Method for manufacturing composite bamboo floor

A manufacturing method and technology of bamboo flooring, applied in the direction of manufacturing tools, joining of wooden veneers, chemical instruments and methods, etc., can solve the problems of low bamboo utilization rate and high production cost, and achieve convenient blank assembly, low production cost, The effect of small glue consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

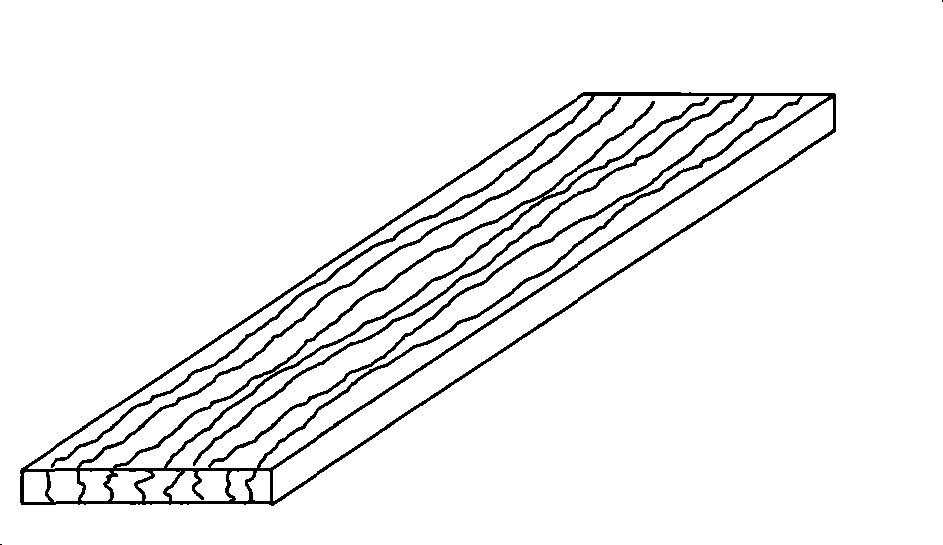

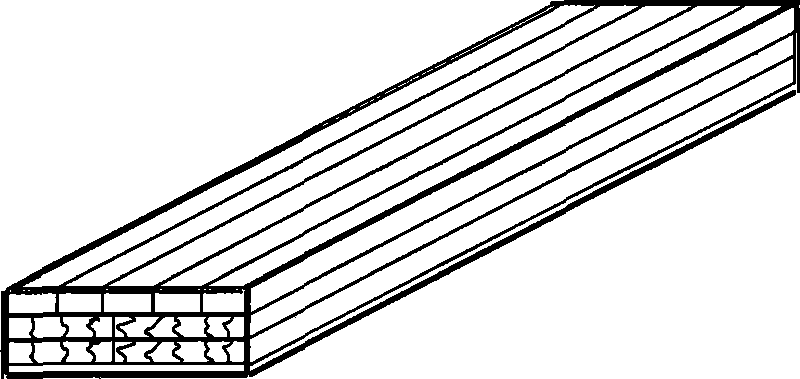

[0027] refer to figure 1 and figure 2 , a kind of manufacture method of composite bamboo floor, comprises the following steps: 1. cut off the protruding part of the branch on the bamboo tip; ; 3. rolling the bamboo chips with a bamboo rolling machine to obtain the rolled bamboo chips; 4. processing the rolled bamboo chips with a fixed width and thickness;

[0028] Then, the 2-4 layers of rolled bamboo slices are glued and assembled along the grain, and then hot-pressed into a bamboo core board, and the sides of the large-diameter bamboo strips are glued and assembled, and then hot-pressed into a bamboo veneer, and then press the surface Bamboo veneer, core layer bamboo chip core board, back layer wood veneer or bamboo veneer are glued and assembled, and the slab is sent to the press for secondary hot pressing to obtain a four-layer slab; The billets are then processed into bamboo flooring through trimming, tenoning, sanding, finishing, drying and other processes.

[0029] ...

Embodiment 2

[0039] In this example, the sides of the large-diameter bamboo strips are coated with glue to assemble the blanks, and then hot-pressed into bamboo strip veneers, and then the surface layer bamboo strip veneer, the core layer rolled bamboo slices, the back layer wood veneer or bamboo veneer Apply glue to assemble the slabs, and send the slabs into the press for secondary hot pressing to form slabs.

[0040] Other steps in this embodiment are the same as in Embodiment 1.

Embodiment 3

[0042] refer to figure 1 and figure 2 , the steps of the present embodiment 1.-4., 8. are the same as embodiment 1. Other steps of this embodiment are:

[0043] ⑤ Apply glue to the finished rolled bamboo chips, large-diameter bamboo strips and wood veneers or bamboo veneers, and the amount of glue applied is controlled at 160-200g / m 2 .

[0044] ⑥According to the surface bamboo strips, core bamboo slices, back wood veneer or bamboo veneer, the blanks are assembled along the grain, and then tied with nylon ropes. When the core layer bamboo chips are assembled, the green side and the yellow side should be arranged alternately in sequence.

[0045] ⑦ Send the assembled slabs into the press for hot pressing, the positive pressure is 2.0-3.0MPa, the side pressure is 2.5-3.5MPa, the hot-pressing time is 0.5-0.8min / mm, and the hot-pressing temperature is 90-110°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com