Electric heating bamboo floor

A bamboo floor, electric heating technology, applied in the field of building materials decoration, to achieve the effect of reducing interference radiation, avoiding water stains and soaking, and quickly and evenly heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings, but the implementation of the present invention is not limited thereto.

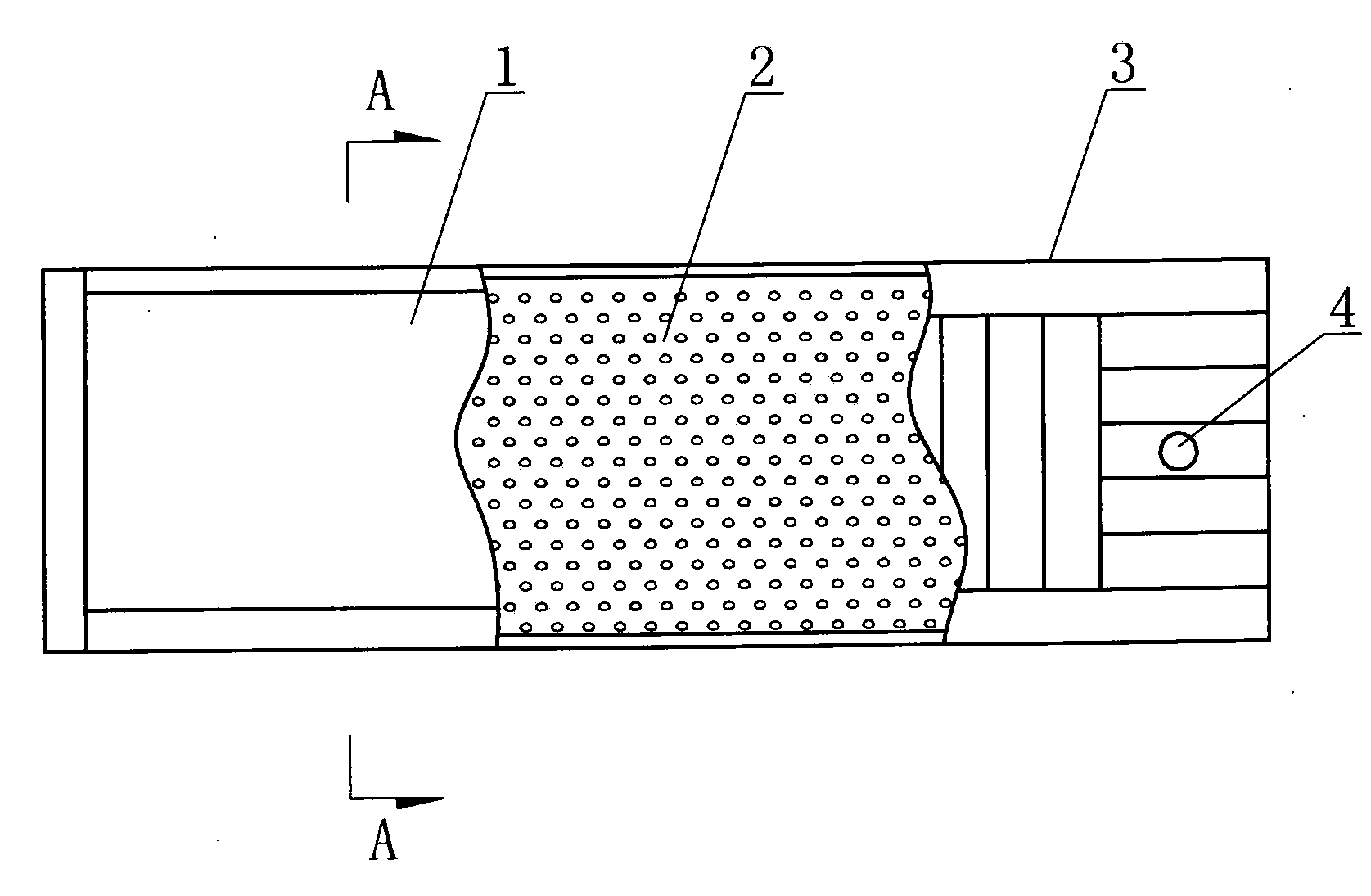

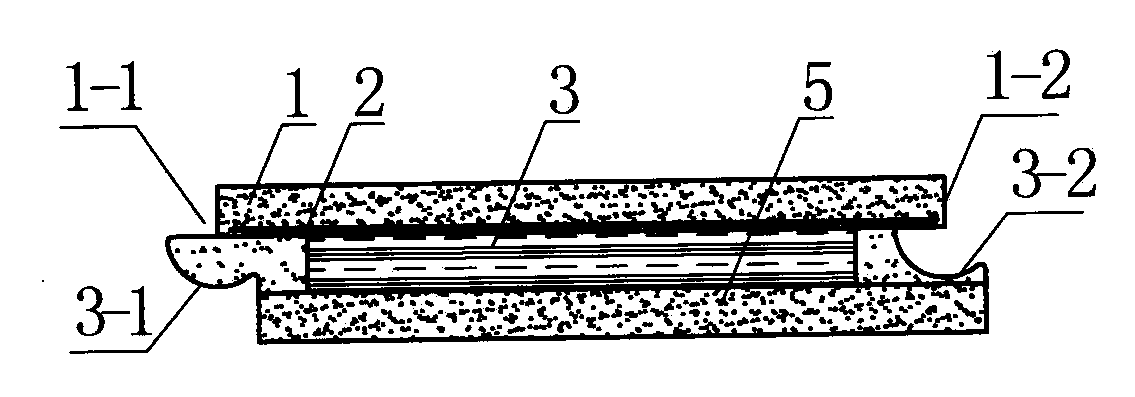

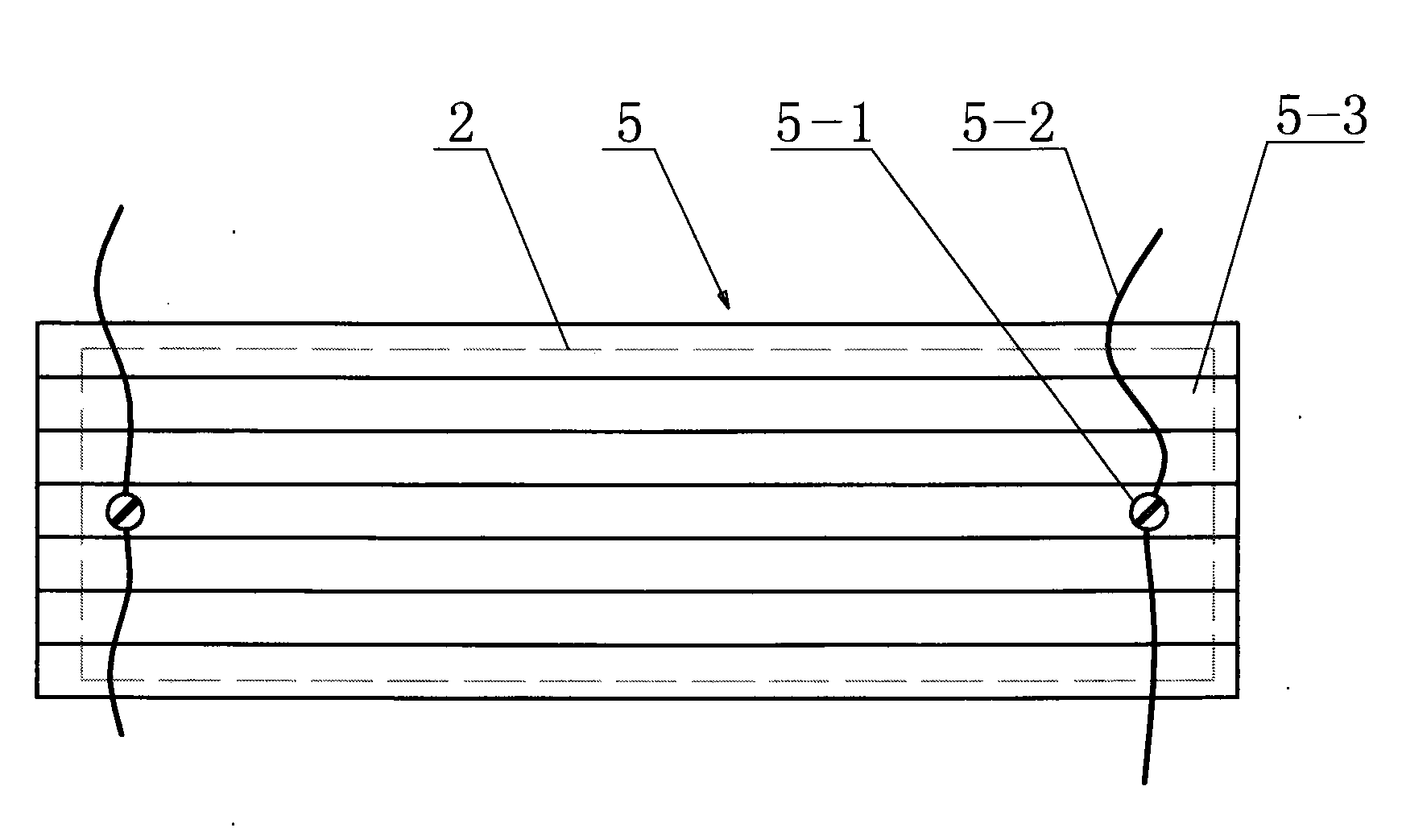

[0030] figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 Embodiments of the invention are shown.

[0031] An electric heating bamboo floor, comprising a heat conduction panel 1, an electric heating body layer 2, a middle plate 3, and a bottom plate 5, and the heat conduction panel, the middle plate, and the bottom plate are sequentially connected into one body by bonding high temperature and high pressure from bottom to top Plate shape, on the bonding surface of the middle plate 3 and the heat conduction panel 1, there is a sheet-like electric heating body layer 2, the electric heating body layer 2 is electrically connected with the electrode connecting screw 5-1 through the conductive hole 4, and each forming plate The corresponding lock-t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com