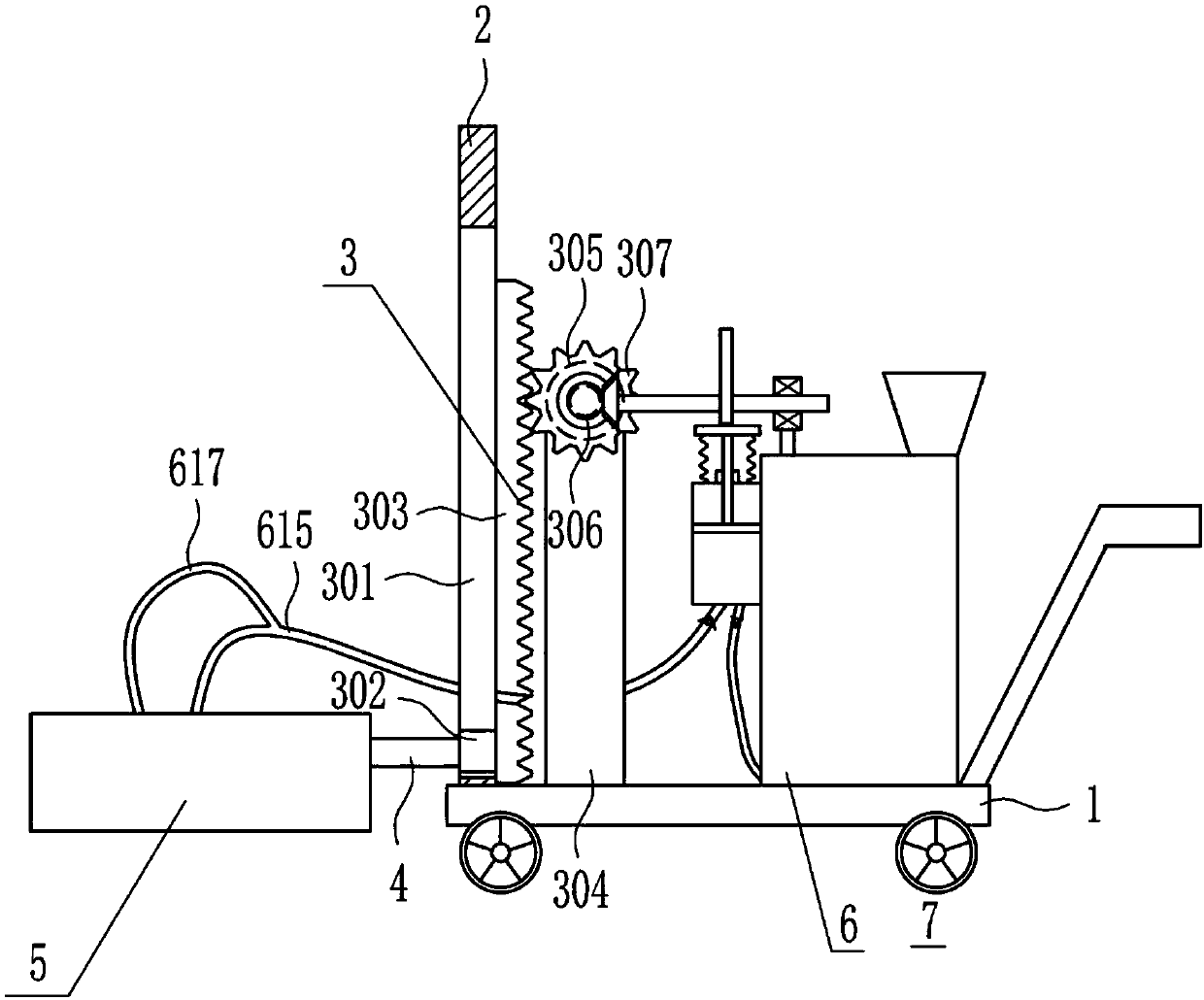

InactiveCN107638972AWhite evenlyWhitewash fastLiquid surface applicatorsLiquid spraying apparatusWhitening AgentsLandscaping

The invention relates to a whitewashing machine for landscaping, in particular to a trunk whitewashing machine for landscaping. The invention aims to provide a trunk whitewashing machine for landscaping, which reduces the labor intensity of workers, increases the coating speed, and is convenient to use and simple in operation. In order to solve the above technical problem, the trunk whitewashing machine for landscaping includes a trolley and the like. The left side of the top of the trolley is vertically connected with a supporting plate, and the supporting plate is provided with a vertical moving device. The vertical moving device is connected with a transverse plate, and a whitewashing device is arranged on the left side of the transverse plate. The trunk whitewashing machine for landscaping can spray the whitening agent on the trunk through a liquid spraying device, and can evenly coat the whitening agent by moving the whitewashing device up and down by the vertical moving device soas to reduce the labor intensity of the workers, increase the coating speed, and achieve easy use and simple operation effects.

Owner:郭昌磊

Plastic part surface paint spraying device

InactiveCN107952615AEvenly paintedReduce labor intensitySpray boothsEngineeringMechanical engineering

The invention relates to a plastic part surface paint spraying device, comprises a rack and a spray gun. The rack is fixedly provided with a paint spraying box. The paint spraying box is internally rotatably connected with a rotating shaft. The rotating shaft is fixedly connected with a rotating disk. The rotating shaft is fixedly provided with a fan gear. The fan gear is meshed with a rack. The rack is pivoted with a pawl. The rack is rotatably connected with a ratchet wheel. The pawl is meshed with the ratchet wheel. The rack is provided with a first button. The ratchet wheel is coaxially connected with a cam. The rack is fixedly provided with an inflator. The inflator is internally slidably connected with a piston. The inflator is communicated with an air outlet pipe. The rack is fixedly provided with an air bag. The air outlet pipe is communicated with the air bag. The air outlet pipe is provided with a one-way valve. The paint spraying box is internally fixedly provided with an annular pipe. The rotating disk is rotatably connected in the annular pipe. The rotating disk is communicated with the annular pipe. The rotating disk is provided with an air outlet. Compared with the prior art, the scheme can ensure uniform paint spaying on each position of a plastic product. The device is arranged in a full mechanization manner, and labor intensity is reduced. The plastic productis not needed to be dried again. The device is simpler to operate.

Owner:宁波得晴电器科技有限公司

Driverless car shell paint spraying device

InactiveCN106378275AImprove work efficiencySimple structureLiquid spraying apparatusEngineeringCheck valve

The invention relates to the technical field of unmanned equipment, in particular to a driverless car shell paint spraying device. The driverless car shell paint spraying device needs to solve the technical problem of providing a driverless car shell paint spraying device which is simple in structure, high in paint spraying speed and uniform paint spraying. In order to solve the above technical problem, the driverless car shell paint spraying device comprises a bottom plate, a first check valve, a first cylinder body, a second cylinder body, a first slide rail, a first slider, a first pipeline, a piston, a first fixing plate, a first baffle and the like; the left side of the top of the bottom plate is connected with the first cylinder body in a bolt connection manner; and the middle of the top of the bottom plate is connected with the second cylinder body in a bolt connection manner. The driverless car shell paint spraying device achieves the effects that the structure is simple, the paint spraying speed is high, and paint spraying is uniform, a worker can achieve fast paint spraying operation of a shell of a driverless car by means of the device, and operation is easy.

Owner:梁海英

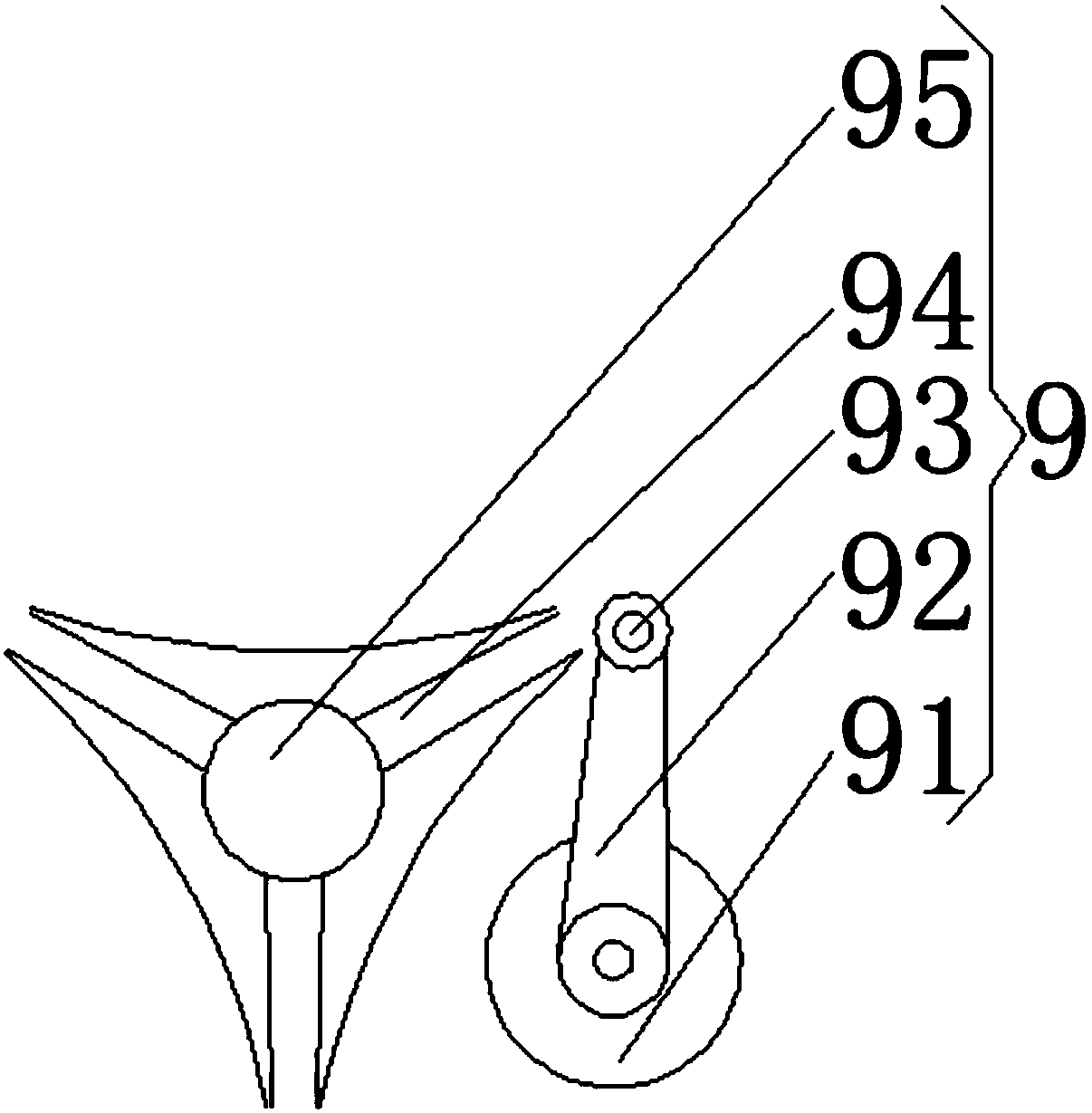

Pipeline spraying device

ActiveCN108787218AEasy to moveStable output speedLiquid surface applicatorsLiquid spraying apparatusUniversal jointSpray nozzle

The invention discloses a pipeline spraying device comprising a feeding module and a clamping module. The feeding module comprises a machine frame, a spraying cavity formed in the upper portion of themachine frame, a drive motor arranged on the upper portion of the spraying cavity, a two-way lead screw movably connected with the lower portion of the drive motor, spray nozzles connected to the left side and the right side of the two-way lead screw correspondingly, and a liquid guide pipe arranged on the lower portion of the spraying cavity and communicating with each other. The lower portion of the liquid guide pipe is connected with the spray nozzles. The clamping module comprises a universal joint connected to the left side of the two-way lead screw in a rolling manner, a triangle clamping column used for clamping a pipeline and arranged on the universal joint, a regulation wheel arranged on the right side of the machine frame, and a triangle clamping column used for clamping the pipeline and arranged on the regulation wheel. Paint vehicle on the surface of the pipeline is comprehensively sprayed, and the paint vehicle is evenly sprayed.

Owner:邵勤俏

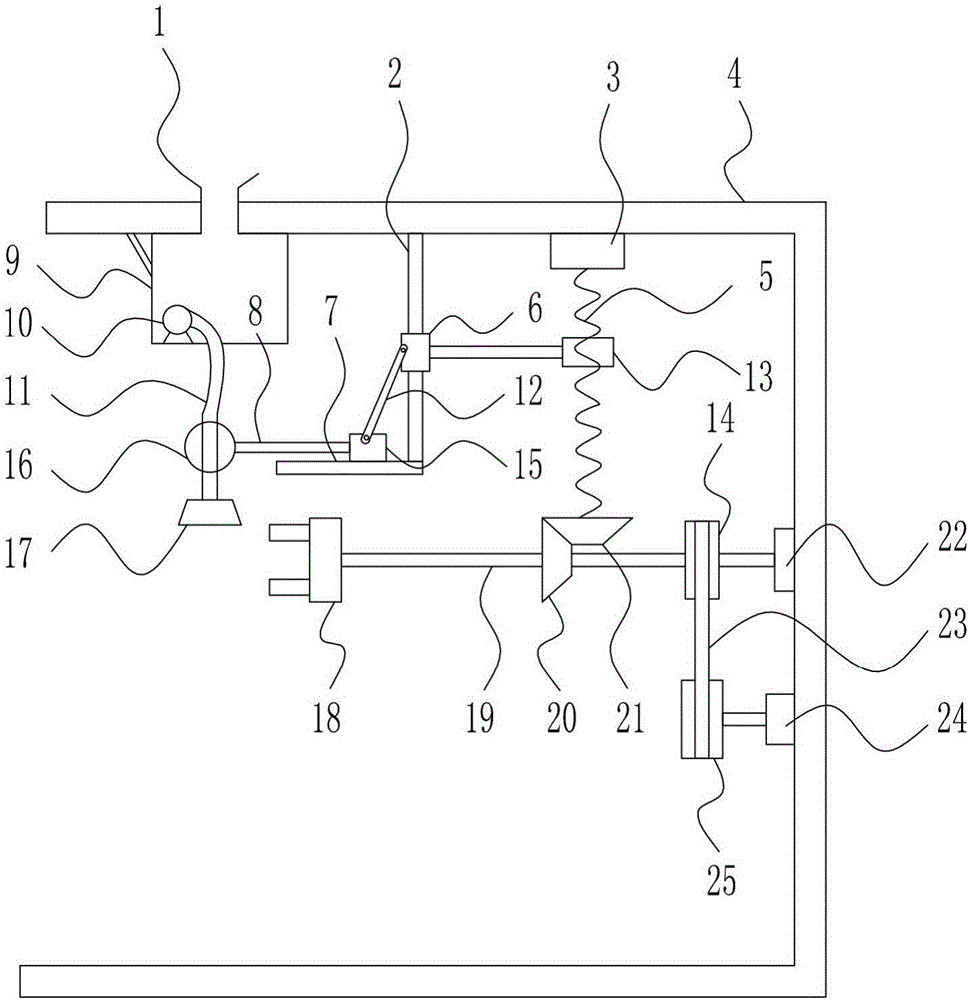

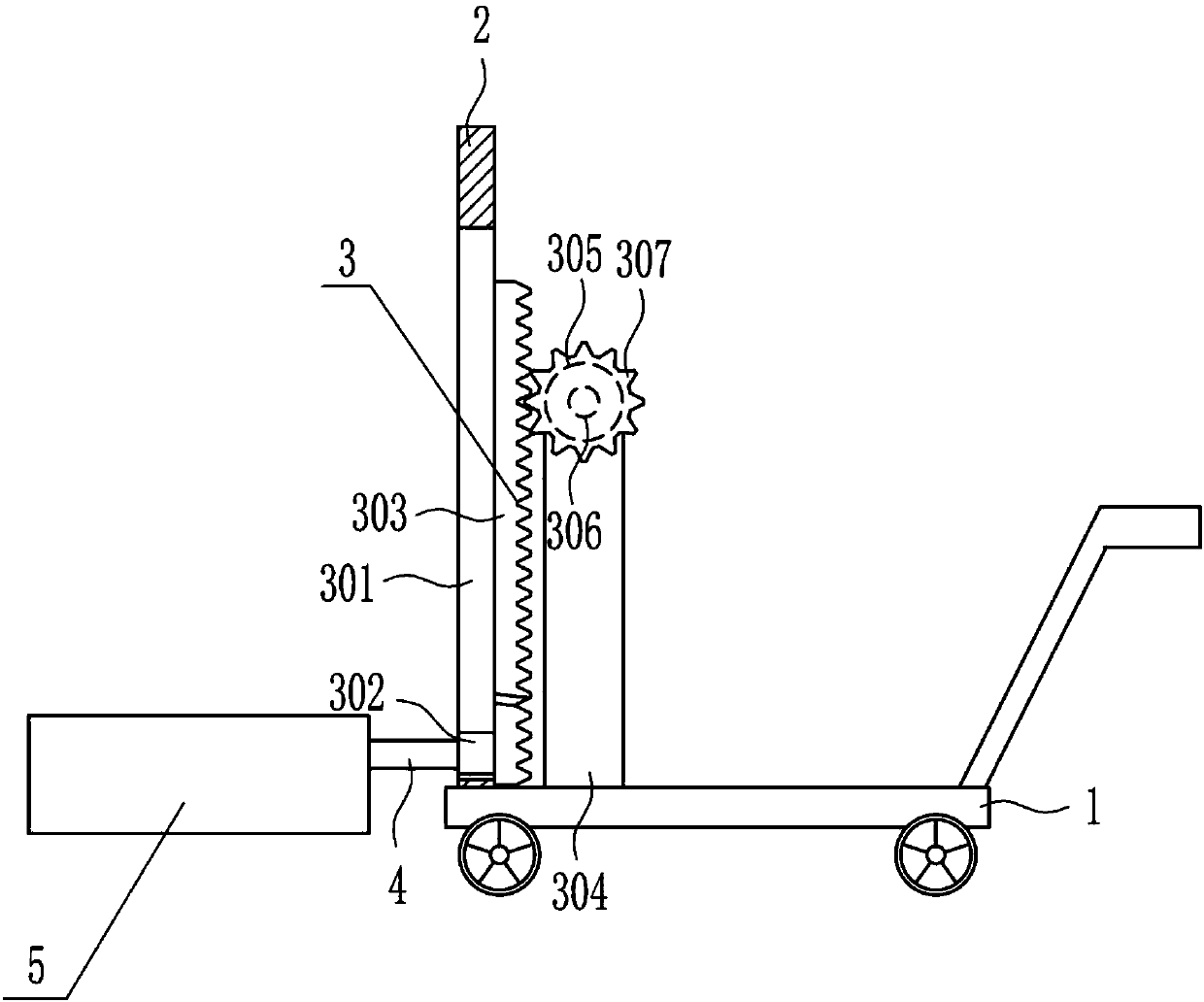

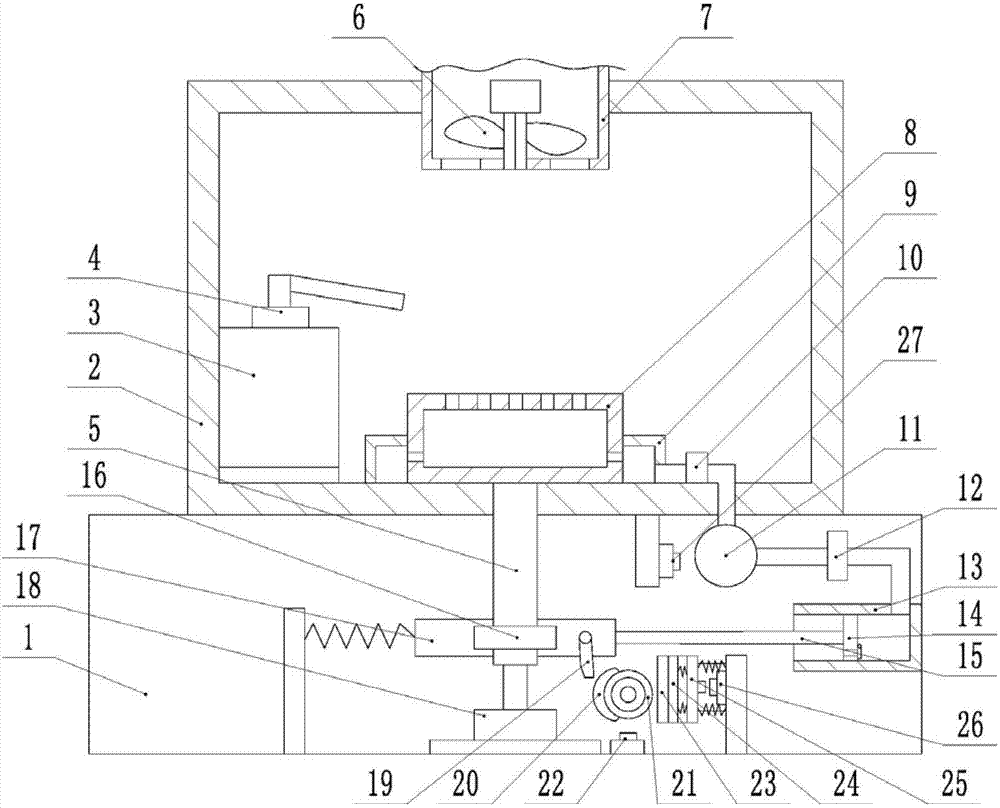

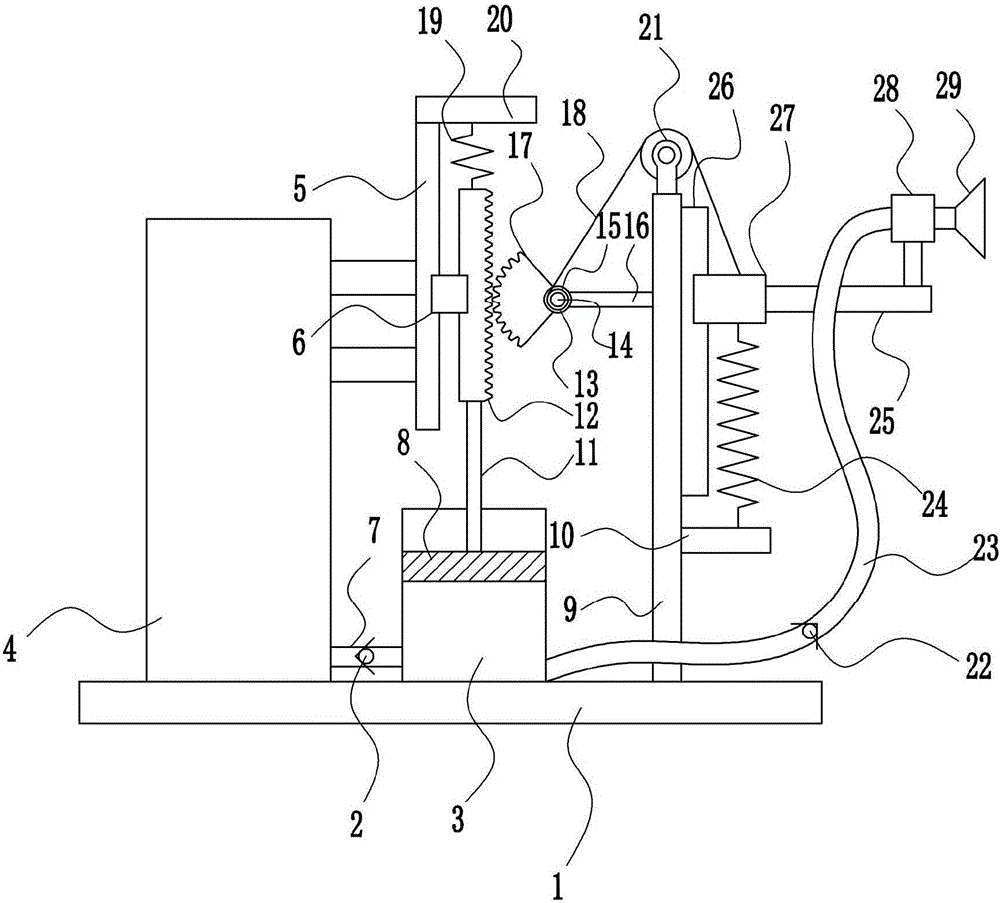

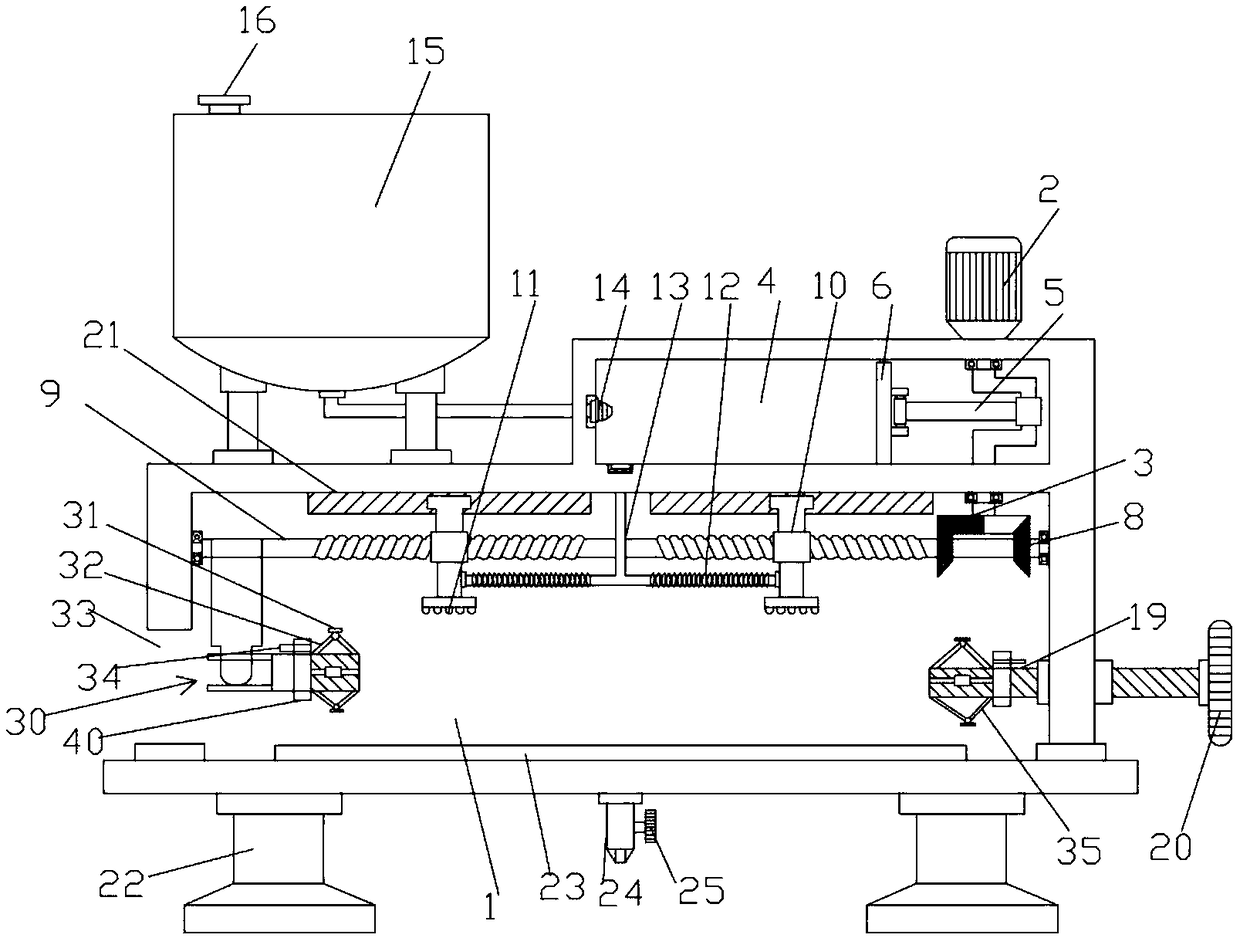

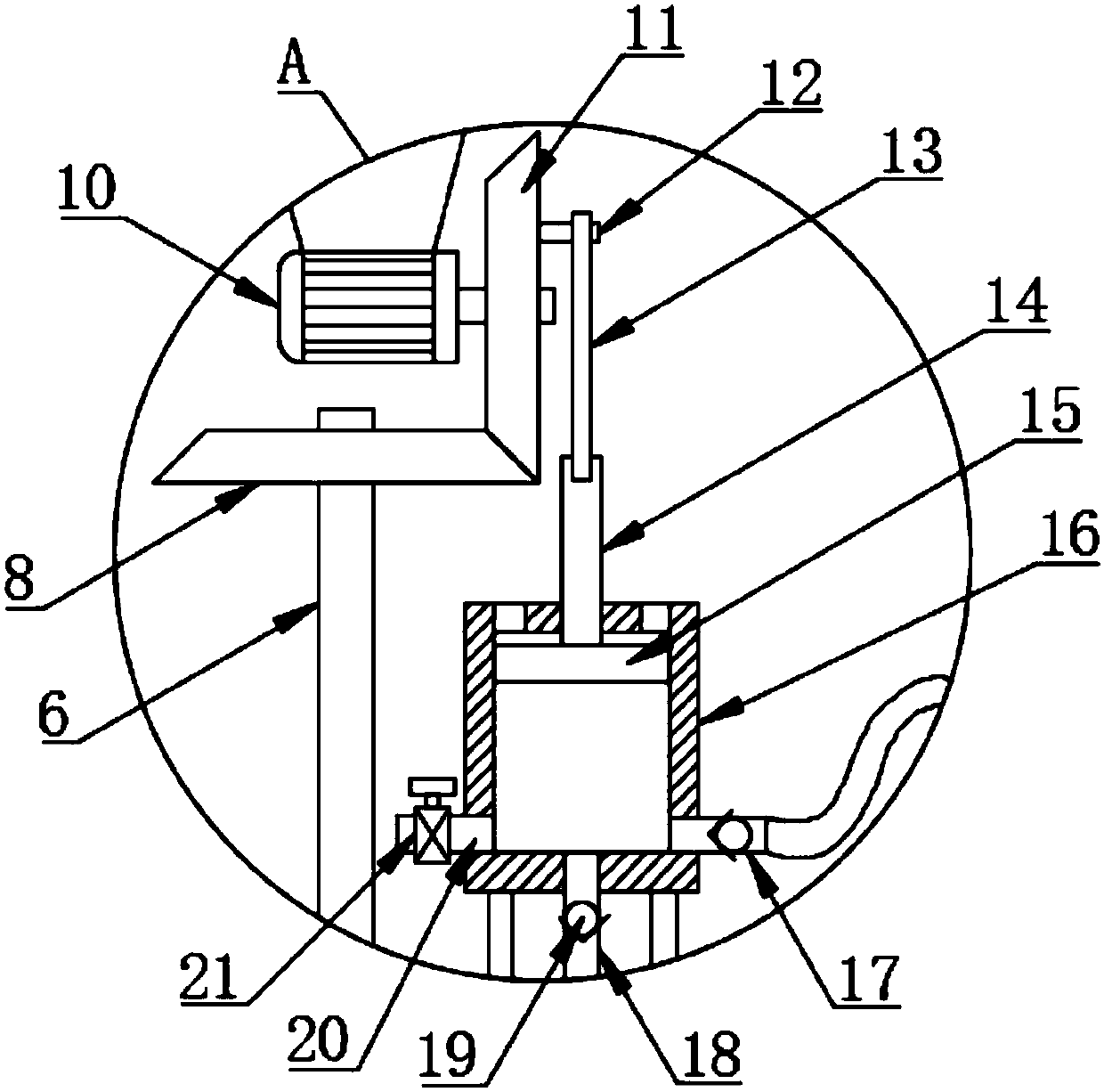

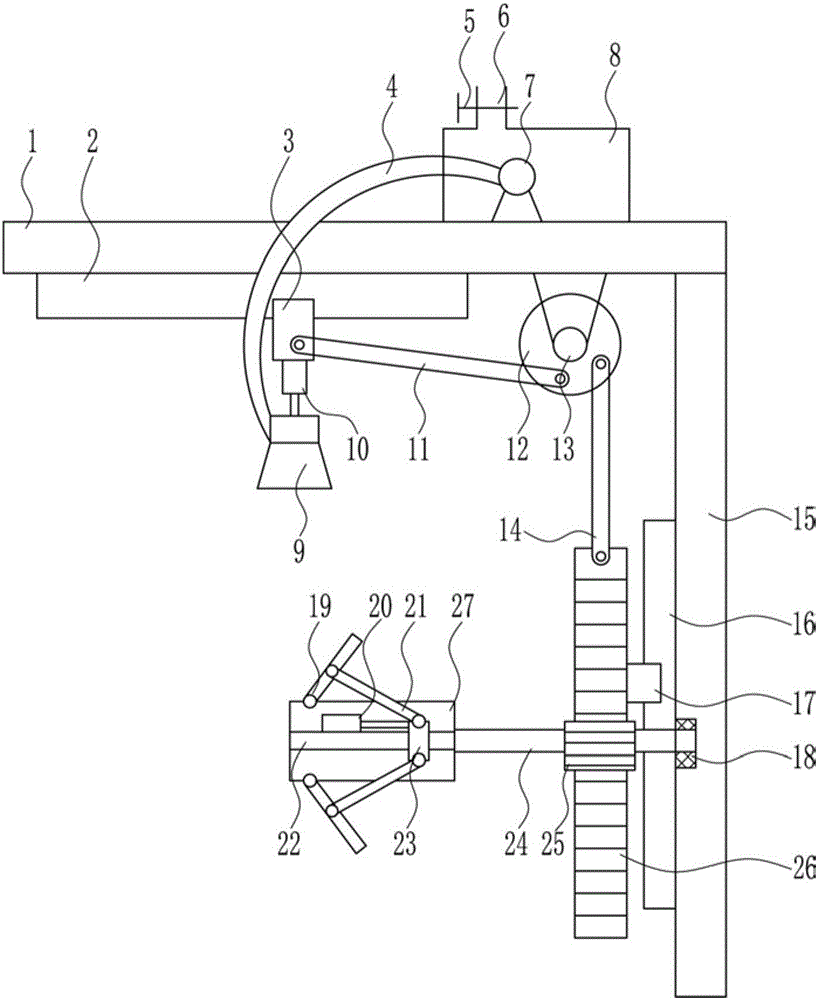

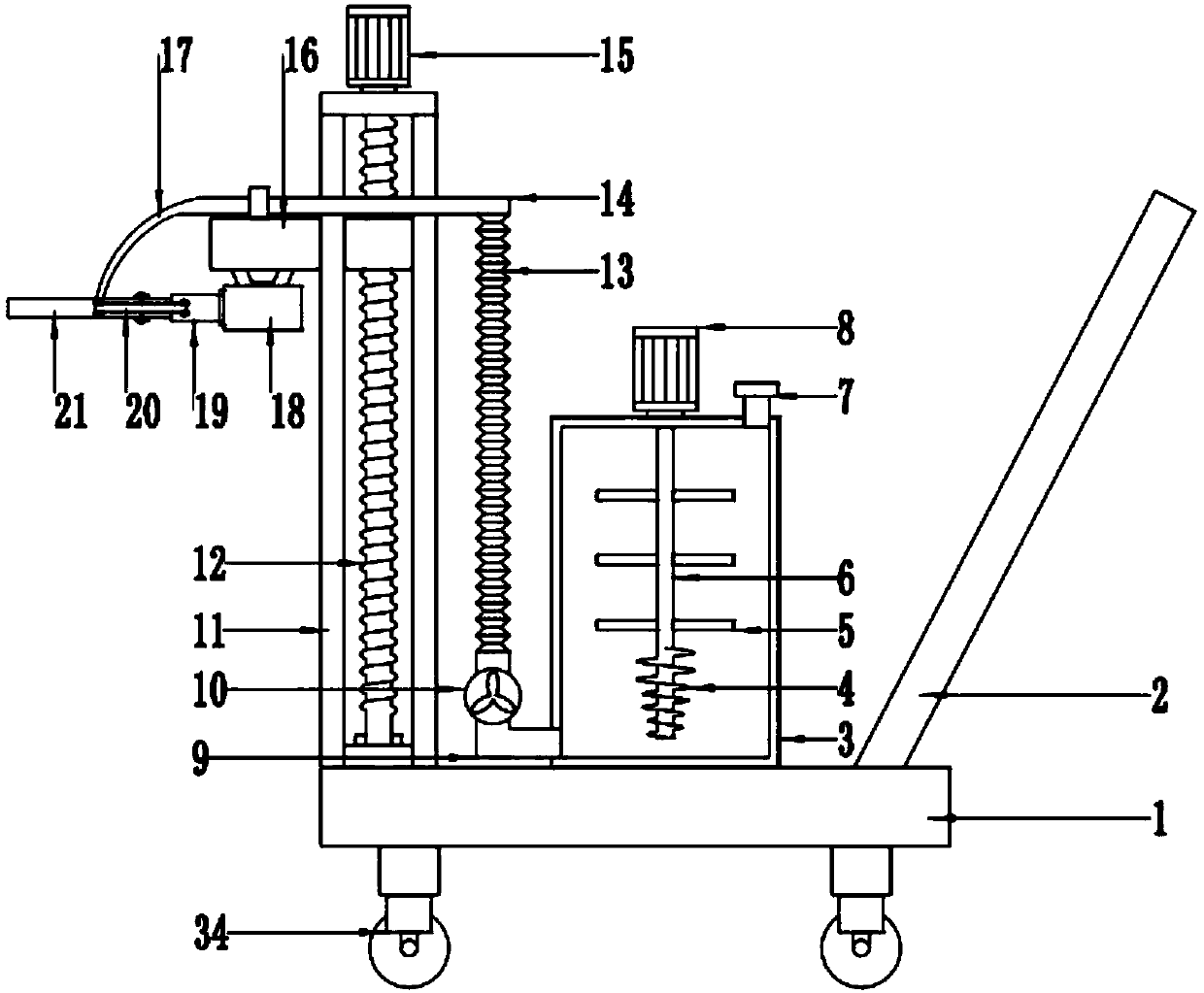

Fruit tree trunk coating machine for agricultural planting

InactiveCN107597467AEvenly paintedReduce labor intensityLiquid surface applicatorsLiquid spraying apparatusFruit treeTree trunk

The invention relates to a coating machine for agricultural planting, in particular to a fruit tree trunk coating machine for agricultural planting. The fruit tree trunk coating machine for agricultural planting can relieve the labor intensity, can improve the coating efficiency, and is simple in operation and convenient to use. The fruit tree trunk coating machine for agricultural planting comprises a cart and the like. A supporting plate is vertically connected with the left side of the top of the cart, a driving device is arranged on the supporting plate, a cross rod is connected with the driving device, and a coating device is arranged at the left end of the cross rod; and a liquid spraying device is arranged on the right side of the top of the cart, and a liquid spraying part of the liquid spraying device is arranged on a coating part of the coating device. According to the fruit tree trunk coating machine for agricultural planting, the driving device can drive the liquid sprayingdevice to spray whitewash on a tree trunk, and the effects that the labor intensity can be relieved, the coating efficiency can be improved, operation is simple, and using is convenient are achieved.

Owner:深圳诺智研机械研究设计有限公司

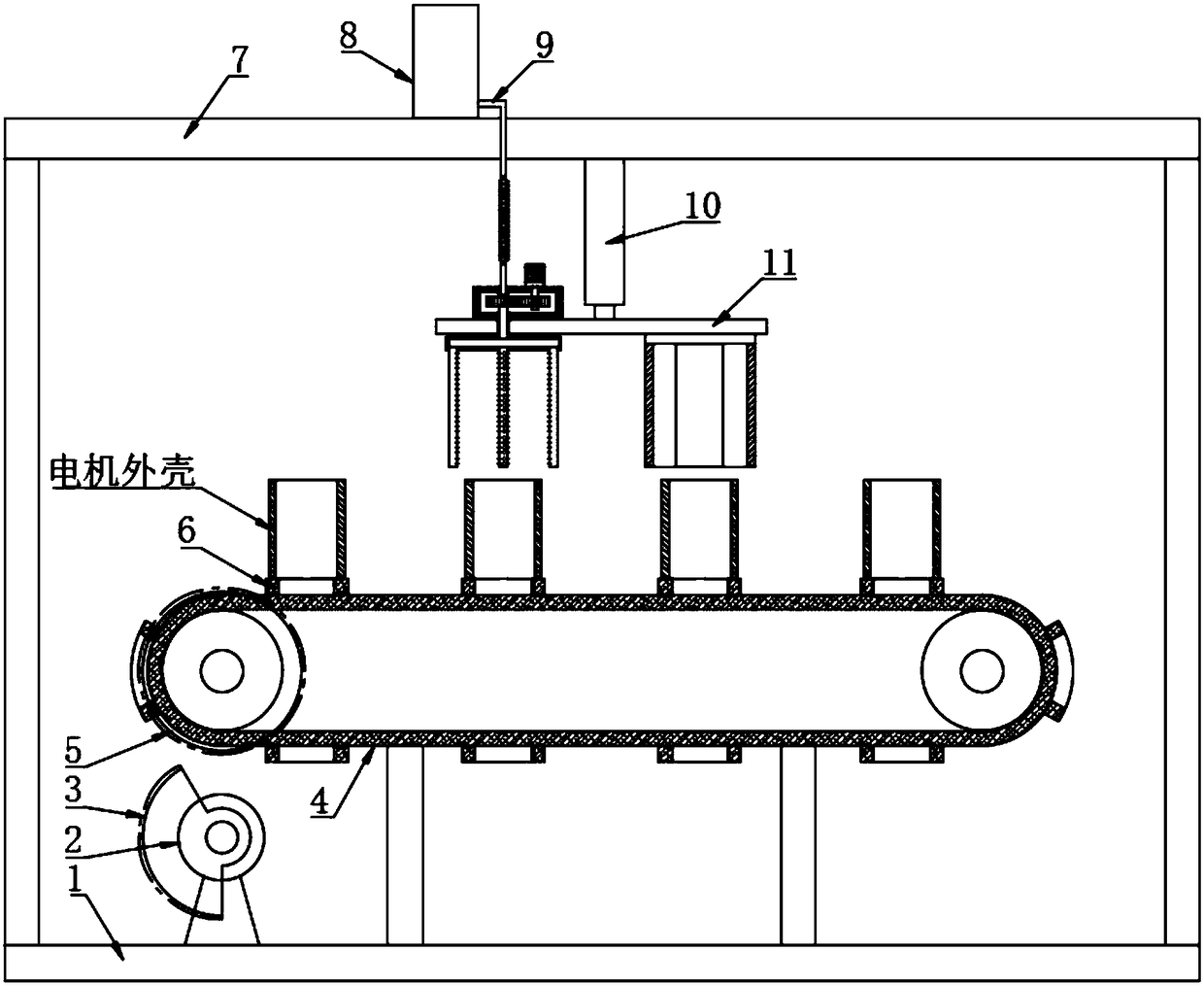

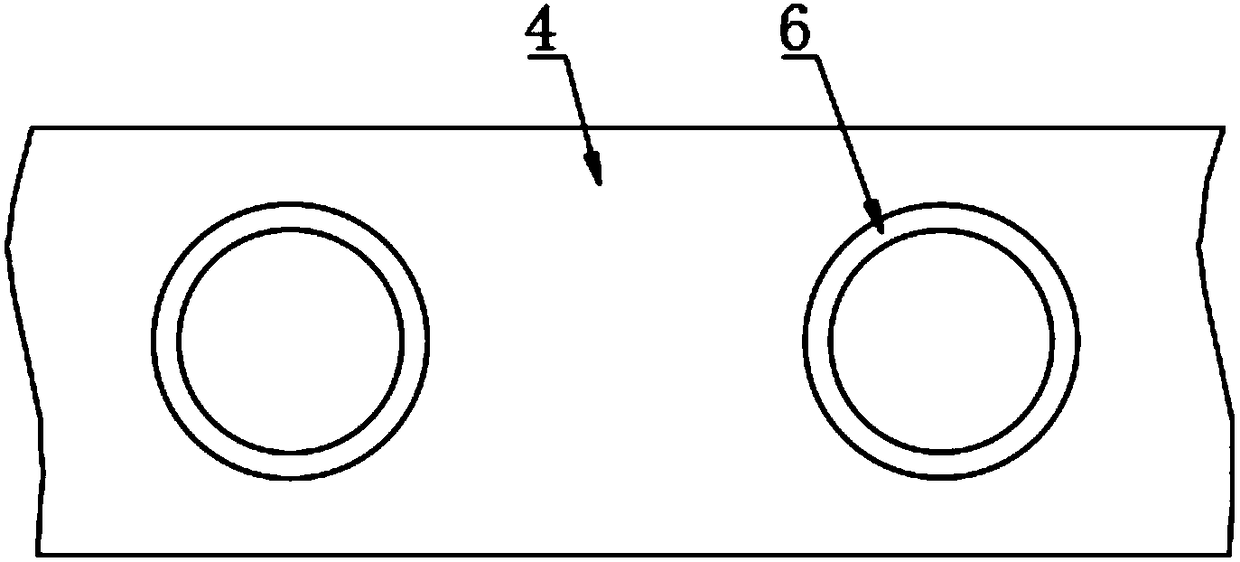

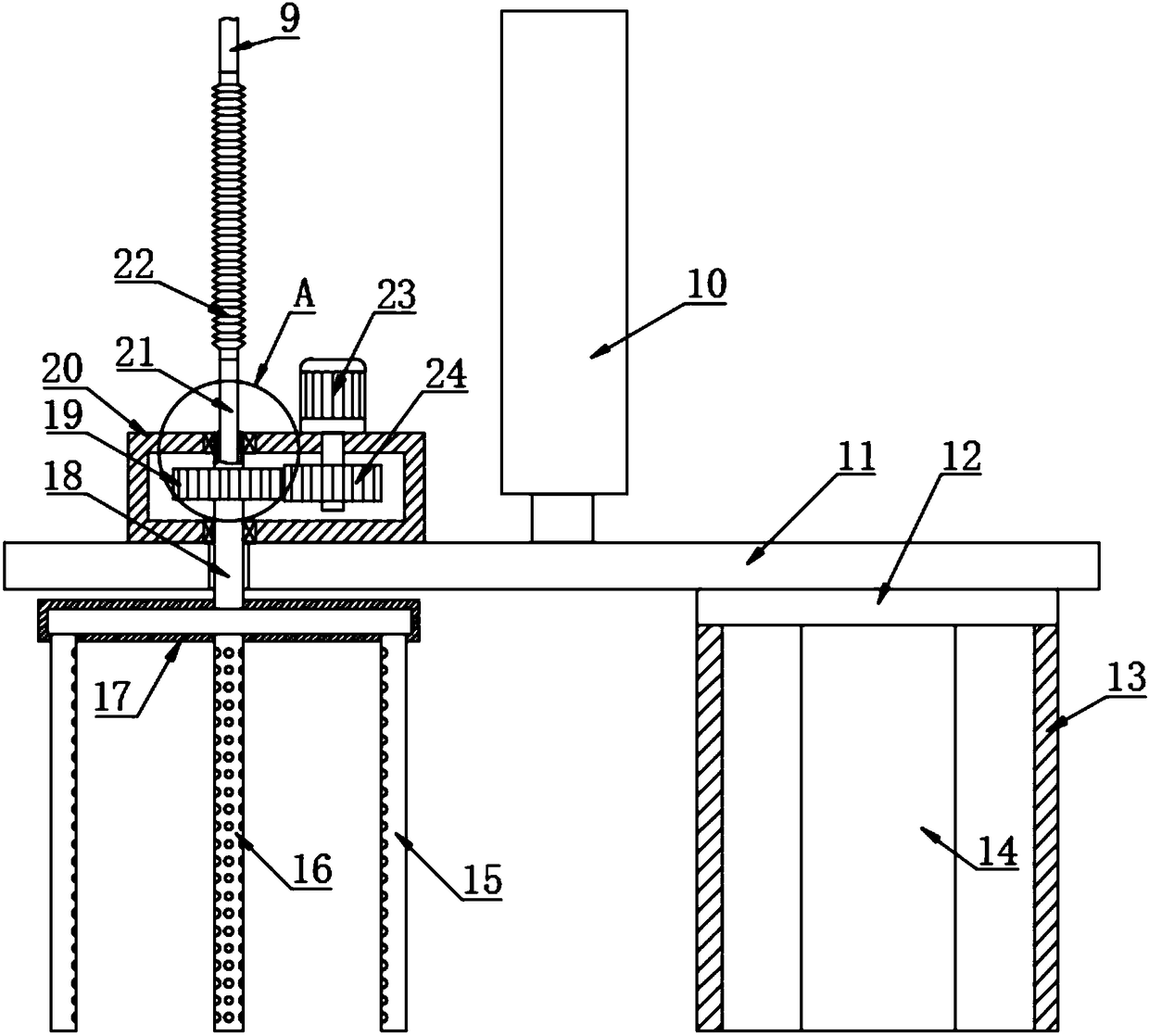

Motor shell painting and drying device

InactiveCN108452990AImprove processing efficiencyEvenly paintedSpray boothsElectric machineryAgricultural engineering

The invention discloses a motor shell painting and drying device. The motor shell painting and drying device comprises a base; a conveying belt is arranged at the top of the base through a bracket; atop plate is fixedly arranged at the top of the base through a bracket; an electric push rod is fixedly arranged at the bottom of the top plate; a push rod at the bottom end of the electric push rod is fixedly connected with a lifting plate; a gear box is fixedly arranged on the left side of the top of the lifting plate; a rotating pipe is arranged in the gear box, and is rotationally connected with the gear box; the bottom end of the rotating pipe penetrates through the lifting plate, and is fixedly connected with a hollow disc; the bottom center of the hollow disc is fixedly connected with an inner spraying pipe; outer spraying pipes are fixedly connected to the left and right sides of the bottom of the hollow disc; a painting pump is arranged at the top of the top plate; a discharge port of the painting pump is connected with a discharge pipe; the discharge pipe is connected with a supply pipe through an extension pipe; and the supply pipe is connected into a rotating pipe. Througharrangement of the outer spring pipes and the inner spraying pipe, the inner and outer walls of motor shells are painted at the same time to achieve high machining efficiency; and the inner and outerspraying pipes are rotated in the painting process to achieve more uniform painting.

Owner:ZHEJIANG OUDAO AUTOMATION EQUIP CO LTD

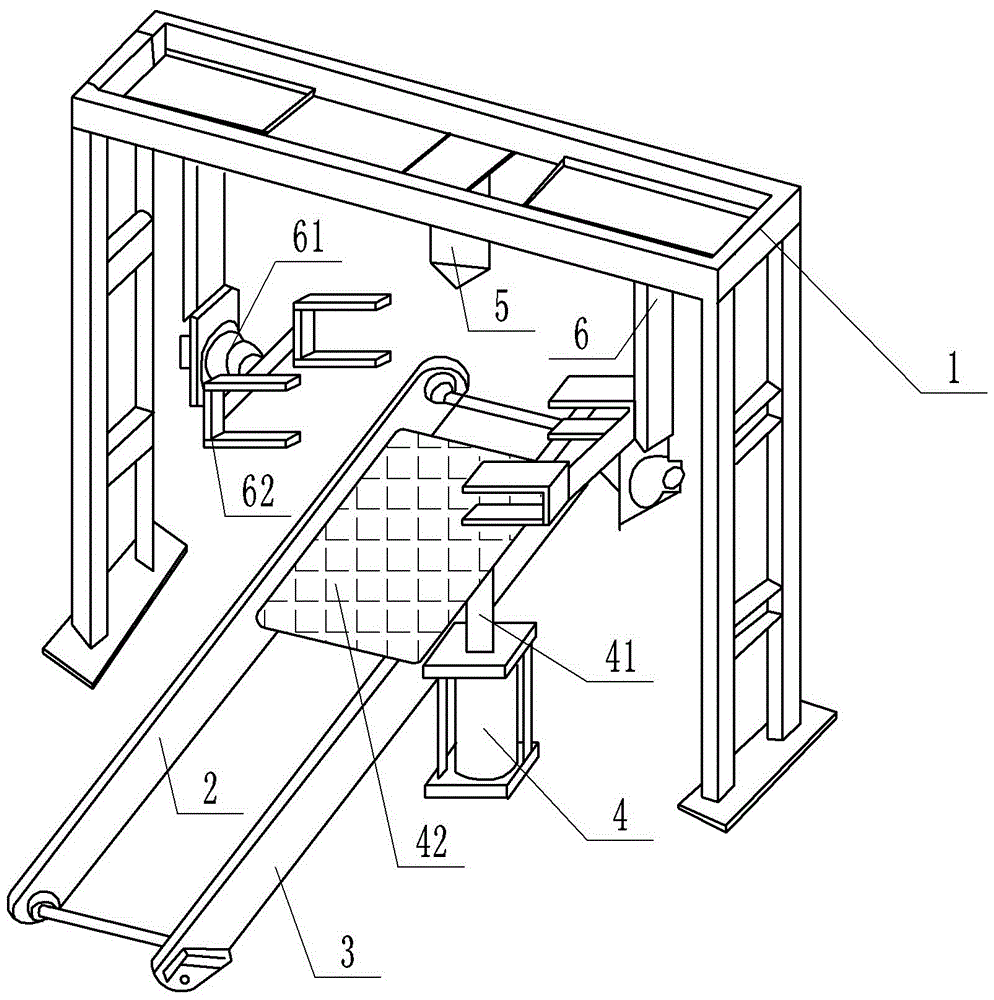

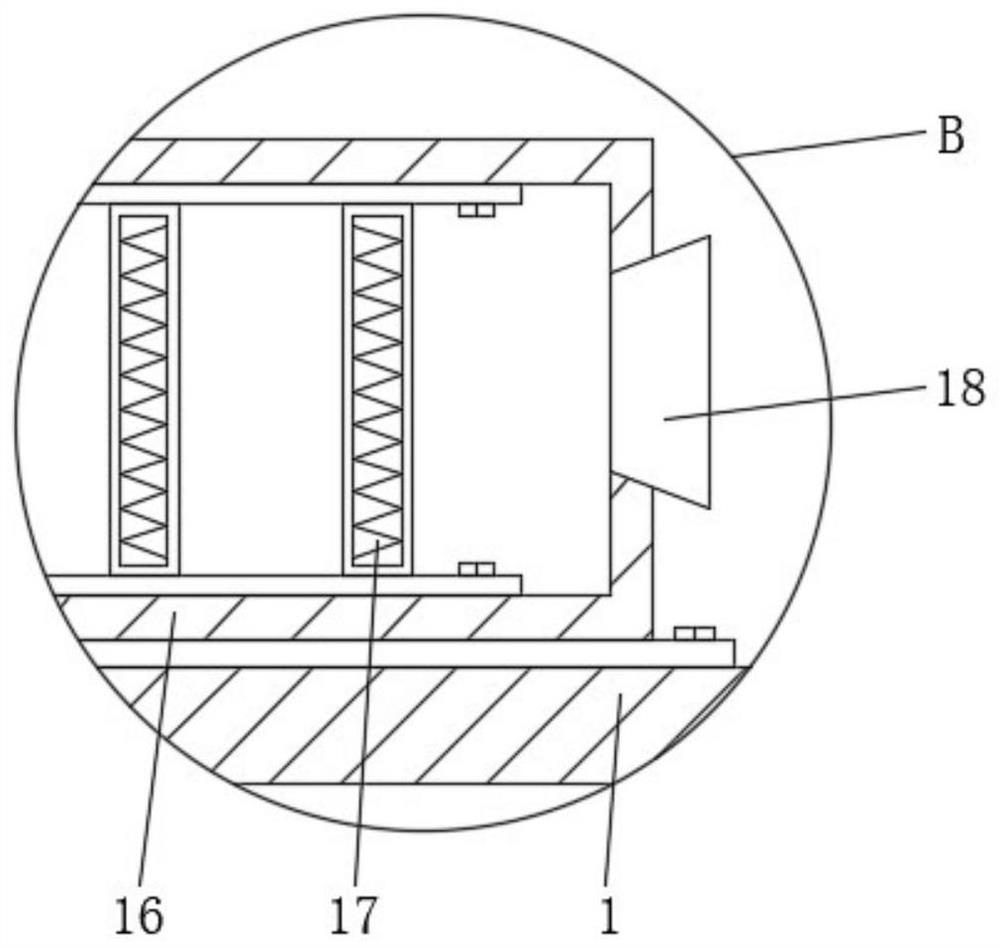

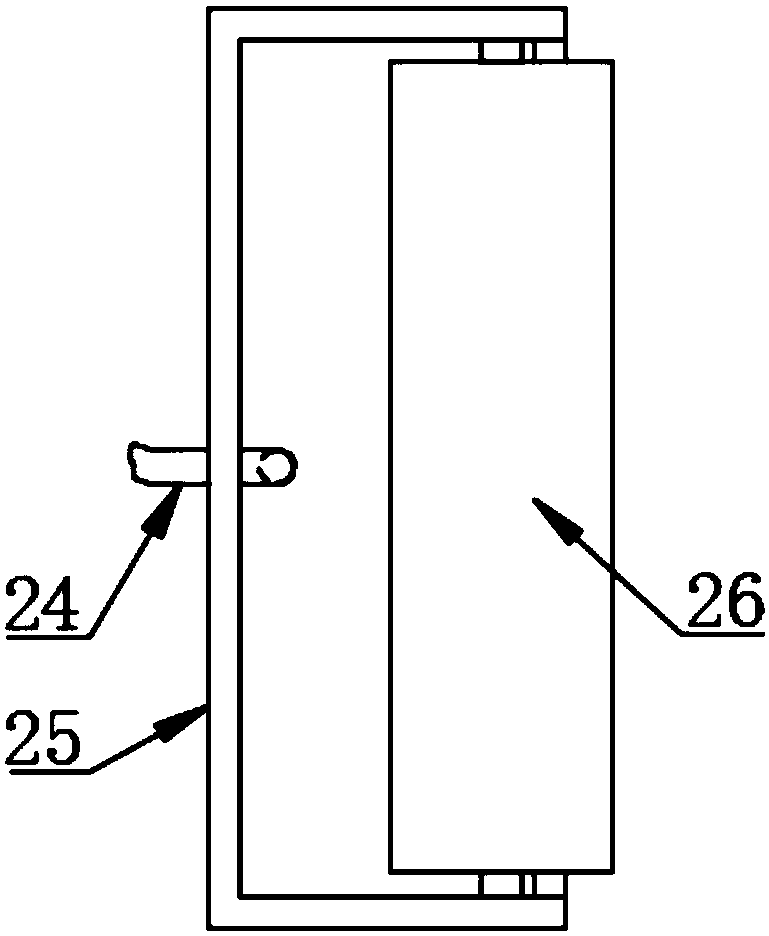

Automatic device for paint spraying of wood door

InactiveCN106423652ARealize all-round paintingReduce labor intensitySpraying apparatusUltimate tensile strengthAutomation

The invention relates to the technical field of paint spraying equipment, in particular to an automatic device for the paint spraying of a wood door. The automatic device comprises a bracket, a conveying device, a lifting device and an automatic paint spraying device, wherein the bracket is located at one side of the transporting direction of the conveying device; the conveying device comprises a left conveying chain and a right conveying chain; the lifting device is located between the left conveying chain and the right conveying chain; a clamping rotating device is arranged above the lifting device, and the clamping rotating device is fixed to the bracket; and the automatic paint spraying device is fixed to the bracket and located above the lifting device. By adopting the technical scheme, the all-dimensional paint spraying of the wood door can be realized, the automation degree is high, the labor intensity of workers is reduced, and the paint spraying efficiency is increased; and as paint spraying is carried out by the machine without depending on the experience of the workers, paint spraying is even, and the spraying effect is great.

Owner:遵义市美呈美居工贸有限公司

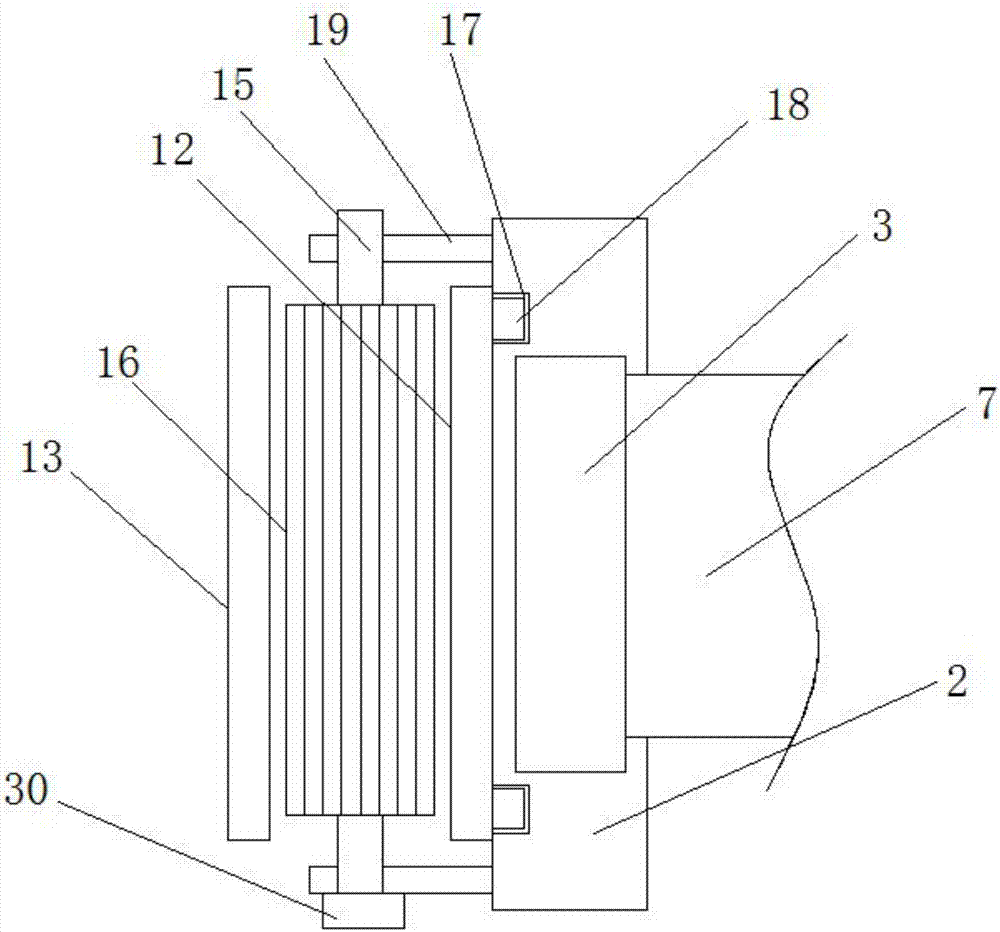

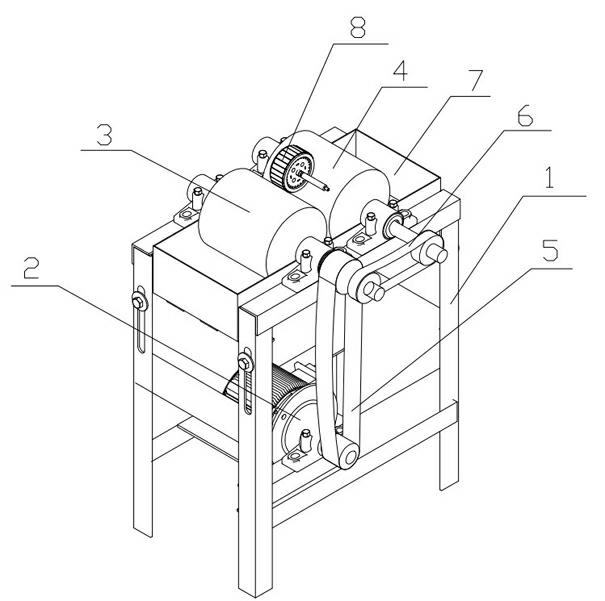

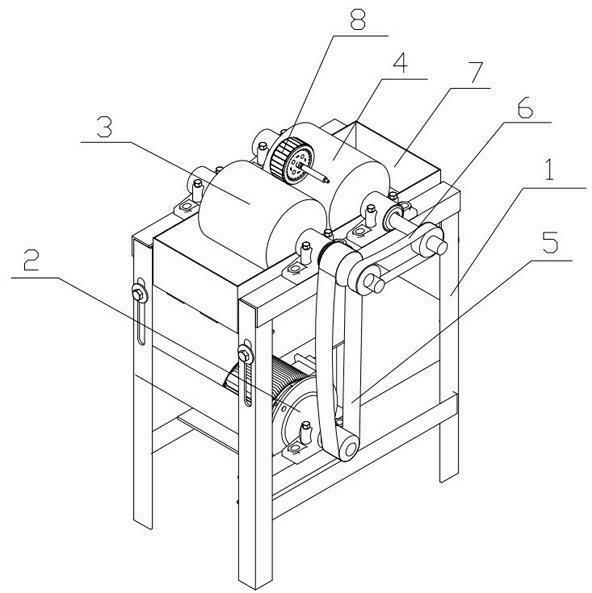

Simple rotor painting machine

The invention relates to the painting field of a motor rotor, and particularly relates to a simple rotor painting machine. The simple rotor painting machine comprises a bracket (1), a motor (2), a driving painting roller (3), a driven painting roller (4), a driving belt (5) and a driven belt (6), wherein the motor (2), the driving painting roller (3) and the driven painting roller (4) are all arranged on the bracket (1); the motor (2) is connected with the driving painting roller (3) through the driving belt (5); the driving painting roller (3) is connected with the driven painting roller (4) through the driven belt (6); the simple rotor painting machine also comprises a paint box (7) which is arranged on the bracket (1), provided with an opening at the upper end and filled with paint in the internal part, and part of the driving painting roller (3) and part of the driven painting roller (4) are soaked in the paint of the paint box (7). Therefore, the coating machine is high in painting efficiency, uniform in coating and low in cost.

Environment-friendly reversible wood board double-sided paint spraying chamber

The invention discloses an environment-friendly reversible wood board double-sided paint spraying chamber in the technical field of coating and paint spraying. The environment-friendly reversible woodboard double-sided paint spraying chamber comprises a paint spraying chamber body, a stirring tank is arranged at the top end of the left side of the paint spraying chamber body, a stirring shaft isarranged in an inner cavity of the stirring tank, a first motor is arranged in the middle of the top end of the stirring tank, and a liquid inlet is formed in the top end of the right side of the stirring tank. According to the environment-friendly reversible wood board double-sided paint spraying chamber, through the arrangement of a turnover mechanism and a movable telescopic paint spraying mode, paint spraying can be carried out on the two faces of a wood board, the paint spraying area is adjustable, the environment-friendly reversible wood board double-sided paint spraying chamber can adapt to wood boards of different sizes, paint spraying is uniform; through the arrangement of a heating device, rapidly drying and heating one paint-sprayed face of the wood board can be carried out; through an arranged stirring device, stirring paint can be carried out; through an arranged water washing box, waste gas in the paint spraying chamber can be pumped out, purified and exhausted in time; and through an arranged fixing device, fixing the non-paint-spraying face of the wood board is carried out, and paint spraying of the paint spraying face is more complete.

Owner:张欣欣

Efficient iron pipe paint-spraying device for hardware

ActiveCN106140552AEvenly paintedGood paint effectLiquid surface applicatorsCoatingsPistonEngineering

The invention relates to an iron pipe paint-spraying device, in particular to an efficient iron pipe paint-spraying device for hardware. By the adoption of the efficient iron pipe paint-spraying device for hardware, the technical purposes of good paint spraying effect, high paint spraying efficiency and simple operation are achieved. For achieving the technical purposes, the efficient iron pipe paint-spraying device for hardware comprises a base plate, a left side plate, a pulley, a first sliding rail, a 7-shaped support, a first motor, a storage plate, a gear, a disc, a first connecting rod, a second connecting rod, a second connecting rod, a supporting rod, an air cylinder, a paint spraying head, a second sliding rail, a compression cylinder, a piston, a first hose, a first one-way valve, a brush, a first sliding block, a first spring and the like. The left side plate, the pulley, the first sliding rail and the 7-shaped support are arranged at the top of the base plate in sequence from left to right. According to the efficient iron pipe paint-spraying device for hardware, a transverse plate and a third spring are utilized, so that the bush and an iron pipe are kept being in contact all the time, and the good paint spraying effect and high paint spraying efficiency are achieved.

Owner:江苏德祐精密钢管有限公司

Paint spraying system and method for environment-friendly furniture production

InactiveCN112387442AAvoid pollutionImprove quality and efficiencyPretreated surfacesLiquid spraying apparatusThermodynamicsProcess engineering

The invention relates to the technical field of paint spraying devices, and particularly relates to a paint spraying system and method for environment-friendly furniture production. The paint sprayingsystem comprises a paint spraying box, a paint box and a treatment box, wherein the paint box and the treatment box are located on the two sides of the paint spraying box correspondingly; a partitionplate is connected to an inner cavity of the paint spraying box in a bolted mode; a mounting plate is arranged at the top of the partition plate; a rotating shaft is connected to the bottom of the mounting plate in a bolted mode; and the rotating shaft penetrates through the bottom of the partition plate. The paint spraying system has the advantages that the paint spraying effect is good, the paint spraying uniformity can be guaranteed, waste gas generated by paint spraying can be absorbed, air pollution is prevented, meanwhile, the paint solidification time can be effectively shortened, andthen the furniture production quality and the production efficiency can be improved; and the problems that a paint spraying device used for furniture production at present is poor in paint spraying effect, uneven paint spraying on the surface of furniture is prone to being caused, the waste gas generated by paint spraying cannot be absorbed and treated, and therefore air pollution can be caused, and the body health of workers is affected are solved.

Owner:章 忠

Efficient and uniform wooden product paint spraying equipment

The invention discloses efficient and uniform wooden product paint spraying equipment, and belongs to the field of wooden product machining equipment. The device comprises a base, supporting columns,a top plate, a paint spraying and drying device, a fixing device and a recycling device; the paint spraying and drying device comprises a threaded rod, a positive and negative rotating motor, a threaded sleeve, a paint spraying mechanism and a drying mechanism; an installing rack is fixedly connected to the right end of the threaded sleeve; the paint spraying mechanism comprises a paint box, a paint pump and paint sprayers; the drying mechanism comprises a hot air chamber, a hot air blower and air nozzles; the paint sprayers are fixedly installed at one end of the installing rack; and the airnozzles are fixedly installed at the other end of the installing rack. According to the efficient and uniform wooden product paint spraying equipment, efficient, uniform and comprehensive paint spraying and drying operation can be conducted on wooden products, redundant paint in the paint spraying process can be recycled, and unnecessary waste can be reduced.

Owner:安徽菌仙菇农业开发有限公司

Self-loading type building wall paint coating device

InactiveCN107859296AImprove painting efficiencyEvenly paintedBuilding constructionsMotor shaftLacquer

The invention discloses a self-loading type building wall paint coating device comprising a base seat, and the top of the base seat is fixedly provided with a fixing plate which is in an L shape; theright side wall of the fixing plate is fixedly provided with a slide rail, and a lifting plate is connected to the right side of the slide rail in a slide mode; a paint box is fixedly arranged on thetop portion of the lifting plate, a brush roller is connected with the right side of the paint box in a rotation mode, and the right end of a discharging pipe is connected to the interior of the paintbox by a telescopic hose. A second deceleration motor is also fixed on the bottom of the right side wall of the slide rail; a motor shaft at the top of the second deceleration motor is connected witha screw, and the screw is left handed; and the screw passes through the lifting plate and is connected with the lifting plate in a threaded mode. The device drives the lifting plate to move up and down through the rotation of the screw, thereby driving the brush roller to rotate and move up and down to perform paint brushing; the paint brushing height can be freely adjusted, the safety of the personnel is ensured, the painting efficiency is high, the paint brushing is uniform, and the labor quantity is effectively reduced.

Owner:ZHENGZHOU UNIVERSITY OF AERONAUTICS

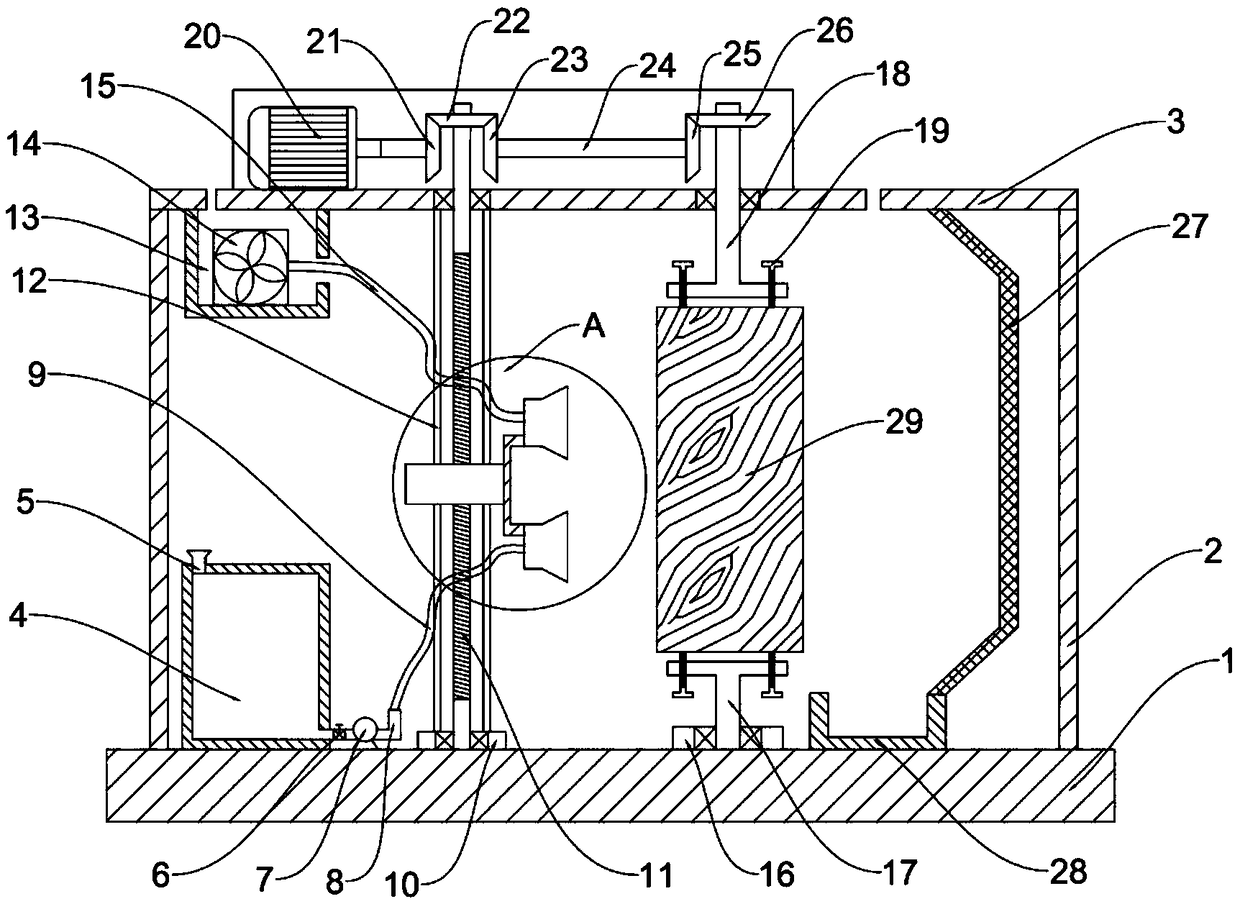

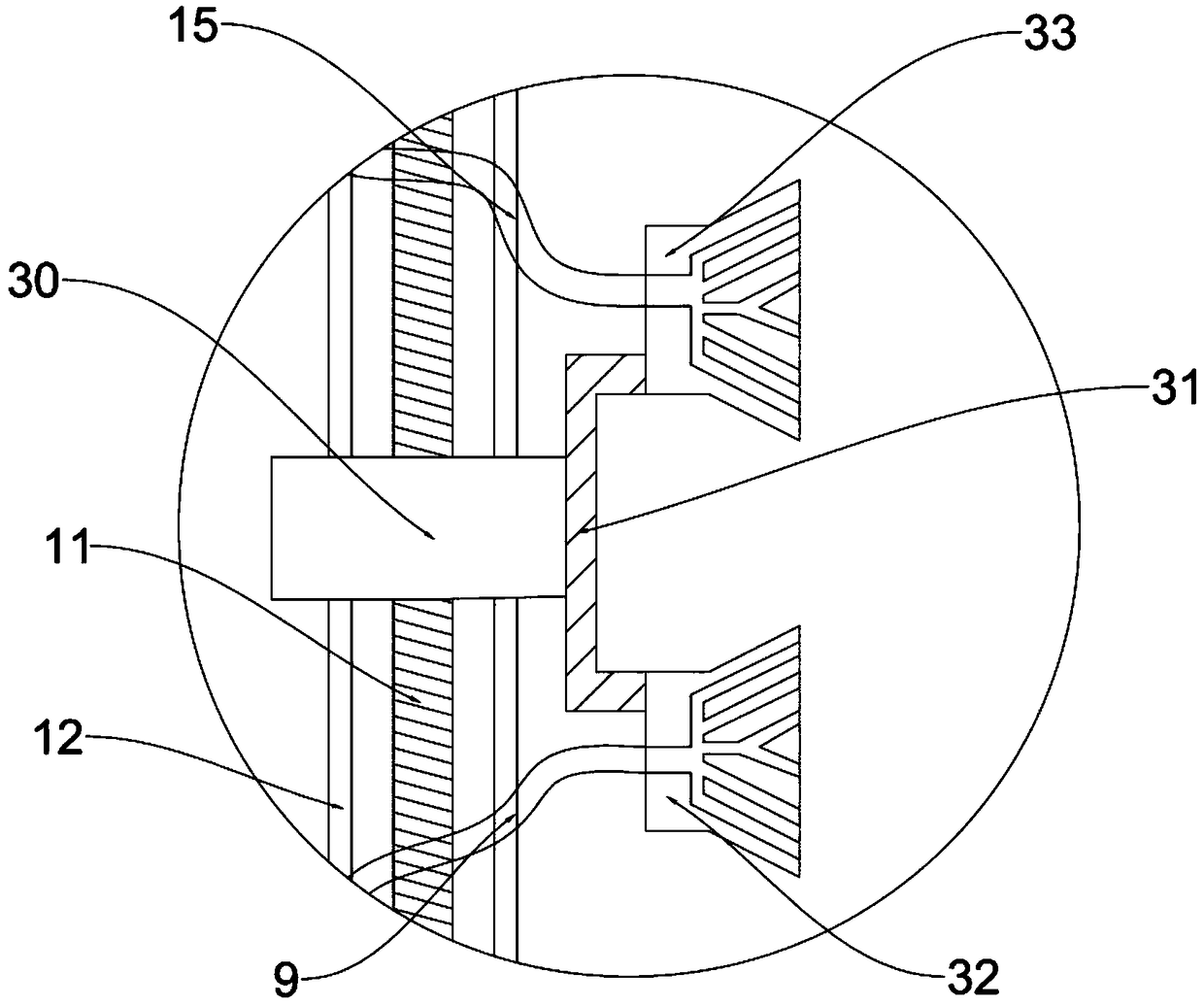

Spray paint device of loudspeaker box

InactiveCN107812647AAvoid close contactRealize automatic feeding processLiquid spraying apparatusSpray boothsElectric machineryEngineering

The invention discloses a spray paint device of a loudspeaker box. The spray paint device comprises a box, and a driving roller and a driven roller are rotatably connected between two opposite sides of the inner wall of the box in sequence; one side of the bottom of the inner wall of the box is fixedly connected to a first motor, and the output shaft end of the first motor is connected to a rotating device through a belt; one side of the rotating device is fixedly connected to one end of the driving roller, and the driving roller is rotatably connected to the surface of the driven roller through a conveyor chain; the bottom of the inner wall of the box is fixedly connected to a lifting rotation device, and the top of the box is fixedly connected to a third motor; and two opposite sides ofthe inner wall of the box are rotatably connected to second screw rods through bases, and the surfaces of the second screw rods are fixedly connected to first nozzle bases through electric telescopicrods of movable blocks. The invention relates to the technical field of loudspeaker machining. According to the spray paint device of the loudspeaker box, the problem of uneven thickness of existing spray paint is solved; and the purpose of automatic uniform spray paint is achieved, and the paint harm to human bodies is reduced.

Owner:湖州宏跃电子器件厂

Steel pipe painting device and application method thereof

The invention relates to the field of building construction, in particular to a steel pipe painting device and an application method thereof. The steel pipe painting device comprises a base, a supporting plate, a transverse plate, a first vertical plate, a first motor, a first conical block, a first T-shaped sliding groove, a first T-shaped sliding block, a second vertical plate, a threaded rod and a second conical block, wherein through reasonable design of the structures, the first conical block and the second conical block form a steel pipe clamping structure; the steel pipe painting devicealso comprises a supporting plate, a trapezoid block, a rack, a second T-shaped sliding groove and a second T-shaped sliding block, wherein the structures form a sliding platform for a paint storagegroove; and sliding of the paint storage groove and the painting work on a steel pipe are realized through a rolling brush, an L-shaped plate, a second motor, a half gear, a positioning groove, a mounting plate, a speed reducer, a ball and a second retaining ring. According to the steel pipe painting device, manual painting is not needed, the painting is uniform, waste of a large amount of paint is avoided, damage to the health of a human body and the pollution to the environment are avoided, and the working efficiency is high.

Owner:CHINA MCC17 GRP

Device for rapidly spraying paint on surfaces of iron pipes

The invention relates to a device for spraying paint on surfaces of iron pipes, in particular to a device for rapidly spraying paint on surfaces of iron pipes, and aims to provide the device which is used for rapidly spraying the paint on the surfaces of the iron pipes and is uniform in paint spraying, high in working efficiency and simple to operate. The device for rapidly spraying the paint on the surfaces of the iron pipes is provided to solve technical problems and comprises a top plate, a first sliding rail, a first sliding block, a paint spraying hose, a valve, a feeding pipe, a paint pump, a paint box, a spray head, a first air cylinder, a first connecting rod, a disk, a motor, a second connecting rod, a support, a second sliding rail, a second sliding block, a bearing block, supporting rods, a second air cylinder, third connecting rods, a guide rod, a guide sleeve, a rotating shaft, a gear, a rack and a fixed block, wherein the paint box is arranged at the top of the top plate; the feeding pipe is arranged at the top of the paint box; the valve is arranged on the feeding pipe; and the paint pump is arranged at the bottom inside the paint box. The device realizes effects of being uniform in paint spraying, high in working efficiency and simple to operate.

Owner:ZHEJIANG TIANYANG STEEL TUBE CO LTD

Reciprocating type external facade uniform paint spraying device

The invention discloses a reciprocating type external facade uniform paint spraying device. A drive motor is arranged on the left side of the upper portion of the device body, the right side of the drive motor is rotatably connected with a crankshaft, a mixing chamber is arranged on the left side of the device body, the left side of the crankshaft is fixedly connected with a first conical gear, asecond conical gear is fixedly connected with a driven shaft, the driven shaft is rotatably connected with the mixing chamber, multiple stirring rods are arranged on the surface of the driven shaft, apaint spraying chamber is arranged on the right side of the mixing chamber, the lower end of the mixing chamber is provided with a one-way valve, the one-way valve is communicated with the paint spraying chamber, according to the device, the rotating crankshaft drives the first conical gear to rotate so as to drive the driven shaft to rotate, the driven shaft drives the stirring rods to enable paint in the mixing chamber to be sufficiently mixed and stirred, meanwhile, a connecting rod drives a piston plate to do reciprocating up and down sliding along the inner wall of the paint spraying chamber to extrude paint in the paint spraying chamber, a thread rod which rotates positively and reversely in a reciprocating manner drives a casing block to reciprocate and move up and down along a sliding groove so as to drive a spraying head to spray paint along with the reciprocated up and down moving, paint spraying is more uniform, and continuous work of paint spraying of the external facade can be achieved.

Owner:纪美

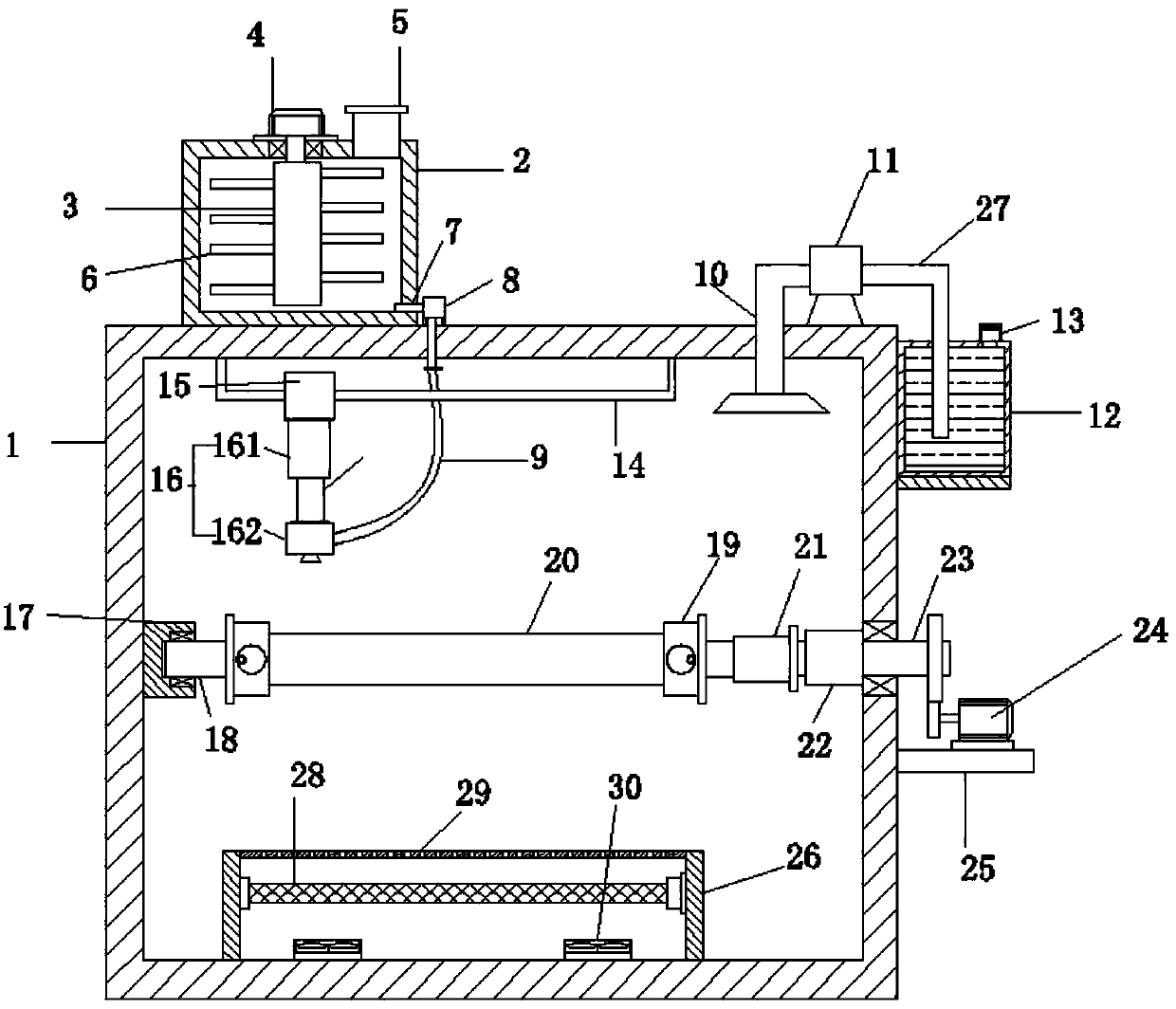

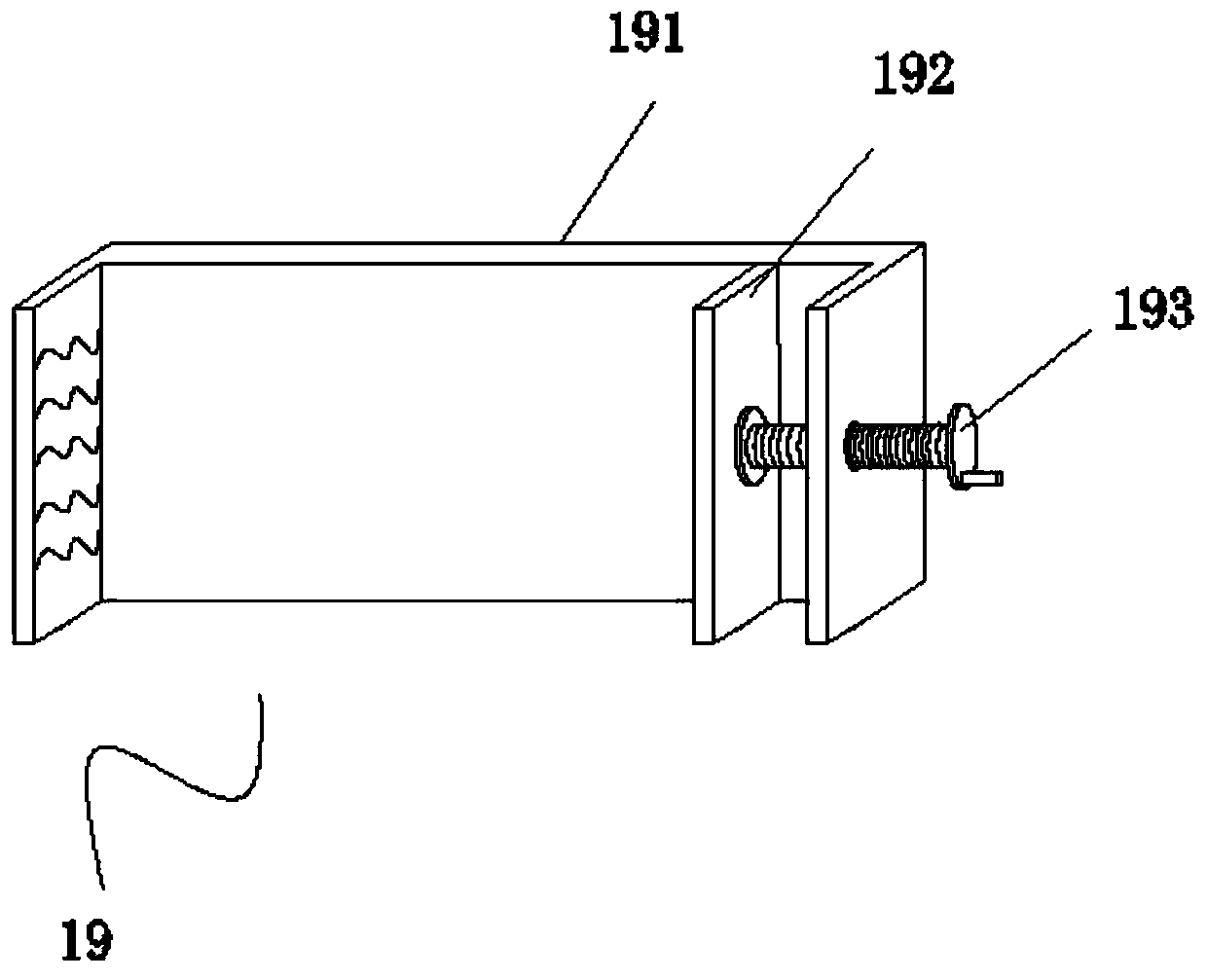

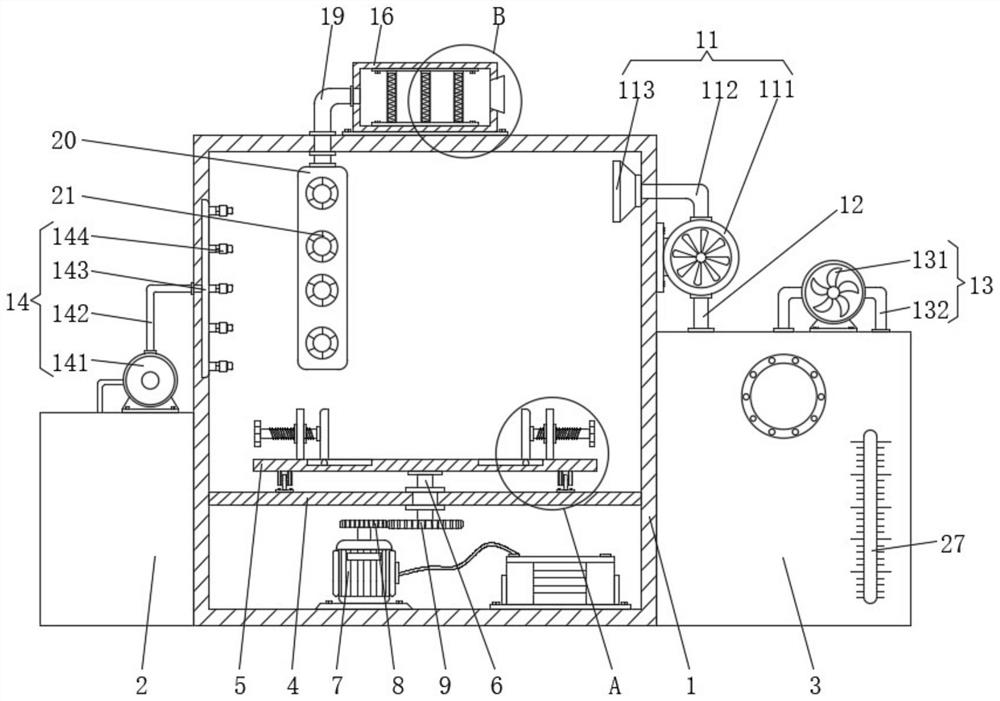

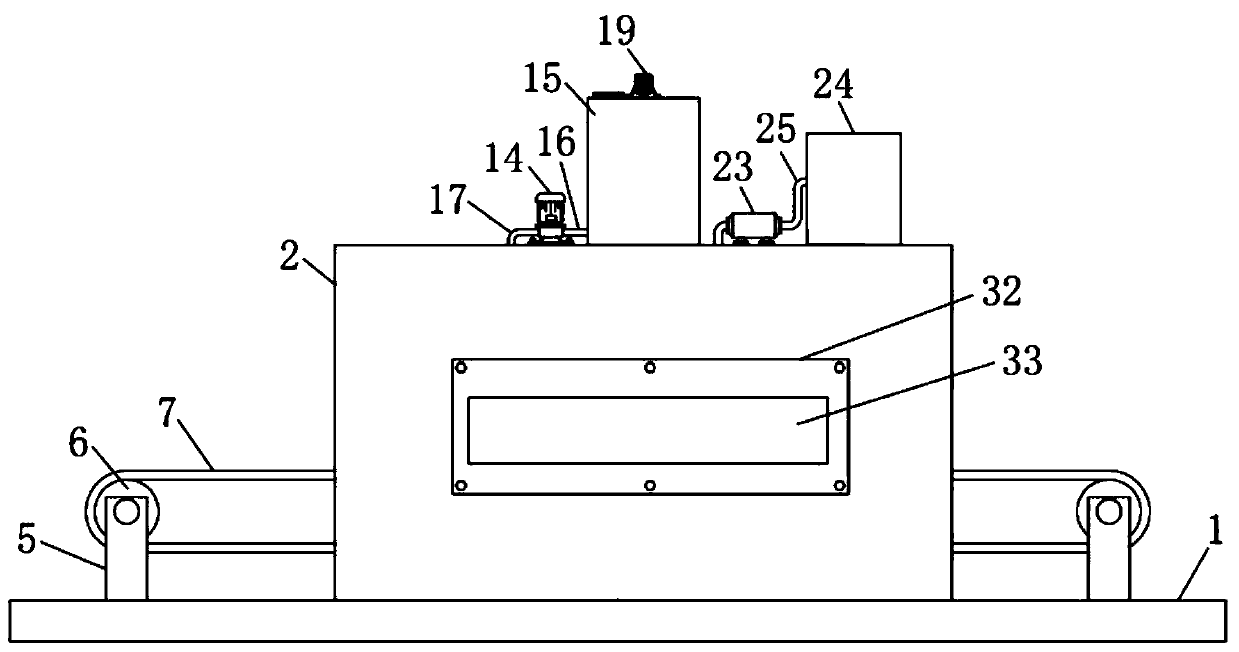

Intelligent spraying and drying production line

InactiveCN108043646AIntelligent temperature controlEvenly paintedSpray boothsAgricultural engineeringProduction line

The invention discloses an intelligent spraying and drying production line. The intelligent spraying and drying production line comprises a rack, a transmission mechanism, a spraying mechanism, a drying mechanism, a circulating ventilation mechanism, a feeding and discharging mechanism, a positioning device, a detection device and a control mechanism, wherein the transmission mechanism is composedof a servo motor, a first bearing pack, a driving rotating shaft, a driving gear, a second bearing pack, a driven rotating shaft, a driven gear, a drag chain, a tensioner and a panel type chain plate, the spraying mechanism is composed of a first spraying housing, a first spraying robot, a first exhaust pipe, a first air ejecting fan, a second spraying housing, a second spraying robot, a second exhaust pipe and a second air ejecting fan, and the drying mechanism is composed of a first drying housing, a first infrared heating pipe, a first temperature sensor, a second drying housing, a secondinfrared heating pipe and a second temperature sensor. The intelligent spraying and drying production line has the beneficial effects of simple structure and high practicability.

Owner:俞尧芳

Efficient iron pipe painting device

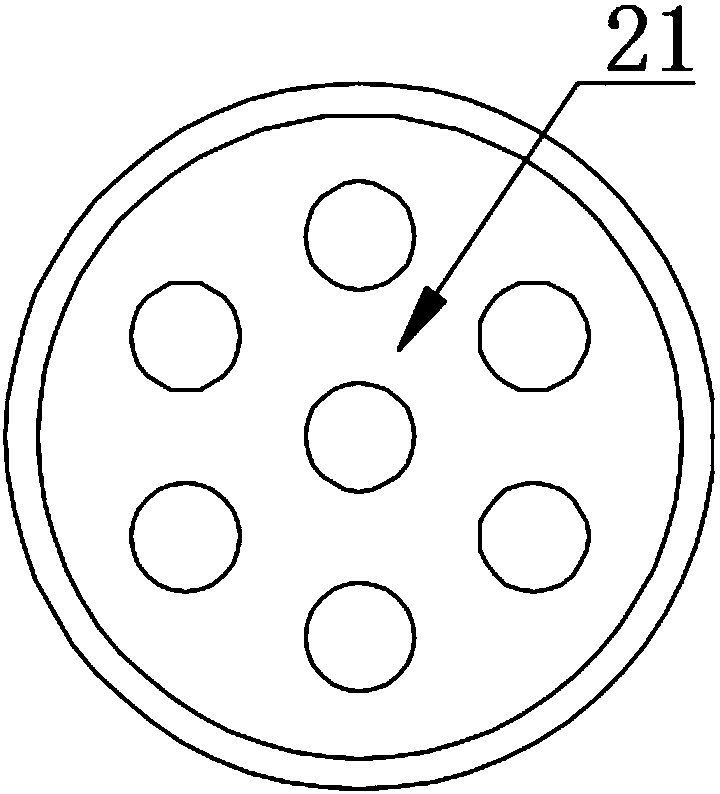

ActiveCN106140537AEvenly paintedEasy to fixGrinding carriagesPolishing machinesEngineeringBevel gear

The invention relates to an iron pipe painting device, in particular to an efficient iron pipe painting device. The technical problem to be solved is to provide the efficient iron pipe painting device which is even in painting, reasonable in design and capable of saving energy. The efficient iron pipe painting device comprises a bottom plate, left side plates, a first bearing seat, a second bearing seat, a right side plate, a top plate, a sliding rail, a motor, a third bearing seat, a fourth bearing seat, a fifth bearing seat, a paint box, a first rotary shaft, a first gear, a first bevel gear, a water pump, a sliding block, a rack, a nozzle, a hose, a second rotary shaft, a second bevel gear, a first belt wheel, a third rotary shaft and the like. The left side plates arranged on the bottom plate sequentially from left to right. The spray nozzle is used for the efficient iron pipe painting device provided by the invention, the hole diameter of the nozzle is 10 mm, and holes are concentrated and distributed in the middle of the nozzle evenly.

Owner:唐尾娥

Part surface paint spraying device for automobile manufacturing

ActiveCN108080188ANice appearanceEnsure personal safetySpraying apparatusFixed frameMotor vehicle part

The invention relates to a paint spraying device, in particular to a part surface paint spraying device for automobile manufacturing and aims to realize convenience in use, labor saving and time saving of the part surface paint spraying device for automobile manufacturing. The part surface paint spraying device for automobile manufacturing comprises a fixing frame, a slide rod, a slide sleeve, a first connection block, a first motor, a first belt pulley, a first connection belt, a connection pipe, a first bearing, a hollow rotating shaft and the like. The slide sleeve is slidably mounted on the slide rod which is mounted on the upper portion of the fixing frame, and a supporting plate is mounted at the lower end of the first connection block which is mounted on the lower portion of the slide sleeve. The part surface paint spraying device has advantages of convenience in use, labor saving, time saving, quick in automobile part paint spraying operation, high in practicality and saving ofa great quantity of manpower, processed finished products are attractive in appearance, uniformity in paint spraying and safety in use are achieved, and personal safety of workers is guaranteed.

Owner:广州聚晟宏科技有限公司

Automobile part paint spraying device capable of uniformly spraying

InactiveCN111495661AAvoid settling and stratificationSpeed up the solidificationPretreated surfacesCoatingsAutomotive engineeringManufacturing engineering

Owner:高敏

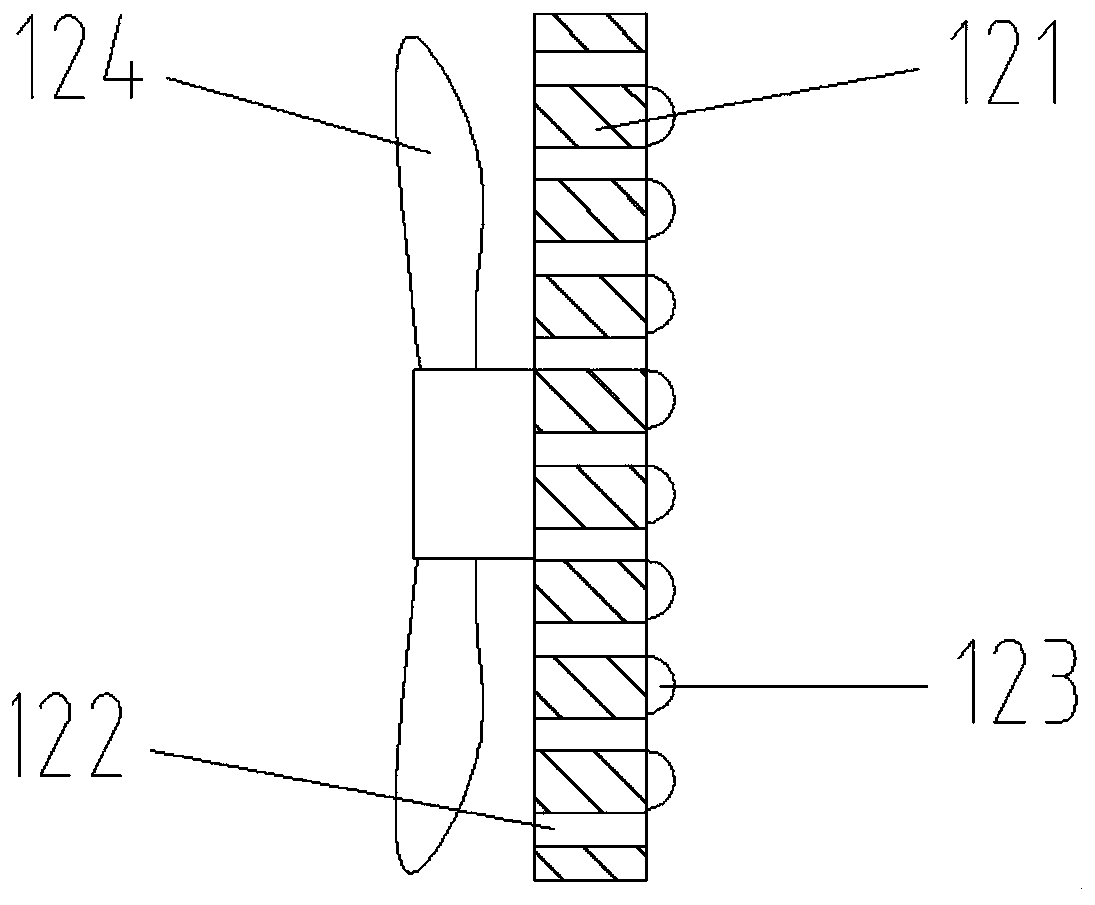

Whitewash device applicable to trees with different diameters

InactiveCN107583813AIncrease whitening perimeterEvenly paintedLiquid surface applicatorsRotary stirring mixersEngineeringWhitewash

The invention discloses a whitewash device applicable to trees with different diameters. The whitewash device comprises a bottom plate, a pushing handle, a material storage mechanism, a lifting mechanism and a paintingbrushing mechanism, wherein the pushing handle is arranged on the bottom plate, and the material storage mechanism is arranged on the left side of the pushing handle; the lifting mechanism is arranged on the left side of the material storage mechanism and comprises a lifting chamber, a threaded rod, a forward and reverse rotating motor A, a moving block and a fixed block; the painting mechanism is arranged on the left side of the lifting mechanism and comprises an electric telescopic rod A, connecting rods, arc plates A, arc plates B, arc chutes, arc racks, electric telescopic rods B, gears, forward and reverse rotating motors B, arc chambers, chutes, sliders, painting rollers, connecting ports and movable blocks. The whitewash device can paint the trees with different diameters white, is widely applied and has good painting effect and high whitewash efficiency.

Owner:SHENZHEN SHENGXIANG INTPROP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com