Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

160results about How to "Improve the carbonization effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Charcoal fertilizer as well as preparation method and application thereof

InactiveCN105753546AImprove carbonization rateImprove the carbonization effectAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersAdjuvantCarbonization

The invention discloses a charcoal fertilizer, prepared from the following raw materials in percentage by weight: 10-50% of charcoal powder, 20-70% of compound fertilizer and 5-30% of adjuvant, wherein the charcoal powder is obtained by putting straws in a carbonization furnace for dehydration and deoxygenation treatment and smashing the straws to a particle size of not more than 0.5mm after high-temperature carbonization. A preparation method of the charcoal fertilizer comprises the following steps: feeding the straws into the carbonization furnace; performing the dehydration and deoxygenation treatment for 1-2 hours at a temperature of 100-250 DEG C; carbonizing the straws at a high temperature of 600-700 DEG C for 30-240min; cooling the carbonized product and then smashing the carbonized product to form the charcoal powder with the particle size of not more than 0.5mm; uniformly mixing the charcoal powder, the compound fertilizer and the adjuvant in proportion to obtain a mixture and then pelleting the mixture to obtain pellets; cooling and screening the pellets to a particle size of 1.5-4.75mm; packing the screened pellets. The charcoal fertilizer disclosed by the invention has the advantages of an extensive source of the raw material straws, a good carbonization effect, high carbon content, conformity with the concept of environmental protection, simplicity in preparation technique, low energy consumption, high product strength and capability of processing the raw materials in a centralized manner and obviously increasing the utilization rate and quality stability of the fertilizer. The invention further discloses an application of the charcoal fertilizer in crop growth.

Owner:SHENZHEN BATIAN ECOTYPIC ENG

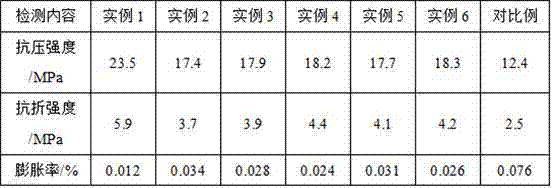

Method for preparing composite steel slag carbonized bricks

The invention discloses a method for preparing composite steel slag carbonized bricks, and belongs to the technical field of industrial waste slag utilization. According to the method, steel slags, kerosene and grinding aids are mixed, ball milled, ignited and cooled to obtain combustion slags; the combustion slags are then crushed and sieved to obtain pretreated steel slag powder; aggregates, thepretreated steel slag powder and hydrated lime are stirred and mixed with dispersion liquid to be poured into shape and placed at constant temperature and humidity to obtain unburned bricks; the unburned bricks are subjected to autoclave oxidation and fumigated with vinegar to obtain fumigated bricks; the fumigated bricks are then transferred to a carbonization box and subjected to carbonizationat constant temperature and humidity, and the composite steel slag carbonized bricks are obtained after discharge. The composite steel slag carbonized bricks prepared by adopting the method have excellent strength and stability.

Owner:CHANGZHOU OPTICAL MATERIAL

Method for machining bamboo floor

InactiveCN102729309AHigh strengthImprove the carbonization effectLiquid surface applicatorsDomestic articlesProcess engineeringBamboo floor

The invention relates to the technical field of floor materials and particularly relates to a method for machining a bamboo floor. By improving a carbonization process, a gluing process, a painting process and the like and adding a new process, the total quality of the bamboo floor is improved; the carbonization is good; the bamboo floors with different colors can be produced according to production demands; and the color is uniform. The total quality of the bamboo floor can be further improved by finely polishing; the gluing process is better, so that the integral strength of the floor can be effectively improved with a hot pressing process, the glue using amount is effectively controlled, and the production cost is effectively reduced; and the painting technique is improved, and a coating quantity is reduced, so that the painting amount is greatly reduced, the coating is more stable, and the quality is higher.

Owner:安吉华信竹木制品有限公司

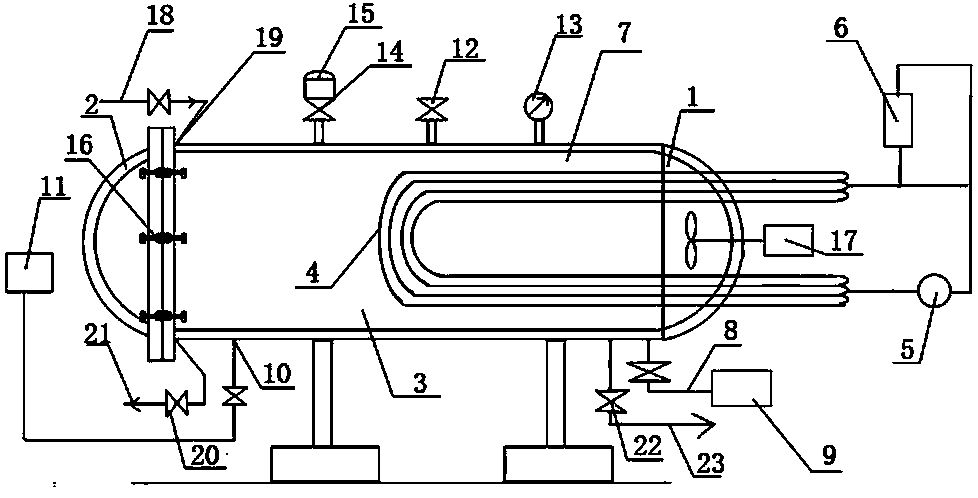

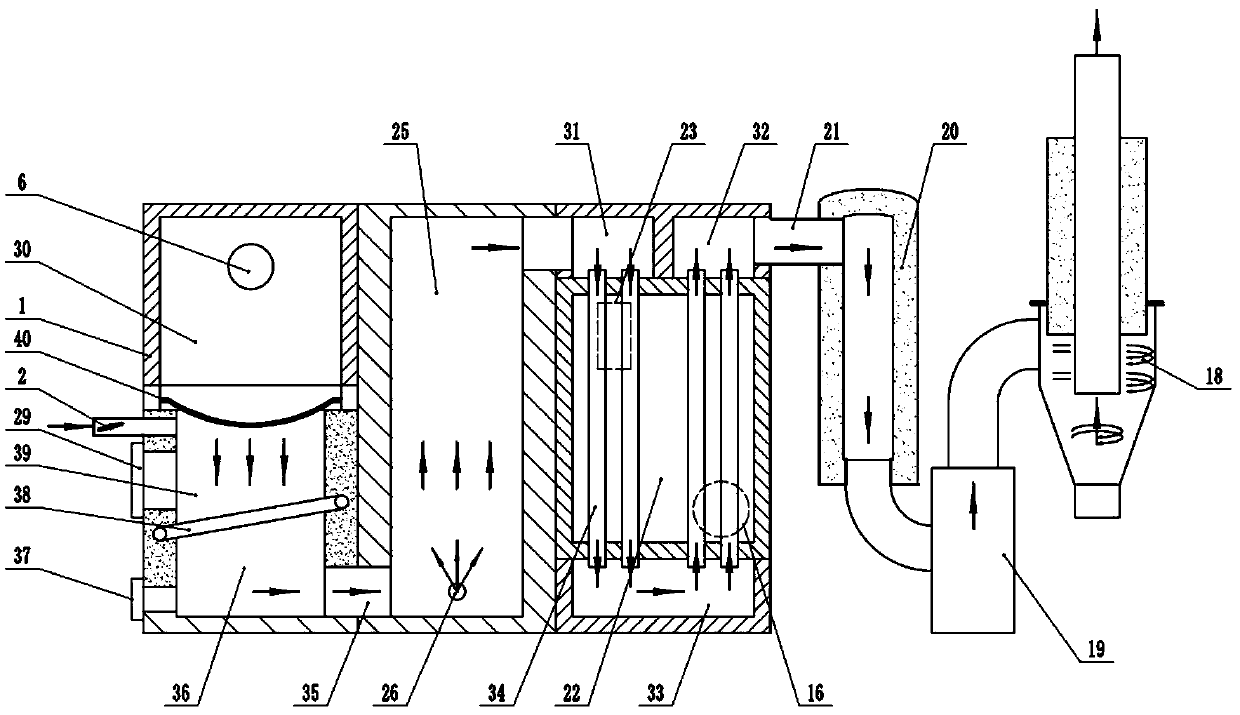

High-temperature physical carbonization method of carbide furnace and wood

The invention provides a high-temperature physical carbonization method of a carbonization furnace and wood. The carbide furnace comprises a horizontal carbonization tank, wherein one end of the horizontal carbonization tank is provided with an end socket, the other end of the horizontal carbonization tank is provided with a tank cover, the periphery in the carbonization tank is provided with a heat-conducting pipe through which heat-conducting media flow, the heat-conducting pipe is communicated with a heat-conducting oil feeding device arranged outside, and the heat-conducting oil feeding device is composed of a heat-conducting oil pump and a heat-conducting oil heater; the middle of the carbonization tank is provided with a lace bar frame used for containing the wood; a vacuum pumping machine connected with the carbonization tank through a vacuum pumping pipe is arranged outside the carbonization tank; the carbonization tank is connected with an external steam generating and feeding device through a steam connection pipe; the carbonization tank is further provided with a safe valve, a pressure gage and a wood still gas releasing pipe with a switch valve. The high-temperature physical carbonization method comprises the steps that (a) the wood is placed in the furnace; (b) a steam valve is opened for humidification; (c) vacuum pumping and drying are conducted; (d) temperature is increased and carbonization is conducted; (e) carbonized wood is manufactured after the temperature is decreased and preserving is conducted. The high-temperature physical carbonization method has the advantages that the used carbonization furnace is simple in structure, safe to operate and use, and convenient and reliable to use, the carbonization process is simple, the carbonization effect is good, and a use range of the carbonized wood is enlarged.

Owner:浙江华凯木业有限公司

Biomass carbonization molding material and preparation method thereof

ActiveCN104610988AIncrease stomataImprove water absorptionOther chemical processesDispersed particle separationBiomassWater quality

The invention discloses a preparation method of a biomass carbonization molding material. The preparation method successively comprises the following steps: 1) crushing natural biomass materials so as to obtain powder of which the sieving rate is equal to or larger than 100 meshes; 2) adding clay to the powder, uniformly mixing the clay and the powder so as to obtain a mixed material, wherein the powder accounts for 10-45% of the total weight of the mixed material, and the clay accounts for 55-90% of the total weight of the mixed material, adding water accounting for 5-30% of total weight of the mixed material to the mixed material, and mixing and stirring the mixed material with the water; 3) injecting the obtained mixture in a mold to perform compression molding, after demolding, drying the demolded object until the moisture content is equal to or smaller than 8%, performing smoldering treatment under 800-1300 DEG C and the anoxic condition of sealing for 0.5-10 hours so as to obtain the biomass carbonization molding material. The carbonization molding material prepared by adopting the preparation method disclosed by the invention not only has good mechanical strength, but also has the characteristics of being green and environment-friendly, capable of purifying air / water quality and the like, and adsorbing harmful substances in the air / water.

Owner:LISHUI GREEN ROCK IND DESIGN

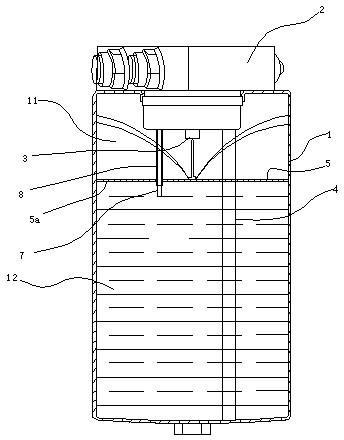

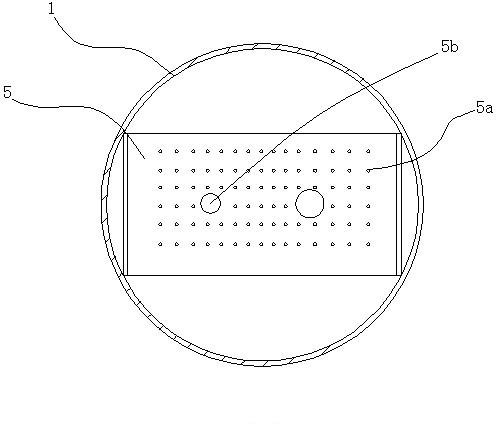

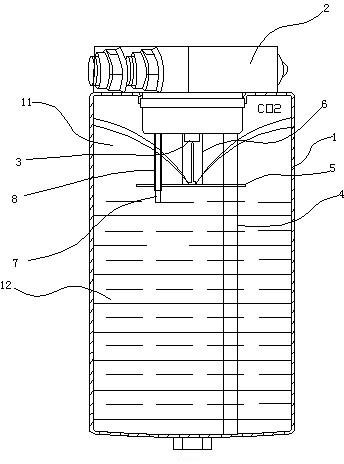

Carbonizing tank with atomizing device for soda water machine

InactiveCN102551541AGood carbonization effectAvoid direct impactBeverage vesselsContact timeSpray nozzle

The invention discloses a carbonizing tank with an atomizing device for a soda water machine, which comprises a tank body with an opening on the upper portion. A combined valve is disposed at the opening of the tank body and communicated with a spray nozzle and a water outlet tube, a water baffle plate is disposed in a tube body, the inside of the tank body is divided into an upper space and a lower space by the water baffle plate, the upper space is used for holding carbon dioxide gas, the lower space is used for holding water, an overflow channel is arranged between the upper space and the lower space, and a plate surface of the water baffle plate faces to a water outlet of the spray nozzle. Compared with the prior art, the carbonizing tank has the advantages that contact time of the water and the CO2 is effectively prolonged, contact area is large, and a carbonizing effect is obvious; due to the spray nozzle, water flow is high, and water injection time is short; and furthermore, water columns jetted out via the spray nozzle are atomized when impacting onto the baffle plate, and drop on the water baffle plate to overflow downwards after being effectively combined with the CO2 to be carbonized, the problem that high-speed non-carbonized water directly impacts carbonized water at the bottom can be avoided effectively, and the carbonizing effect of bottom outflow water is guaranteed.

Owner:NINGBO RDWORKS ELECTRIC TECH DEV

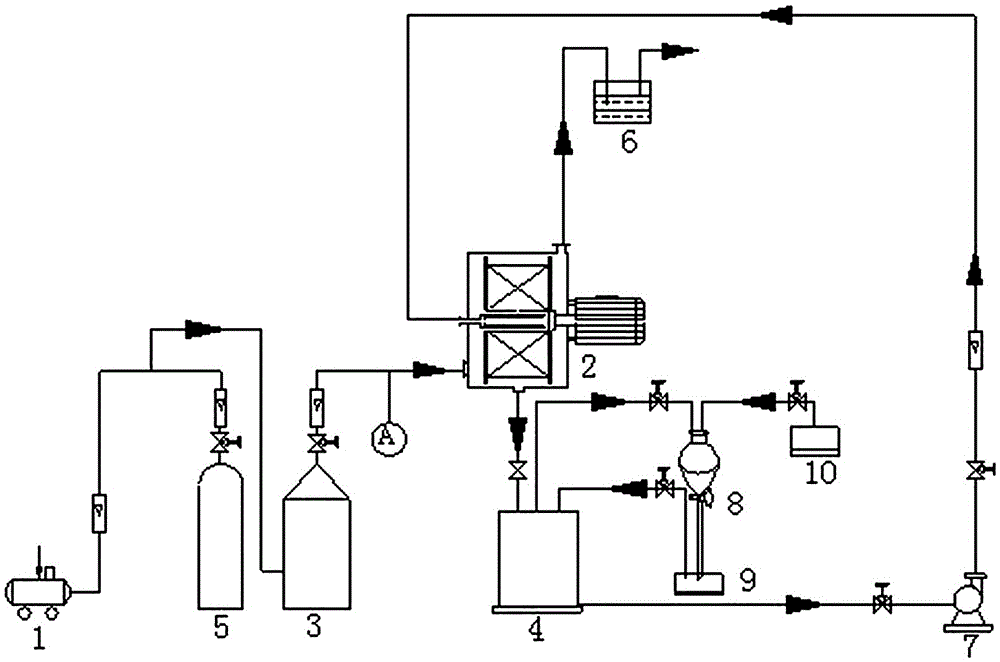

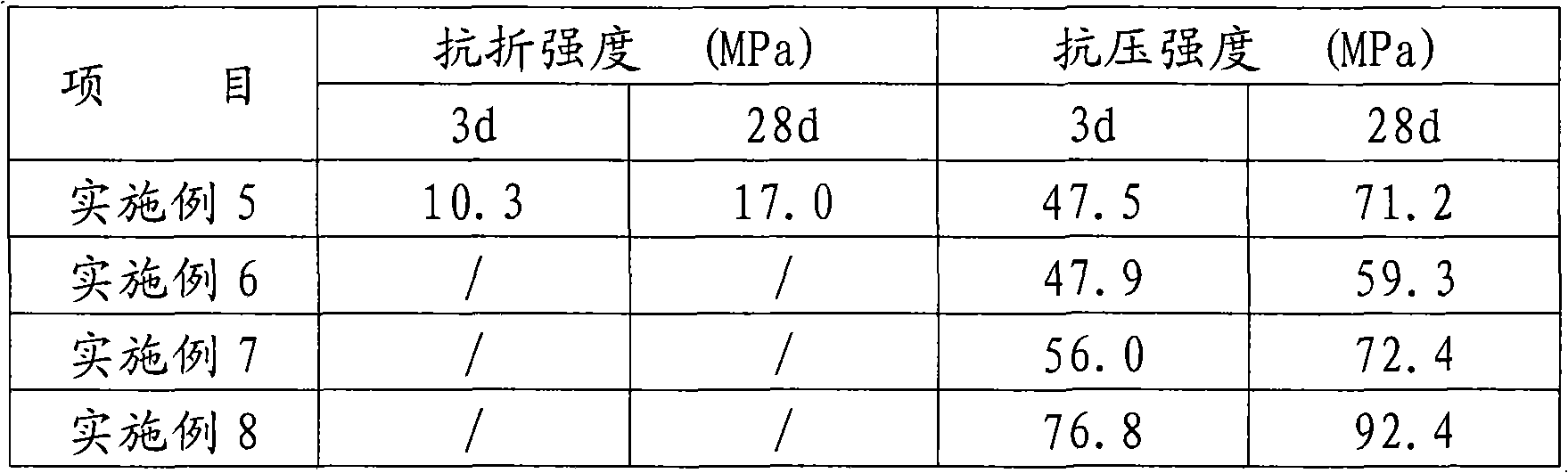

Method for producing controllable-particle-size calcium carbonate by continuous carbonization

ActiveCN106976898AImprove the carbonization effectHigh speed dispersionCalcium/strontium/barium carbonatesCalcium hydroxideDispersity

The invention discloses a method for producing controllable-particle-size calcium carbonate by continuous carbonization. A water ring air compressor, a primary carbonization tower, a gas distributor, a primary carbonization stirring device, a gas storage tank, a secondary carbonization tower, a secondary carbonization stirring device, a circulating emulsification pump, a calcium hydroxide storage tank, a venturi ejector and the like are applied. The method includes specific operation steps of primary carbonization, circulating emulsification, CO2 gas suction, calcium hydroxide slurry feeding and secondary circulating carbonization. The particle size of calcium carbonate prepared according to the method can be controlled in a range of 80-200nm, and a product is uniform in crystalline form, regularly cubic in morphology, small in agglomerated particle quantity, high in dispersity, narrow in particle size distribution and low in oil absorption value.

Owner:FUJIAN HONGFENG NANO TECH

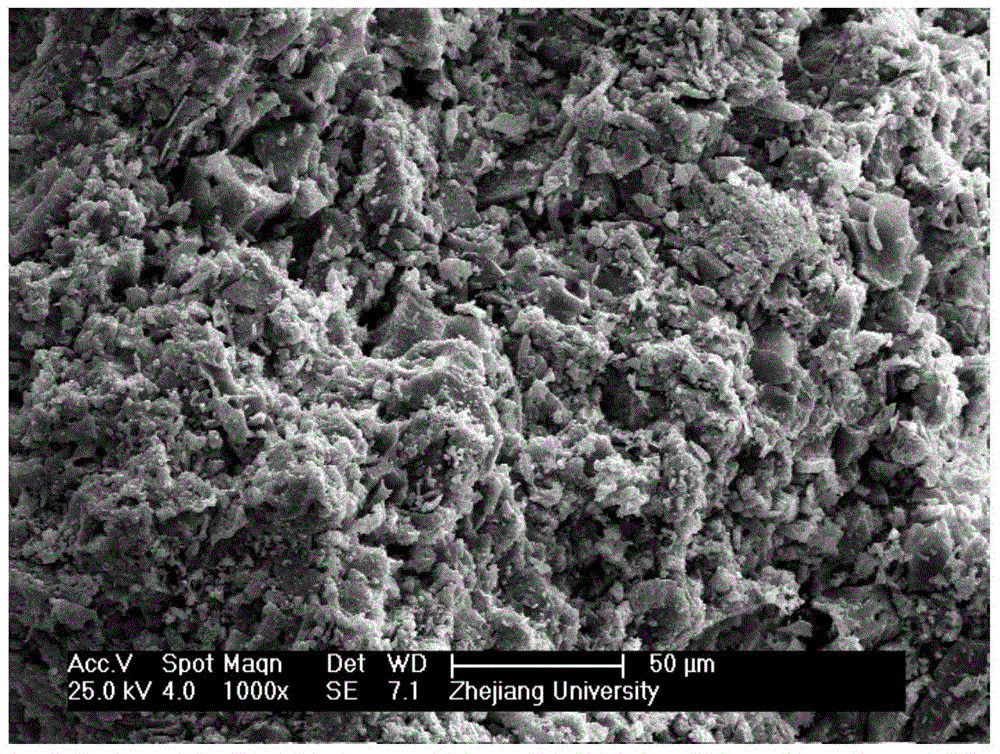

Lignin Porous Carbon Nanosheet, Preparation Method Therefor, and Application Thereof in Supercapacitor Electrode Materials

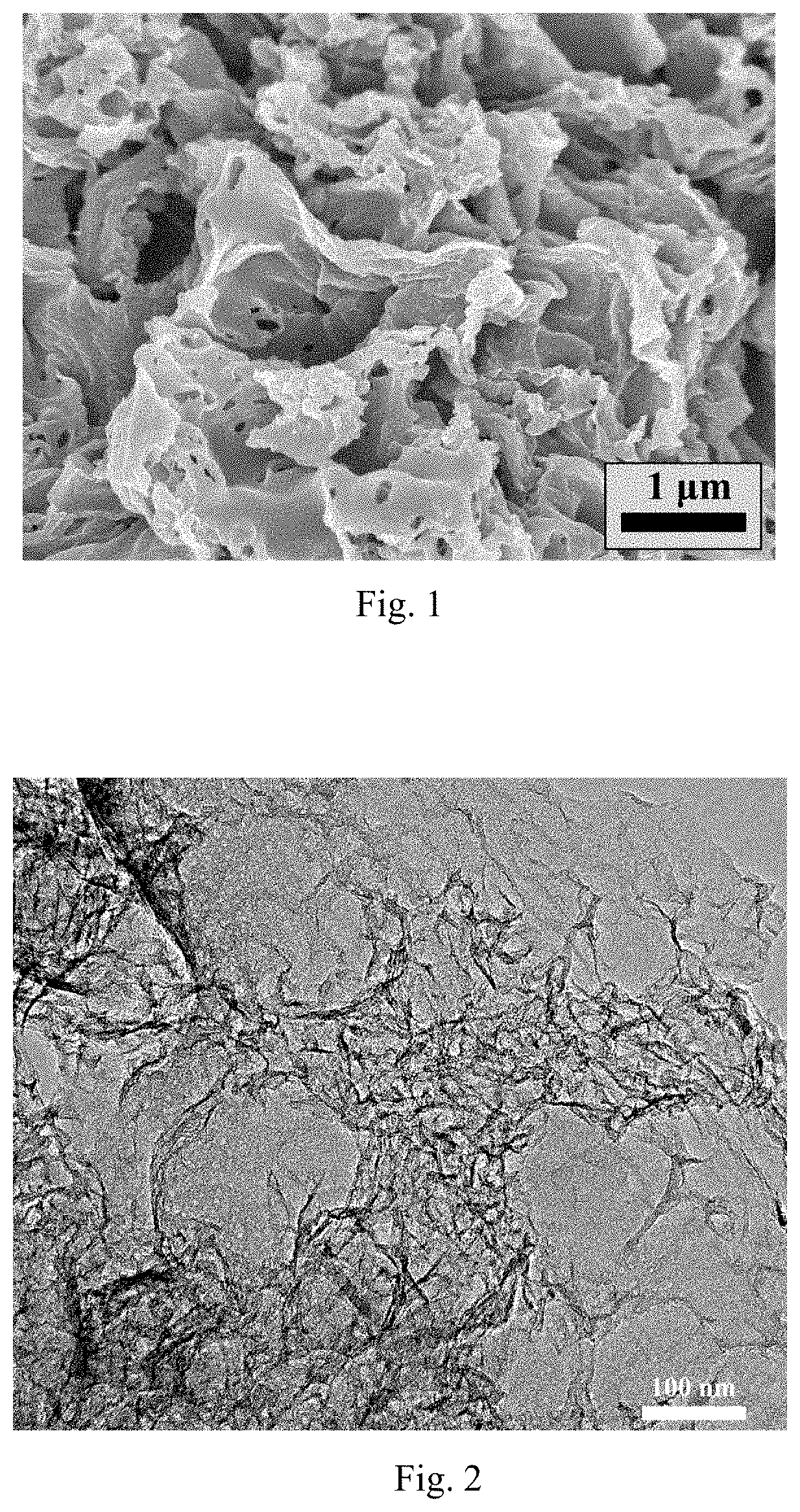

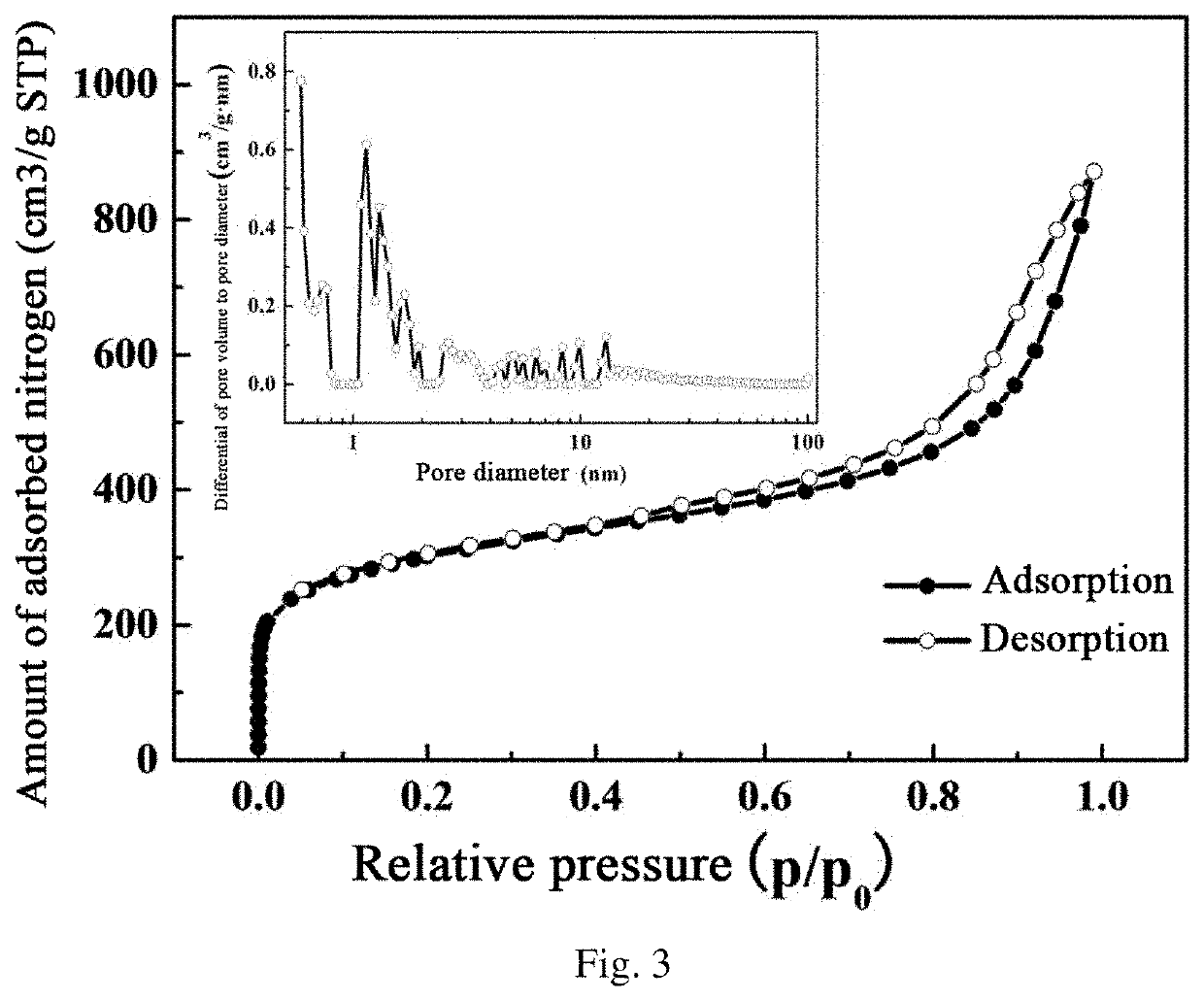

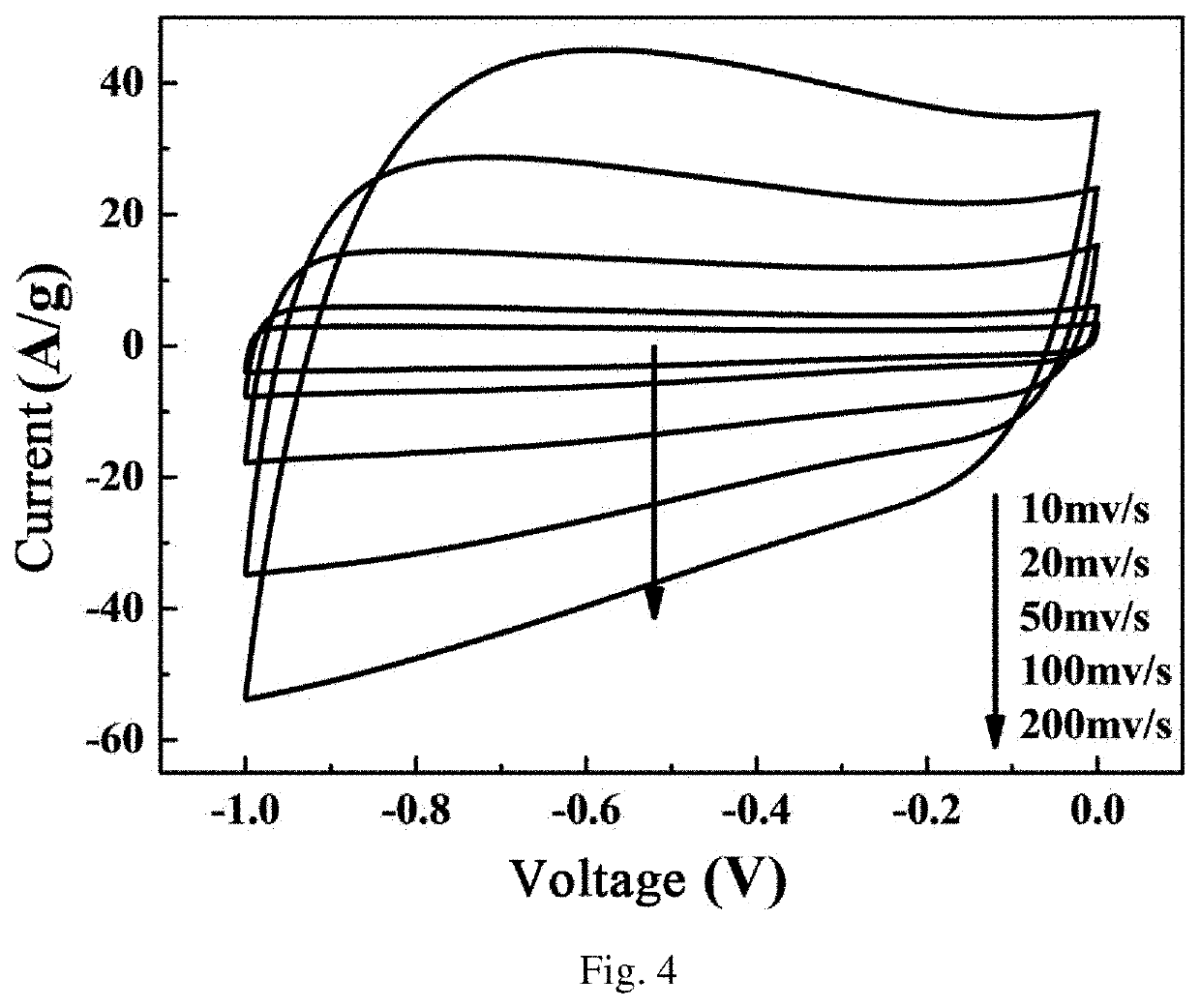

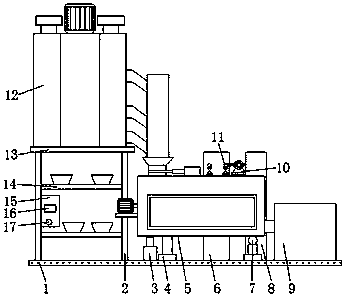

PendingUS20210323825A1Reasonable pore structureAbundant poreHybrid capacitor electrodesNano-carbonCapacitancePorous carbon

The present invention belongs to the technical field of biomass carbon materials, and relates to a lignin porous carbon nanosheet, a preparation method therefor, and an application thereof in supercapacitor electrode materials. The method of the present invention performs layer-by-layer self-assembly of sulfonated lignin and oxalate in a selective solvent to prepare a layer-by-layer self-assembled lignin / oxalate composite, which is then carbonized and pickled to obtain the lignin porous carbon nanosheets. The lignin porous carbon nanosheets prepared by the above method of the present invention have a specific surface area of 200-1500 m2 / g, a micropore specific surface area of 100-500 m2 / g, a mesoporous specific surface area of 100-1000 m2 / g, a pore diameter of 0.5-30 nm, and a pore volume of 0.5-1.5 cm3 / g; they can be applied to supercapacitor electrode materials, showing higher specific capacitance and excellent rate performance (with a specific capacitance retention rate of 76.6%), having good potential application value.

Owner:SOUTH CHINA UNIV OF TECH

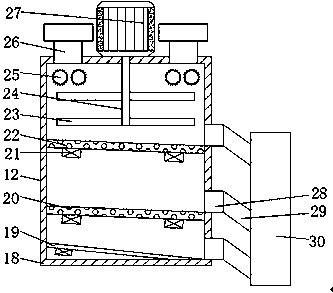

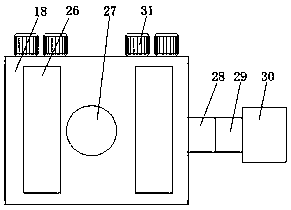

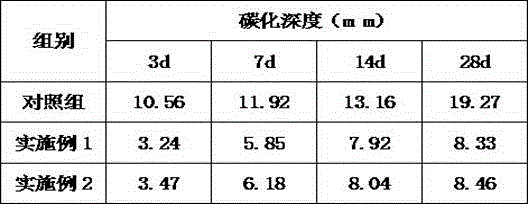

High-efficiency recycled aggregate carbonization device

InactiveCN110385187AImprove crushing efficiencyImprove screening effectSolid waste managementGrain treatmentsCarbonizationEngineering

The invention belongs to the technical field of aggregate carbonization equipment, and particularly relates to a high-efficiency recycled aggregate carbonization device which aims at solving the problems that grading crushing cannot be carried out, the crushing effect is poor, the utilization rate of carbon dioxide is low when aggregates are carbonized after being crushed, and the detection of theaggregates is troublesome after carbonizing. According to the scheme, the device comprises a bottom plate, wherein four fixing rods are welded to the top part of the bottom plate, and a supporting plate is welded on the top parts of the four fixing rods; a crushing device is arranged on the top part of the supporting plate; four weight measuring devices which are distributed in a rectangle form are arranged on the outer wall of the top part of the bottom plate; and each weight measuring device comprises a fixing block. With the adoption of the device, aggregates with different specificationscan be screened, so that the sieving performance and the adjustability of the device are improved; the sealing performance of a carbonization box is improved; the waste of resources caused by the outflow of carbon dioxide gas is prevented; a hanging rod is driven to rotate to uniformly spread the raw materials to be detected; the carbonization rate can be conveniently detected through phenolphthalein, and thus the detection efficiency is improved.

Owner:六安市匠心信息科技有限公司

Solid electrolyte aluminium electrolytic capacitor and method for manufacturing same

InactiveCN102610401AAvoid meltingImprove the carbonization effectSolid electrolytic capacitorsSilver coatingOxidizing agent

The invention discloses a solid electrolyte aluminium electrolytic capacitor, wherein a core wrap is connected with a positive terminal and a negative terminal, the external surfaces of the positive and the negative terminals are plated with silver coatings, and the method for manufacturing the capacitor comprises the following steps: 1) the external surfaces of the positive and the negative terminals are plated with silver coatings; 2) an electrolytic paper is interposed between an anode formed aluminium foil and a cathode foil and is wound to be core wrap, and the cathode foil faces the outer side, wraps the electrolytic paper and is fixed by a high-temperature tape; 2) the core wrap is soaked into formed liquid to undergo formation repair; 3) the core wrap is placed in an oven to undergo the carbonating; 4) the core wrap is subjected to the formation repair treatment; 5) the core wrap is dried; 6) the core wrap is respectively placed into a monomer and an oxidizing agent to be impregnated, heated and aggregated; and 7) a rubber cover is assembled on the core wrap, the core wrap is assembled in an aluminium shell, sealed and aged into a product. Because the terminals adopt silver coating instead of tinning, tin melting is avoided during the high-temperature carbonating, a higher-temperature carbonating mode can be adopted, so a better carbonating effect can be obtained within shorter time, energy resources are saved, and the cost is reduced.

Owner:ZHAOQING BERYL ELECTRONICS TECH

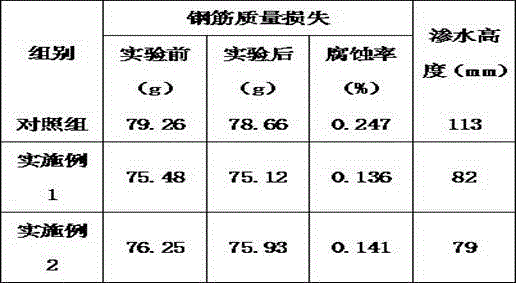

Better-durability concrete

InactiveCN106116329AImprove adhesionAdequate responseSolid waste managementCarbonizationChlorinated paraffins

The invention discloses better-durability concrete prepared from the following raw materials: cement, fly ash, modified superfine quartz powder, illite, tire powder, chlorite, coal gangue, alkalized rice husks, polycarbonate resin, triphenethyl phenol polyoxyethylene ether, chlorinated paraffin, polyisobutylene, and water. Compared with the prior art, the better-durability concrete has the following advantages: with combined action of the modified superfine quartz powder and the alkalized rice husks, the binding capacity of the concrete is strengthened, mixing and curing are performed under specified conditions, the reactions among the raw materials are full, surface or internal cracks caused due to temperature, dry shrinkage and other non-structural reasons can be effectively prevented, and the concrete has the advantages of relatively good safety performance, relatively high tensile strength, and excellent impermeability, frost resistance, corrosion resistance and carbonization performance, can maintain higher compressive strength and appearance integrity for a long term, and reduces implementation of maintenance work.

Owner:安徽金丰新型建材有限公司

Wood carbonization treatment method and device

ActiveCN111216208AUniform moisture content inside and outsideRealize deep drying and carbonizationBark-zones/chip/dust/waste removalWood charring/burningPolymer scienceWater vapor

A wood carbonization treatment method comprises the following steps: (1) stacking wood in a carbonization box to carry out balanced water content treatment, wherein the temperature in the carbonization box is 60-120 DEG C, the humidity is 100% RH, the working time is 96 hours, and the temperature raises in stages; (2) drying the wood, wherein the temperature in the carbonization box is 100-120 DEGC, the humidity is 100-20% RH, humidity gradient is decreased, and the working time is 72 hours; (3) carbonizing the wood, and raising the carbonizing temperature in the carbonization box from 120 DEG C to 190-220 DEG C, wherein 10 DEG C is raised every 2 hours and the carbonization speed is 10 mm / hour; and (4) after the carbonization treatment is finished, adding steam to humidify, so that the ambient temperature in the carbonization box is gradually reduced to 60 DEG C from above 150 DEG C; and when the temperature of the carbonization box is close to the outdoor temperature, taking out thewood. According to the method, the proportion of hot air to water vapor in warm and wet airflow is adjusted to achieve the purpose of thermal modification of the wood.

Owner:广西格卡环保科技有限公司

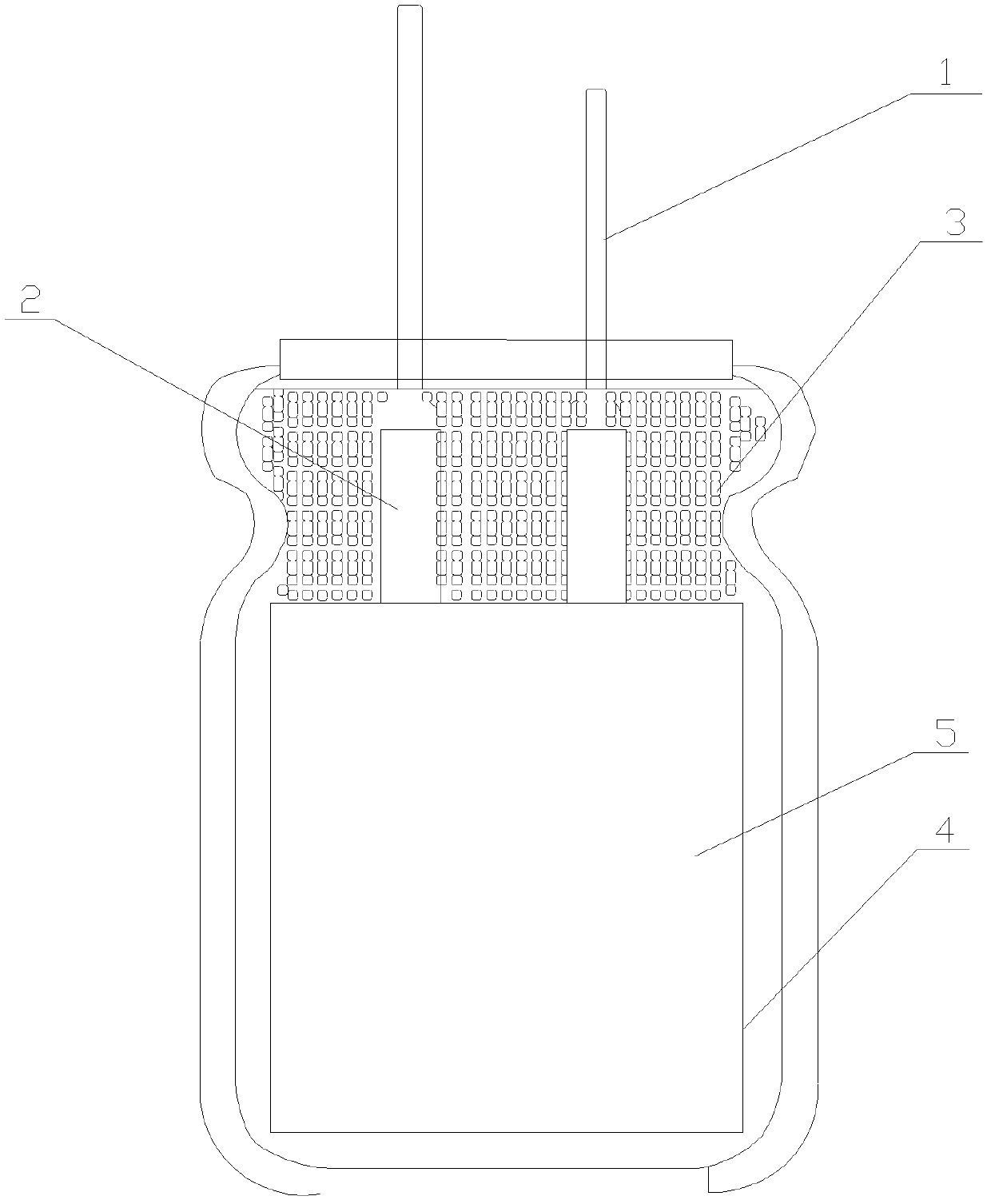

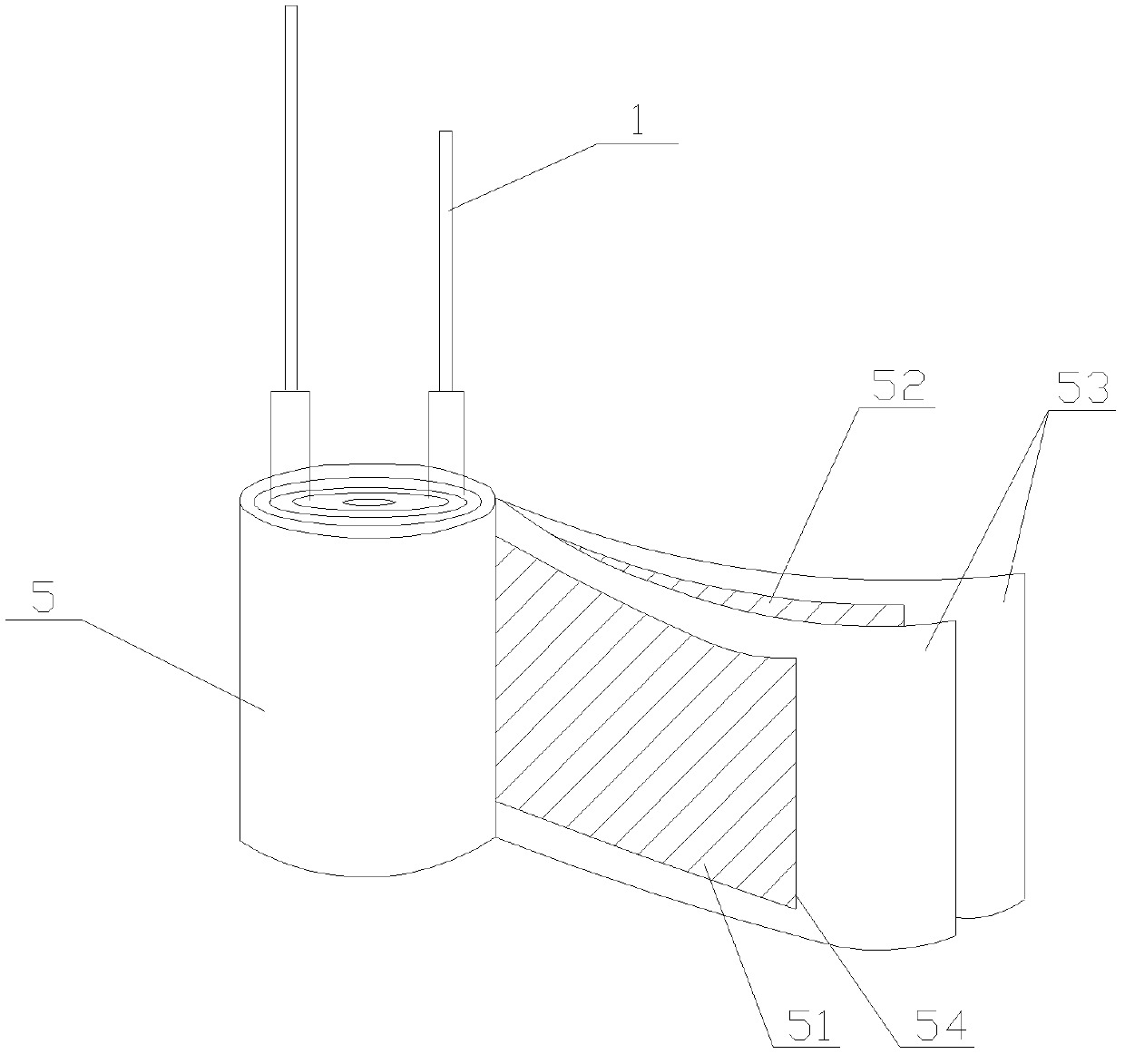

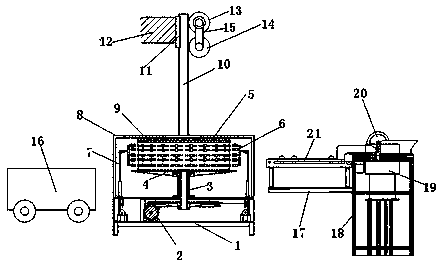

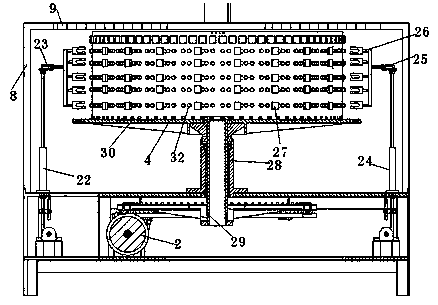

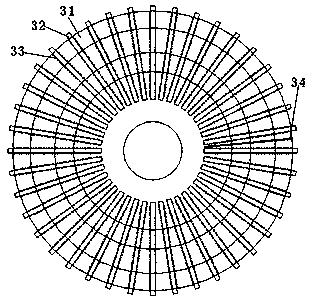

Device for preparing biochar by means of straw

ActiveCN108822880AImprove efficiency and automationEnsure accurate controlBiofuelsSpecial form destructive distillationCarbonizationMaterials science

The invention discloses a device for preparing biochar by means of straw. The device for preparing the biochar by means of the straw can greatly improve the biochar preparation efficiency and the automation degree, a rotatable ceramic carbonization disk is adopted for carbonization, not only can accurate control of a carbonization temperature be ensured, but also automatic loading and unloading can be achieved, the labor intensity of a labor is reduced, meanwhile, to-be-carbonized straw blank bars are placed in the ceramic carbonization disk in a radical direction, not only can occupied spacebe reduced, but also the condition that each straw blank can be subjected to carbonization accurately and evenly is ensured, the carbonization effect is excellent, the carbonization performance is ensured, and in a carbonization process, accurate temperature monitoring and control can be conducted, so that the carbonization effect is ensured.

Owner:ANHUI SCI & TECH UNIV

Device and process for treating ammonium chloride wastewater by supergravity carbonization reaction

ActiveCN105668753AIncrease contact areaEnhanced mass transferWater contaminantsWater/sewage treatmentHigh concentrationFiltration

The invention belongs to the technical field of treating industrialammonium chloride wastewater, and provides a device and a process for treating the ammonium chloride wastewater by a supergravity carbonization reaction, aiming at solving the problems that the current common electro-osmotic method for treating the ammonium chloride wastewater cannot realize an electrodialysis technology which is not only economical but also effective, the high-concentration ammonium chloride wastewater is hardly treated in an effective way by a membrane separation technology, and the cost is overhigh, etc. Ammonium chloride, organic amine and carbon dioxide react in a supergravity rotary packed bed to generate a mixed hydrochloric acid solution of ammonium bicarbonate and organic amine; after the ammonium bicarbonate and the organic amine are separated in a separating funnel, an organic amine solution reacts with ammonium hydroxide to regenerate organic amine; an obtained ammonium chloride solution through the regeneration is subjected to concentration, crystallization, filtration, and drying to obtain industrial grade ammonium chloride. The carbonization effect is improved; the carbonization reaction time is shortened; the treatment effect is improved; energies are saved; environment protection is realized; by adopting the method provided by the invention, reaction equipment can be minimized, the carbonization time can be shortened, the treatment effect can be improved, and the operation cost can be reduced.

Owner:ZHONGBEI UNIV

Biochar fertilizer and preparation method thereof

InactiveCN106316673AImprove yieldImprove carbonization rateAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersOrganic farmingCarbonization

The invention discloses a biochar fertilizer which is prepared from the following raw materials in parts by weight: 60-80 parts of biochar, 20-50 parts of compound fertilizers and 15-25 parts of additives. According to the biochar fertilizer disclosed by the invention, crop straws serve as raw material components, the adopted raw straws are low in cost and highly available in source, are subjected to dehydration and deoxygenation treatment and ground into biochar powder in a high temperature carbonization manner, the carbonization effect is good, the char content is 25% or higher, the carbonization rate of the straws is effectively improved, and the char fertilizer is high in yield, good in fertilization effect and capable of passivating heavy metals in soil and improving the activity of microbes in the soil. Moreover, the fertilizer has large specific surface area, and the content of organic matters in the soil is improved. As a low-cost non-chemical fertilizer, the product disclosed by the invention can provide a yield guarantee for organic agriculture and green agriculture, and the preparation method is simple, controllable and easy to implement.

Owner:刘建伟

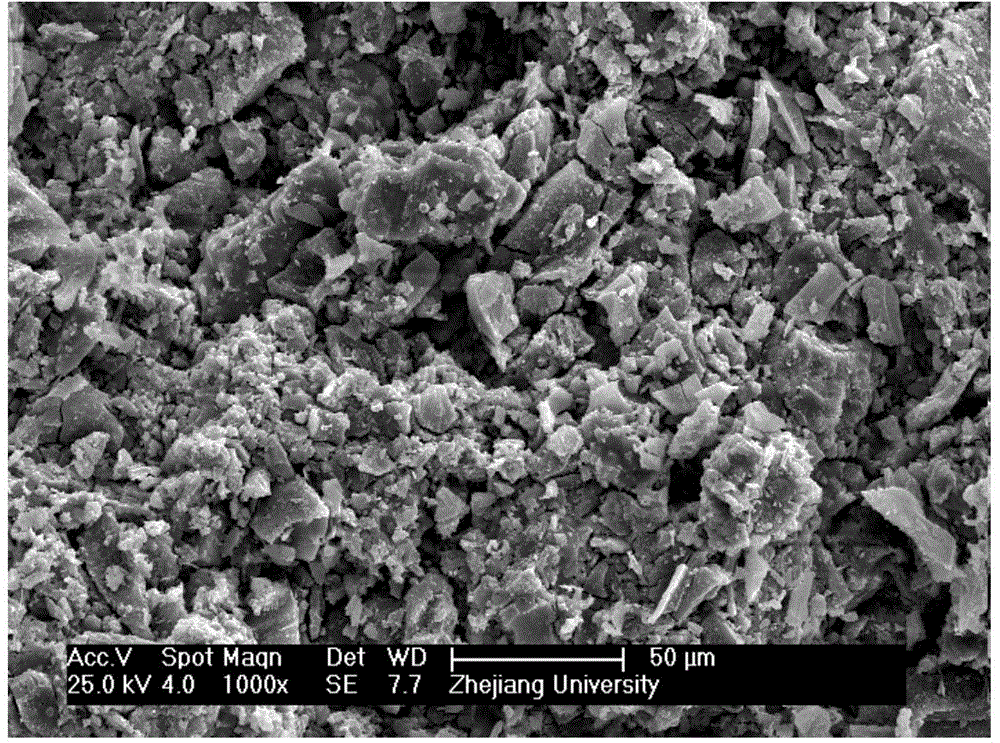

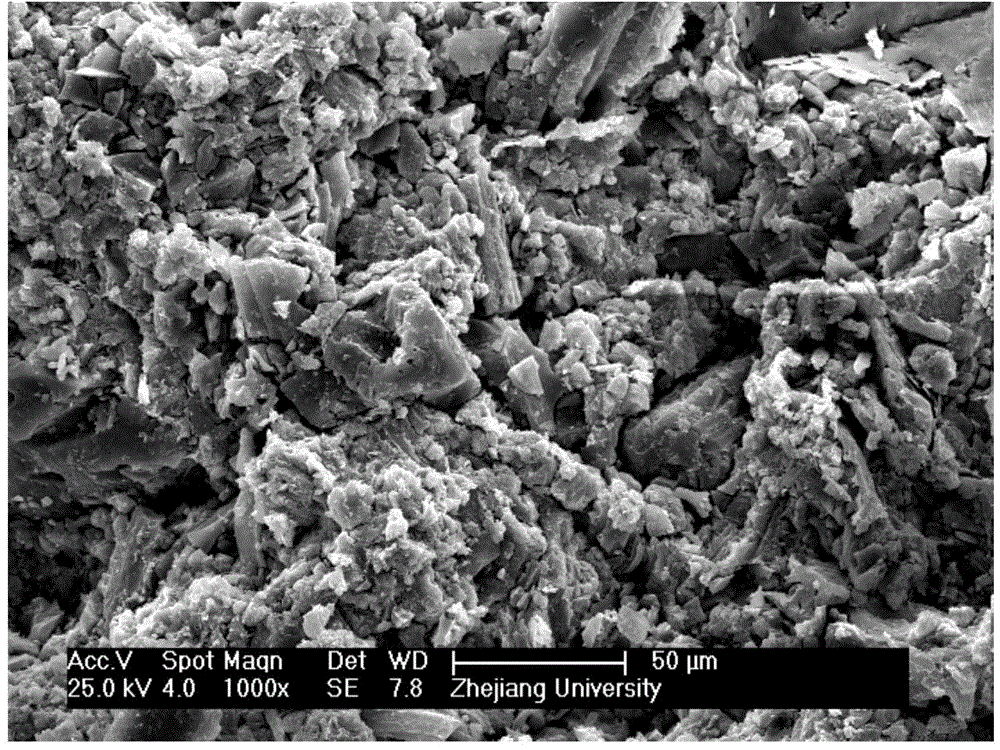

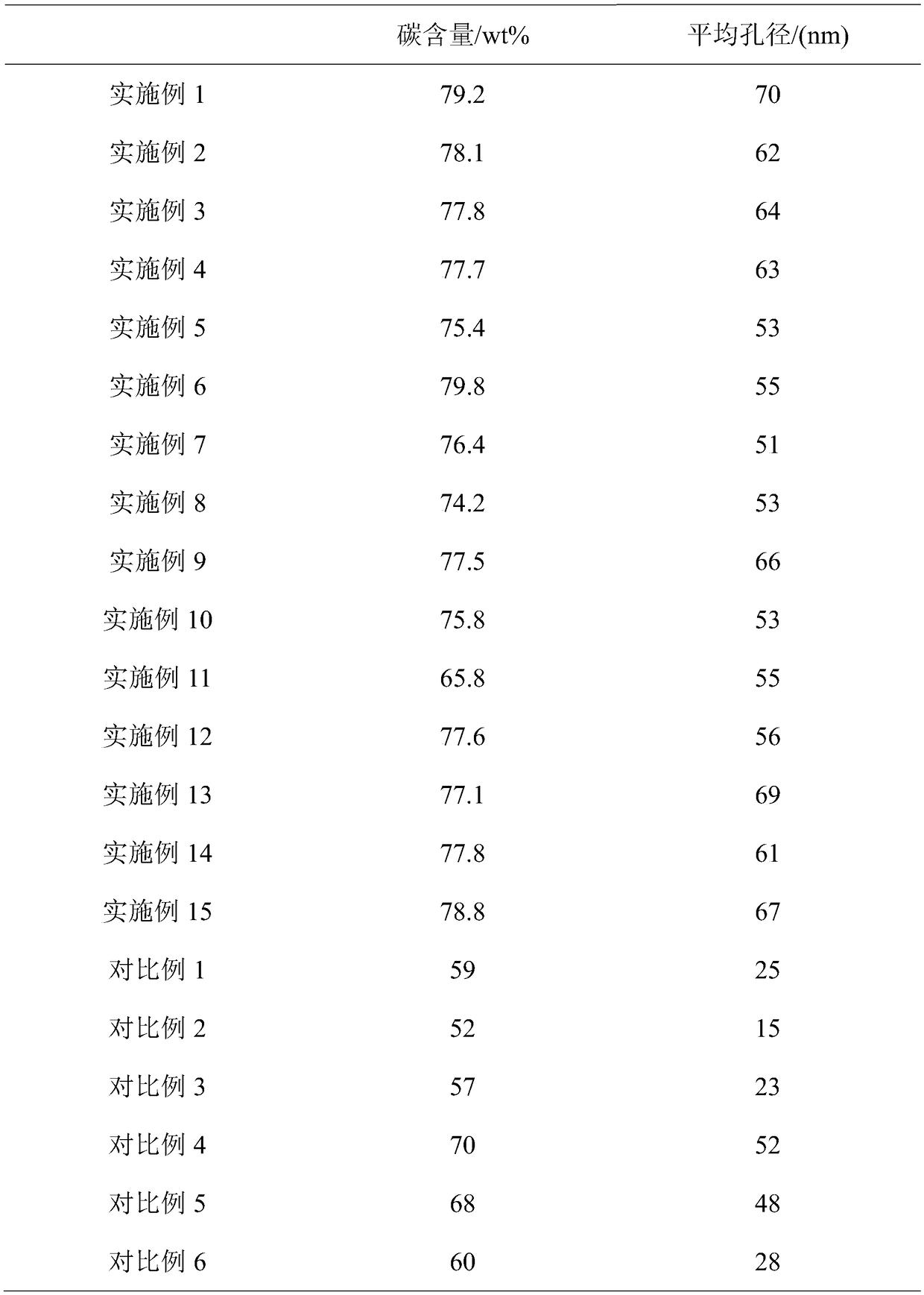

Biomass carbon and preparation method and application thereof

ActiveCN109250703AHigh porosityIncrease the apertureCarbon preparation/purificationOrganic fertilisersBiomass carbonCarbonization

The invention discloses biomass carbon and a preparation method and application thereof. The preparation method comprises the following steps that (1) biomass raw materials are preliminarily carbonized, so that preliminarily carbonized biomass is obtained; and (2) the preliminarily carbonized biomass obtained in the step (1) is deep carbonized, so that the biomass carbon is obtained. Preliminary carbonization treatment in step (1) is preliminary pyrolysis, and the temperature of preliminary pyrolysis is 100-300 DEG C; and deep carbonization treatment in the step (2) is deep pyrolysis, and thetemperature of deep pyrolysis is 350-600 DEG C. The technological process is clear in structure, techniques are mature and operable, the characteristics of small investment, quick effect and high output are achieved, the obtained biomass carbon can effectively improve physical and chemical properties of soil, maintain water, retain nutrients in the soil and promote growth of beneficial microorganisms in the soil, the crop yield and quality improvement are comprehensively promoted, and the plant economy income of farmers is increased.

Owner:时科生物科技(上海)有限公司

Preparation method for nano calcium carbonate special for low modulus silicone adhesive

ActiveCN107118590AGood compatibilityReduce reunionNon-macromolecular adhesive additivesPigment treatment with macromolecular organic compoundsCarbonizationSlurry

The invention discloses a preparation method for nano calcium carbonate special for low modulus silicone adhesive. The preparation method is implemented according to the following steps: 1) preparing Ca(OH)2 slurry; 2) carrying out carbonization; 3) adding a crystal form conditioning agent; 4) carrying out surface treatment; 5) adding a modulus conditioning agent; 6) carrying out filter pressing, drying and smashing on calcium carbonate boiled size in after the modulus conditioning agent is added to prepare the nano calcium carbonate special for the low modulus silicone adhesive, wherein the moisture of the nano calcium carbonate is less than or equal to 0.3%. The nano calcium carbonate prepared by the preparation method has good compatibility with polydimethylsiloxane, and cohesive energy is reduced after the nano calcium carbonate and the polydimethylsiloxane are mixed so as to achieve an effect of lowering silicone adhesive product modulus.

Owner:FUJIAN HONGFENG NANO TECH

Carbonization treatment method of wood plate

ActiveCN107160519APromote looseIncreasing the thicknessPressure wood treatmentWood treatment detailsSurface layerCarbonization

The invention discloses a carbonization treatment method of a wood plate. The carbonization treatment method comprises the following steps of (1) plate cleaning, (2) surface modification treatment, (3) soaking treatment, (4) carbonization treatment, and (5) cooling treatment. According to the carbonization treatment method, the carbonization effect on the wood plate can be effectively improved, the thickness of a surface carbonization layer of the wood plate is effectively increased, the carbonization rate of a surface layer material of the wood plate is also well increased, meanwhile, reasonably-added nanometer silica enhances the density and mechanical property of the surface layer, the machining defective rate is obviously decreased, and good service value is achieved.

Owner:FUNAN NATURE ARTS & CRAFTS

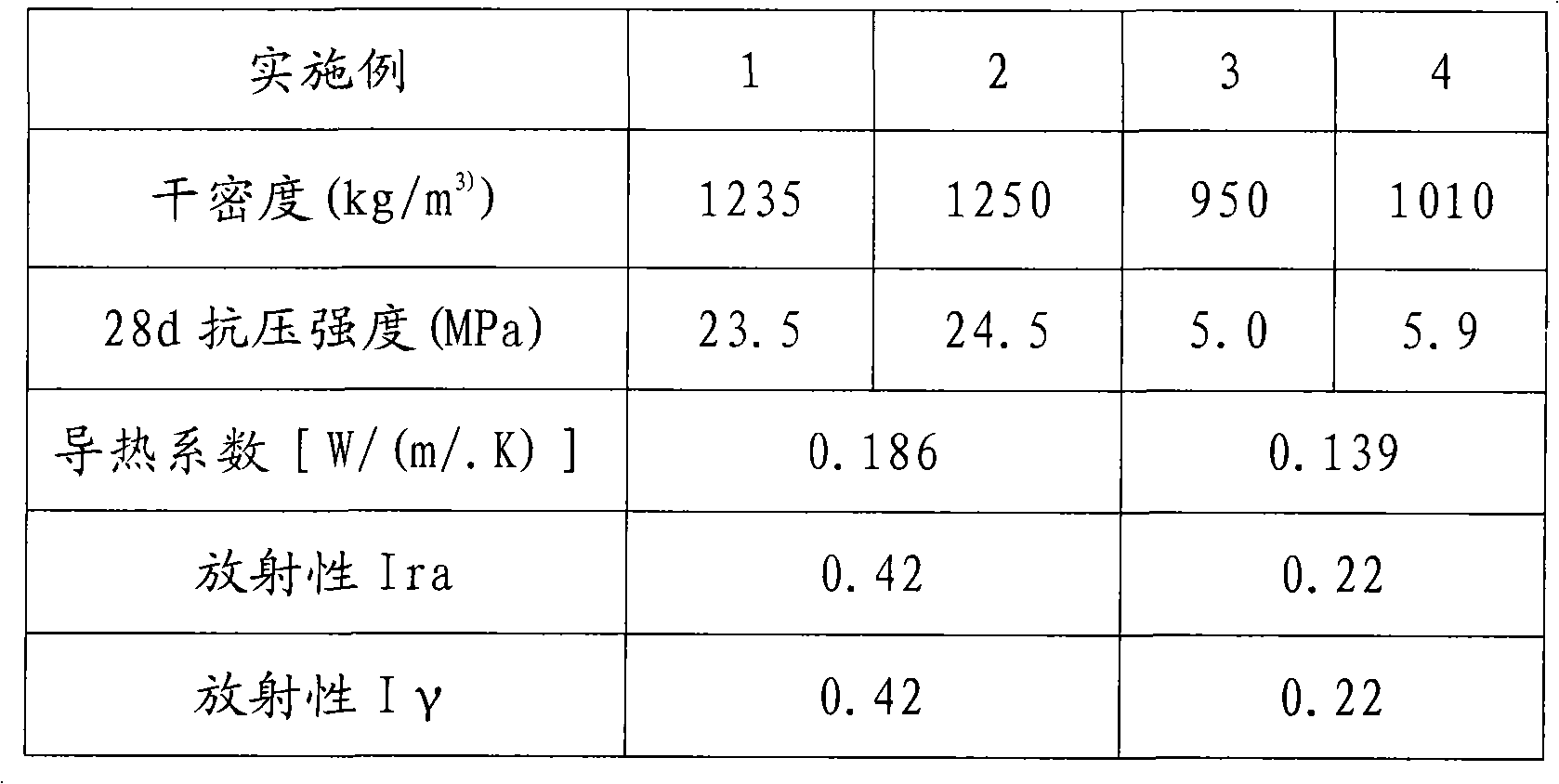

Roller steel slag fine aggregate and composite slag powder cemented material

InactiveCN101935172AIncreases hydration activityPromote sustainable economic developmentCement productionHigh strength concreteSlag

The invention relates to a roller steel slag fine aggregate and composite slag powder cemented material, which solves the problem that the existing steel slag can not completely replace cement for producing the cemented material owing to high production cost and can be only made into low-strength (less than C30) concrete. The cemented material is composed of composite slag powder and roller steel slag in the weight ratio of 1:1-4; and the composite slag powder is composed of 8-35wt% of a blended material and 65-92wt% of the slag powder, wherein, the blended material is made by finely grinding at least one of 25-99wt% of plaster, 0-75wt% of silicate cement clinker and 0-5wt% of an additive. The cemented material of the invention can completely replace a cementitious material, and the material has the advantages of high strength grade, simple production process, low production cost and stable product performances, thus being especially applicable to preparing high-strength concrete with good service performances and various engineering with higher flexural strength requirement.

Owner:武汉钢铁有限公司

Method for producing energy-saving and environmentally-friendly concrete

InactiveCN101774224AImprove insulation effectReduce heat lossSolid waste managementCement mixing apparatusSlagExpanded clay aggregate

The invention discloses a method for producing energy-saving and environmentally-friendly concrete. The method comprises the following steps of: weighing the following materials in part by weight: 24 to 143 parts of cement, 11 to 38 parts of fly ash, 57 to 95 parts of ceramic granules, 43 to 100 parts of phosphorous slag sand, 39 to 43 parts of mountain sand and 0.3 to 1.7 parts of polycarboxylic acid type high-efficiency water reducing agent; placing the materials into a stirrer, and stirring the mixture to obtain uniformly-mixed powder; and adding 22 to 54 parts of water in the mixture, and stirring to obtain the uniformly-mixed energy-saving and environmentally-friendly concrete. The method has the advantages that: the energy-saving and environmentally-friendly concrete produced by the method has the characteristics of light weight, good insulating performance, low heat loss, environmental protection, no pollution, anti-permeability superior to that of the common concrete, good fire resistance and good durability; and compared with the common concrete, the energy-saving and environmentally-friendly concrete produced by the method has the advantages of: 1, no alkaline corrosion to steel bars; 2, good frost resistance; 3, good contractibility; and 4, good carbonization resistance.

Owner:NO 3 ENG COMPANY OF CHINA RAILWAY NO 8 ENG GRP

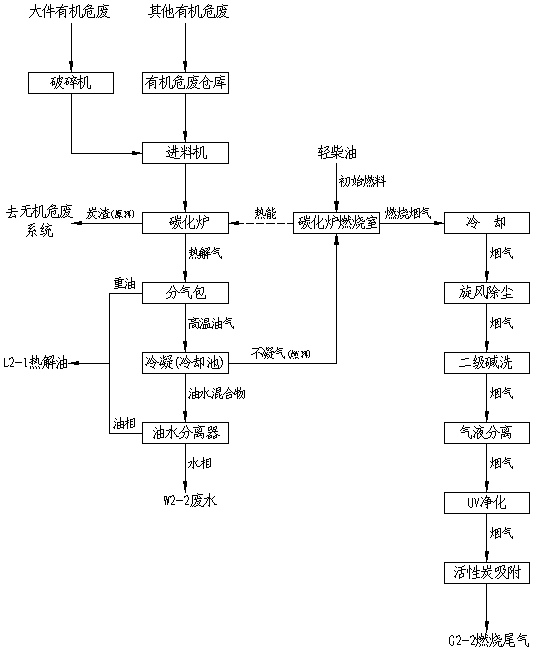

Low-temperature oxygen-free pyrolysis process for organic hazardous waste

InactiveCN109735353AImprove processing efficiencyIncrease added valueGas purification by catalytic conversionRetortsCombustion chamberSlag

The invention discloses a low-temperature oxygen-free pyrolysis process for organic hazardous waste. The process includes, firstly, entering, by materials, a carbonizer after pretreatment, and adjusting the distribution of the materials in the carbonizer; gradually heating the materials in the carbonizer by a combustion chamber; entering, by pyrolysis gas generated by pyrolysis of the materials, agas distribution bag; after cooling and water washing, combusting the pyrolyzed materials in a hearth to become carbon slag; finally, until no pyrolysis gas is generated in the carbonizer, stopping heating, and after the carbonizer is gradually cooled down, discharging the carbon residue. The organic hazardous waste material is treated by the low-temperature anaerobic pyrolysis process of the organic hazardous waste, so that the harmless treatment efficiency of the hazardous waste and the added value of the low-temperature anaerobic pyrolysis recovery product can be improved, the defects in the existing technical field of organic hazardous waste treatment are made up, and the organic hazardous waste pyrolysis process with safety, environmental protection, good carbonization effect and high carbonization efficiency is provided.

Owner:兰州何捷环保科技有限公司 +1

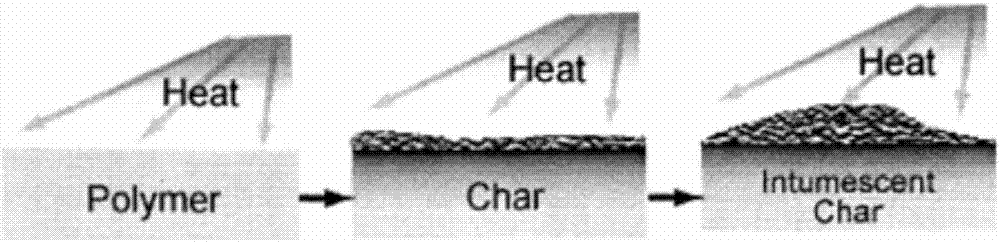

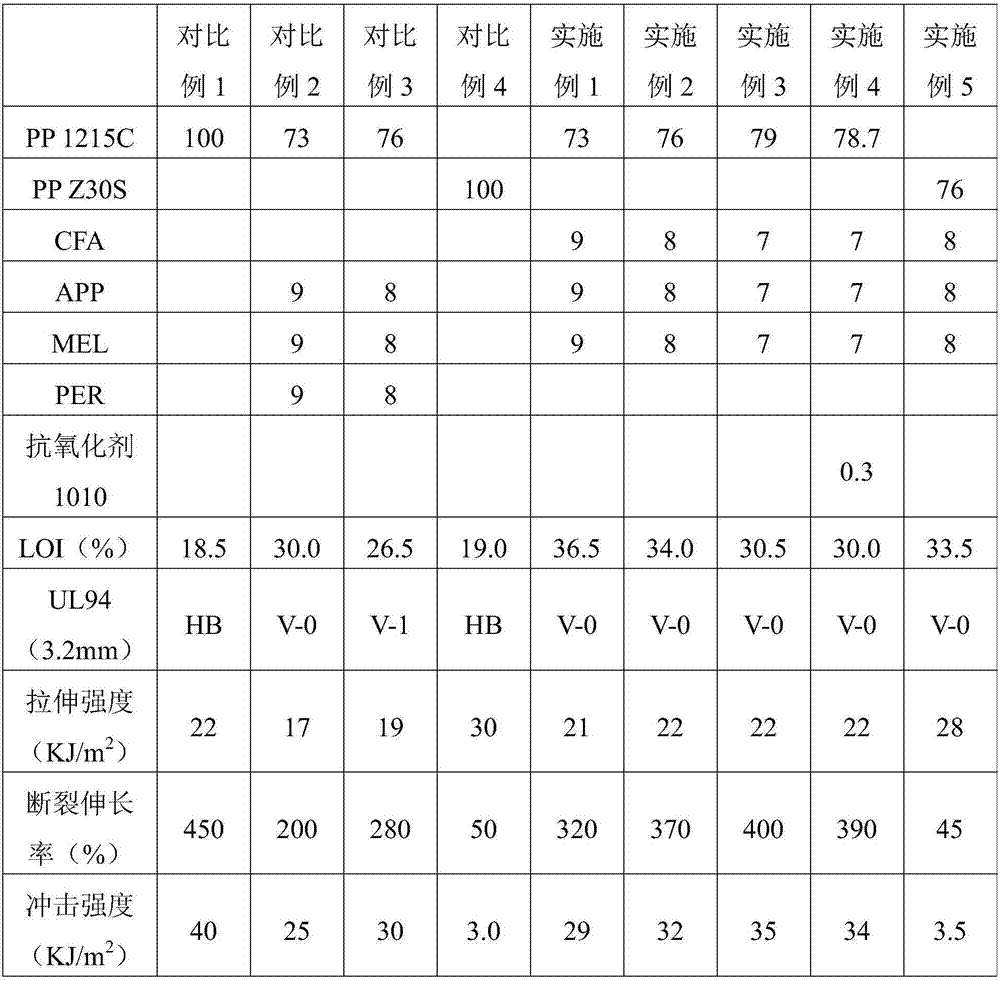

Halogen-free flame-resistant polypropylene composition containing triazine expansion flame retardants and preparation of composition

The invention relates to a halogen-free flame-resistant polypropylene composition containing triazine expansion flame retardants and preparation of the composition. The halogen-free flame-resistant polypropylene composition is prepared by a method including the steps: weighing 65-90 parts of polypropylene and 15-35 parts of triazine expansion flame retardants according to a formula; mixing the polypropylene and the triazine expansion flame retardants; adding mixture into a double-screw extruder; performing melt mixing, extrusion and granulation at the temperature of 190-220 DEG C to obtain the halogen-free flame-resistant polypropylene composition. Compared with the prior art, the composition has the advantages that the expansion flame retardants are adopted, a triazine derivative serving as a charring agent is used for modifying the polypropylene in a flame-resistant manner, fewer flame retardants are added, and the halogen-free flame-resistant polypropylene composition is good in mechanical property and high in flame-resistant efficiency.

Owner:江苏启蓝新材料有限公司

Carbonization processing method of corn stalk

InactiveCN108753328ALarge specific surface areaImprove responseBiofuelsSolid fuelsCarbonizationBiological activation

The invention belongs to the field of agricultural resource environment sustainable development utilization industry, and discloses a carbonization processing method of corn stalk. The carbonization processing method comprises following steps: corn stalk is subjected to pretreatment to increase stalk strength and reduce ash content, gradient charing heating is adopted, so that charing effect is improved, and energy is saved; and at last, activation treatment is carried out, so that gasification reaction and micropore formation rates are increased, the prepared biomass charcoal possesses excellent density and pore structures, the specific surface area is as large as 1200m<2> / g, the adsorption capacity is high, the adsorption amount at room temperature is 140mg / g. The carbonization processing method is capable of improving comprehensive performance of processing of corn stalk into biomass charcoal such as the yield; operation is simple; efficiency is high; operation is convenient, safe,and reliable; energy is saved; and the carbonization processing method is worthy of popularization.

Owner:FUNAN SHENGTIAN NEW ENERGY DEV CO LTD

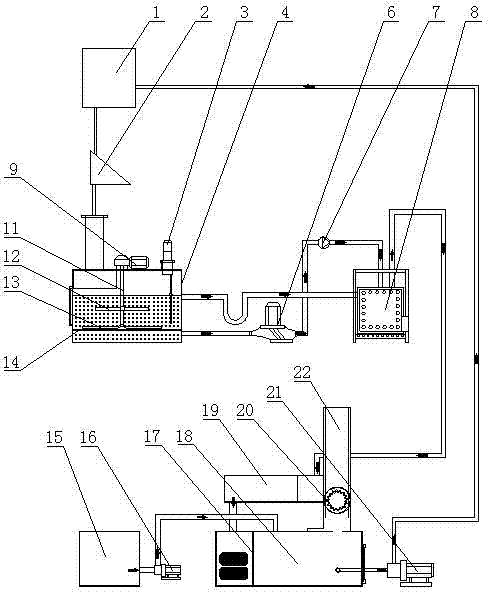

Carbonization reaction device and method for nano calcium carbonate production

ActiveCN104891545AAvoid backmixingGood for pulpingCalcium/strontium/barium carbonatesMaterial nanotechnologyRefluxCarbonization

The invention discloses a carbonization reaction device and a carbonization reaction method for nano calcium carbonate production. The carbonization reaction device comprises a Ca(OH)2 slurry feeding tube, a carbonization tower, a stirrer, an annular gas-liquid distributor, a CO2 gas inlet tube and an emulsion dispersing machine. The carbonization reaction method comprises the following steps: (1) feeding Ca(OH)2 slurry into a reflux area of the carbonization tower; (2) continuously feeding the Ca(IH)2 slurry into the emulsion dispersing machine to mix and react with a CO2 gas, and feeding the obtained product into the reaction area of the carbonization tower; (3) continuously circulating the mixed slurry between the carbonization tower and the emulsion dispersing machine for carbonization and emulsion dispersion; (4) adding a dispersing agent, continuously circulating the mixed slurry between the carbonization tower and the emulsion dispersing machine for secondary carbonization and emulsion dispersion; and (5) stopping introduction of CO2 for reaction and operation of the emulsion dispersing machine, thereby obtaining prepared nano calcium carbonate slurry. The carbonization reaction device and the carbonization reaction method for nano calcium carbonate production are rapid in carbonization reaction speed, high efficiency, good effect, small investment and low cost.

Owner:FUJIAN HONGFENG NANO TECH

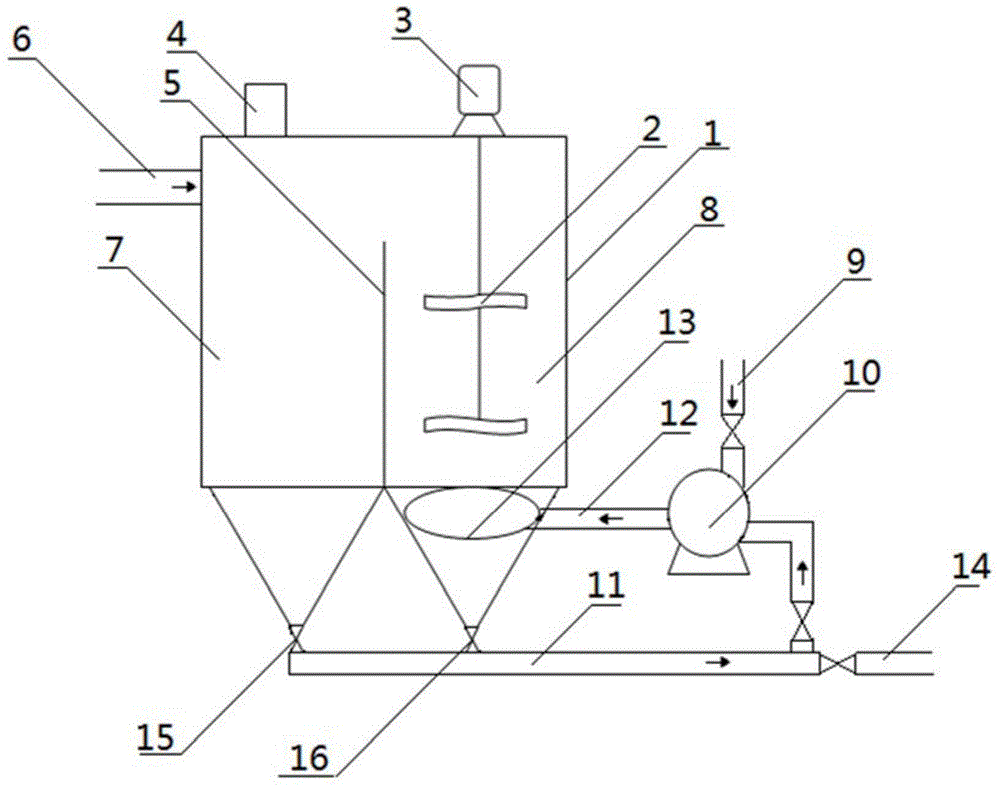

Rice husk carbonization device

PendingCN107880916APlay the role of heating carbonizationGood carbonization effectGas treatmentDispersed particle filtrationInsulation layerHeat conducting

The invention discloses a rice husk carbonization device comprising a carbonization furnace; the outer surface of the carbonization furnace is fixedly connected with a heat conducting layer; two sidesof the heat conducting layer are fixedly connected with heating resistance wires; the outer surface of the heat conducting layer is fixedly connected with a heat insulation layer; the top of the carbonization furnace is provided with a motor; the output end of the motor is fixedly connected with a rotating shaft; the outer surface of the rotating shaft is fixedly connected with a stirring paddleand a stirring rod; and one end of the stirring rod is fixedly connected with a first scraper. Due to the adoption of the heating resistance wires, the effects of heating and carbonizing rice husks can be achieved; due to the adoption of the heat conducting layer prepared from graphite, and heat of the heating resistance wires can be rapidly and effectively transferred to the rice husks, so that the carbonization effect of the rice husks is more obvious; due to the adoption of the heat insulation layer, the heat is prevented from being rapidly diffused, so that the aim of saving energy is achieved; and due to the arrangement of the motor, the rotating shaft, the stirring paddle and the stirring rod, the contact among materials can be increased, and the materials can be uniformly stirred toensure that the materials sufficiently contact to react.

Owner:建始惠万农生物科技有限公司

Preparation and use method of biochar pesticide adsorbing material based on corn stalks

ActiveCN105498692AImprove the carbonization effectImprove quality and adsorption effectOther chemical processesWater contaminantsWaxCorn stover

The invention relates to the field of removal of pesticide residue, in particular to preparation and a use method of biochar pesticide adsorbing material based on corn stalks. The preparation comprises the following steps: adding wax and corn stalk powder into an oscillator; carrying out oscillation to obtain a fluffy mixture; carbonizing the mixture in a heating furnace to obtain a corn stalk carbide; washing the corn stalk carbide in deionized water; airing the washed corn stalk carbide; adding 0.1 mol / L hydrochloric acid to adjust the pH value while oscillation is carried out; washing to obtain a neutral semi-product; drying the neutral semi-product at 70 to 80 DEG C, so as to obtain the biochar pesticide adsorbing material based on the corn stalks. The invention further discloses the use method of the biochar pesticide adsorbing material. The prepared biochar pesticide adsorbing material is high in quality, adsorption efficiency and yield.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

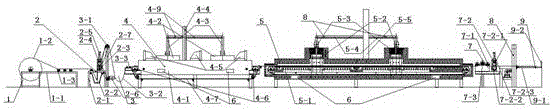

Continuous production line of high-silica fiber meshes

ActiveCN106179869ASimple structureIngenious designInspecting textilesSevering textilesFiberProduction line

The invention provides a continuous production line of high-silica fiber meshes. The continuous production line comprises a cloth placement mechanism, an impregnation mechanism, a mesh correcting mechanism, a solidifying mechanism, a carbonization mechanism, a slicing mechanism and a mesh collecting mechanism, wherein the cloth placement mechanism is connected to the impregnation mechanism, the impregnation mechanism is connected to the mesh correcting mechanism, the mesh correcting mechanism is connected to the solidifying mechanism, the solidifying mechanism is connected to the carbonization mechanism, the carbonization mechanism is connected to the slicing mechanism, and the slicing mechanism is connected to the mesh collecting mechanism. The continuous production line has the advantages that the structure is simple, the design is ingenious, a traditional production line is improved, the mesh correcting mechanism is additionally arranged, impregnated screen cloth meshes are protected against misalignment caused by tension, the carbonization effect of products is improved through a solidifying furnace body and a carbonization furnace body, the product quality is improved, and the production risk is lowered.

Owner:JIANGSU HENGZHOU SPECIAL GLASS FIBER MATERIAL

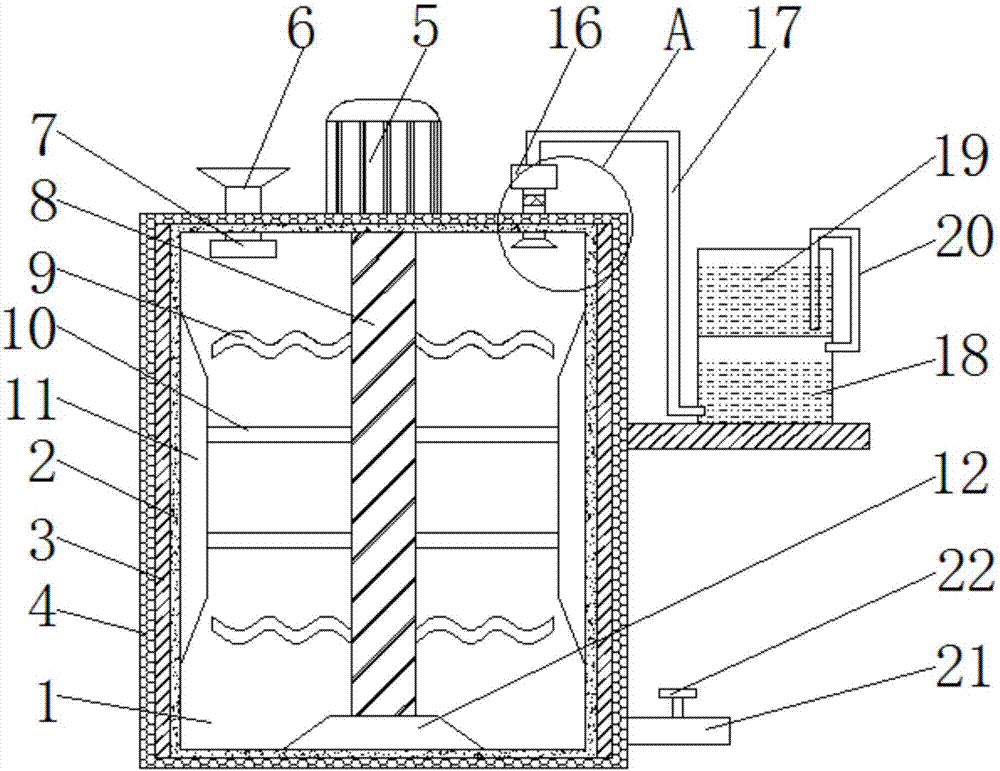

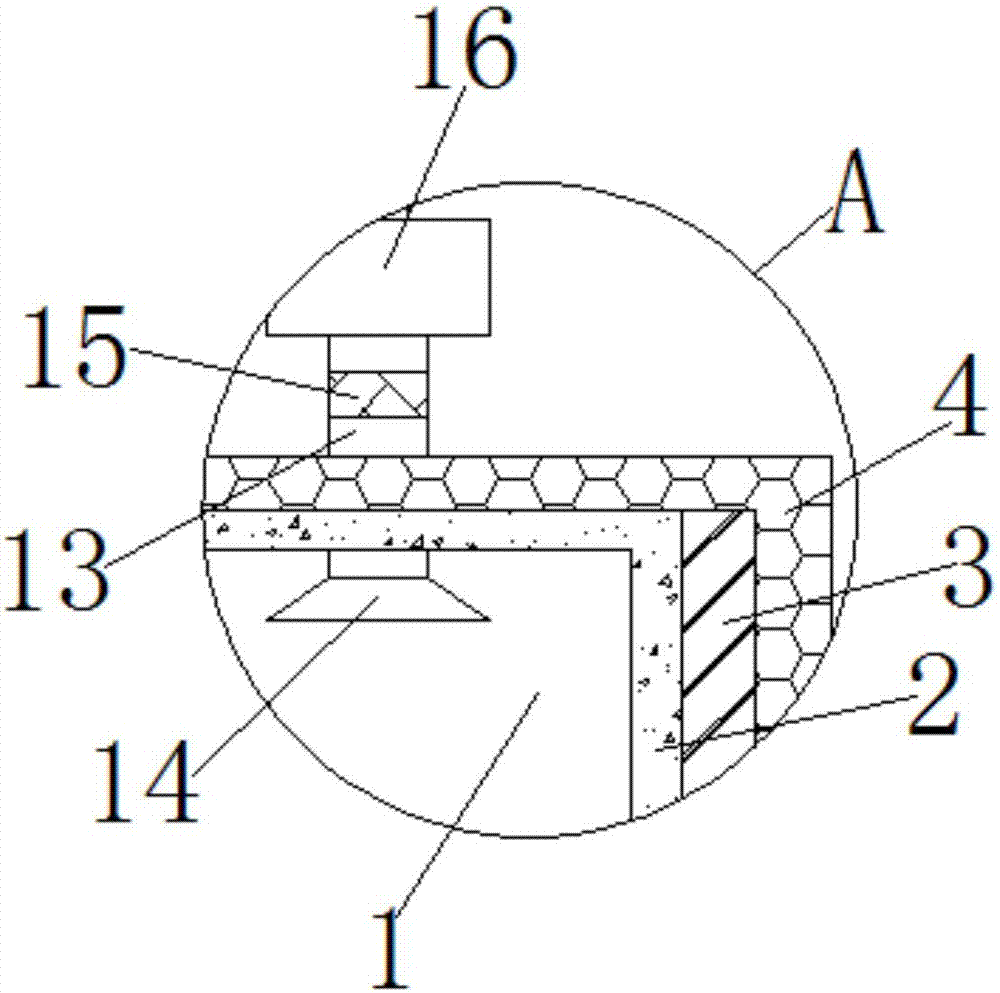

Environment-friendly excrement carbonization toilet

InactiveCN104499562AShorten the timeNot easy to get stuckSludge treatmentSewerage structuresWater storage tankCarbonization

The invention discloses an environment-friendly excrement carbonization toilet, and relates to a public sanitary facility. The environment-friendly excrement carbonization toilet comprises a closestool, a water storage tank, a sewage tank, a carbonization furnace, a condensing tank and a purification tank, and is characterized in that a stirring motor is arranged on the sewage tank; a filtering division plate is arranged in the lower part of the sewage tank and divides the sewage tank into an upper sewage cavity and a lower sewage cavity; filtering holes are uniformly formed in the filtering division plate; stirring blades and scraping blades are respectively arranged at the middle part and the lower part in the upper sewage cavity; the stirring motor is connected with the stirring blades and the scraping blades through a speed reducer; an exhaust pipe is arranged at the upper part of the purification tank; a pressurization fan is arranged in the exhaust pipe. The environment-friendly excrement carbonization toilet has the advantages of water resource saving, good excrement carbonization effect and low energy consumption and the advantages that water in vapor is fully condensed, no peculiar smell is generated during emission, secondary pollution is avoided and the like.

Owner:WEIHAI ANTAI ELECTRONICS REFRIGERATION EQUIP CO LTD

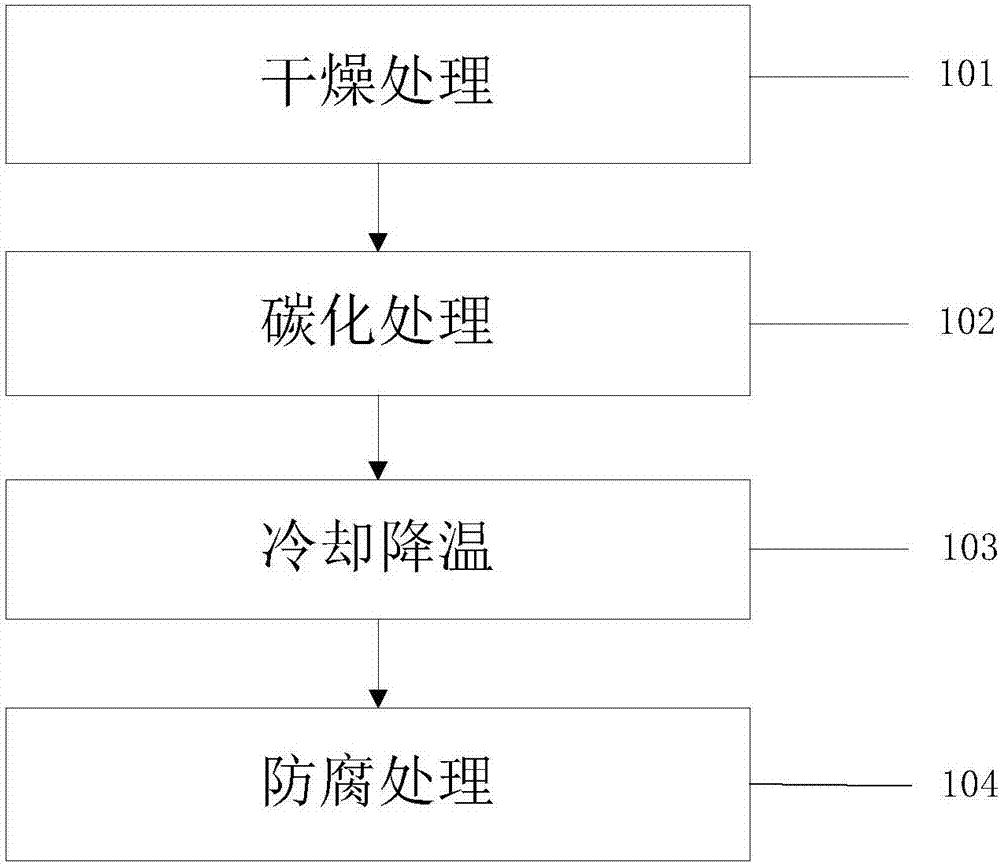

Wood preservation carbonizing method

InactiveCN107243972AImprove anti-corrosion performanceAnti-corrosion treatment and environmental protectionOpen tank impregnationWood charring/burningReduction treatmentWater vapor

The invention discloses a wood preservation carbonizing method. The wood preservation carbonizing method comprises the steps of drying treatment, wherein a cropped wood is subjected to step-by-step drying; carbonizing treatment, wherein the wood subjected to drying treatment is warmed and pre-heated and then carbonized; cooling for temperature reduction, wherein steam is introduced into a carbonizing kiln to carry out temperature reduction treatment; and preservative treatment is carried out, wherein the wood which is subjected to temperature reduction treatment is put into a preservative solution to be soaked. By means of the wood preservation carbonizing method, the plant preservation solution is adopted to carry out secondary preservative treatment on the carbonized wood, the preservative performance of the wood is greatly enhanced, the wood can adapt to the harsh external environment, and meanwhile preservation treatment is environmentally friendly, healthy and free of toxicity; and by arranging primary carbonizing, secondary carbonizing and tertiary carbonizing, cellulose, hemicelluloses and lignin in the wood are sufficiently carbonized, carbonizing is more sufficient, and the carbonizing effect is better.

Owner:芜湖斯塔克智能科技有限公司

Charcoal fertilizer capable of reducing heavy metal pollution

InactiveCN106278733AImprove yieldImprove carbonization rateOrganic fertilisersUrea compound fertilisersOrganic farmingCarbonization

The invention discloses a charcoal fertilizer capable of reducing heavy metal pollution. The charcoal fertilizer is prepared from the following raw materials in parts by weight: 60-80 parts of charcoal, 10-12 parts of a composite fertilizer, 10-12 parts of fermentation broth and 6-10 parts of additives. The charcoal fertilizer disclosed by the invention adopts crop straw as a raw material component, and the raw material straw is low in cost and easy to obtain, is subjected to dehydration deoxygenation treatment, and is crushed into charcoal powder in a high-temperature carbonization mode, so that a good carbonization effect can be achieved, the carbon content is greater than 25%, the carbonization rate of the straw is effectively increased, the charcoal fertilizer is high in finished product rate and good in application effect, heavy metals in soil can be passivated, and the activity of microorganisms of the soil can be improved. In addition, the charcoal fertilizer is relatively large in specific surface area, and the content of organic matters in the soil can be increased; as a low-cost non-chemical fertilizer, the charcoal fertilizer disclosed by the invention is capable of ensuring the yield of organic agriculture and green agriculture, and is simple in preparation method, good in controllability and easy to apply.

Owner:刘建伟

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com