Method of treating bamboo floor using plasma

A technology of plasma and bamboo flooring, which is applied in wood treatment, wood treatment details, jointing of wooden veneers, etc. It can solve the problems of poor bonding performance and surface finishing performance of bamboo sheets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Bamboo slices are dried at a temperature of 60° C., and the moisture content of bamboo slices is 3%.

[0016] The dried bamboo chips are processed by plasma, and the operating parameters of the plasma are: output power 20W; reflection power 0W; vacuum degree 2Pa; working gas O 2 ; The treatment time is 10min, so that the wetting angle of the bamboo surface is 24°.

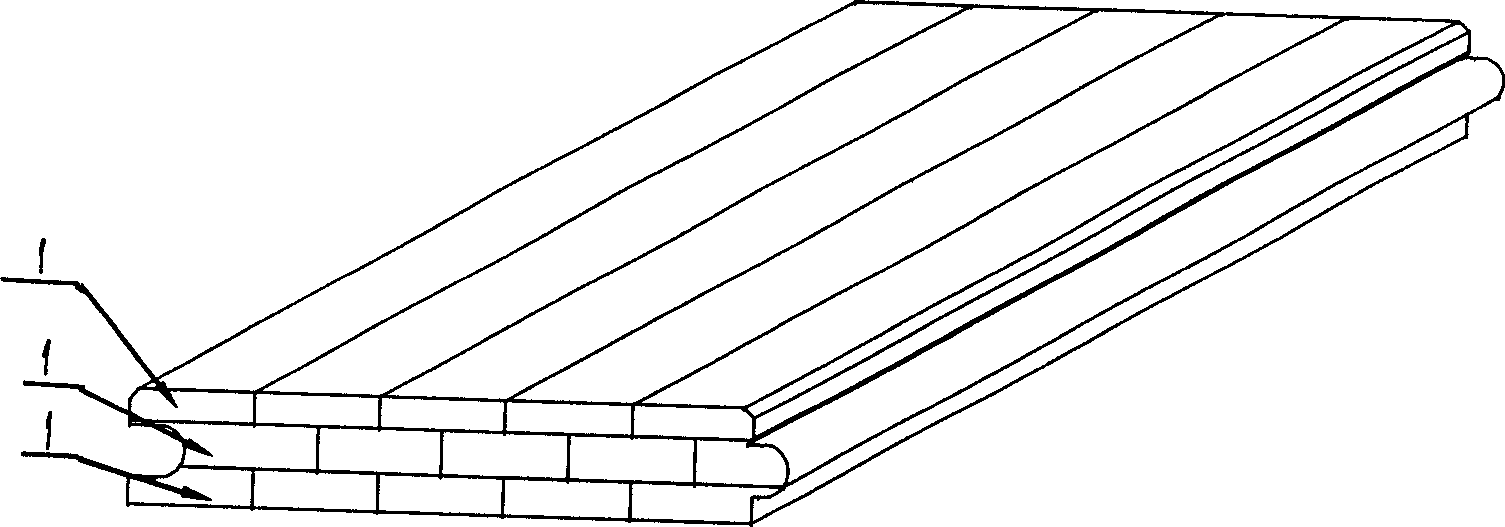

[0017] The bamboo slices after plasma treatment enter the process step of gluing and forming blanks. The three-layer structure is a bamboo blank board composed of three layers of longitudinal bamboo slices. The bamboo slices are coated with urea-formaldehyde resin adhesive (model NQTRH), and the glue coating amount is 300g / m 2 .

[0018] The bamboo slabs after the glue-coating process are hot-pressed by a hot press, hot-pressing temperature: 110°C, hot-pressing time: 1.1min / mm, pressure: 2MPa / cm 2 .

[0019] The bonding strength of the bamboo floor after hot pressing can be increased by 30%.

Embodiment 2

[0021] Bamboo chip is dried under the condition of temperature 80 ℃, makes the moisture content of bamboo chip 3.5%.

[0022] The dried bamboo chips are processed by plasma, and the working parameters of the plasma are: output power 20W; reflection power 1W; vacuum degree 3Pa; working gas O 2 ; The treatment time is 10 minutes, so that the wetting angle of the bamboo surface is 23°.

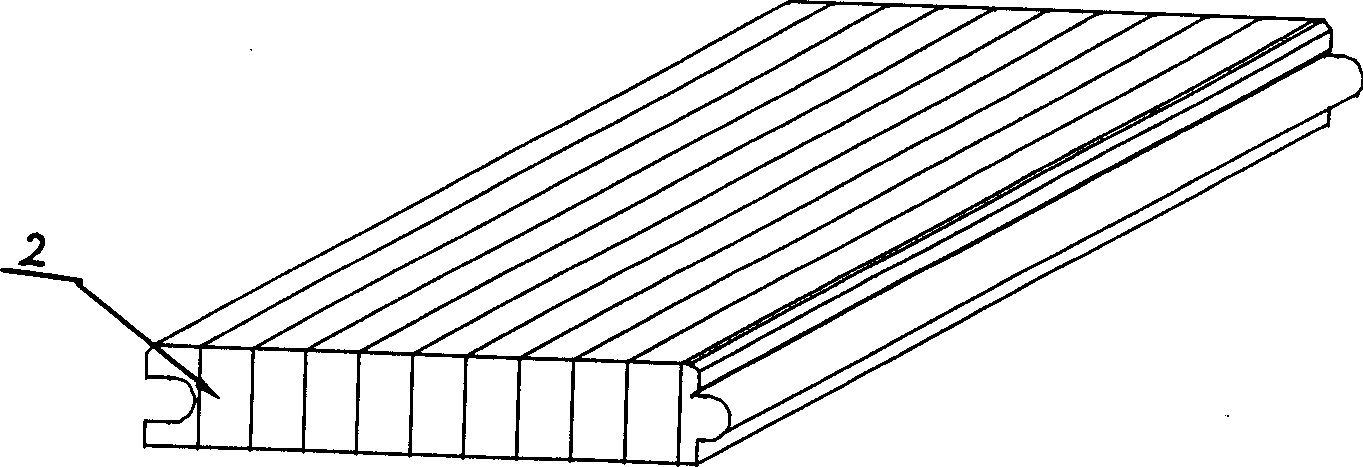

[0023] The bamboo chips after plasma treatment enter the process step of gluing and assembling blanks. The structure is a bamboo blank board composed of a single layer of vertical bamboo chips. The bamboo chips are coated with urea-formaldehyde resin adhesive (model NQTRH), and the glue coating amount is 350g / m 2 .

[0024] The bamboo slab after the glue coating process is hot-pressed by a hot press, hot-pressing temperature: 125°C, hot-pressing time: 1.1min / mm, pressure: 3MPa / cm 2 .

[0025] The bonding strength of the bamboo floor after hot pressing can be increased by 30%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com