Polyvinyl chloride low-foaming car plate and preparation method thereof

A polyvinyl chloride, low-foaming technology, applied in the field of polyvinyl chloride low-foaming automotive panels, can solve the problems of immature production technology and density drop, and achieve light weight, small linear expansion coefficient and good dimensional stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

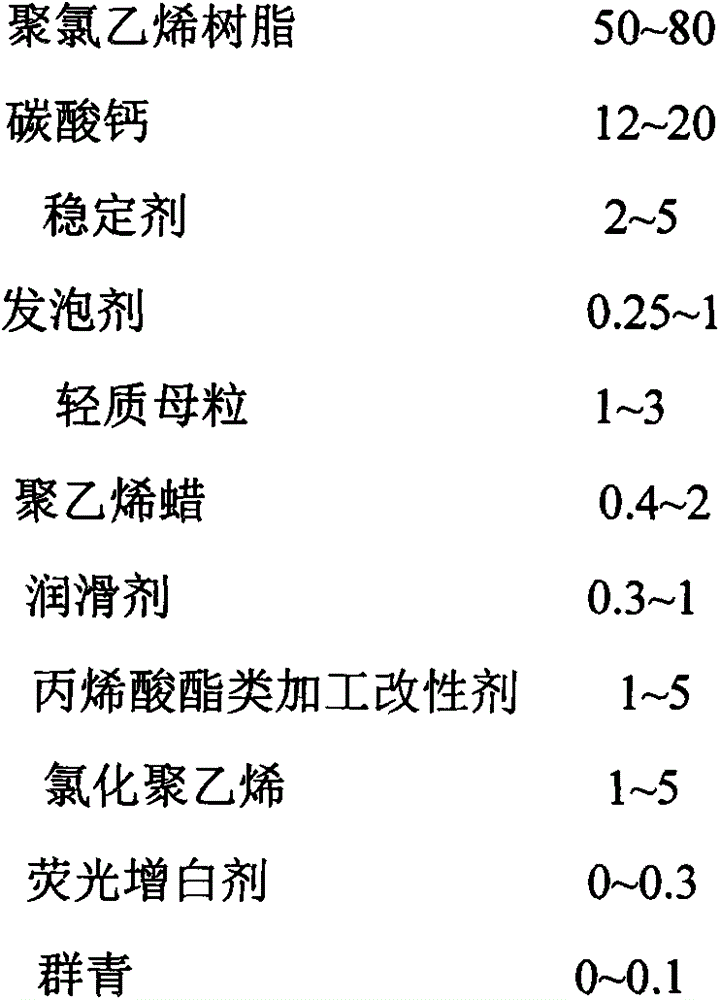

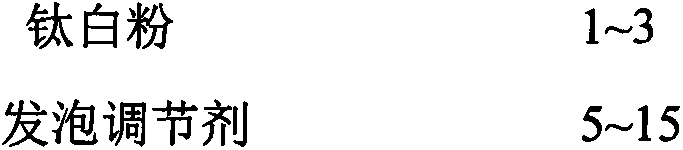

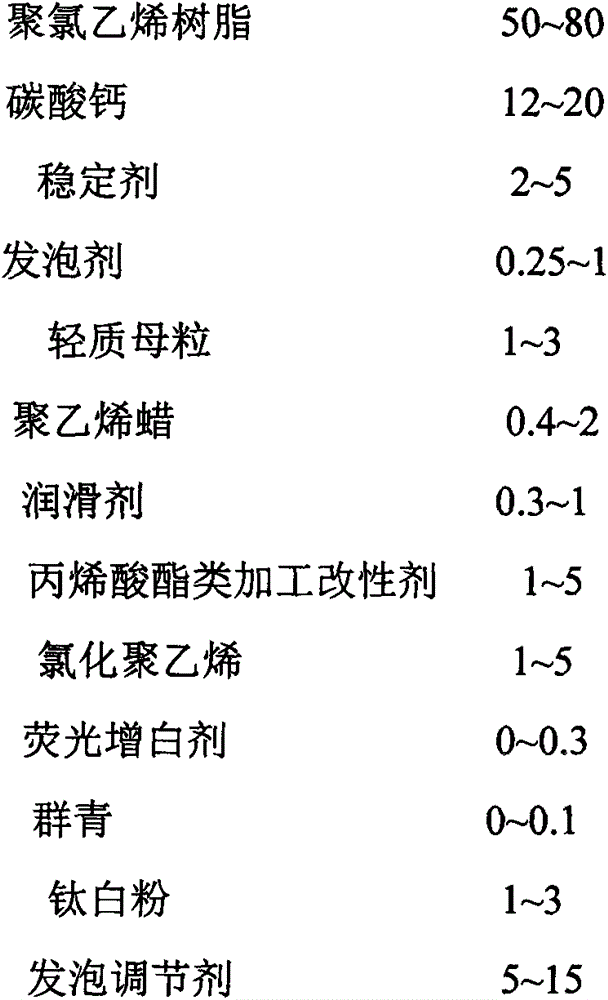

Method used

Image

Examples

Embodiment 1

[0026] 72 parts by weight of polyvinyl chloride resin with a degree of polymerization of 750, 11 parts by weight of calcium carbonate, 2 parts by weight of calcium zinc stabilizer, 0.2 parts by weight of azobisisobutyronitrile, 0.3 parts by weight of ammonium bicarbonate, The lightweight masterbatch of 1.5 parts by weight, the polyethylene wax of 0.5 parts by weight, the polyalcohol polyfatty acid ester of 0.5 parts by weight, the acrylic ester processing modifier of 2.0 parts by weight, the chlorinated polyethylene of 2.5 parts by weight, 0.1 Fluorescent whitening agent in parts by weight, ultramarine blue in 0.01 parts by weight, titanium dioxide in 1.4 parts by weight, polyacrylate foam regulator ZB740 in 6 parts by weight. The above materials are put into a high-speed mixer and heated to 100°C for mixing, cooled to 40°C and extruded into a conical twin-screw extruder with a screw speed of 18 rpm, a screw barrel heating temperature of 170°C, and a screw oil temperature of 85...

Embodiment 2

[0029] According to embodiment 1, change the polyvinyl chloride resin that 65 parts by weight of polymerization degrees are 750, the calcium carbonate of 17 parts by weight, the calcium zinc class stabilizer of 2 parts by weight, the azobisisobutyronitrile of 0.2 parts by weight, 0.3 parts by weight The ammonium bicarbonate of 1.5 parts by weight, the lightweight masterbatch of 1.5 parts by weight, the polyethylene wax of 0.5 parts by weight, the polyalcohol polyfatty acid ester of 0.5 parts by weight, the acrylate processing modifier of 2.5 parts by weight, the Chlorinated polyethylene, 0.1 parts by weight of fluorescent whitening agent, 0.01 parts by weight of ultramarine blue, 1.4 parts by weight of titanium dioxide, and 7 parts by weight of polyacrylate foam regulator ZB740. The preparation method is as in Example 1.

[0030] The product density that present embodiment prepares is 540kg / m 3 , Board hardness (Shore hardness) D = 60.

Embodiment 3

[0032] 70 parts by weight of polyvinyl chloride resin with a degree of polymerization of 1000, 13 parts by weight of calcium carbonate, 2 parts by weight of calcium zinc stabilizer, 0.2 parts by weight of azobisisobutyronitrile, 0.3 parts by weight of ammonium bicarbonate, The lightweight masterbatch of 1.5 parts by weight, the polyethylene wax of 0.5 parts by weight, the polyalcohol polyfatty acid ester of 0.5 parts by weight, the acrylic ester processing modifier of 2.0 parts by weight, the chlorinated polyethylene of 2.5 parts by weight, 0.1 Fluorescent whitening agent in parts by weight, ultramarine blue in 0.01 parts by weight, titanium dioxide in 1.4 parts by weight, polyacrylate foam regulator ZB750 in 6 parts by weight. The above materials are put into a high-speed mixer and heated to 100°C to mix them evenly. After cooling to 30°C, they are extruded into a conical twin-screw extruder. The screw speed is 18 rpm, the heating temperature of the screw barrel is 180°C, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com